Experimental Study on Early Age Characteristics of Lime-GGBS-Treated Gypseous Clays under Wet–Dry Cycles

Abstract

1. Introduction

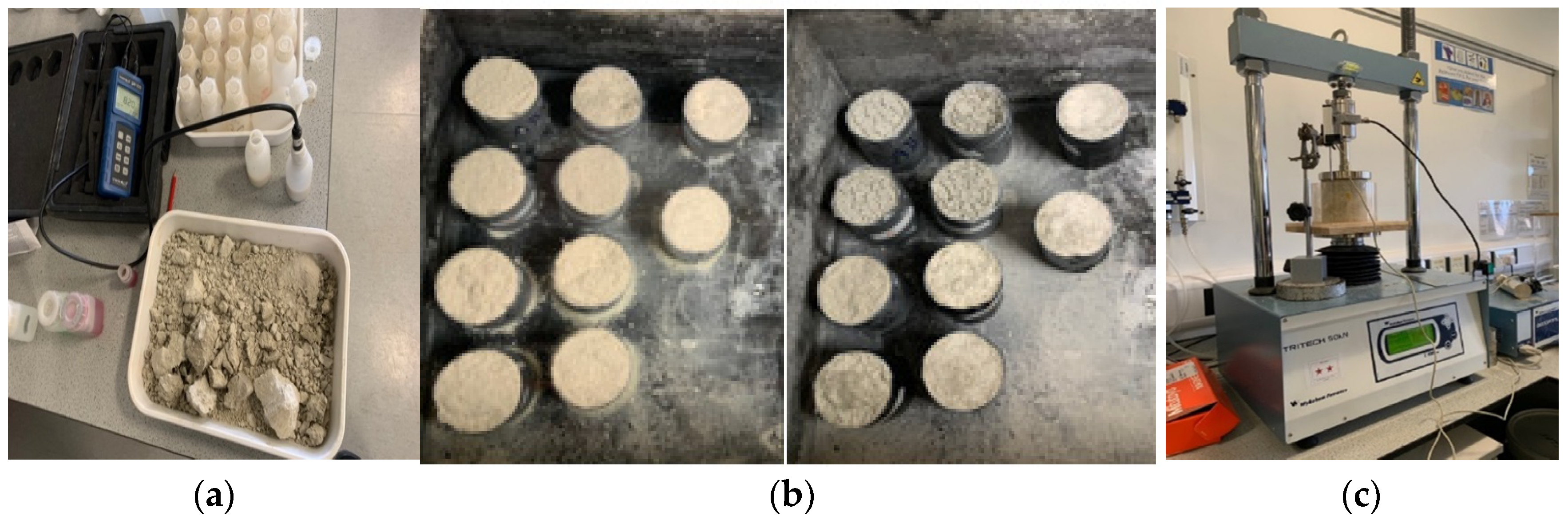

2. Materials and Methods

Experimental Testing

3. Discussion of Results

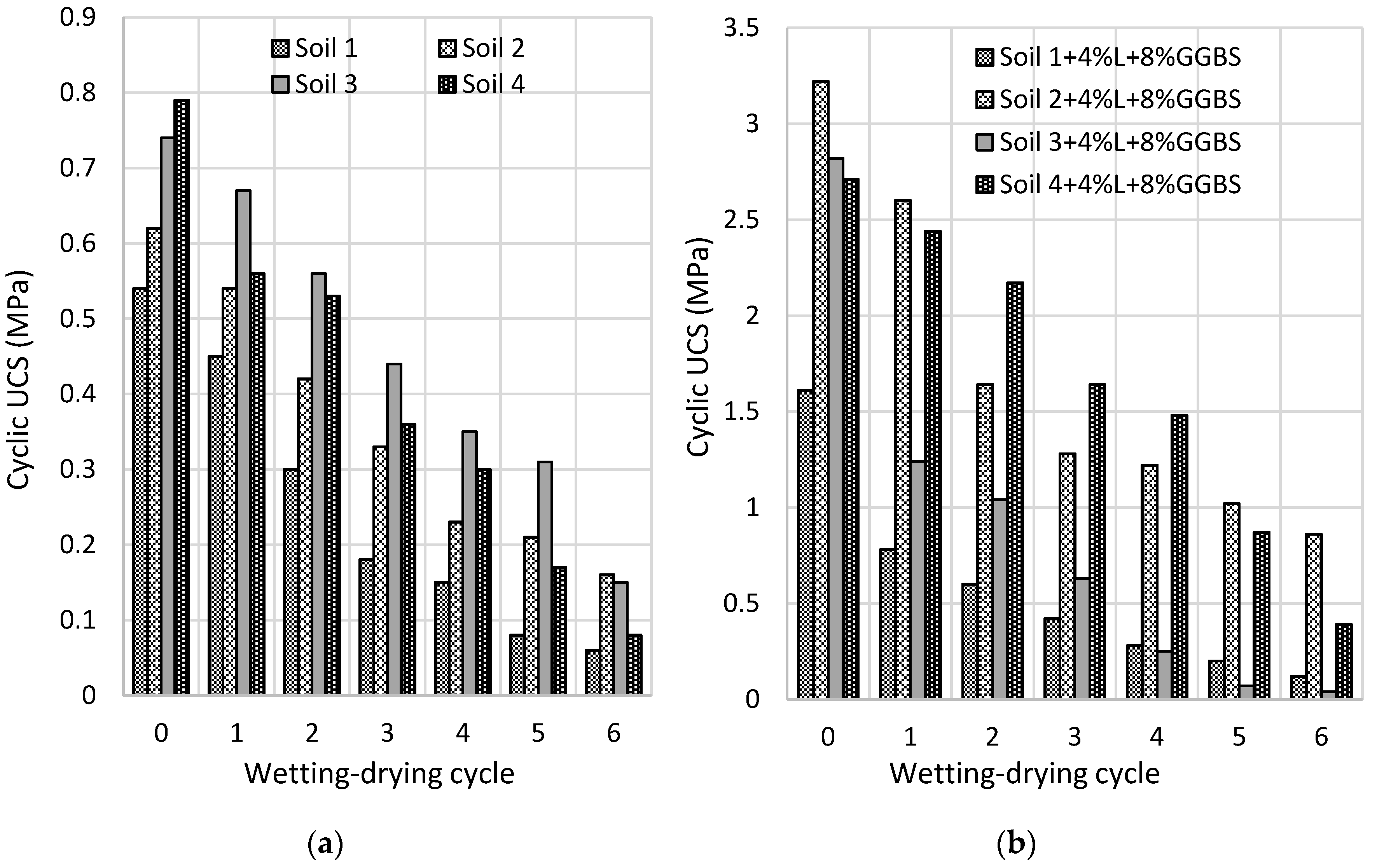

3.1. Cyclic UCS

3.2. Water Absorption of the Untreated and Treated Soils

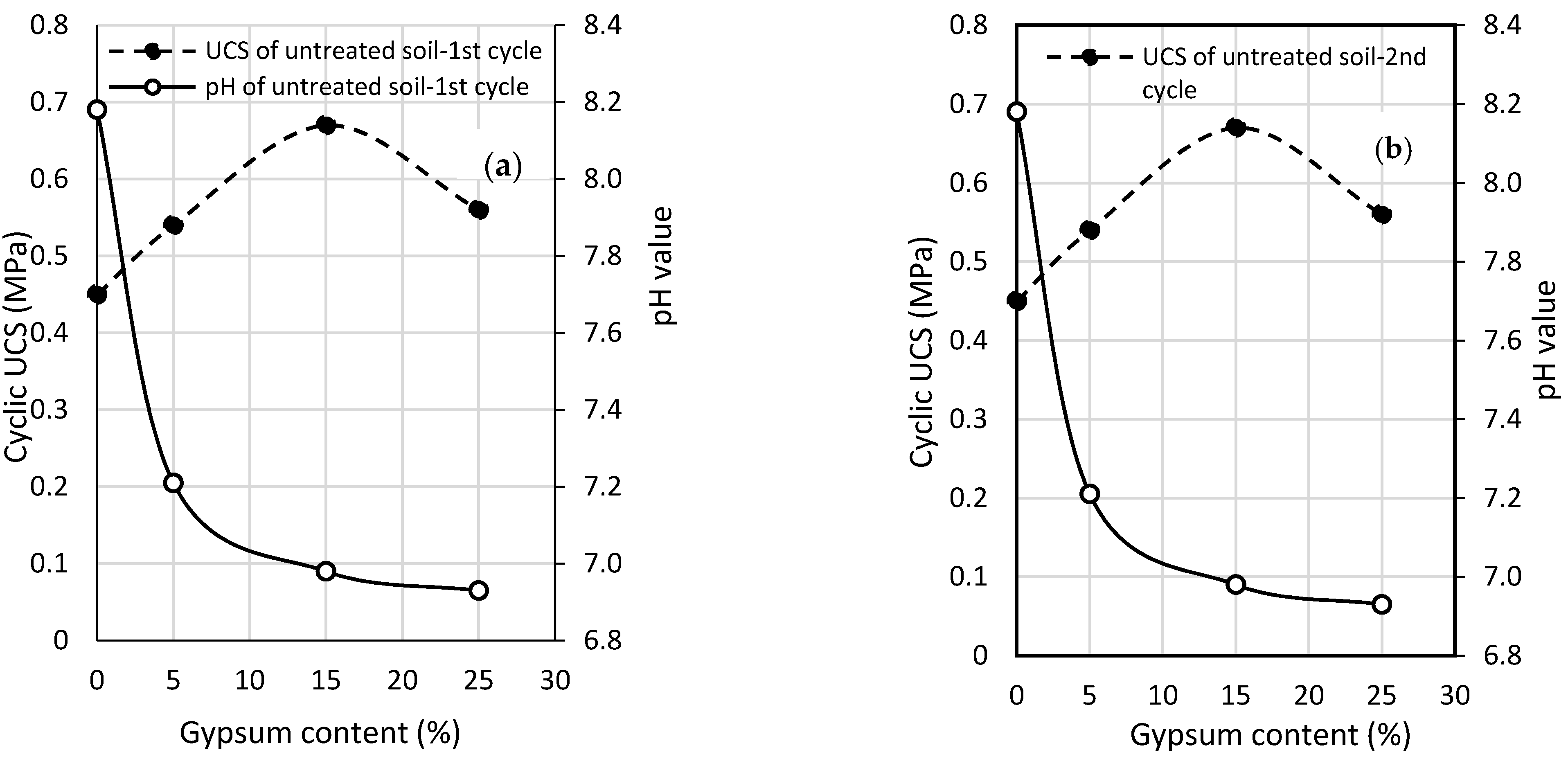

3.3. Effects of Gypsum Content and pH

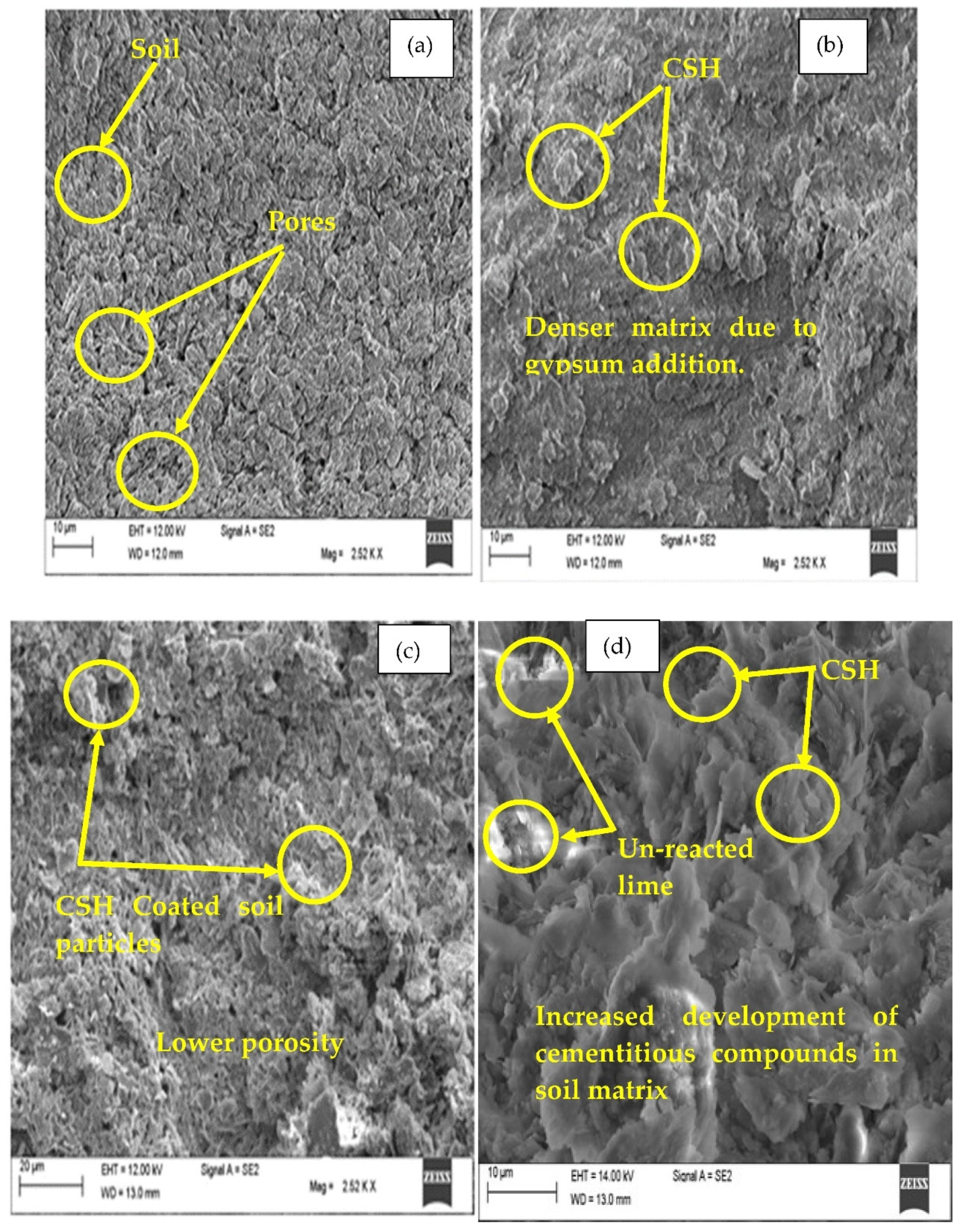

3.4. Microstructural Characteristics

4. Conclusions

- The use of 4% lime and 8% GGBS is an effective binder combination for improvement of gypseous soils with 5–25% gypsum content.

- The addition of lime and GGBS to gypseous soils improves the early age characteristics of the treated soil under cyclic wet–dry conditions and is a suitable treatment for gypseous materials under the influence of environmental changes faced by subgrade materials in tropical regions.

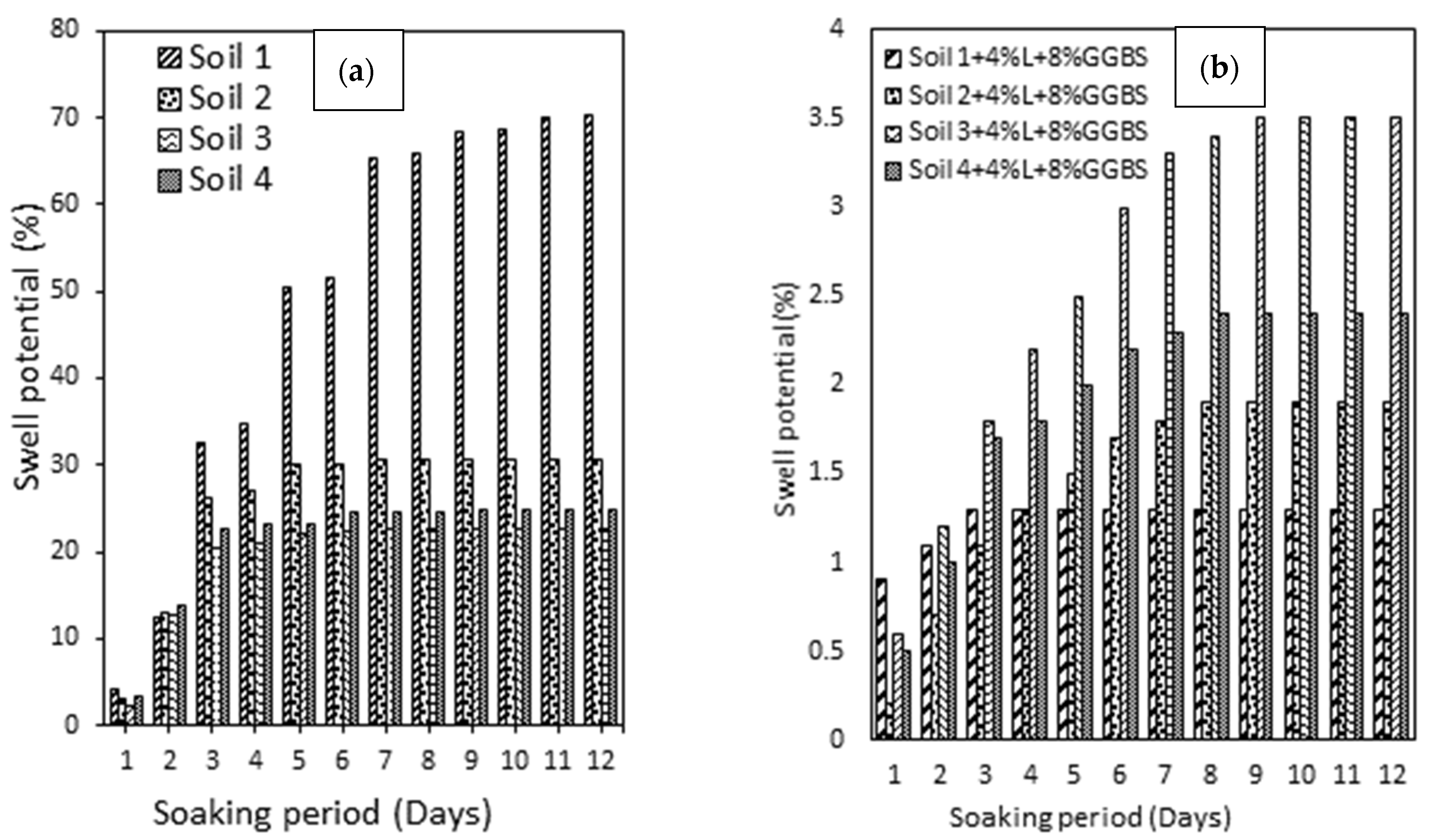

- Lime and GGBS treatment is effective in improving the water absorption of treated gypseous soils under wet–dry cycles. The application of GGBS and lime in stabilisation of a sulphate-bearing subgrade soil proved effective in improving strength and reducing swell of treated sulphate soils.

- The addition of lime and GGBS improves the microstructural properties of treated gypseous soils through the precipitation of cementitious compounds, which increases the strength of interparticle bonds, reduces porosity, and improves resistance to development of desiccation cracks under wet–dry conditions.

- It is also logical to conclude from this study that extending the wet–dry cycle period may have eventually led to a lower UCS value for soil 4 with 25% gypsum following further dissolution of gypsum as envisaged.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| UCS | Unconfined compressive strength |

| pH | Potential of hydrogen |

| GGBS | Ground granulated blast furnace slag |

| PFA | Pulverised fuel ash |

| SEM | Scanning electron microscopy |

| CSH | Calcium silicate hydrate |

| CAH | Calcium aluminate hydrate |

| OLC | Optimum lime content |

References

- Kavak, A.; Akyarlı, A. A field application for lime stabilization. Environ. Geol. 2007, 51, 987–997. [Google Scholar] [CrossRef]

- Al-Mukhtar, M.; Lasledj, A.; Alcover, J.F. Behaviour and mineralogy changes in lime-treated expansive soil at 20 °C. Appl. Clay Sci. 2010, 50, 191–198. [Google Scholar] [CrossRef]

- Mandal, T.; Edil, T.B.; Tinjum, J.M. Study on flexural strength, modulus, and fatigue cracking of cementitiously stabilised materials, Road Mater. Pavement Des. 2018, 19, 1546–1562. [Google Scholar] [CrossRef]

- Sharma, L.K.; Sirdesai, N.N.; Sharma, K.M.; Singh, T.N. Experimental study to examine the independent roles of lime and cement on the stabilization of a mountain soil: A comparative study. Appl. Clay Sci. 2018, 152, 183–195. [Google Scholar] [CrossRef]

- Pongsivasathita, S.; Horpibulsuk, S.; Piyaphipat, S. Assessment of mechanical properties of cement stabilized soils. Case Stud. Constr. Mater. 2019, 11, e00301. [Google Scholar] [CrossRef]

- Abbey, S.J.; Ngambi, S.; Ganjian, E. Development of strength models for prediction of unconfined compressive strength of cement/by-product material improved soils. Geotech. Test. J. 2017, 40, 928–935. [Google Scholar] [CrossRef]

- Abbey, S.J.; Ngambi, S.; Coakley, E. Effect of cement and by-product material inclusion on plasticity of deep mixing improved soils. Int. J. Civ. Eng. Technol. 2016, 7, 265–274. [Google Scholar]

- Abbey, S.J.; Ngambi, S.; Olubanwo, A.O.; Tetteh, F.K. Strength and hydraulic conductivity of cement and by-product cementitious materials improved soil. Int. J. Appl. Eng. Res. 2018, 13, 8684–8694. [Google Scholar]

- Eyo, E.U.; Ng’Ambi, S.; Abbey, S.J. Performance of clay stabilized by cementitious materials and inclusion of zeolite/alkaline metals-based additive. Transp. Geotech. 2020, 23, 100330. [Google Scholar] [CrossRef]

- Jeremiah, J.J.; Abbey, S.J.; Booth, C.A.; Kashyap, A. Results of Application of Artificial Neural Networks in Predicting Geo-Mechanical Properties of Stabilised Clays—A Review. Geotechnics 2021, 1, 8. [Google Scholar] [CrossRef]

- Fattaha, M.Y.; Al-Ania, M.M.; Al-Lamy MT, A. Studying Collapse Potential of Gypseous Soil Treated by Grouting. Soils Found. 2014, 54, 396–404. [Google Scholar] [CrossRef]

- Barazanji, A.F. Gypseous Soil of Iraq. Ph.D. Thesis, State University of Ghent, Ghent, Belgium, 1973. [Google Scholar]

- Sherwooh, P.T. Effect of sulfates on cement-and lime-stabilized soils. Highway Res. Board Bull. 1962, 353, 98–107. [Google Scholar]

- Mitchell, P.W.; Avalle, D.L. A Technique to Predict Expansive Soil Movements. In Proceedings of the Fifth International Conference on Expansive Soils, Adelaide, Australia, 21–23 May 1984. [Google Scholar]

- Hunter, D. Lime-induced heave in sulfate-bearing clay soils. J. Geotech. Eng. 1988, 114, 150–167. [Google Scholar] [CrossRef]

- Tixier, R.; Mobasher, B. Modeling of damage in cement-based materials subjected to external sulfate attack. I: Formulation. J. Mater. Civ. Eng. 2003, 15, 305–313. [Google Scholar] [CrossRef]

- Sirivitmaitrie, C.; Puppala, A.J.; Chikyala, V.; Saride, S.; Hoyos, L.R. Combined lime and cement treatment of expansive soils with low to medium soluble sulfate levels. In GeoCongress 2008: Geosustain Geohazard Mitigation; ASCE: Reston, VA, USA, 2008; pp. 646–653. [Google Scholar]

- Little, D.N.; Nair, S.; Herbet, B. Addressing sulfate-induced heave in lime treated soils. J. Geotech. Geoenviron. 2010, 136, 110–118. [Google Scholar] [CrossRef]

- Knopp, J.; Moormann, C. Ettringite Swelling in the Treatment of Sulfate-Containing Soils Used as Subgrade for Road Constructions. Procedia Eng. 2016, 143, 128–137. [Google Scholar] [CrossRef]

- Ehwailat, K.I.A.; Ismail, M.A.M.; Ezreig, A.M.A. Novel Approach for Suppression of Ettringite Formation in Sulfate-Bearing Soil Using Blends of Nano-Magnesium Oxide, Ground Granulated Blast-Furnace Slag and Rice Husk Ash. Appl. Sci. 2021, 11, 6618. [Google Scholar] [CrossRef]

- Jebli, M.; Jamin, F.; Pelissou, C.; Lhopital, E.; El Youssoufi, M.S. Characterization of the expansion due to the delayed ettringite formation at the cement paste-aggregate interface. Constr. Build. Mater. 2021, 289, 122979. [Google Scholar] [CrossRef]

- Li, W.; Yi, Y.; Puppala, A.J. Utilization of carbide slag-activated ground granulated blastfurnace slag to treat gypseous soil. Soils Found. 2019, 59, 1496–1507. [Google Scholar] [CrossRef]

- Wang, S.D.; Scrivener, K.L. Hydration products of alkali activated slag cement. Cem. Concr. Res. 1995, 25, 561–571. [Google Scholar] [CrossRef]

- Shi, C.; Roy, D.; Krivenko, P. Alkali-Activated Cements and Concretes; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Harris, P.; von Holdt, J.; Sebesta, S.; Scullion, T. Part 3: Cementitious, chemical, and mechanical stabilization: Recommendations for stabilization of high-sulfate soils in Texas. Transport. Res. Rec. 2006, 1952, 71–79. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, S.; Mehrotra, S.P. Towards sustainable solutions for fly ash through mechanical activation. Resour. Conserv. Recycl. 2007, 52, 157–179. [Google Scholar] [CrossRef]

- Abbeche, K.; Bahloul, O.; Ayadat, T.; Bahlou, A. Treatment of collapsible soils by salts using the double consolidation method. In Experimental and Applied Modeling of Unsaturated Soils; Geotechnical Special Publications, ASCE: Reston, VA, USA, 2010; pp. 69–78. [Google Scholar]

- Mori, A.; Tainura, M.; Fukui, Y. Distributionofgroutsinsolidified region in chemical grouts. J. Soil Mech. Found. Eng. 1989, 29, 127–134. [Google Scholar] [CrossRef]

- Al-Lamy, M.T.A. The Use of Acrylatein Grouting Some Iraqi Gypseous Soils. Ph.D. Thesis, Building and Construction Engineering Department, University of Technology, Baghdad, Iraq, 2008. [Google Scholar]

- Eyo, E.U.; Ng’ambi, S.; Abbey, S.J. Incorporation of a nanotechnology-based additive in cementitious products for clay stabilisation. J. Rock Mech. Geotech. Eng. 2020, 12, 1056–1069. [Google Scholar] [CrossRef]

- Wild, S.; Kinuthia, J.M.; Jones, G.I.; Higgins, D.D. Effects of Partial Substitution of Lime with Ground Granulated Blast Furnace Slag (GGBS) on the Strength Properties of Lime-Stabilized Sulphate-Bearing Clay Soils. Eng. Geol. 1998, 51, 37–53. [Google Scholar] [CrossRef]

- Harris, P.; Sebesta, S.; Scullion, T. Hydrated lime stabilization of sulfate-bearing vertisols in Texas. Transp. Res. Rec. 2004, 1868, 31–39. [Google Scholar] [CrossRef]

- Celik, E.; Nalbantoglu, Z. Effects of ground granulated blastfurnace slag (GGBS) on the swelling properties of lime-stabilized sulfate-bearing soils. Eng. Geol. 2013, 163, 20–25. [Google Scholar] [CrossRef]

- Wild, S.; Kinuthia, J.M.; Jones, G.I.; Higgins, D.D. Suppression of swelling associated with ettringite formation in lime stabilized sulphate bearing clay soils by partial substitution of lime with ground granulated blastfurnace slag. Eng. Geol. 1999, 51, 257–277. [Google Scholar] [CrossRef]

- Higgins, D.D. Soil stabilisation with ground granulated blastfurnace slag. UK Cem. Slag Mak. Assoc. 2005, 1, 15. [Google Scholar]

- Tasong, W.; Wild, S.; Tilley, R.J.D. Mechanisms by which ground Granulated blastfurnace slag controls the sulphate resistance of lime-stabilised kaolinite soils. Cem. Concr. Res. 1999, 29, 975–982. [Google Scholar] [CrossRef]

- ASTM D6276-19. Standard Test Method for Using pH to Estimate the Soil-Lime Proportion Requirement for Soil Stabilization; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Okeke, C.; Abbey, S.J.; Oti, J.; Eyo, E.U.; Johnson, A.; Ngambi, S.; Abam, T.; Ujile, M. Appropriate Use of Lime in the Study of the Physicochemical Behaviour of Stabilised Lateritic Soil under Continuous Water Ingress. Sustainability 2021, 13, 257. [Google Scholar] [CrossRef]

- ASTM D 2166-91. Standard Test Methods for Unconfined Compressive Strength of Cohesive Soils. Annu. Book ASTM Stand. 1994, 4, 163–167. [Google Scholar]

- ASTM D 4546-90. Standard Test Methods for One-Dimensional Swell or Settlement Potential of Cohesive Soils. Annu. Book ASTM Stand. 1994, 4, 693–699. [Google Scholar]

- Jha, A.K.; Sivapullaiah, P.V. Volume change behavior of lime treated gypseous soil—Influence of mineralogy and microstructure. Appl. Clay Sci. 2016, 119, 202–212. [Google Scholar] [CrossRef]

- Lebedev, A.L.; Kosorukov, V.L. Gypsum solubility in water at 25 °C. Geochem. Int. 2017, 55, 205–210. [Google Scholar] [CrossRef]

- Yilmaz, I.; Civelekoglu, B. Gypsum: An additive for stabilization of swelling clay soils. Appl. Clay Sci. 2009, 44, 166–172. [Google Scholar] [CrossRef]

- Cheng, Q.; Tang, C.; Chen, Z.; El-Maarry, M.R.; Zeng, H.; Shi, B. Tensile behaviour of clayey soils during desiccation cracking process. Eng. Geol. 2020, 279, 105909. [Google Scholar] [CrossRef]

- Burkart, B.; Goss, G.C.; Kern, J.P. The role of gypsum in production of sulfateinduced deformation of lime-stabilized soils. Environ. Eng. Geosci. 1999, 5, 173–187. [Google Scholar] [CrossRef]

- Caselles, L.D.; Hot, J.; Roosz, C.; Cyr, M. Stabilization of soils containing sulfates by using alternative hydraulic binders. Appl. Geochem. 2020, 113, 104494. [Google Scholar] [CrossRef]

- Adams, A.G.; Dukes, O.M.; Tabet, W.; Cerato, A.B.; Miller, G.A. Sulphate induced heave in Oklahoma soils due to lime stabilization. In GeoCongress 2008: Characterization, Monitoring, and Modeling of GeoSystems; ASCE: Reston, VA, USA, 2008; pp. 444–451. [Google Scholar]

- Thompson, M.; McBridge, J.; Horton, R. Effects of Drying Treatments on Porosity of Soil Materials; U.S. Environmental Protection Agency: Washington, DC, USA, 2002. [Google Scholar]

- Oliveira, J.A.T.; C’assaro, F.A.M.; Pires, L.F. Estimating soil porosity and pore size distribution changes due to wetting-drying cycles by morphometric image analysis. Soil Tillage Res. 2021, 205, 104814. [Google Scholar] [CrossRef]

- Pires, L.F.; Reichardt, K.; Cooper, M.; C´assaro, F.A.M.; Dias, N.M.P.; Bacchi, O.O.S. Pore system changes of damaged Brazilian oxisols and nitosols induced by wet-dry cycles as seen in 2-D micromorphologic image analysis. An. Da Acad. Bras. De Cienc. 2009, 81, 151–161. [Google Scholar] [CrossRef][Green Version]

- Viana, J.H.M.; Fernandes Filho, E.I.; Schaefer, C.E.G.R. Effects of wetting and drying cycles on the reorganization of the microgranular structure of latosols. Rev. Bras. De Ciência Do Solo 2004, 28, 11–19. [Google Scholar] [CrossRef]

- Pires, L.F.; Auler, A.C.; Roque, W.L.; Mooney, S.J. X-ray microtomography analysis of soil pore structure dynamics under wetting and drying cycles. Geoderma 2020, 362, 114103. [Google Scholar] [CrossRef]

- Aldaood, A.; Bouasker, M.; Al-Mukhtar, M. Impact of wetting–drying cycles on the microstructure and mechanical properties of lime-stabilized gypseous soils. Eng. Geol. 2014, 174, 11–21. [Google Scholar] [CrossRef]

- Eyo, E.; Abbey, S.; Oti, J.; Ng’ambi, S.; Ganjian, E.; Coakley, E. Microstructure and Physical Mechanical Characteristics of Treated Kaolin-Bentonite Mixture for Application in Compacted Liner Systems. Sustainability 2021, 13, 1617. [Google Scholar] [CrossRef]

- Yi, Y.; Gu, L.; Liu, S. Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blast furnace slag. Appl. Clay Sci. 2015, 103, 71–76. [Google Scholar] [CrossRef]

- Abbey, S.J.; Eyo, E.U.; Ng’ambi, S. Swell and microstructural characteristics of high-plasticity clay blended with cement. Bull. Eng. Geol. Environ. 2020, 79, 2119–2130. [Google Scholar] [CrossRef]

- Eyo, E.U.; Ngambi, S.; Abbey, S.J. Effect of intrinsic microscopic properties and suction on swell characteristics of compacted expansive clays. Transp. Geotech. 2019, 18, 124–131. [Google Scholar] [CrossRef]

- Abbey, S.J.; Eyo, E.U.; Oti, J.; Amakye, S.Y.; Ngambi, S. Mechanical Properties and Microstructure of Fibre-Reinforced Clay Blended with By-Product Cementitious Materials. Geosciences 2020, 10, 241. [Google Scholar] [CrossRef]

| Gypsum Content (%) | Classification |

|---|---|

| 0–0.3 | Non-gypseous |

| 0.3–3 | Very lightly gypseous |

| 3–10 | Slightly gypseous |

| 10–25 | Moderately gypseous |

| 25–50 | Highly gypseous |

| Oxide | Kaolinite | Bentonite | Gypsum | Lime | GGBS |

|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | (%) | |

| SiO2 | 49 | 57.1 | 10.93 | 1 | 34.1 |

| Al2O3 | 36 | 17.79 | 2.88 | 0.3 | 13 |

| Fe2O3 | 0.75 | 4.64 | 1.16 | 0.5 | 0.51 |

| CaO | 0.06 | 3.98 | 26.32 | 94 | 39 |

| MgO | 0.3 | 3.68 | - | 2 | 9.5 |

| K2O | 1.85 | 0.9 | 0.83 | - | 0.5 |

| TiO2 | 0.02 | 0.77 | 0.15 | - | 1.3 |

| Na2O | 0.1 | 3.27 | 0.18 | - | 0.3 |

| SO3 | - | 0.11 | 34.70 | - | 0.3 |

| Mn2O3 | - | 0.06 | - | 1.2 | 0.7 |

| LOI | 12 | 7.85 | 19.80 | - | 1.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbey, S.J.; Eyo, E.U.; Jeremiah, J.J. Experimental Study on Early Age Characteristics of Lime-GGBS-Treated Gypseous Clays under Wet–Dry Cycles. Geotechnics 2021, 1, 402-415. https://doi.org/10.3390/geotechnics1020019

Abbey SJ, Eyo EU, Jeremiah JJ. Experimental Study on Early Age Characteristics of Lime-GGBS-Treated Gypseous Clays under Wet–Dry Cycles. Geotechnics. 2021; 1(2):402-415. https://doi.org/10.3390/geotechnics1020019

Chicago/Turabian StyleAbbey, Samuel J., Eyo U. Eyo, and Jeremiah J. Jeremiah. 2021. "Experimental Study on Early Age Characteristics of Lime-GGBS-Treated Gypseous Clays under Wet–Dry Cycles" Geotechnics 1, no. 2: 402-415. https://doi.org/10.3390/geotechnics1020019

APA StyleAbbey, S. J., Eyo, E. U., & Jeremiah, J. J. (2021). Experimental Study on Early Age Characteristics of Lime-GGBS-Treated Gypseous Clays under Wet–Dry Cycles. Geotechnics, 1(2), 402-415. https://doi.org/10.3390/geotechnics1020019