Design of a Friendly Solar Food Dryer for Domestic Over-Production

Abstract

Highlights

- Using low-cost and reused materials it is possible to design and construct clean and cheap solar dryer prototypes;

- Drying kinetics in different products on our prototypes prove to be similar compared to an electric commercial dryer;

- Solar dehydration of vegetables and fruits over-production greatly reduces waste and the costs of final products;

Abstract

1. Introduction

- (i)

- Air movement.

- (ii)

- Heat transfer.

- (iii)

- Type of drying chamber.

- (1)

- Direct, normally with low-cost construction, composed of a drying chamber covered by a transparent glass or plastic. The main disadvantages are the large amount of space needed to its installation and the doubtful quality of the products due to the direct exposition to sun [22].

- (2)

- Indirect, with a solar panel and a drying chamber. The air is warmed in the solar panel and conducted inside the drying chamber, transferring heat to the material, and evaporating the moisture. They are more effective than the direct type; the drying rate is higher, air velocity and temperature can be controlled, and the products quality is preserved. Nevertheless, this system can be more expensive [23].

- (3)

- Mixed solar dryer, which uses both direct and indirect solar energy. A separate collector preheats the air before it enters the drying chamber, and the sun helps heat the products. This system could be more powerful but is more complex and expensive [24].

- (4)

- Hybrid solar dryer, combines other heating processes (fossil fuel, biomass or electric) with solar heating. The major advantage is that it can operate without solar energy, or during the night. It reduces the drying time compared to other transfers described. However, it has an increasing environmental footprint and running costs [25].

2. Materials and Methods

2.1. Dryers

2.1.1. Solar Dryer—Prototype 1

2.1.2. Solar Dryer—Prototype 2

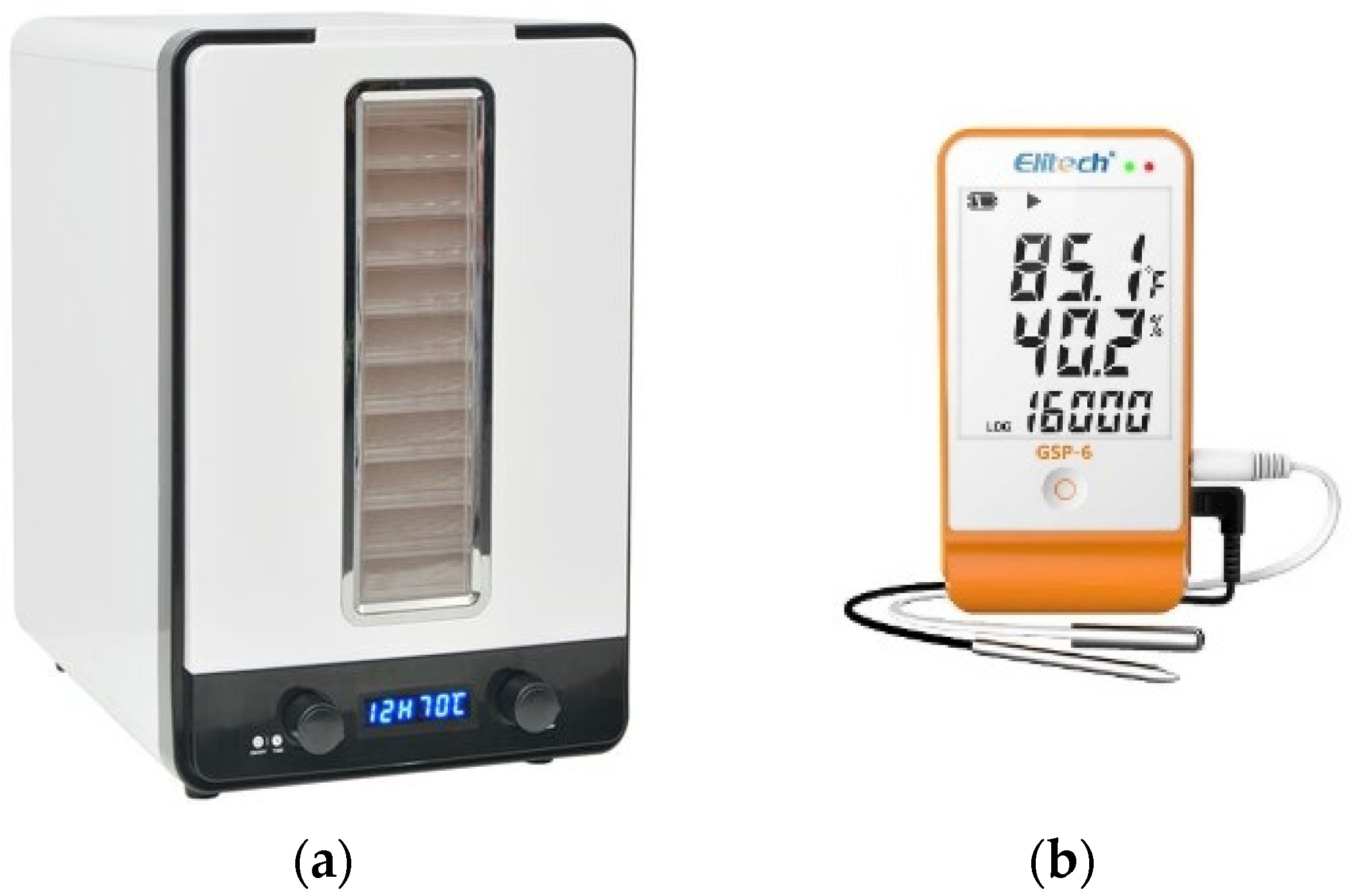

2.1.3. Electric Commercial Dryer

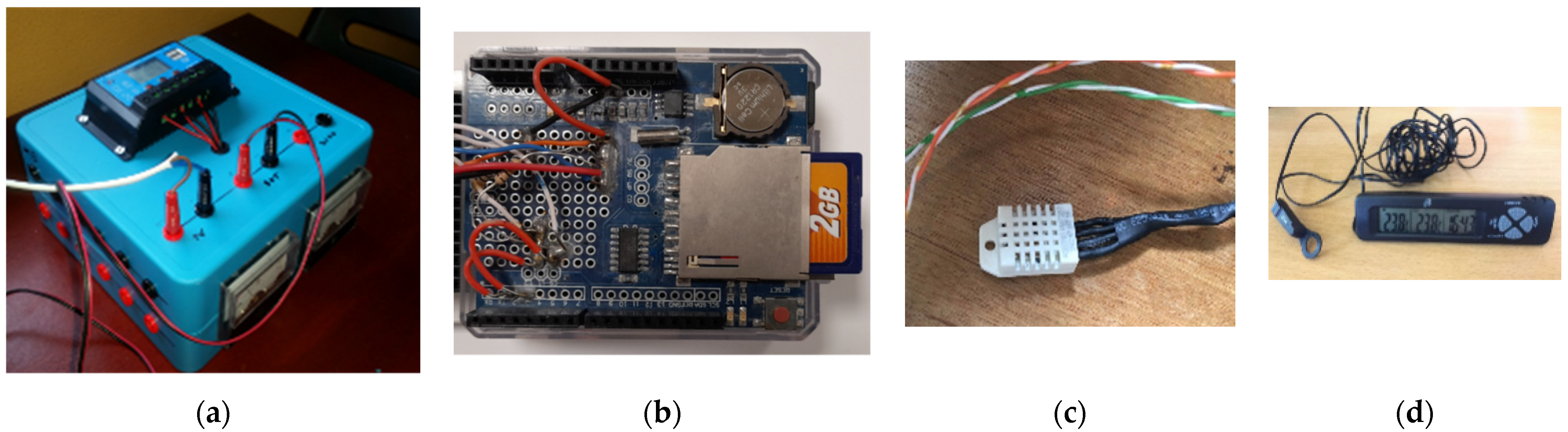

2.2. Data Acquisition Systems

3. Dryers Characterization

3.1. Available Solar Energy

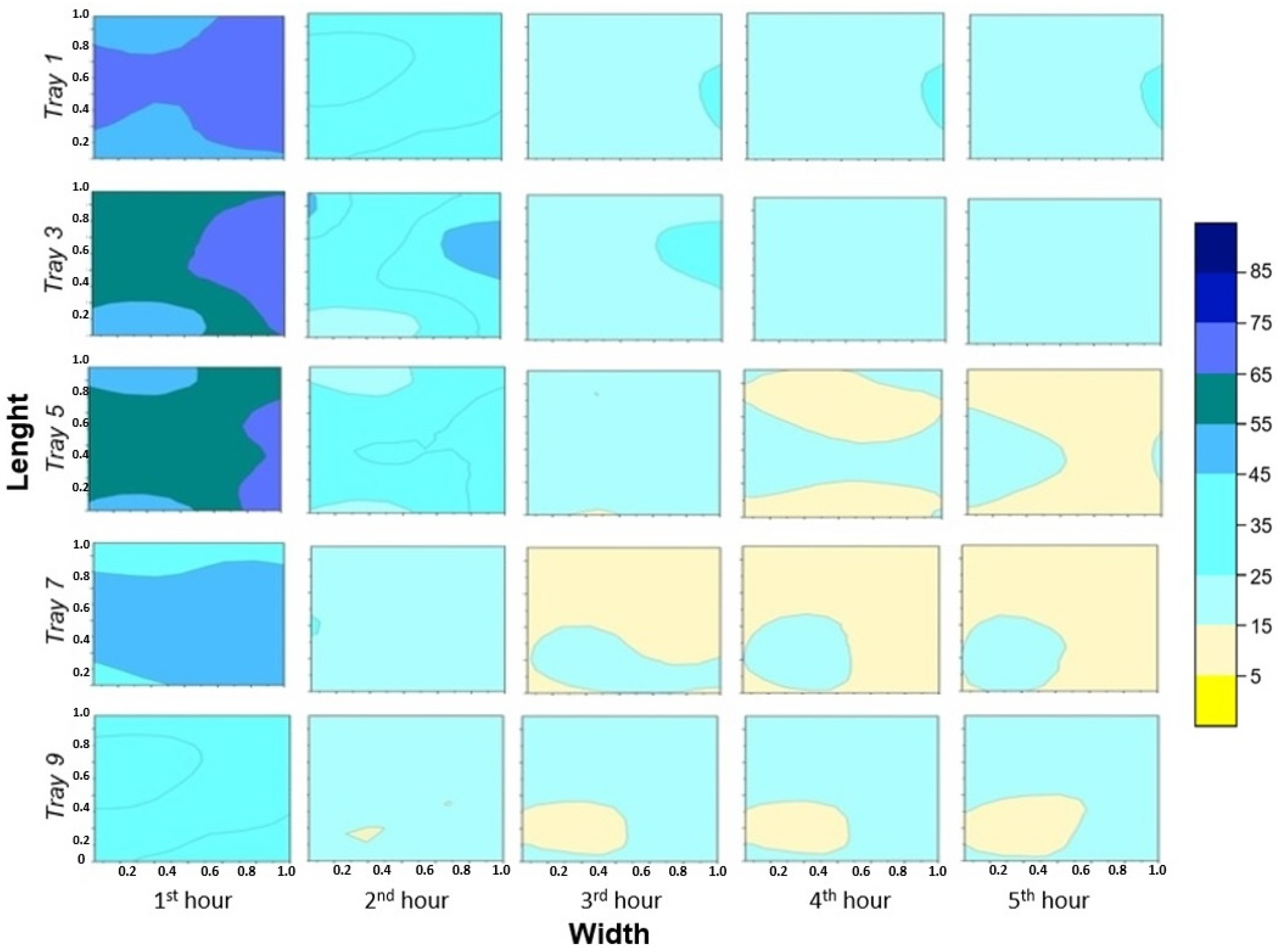

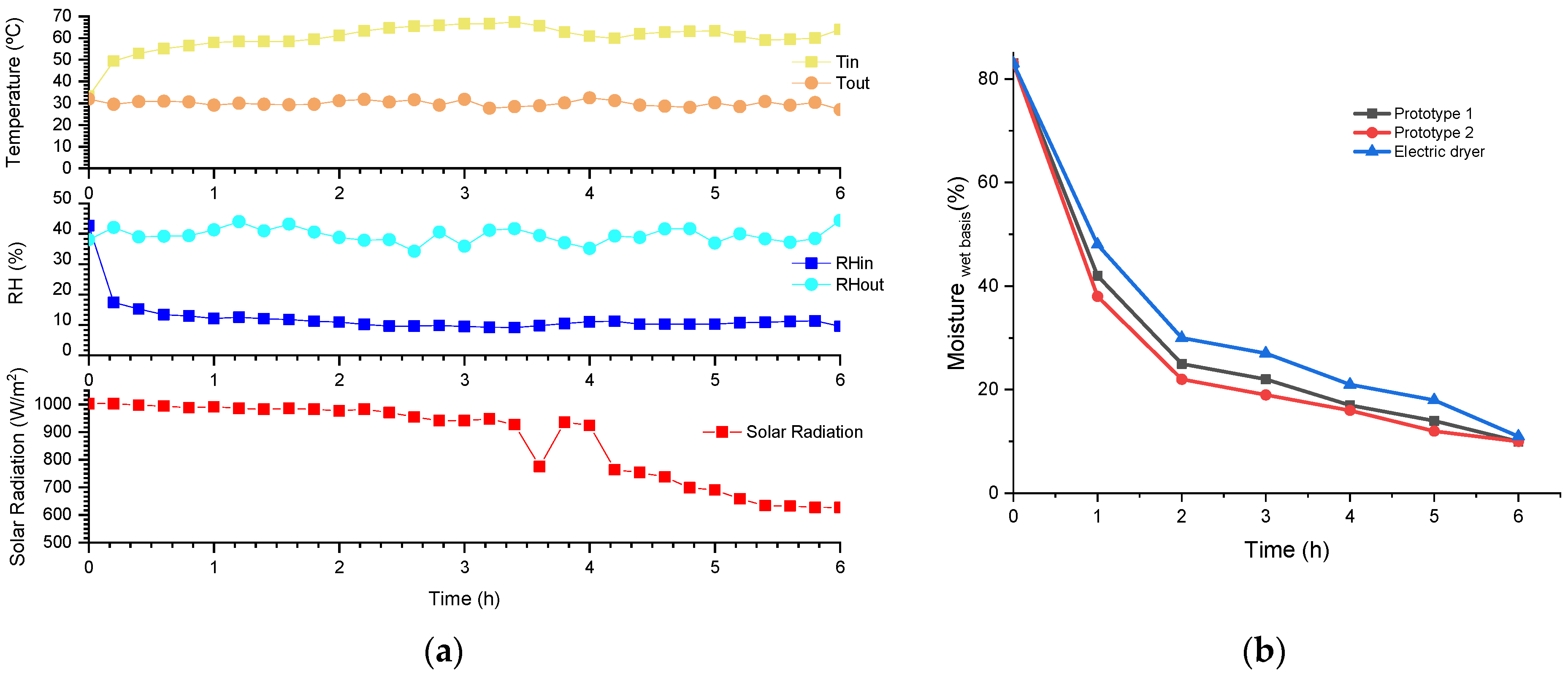

3.2. Assessment of Dehydrators Dynamics

3.3. Solar Fluctuations

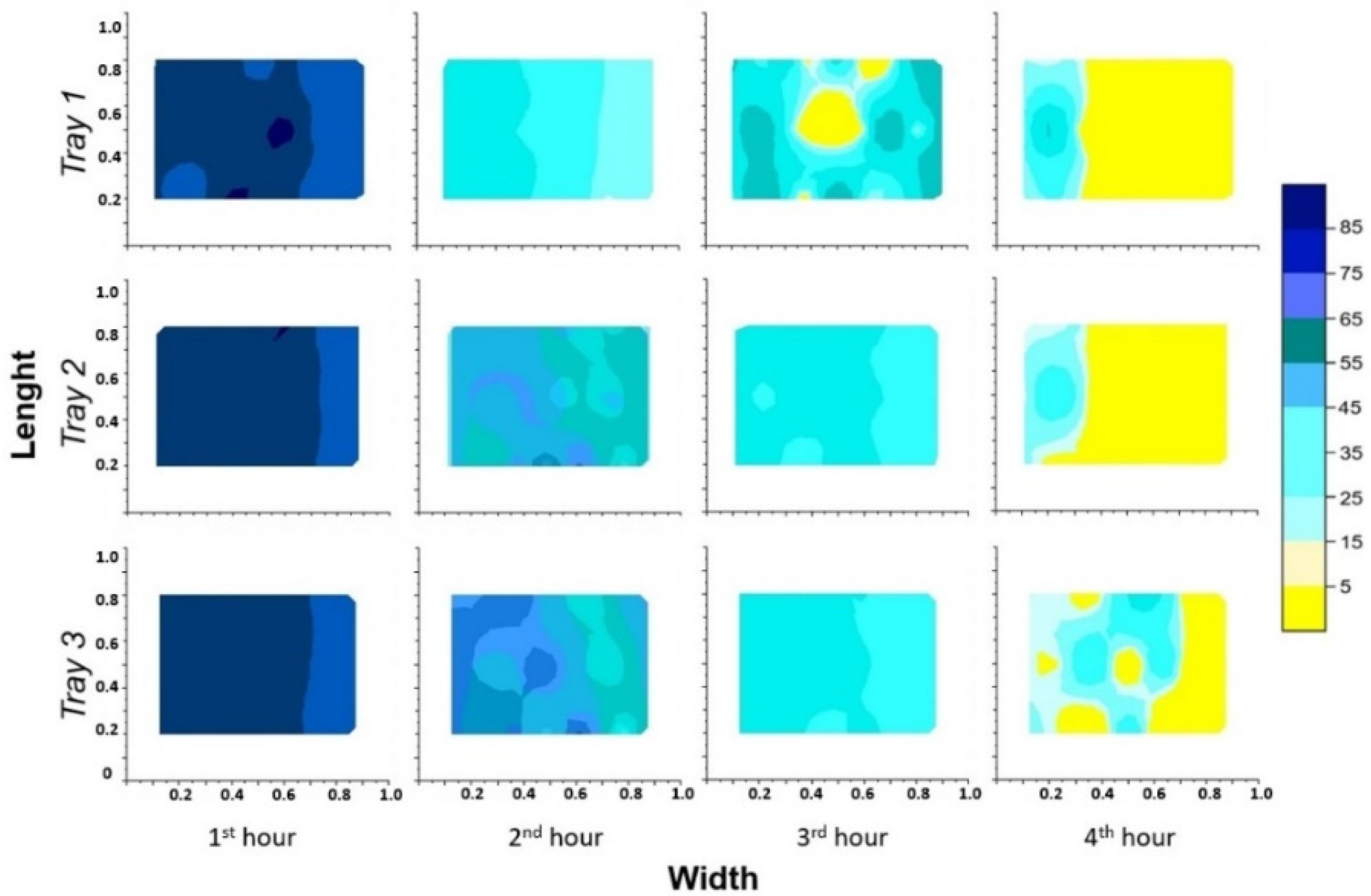

3.4. Comparative Study between Prototype 2 and the Electric Commercial Dryer

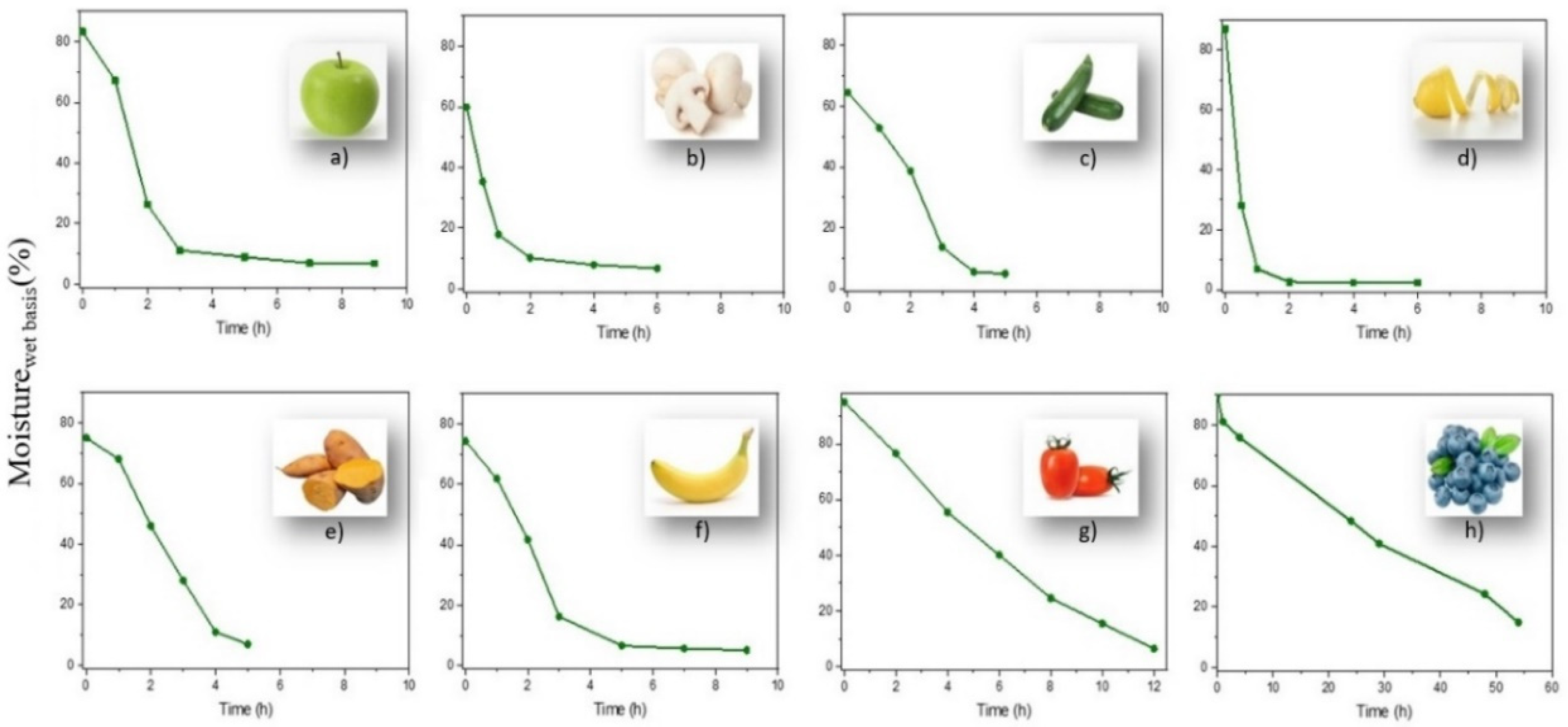

4. Drying Tests

5. Economic Analysis

6. Final Remarks and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stiling, J.; Li, S.; Stroeve, P.; Thompson, J.; Mjawa, B.; Kornbluth, K.; Barrett, D.M. Performance evaluation of an enhanced fruit solar dryer using concentrating panels. Energy Sustain. Dev. 2012, 16, 224–230. [Google Scholar] [CrossRef]

- Sharif, Z.; Mustapha, F.; Jai, J.; Mohd Yusof, N.; Zaki, N. Review on methods for preservation and natural preservatives for extending the food longevity. Chem. Eng. Res. Bull. 2017, 19, 145. [Google Scholar] [CrossRef]

- Elzubeir, A.O. Solar Dehydration of Sliced Onion. Int. J. Veg. Sci. 2014, 20, 264–269. [Google Scholar] [CrossRef]

- Yang, D.; Wang, W.; Gueymard, C.A.; Hong, T.; Kleissl, J.; Huang, J.; Perez, M.J.; Perez, R.; Bright, J.M.; Xia, X.; et al. A review of solar forecasting, its dependence on atmospheric sciences and implications for grid integration: Towards carbon neutrality. Renew. Sustain. Energy Rev. 2022, 161, 112348. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, K.U.; Singh, M.K.; Kushwaha, A.K.S.; Kumar, A.; Mahato, S. Design and Fabrication of Solar Dryer System for Food Preservation of Vegetables or Fruit. J. Food Qual. 2022, 22, 6564933. [Google Scholar] [CrossRef]

- Musembi, M.N.; Kiptoo, K.S.; Yuichi, N. Design and Analysis of Solar Dryer for Mid-Latitude Region. Energy Procedia 2016, 100, 98–110. [Google Scholar] [CrossRef]

- Tekin, Z.H.; Başlar, M.; Karasu, S.; Kilicli, M. Dehydration of green beans using ultrasound-assisted vacuum drying as a novel technique: Drying kinetics and quality parameters. J. Food Process. Preserv. 2017, 41, e13227. [Google Scholar] [CrossRef]

- Njoku, P.; Ayuk, A.; Okoye, C. Temperature effects on Vitamin C content in citrus fruits. Pak. J. Nutr. 2011, 10, 1168–1169. [Google Scholar] [CrossRef]

- Iglesias Díaz, R.; José Gómez, R.A.; Lastres Danguillecourt, O.; López de Paz, P.; Farrera Vázquez, N.; Ibáñez Duharte, G. Diseño, construcción y evaluación de un secador solar para mango Ataulfo. Rev. Mex. Cienc. Agrícolas 2017, 8, 1719–1732. [Google Scholar] [CrossRef][Green Version]

- Souto Ribeiro, W.; Sant’Ana Silva, A.; Ferreira da Silva, Á.; Marinho do Nascimento, A.; Rocha Limão, M.; Bezerra da Costa, F.; de Souza, P.; de Melo Queiroz, A.; Soares da Silva, O.; Oliveira Galdino, P.; et al. Handmade solar dryer: An environmentally and economically viable alternative for small and medium producers. Sci. Rep. 2021, 11, 17177. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; Porciuncula, B.D.A.; Laurindo, J.B. A convective multi-flash drying process for producing dehydrated crispy fruits. J. Food Eng. 2012, 108, 523–531. [Google Scholar] [CrossRef]

- Defraeye, T.; Radu, A. Convective drying of fruit: A deeper look at the air-material interface by conjugate modeling. Int. J. Heat Mass Transf. 2017, 108, 1610–1622. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; Gonçalves, J.C.; Calado, A.R.P.; Correia, P.M.R. Evaluation of thermo-physical properties and drying kinetics of carrots in a convective hot air drying system. Agric. Eng. Int. CIGR J. 2016, 18, 245–257. [Google Scholar]

- El-Sebaii, A.A.; Shalaby, S.M. Experimental investigation of an indirect-mode forced convection solar dryer for drying thymus and mint. Energy Convers. Manag. 2013, 74, 109–116. [Google Scholar] [CrossRef]

- Kahraman, O.; Malvandi, A.; Vargas, L.; Feng, H. Drying characteristics and quality attributes of apple slices dried by a non-thermal ultrasonic contact drying method. Ultrason. Sonochem. 2021, 73, 105510. [Google Scholar] [CrossRef]

- Yadav, A.K.; Singh, S.V. Osmotic dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2014, 51, 1654–1673. [Google Scholar] [CrossRef]

- Timoumi, S.; Mihoubi, D.; Zagrouba, F. Shrinkage, vitamin C degradation and aroma losses during infra-red drying of apple slices. LWT-Food Sci. Technol. 2007, 40, 1648–1654. [Google Scholar] [CrossRef]

- Joseph Bassey, E.; Cheng, J.H.; Sun, D.W. Improving drying kinetics, physicochemical properties and bioactive compounds of red dragon fruit (Hylocereus species) by novel infrared drying. Food Chem. 2022, 375, 131886. [Google Scholar] [CrossRef]

- Moreno, Á.H.; Aguirre, Á.J.; Hernández Maqueda, R.; Jiménez Jiménez, G.; Torres Miño, C. Effect of temperature on the microwave drying process and the viability of amaranth seeds. Biosyst. Eng. 2022, 215, 49–66. [Google Scholar] [CrossRef]

- Bala, B.K.; Debnath, N. Solar Drying Technology: Potentials and Developments. J. Fundam. Renew. Energy Appl. 2012, 2, 1–5. [Google Scholar] [CrossRef]

- Gulcimen, F.; Karakaya, H.; Durmus, A. Drying of sweet basil with solar air collectors. Renew. Energy 2016, 93, 77–86. [Google Scholar] [CrossRef]

- Zarezade, M.; Mostafaeipour, A. Identifying the effective factors on implementing the solar dryers for Yazd province, Iran. Renew. Sustain. Energy Rev. 2016, 57, 765–775. [Google Scholar] [CrossRef]

- Lingayat, A.B.; Chandramohan, V.P.; Raju, V.R.K.; Meda, V. A review on indirect type solar dryers for agricultural crops—Dryer setup, its performance, energy storage and important highlights. Appl. Energy 2020, 258, 114005. [Google Scholar] [CrossRef]

- Forson, F.K.; Nazha, M.A.A.; Akuffo, F.O.; Rajakaruna, H. Design of mixed-mode natural convection solar crop dryers: Application of principles and rules of thumb. Renew. Energy 2007, 32, 2306–2319. [Google Scholar] [CrossRef]

- Suherman, S.; Hadiyanto, H.; Susanto, E.E.; Utami, I.A.P.; Ningrum, T. Hybrid solar dryer for sugar-palm vermicelli drying. J. Food Process Eng. 2020, 43, e13471. [Google Scholar] [CrossRef]

- An, C.H.; Ri, H.J.; Han, T.U.; Kim, S.I.; Ju, U.S. Feasibility of winter cultivation of fruit vegetables in a solar greenhouse in temperate zone; experimental and numerical study. Sol. Energy 2022, 233, 18–30. [Google Scholar] [CrossRef]

- Ghaffari, A.; Mehdipour, R. Modeling and Improving the Performance of Cabinet Solar Dryer Using Computational Fluid Dynamics. Int. J. Food Eng. 2015, 11, 157–172. [Google Scholar] [CrossRef]

- Xiii, T.; August, F.; Ingeaua, M.; Prisecaru, T.; Sorica, C. ANNALS of Faculty Engineering Hunedoara—International Journal of Engineering Sizing Convective Drying Chambers Designed to Fruits; University Politehnica Timișoara: Timișoara, Romania, 2015; pp. 233–239. [Google Scholar]

- Defraeye, T.; Verboven, P. Convective drying of fruit: Role and impact of moisture transport properties in modelling. J. Food Eng. 2017, 193, 95–107. [Google Scholar] [CrossRef]

- Ferreira, L.C.; Fernandes, J.R.; Rodríguez-Chueca, J.; Peres, J.A.; Lucas, M.S.; Tavares, P.B. Photocatalytic degradation of an agro-industrial wastewater model compound using a UV LEDs system: Kinetic study. J. Environ. Manag. 2020, 269, 110740. [Google Scholar] [CrossRef]

- Herrmann, H.; Bucksch, H. Dehydra(ta)tion f. Wörterbuch GeoTechnik/Dictionary Geotechnical Engineering; Springer: Berlin/Heidelberg, Germany, 2013; p. 227. [Google Scholar]

- Lamidi, R.O.; Jiang, L.; Pathare, P.B.; Wang, Y.D.; Roskilly, A.P. Recent advances in sustainable drying of agricultural produce: A review. Appl. Energy 2019, 233–234, 367–385. [Google Scholar] [CrossRef]

- Derossi, A.; Severini, C.; Cassi, D. Mass Transfer Mechanisms during Dehydration of Vegetable Food: Traditional and Innovative Approaches. In Advanced Topics in Mass Transfer; IntechOpen: London, UK, 2011; pp. 305–354. [Google Scholar]

- Lewicki, P.P. Effect of pre-drying treatment, drying and rehydration on plant tissue properties: A review. Int. J. Food Prop. 1998, 1, 1–22. [Google Scholar] [CrossRef]

- Tzempelikos, D.A.; Vouros, A.P.; Bardakas, A.V.; Filios, A.E.; Margaris, D.P. Case studies on the effect of the air drying conditions on the convective drying of quinces. Case Stud. Therm. Eng. 2014, 3, 79–85. [Google Scholar] [CrossRef]

- Inyang, U.E.; Oboh, I.O.; Etuk, B.R. Kinetic Models for Drying Techniques—Food Materials. Adv. Chem. Eng. Sci. 2018, 8, 27–48. [Google Scholar] [CrossRef]

- Borges, J.; Oliveira, A.; Carvalho, J.; Nunes, L.; Barcelos, M.; Carvalho, S.; Paula, C.; Moraes, D. Avaliação Física E Sensorial De Chips Desidratados De Maçã Sabor Natural E Canela/Physical and Sensory Assessment of Dehydrated Apple Chips with Natural and Cinnamon Flavor. Braz. J. Dev. 2020, 6, 66554–66573. [Google Scholar] [CrossRef]

- Voulvoulis, N.; Burgman, M.A. The contrasting roles of science and technology in environmental challenges. Crit. Rev. Environ. Sci. Technol. 2019, 49, 1079–1106. [Google Scholar] [CrossRef]

- Sámano Delgado, E.; Martinez-Flores, H.; Garnica-Romo, M.; Aranda-Sanchez, J.; Sosa-Aguirre, C.; De Jesús Cortés-Penagos, C.; Fernández-Muñoz, J. Optimization of solar dryer for the dehydration of fruits and vegetables. J. Food Process. Preserv. 2013, 37, 489–495. [Google Scholar] [CrossRef]

- Tiwari, A. A Review on Solar Drying of Agricultural Produce. J. Food Process. Technol. 2016, 7, 1–12. [Google Scholar] [CrossRef]

- Oztop, H.F.; Bayrak, F.; Hepbasli, A. Energetic and exergetic aspects of solar air heating (solar collector) systems. Renew. Sustain. Energy Rev. 2013, 21, 59–83. [Google Scholar] [CrossRef]

| Electric Dryer | Prototype 1 | Prototype 2 | ||

|---|---|---|---|---|

| Acquisition | (€) | 163 | 142 | 62 |

| Reintegration time | (years) | 5 | 4 | 3 |

| Number of runs/year | (n) | 60 | 50 | 40 |

| Loading capacity | (kg) | 1.50 | 4 | 2 |

| Energy/batch 8 h | (kWh) | 2.67 | 0 | 0 |

| Energy cost/batch 8 h | (€/kWh) | 0.481 | 0 | 0 |

| CO2e/batch 8 h | (kg) | 1.30 | 0 | 0 |

| Weight of dried product | (kg) | 0.150 | 0.400 | 0.300 |

| Cost of dry apple slices without purchase the fruit | (€/kg dry) | 6.83 | 1.78 | 1.72 |

| Apple cost | (€/kg) | 1.50 | 1.50 | 1.50 |

| Cost of dry apple slices including purchase the fruit | (€/kg dry) | 21.83 | 16.78 | 16.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandes, L.; Fernandes, J.R.; Tavares, P.B. Design of a Friendly Solar Food Dryer for Domestic Over-Production. Solar 2022, 2, 495-508. https://doi.org/10.3390/solar2040029

Fernandes L, Fernandes JR, Tavares PB. Design of a Friendly Solar Food Dryer for Domestic Over-Production. Solar. 2022; 2(4):495-508. https://doi.org/10.3390/solar2040029

Chicago/Turabian StyleFernandes, Lisete, José R. Fernandes, and Pedro B. Tavares. 2022. "Design of a Friendly Solar Food Dryer for Domestic Over-Production" Solar 2, no. 4: 495-508. https://doi.org/10.3390/solar2040029

APA StyleFernandes, L., Fernandes, J. R., & Tavares, P. B. (2022). Design of a Friendly Solar Food Dryer for Domestic Over-Production. Solar, 2(4), 495-508. https://doi.org/10.3390/solar2040029