Taikobot: A Full-Size and Free-Flying Humanoid Robot for Intravehicular Astronaut Assistance and Spacecraft Housekeeping

Abstract

:1. Introduction

2. System Overview and Mechatronic Design

- Autonomous inspection and search in the space station.

- Astronaut accompanying and work assistance.

- Basic operations and maintenance of the space station between human visits.

2.1. Mechanical Design

- (1)

- Human-Like Dual Arm System

- (2)

- End Effectors

- (3)

- Zero-g Legs and Torso

2.2. Sensors and Computing Architecture

3. Locomotion Strategy in Microgravity

3.1. Centroidal Dynamics Model

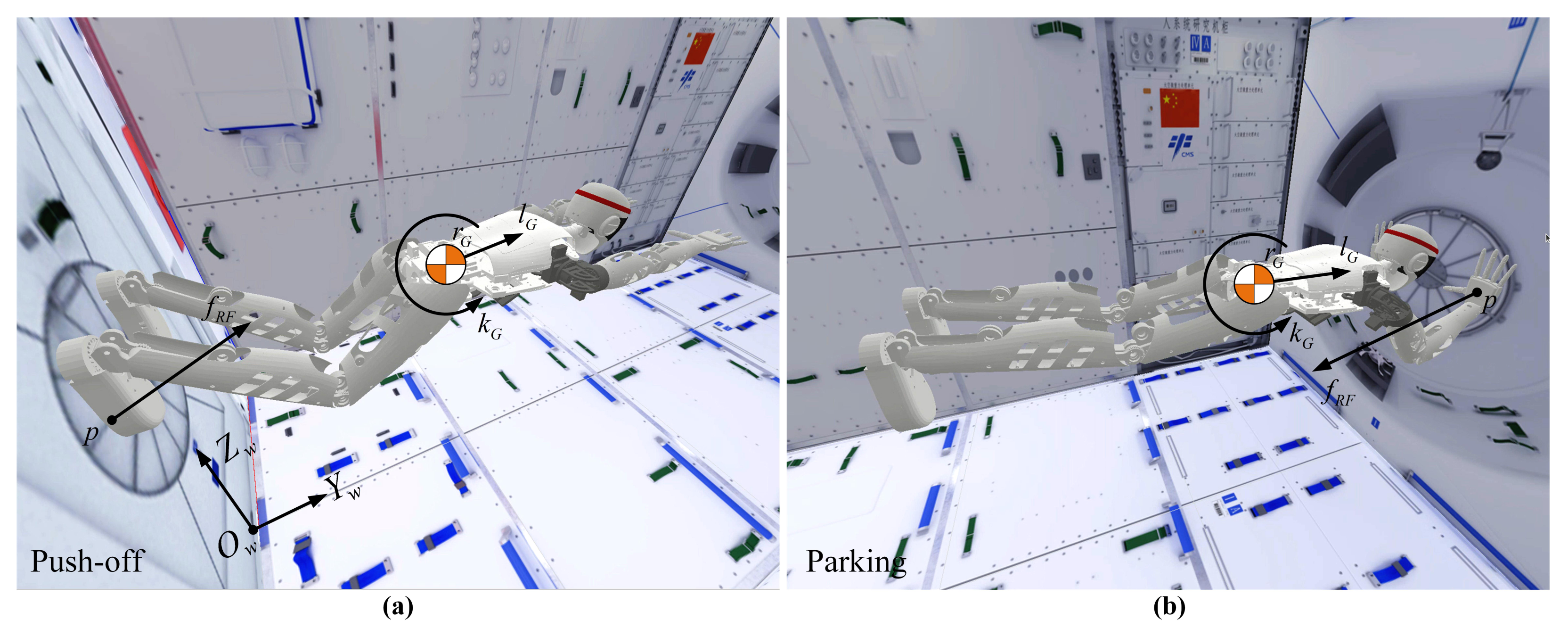

3.2. PFP Motion Planning and Control

- (1)

- The Lower-Level Problem

- (2)

- The Upper-Level Problem

- (3)

- PFP Motion Control

3.3. Local Locomotion in Docking Mode

- (1)

- Docking with Handrails

- (2)

- Docking with Foot Restraints

4. Experimental Results and Discussion

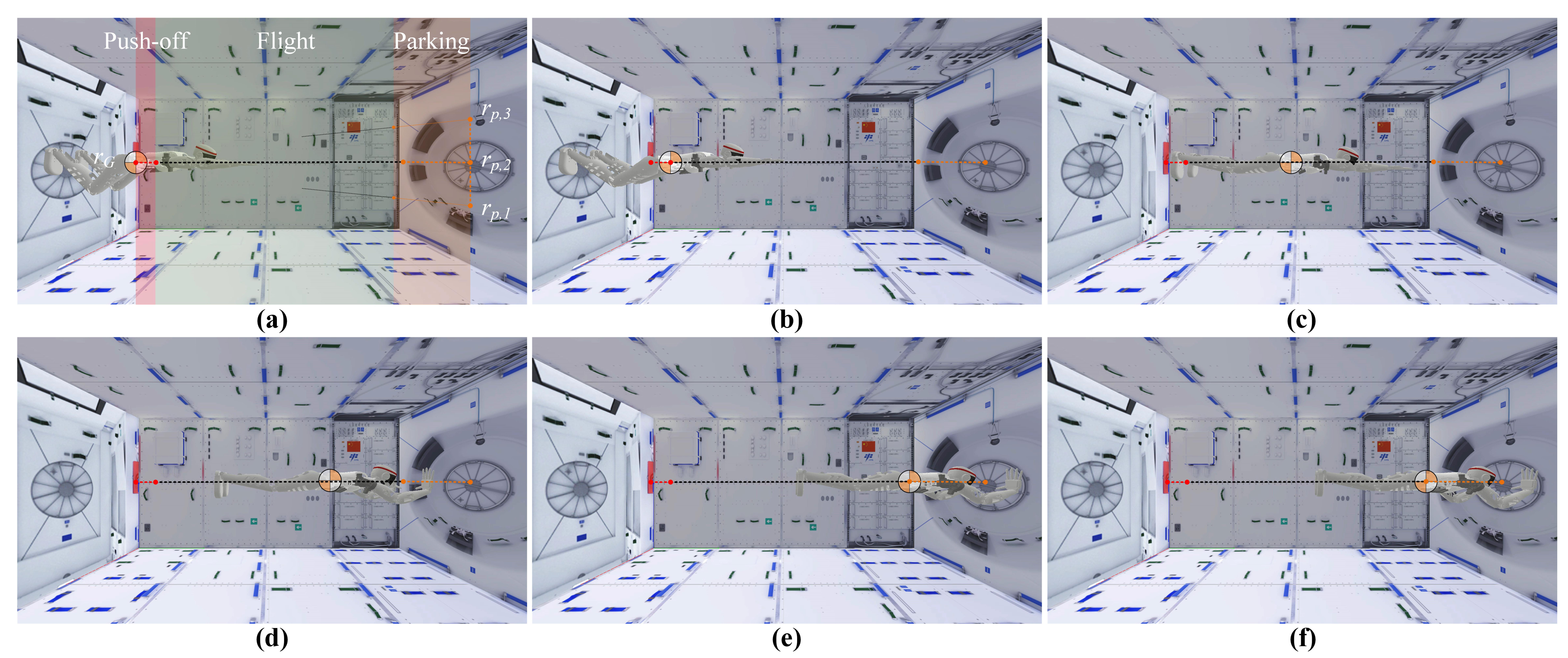

4.1. Verification of the Intravehicular PFP Locomotion

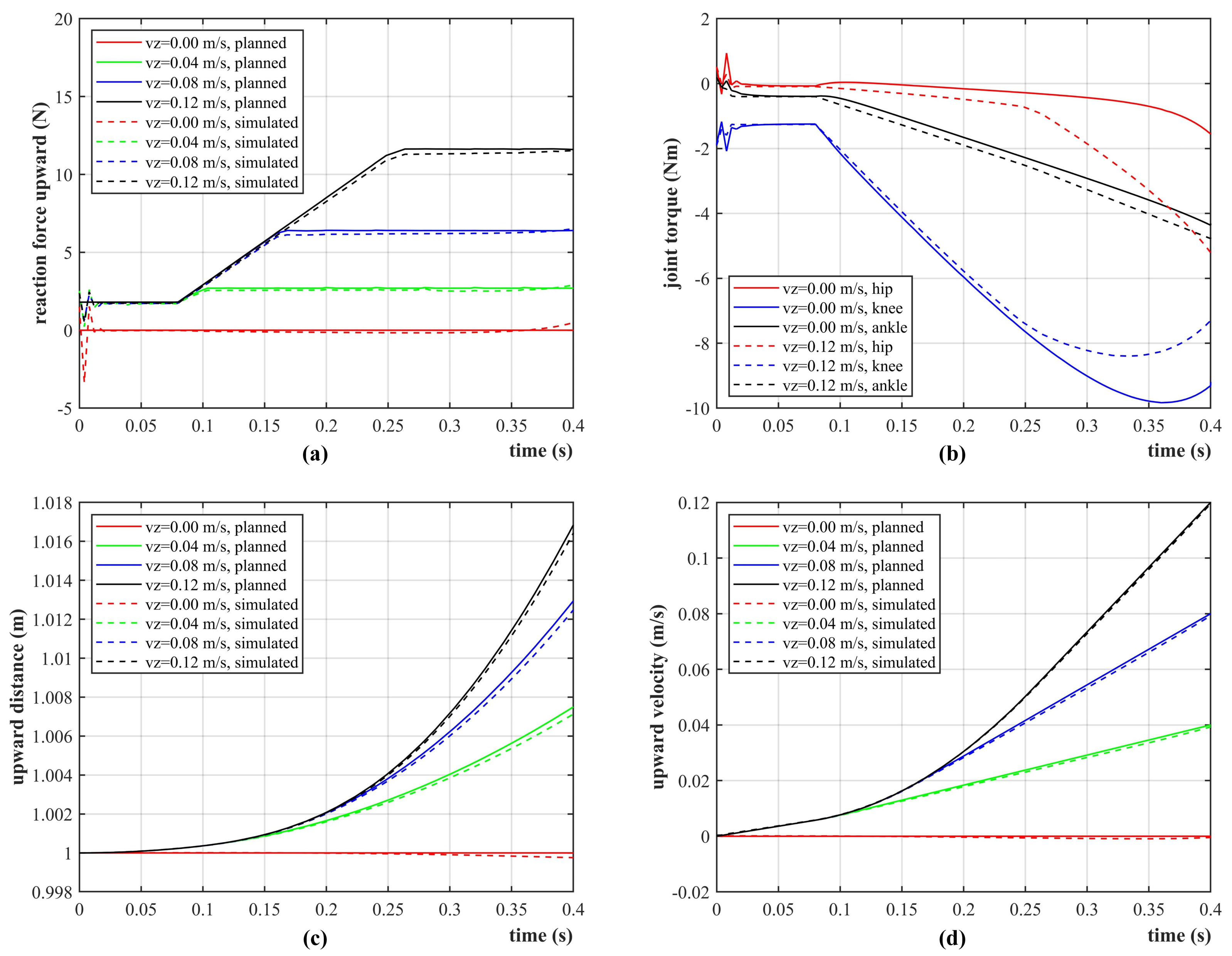

- (1)

- Results of the Lower-Level Optimizer targeted at Desired Velocity

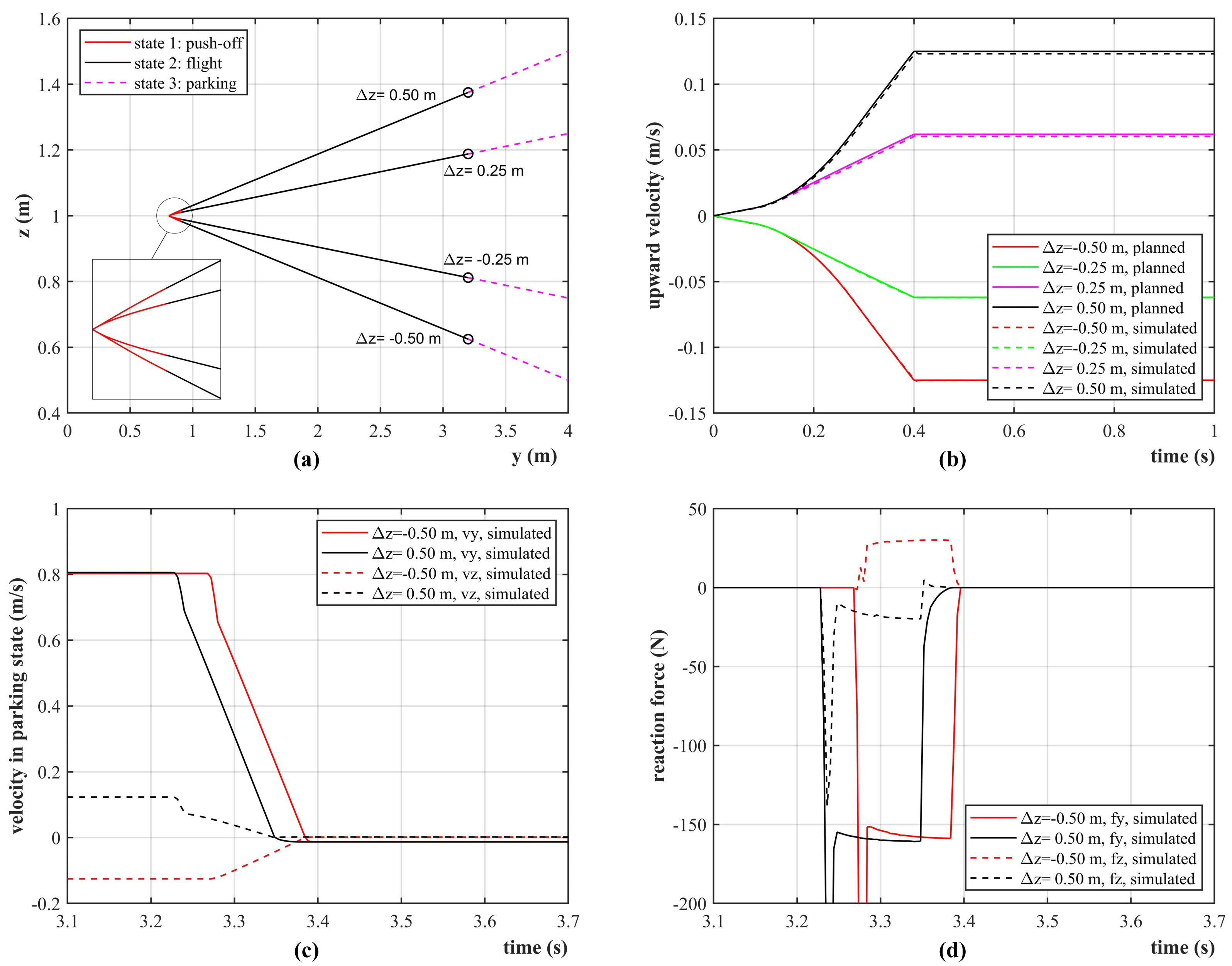

- (2)

- Results of the Bilevel Optimizer targeted at Desired Parking Point

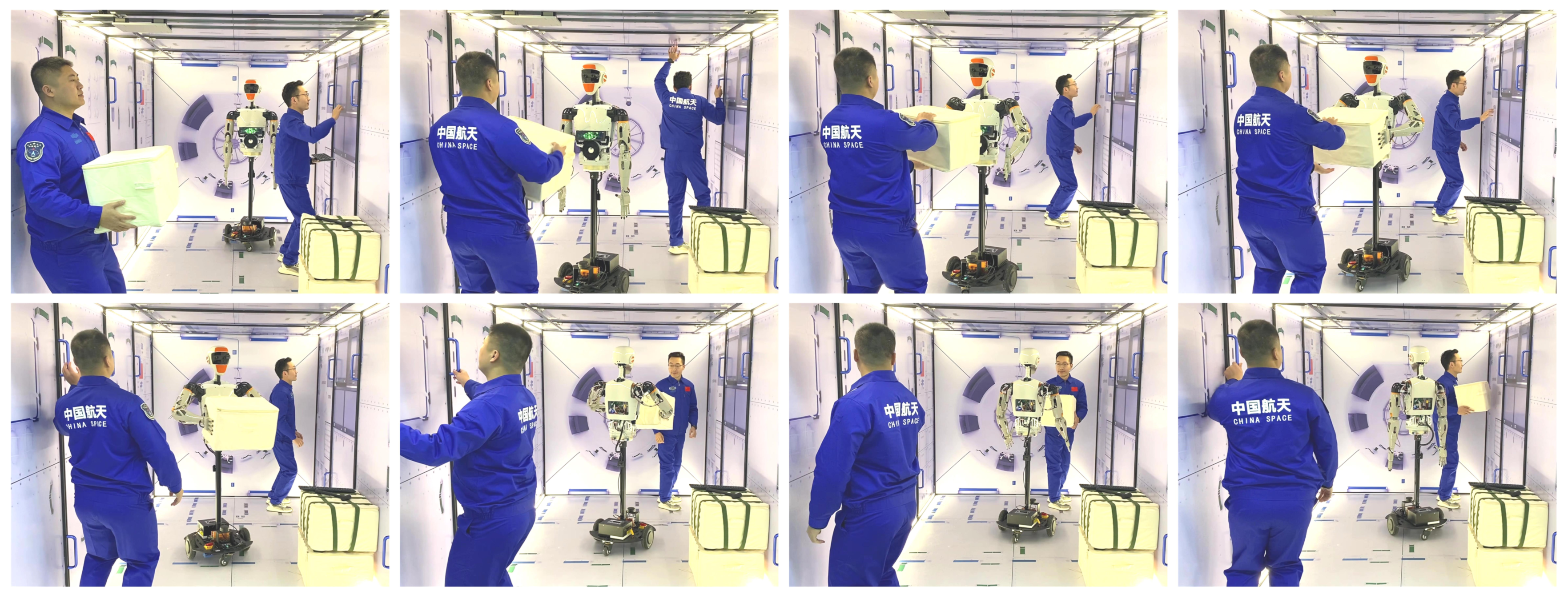

4.2. Experiments on Astronaut Assistance

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| COM | Center of Mass |

| PFP | Push–Flight–Park |

| PSA | Personal Satellite Assistant |

| SPHERES | Synchronized Position Hold, Engage, Reorient, Experimental Satellite |

| RFID | Radio Frequency Identification |

| DOF | Degrees of Freedom |

| WLAN | Wireless Local Area Network |

References

- Sgobba, T.; Kanki, B.; Clervoy, J.F. Space Safety and Human Performance, 1st ed.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 357–376. Available online: https://www.elsevier.com/books/space-safety-and-human-performance/sgobba/978-0-08-101869-9 (accessed on 10 September 2022).

- Jason, C.; Marshall, S.; Douglas, C. Deep space gateway concept: Extending human presence into cislunar space. In Proceedings of the 2018 IEEE Aerospace Conference, Yellowstone Conference Center, Big Sky, MT, USA, 3–10 March 2018; Available online: https://ieeexplore.ieee.org/document/8396541 (accessed on 10 September 2022).

- Micco, V.; Amitrano, C. Effect of light quality and ionizing radiation on morphological and nutraceutical traits of sprouts for astronauts’ diet. Acta Astronaut. 2021, 185, 188–197. [Google Scholar] [CrossRef]

- Ayşe Meriç, Y.; Satyam, T. Space tourism: An initiative pushing limits. J. Tour. Leis. Hosp. 2021, 3, 38–46. [Google Scholar] [CrossRef]

- Ding, X.L.; Wang, Y.C.; Wang, Y.B. A review of structures, verification, and calibration technologies of space robotic systems for on-orbit servicing. Sci. China Technol. Sci. 2020, 64, 462–480. Available online: https://link.springer.com/article/10.1007/s11431-020-1737-4 (accessed on 10 September 2022). [CrossRef]

- Mitani, S.; Goto, M.; Konomura, R. Int-ball: Crew-supportive autonomous mobile camera robot on ISS/JEM. In Proceedings of the 2019 IEEE Aerospace Conference, Yellowstone Conference Center, Big Sky, MT, USA, 2–9 March 2019. [Google Scholar] [CrossRef]

- Smith, T.; Barlow, J.; Bualat, M. Astrobee: A new platform for free-flying robotics on the international space station. In Proceedings of the 13th International Symposium on Artificial Intelligence, Robotics, and Automation in Space, Beijing, China, 20–22 June 2016; Available online: https://ntrs.nasa.gov/citations/20160007769 (accessed on 10 September 2022).

- Dorais, G.A.; Gawdiak, Y. The personal satellite assistant: An internal spacecraft autonomous mobile monitor. In Proceedings of the 2003 IEEE Aerospace Conference, Big Sky, MT, USA, 8–15 March 2003. [Google Scholar] [CrossRef] [Green Version]

- Saenz-Otero, A.; Miller, D.W. Initial SPHERES operations aboard the International Space Station. In Proceedings of the 6th IAA Symposium on Small Satellites for Earth Observation, Berlin, Germany, 23–26 April 2008. [Google Scholar] [CrossRef]

- Park, I.W.; Smith, T.; Sanchez, H. Developing a 3-DOF compliant perching arm for a free-flying robot on the International Space Station. In Proceedings of the 2017 IEEE International Conference on Advanced Intelligent Mechatronics, Munich, Germany, 26–30 June 2017. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; Wang, Z.K.; Zhang, Y.L. A person-following nanosatellite for in-cabin astronaut assistance: System design and deep-learning-based astronaut visual tracking implementation. Acta Astronaut. 2019, 162, 121–134. [Google Scholar] [CrossRef]

- Farrell, L.; Strawser, P.; Hambuchen, K. Supervisory control of a humanoid robot in microgravity for manipulation tasks. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vancouver, BC, Canada, 24–28 September 2017. [Google Scholar] [CrossRef] [Green Version]

- Badger, J.M.; Strawser, P.; Farrell, L. Robonaut 2 and watson: Cognitive dexterity for future exploration. In Proceedings of the 2018 IEEE Aerospace Conference, Yellowstone Conference Center, Big Sky, MT, USA, 3–10 March 2018. [Google Scholar] [CrossRef]

- NASA Facts Robonaut 2, Technical Report. Available online: https://www.nasa.gov/sites/default/files/files/Robonaut2_508.pdf (accessed on 10 September 2022).

- Meet Skybot F-850, the Humanoid Robot Russia Is Launching into Space. Available online: https://www.space.com/russia-launching-humanoid-robot-into-space.html (accessed on 10 September 2022).

- Nicolaus, A.; Philip, S.; Kimberly, H. Valkyrie: Nasa’s first bipedal humanoid robot. J. Field Robot. 2015, 32, 397–419. [Google Scholar] [CrossRef]

- Angeliki, Z.; Loannis, K. Safety bounds in human robot interaction: A survey. Saf. Sci. 2020, 127, 104667. [Google Scholar] [CrossRef]

- Abdel-Nasser, S.; Panagiotis, N.K. Human-robot Interaction: A review and analysis on variable admittance control, safety, and perspectives. Machines 2022, 10, 591. Available online: https://www.mdpi.com/2075-1702/10/7/591 (accessed on 10 September 2022).

- Cheng, H.T.; Ji, G.F. Design and implementation of a low cost 3D printed humanoid robotic platform. In Proceedings of the 6th IEEE International Conference on Cyber Technology in Automation, Control and Intelligent Systems, Chengdu, China, 19–22 June 2016; Available online: https://ieeexplore.ieee.org/document/7574801 (accessed on 10 September 2022).

- Korovin, I.S.; Klimenko, A.B.; Kalyaev, I.A. An experience of the cognitive map-based classifier usage in astronaut’s emotional state monitoring. Acta Astronaut. 2021, 181, 537–543. [Google Scholar] [CrossRef]

- Kenji, K.; Hiroshi, K. Humanoid robot HRP-5P: An electrically actuated humanoid robot with high-power and wide-range joints. IEEE Robot. Autom. Lett. 2019, 4, 1431–1438. Available online: https://ieeexplore.ieee.org/document/8630006 (accessed on 10 September 2022).

- Dafarra, S.; Bertr, S.; Griffin, R.J. Non-linear trajectory optimization for large step-ups: Application to the humanoid robot atlas. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 25–29 October 2020; Available online: https://ieeexplore.ieee.org/document/9341587 (accessed on 10 September 2022).

- Orin, D.E.; Ambarish, G. Centroidal momentum matrix of a humanoid robot: Structure and properties. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.H.; Yu, Z.C.; Li, C.Y.; He, M.J.; Hua, B.; Chen, Z.M. Reinforcement learning in dual-arm trajectory planning for a free-floating space robot. Aerosp. Sci. Technol. 2020, 98, 105657. [Google Scholar] [CrossRef]

- Pybullet Homepage. Available online: https://pybullet.org/wordpress/ (accessed on 10 September 2022).

- Ramón, L.; Ramon, C.; Adrian, T. Trajectory optimization and control of a free-floating two-arm humanoid robot. J. Guid. Control Dyn. 2022. Available online: https://arc.aiaa.org/doi/abs/10.2514/1.G006828 (accessed on 10 September 2022).

| Joint Index | Transmission Mechanism | Max. Speed | Max. Torque | Range of Motion |

|---|---|---|---|---|

| A—shoulder roll | multi-thread lead screw | 40/s | 60 Nm | 0∼90 |

| B—shoulder pitch | worm gear | 40/s | 60 Nm | −45∼135 |

| C—shoulder yaw | worm gear | 40/s | 60 Nm | −135∼135 |

| D—elbow | multi-thread lead screw | 40/s | 50 Nm | 0∼90 |

| E—forearm | spur gear | 80/s | 20 Nm | −135∼135 |

| F—wrist | spur gear | 80/s | 20 Nm | −90∼90 |

| G—fingers | cable-driven | 80/s | 2 Nm | 0∼90 |

| H—neck pitch | multi-thread lead screw | 80/s | 20 Nm | −30∼30 |

| I—neck yaw | spur gear | 80/s | 20 Nm | −90∼90 |

| J—torso yaw | worm gear | 20/s | 120 Nm | −135∼135 |

| K—torso roll | multi-thread lead screw | 20/s | 120 Nm | −15∼15 |

| L—hip | worm gear | 40/s | 60 Nm | −90∼90 |

| M—knee | multi-thread lead screw | 40/s | 60 Nm | 0∼90 |

| N—ankle pitch | multi-thread lead screw | 40/s | 60 Nm | −30∼30 |

| O—ankle yaw | worm gear | 40/s | 60 Nm | −135∼135 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Zhao, C.; Fan, L.; Zhang, Y. Taikobot: A Full-Size and Free-Flying Humanoid Robot for Intravehicular Astronaut Assistance and Spacecraft Housekeeping. Machines 2022, 10, 933. https://doi.org/10.3390/machines10100933

Zhang Q, Zhao C, Fan L, Zhang Y. Taikobot: A Full-Size and Free-Flying Humanoid Robot for Intravehicular Astronaut Assistance and Spacecraft Housekeeping. Machines. 2022; 10(10):933. https://doi.org/10.3390/machines10100933

Chicago/Turabian StyleZhang, Qi, Cheng Zhao, Li Fan, and Yulin Zhang. 2022. "Taikobot: A Full-Size and Free-Flying Humanoid Robot for Intravehicular Astronaut Assistance and Spacecraft Housekeeping" Machines 10, no. 10: 933. https://doi.org/10.3390/machines10100933

APA StyleZhang, Q., Zhao, C., Fan, L., & Zhang, Y. (2022). Taikobot: A Full-Size and Free-Flying Humanoid Robot for Intravehicular Astronaut Assistance and Spacecraft Housekeeping. Machines, 10(10), 933. https://doi.org/10.3390/machines10100933