Effects of Pre-Weld Heat Treatment and Heat Input on Metallurgical and Mechanical Behaviour in HAZ of Multi-Pass Welded IN-939 Superalloy

Abstract

:1. Introduction

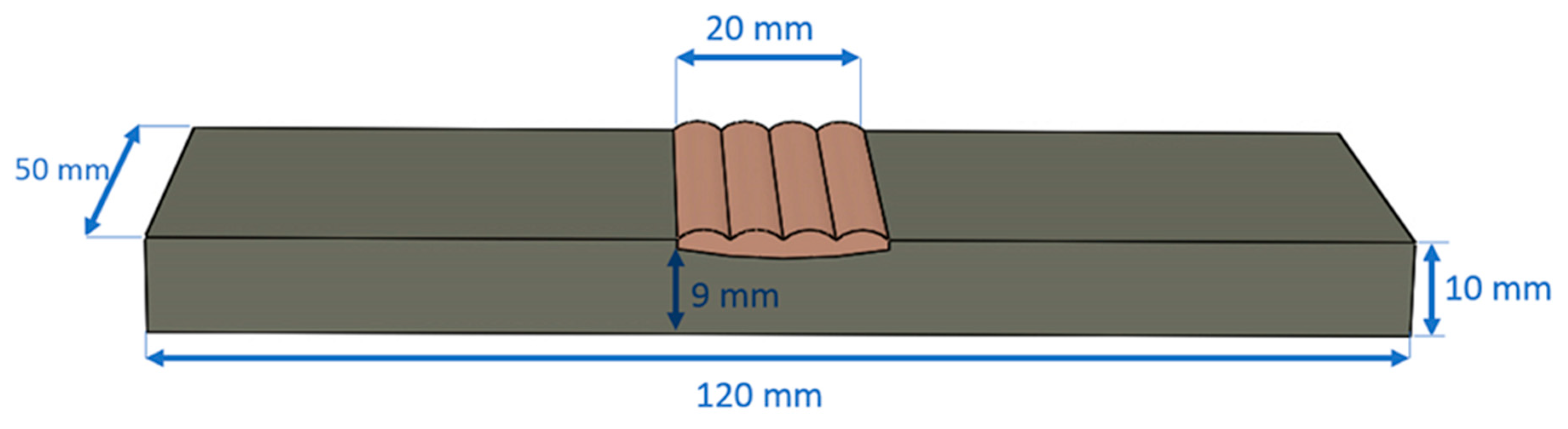

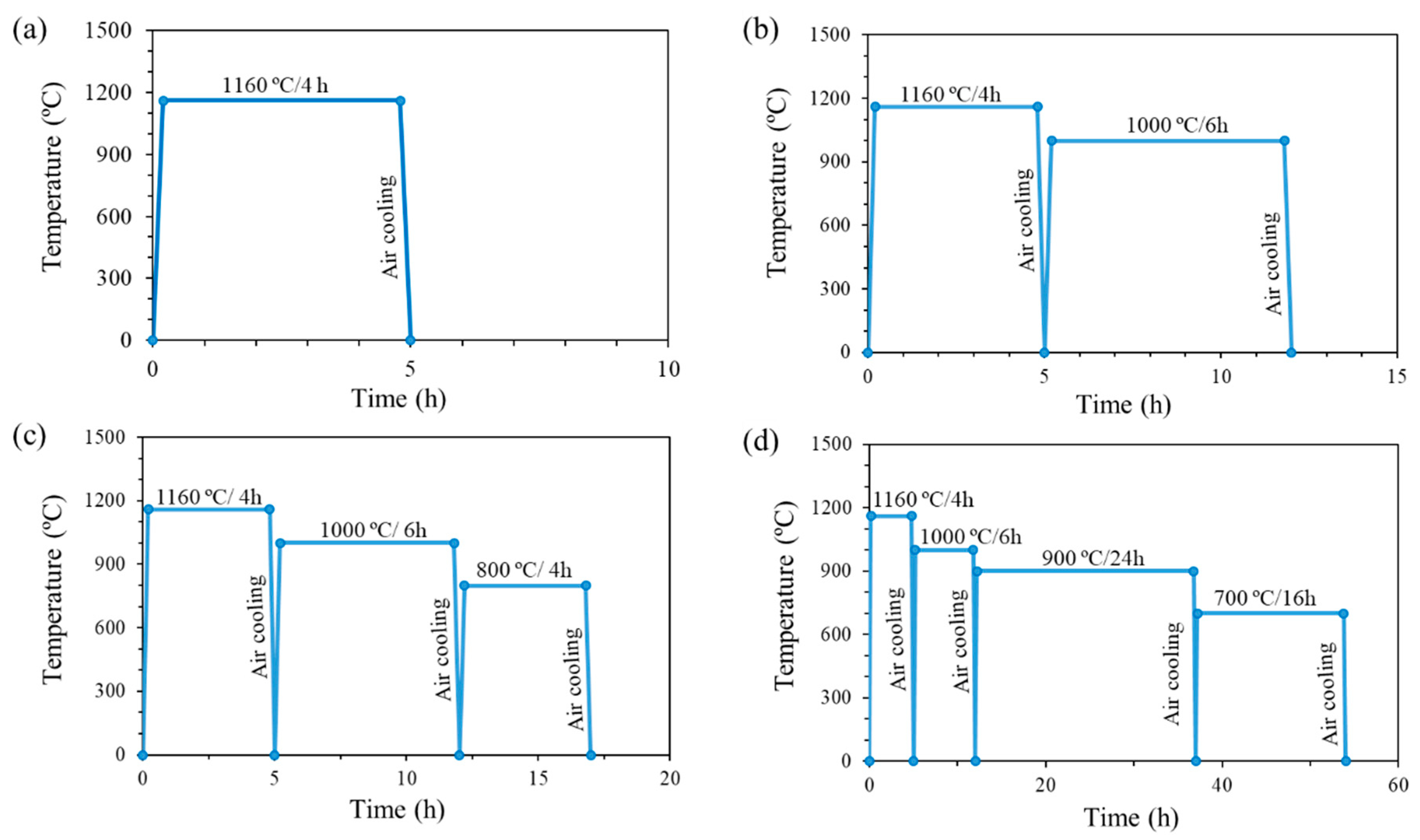

2. Materials and Methods

3. Results and Discussion

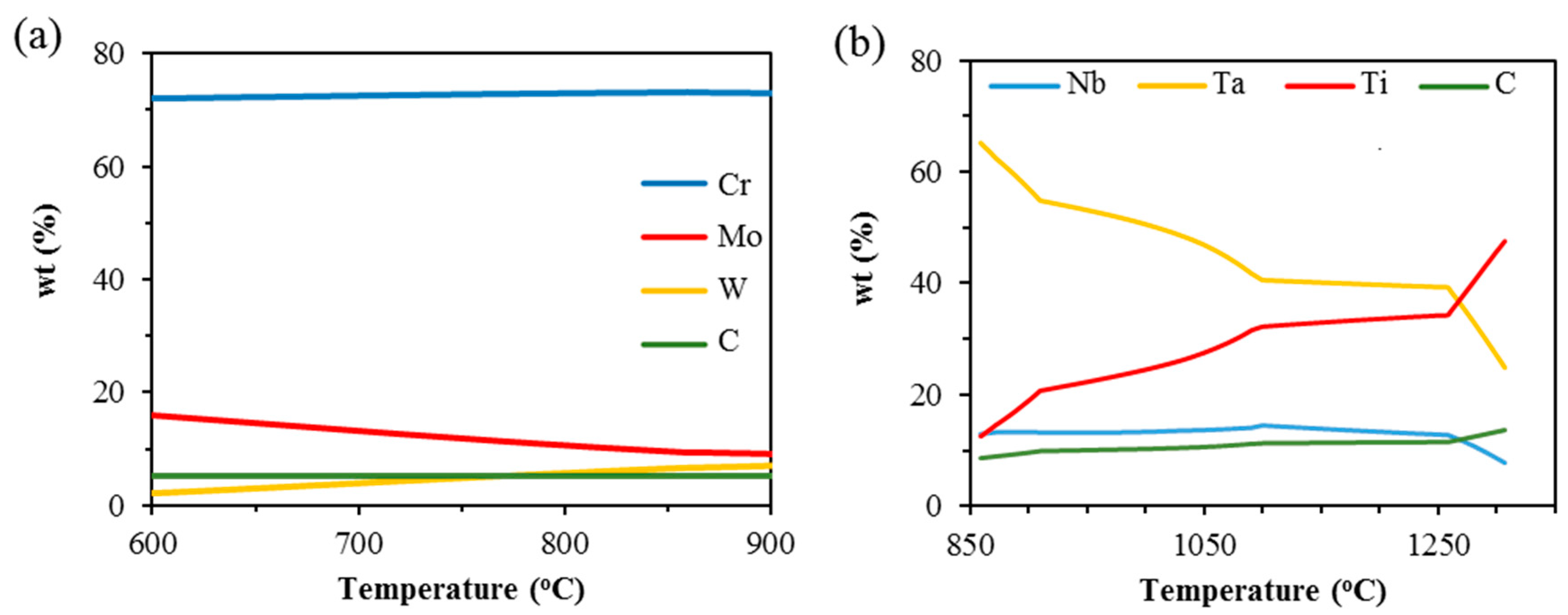

3.1. Phase Equilibrium Diagram

3.2. Microstructural Examination

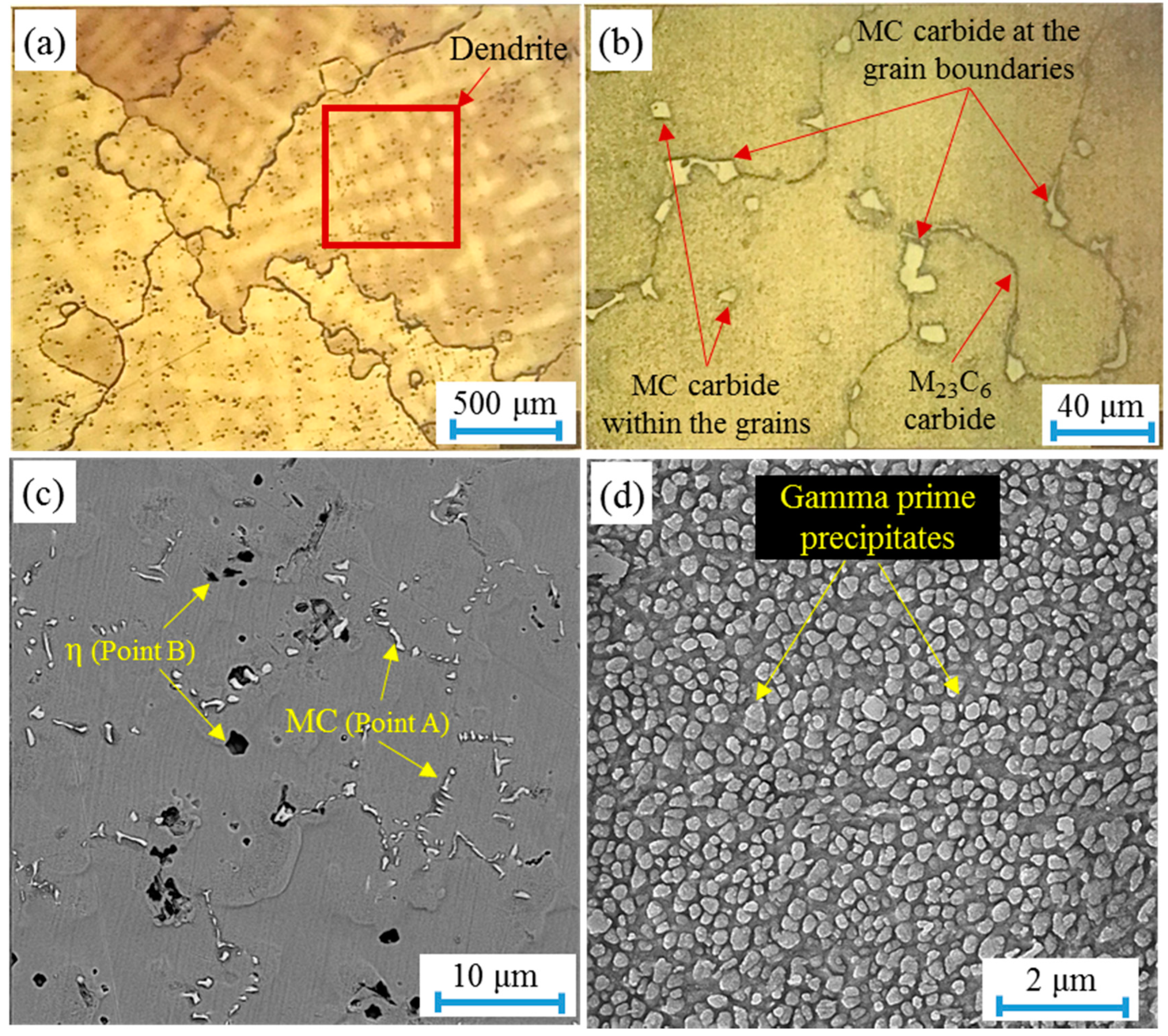

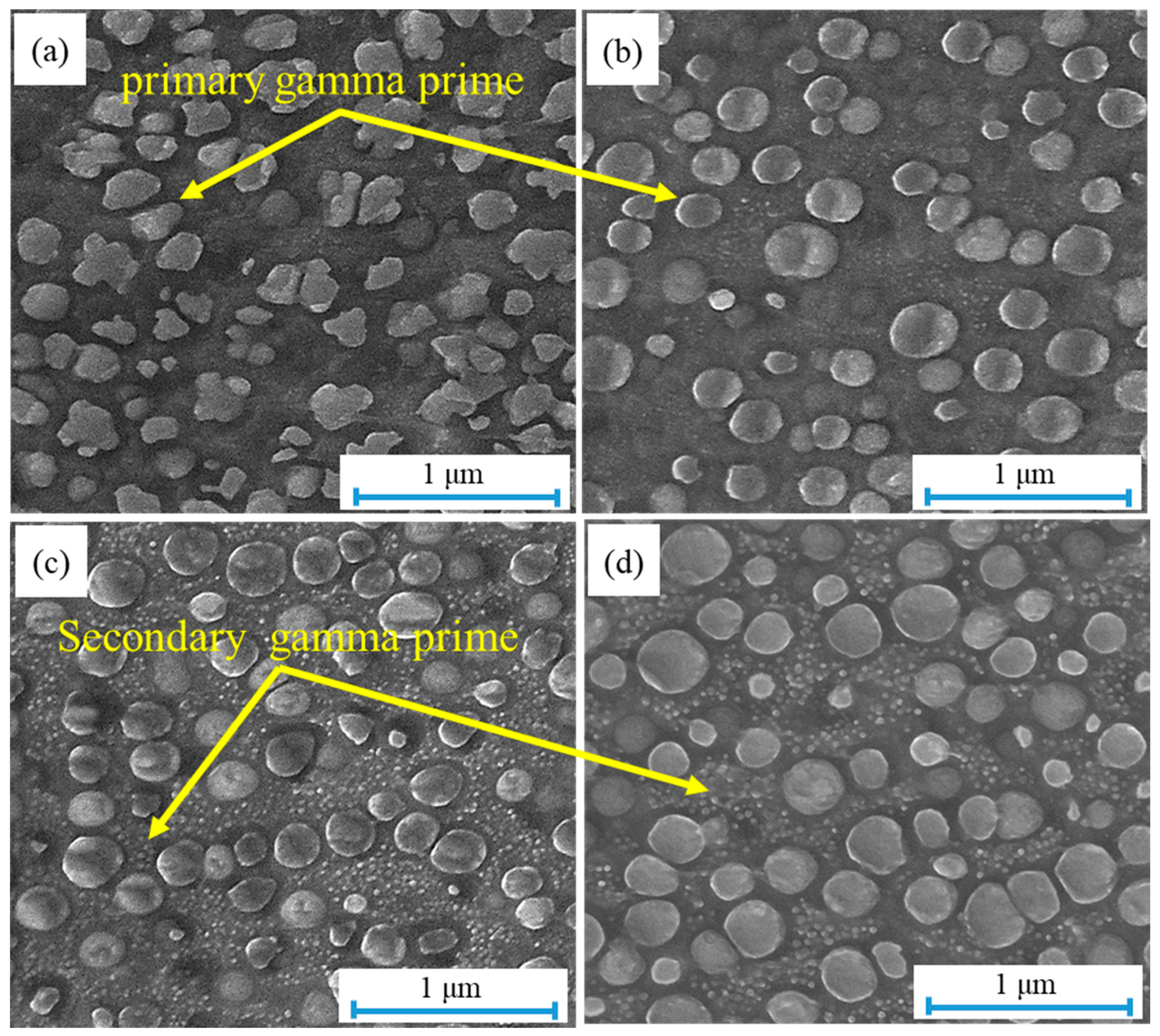

3.2.1. Base Metal Microstructure

3.2.2. Pre-Weld Heat Treatment Effect on the Microstructure

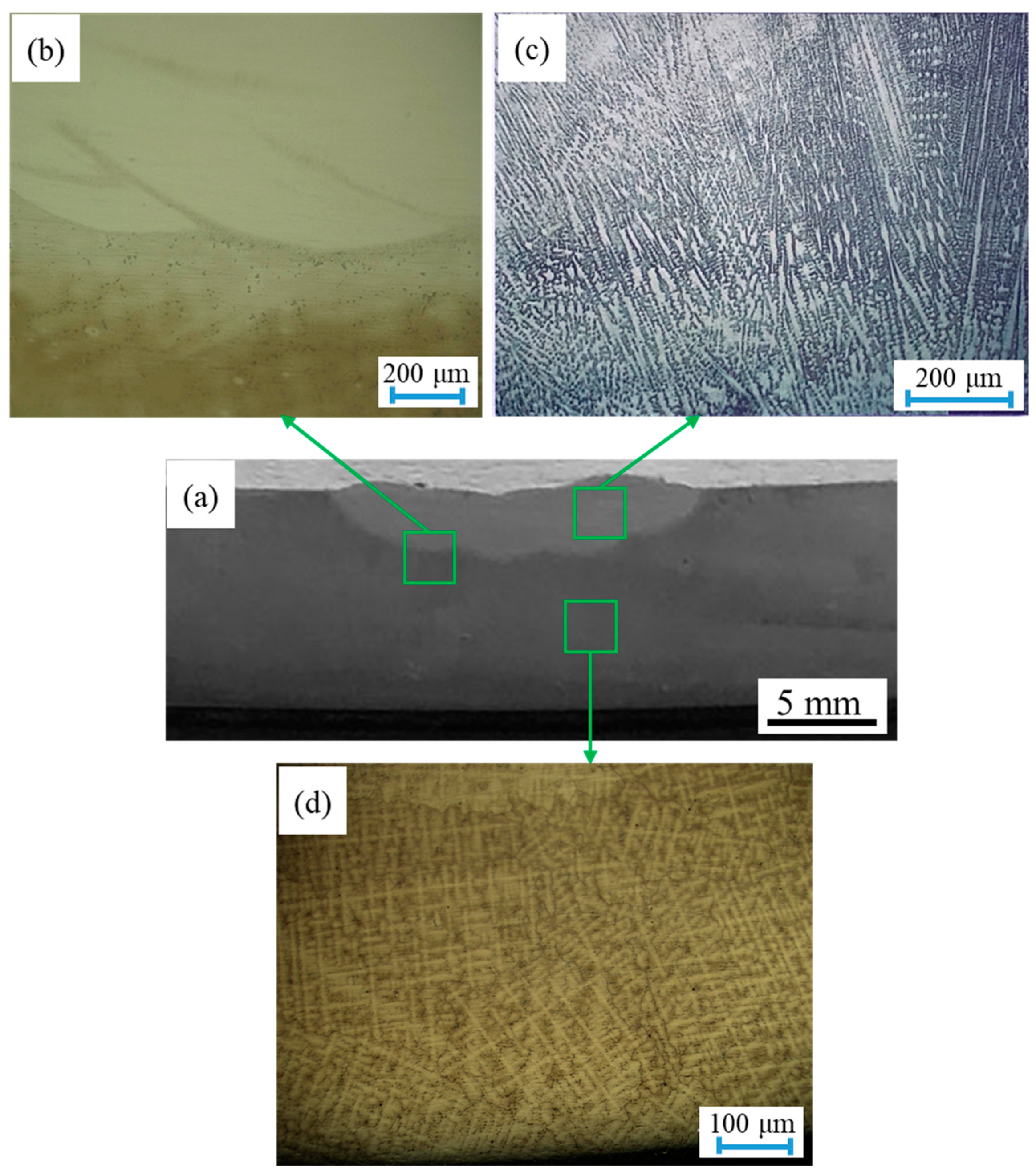

3.2.3. Welded Specimen Microstructure

3.3. Mechanical Properties

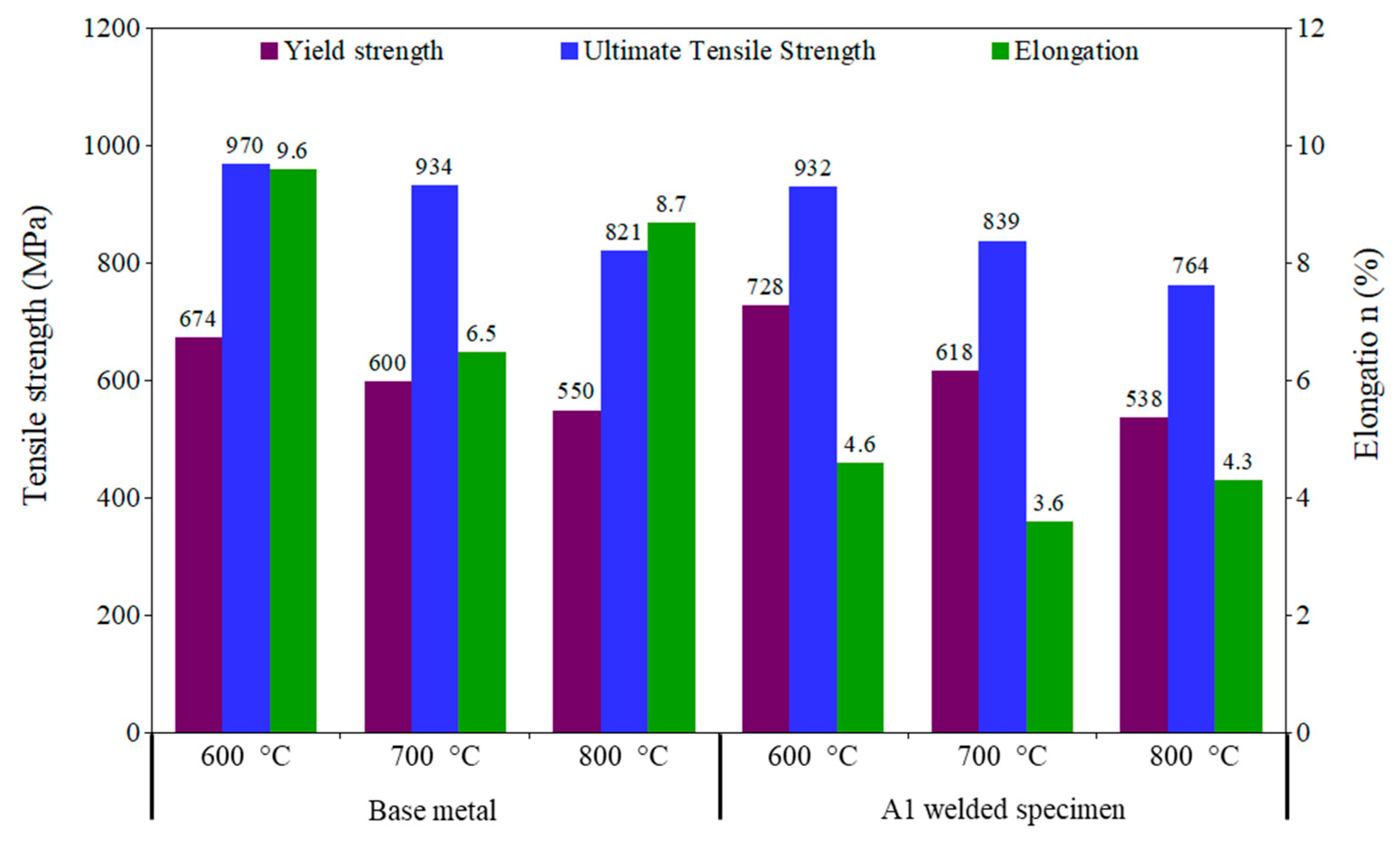

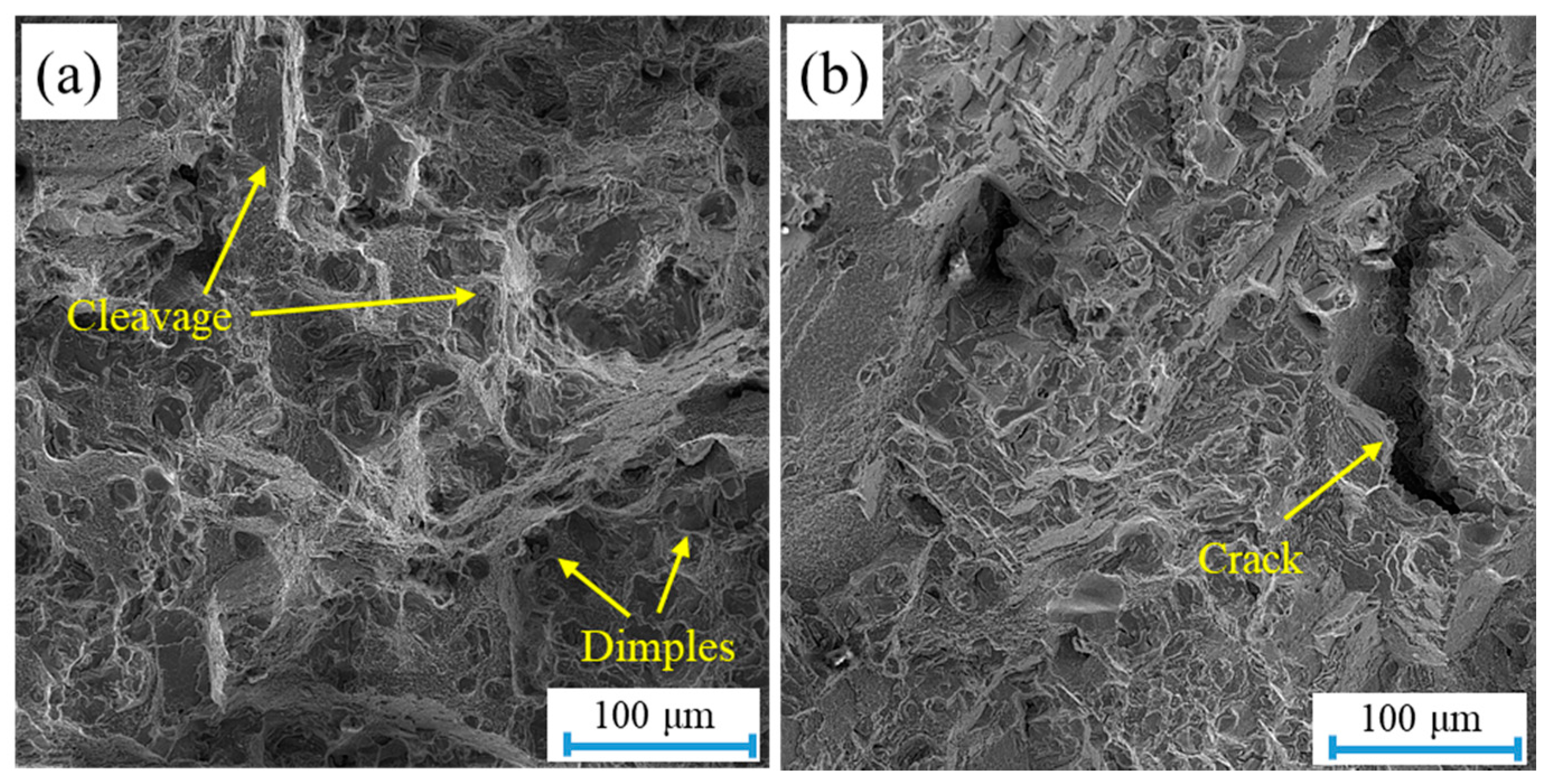

3.3.1. Tensile Strength

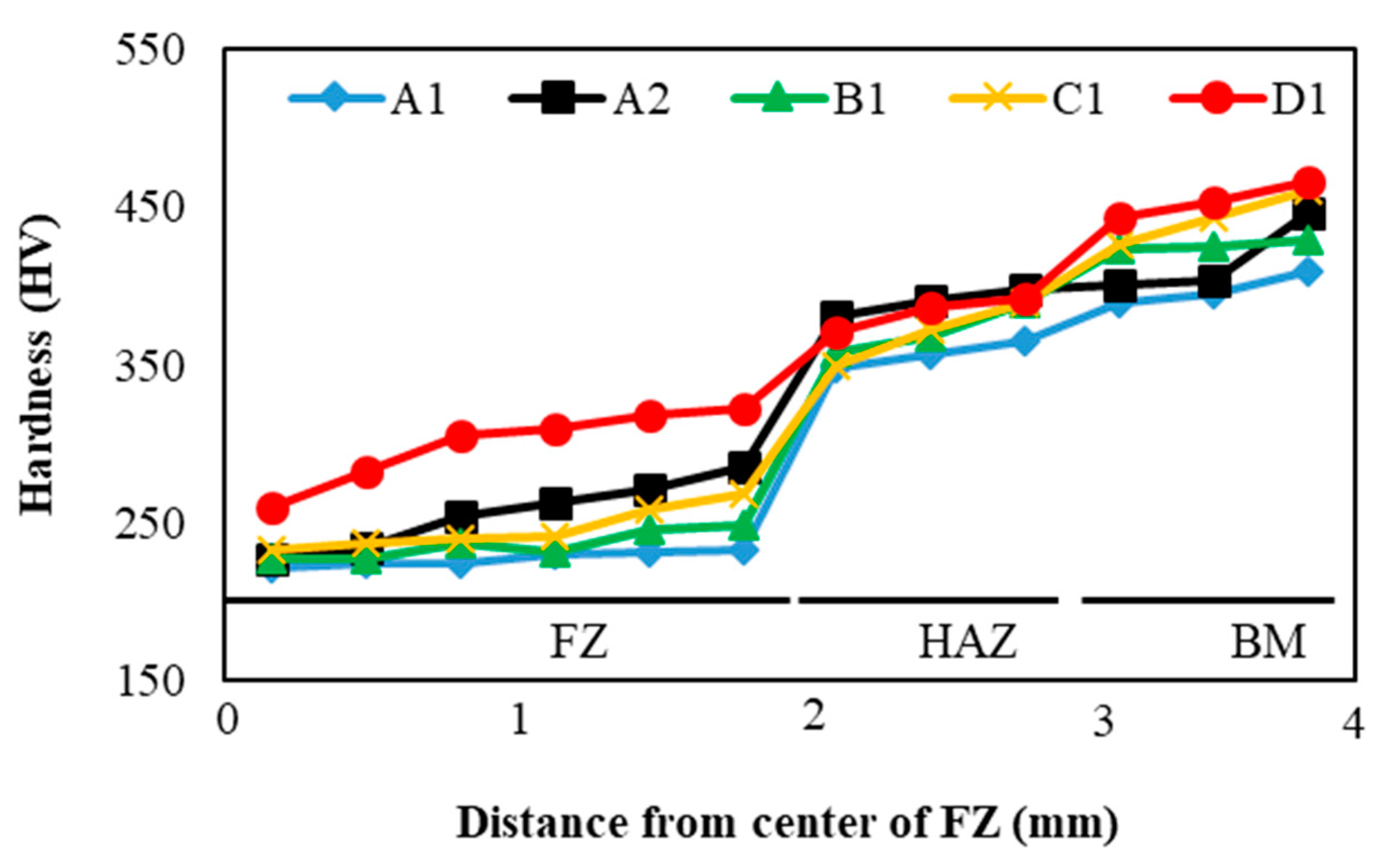

3.3.2. Hardness Profile

4. Conclusions

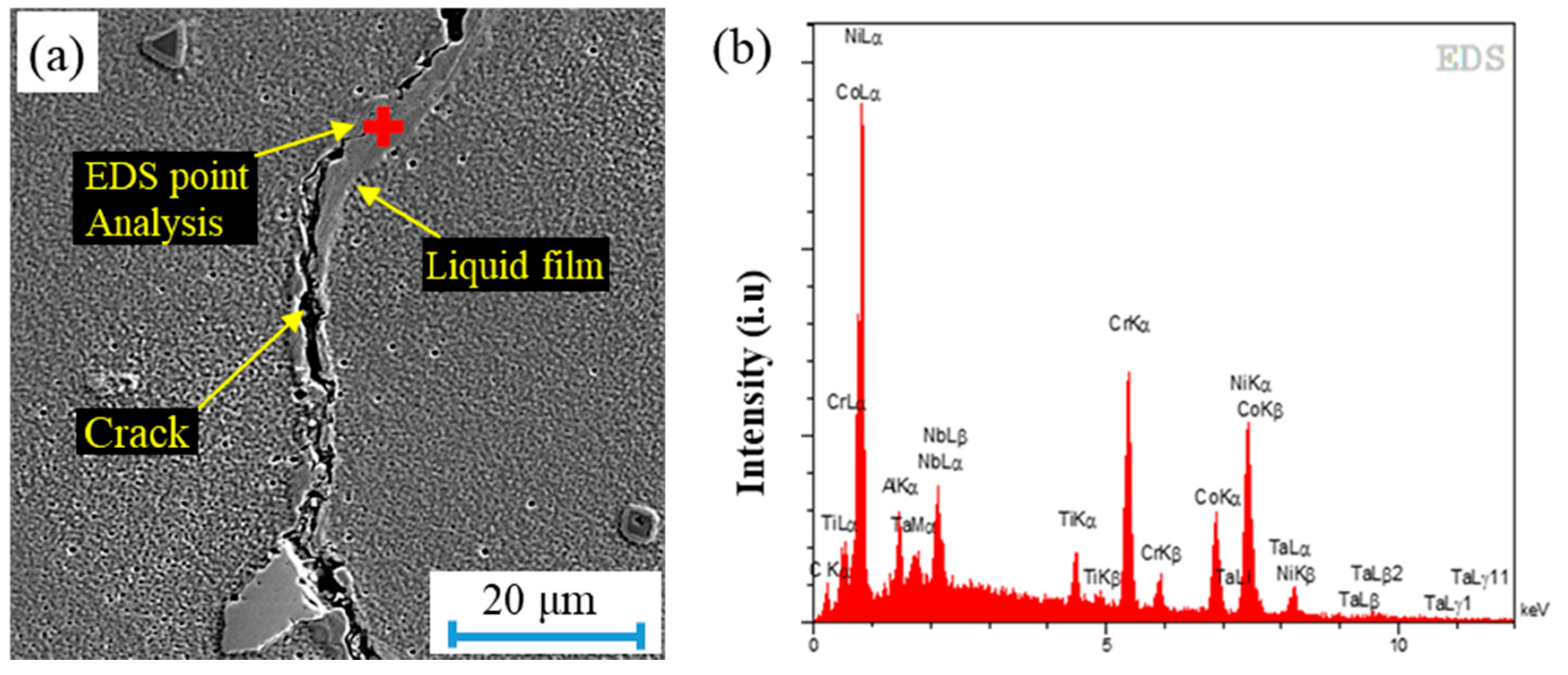

- Metallographic investigations indicated that the microstructures of IN-939 were highly susceptible to cracking during welding. The grain-boundary type cracks were initiated from the boundary between the weld metal and HAZ and mostly were propagated into the base metal. Many re-melting zones existed in the vicinity of the cracks, which were directly formed from the reaction between intergranular liquation and mechanical driving force due to tensile stresses created during welding.

- The elemental analysis of the melted layer showed the existence of Ni, C, Cr and Co as well as the co-existence of M23C6 carbide and γ phase. This finding signified the formation of M23C6 carbides at the grain boundaries and γ′ precipitates around grain boundaries, which are the major causes of intergranular liquation.

- Pre-weld heat treatment and welding heat input affected the microstructure and grain sizes of the HAZ. In all specimens, the volume fraction and average diameter of gamma-prime precipitates in the HAZ were affected by welding, resulting in a sharp decrease in hardness. The outcomes of the hardness tests and metallographic investigations indicated that the total length of welding-induced cracks increased with increasing HAZ hardness.

- Tensile tests were performed on the base metal and welded specimens with the best properties. Welding did not affect the yield strength of the superalloy but reduced the ultimate strength and elongation by as much as 92% and 50%, respectively, of those of the BM within 600 °C–800 °C.

- The increase in temperature decreased the hot tensile, yield and ultimate strengths of the base metal and welded specimen. However, the lowest tensile elongation was observed at 700 °C.

Author Contributions

Funding

Conflicts of Interest

References

- Chang, B.; Yang, S.; Liu, G.; Li, W.; Du, D.; Ma, N. Influences of Cooling Conditions on the Liquation Cracking in Laser Metal Deposition of a Directionally Solidified Superalloy. Metals 2020, 10, 466. [Google Scholar] [CrossRef] [Green Version]

- Diaz-Álvarez, A.; Miguélez, H.; Cantero, J.L. Finishing turning of Ni superalloy haynes 282. Metals 2018, 8, 843. [Google Scholar] [CrossRef] [Green Version]

- Doroudi, A.; Shamsipur, A.; Omidvar, H.; Vatanara, M. Effect of transient liquid phase bonding time on the microstructure, isothermal solidification completion and the mechanical properties during bonding of Inconel 625 superalloy using Cr-Si-B-Ni filler metal. J. Manuf. Process. 2019, 38, 235–243. [Google Scholar] [CrossRef]

- Nowak, W.J.; Ochał, K.; Wierzba, P.; Gancarczyk, K.; Wierzba, B. Effect of substrate roughness on oxidation resistance of an aluminized ni-base superalloy. Metals 2019, 9, 782. [Google Scholar] [CrossRef] [Green Version]

- Bapokutty, O.; Sajuri, Z.; Syarif, J.; Said, A.R. Fracture Behavior of Inconel 718 at High Temperature. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; Volume 462, pp. 1244–1249. [Google Scholar]

- Doroudi, A.; Pilehrood, A.E.; Mohebinia, M.; Dastgheib, A.; Rajabi, A.; Omidvar, H. Effect of the isothermal solidification completion on the mechanical properties of Inconel 625 transient liquid phase bond by changing bonding temperature. J. Mater. Res. Technol. 2020, 9, 10355–10365. [Google Scholar] [CrossRef]

- Zhao, J.-R.; Hung, F.-Y.; Lui, T.-S. Erosion Resistance and Particle Erosion-Induced Tensile Embrittlement of 3D-Selective Laser Melting Inconel 718 Superalloy. Metals 2020, 10, 21. [Google Scholar] [CrossRef] [Green Version]

- Kangazian, J.; Shamanian, M. Electron Back Scattered Diffraction Study of Dissimilar Welding Between the Super Duplex Stainless Steel and the Ni - Based Superalloy. Met. Mater. Int. 2019, 25, 1287–1300. [Google Scholar] [CrossRef]

- Chen, K.-C.; Chen, T.-C.; Shiue, R.-K.; Tsay, L.-W. Liquation cracking in the heat-affected zone of IN738 superalloy weld. Metals 2018, 8, 387. [Google Scholar] [CrossRef] [Green Version]

- Ramkumar, K.D.; Sai, R.J.; Sridhar, G.; Reddy, V.S.; Prabaharan, P.; Arivazhagan, N.; Sivashanmugham, N. Influence of filler metals in the control of deleterious phases during the multi-pass welding of Inconel 718 plates. Acta Metall. Sin. Engl. Lett. 2015, 28, 196–207. [Google Scholar] [CrossRef]

- Wang, T.F.; Di, X.J.; Li, C.N.; Wang, J.M.; Wang, D.P. Effect of δ Phase on Microstructure and Hardness of Heat-Affected Zone in TIG-Welded GH4169 Superalloy. Acta Metall. Sin. Engl. Lett. 2018. [Google Scholar] [CrossRef] [Green Version]

- Taheri, M.; Halvaee, A.; Farshid, S.; Bozorg, K. Effect of Pre- and Post-weld Heat Treatment on Microstructure and Mechanical Properties of GTD-111 Superalloy Welds. Met. Mater. Int. 2019. [Google Scholar] [CrossRef]

- Said, A.; Syarif, J.; Sajuri, Z. HAZ Characterization of GTD-111 Nickel based superalloy welding. Int. J. Mater. Eng. Tech. 2009, 2, 133–139. [Google Scholar]

- Xie, J.; Ma, Y.; Xing, W.; Zhang, L.; Ou, M.; Liu, K. Heat-affected zone crack healing in IN939 repaired joints using hot isostatic pressing. Weld. World 2018, 62, 471–479. [Google Scholar] [CrossRef]

- Bidron, G.; Doghri, A.; Malot, T.; Fournier-dit-chabert, F.; Thomas, M.; Peyre, P. Reduction of the hot cracking sensitivity of CM-247LC superalloy processed by laser cladding using induction preheating. J. Mater. Process. Tech. 2020, 277, 116461. [Google Scholar] [CrossRef] [Green Version]

- Sidhu, R.K.; Ojo, O.A.; Chaturvedi, M.C. Microstructural analysis of laser-beam-welded directionally solidified INCONEL 738. Metall. Mater. Trans. A 2007, 38, 858–870. [Google Scholar] [CrossRef]

- Sajuri, Z.; Said, A.R.; Ibrahim, M.L.; Syarif, J. Premature Failure of Gas Turbine Blade. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; Volume 462, pp. 325–330. [Google Scholar]

- Ye, X.; Zhang, P.; Zhao, J.; Ma, P. E ff ect of macro- and micro-segregation on hot cracking of Inconel 718 superalloy argon-arc multilayer cladding. J. Mater. Process. Tech. 2018, 258, 251–258. [Google Scholar] [CrossRef]

- Ola, O.T.; Ojo, O.A.; Chaturvedi, M.C. Role of filler alloy composition on laser arc hybrid weldability of nickel-base IN738 superalloy. Mater. Sci. Technol. 2014, 30, 1461–1469. [Google Scholar] [CrossRef]

- Tajally, M. Effects of Filler Metals on Heat-Affected Zone Cracking in IN-939 Superalloy Gas-Tungsten-Arc Welds. J. Mater. Eng. Perform. 2020, 29, 1068–1079. [Google Scholar] [CrossRef]

- González, M.A.; Martínez, D.I.; Pérez, A.; Guajardo, H.; Garza, A. Microstructural response to heat affected zone cracking of prewelding heat-treated Inconel 939 superalloy. Mater. Charact. 2011, 62, 1116–1123. [Google Scholar] [CrossRef]

- Albarrán, M.A.G.; Martínez, D.I.; Díaz, E.; Díaz, J.C.; Guzman, I.; Saucedo, E.; Guzman, A.M. Effect of preweld heat treatment on the microstructure of heat-affected zone (HAZ) and weldability of Inconel 939 superalloy. J. Mater. Eng. Perform. 2014, 23, 1125–1130. [Google Scholar] [CrossRef]

- Kazempour-Liasi, H.; Tajally, M.; Abdollah-Pour, H. Effects of pre-and post-weld heat treatment cycles on the liquation and strain-age cracking of IN939 superalloy. Eng. Res. Express 2019, 1, 25026. [Google Scholar] [CrossRef]

- Arhami, F.; Mirsalehi, S.E. The effect of heat treatment sequence on microstructure and mechanical properties of diffusion brazed IN-939 superalloy. J. Mater. Process. Technol. 2019, 266, 351–362. [Google Scholar] [CrossRef]

- Marchese, G.; Bassini, E.; Aversa, A.; Lombardi, M.; Ugues, D.; Fino, P.; Biamino, S. Microstructural evolution of post-processed hastelloy X alloy fabricated by laser powder bed fusion. Materials 2019, 12, 486. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Raza, T.; Hurtig, K.; Asala, G.; Andersson, J.; Svensson, L.-E.; Ojo, O.A. Influence of heat treatments on heat affected zone cracking of gas tungsten arc welded additive manufactured alloy 718. Metals 2019, 9, 881. [Google Scholar] [CrossRef] [Green Version]

- Yin, H.; Gao, Y.; Gu, Y. Effects of post-welding heat treatment on microstructure and mechanical properties of welding joint of new Ni-Fe based superalloy with Haynes 282 filler metal. Mater. Sci. Eng. A 2017, 708, 118–128. [Google Scholar] [CrossRef]

- Hu, R.; Bai, G.; Li, J.; Zhang, J.; Zhang, T.; Fu, H. Precipitation behavior of grain boundary M23C6 and its effect on tensile properties of Ni--Cr--W based superalloy. Mater. Sci. Eng. A 2012, 548, 83–88. [Google Scholar] [CrossRef]

- Gong, L.; Chen, B.; Du, Z.; Zhang, M.; Liu, R.; Liu, K. Investigation of Solidification and Segregation Characteristics of Cast Ni-Base superalloy K417G. J. Mater. Sci. Technol. 2018, 34, 541–550. [Google Scholar] [CrossRef]

- Jahangiri, M.R.; Arabi, H.; Boutorabi, S.M.A. Comparison of microstructural stability of IN939 superalloy with two different manufacturing routes during long-time aging. Trans. Nonferrous Met. Soc. China 2014, 24, 1717–1729. [Google Scholar] [CrossRef]

- Kuo, C.; Yang, Y.; Bor, H.; Wei, C.; Tai, C. Aging effects on the microstructure and creep behavior of Inconel 718 superalloy. Mater. Sci. Eng. A 2009, 511, 289–294. [Google Scholar] [CrossRef]

- Liu, L.R.; Jin, T.; Zhao, N.R.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Formation of carbides and their effects on stress rupture of a Ni-base single crystal superalloy. Mater. Sci. Eng. A 2003, 361, 191–197. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Yao, X.L.; Dong, W.J. Effect of Aging Heat Treatment on the Microstructure and Creep Properties of the Cast Ni-Based Superalloy at Low Temperature. Acta Metall. Sin. Engl. Lett. 2018, 32, 651–658. [Google Scholar] [CrossRef] [Green Version]

- Lvov, G.; Levit, V.I.; Kaufman, M.J. Mechanism of primary MC carbide decomposition in Ni-base superalloys. Metall. Mater. Trans. A 2004, 35, 1669–1679. [Google Scholar] [CrossRef]

- Tan, Y.G.; Liu, F.; Wen, A.; Wei, D.; Xiao, H.; Yao, Y.; Zhang, W.W.; Sun, W.R. Element Segregation and Solidification Behavior of a Nb, Ti, Al Co - Strengthened Superalloy ЭK151. Acta Metall. Sinica (English Lett.) 2019. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Lei, W.; Yang, L.I.U.; Fu, S.-M.; Wu, J.-T.; Ping, Y.A.N. Microstructure evolution of a new directionally solidified Ni-based superalloy after long-term aging at 950° C upto 1000 h. Trans. Nonferrous Met. Soc. China 2011, 21, 2199–2204. [Google Scholar] [CrossRef]

- Bai, G.; Li, J.; Hu, R.; Tang, Z.; Xue, X.; Fu, H. Effect of temperature on tensile behavior of Ni–Cr–W based superalloy. Mater. Sci. Eng. A 2011, 528, 1974–1978. [Google Scholar] [CrossRef]

- Kazempour-Liasi, H.; Tajally, M.; Abdollah-Pour, H. A Study on Microstructure and Phase Transformation in the Weld Fusion Zone of TIG-Welded IN939 with IN625 and IN718 as Filler Metal. Metall. Mater. Trans. A 2020, 51, 2163–2179. [Google Scholar] [CrossRef]

- Lachowicz, M.; Dudziński, W.; Podrez-Radziszewska, M. TEM observation of the heat-affected zone in electron beam welded superalloy Inconel 713C. Mater. Charact. 2008, 59, 560–566. [Google Scholar] [CrossRef]

- Danis, Y.; Arvieu, C.; Lacoste, E.; Larrouy, T.; Quenisset, J.M. An investigation on thermal, metallurgical and mechanical states in weld cracking of Inconel 738LC superalloy. Mater. Des. 2010, 31, 402–416. [Google Scholar] [CrossRef]

- Yan, F.; Liu, S.; Hu, C.; Wang, C.; Hu, X. Liquation cracking behavior and control in the heat affected zone of GH909 alloy during Nd: YAG laser welding. J. Mater. Process. Technol. 2017, 244, 44–50. [Google Scholar] [CrossRef]

- Li, S.; Li, K.; Cai, Z.; Pan, J. Behavior of M23C6 phase in Inconel 617B superalloy during welding. J. Mater. Process. Technol. 2018, 258, 38–46. [Google Scholar] [CrossRef]

- Pilehrood, A.E.; Omidvar, H.; Shamsipur, A.; Sajuri, Z. Influence of transient liquid phase bonding followed by homogenization on the fatigue lifetimes of inconel 738 at elevated temperature. J. Manuf. Process. 2020, 55, 348–358. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Nategh, S.; Isac, M.; Zebarjad, S.M. Tensile deformation mechanisms at different temperatures in the Ni-base superalloy GTD-111. J. Mater. Process. Technol. 2004, 155, 1900–1904. [Google Scholar] [CrossRef]

- Pilehrood, A.E.; Omidvar, H.; Shamsipur, A.; Khakian-Ghomi, M. Effect of transient liquid phase bonding followed by homogenization on the microstructure and hot tensile behavior of Inconel 738 superalloy. J. Manuf. Process. 2019, 48, 110–118. [Google Scholar] [CrossRef]

- Shi, Z.; Liu, S.; Yu, J.; Li, J. Tensile Behavior of the Second Generation Single Crystal Superalloy DD6. J. Iron Steel Res. Int. 2015, 22, 738–742. [Google Scholar] [CrossRef]

| Material Grade | Ni | Al | Ti | Mn | B | Nb | Mo | Ta | C | W | Co | Cr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN-939 | Balance | 1.59 | 3.22 | 0.02 | 0.01 | 0.65 | 0.24 | 2.00 | 0.14 | 2.53 | 16.08 | 27.1 |

| IN-625 | Balance | 0.40 | 0.40 | 0.50 | - | 3.15 | 10.00 | - | 1.00 | - | 1.00 | 20.00 |

| No. | Specimen Name | Heat Treatment | Current (A) | Heat Input (kJ/mm) |

|---|---|---|---|---|

| 1 | A1 | 1160 °C/4 h | 60 | 0.45 |

| 2 | A2 | 1160 °C/4 h | 70 | 0.45 |

| 3 | B1 | 1160 °C/4 h + 1000 °C/6 h | 60 | 0.45 |

| 4 | B2 | 1160 °C/4 h + 1000 °C/6 h | 70 | 0.60 |

| 5 | C1 | 1160 °C/4 h + 1000 °C/6 h + 800 °C/4 h | 60 | 0.45 |

| 6 | C2 | 1160 °C/4 h + 1000 °C/6 h + 800 °C/4 h | 70 | 0.60 |

| 7 | D1 | 1160 °C/4 h + 1000 °C/6 h + 900 °C/24 h + 700 °C/16 h | 60 | 0.45 |

| 8 | D2 | 1160 °C/4 h + 1000 °C/6 h + 900 °C/24 h + 700 °C/16 h | 70 | 0.60 |

| Location Point | Ni | Ti | Nb | Ta | Co | Cr | Phase |

|---|---|---|---|---|---|---|---|

| Point A | 2.06 | 47.04 | 25.24 | 28.68 | 0.45 | 0.24 | MC |

| Point B | 50.93 | 27.05 | 5.89 | 6.02 | 2.49 | 5.06 | η |

| Sample Name | γ′ Phase Fraction (%) | γ′ Particle Sizes (nm) | ||

|---|---|---|---|---|

| Primary | Secondary | |||

| Base Metal | A | 32.4 | 220 | - |

| B | 38.6 | 248 | - | |

| C | 45.2 | 250 | 35 | |

| D | 49.4 | 266 | 36 | |

| Heat-Affected Zone | A1 | 27.7 | 238 | - |

| A2 | 28.8 | 249 | - | |

| B1 | 32.6 | 254 | - | |

| B2 | 34.3 | 270 | - | |

| C1 | 33.1 | 268 | - | |

| C2 | 34.8 | 277 | - | |

| D1 | 37.8 | 278 | - | |

| D2 | 49.1 | 294 | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mashhuriazar, A.; Omidvar, H.; Sajuri, Z.; Gur, C.H.; Baghdadi, A.H. Effects of Pre-Weld Heat Treatment and Heat Input on Metallurgical and Mechanical Behaviour in HAZ of Multi-Pass Welded IN-939 Superalloy. Metals 2020, 10, 1453. https://doi.org/10.3390/met10111453

Mashhuriazar A, Omidvar H, Sajuri Z, Gur CH, Baghdadi AH. Effects of Pre-Weld Heat Treatment and Heat Input on Metallurgical and Mechanical Behaviour in HAZ of Multi-Pass Welded IN-939 Superalloy. Metals. 2020; 10(11):1453. https://doi.org/10.3390/met10111453

Chicago/Turabian StyleMashhuriazar, Amirhossein, Hamid Omidvar, Zainuddin Sajuri, C. Hakan Gur, and Amir Hossein Baghdadi. 2020. "Effects of Pre-Weld Heat Treatment and Heat Input on Metallurgical and Mechanical Behaviour in HAZ of Multi-Pass Welded IN-939 Superalloy" Metals 10, no. 11: 1453. https://doi.org/10.3390/met10111453

APA StyleMashhuriazar, A., Omidvar, H., Sajuri, Z., Gur, C. H., & Baghdadi, A. H. (2020). Effects of Pre-Weld Heat Treatment and Heat Input on Metallurgical and Mechanical Behaviour in HAZ of Multi-Pass Welded IN-939 Superalloy. Metals, 10(11), 1453. https://doi.org/10.3390/met10111453