Fabrication and Characterization of Transparent and Scratch-Proof Yttrium/Sialon Thin Films

Abstract

1. Introduction

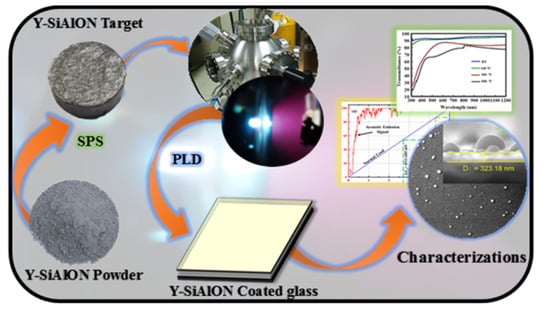

2. Materials and Methods

2.1. Fabrication of Y/Sialon Target by Spark Plasma Sintering (SPS)

2.2. Fabrication of Y/Sialon Thin Films

2.3. Characterization Techniques

3. Results and Discussion

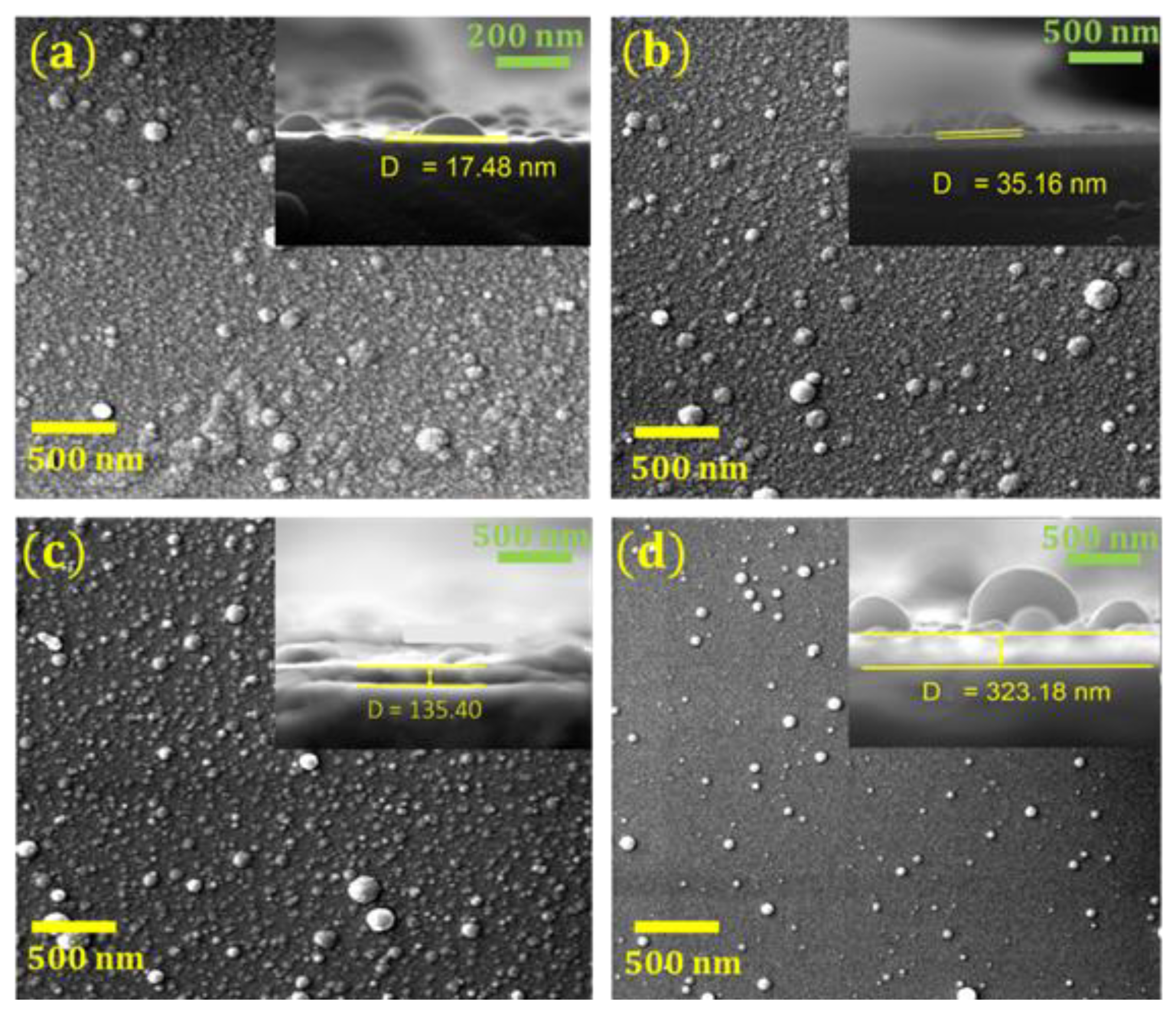

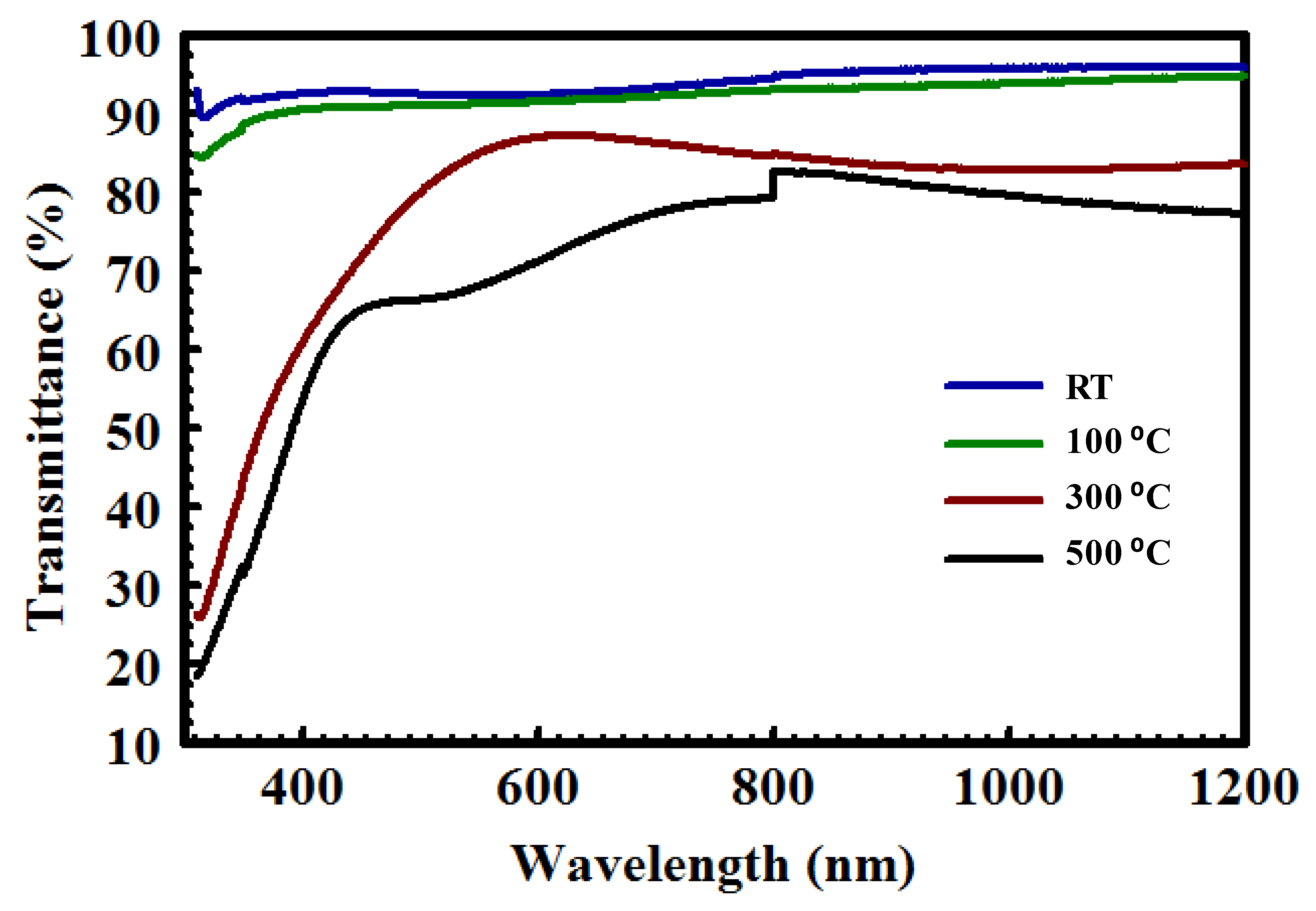

3.1. Microstructure and Phase Analysis

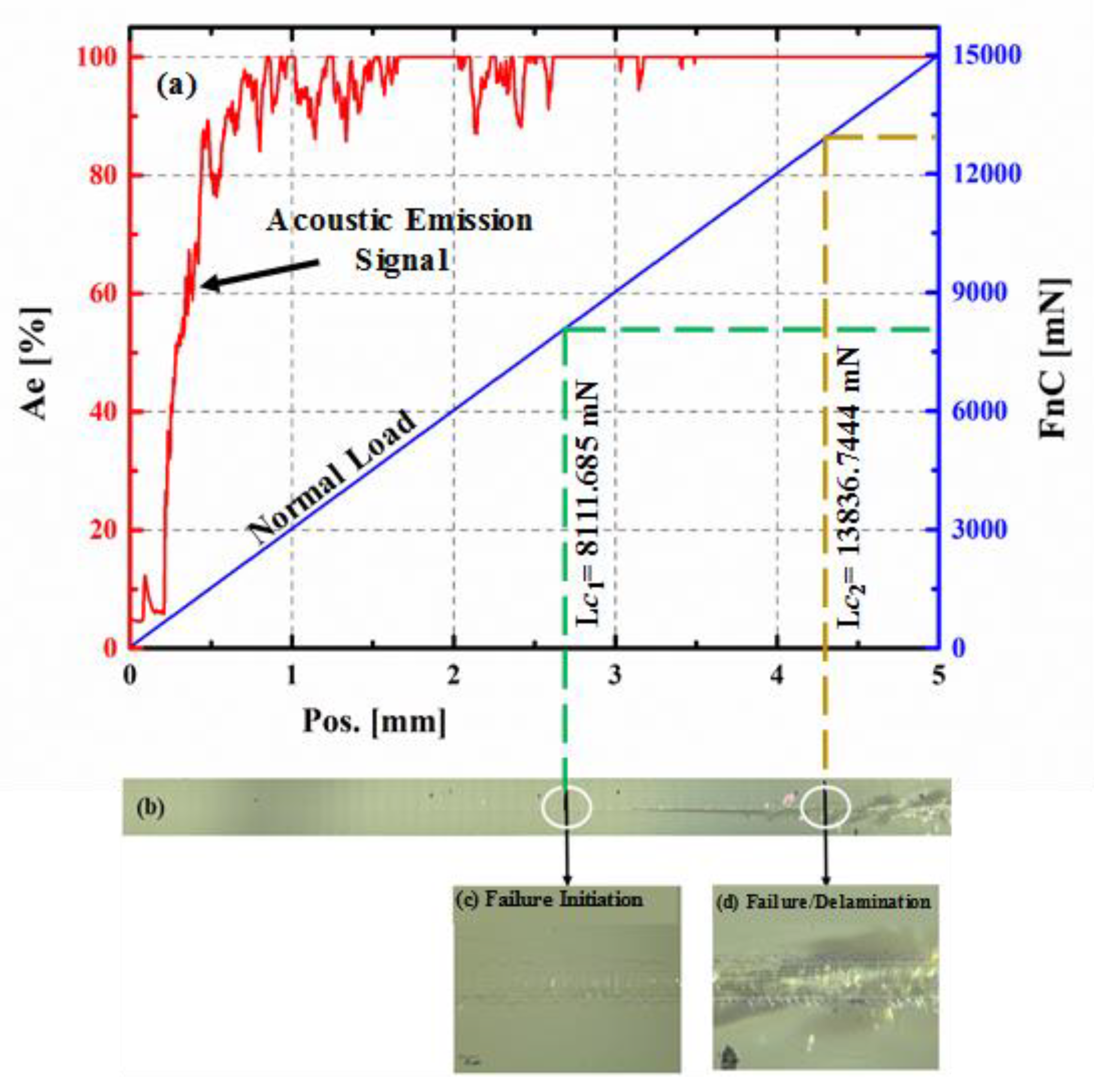

3.2. Effect of Substrate Temperature on the Scratch Resistance of Coatings

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Meng, L.; Yang, X.; Chai, H.; Lv, Z.; Yang, T. Sol-gel derived Zn1−xMgxO: Al transparent conductive thin film and its application to thin film solar cells. Thin Solid Film. 2019, 672, 186–191. [Google Scholar] [CrossRef]

- Zhou, L.; He, Z.; Han, C.; Zhang, L.; Yang, H. Switchable anti-peeping film for liquid crystal displays from polymer dispersed liquid crystals. Liq. Cryst. 2019, 46, 718–724. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Yeo, L.P.; Mandler, D.; Magdassi, S.; Tok, A.I.Y. Electrodeposition of amorphous WO3 on SnO2–TiO2 inverse opal nano-framework for highly transparent, effective and stable electrochromic smart window. RSC Adv. 2019, 9, 16730–16737. [Google Scholar] [CrossRef]

- Kim, D.-J.; Shin, H.-I.; Ko, E.-H.; Kim, K.-H.; Kim, T.-W.; Kim, H.-K. Roll-to-roll slot-die coating of 400 mm wide, flexible, transparent Ag nanowire films for flexible touch screen panels. Sci. Rep. 2016, 6, 34322. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.; Paul, B.; Magnusson, R.; Greczynski, G.; Broitman, E.; Jonson, B.; Eklund, P.; Birch, J.J.V. Novel transparent MgSiON thin films with high hardness and refractive index. Vacuum 2016, 131, 1–4. [Google Scholar] [CrossRef][Green Version]

- San Vicente, G.; Bayón, R.; Germán, N.; Morales, A. Surface modification of porous antireflective coatings for solar glass covers. Sol. Energy 2011, 85, 676–680. [Google Scholar] [CrossRef]

- Kim, H.J.; Song, J.H. Improvement in the mechanical properties of carbon and aramid composites by fiber surface modification using polydopamine. Compos. Part B Eng. 2019, 160, 31–36. [Google Scholar] [CrossRef]

- Fu, Y.; Li, J.; Li, P.; Tao, H.; Luo, X.; Wang, D.; Shan, Y.; Zhou, H. Fabrication of a high-performance film of CaO–B2O3–SiO2 glass-ceramic via surface modification with titanate coupling agent. J. Alloys Compd. 2020, 815, 152387. [Google Scholar] [CrossRef]

- Kermad, A.; Hassani, A.; Hadjaj, N.; Sam, S.; Belaid, S.; Kaci, S.; Touati, Y.; Belhouse, S.; Manseri, A.; Mennari, H. Enhancing anti-reflective and hydrophobic properties of glass surfaces by nanostructuration and grafting of saturated carbon chains. Appl. Surf. Sci. 2020, 507, 144843. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, Z.; Shen, L.; Zhang, J.; Yi, S. Surface modification of ion-exchanged float aluminosilicate glass during deposition of amorphous alumina coatings by e-beam evaporation. J. Non-Cryst. Solids 2016, 447, 80–84. [Google Scholar] [CrossRef]

- Fang, Z.; Ding, Z.; Shao, T.; Zhang, C. Hydrophobic surface modification of epoxy resin using an atmospheric pressure plasma jet array. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2288–2293. [Google Scholar] [CrossRef]

- Schlaich, C.; Li, M.; Cheng, C.; Donskyi, I.S.; Yu, L.; Song, G.; Osorio, E.; Wei, Q.; Haag, R. Mussel-Inspired Polymer-Based Universal Spray Coating for Surface Modification: Fast Fabrication of Antibacterial and Superhydrophobic Surface Coatings. Adv. Mater. Interfaces 2018, 5, 1701254. [Google Scholar] [CrossRef]

- Etiemble, A.; Der Loughian, C.; Apreutesei, M.; Langlois, C.; Cardinal, S.; Pelletier, J.-M.; Pierson, J.-F.; Steyer, P. Innovative Zr-Cu-Ag thin film metallic glass deposed by magnetron PVD sputtering for antibacterial applications. J. Alloys Compd. 2017, 707, 155–161. [Google Scholar] [CrossRef]

- Ali, S.; Paul, B.; Magnusson, R.; Broitman, E.; Jonson, B.; Eklund, P.; Birch, J.J.S.; Technology, C. Synthesis and characterization of the mechanical and optical properties of Ca-Si-ON thin films deposited by RF magnetron sputtering. Surf. Coat. Technol. 2017, 315, 88–94. [Google Scholar] [CrossRef]

- Ali, S.; Paul, B.; Magnusson, R.; Ekström, E.; Pallier, C.; Jonson, B.; Eklund, P.; Birch, J.J.S.; Technology, C. Optical and mechanical properties of amorphous Mg-Si-ON thin films deposited by reactive magnetron sputtering. Surf. Coat. Technol. 2019, 372, 9–15. [Google Scholar] [CrossRef]

- McEntire, B.; Bal, B.S.; Rahaman, M.; Chevalier, J.; Pezzotti, G. Ceramics and ceramic coatings in orthopaedics. J. Eur. Ceram. Soc. 2015, 35, 4327–4369. [Google Scholar] [CrossRef]

- Majumdar, A.; Jana, S. Glass and glass-ceramic coatings, versatile materials for industrial and engineering applications. Bull. Mater. Sci. 2001, 24, 69–77. [Google Scholar] [CrossRef]

- Piispanen, M.; Hupa, L. Comparison of self-cleaning properties of three titania coatings on float glass. Appl. Surf. Sci. 2011, 258, 1126–1131. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, J.; Hu, B.; Yao, Z.; Xia, Q.; Jiang, Z. Preparation of a novel yellow ceramic coating on Ti alloys by plasma electrolytic oxidation. Surf. Coat. Technol. 2016, 307, 1297–1302. [Google Scholar] [CrossRef]

- Das, S.; Mukhopadhyay, A.K.; Datta, S.; Das, G.; Basu, D. Hard glass-ceramic coating by microwave processing. J. Eur. Ceram. Soc. 2008, 28, 729–738. [Google Scholar] [CrossRef]

- Bernhardt, G.; Krassikoff, J.; Sturtevant, B.; Lad, R. Properties of amorphous SiAlON thin films grown by RF magnetron co-sputtering. Surf. Coat. Technol. 2014, 258, 1191–1195. [Google Scholar] [CrossRef]

- Khan, R.M.A.; Al Malki, M.M.; Hakeem, A.S.; Ehsan, M.A.; Laoui, T. Development of a single-phase Ca-α-SiAlON ceramic from nanosized precursors using spark plasma sintering. Mater. Sci. Eng. A 2016, 673, 243–249. [Google Scholar] [CrossRef]

- Merkx, E.P.; van Overbeek, S.; van der Kolk, E. Functionalizing window coatings with luminescence centers by combinatorial sputtering of scatter-free amorphous SiAlON: Eu2+ thin film composition libraries. J. Lumin. 2019, 208, 51–56. [Google Scholar] [CrossRef]

- Xie, R.J.; Hintzen, H.T. Optical properties of (oxy) nitride materials: A review. J. Am. Ceram. Soc. 2013, 96, 665–687. [Google Scholar] [CrossRef]

- Al Malki, M.M.; Khan, R.M.A.; Hakeem, A.S.; Hampshire, S.; Laoui, T. Effect of Al metal precursor on the phase formation and mechanical properties of fine-grained SiAlON ceramics prepared by spark plasma sintering. J. Eur. Ceram. Soc. 2017, 37, 1975–1983. [Google Scholar] [CrossRef]

- Hakeem, A.S.; Daucé, R.; Leonova, E.; Edén, M.; Shen, Z.; Grins, J.; Esmaeilzadeh, S. Silicate glasses with unprecedented high nitrogen and electropositive metal contents obtained by using metals as precursors. Adv. Mater. 2005, 17, 2214–2216. [Google Scholar] [CrossRef]

- Leonova, E.; Hakeem, A.S.; Jansson, K.; Stevensson, B.; Shen, Z.; Grins, J.; Esmaeilzadeh, S.; Edén, M. Nitrogen-rich La–Si–Al–O–N oxynitride glass structures probed by solid state NMR. J. Non-Cryst. Solids 2008, 354, 49–60. [Google Scholar] [CrossRef]

- Joshi, B.; Lee, H.H.; Wang, H.; Fu, Z.; Niihara, K.; Lee, S.W. The effect of different rare earth oxides on mechanical and optical properties of hot pressed α/β-Sialon ceramics. J. Eur. Ceram. Soc. 2012, 32, 3603–3610. [Google Scholar] [CrossRef]

- Leitzke, D.; Cholant, C.; Landarin, D.; Lucio, C.; Krüger, L.; Gündel, A.; Flores, W.; Rodrigues, M.; Balboni, R.; Pawlicka, A. Electrochemical properties of WO3 sol-gel thin films on indium tin oxide/poly (ethylene terephthalate) substrate. Thin Solid Film. 2019, 683, 8–15. [Google Scholar] [CrossRef]

- Lee, J.-H.; Song, W.-C.; Yi, J.-S.; Yang, K.-J.; Han, W.-D.; Hwang, J. Growth and properties of the Cd1−xZnxS thin films for solar cell applications. Thin Solid Film. 2003, 431, 349–353. [Google Scholar] [CrossRef]

- Boyko, T.D.; Gross, T.; Schwarz, M.; Fuess, H.; Moewes, A. The local crystal structure and electronic band gap of β-sialons. J. Mater. Sci. 2014, 49, 3242–3252. [Google Scholar] [CrossRef]

- Sekler, J.; Steinmann, P.; Hintermann, H. The scratch test: Different critical load determination techniques. Surf. Coat. Technol. 1988, 36, 519–529. [Google Scholar] [CrossRef]

- Randall, N.X. The current state-of-the-art in scratch testing of coated systems. Surf. Coat. Technol. 2019, 380, 125092. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, Z.; Fei, F.; Wei, Q.; Yang, H.; Liu, Q. Hard antireflective films of SiAlON for zinc sulfide in 3–5 μm regions. Infrared Phys. Technol. 2013, 60, 118–120. [Google Scholar] [CrossRef]

- Jacobs, M.; Bodart, F.; Terwagne, G.; Schryvers, D.; Poulet, A. Nanohardness and structure of nitrogen implanted SixAly coatings post-implanted with oxygen. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1999, 147, 231–237. [Google Scholar] [CrossRef]

- Chauhan, A.; Moran, W.; Ge, S.; Si, W.; White, H.J. Pulsed laser deposition of silicon carbide on heat resistant materials. Scr. Mater. 2005, 52, 735–738. [Google Scholar] [CrossRef]

- Wei, Q.; Sharma, A.K.; Sankar, J.; Narayan, J. Mechanical properties of diamond-like carbon composite thin films prepared by pulsed laser deposition. Compos. Part B Eng. 1999, 30, 675–684. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, J.; Wu, J.D.; Wang, P.N.; Shen, W. Determination of adhesion energy of CNx thin film on silicon from micro-scratch testing. Tribol. Trans. 2004, 47, 130–137. [Google Scholar] [CrossRef]

- Xiao, R.F.; Ng, L.C.; Jiang, C.; Yang, Z.; Wong, G.K. Preparation of silicon oxynitride (SiOxNy) thin films by pulsed laser deposition. Thin Solid Film. 1995, 260, 10–13. [Google Scholar] [CrossRef]

- Camps, I.; Mariscal, A.; Serna, R. Preparation and broadband white emission of Eu-doped thin films based on SiAlON. J. Lumin. 2017, 191, 97–101. [Google Scholar] [CrossRef]

- Desbiens, E.; Dolbec, R.; El Khakani, M.A. Reactive pulsed laser deposition of high-k silicon dioxide and silicon oxynitride thin films for gate-dielectric applications. J. Vac. Sci. Technol. A Vac. Surf. Film. 2002, 20, 1157–1161. [Google Scholar] [CrossRef]

| Chemicals | α-Si3N4 | AlN | Y2O3 | SiO2 | Al2O3 |

|---|---|---|---|---|---|

| Wt. (g) | 4.3550 | 0.9003 | 0.3822 | 0.1342 | 0.2282 |

| WT. (%) | 72.58 | 15.01 | 6.37 | 2.24 | 3.80 |

| Elements | Si | Al | Y | O | N |

| Mole% | 33.1769 | 9.1766 | 1.1753 | 5.6471 | 50.8241 |

| Sample | Thickness (nm) | RMS (nm) | |

|---|---|---|---|

| 1 | Y- Sialon (RT) | 18 | 16.0 |

| 2 | Y- Sialon (100 °C) | 35 | 14.5 |

| 3 | Y- Sialon (300 °C) | 135 | 11.4 |

| 4 | Y- Sialon (500 °C) | 323 | 9.7 |

| Name | Peak BE | FWHM eV | Area (P) CPS.eV | Atomic % | |

|---|---|---|---|---|---|

| Y/Sialon RT °C | O1s | 532.91 | 3.17 | 1,040,178 | 48.9 |

| Si2p | 103.25 | 3.24 | 210,528.4 | 30.84 | |

| N1s | 398.3 | 3.23 | 87,008.34 | 6.32 | |

| Al2p | 75.86 | 3.02 | 38,248.16 | 8.46 | |

| Y3d | 154.25 | 3.57 | 270,047.6 | 5.48 | |

| Y/Sialon 100 °C | O1s | 532.84 | 3.22 | 1,035,674 | 48.79 |

| Si2p | 103.14 | 3.26 | 207,127 | 30.4 | |

| N1s | 398.28 | 3.41 | 64,431.87 | 4.69 | |

| Al2p | 75.85 | 3.02 | 48,034.71 | 10.65 | |

| Y3d5 | 154.14 | 3.64 | 269,156.5 | 5.47 | |

| Y/Sialon 300 °C | O1s | 533.16 | 3.06 | 384,019.3 | 43.71 |

| Si2p | 103.25 | 3.6 | 90,340.59 | 32.04 | |

| N1s | 398.87 | 2.97 | 47,364.59 | 8.33 | |

| Al2p | 76.2 | 2.87 | 19,389.59 | 10.39 | |

| Y3d | 154.18 | 4.14 | 112,483.3 | 5.52 | |

| Y/Sialon 500 °C | O1s | 532.99 | 3.13 | 644,686.3 | 40.88 |

| Si2p | 102.99 | 3.41 | 158,230.6 | 31.26 | |

| N1s | 398.77 | 3.09 | 94,786.28 | 9.29 | |

| Al2p | 75.99 | 2.99 | 45,746.21 | 13.65 | |

| Y3d | 153.97 | 3.75 | 179,897.7 | 4.92 |

| # | Substrate | Coating | Technique | Film Thickness (nm) | Scratch Resistance | Hardness (GPa) | Fracture Toughness | Comment | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Float glass | MgSiON | Co-sputtering | 372–463 | Not reported | Coating = 21 Substrate = 7 | not reported | E(coating) = 166 GPA E(substrate) = 72 GPA | [5] |

| 2 | Uncoated or Pt-coated sapphire | SiAlON | RF magnetron sputtering | 200 | not reported | not reported | not reported | films are very wear resistant than sapphire | [21] |

| 3 | Zinc sulfide window materials | SiAlON | Ion beam sputtering method. | 633 | not reported | film = 7.1 Subs = 4.1 | not reported | micro hardness of the zinc sulfide was improved by 75% on average after being coated with SiAlON films | [34] |

| 4 | Glassy carbon substrates | None | DC magnetron sputtering | 200 | not reported | subs = 3 Film = 10 | not reported | [35] | |

| 5 | HK40 (Fe-Ni-Cr) Alloy | Silicon Carbide | Pulsed Laser Deposition | 1000 | InitialFailure @ 0.48 N Complete delamination @ 4.37 N | not reported | not reported | Shot peening and heating of surface of substrate improves both coverage and adhesion of film | [36] |

| 6 | p-type Silicon Wafers | Diamond like Carbon Films Copper Doped) | Pulsed Laser Deposition | 400–600 | Improved adhesion compared to undoped film | 38 | not reported | A constant load of 10 g was used for scratch test. | [37] |

| 7 | Silicon Wafers | Carbon Nitride | Plasma Assisted Pulsed Laser Deposited | NA | Initial Failure @ 80 mN | 13.5 | not reported | E = 100 GPa | [38] |

| 8 | Silicon &NaCl | silicon oxynitride | Pulsed Laser Deposition | NA | not reported | not reported | not reported | [39] | |

| 9 | NA | Eu Doped SiAlON | Pulsed Laser Deposition | 150 | Not reported | Not reported | Not reported | [40] | |

| 10 | Si & Pt-coated Si substrates. | SiO2 and SiOxNy | Reactive Pulsed Laser Deposition | 10–2000 | not reported | not reported | not reported | [41] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamedkhair, A.K.; Hakeem, A.S.; Drmosh, Q.A.; Mohammed, A.S.; Baig, M.M.A.; Ul-Hamid, A.; Gondal, M.A.; Yamani, Z.H. Fabrication and Characterization of Transparent and Scratch-Proof Yttrium/Sialon Thin Films. Nanomaterials 2020, 10, 2283. https://doi.org/10.3390/nano10112283

Mohamedkhair AK, Hakeem AS, Drmosh QA, Mohammed AS, Baig MMA, Ul-Hamid A, Gondal MA, Yamani ZH. Fabrication and Characterization of Transparent and Scratch-Proof Yttrium/Sialon Thin Films. Nanomaterials. 2020; 10(11):2283. https://doi.org/10.3390/nano10112283

Chicago/Turabian StyleMohamedkhair, Amar Kamal, Abbas Saeed Hakeem, Qasem Ahmed Drmosh, Abdul Samad Mohammed, Mirza Murtuza Ali Baig, Anwar Ul-Hamid, Mohammed Ashraf Gondal, and Zain Hassan Yamani. 2020. "Fabrication and Characterization of Transparent and Scratch-Proof Yttrium/Sialon Thin Films" Nanomaterials 10, no. 11: 2283. https://doi.org/10.3390/nano10112283

APA StyleMohamedkhair, A. K., Hakeem, A. S., Drmosh, Q. A., Mohammed, A. S., Baig, M. M. A., Ul-Hamid, A., Gondal, M. A., & Yamani, Z. H. (2020). Fabrication and Characterization of Transparent and Scratch-Proof Yttrium/Sialon Thin Films. Nanomaterials, 10(11), 2283. https://doi.org/10.3390/nano10112283