Complex Study of Magnetization Reversal Mechanisms of FeNi/FeMn Bilayers Depending on Growth Conditions

Abstract

:1. Introduction

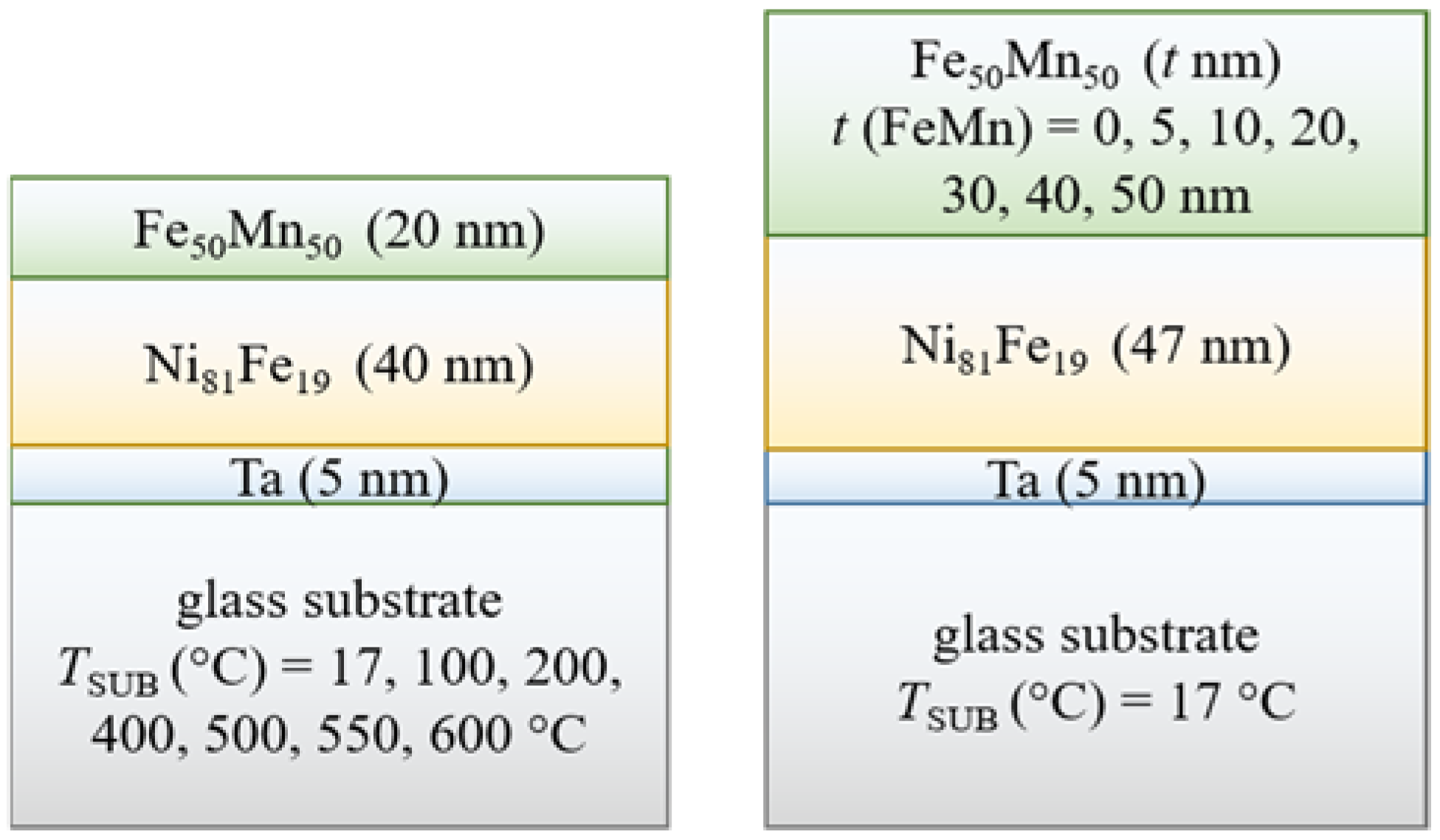

2. Materials and Methods

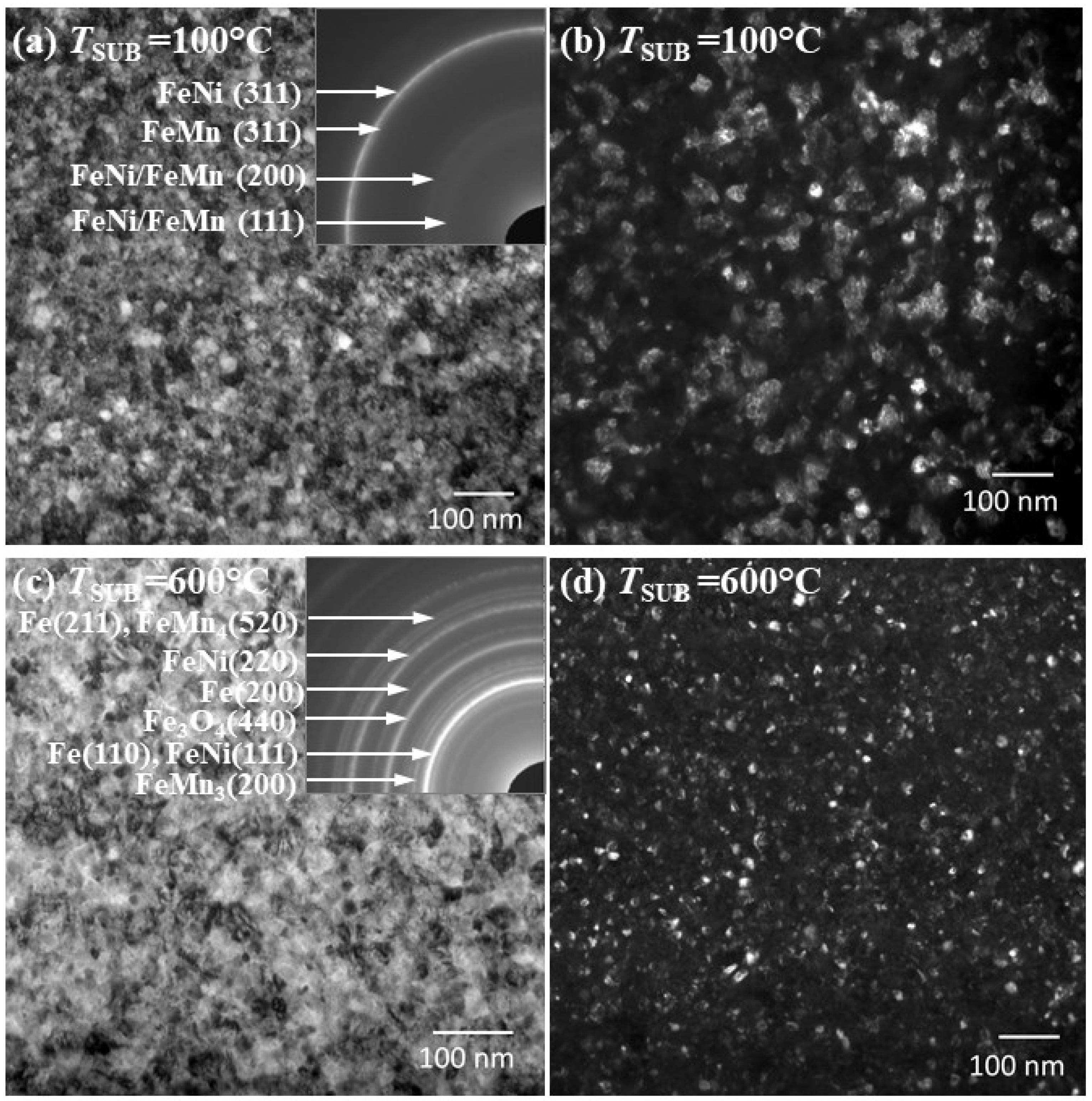

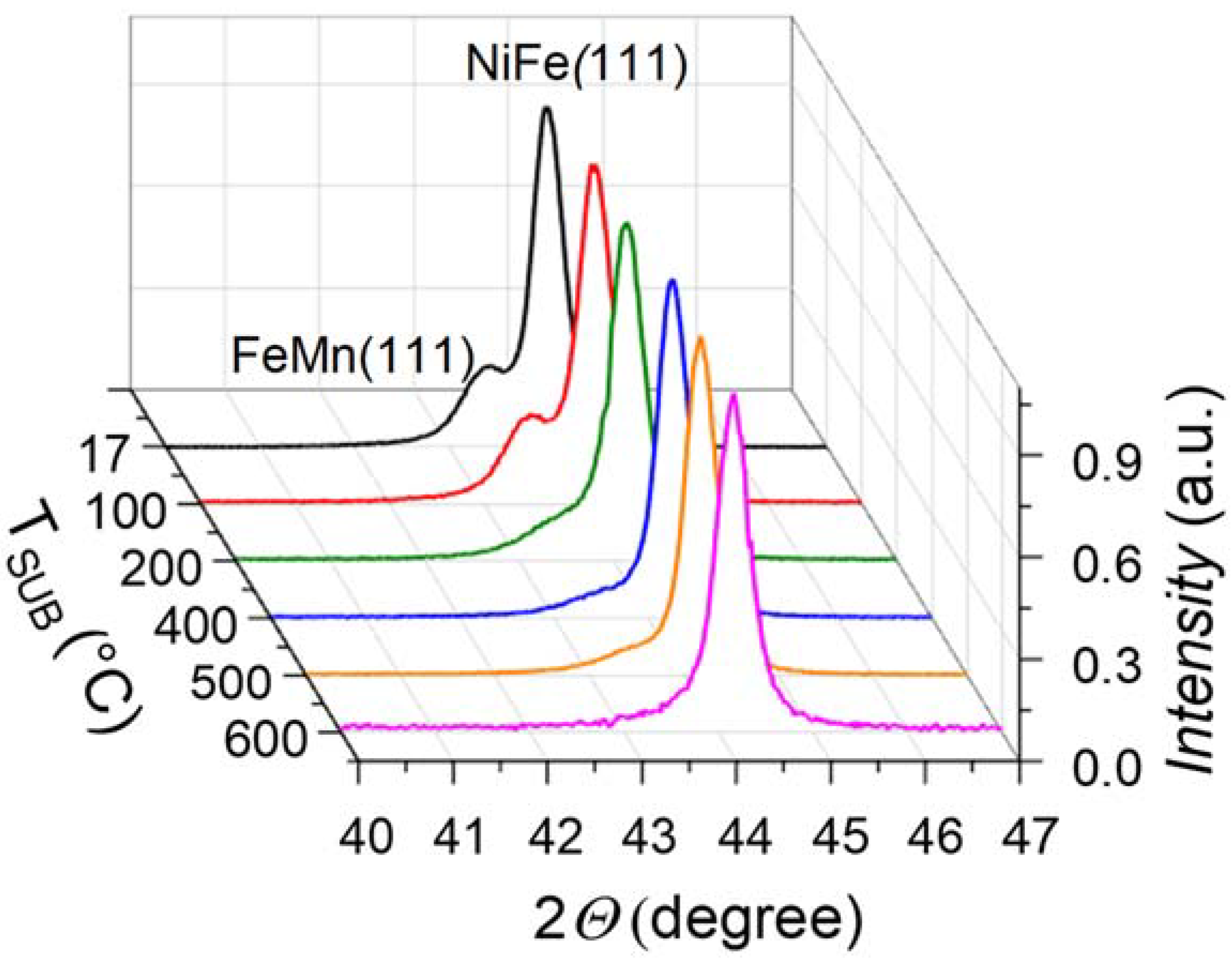

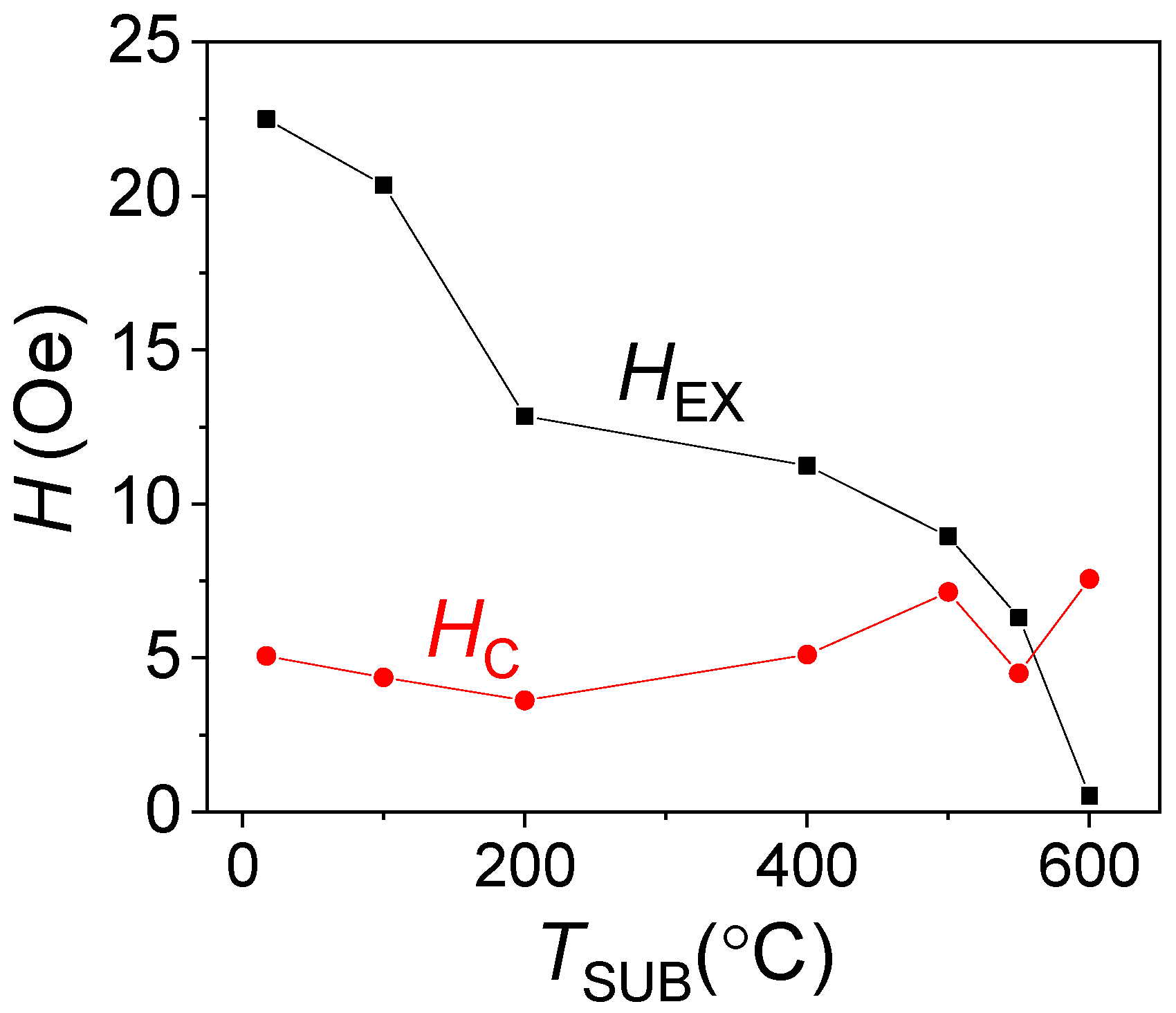

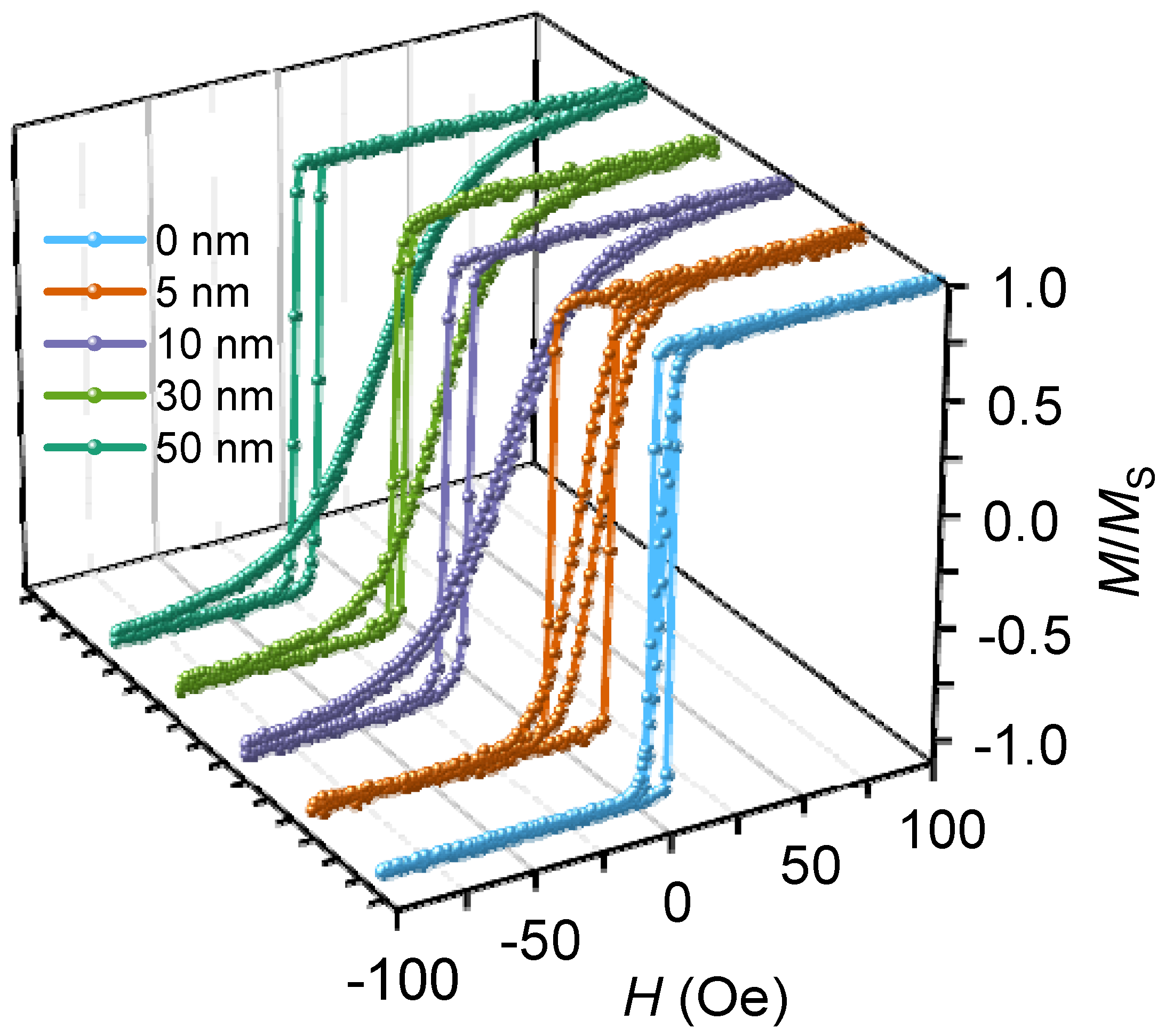

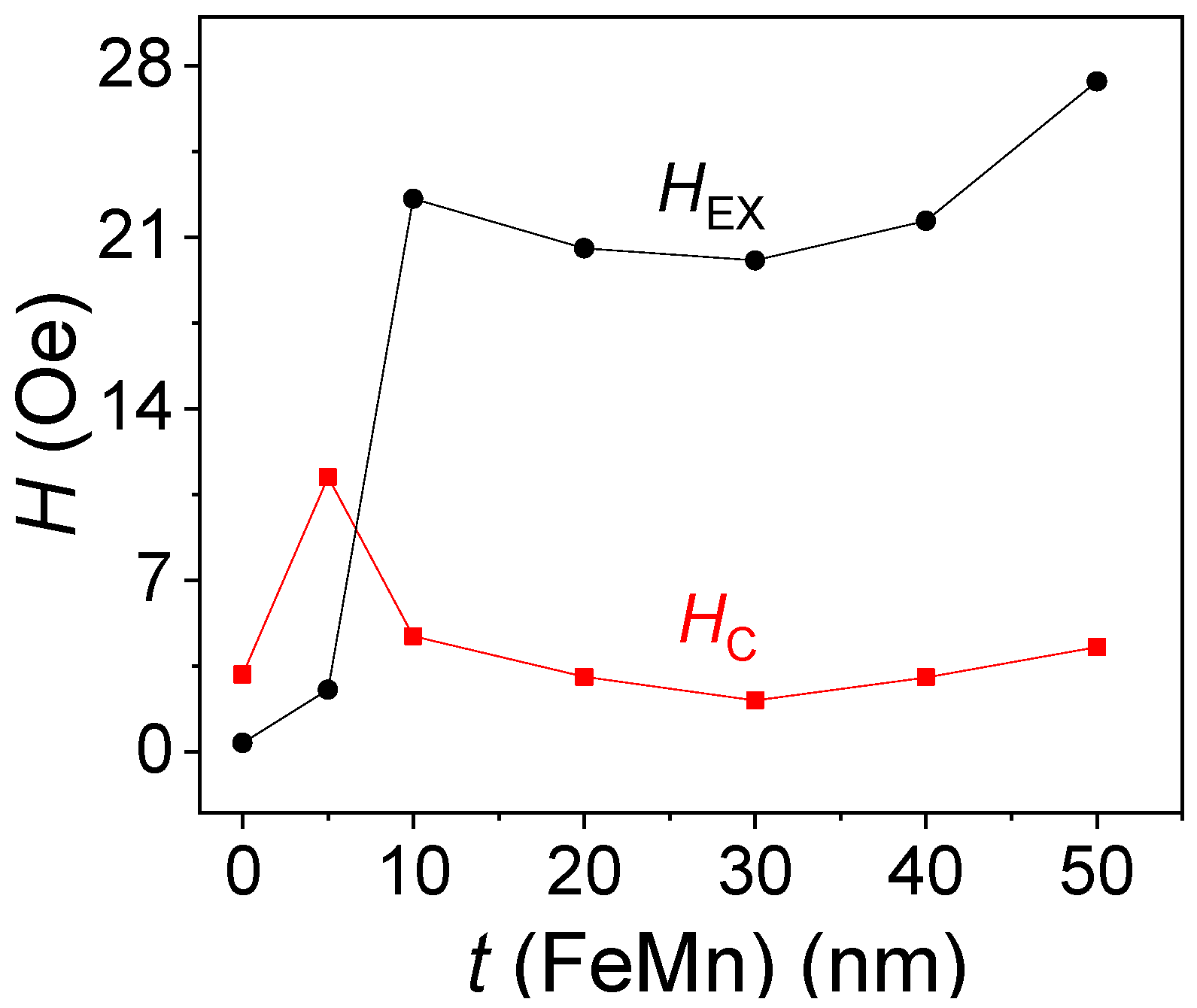

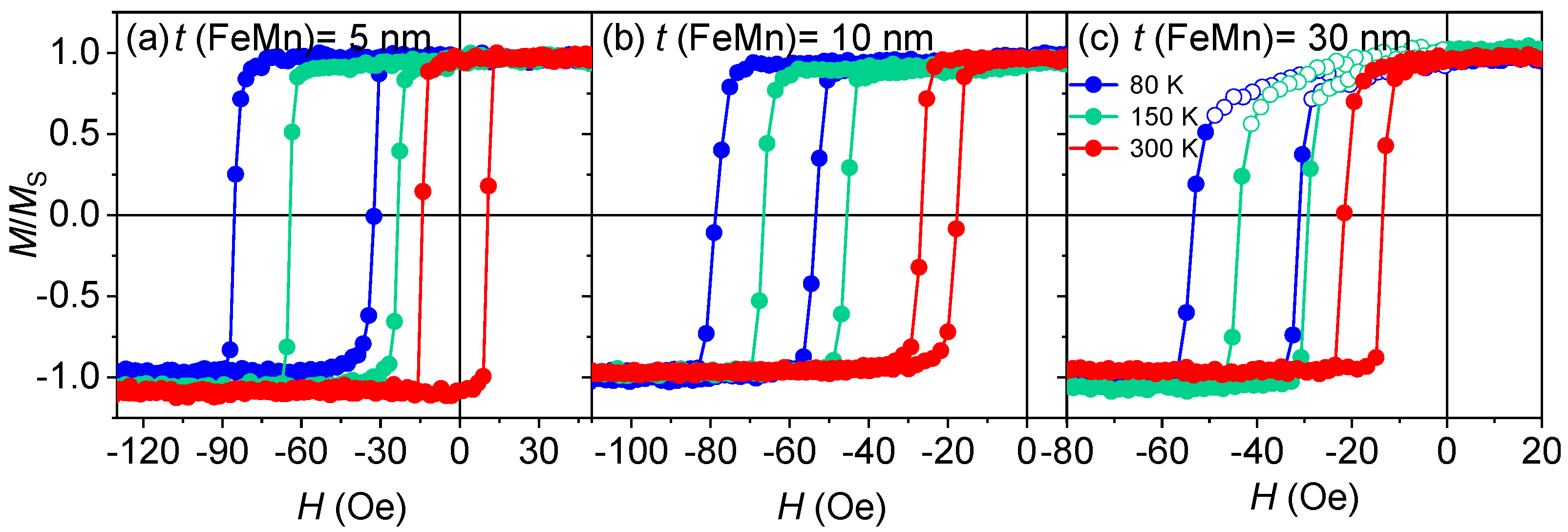

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Da Silva, R.B.; Viegas, A.D.C.; Nascimento, V.P.; Corrêa, M.A.; Schelp, L.F.; Baggio-Saitovitch, E.; Sommer, R.L. High Frequency Magnetoimpedance in Ni81 Fe19/Fe50 Mn50 Exchange Biased Multilayer. Appl. Phys. Lett. 2009, 94, 3–5. [Google Scholar] [CrossRef]

- Garcia, C.; Florez, J.M.; Vargas, P.; Ross, C.A. Asymmetrical Giant Magnetoimpedance in Exchange-Biased NiFe Thermodynamical Properties of Nanomagnets: Quantum Systems View Project Magnetoimpedance: Experiments and Modeling View Project. Appl. Phys. Lett. 2010, 96, 232501. [Google Scholar] [CrossRef]

- Vas’kovskiy, V.; Lepalovskij, V.; Gor’kovenko, A.N.; Kulesh, N.A.; Svalov, A.V.; Shcheglova, N.N.; Yuvchenko, A.A. Magnetoresistive Medium Based on the Film Structure of Fe20Ni80/Fe50Mn50. J. Tech. Phys. 2015, 85, 118–125. [Google Scholar]

- Vinai, G.; Moritz, J.; Bandiera, S.; Prejbeanu, I.L.; Dieny, B. Large Exchange Bias Enhancement in (Pt(or Pd)/Co)/IrMn/Co Trilayers with Ultrathin IrMn Thanks to Interfacial Cu Dusting. Appl. Phys. Lett. 2014, 104, 162401. [Google Scholar] [CrossRef]

- Merenkov, D.N.; Bludov, A.N.; Gnatchenko, S.L.; Baran, M.; Szymczak, R.; Novosad, V.A. Exchange Anisotropy in Polycrystalline FeNiFeMn Films with Hysteresis Loop Asymmetry. Low Temp. Phys. 2007, 33, 957–964. [Google Scholar] [CrossRef]

- Svalov, A.V.; Adanakova, O.A.; Gorkovenko, A.N.; Lepalovskij, V.N.; Stepanova, E.A.; Selezneva, N.V.; Vaśkovskiy, V.O. Exchange Bias Features in FeNi/FeMn/Gd-Co Films. J. Magn. Magn. Mater. 2020, 507, 166839. [Google Scholar] [CrossRef]

- Gnatchenko, S.L.; Merenkov, D.N.; Bludov, A.N.; Pishko, V.V.; Shakhayeva, Y.A.; Baran, M.; Szymczak, R.; Novosad, V.A. Asymmetrically Shaped Hysteresis Loop in Exchange-Biased FeNi/FeMn Film. J. Magn. Magn. Mater. 2006, 307, 263–267. [Google Scholar] [CrossRef]

- Nogués, J.; Schuller, I.K. Exchange Bias. J. Magn. Magn. Mater. 1999, 192, 203–232. [Google Scholar] [CrossRef]

- Kurlyandskaya, G.V.; Bhagat, S.M.; Svalov, A.V.; Fernandez, E.; Garcia-Arribas, A.; Barandiaran, J.M. FeNi-Based Film Nanostructures for High Frequency Applications: Design and Characterization. Solid State Phenom. 2011, 168, 257–260. [Google Scholar] [CrossRef] [Green Version]

- Kateb, M.; Hajihoseini, H.; Gudmundsson, J.T.; Ingvarsson, S. Comparison of Magnetic and Structural Properties of Permalloy Ni80Fe20 Grown by Dc and High Power Impulse Magnetron Sputtering. J. Phys. D. Appl. Phys. 2018, 51, 285005. [Google Scholar] [CrossRef] [Green Version]

- Kilic, U.; Ross, C.A.; Garcia, C. Tailoring the Asymmetric Magnetoimpedance Response in Exchange-Biased Ni-Fe Multilayers. Phys. Rev. Appl. 2018, 10, 34043. [Google Scholar] [CrossRef] [Green Version]

- Chlenova, A.A.; Novoselova, I.P.; Salikhov, R.; Farle, M.; Lepalovskij, V.N.; Totoricaguena Gorriño, J.; Kurlyandskaya, G.V. FexNi100-x Thin Film Systems with Slight Deviations from Zero Magnetostriction Compositions: Focus on Pressure Sensor Applications. Key Eng. Mater. 2019, 826, 11–18. [Google Scholar] [CrossRef]

- Gritsenko, C.; Dzhun, I.; Chechenin, N.; Babaytsev, G.; Rodionova, V. Dependence of the Exchange Bias on the Thickness of Antiferromagnetic Layer in the Trilayered NiFe/IrMn/NiFe Thin-Films. Phys. Procedia 2015, 75, 1066–1071. [Google Scholar] [CrossRef] [Green Version]

- Rodionova, V.; Dzhun, I.; Chichay, K.; Shevyrtalov, S.; Chechenin, N. Enhancement of exchange bias in NiFe/IrM, IrMn/NiFe AND NiFe/IrMn/NiFe structures with different thickness of antiferromagnetic layer. Solid State Phenom. 2015, 233, 427–430. [Google Scholar] [CrossRef]

- Lang, X.Y.; Zheng, W.T.; Jiang, Q. Dependence of the Blocking Temperature in Exchange Biased Ferromagnetic/Antiferromagnetic Bilayers on the Thickness of the Antiferromagnetic Layer. Nanotechnology 2007, 18, 155701. [Google Scholar] [CrossRef]

- Choe, G.; Gupta, S. High Exchange Anisotropy and High Blocking Temperature in Strongly Textured NiFe(111)/FeMn(111) Films. Appl. Phys. Lett. 1997, 70, 1766–1768. [Google Scholar] [CrossRef]

- Sankaranarayanan, V.K.; Yoon, S.M.; Kim, D.Y.; Kim, C.O.; Kim, C.G. Exchange Bias in NiFe/FeMn/NiFe Trilayers. J. Appl. Phys. 2004, 96, 7428–7434. [Google Scholar] [CrossRef]

- Savin, P.A.; Lepalovskij, V.N.; Svalov, A.V.; Vas’kovskiy, V.O.; Kurlyandskaya, G.V. Effect of Phase Separation in an Fe20Ni80/Fe50Mn50 Structure with Exchange Coupling. Phys. Met. Metallogr. 2014, 115, 856–863. [Google Scholar] [CrossRef]

- Uspenskaya, L.S.; Tikhomirov, O.A. Low-Temperature Magnetization Switching of Bilayer FeNi/FeMn Films. J. Exp. Theor. Phys. 2019, 128, 624–629. [Google Scholar] [CrossRef]

- Camarero, J.; Sort, J.; Hoffmann, A.; García-Martín, J.M.; Dieny, B.; Miranda, R.; Nogués, J. Origin of the Asymmetric Magnetization Reversal Behavior in Exchange-Biased Systems: Competing Anisotropies. Phys. Rev. Lett. 2005, 95, 057204. [Google Scholar] [CrossRef] [Green Version]

- Jimé Nez, E.; Camarero, J.; Perna, P.; Mikuszeit, N.; Terán, F.J.; Sort, J.; Nogués, J.; García-Martín, J.M.; Hoffmann, A.; Dieny, B.; et al. Role of Anisotropy Configuration in Exchange-Biased Systems. Am. Inst. Phys. 2011, 109, 07D730. [Google Scholar] [CrossRef] [Green Version]

- Gornakov, V.S.; Kabanov, Y.P.; Tikhomirov, O.A.; Nikitenko, V.I.; Urazhdin, S.V.; Yang, F.Y.; Chien, C.L.; Shapiro, A.J.; Shull, R.D. Experimental Study of the Microscopic Mechanisms of Magnetization Reversal in FeNi/FeMn Exchange-Biased Ferromagnet/Antiferromagnet Polycrystalline Bilayers Using the Magneto-Optical Indicator Film Technique. Phys. Rev. B 2006, 73, 184428. [Google Scholar] [CrossRef]

- Radu, F.; Zabel, H. Exchange Bias Effect of Ferro-/Antiferromagnetic Heterostructures. In Magnetic Heterostructures; Bader, S., Zabel, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 97–184. ISBN 978-3-540-73461-1. [Google Scholar]

- Scholl, A.; Liberati, M.; Arenholz, E.; Ohldag, H.; Stöhr, J. Creation of an Antiferromagnetic Exchange Spring. Phys. Rev. Lett. 2004, 92, 247201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, K.; Choi, H.; You, C.; Lee, J. Annealing Effect on Exchange Bias in NiFe/FeMn/CoFe Trilayer Thin Films. J. Magn. 2008, 13, 97–101. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.W.; Kim, J.K.; Kim, J.H. Mn Diffusion Effect in the Exchange Biased NiFe/FeMn/NiFe Trilayers ARTICLES YOU MAY BE INTERESTED IN. J. Appl. Phys. 2003, 93, 6602. [Google Scholar] [CrossRef]

- Svalov, A.; Savin, P.; Lepalovskij, V.; Larrañaga, A.; Vas, V.; García-arribas, A.; Kurlyandskaya, G. Tailoring the Exchange Bias in FeNi/FeMn Bilayers by Heat Treatment and FeMn Surface Oxidation. IEEE Trans. Magn. 2014, 50, 3–6. [Google Scholar] [CrossRef]

- Xue, X.; Zhou, Z.; Peng, B.; Zhu, M.; Zhang, Y.; Ren, W.; Ren, T.; Yang, X.; Nan, T.; Sun, N.X.; et al. Electric Field Induced Reversible 180° Magnetization Switching through Tuning of Interfacial Exchange Bias along Magnetic Easy-Axis in Multiferroic Laminates. Sci. Rep. 2015, 5, 16480. [Google Scholar] [CrossRef] [Green Version]

- Adanakova, O.; Lepalovskij, V.; Svalov, A.; Larrañaga, A.; Trubin, A.; Vas’Kovskiy, V. Magnetic Properties of NixFe100- x Layers in Exchange-Coupled FeMn/NixFe100- x Film Structures. AIP Conf. Proc. 2016, 1767, 020001. [Google Scholar] [CrossRef] [Green Version]

- Svalov, A.V.; Savin, P.A.; Lepalovskij, V.N.; Larrañaga, A.; Vas’Kovskiy, V.O.; Arribas, A.G.; Kurlyandskaya, G.V. Exchange Biased FeNi/FeMn Bilayers with Coercivity and Switching Field Enhanced by FeMn Surface Oxidation. AIP Adv. 2013, 3, 092104. [Google Scholar] [CrossRef] [Green Version]

- Savin, P.; Guzmán, J.; Lepalovskij, V.; Svalov, A.; Kurlyandskaya, G.; Asenjo, A.; Vas’Kovskiy, V.; Vazquez, M. Exchange Bias in Sputtered FeNi/FeMn Systems: Effect of Short Low-Temperature Heat Treatments. J. Magn. Magn. Mater. 2016, 402, 49–54. [Google Scholar] [CrossRef]

- Patterson, A.L. The Scherrer Formula for I-Ray Particle Size Determination. Phys. Rev. 1939, 56, 978. [Google Scholar] [CrossRef]

- Wang, W.; Chai, G.; Xue, D. Omnidirectional Zero-Field Ferromagnetic Resonance Driven by Rotatable Anisotropy in FeNi/FeMn Bilayers without Exchange Bias. Sci. Rep. 2017, 7, 1341. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vallejo-Fernandez, G.; Fernandez-Outon, L.E.; O’Grady, K. Antiferromagnetic Grain Volume Effects in Metallic Polycrystalline Exchange Bias Systems. J. Phys. D Appl. Phys. 2008, 41, 112001. [Google Scholar] [CrossRef]

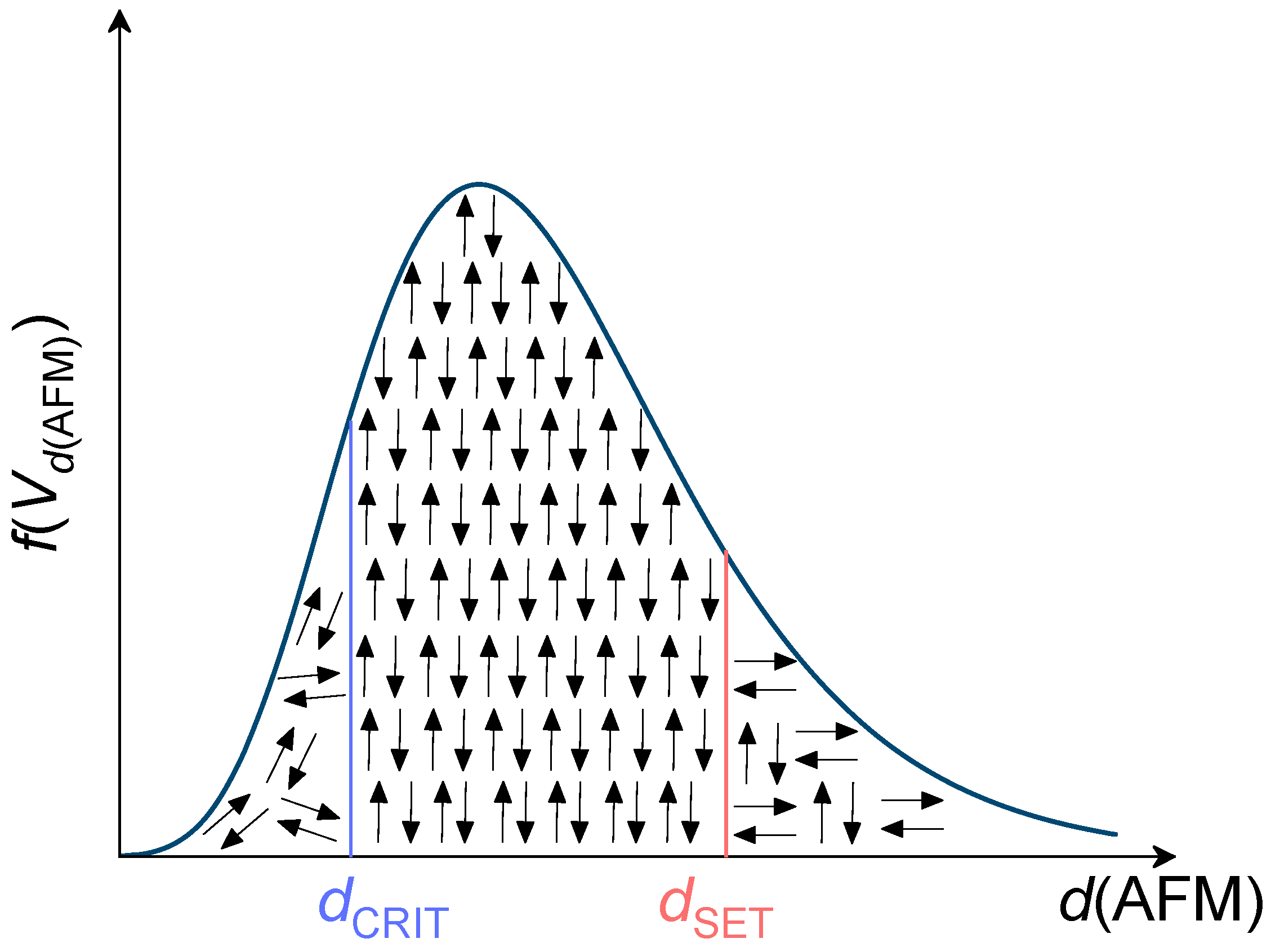

- O’Grady, K.; Fernandez-Outon, L.E.; Vallejo-Fernandez, G. A New Paradigm for Exchange Bias in Polycrystalline Thin Films. J. Magn. Magn. Mater. 2010, 322, 883–899. [Google Scholar] [CrossRef]

- Pan, M.; You, B.; Zhao, Y.; Mu, L.; An, H.; Hongru, Z. Thermal Stability of Exchange Bias in FeMn Based Bilayers Minghu. J. Appl. Phys. 2002, 91, 5272. [Google Scholar] [CrossRef]

- Yoon, S.M.; Lim, J.J.; Lee, Y.W.; Kim, C.G.; Kim, C.O. Exchange Bias Affected by Ion Beam Etching of FeMn Surface in Ta/NiFe/FeMn. Phys. Status Solidi 2004, 201, 1736–1738. [Google Scholar] [CrossRef]

- Gao, T.R.; Yang, D.Z.; Zhou, S.M.; Chantrell, R.; Asselin, P.; Du, J.; Wu, X.S. Hysteretic Behavior of Angular Dependence of Exchange Bias in FeNi/FeMn Bilayers. Phys. Rev. Lett. 2007, 99, 057201. [Google Scholar] [CrossRef] [Green Version]

- King, J.; Chapman, J.; Gillies, M.; Kools, J. Magnetization Reversal of NiFe Films Exchange-Biased by IrMn and FeMn. J. Phys. D Appl. Phys. 2001, 34, 528–538. [Google Scholar] [CrossRef]

- Martínez-García, J.C.; Rivas, M.; Lago-Cachón, D.; García, J.A. First-Order Reversal Curves Analysis in Nanocrystalline Ribbons. J. Phys. D. Appl. Phys. 2014, 47, 015001. [Google Scholar] [CrossRef]

- Kim, J.; Stamps, R.L. Hysteresis from Antiferromagnet Domain-Wall Processes in Exchange-Biased Systems: Magnetic Defects and Thermal Effects. Phys. Rev. B 2005, 71, 094405. [Google Scholar] [CrossRef]

- Nikitenko, V.I.; Gornakov, V.S.; Shapiro, A.J.; Shull, R.D.; Liu, K.; Zhou, S.M.; Chien, C.L. Asymmetry in Elementary Events of Magnetization Reversal in a Ferromagnetic/Antiferromagnetic Bilayer. Phys. Rev. Lett. 2000, 84, 765. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gornakov, V.S.; Shashkov, I.V.; Lebyodkin, M.A.; Lebedkina, T.A. Domain Structure and Magnetization Reversal Micromechanisms in Quasi-Two-Dimensional Exchange-Biased Nanomagnetics. Phys. Solid State 2018, 60, 2181–2189. [Google Scholar] [CrossRef]

- Feng, C.; Li, Y.; Wang, L.; Cao, Y.; Yao, M.; Meng, F.; Yang, F.; Li, B.; Wang, K.; Yu, G. Giant Strain Control of Antiferromagnetic Moment in Metallic FeMn by Tuning Exchange Spring Structure. Adv. Funct. Mater. 2020, 30, 1909708. [Google Scholar] [CrossRef]

| TSUB (°C) | d (FeMn) ± 1 (nm) |

|---|---|

| 17, 100 | 12 |

| 200, 400, 500 | 7 |

| 600 | <7 |

| t (FeMn) (nm) | d (FeMn) ± 1 (nm) |

|---|---|

| 5 | <7 |

| 10 | 7 |

| 20 | 12 |

| 30, 40, 50 | 18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gritsenko, C.; Lepalovskij, V.; Volochaev, M.; Komanický, V.; Gorkovenko, A.; Pazniak, H.; Gazda, M.; Andreev, N.; Rodionova, V. Complex Study of Magnetization Reversal Mechanisms of FeNi/FeMn Bilayers Depending on Growth Conditions. Nanomaterials 2022, 12, 1178. https://doi.org/10.3390/nano12071178

Gritsenko C, Lepalovskij V, Volochaev M, Komanický V, Gorkovenko A, Pazniak H, Gazda M, Andreev N, Rodionova V. Complex Study of Magnetization Reversal Mechanisms of FeNi/FeMn Bilayers Depending on Growth Conditions. Nanomaterials. 2022; 12(7):1178. https://doi.org/10.3390/nano12071178

Chicago/Turabian StyleGritsenko, Christina, Vladimir Lepalovskij, Mikhail Volochaev, Vladimir Komanický, Aleksandr Gorkovenko, Hanna Pazniak, Maria Gazda, Nikolai Andreev, and Valeria Rodionova. 2022. "Complex Study of Magnetization Reversal Mechanisms of FeNi/FeMn Bilayers Depending on Growth Conditions" Nanomaterials 12, no. 7: 1178. https://doi.org/10.3390/nano12071178

APA StyleGritsenko, C., Lepalovskij, V., Volochaev, M., Komanický, V., Gorkovenko, A., Pazniak, H., Gazda, M., Andreev, N., & Rodionova, V. (2022). Complex Study of Magnetization Reversal Mechanisms of FeNi/FeMn Bilayers Depending on Growth Conditions. Nanomaterials, 12(7), 1178. https://doi.org/10.3390/nano12071178