Application of Sapphire-Fiber-Bragg-Grating-Based Multi-Point Temperature Sensor in Boilers at a Commercial Power Plant

Abstract

:1. Introduction

2. Materials and Methods

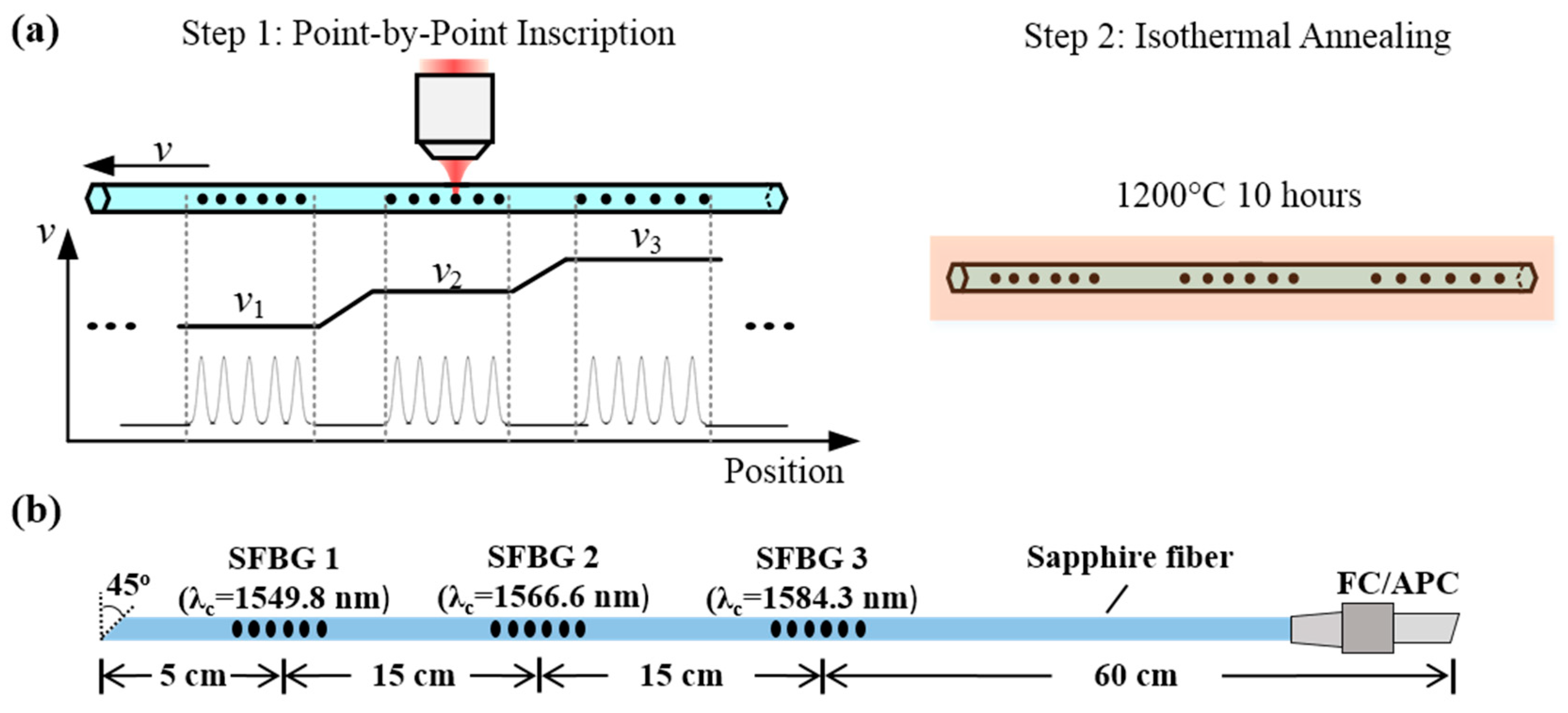

2.1. Fabrication and Working Principle of SFBGs Sensor

2.2. Sensor Packaging

2.3. Interrogation System and Sensor Calibration

3. Results

3.1. Sensor Calibration and Stability

3.2. Sensor Deployment and Performace

3.2.1. Coal-Fired Boiler

3.2.2. Gas-Fired Boiler

3.2.3. Interrogation System and User Interface

4. Conclusions

Author Contributions

Funding

Acknowledgments

Disclaimer

References

- Lockwood, T. Advanced Sensors and Smart Controls for Coal-Fired Power Plant Controls for Coal-Fired Power Plant; IEA Clean Coal Center: London, UK, 2015. [Google Scholar]

- Richardson, A.; Keairns, D.; White, B. The role of sensors and controls in transforming the energy landscape. In Proceedings of the Micro-and Nanotechnology Sensors, Systems, and Applications X, Orlando, FL, USA, 15–19 April 2018. [Google Scholar]

- Yan, W.; Ya, Y.; Du, F.; Shao, H.; Zhao, P. Spectrometer-Based Line-of-Sight Temperature Measurements during Alkali-Pulverized Coal Combustion in a Power Station Boiler. Energies 2017, 10, 1375. [Google Scholar] [CrossRef]

- Bergmans, J.L.; Jenkins, T.P.; Baukal, C.E. Accuracy of a tunable diode laser sensor in large scale furnaces: Initial test results. In Proceedings of the American Flame Research Committee International Symposium on Dynamics and Control of Industrial Combustion Processes, Atlanta, GA, USA, 7–8 November 2005. [Google Scholar]

- Santos, J.L.; Farahi, F. Handbook of Optical Sensors; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Nishikawa, H.; Tohmon, R.; Ohki, Y.; Nagasawa, K.; Hama, Y. Defects and optical absorption bands induced by surplus oxygen in high-purity synthetic silica. J. Appl. Phys. 1989, 65, 4672–4678. [Google Scholar] [CrossRef]

- Yu, L.; Bonnell, E.; Homa, D.; Pickrell, G.; Wang, A.; Ohodnicki, P.R., Jr.; Woodruff, S.; Chorpening, B.; Buric, M. Observation of temperature dependence of the IR hydroxyl absorption bands in silica optical fiber. Opt. Fiber Technol. 2016, 30, 1–7. [Google Scholar] [CrossRef]

- Xiao, H.; Deng, J.; Pickrell, G.; May, R.; Wang, A. Single-crystal sapphire fiber-based strain sensor for high-temperature applications. J. Lightware Technol. 2003, 21, 2276–2283. [Google Scholar] [CrossRef]

- Wang, J.; Dong, B.; Lally, E.; Gong, J.; Han, M.; Wang, A. Multiplexed high temperature sensing with sapphire fiber air gap-based extrinsic Fabry Perot interferometers. Opt. Lett. 2010, 35, 619–621. [Google Scholar] [CrossRef] [PubMed]

- Yan, A.; Chen, R.; Zaghloul, M.; Poole, Z.; Ohodnicki, P.; Chen, K. Sapphire fiber optical hydrogen sensors for high-temperature environments. IEEE Photonics Tech. Lett. 2016, 28, 47–50. [Google Scholar] [CrossRef]

- Grobnic, D.; Mihailov, S.; Smelser, C.; Ding, H. Sapphire fiber Bragg grating sensor made using femtosecond laser radiation for ultrahigh temperature applications. IEEE Photonics Tech. Lett. 2004, 16, 2505–2507. [Google Scholar] [CrossRef]

- Liu, B.; Yu, Z.; Hill, C.; Cheng, Y.; Homa, D.; Pickrell, G.; Wang, A. Sapphire-fiber-based distributed high-temperature sensing system. Opt. Lett. 2016, 41, 4405–4408. [Google Scholar] [CrossRef]

- Busch, M.; Ecke, W.; Latka, I.; Fischer, D.; Willsch, R.; Bartelt, H. Inscription and characterization of Bragg gratings in single-crystal sapphire optical fibres for high-temperature sensor applications. Meas. Sci. Technol. 2009, 20, 115301. [Google Scholar] [CrossRef]

- Elsmann, T.; Habisreuther, T.; Graf, A.; Rothhardt, M.; Bartelt, H. Inscription of first-order sapphire Bragg gratings using 400 nm femtosecond laser radiation. Opt. Express 2013, 21, 4591–4597. [Google Scholar] [CrossRef]

- Yang, S.; Hu, D.; Wang, A. Point-by-point fabrication and characterization of sapphire fiber Bragg gratings. Opt. Lett. 2017, 42, 4219–4222. [Google Scholar] [CrossRef] [PubMed]

- Thapa, J.; Liu, B.; Woodruff, S.D.; Chorpening, B.T.; Buric, M.P. Raman scattering in single-crystal sapphire at elevated temperatures. Appl. Opt. 2017, 56, 8598–8606. [Google Scholar] [CrossRef] [PubMed]

- Mihailov, S.J. Fiber Bragg grating sensors for harsh environments. Sensors 2012, 12, 1898–1918. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings, 2nd ed.; Academic Press: Cambridge, MA, USA, 1999; p. 130. [Google Scholar]

- Mihailov, S.J.; Grobnic, D.; Smelser, C.W. High-temperature multiparameter sensor based on sapphire fiber Bragg gratings. Opt. Lett. 2010, 35, 2810–2812. [Google Scholar] [CrossRef] [PubMed]

- Grobnic, D.; Mihailov, S.J.; Ding, H.; Bilodeau, F.; Smelser, C.W. Single and low order mode interrogation of a multimode sapphire fibre Bragg grating sensor with tapered fibres. Meas. Sci. Technol. 2006, 17, 980. [Google Scholar] [CrossRef]

- Guo, Q.; Yu, Y.S.; Zheng, Z.M.; Chen, C.; Wang, P.L.; Tian, Z.N.; Zhao, Y.; Ming, X.Y.; Chen, Q.D.; Yang, H.; et al. Femtosecond Laser Inscribed Sapphire Fiber Bragg Grating for High Temperature and Strain Sensing. IEEE Trans. Nanotechnol. 2019, 18, 208–211. [Google Scholar] [CrossRef]

- Habisreuther, T.; Elsmann, T.; Pan, Z.; Graf, A.; Willsch, R.; Schmidt, M.A. Sapphire fiber Bragg gratings for high temperature and dynamic temperature diagnostics. Appl. Therm. Eng. 2015, 91, 860–865. [Google Scholar] [CrossRef]

- Habisreuther, T.; Elsmann, T.; Graf, A.; Schmidt, M.A. High-temperature strain sensing using sapphire fibers with inscribed first-order bragg gratings. IEEE Photonics J. 2016, 8, 1–8. [Google Scholar] [CrossRef]

- Yang, S.; Homa, D.; Heyl, H.; Theis, L.; Beach, J.; Dudding, B.; Acord, G.; Taylor, D.; Pickrell, G.; Wang, A. Commercial boiler test for distributed temperature sensor based on wavelength-multiplexed sapphire fiber bragg gratings. In Proceedings of the Fiber Optic Sensors and Applications XVI, SPIE Defense Commercial Sensing, Baltimore, MD, USA, 14 May 2019. [Google Scholar]

- Yang, S.; Homa, D.; Pickrell, G.; Wang, A. Fiber Bragg grating fabricated in micro-single-crystal sapphire fiber. Opt. Lett. 2018, 43, 62–65. [Google Scholar] [CrossRef]

- Makowska, A.; Markiewicz, K.; Szostkiewicz, L.; Kolakowska, A.; Fidelus, J.; Stanczyk, T.; Wysokinski, K.; Budnicki, D.; Ostrowski, L.; Szymanski, M.; et al. A fiber optic temperature sensor based on multi-core microstructured fiber with coupled cores for a high temperature environment. In Proceedings of the Physics and Simulation of Optoelectronic Devices XXVI, SPIE OPTO, San Francisco, CA, USA, 11 April 2018. [Google Scholar]

- Mamidi, V.R.; Kamineni, S.; Ravinuthala, L.P.; Madhuvarasu, S.S.; Thumu, V.R.; Pachava, V.R.; Putha, K. Fiber Bragg grating-based high temperature sensor and its low cost interrogation system with enhanced resolution. Opt. Appl. 2014, 44, 299–308. [Google Scholar]

- Wang, S.; Yang, T.; Jheng, D.; Hsu, C.; Yang, T.; Ho, T.; Huang, S. Broadband and high-brightness light source: Glass-clad Ti: Sapphire crystal fiber. Opt. Lett. 2015, 40, 5594–5597. [Google Scholar] [CrossRef] [PubMed]

- Hill, C.; Homa, D.; Liu, B.; Yu, Z.; Wang, A.; Pickrell, G. Submicron diameter single crystal sapphire optical fiber. Mater. Lett. 2015, 138, 71–73. [Google Scholar] [CrossRef]

- Dobrovinskaya, E.R.; Lytvynov, L.A.; Pishchik, V. Properties of Sapphire. In Sapphire: Material, Manufacturing, Applications; Springer Science & Business Media: Berlin, Germany, 2009; p. 85. [Google Scholar]

| Component | Material | Vendor |

|---|---|---|

| Ceramic Tube | High Purity Alumina (99.8%) | McDanel Advanced Ceremic, CoorsTek |

| Stainless Steel Fitting | 304 Stainless Steel | McMaster Carr |

| Ferrule | Graphite | Ohio Valley Specialty |

| Fiber Connecter | Zirconia, Stainless steel | Thorlabs |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Homa, D.; Heyl, H.; Theis, L.; Beach, J.; Dudding, B.; Acord, G.; Taylor, D.; Pickrell, G.; Wang, A. Application of Sapphire-Fiber-Bragg-Grating-Based Multi-Point Temperature Sensor in Boilers at a Commercial Power Plant. Sensors 2019, 19, 3211. https://doi.org/10.3390/s19143211

Yang S, Homa D, Heyl H, Theis L, Beach J, Dudding B, Acord G, Taylor D, Pickrell G, Wang A. Application of Sapphire-Fiber-Bragg-Grating-Based Multi-Point Temperature Sensor in Boilers at a Commercial Power Plant. Sensors. 2019; 19(14):3211. https://doi.org/10.3390/s19143211

Chicago/Turabian StyleYang, Shuo, Daniel Homa, Hanna Heyl, Logan Theis, John Beach, Billy Dudding, Glen Acord, Dwyn Taylor, Gary Pickrell, and Anbo Wang. 2019. "Application of Sapphire-Fiber-Bragg-Grating-Based Multi-Point Temperature Sensor in Boilers at a Commercial Power Plant" Sensors 19, no. 14: 3211. https://doi.org/10.3390/s19143211

APA StyleYang, S., Homa, D., Heyl, H., Theis, L., Beach, J., Dudding, B., Acord, G., Taylor, D., Pickrell, G., & Wang, A. (2019). Application of Sapphire-Fiber-Bragg-Grating-Based Multi-Point Temperature Sensor in Boilers at a Commercial Power Plant. Sensors, 19(14), 3211. https://doi.org/10.3390/s19143211