A Comparison of the Ballistic Performances of Various Microstructures in MIL-A-12560 Armor Steel

Abstract

:1. Introduction

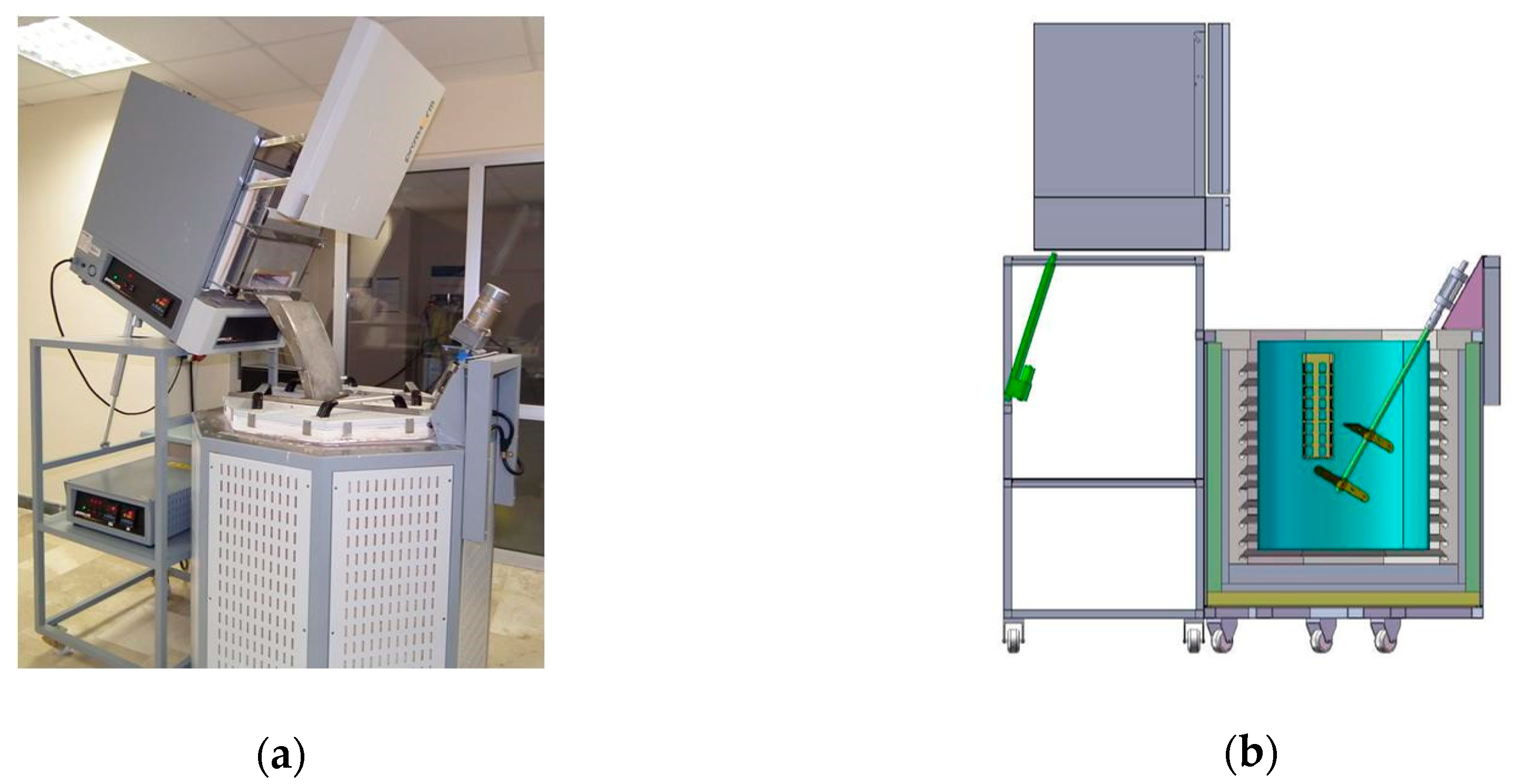

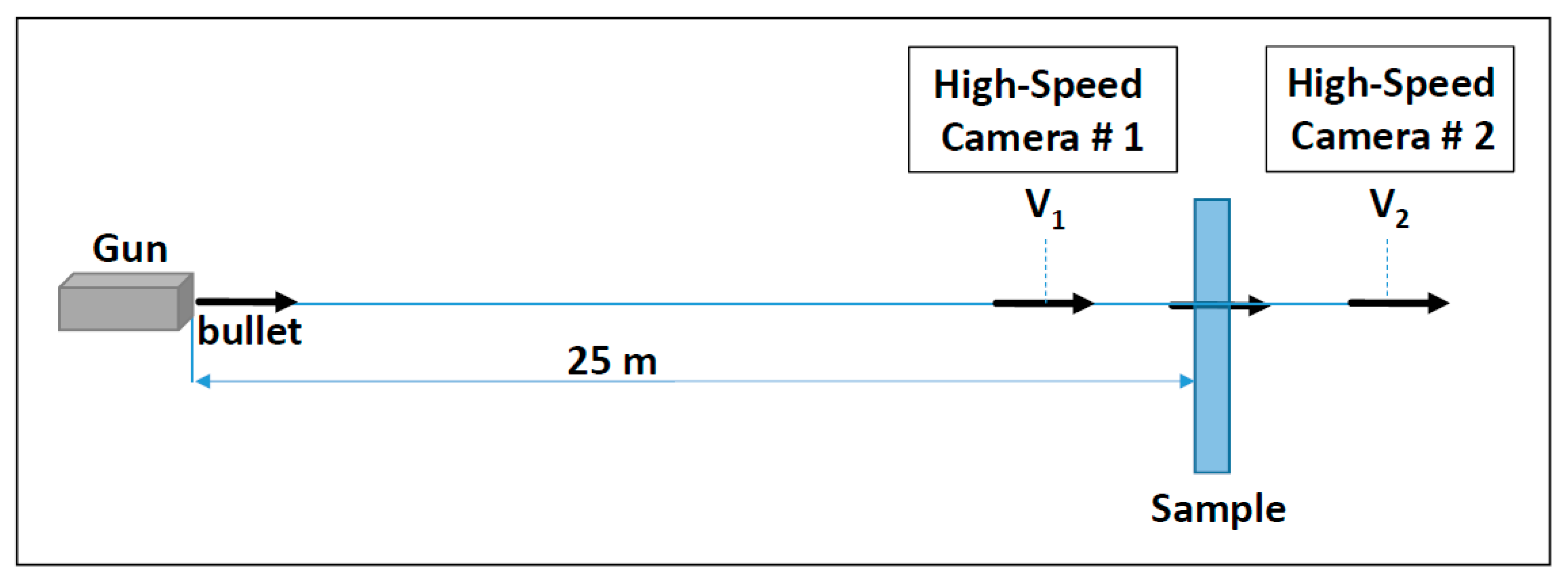

2. Materials and Methods

3. Results

3.1. Hardness and Impact Test Results of the Samples

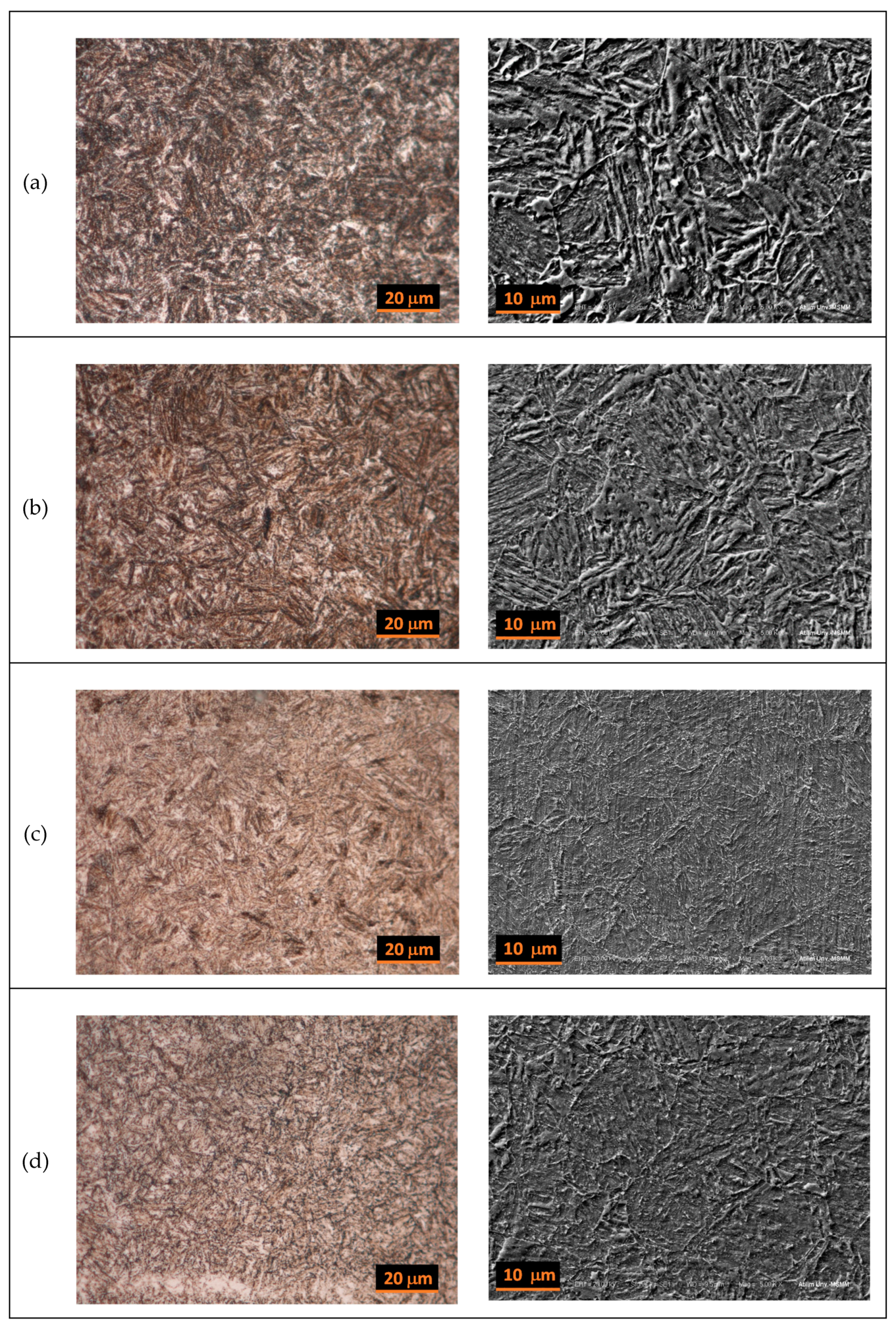

3.2. Microstructural Examination of the Samples

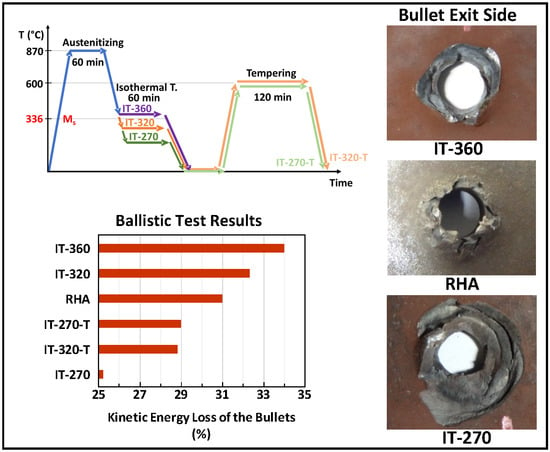

3.3. Results of the Ballistic Tests

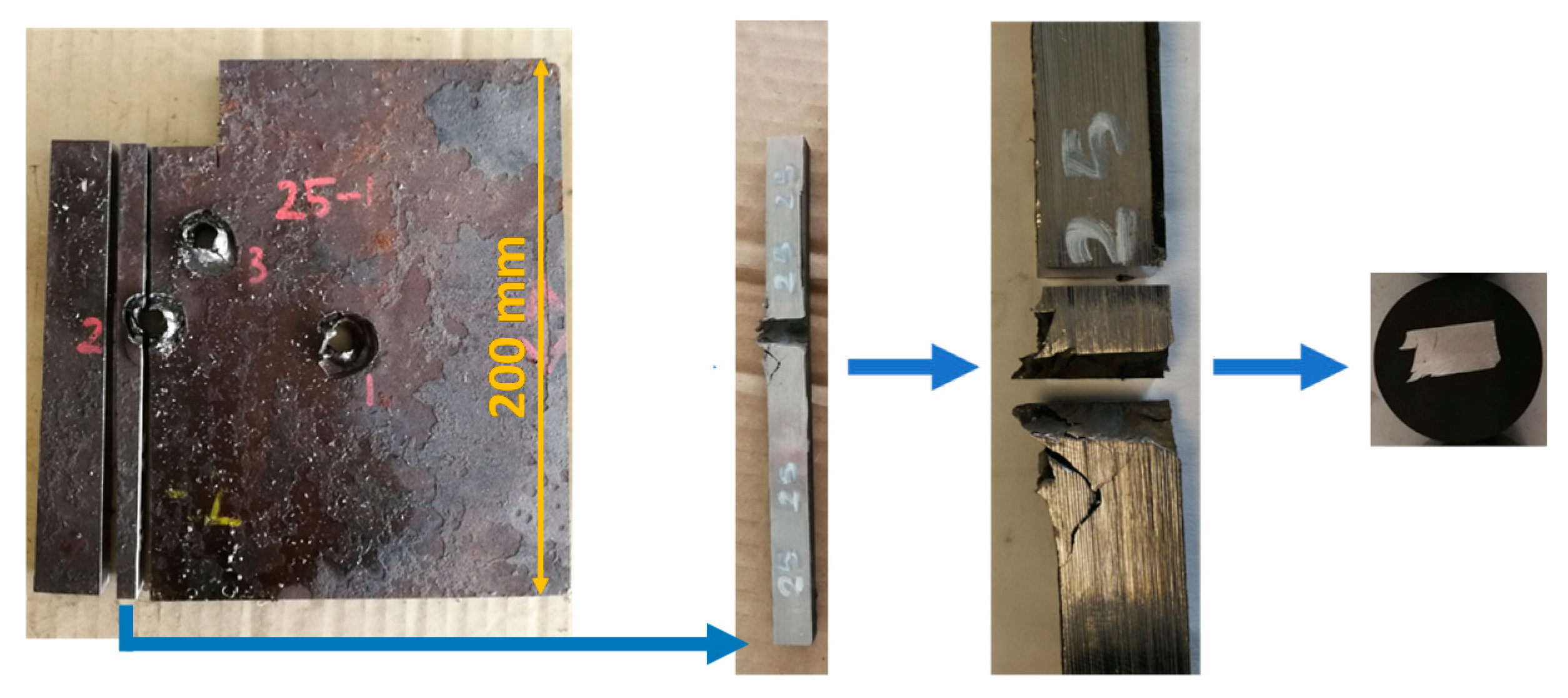

3.4. Macro Examination of the Samples after the Ballistic Tests

3.5. Micro Examinations of the Hole Cross-Sections

4. Discussion

4.1. Factors Determining the Ballistic Protection Performance of an Armor Material

4.2. Relations between Microstructure, Mechanical Properties, and Ballistic Protection Performance

5. Conclusions

- It was found that the samples with essentially bainitic microstructures provided slightly higher ballistic protection than the regular RHA sample. This observation suggests that it may be possible to improve the ballistic performance through bainitic microstructures even in an armor steel of conventional chemical composition.

- Although they had higher combinations of hardness and impact energy values, the ballistic performances of the isothermally treated samples decreased as the treatment temperature was lowered below the Ms temperature.

- Within the limits (363–458 Brinell and 23.2–56.8 J) of this study, no correlation could be established between the ballistic protection performance and the hardness and impact energy values of the samples. It is concluded that the differences in the types and amounts of micro constituents of these samples imposed differences in their dynamic mechanical behavior at ballistic speeds (~900 m/s) and that it is not possible to infer these differences from the conventional mechanical properties determined at relatively static conditions.

- The examination of the bullet holes showed that, although the results of the hardness and impact tests do not precisely predict the ballistic protection performances of the samples, these values can still indicate the type of mechanical behavior to be expected at ballistic speeds.

Funding

Acknowledgments

Conflicts of Interest

References

- Carlucci, D.E.; Jacobson, S.S. Ballistics: Theory and Designs of Guns and Ammunition, 3rd ed.; Taylor & Francis: Boca Raton, FA, USA, 2018; pp. 377–379. [Google Scholar] [CrossRef]

- High Velocity Impact Dynamics, 1st ed.; Zukas, J.A. (Ed.) John Wiley & Sons: New York, NY, USA, 1990; pp. 65–105. [Google Scholar]

- Military Specification. Armor Plate, Steel, Wrought, Homogeneous; MIL-A-12560J (MR); U.S. Army Research Laboratory: Adelphi, MD, USA, 29 July 2009. [Google Scholar]

- Military Specification. Armor Plate, Steel, Wrought, High-Hardness; MIL-DTL-46100E (MR); U.S. Army Research Laboratory: Adelphi, MD, USA, 9 July 2008. [Google Scholar]

- Military Specification. Armor Plate, Steel, Wrought, Ultra-High-Hardness; MIL-DTL-32332 (MR); U.S. Army Research Laboratory: Adelphi, MD, USA, 24 July 2009. [Google Scholar]

- Srivathsa, B.; Ramakrishnan, N. Ballistic performance maps for thick metallic armour. J. Mater. Process. Technol. 1999, 96, 81–91. [Google Scholar] [CrossRef]

- Maweja, K.; Stumpf, W. The design of advanced performance high strength low-carbon martensitic armour steels: Microstructural considerations. Mater. Sci. Eng. A 2008, 480, 160–166. [Google Scholar] [CrossRef]

- Maweja, K.; Stumpf, W. The design of advanced performance high strength low-carbon martensitic armour steels: Part 1. Mechanical property considerations. Mater. Sci. Eng. A 2008, 485, 140–153. [Google Scholar] [CrossRef]

- Jena, P.K.; Mishra, B.; Babu, M.R.; Babu, A.; Singh, A.K.; SivaKumar, K.; Balakrishna Bhat, T. Effect of heat treatment on mechanical and ballistic properties of a high strength armour steel. Int. J. Impact Eng. 2010, 37, 242–249. [Google Scholar] [CrossRef]

- Kumar, R. Physical Metallurgy of Iron and Steel; Asia Publishing House: London, UK, 1968; pp. 186–187. [Google Scholar]

- Verhoeven, J.D. Fundamentals of Physical Metallurgy; Wiley: Singapore, 1975; pp. 500–508. [Google Scholar]

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloys, 2nd ed.; Chapman & Hall: London, UK, 1992; pp. 334–337. [Google Scholar]

- Abbaszadeh, K.; Saghafian, H.; Kheirandish, S. Effect of Bainite Morphology on Mechanical Properties of the Mixed Bainite-martensite Microstructure in D6AC Steel. J. Mater. Sci. Technol. 2012, 28, 336–342. [Google Scholar] [CrossRef]

- Niccols, E.H. Literature Review: Impact Toughness of Bainite vs Martensite; Technical Report WVT-TR-70012; US Army Armament Command: Watervliet, NY, USA, 1976. [Google Scholar]

- Barranco, M.; Cote, P.J.; Kapp, J.A. Tempering Effects For. Lower Bainite, Martensite and Mixed Microstructures on Impact, Fracture and Related Mechanical Properties of ASTM A723 Steel; Technical Report ARCCB-TR-92024; US Army Armament Research Development and Engineering Center: Picatinny, NJ, USA, 1992. [Google Scholar]

- Tomita, Y.; Okabayashi, K. Improvement in lower temperature mechanical properties of 0.40 pct C-Ni-Cr-Mo ultrahigh strength steel with the second phase lower bainite. Metall. Trans. A 1983, 14, 485–492. [Google Scholar] [CrossRef]

- Young, C.H.; Bhadeshia, H.K.D.H. The Strength of Mixtures of Bainite and Martensite. Mater. Sci. Technol. 1994, 10, 209–214. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Garcia-Mateo, C.; Brown, P. Super Bainite Steels and Manufacture Thereof; World Intellectual Property Organisation (WIPO): Geneva, Switzerland, 2010; International Publication Number WO 2010/013054 A2. [Google Scholar]

- Bhadeshia, H.K.D.H.; Edmonds, D.V. Bainite in silicon steels: New composition-property approach Part 1. Metal. Sci. 1983, 17, 411–419. [Google Scholar] [CrossRef]

- Suzuki, T.; Ono, Y.; Miyamoto, G.; Furuhara, T. Effects of Si and Cr on Bainite Microstructure of Medium Carbon Steels. ISIJ Int. 2010, 50, 1476–1482. [Google Scholar] [CrossRef] [Green Version]

- Bhadeshia, H.K.D.H.; Edmonds, D.V. Bainite in silicon steels: New composition–property approach Part 2. Metal. Sci. 1983, 17, 420–425. [Google Scholar] [CrossRef]

- Super Bainite Armour Steel. Available online: https://www.ploughshareinnovations.com/technology/super-bainite-steel/ (accessed on 6 March 2020).

- Super Bainite Steel-perfection in Impenetrability. Available online: https://www.army-technology.com/features/featuresuper-bainite-steel-perfection-in-impenetrability-4346392/ (accessed on 6 March 2020).

- Burian, W.; Marcisz, J.; Garbarz, B.; Starczewski, L. Nanostructured Bainite-Austenite Steel for Armours Construction. Arch. Metall. Mater. 2014, 59, 1211–1216. [Google Scholar] [CrossRef] [Green Version]

- Chu, H.; Lillo, T.; Anderson, J.; Zagula, T. Development of a Scalable Thermomechanical Process (TMP) for Thick Bainitic Armor Steel. In Proceedings of the 2018 Ground Vehicle Systems Engineering and Technology Symposium (GVSETS), Novi Michigan, MI, USA, 7–9 August 2018. [Google Scholar]

- Sourmail, T.; Garcia-Mateo, C. Critical assessment of models for predicting the Ms temperature of steels. Comput. Mater. Sci. 2005, 34, 323–334. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Inoue, J.; Okada, M.; Nagata, K. Prediction of Ac3 and Martensite Start Temperatures by a Data-driven Model Selection Approach. ISIJ Int. 2017, 57, 2229–2236. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Zhao, Z.; Northwood, D.O.; Liu, Y. A new empirical formula for the calculation of Ms temperatures in pure iron and super-low carbon alloy steels. J. Mater. Process. Technol. 2001, 113, 556–562. [Google Scholar] [CrossRef]

- Barbier, D. Extension of the Martensite Transformation Temperature Relation to Larger Alloying Elements and Contents. Adv. Eng. Mater. 2014, 16, 122–127. [Google Scholar] [CrossRef]

- Lee, S.; Park, K. Prediction of Martensite Start Temperature in Alloy Steels with Different Grain Sizes. Met. Mat. Trans. A 2013, 44, 3423–3427. [Google Scholar] [CrossRef]

- van Bohemen, S.M.C. Bainite and martensite start temperature calculated with exponential carbon dependence. Mater. Sci. Technol. 2012, 28, 487–495. [Google Scholar] [CrossRef]

| C | Mn | P | S | Si | Ni | Cr | Mo | V |

|---|---|---|---|---|---|---|---|---|

| 0.27 | 0.93 | <0.005 | <0.005 | 0.30 | 1.40 | 1.13 | 0.46 | 0.07 |

| Sample | IT-360 | IT-320 | IT-270 | IT-320-T | IT-270-T | RHA |

|---|---|---|---|---|---|---|

| Austenitization at 870 °C for 60 min | ✓ | ✓ | ✓ | ✓ | ✓ | - |

| Isothermal treatment for 60 min at | 360 °C | 320 °C | 270 °C | 320 °C | 270 °C | - |

| Tempering at 600 °C for 120 min | - | - | - | ✓ | ✓ | - |

| Sample | Hardness (Brinell) | −40 °C Impact Energy (J) |

|---|---|---|

| IT-360 | 390.6 ± 5.4 | 23.2 ± 0.9 |

| IT-320 | 441.2 ± 3.7 | 28.7 ± 1.7 |

| IT-270 | 457.8 ± 5.0 | 30.5 ± 3.2 |

| IT-320-T | 362.8 ± 3.1 | 56.8 ± 6.2 |

| IT-270-T | 369.4 ± 5.6 | 48.0 ± 5.7 |

| RHA | 363.2 ± 1.2 | 49.3 ± 6.1 |

| Sample | Average Kinetic Energy Loss of the Bullets (%) | Change in Ballistic Performance with Respect to the RHA Sample (%) |

|---|---|---|

| RHA | 31.0 ± 2.3 | - |

| IT-360 | 34.0 ± 2.0 | +9.9 |

| IT-320 | 32.3 ± 0.7 | +4.2 |

| IT-270 | 25.2 ± 1.4 | −18.6 |

| IT-270-T | 29.0 ± 0.2 | −6.5 |

| IT-320-T | 28.8 ± 1.5 | −7.2 |

| The average bullet speed before impact was 902 ± 9 m/s. | ||

| Sample | Average Kinetic Energy Loss of the Bullets (%) | Hardness (Brinell) | −40 °C Impact Energy (J) | Microstructure | Main Mode of Perforation |

|---|---|---|---|---|---|

| IT-360 | 34.0 ± 2.0 | 390.6 ± 5.4 | 23.2 ± 0.9 | Bainite | Plastic Deformation and Fracture |

| IT-320 | 32.3 ± 0.7 | 441.2 ± 3.7 | 28.7 ± 1.7 | Mostly bainite with some martensite | Fracture and Fragmentation |

| RHA | 31.0 ± 2.3 | 363.2 ± 1.2 | 49.3 ± 6.1 | Tempered martensite | Plastic Deformation and Ductile Hole Growth |

| IT-270-T | 29.0 ± 0.2 | 369.4 ± 5.6 | 48.0 ± 5.7 | Tempered martensite with some bainite | Plastic Deformation and Ductile Hole Growth |

| IT-320-T | 28.8 ± 1.5 | 362.8 ± 3.1 | 56.8 ± 6.2 | Tempered bainite and martensite | Plastic Deformation and Ductile Hole Growth |

| IT-270 | 25.2 ± 1.4 | 457.8 ± 5.0 | 30.5 ± 3.2 | Mostly martensite with some bainite | Fracture and Fragmentation |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konca, E. A Comparison of the Ballistic Performances of Various Microstructures in MIL-A-12560 Armor Steel. Metals 2020, 10, 446. https://doi.org/10.3390/met10040446

Konca E. A Comparison of the Ballistic Performances of Various Microstructures in MIL-A-12560 Armor Steel. Metals. 2020; 10(4):446. https://doi.org/10.3390/met10040446

Chicago/Turabian StyleKonca, Erkan. 2020. "A Comparison of the Ballistic Performances of Various Microstructures in MIL-A-12560 Armor Steel" Metals 10, no. 4: 446. https://doi.org/10.3390/met10040446

APA StyleKonca, E. (2020). A Comparison of the Ballistic Performances of Various Microstructures in MIL-A-12560 Armor Steel. Metals, 10(4), 446. https://doi.org/10.3390/met10040446