Three Point Bending of Laser Engineered Net Shaping (LENS) Repaired Inconel 625 †

Abstract

:1. Introduction

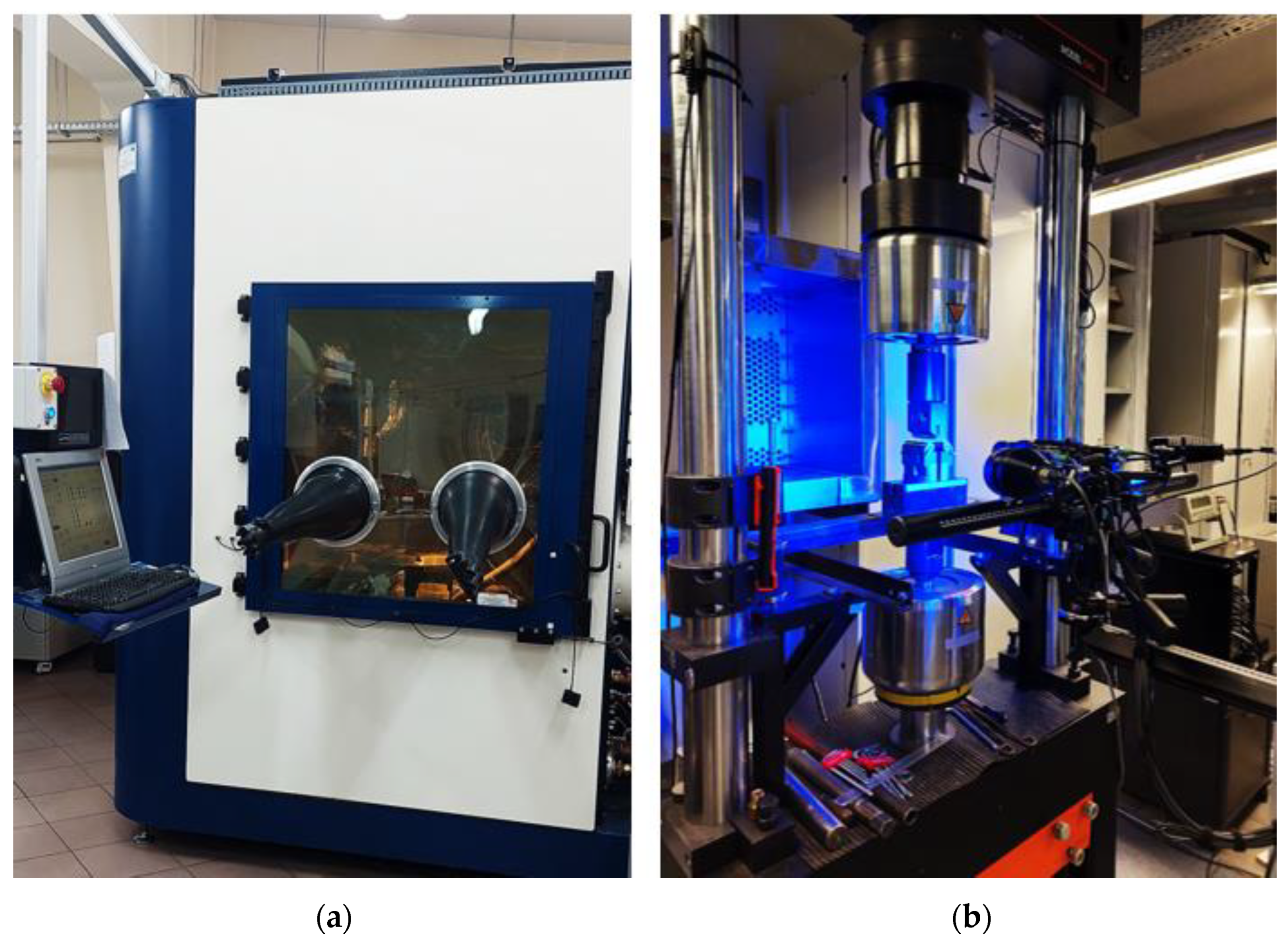

2. Materials and Methods

3. Results and Discussion

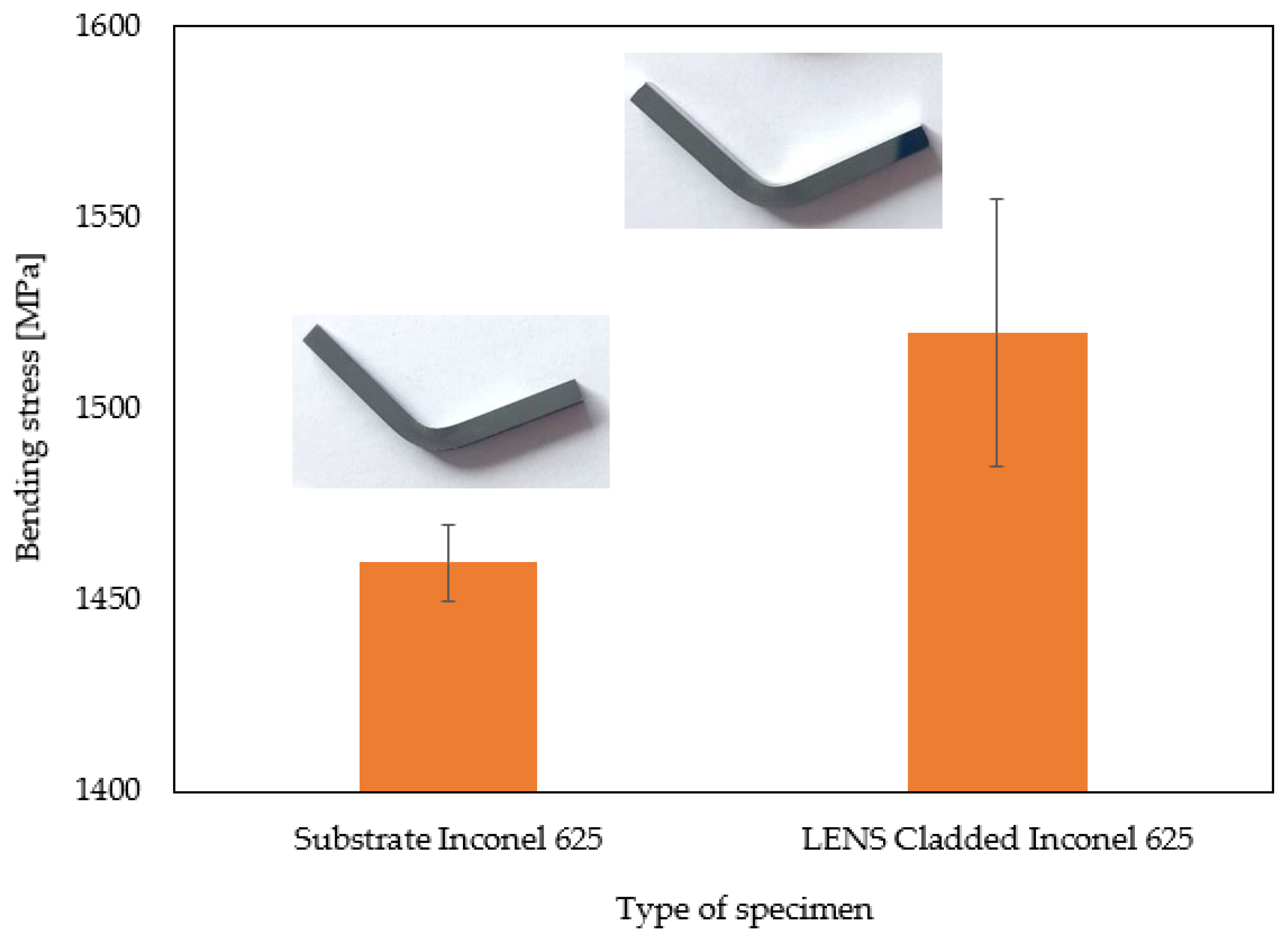

3.1. Three-Point Bending Tests

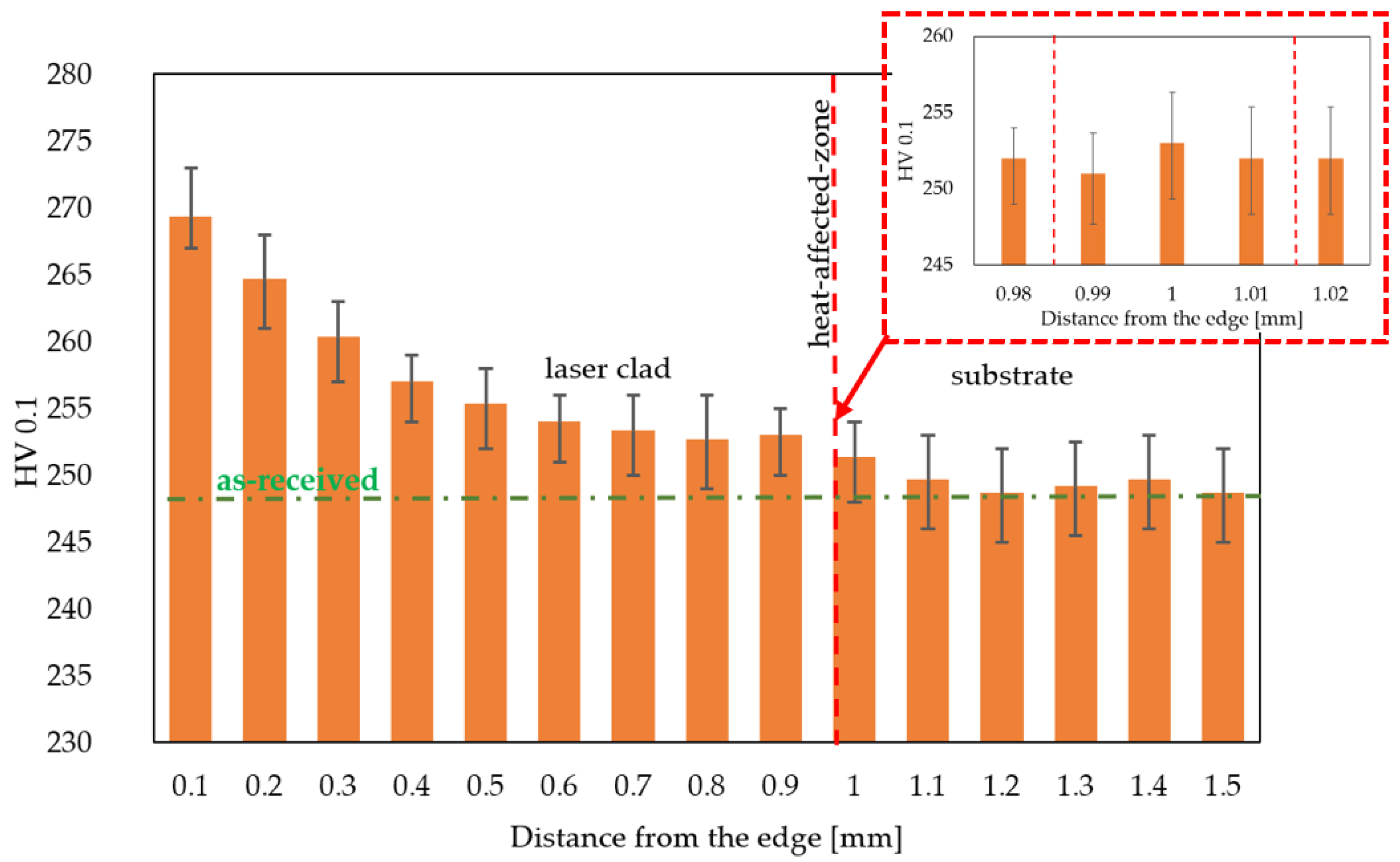

3.2. Microhardness Profile

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dutkiewicz, J.; Rogal, Ł.; Kalita, D.; Berent, K.; Antoszewski, B.; Danielewski, H.; Węglowski, M.; Łazińska, M.; Durejko, T.; Czujko, T. Microstructure and Properties of Inconel 625 Fabricated Using Two Types of Laser Metal Deposition Methods. Materials 2020, 13, 5050. [Google Scholar] [CrossRef]

- Song, Y.; Fan, J.; Liu, X.; Zhang, P.; Li, J. Thermal Processing Map and Microstructure Evolution of Inconel 625 Alloy Sheet Based on Plane Strain Compression Deformation. Materials 2021, 14, 5059. [Google Scholar] [CrossRef]

- Shankar, V.; Rao, K.B.S.; Mannan, S. Microstructure and mechanical properties of Inconel 625 superalloy. J. Nucl. Mater. 2001, 288, 222–232. [Google Scholar] [CrossRef]

- Petrzak, P.; Kowalski, K.; Rozmus-Górnikowska, M.; Dębowska, A.; Jędrusik, M.; Koclęga, D. Annealing effect on microstructure and chemical composition of inconel 625 alloy. Met. Foundry Eng. 2018, 44, 73. [Google Scholar] [CrossRef]

- Evans, R. 2-Selection and testing of metalworking fluids. In Metalworking Fluids (MWFs) for Cutting and Grinding; Woodhead Publishing Series in Metals and Surface Engineering; Woodhead Publishing: Sawston, UK, 2012; pp. 23–78. [Google Scholar]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef] [Green Version]

- Ali, J.; Kevin, L.E. Chapter 5—Case Studies of Using Materials Ranking. In Multi-Criteria Decision Analysis for Supporting the Selection of Engineering Materials in Product Design; Heinemann: Butterworth, Malaysia, 2013; pp. 83–104. [Google Scholar]

- Dilkush; Mohammed, R.; Reddy, G.M.; Rao, K.S. Effect of PWHT on Microstructure, Mechanical and Corrosion Behaviour of Gas Tungsten Arc Welds of IN718 Superalloys. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012030. [Google Scholar] [CrossRef]

- Smith, M.; Bichler, L.; Gholipour, J.; Wanjara, P. Mechanical properties and microstructural evolution of in-service Inconel 718 superalloy repaired by linear friction welding. Int. J. Adv. Manuf. Technol. 2016, 90, 1931–1946. [Google Scholar] [CrossRef]

- Ola, O.; Doern, F. A study of cold metal transfer clads in nickel-base INCONEL 718 superalloy. Mater. Des. 2014, 57, 51–59. [Google Scholar] [CrossRef]

- He, K.; Dong, L.; Wang, Q.; Zhang, H.; Li, Y.; Liu, L.; Zhang, Z. Comparison on the microstructure and corrosion behavior of Inconel 625 cladding deposited by tungsten inert gas and cold metal transfer process. Surf. Coat. Technol. 2022, 435, 128245. [Google Scholar] [CrossRef]

- Tharappel, J.T.; Babu, J. Welding processes for Inconel 718- A brief review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012082. [Google Scholar] [CrossRef]

- Benoît, A.; Jobez, S.; Paillard, P.; Klosek, V.; Baudin, T. Study of Inconel 718 weldability using MIG CMT process. Sci. Technol. Weld. Join. 2011, 16, 477–482. [Google Scholar] [CrossRef]

- Xiang, K.; Chen, L.-Y.; Chai, L.; Guo, N.; Wang, H. Microstructural characteristics and properties of CoCrFeNiNbx high-entropy alloy coatings on pure titanium substrate by pulsed laser cladding. Appl. Surf. Sci. 2020, 517, 146214. [Google Scholar] [CrossRef]

- Avila, J.; Bose, S.; Bandyopadhyay, A. Additive manufacturing of titanium and titanium alloys for biomedical applications. In Titanium in Medical and Dental Applications; Woodhead Publishing: Sawston, UK, 2018; pp. 325–343. [Google Scholar]

- Mudge, R.; Wald, N. Laser Engineered Net Shaping Advances Additive Manufacturing and Repair. Weld. J. 2007, 86, 44–48. [Google Scholar]

- Abioye, T.; McCartney, D.; Clare, A. Laser cladding of Inconel 625 wire for corrosion protection. J. Mater. Process. Technol. 2014, 217, 232–240. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Le, G.; Xu, Q.; Yang, L.; Li, R.; Wang, W. The Interface Microstructures and Mechanical Properties of Laser Additive Repaired Inconel 625 Alloy. Materials 2020, 13, 4416. [Google Scholar] [CrossRef] [PubMed]

| Laser Power [W] | Feed Rate [mm/s] | Powder Flow Rate [g/min] | Laser On/Off Wait [ms] | Substrate Temperature [°C] |

|---|---|---|---|---|

| 550 | 12 | 15 | 400 | 300 |

| Element | O | Fe | Ni | Al | Si | Zr | Nb | Mo | Cr | Mn |

|---|---|---|---|---|---|---|---|---|---|---|

| % wt. | 2.18 | 5.10 | 55.87 | 0.38 | 0.34 | 0.48 | 3.83 | 9.03 | 22.53 | 0.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barwinska, I.; Kopec, M.; Łazińska, M.; Brodecki, A.; Durejko, T.; Kowalewski, Z.L. Three Point Bending of Laser Engineered Net Shaping (LENS) Repaired Inconel 625. Phys. Sci. Forum 2022, 4, 1. https://doi.org/10.3390/psf2022004001

Barwinska I, Kopec M, Łazińska M, Brodecki A, Durejko T, Kowalewski ZL. Three Point Bending of Laser Engineered Net Shaping (LENS) Repaired Inconel 625. Physical Sciences Forum. 2022; 4(1):1. https://doi.org/10.3390/psf2022004001

Chicago/Turabian StyleBarwinska, Izabela, Mateusz Kopec, Magdalena Łazińska, Adam Brodecki, Tomasz Durejko, and Zbigniew L. Kowalewski. 2022. "Three Point Bending of Laser Engineered Net Shaping (LENS) Repaired Inconel 625" Physical Sciences Forum 4, no. 1: 1. https://doi.org/10.3390/psf2022004001

APA StyleBarwinska, I., Kopec, M., Łazińska, M., Brodecki, A., Durejko, T., & Kowalewski, Z. L. (2022). Three Point Bending of Laser Engineered Net Shaping (LENS) Repaired Inconel 625. Physical Sciences Forum, 4(1), 1. https://doi.org/10.3390/psf2022004001