Direct Powder Forging—A New Approach for near Net Shape Processing of Titanium Powders

Abstract

:1. Introduction

2. Materials and Methods

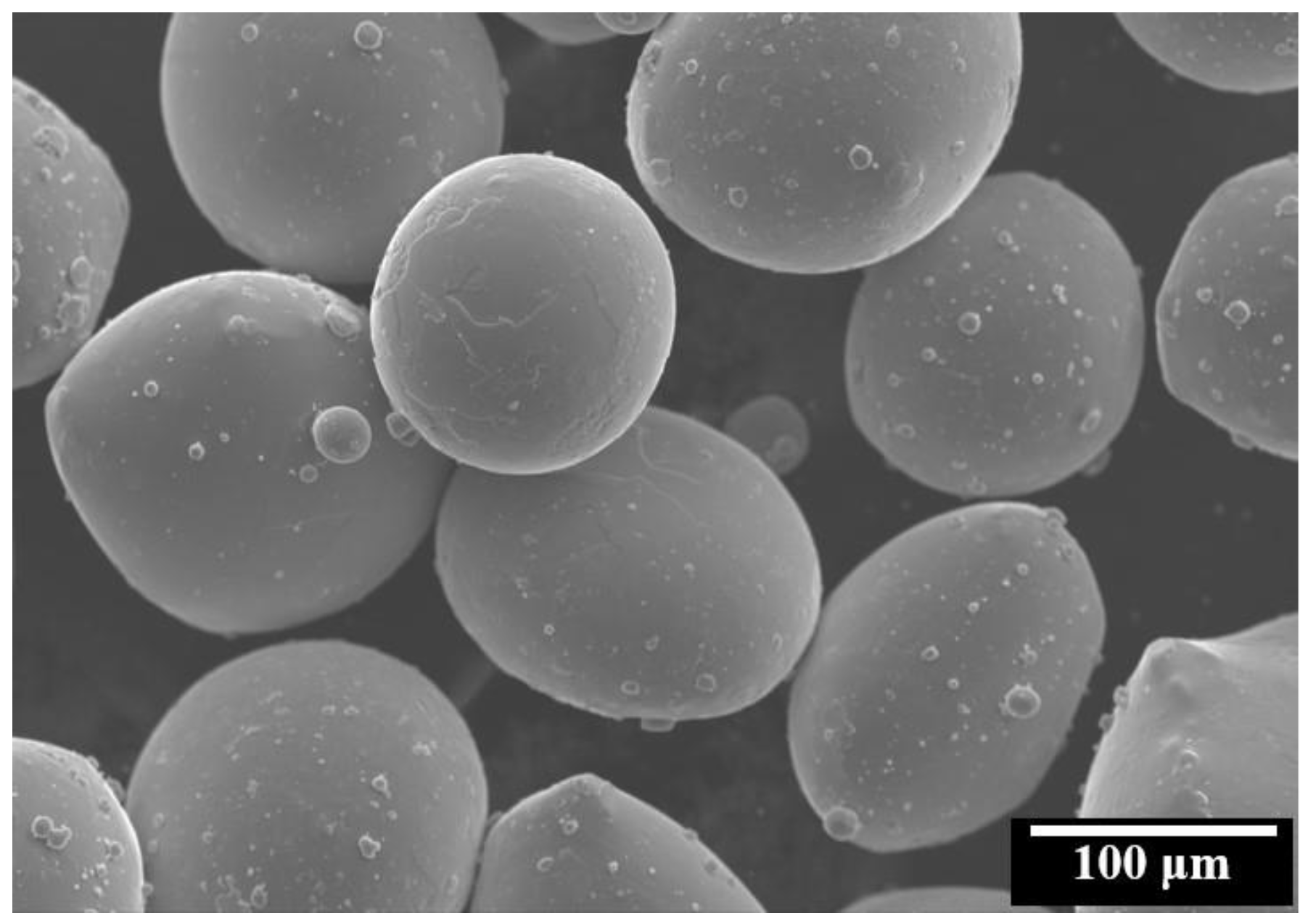

2.1. Materials

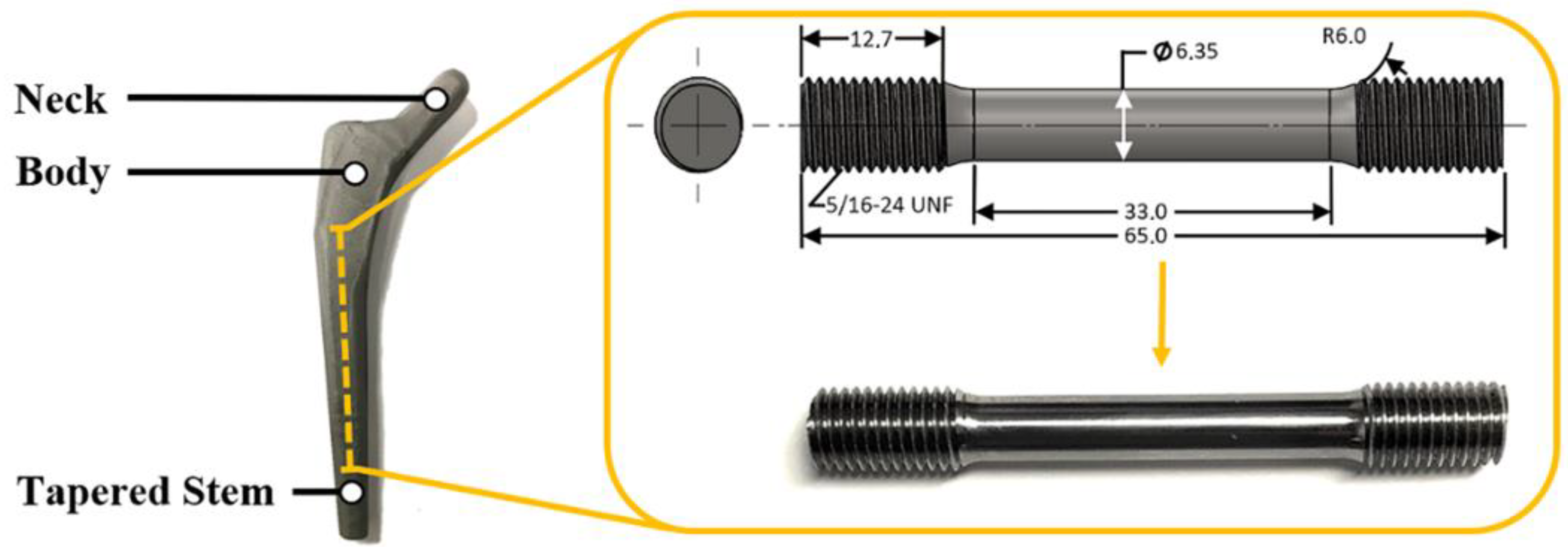

2.2. Forming Process

3. Results and Discussion

3.1. Physical Properties

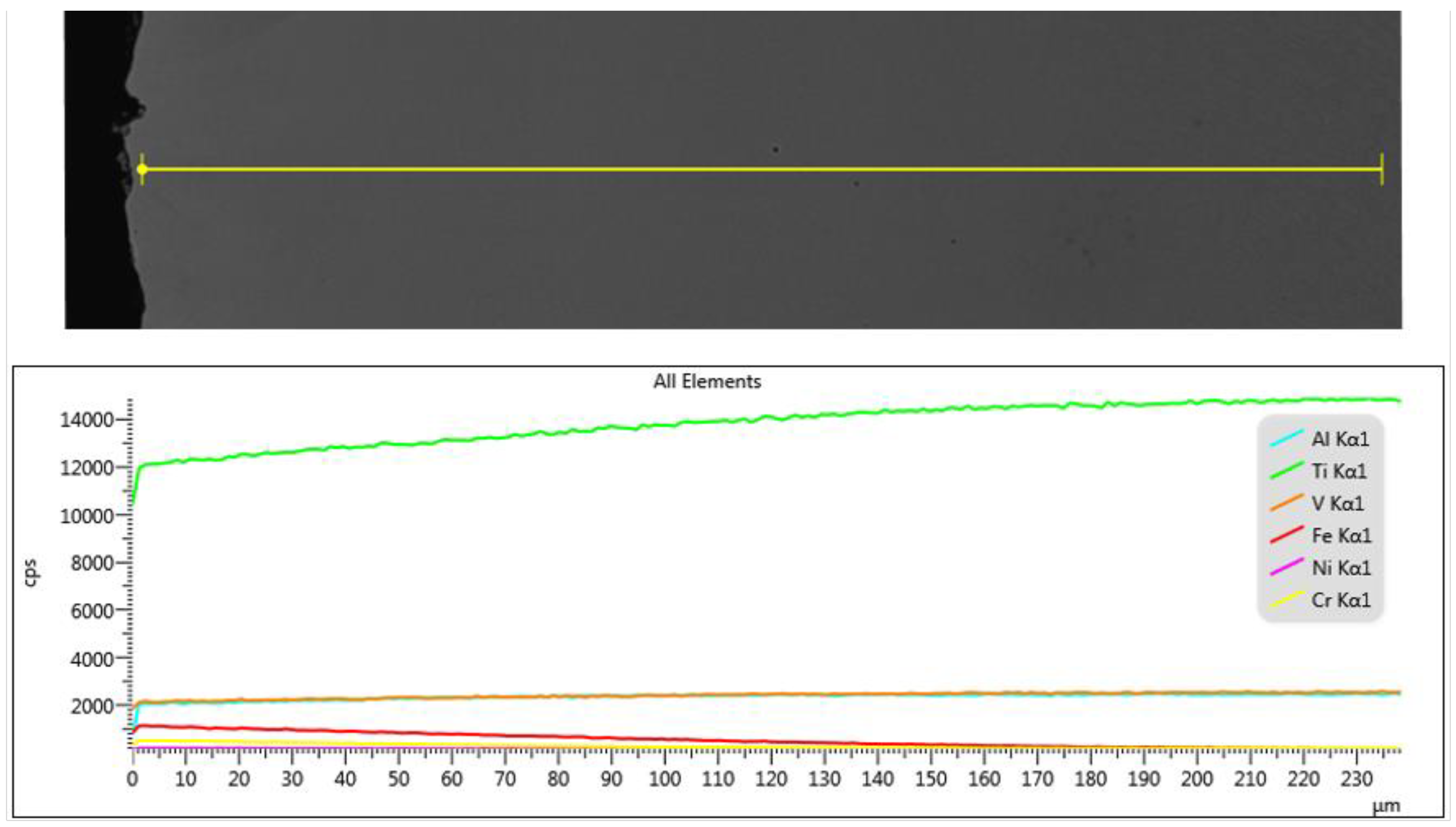

3.2. Chemical Composition

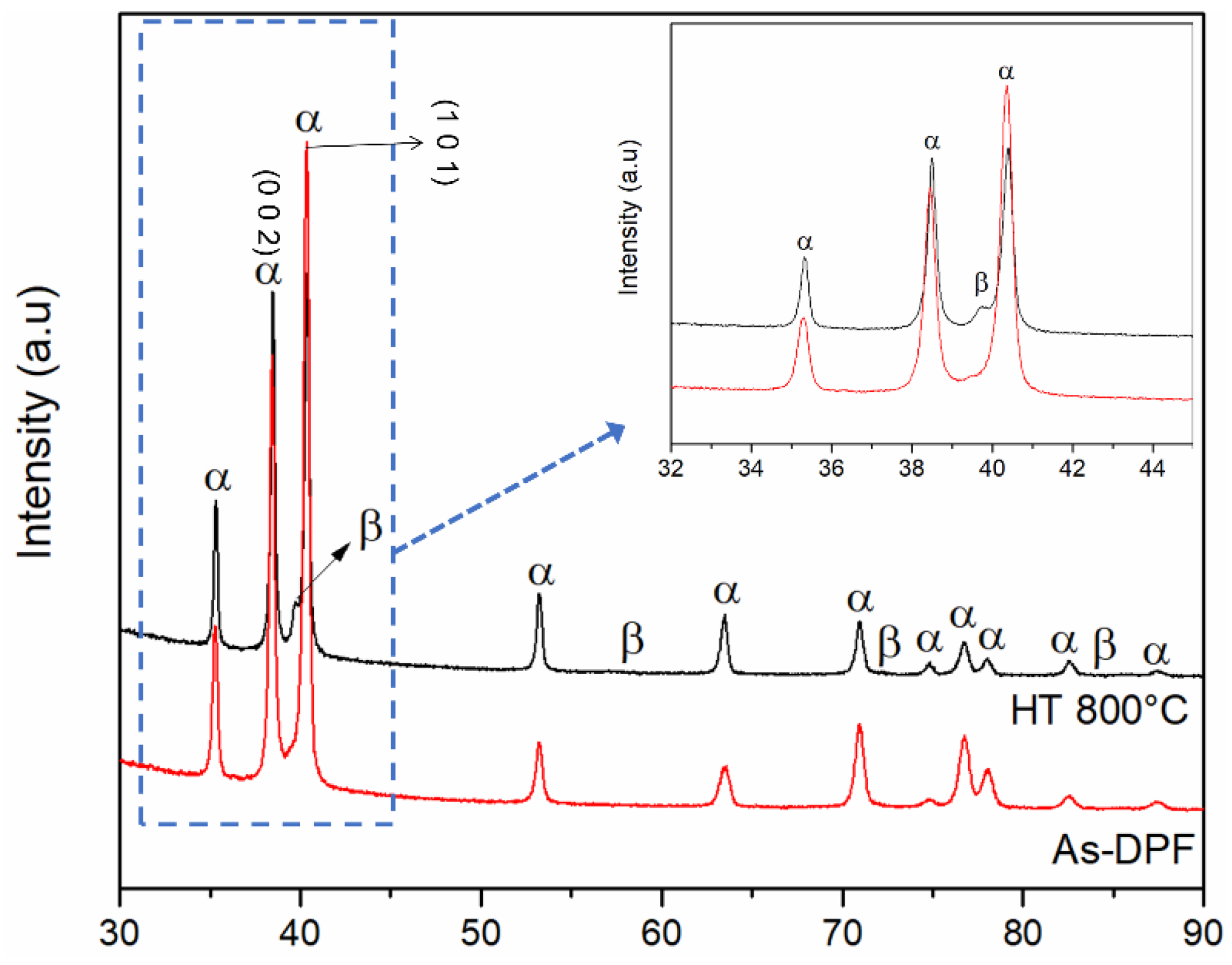

3.3. Phase Identification

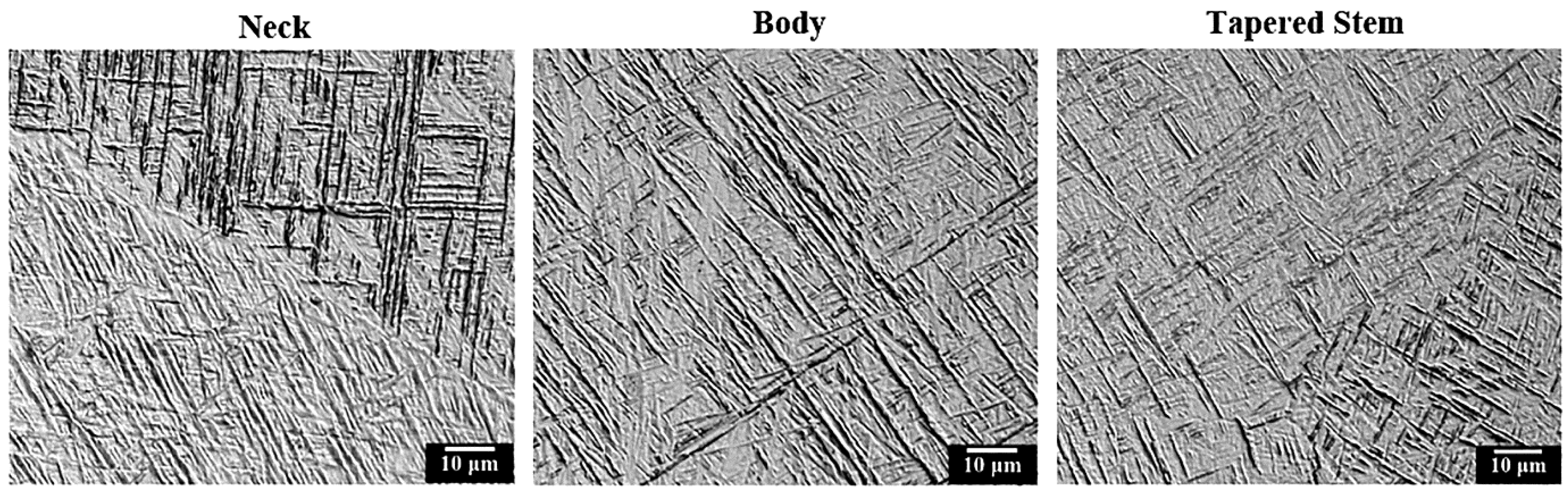

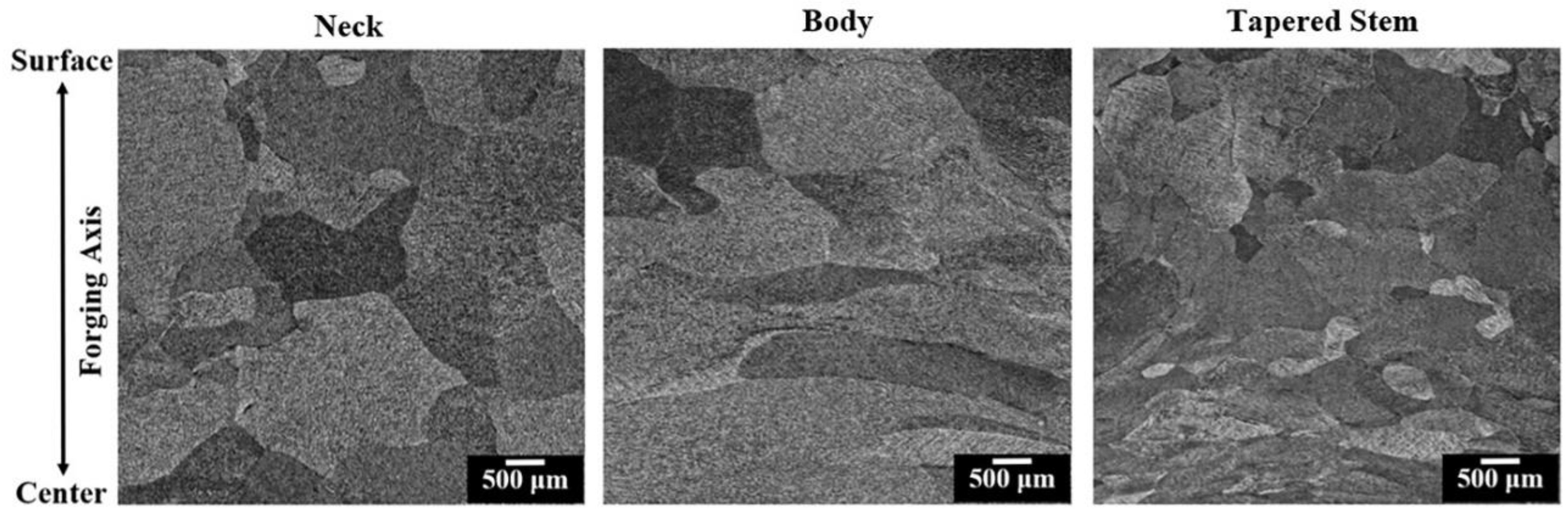

3.4. Microstructures of the As-Forged Femoral Stem

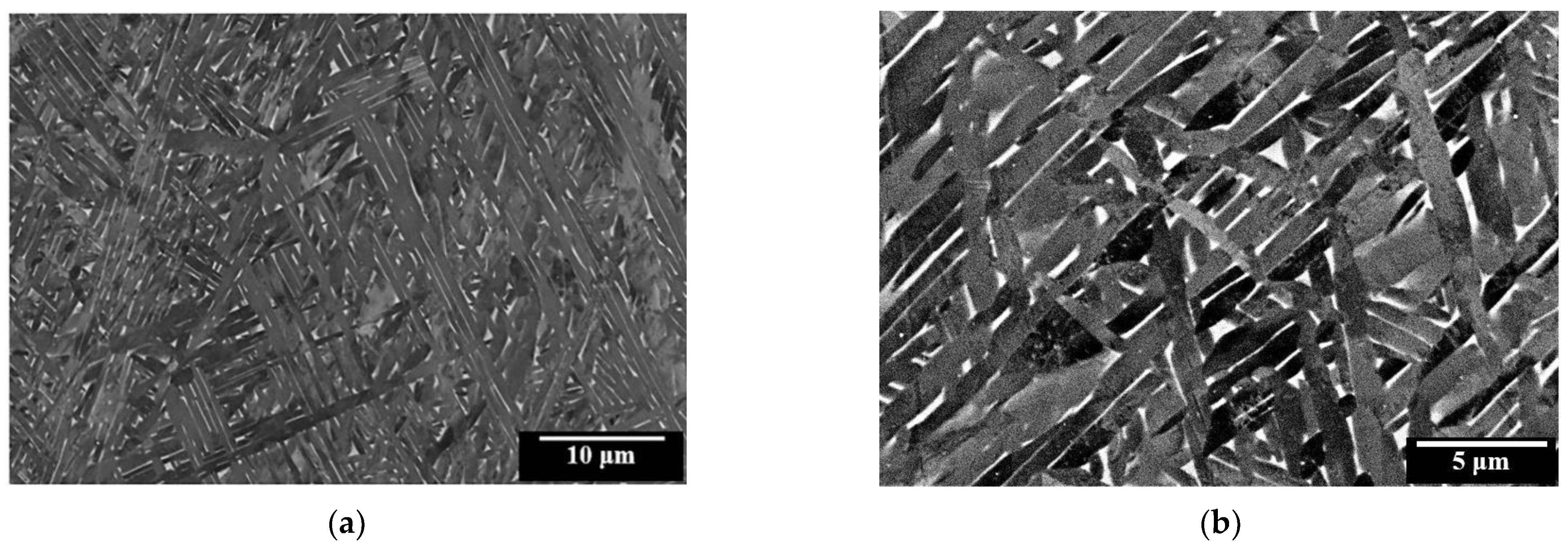

3.5. Effect of Heat Treatment on Microstructure and Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; He, B.; Lyu, T.; Zou, Y. A Review on Additive Manufacturing of Titanium Alloys for Aerospace Applications: Directed Energy Deposition and beyond Ti-6Al-4V. JOM 2021, 73, 1804–1818. [Google Scholar] [CrossRef]

- Wollmann, M.; Kiese, J.; Wagner, L. Properties and Applications of Titanium Alloys in Transport. In Ti-2011; Zhou, L., Chang, H., Lu, Y., Xu, D., Eds.; Science Press Beijing: Beijing, China, 2011; pp. 837–844. [Google Scholar]

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D. Producing hip implants of titanium alloys by additive manufacturing. Int. J. Bioprint. 2016, 2, 78–84. [Google Scholar] [CrossRef] [Green Version]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef]

- Kraft, E.H. Summary of Emerging Titanium Cost Reduction Technologies. In A Study Performed for US Department of Energy and Oak Ridge National Laboratory Subcontract 4000023694; EHK Technologies: Vancouver, WA, USA, 2004. [Google Scholar]

- Raynova, S.; Yang, F.; Bolzoni, L. Mechanical behaviour of induction sintered blended elemental powder metallurgy Ti alloys. Mater. Sci. Eng. A 2020, 799, 140157. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Paramore, J.D.; Sun, P.; Chandran, K.S.R.; Zhang, Y.; Xia, Y.; Cao, F.; Koopman, M.; Free, M. Powder metallurgy of titanium—past, present, and future. Int. Mater. Rev. 2017, 63, 407–459. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Pan, Y.; Sun, J.; Lu, X.; Zhang, J. A net-shape forming process of Ti–6Al–4V sphere joints. Powder Met. 2021, 64, 404–411. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Chown, L.H.; Omotoyinbo, J.A. Omotoyinbo. Development of low-cost titanium alloys: A chronicle of challenges and opportunities. Mater. Today Proc. 2021, 38, 564–569. [Google Scholar] [CrossRef]

- Oke, S.R.; Ogunwande, G.S.; Onifade, M.; Aikulola, E.; Adewale, E.D.; Olawale, O.E.; Ayodele, B.E.; Mwema, F.; Obiko, J.; Bodunrin, M.O. An overview of conventional and non-conventional techniques for machining of titanium alloys. Manuf. Rev. 2020, 7, 34. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, P.; Cao, Y.; Li, X.; Wei, D.; Kato, H.; Wu, Z. New Ti/β-Ti alloy laminated composite processed by powder metallurgy: Microstructural evolution and mechanical property. Mater. Sci. Eng. A 2021, 822, 141702. [Google Scholar] [CrossRef]

- Umeda, J.; Tanaka, T.; Teramae, T.; Kariya, S.; Fujita, J.; Nishikawa, H.; Shibutani, Y.; Shen, J.; Kondoh, K. Microstructures analysis and quantitative strengthening evaluation of powder metallurgy Ti–Fe binary extruded alloys with (α+β)-dual-phase. Mater. Sci. Eng. A 2021, 803, 140708. [Google Scholar] [CrossRef]

- Niu, H.; Zhang, H.; Sun, Q.; Zhang, D. Breaking through the strength-ductility trade-off dilemma in powder metallurgy Ti–6Al–4V titanium alloy. Mater. Sci. Eng. A 2019, 754, 361–369. [Google Scholar] [CrossRef]

- Weston, N.; Jackson, M. FAST-forge—A new cost-effective hybrid processing route for consolidating titanium powder into near net shape forged components. J. Mater. Process. Technol. 2017, 243, 335–346. [Google Scholar] [CrossRef]

- Careau, S.G.; Tougas, B.; Ulate-Kolitsky, E. Effect of direct powder forging process on the mechanical properties and microstructural of Ti-6Al-4E ELI. Materials 2021, 14, 4499. [Google Scholar] [CrossRef]

- Olsson, L.R.; Lampe, V.; Fischmeister, H. Direct forging of high-alloy steel powders to bar stock. Powder Metall. 1974, 17, 347–362. [Google Scholar] [CrossRef]

- Jiang, J. Development of Direct Powder Forging Process. Ph.D. Thesis, Imperial College London, South Kensington, UK, 2017. [Google Scholar] [CrossRef]

- Manière, C.; Lee, G.; Olevsky, E.A. All-Materials-Inclusive Flash Spark Plasma Sintering. Sci. Rep. 2017, 7, 15071. [Google Scholar] [CrossRef] [Green Version]

- Childerhouse, T.; Jackson, M. Near net shape manufacture of titanium alloy components from powder and wire: A review of state-of-the-art process routes. Metals 2019, 9, 689. [Google Scholar] [CrossRef] [Green Version]

- Bai, Q.; Lin, J.; Jiang, J.; Dean, T.; Zou, J.; Tian, G. A study of direct forging process for powder superalloys. Mater. Sci. Eng. A 2015, 621, 68–75. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Fang, S.; Shi, Z.; Jiang, J.; Zhou, X.; Lin, J. Direct powder forging of PM nickel-based superalloy: Densification and recrystallisation. Int. J. Adv. Manuf. Technol. 2017, 88, 2661–2670. [Google Scholar] [CrossRef] [Green Version]

- Calvert, E.; Wynne, B.; Weston, N.; Tudball, A.; Jackson, M. Thermomechanical processing of a high strength metastable beta titanium alloy powder, consolidated using the low-cost FAST-forge process. J. Mater. Process. Technol. 2018, 254, 158–170. [Google Scholar] [CrossRef]

- Pope, J.; Jackson, M. Fast-forge of diffusion bonded dissimilar titanium alloys: A novel hybrid processing approach for next generation near-net shape components. Metals 2019, 9, 654. [Google Scholar] [CrossRef] [Green Version]

- Careau, S.G.; Ulate-Kolitsky, E.; Tougas, B. In-situ alloying of Ti-5Fe titanium alloy using direct powder forging and the effect of the powder mixing method. Materialia 2022, 24, 101471. [Google Scholar] [CrossRef]

- ASTM F136-21; Standard Specification for Wrought Titanium 6Aluminium-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401). ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 22 July 2022).

- Dharavath, B.; Haq, A.U.; Varma, M.D.; Buddi, T.; Singh, S.K.; Naik, M.T. Comparative study of ASS 316L on formability at room temperature and super plastic region. Adv. Mater. Process. Technol. 2020, 6, 384–395. [Google Scholar] [CrossRef]

- ASTM B962-17; Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle. ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 22 July 2022).

- ASTM E2371-21a; Standard Test Method for Analysis of Titanium and Titanium Alloys by Direct Current Plasma and Inductively Coupled Plasma Atomic Emission Spectrometry (Performance-Based Test Methodology). ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 22 July 2022).

- ASTM E8/E8M-21; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016. Available online: www.astm.org (accessed on 22 July 2022).

- Bai, L.; Gong, C.; Chen, X.; Sun, Y.; Zhang, J.; Cai, L.; Zhu, S.; Xie, S.Q. Additive Manufacturing of Customized Metallic Orthopedic Implants: Materials, Structures, and Surface Modifications. Metals 2019, 9, 1004. [Google Scholar] [CrossRef] [Green Version]

- Jaber, H.; Kónya, J.; Kulcsár, K.; Kovács, T. Effects of Annealing and Solution Treatments on the Microstructure and Mechanical Properties of Ti6Al4V Manufactured by Selective Laser Melting. Materials 2022, 15, 1978. [Google Scholar] [CrossRef]

- Zhang, Z.; Qu, S.; Feng, A.; Shen, J. Achieving grain refinement and enhanced mechanical properties in Ti–6Al–4V alloy produced by multidirectional isothermal forging. Mater. Sci. Eng. A 2017, 692, 127–138. [Google Scholar] [CrossRef]

- Guo, L.; Fan, X.; Yu, G.; Yang, H. Microstructure control techniques in primary hot working of titanium alloy bars: A review. Chin. J. Aeronaut. 2016, 29, 30–40. [Google Scholar] [CrossRef] [Green Version]

- Semiatin, S.L. An Overview of the Thermomechanical Processing of α/β Titanium Alloys: Current Status and Future Research Opportunities. Met. Mater. Trans. A. 2020, 51, 2593–2625. [Google Scholar] [CrossRef] [Green Version]

- Chatterjee, R.; Murty, S.V.S.N.; Alankar, A. Dynamic Recrystallization in Titanium Alloys: A Comprehensive Review. Mater Perform. Charact. 2020, 9, 1–42. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, X.; Zou, J.; Ke, Y.; Liu, P.; Ma, L.; Luo, H. Effect of Cooling Rate Following Β Forging on Texture Evolution and Variant Selection during Β→α Transformation in Ti-55511 Alloy. J. Mater. Sci. Technol. 2022, 113, 1–13. [Google Scholar] [CrossRef]

- Fan, X.G.; Yang, H.; Gao, P.F.; Zuo, R.; Lei, P.H. The Role of Dynamic and Post Dynamic Recrystallization on Microstructure Refinement in Primary Working of a Coarse Grained Two-Phase Titanium Alloy. J. Mater. Process. Technol. 2016, 234, 290–299. [Google Scholar] [CrossRef]

- Motyka, M. Martensite Formation and Decomposition during Traditional and AM Processing of Two-Phase Titanium Alloys—An Overview. Metals 2021, 11, 481. [Google Scholar] [CrossRef]

- Ahmed, T.; Rack, H.J. Phase transformations during cooling in α+β titanium alloys. Mater. Sci. Eng. A 1998, 243, 206–211. [Google Scholar] [CrossRef]

- Gil, F.J.; Planell, J.A. Behaviour of normal grain growth kinetics in single phase titanium and titanium alloys. Mater. Sci. Eng. A 2000, 283, 17–24. [Google Scholar] [CrossRef]

| Chemical Composition [%-wt.] | Size | |||||||

|---|---|---|---|---|---|---|---|---|

| Ti | Fe | Al | V | O | N | C | D50 (µm) | |

| Ti-6Al-4V | Bal. | 0.16 | 6.43 | 4.15 | 0.04 | 0.01 | <0.01 | 150 |

| Density (g/cm3) | Relative Density (%) | ||

|---|---|---|---|

| Theoretical | Measured | 99.9 | |

| Ti-6Al-4VDPF | 4.430 | 4.425 ± 0.005 | |

| Chemical Composition [%-wt.] | |||||||

|---|---|---|---|---|---|---|---|

| Ti | Fe | Al | V | O | N | C | |

| Ti-6Al-4VDPF | Bal. | 0.16 | 6.43 | 4.15 | 0.04 | 0.01 | <0.01 |

| ASTM F136 STD | Bal. | 0.25 | 5.5–6.5 | 3.5–4.5 | 0.13 | 0.05 | 0.08 |

| Neck | Body | Tapered Stem | |

|---|---|---|---|

| As-forged | 34.7 ± 0.4 | 33.7 ± 0.2 | 36.6 ± 0.5 |

| HT 800 °C | 34.6 ± 0.1 | 34.6 ± 0.3 | 34.8 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Germain Careau, S.; Ulate-Kolitsky, E.; Tougas, B. Direct Powder Forging—A New Approach for near Net Shape Processing of Titanium Powders. Powders 2023, 2, 21-31. https://doi.org/10.3390/powders2010002

Germain Careau S, Ulate-Kolitsky E, Tougas B. Direct Powder Forging—A New Approach for near Net Shape Processing of Titanium Powders. Powders. 2023; 2(1):21-31. https://doi.org/10.3390/powders2010002

Chicago/Turabian StyleGermain Careau, Sébastien, Elena Ulate-Kolitsky, and Bernard Tougas. 2023. "Direct Powder Forging—A New Approach for near Net Shape Processing of Titanium Powders" Powders 2, no. 1: 21-31. https://doi.org/10.3390/powders2010002

APA StyleGermain Careau, S., Ulate-Kolitsky, E., & Tougas, B. (2023). Direct Powder Forging—A New Approach for near Net Shape Processing of Titanium Powders. Powders, 2(1), 21-31. https://doi.org/10.3390/powders2010002