Long-Wavelength VCSELs: Status and Prospects

Abstract

:1. Introduction

2. Distributed Bragg Reflectors for the 1300–1550 nm Spectral Range

3. Current Confinement and Tunnel Junctions

- -

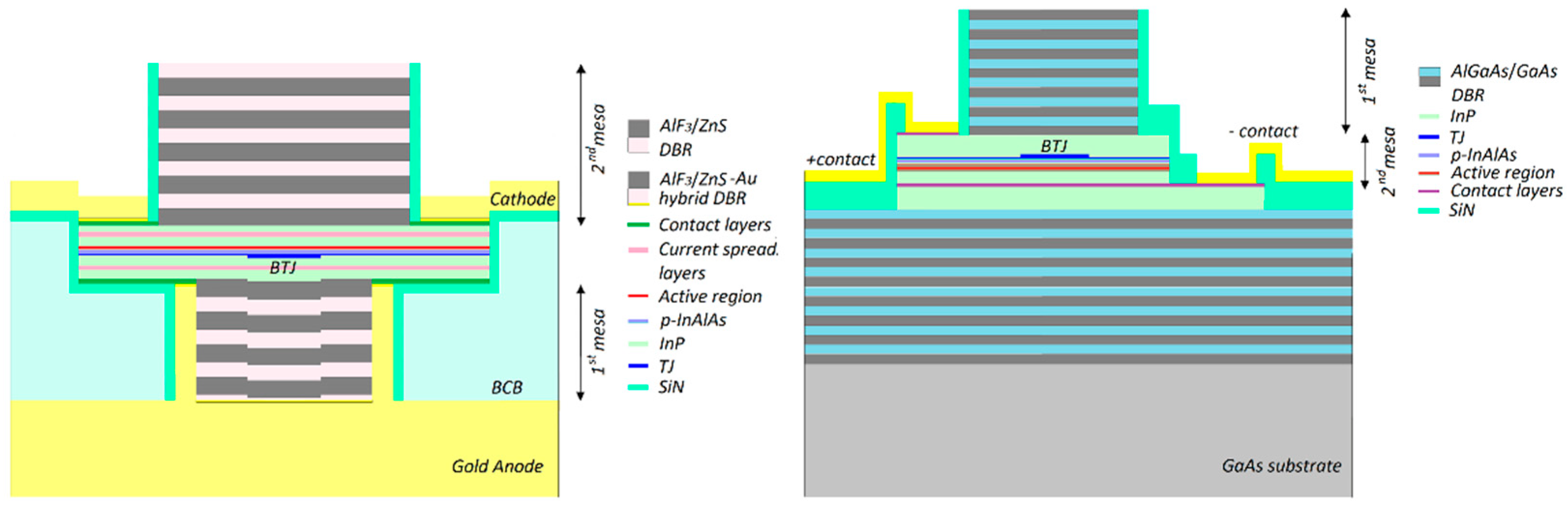

- convert most of the current confinement layers in the p-type region from p- to n-type to get lower electric resistance, reducing self-heating;

- -

- use ohmic contacts from two sides to n-type layers with low contact resistance;

- -

- reduce optical losses in n-type layers used at the former p-side of the laser;

- -

- use intra-cavity contacts with low resistance;

- -

- achieve effective lateral current confinement;

- -

- achieve strong lateral optical confinement [56].

4. Monolithically Grown VCSELs on GaAs Substrates in the 1300–1550 nm Spectral Range

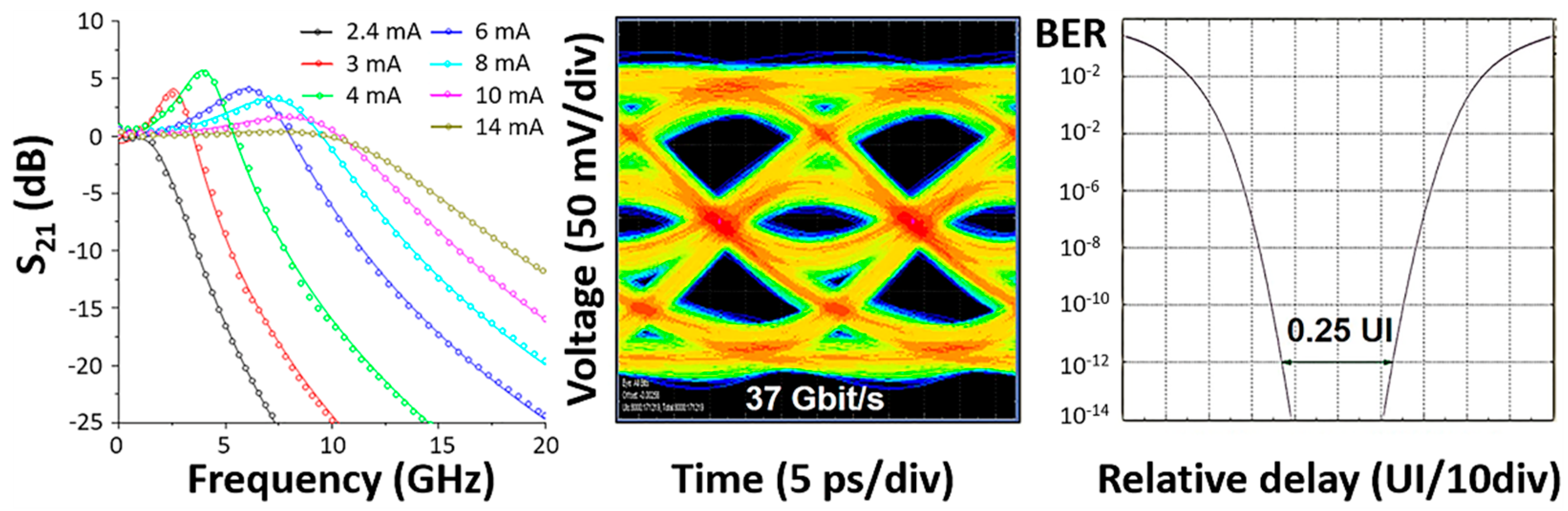

5. Monolithically Grown VCSELs on InP Substrates for the 1300–1550 nm Spectral Range

6. VCSELs with Hybrid (Metal-Dielectric) Distributed Bragg Reflectors

7. VCSELs Fabricated by Wafer Fusion

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- VCSEL Market to Grow at 19.2% CAGR from $1.6bn in 2022 to $3.9bn in 2027. Semicond. TODAY Compd. Adv. Silicon 2022, 17, 60–61. Available online: https://www.semiconductor-today.com/news_items/2022/sep/yole-210922.shtml (accessed on 23 January 2023).

- Zhang, L.; Van Kerrebrouck, J.; Lin, R.; Pang, X.; Udalcovs, A.; Ozolins, O.; Spiga, S.; Amann, M.-C.; Van Steenberge, G.; Gan, L.; et al. Nonlinearity Tolerant High-Speed DMT Transmission with 1.5-μm Single-Mode VCSEL and Multi-Core Fibers for Optical Interconnects. J. Light. Technol. 2019, 37, 380–388. [Google Scholar] [CrossRef]

- Spiga, S.; Amann, M.C. High-Speed InP-Based Long-Wavelength VCSELs. In Green Photonics and Electronics; Eisenstein, G., Bimberg, D., Eds.; Springer: Cham, Switzerland, 2017; Volume 3, pp. 17–35. [Google Scholar] [CrossRef]

- Babichev, A.; Blokhin, S.; Gladyshev, A.; Karachinsky, L.; Novikov, I.; Blokhin, A.; Bobrov, M.; Maleev, N.; Andryushkin, V.; Kolodeznyi, E.; et al. Single-Mode High-Speed 1550 nm Wafer Fused VCSELs for Narrow WDM Systems. IEEE Photonics Technol. Lett. 2023, 35, 297–300. [Google Scholar] [CrossRef]

- Paul, S.; Haidar, M.T.; Cesar, J.; Malekizandi, M.; Kögel, B.; Neumeyr, C.; Ortsiefer, M.; Küppers, F. Far-field, linewidth and thermal characteristics of a high-speed 1550-nm MEMS tunable VCSEL. Opt. Express 2016, 24, 13142. [Google Scholar] [CrossRef]

- Haidar, M.T.; Preu, S.; Cesar, J.; Paul, S.; Hajo, A.S.; Neumeyr, C.; Maune, H.; Küppers, F. Systematic characterization of a 1550 nm microelectromechanical (MEMS)-tunable vertical-cavity surface-emitting laser (VCSEL) with 7.92 THz tuning range for terahertz photomixing systems. J. Appl. Phys. 2018, 123, 023106. [Google Scholar] [CrossRef]

- Zogal, K.H. MEMS weit Abstimmbare VCSEL bei 1.55 µm und 1.95 µm. Ph.D. Thesis, Technische Universität, Darmstadt, Germany, 6 July 2016. [Google Scholar]

- Padullaparthi, B.D.; Tatum, J.A.; Iga, K. VCSEL Industry: Communication and Sensing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022; p. 180. [Google Scholar] [CrossRef]

- NIR VCSELs for Gas Analysis (TDLAS). Available online: https://www.vertilas.com/content/nir-vcsels-gas-analysis-tdlas (accessed on 21 February 2023).

- Blokhin, S.A.; Babichev, A.V.; Gladyshev, A.G.; Karachinsky, L.Y.; Novikov, I.I.; Blokhin, A.A.; Bobrov, M.A.; Maleev, N.A.; Andryushkin, V.V.; Denisov, D.V.; et al. High Power Single Mode 1300-nm Superlattice Based VCSEL: Impact of the Buried Tunnel Junction Diameter on Performance. IEEE J. Quantum Electron. 2022, 58, 1–15. [Google Scholar] [CrossRef]

- Murty, M.V.R.; Wang, J.; Harren, A.L.; Cheng, A.-N.; Dolfi, D.W.; Feng, Z.-W.; Sridhara, A.; Joyo, S.T.; Chu, J.; Giovane, L.M. Development and Characterization of 100 Gb/s Data Communication VCSELs. IEEE Photonics Technol. Lett. 2021, 33, 812–815. [Google Scholar] [CrossRef]

- Ruan, Z.; Zhu, Y.; Chen, P.; Shi, Y.; He, S.; Cai, X.; Liu, L. Efficient Hybrid Integration of Long-Wavelength VCSELs on Silicon Photonic Circuits. J. Light. Technol. 2020, 38, 5100–5106. [Google Scholar] [CrossRef]

- Johnson, A.D.; Nunna, K.; Clark, A.; Joel, A.; Pelzel, R. Long wavelength dilute nitride VCSELs, edge emitters and detectors for 3D sensing applications. In Proceedings of the SPIE OPTO, 2023, San Francisco, CA, USA, 28 January–2 February 2023; Volume PC12439, p. PC124390A. [Google Scholar] [CrossRef]

- Ohiso, Y.; Sato, T.; Shindo, T.; Matsuzaki, H. 1.3-µm buried-heterostructure VCSELs with GaAs/AlGaAs metamorphic DBRs grown by MOCVD. Electron. Lett. 2020, 56, 95–97. [Google Scholar] [CrossRef]

- TRUMPF Industrializing High-Volume Production of InP-based SWIR VCSELs above 1300 nm. Semicond. TODAY Compd. Adv. Silicon 2023, 18, 48. Available online: https://www.semiconductor-today.com/news_items/2023/feb/trumpf-010223.shtml (accessed on 1 March 2023).

- Koerner, R.A.; Bader, S.; Herper, M.; Kischkat-Grimm, T.; Tempeler, J.; van der Lee, A.; Moench, H.; Pruijmboom, A.; Rodriguez, M.A.; Weichmann, U.; et al. Polarization multiplexing in VCSEL-arrays. In Proceedings of the SPIE OPTO, 2023, San Francisco, CA, USA, 28 January–2 February 2023; Volume 12439, p. 1243902. [Google Scholar] [CrossRef]

- Francis, D.A.; Young, D.B.; Walker, J.; Verma, A.; Gold, D.; Decker, C. Monolithic 1310 nm buried heterostructure VCSEL using InGaAsP/InP DBR reflectors. In Proceedings of the Optics East, Boston, MA, USA, 23–26 October 2005; Volume 6013, p. 60130A. [Google Scholar] [CrossRef]

- Miyamoto, T.; Uchida, T.; Yokouchi, N.; Iga, K. Surface emitting lasers grown by chemical beam epitaxy. J. Cryst. Growth 1994, 136, 210–215. [Google Scholar] [CrossRef]

- Kim, J.K.; Hall, E.; Sjölund, O.; Almuneau, G.; Coldren, L.A. Room-temperature, electrically-pumped multiple-active-region VCSELs with high differential efficiency at 1.55 µm. Electron. Lett. 1999, 35, 1084–1085. [Google Scholar] [CrossRef]

- Yang, W.; Gerke, S.A.; Zhu, L.; Chase, C.; Rao, Y.; Chang-Hasnain, C.J. Long-Wavelength Tunable Detector Using High-Contrast Grating. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 178–185. [Google Scholar] [CrossRef]

- Lin, C.-K.; Bour, D.P.; Zhu, J.; Perez, W.H.; Leary, M.H.; Tandon, A.; Corzine, S.W.; Tan, M.R.T. High temperature continuous-wave operation of 1.3- and 1.55-μm VCSELs with InP/Air-Gap DBRs. IEEE J. Sel. Top. Quantum Electron. 2003, 9, 1415–1421. [Google Scholar] [CrossRef]

- Feezell, D.; Johansson, L.A.; Buell, D.A.; Coldren, L.A. Efficient Modulation of InP-based 1.3-/spl mu/m VCSELs with AsSb-based DBRs. IEEE Photonics Technol. Lett. 2005, 17, 2253–2255. [Google Scholar] [CrossRef]

- Lauer, C.; Ortsiefer, M.; Shau, R.; Rosskopf, J.; Böhm, G.; Meyer, R.; Amann, M. InP-based long-wavelength vertical-cavity surface-emitting lasers with buried tunnel junction. Phys. Status Solidi C 2004, 1, 2183–2209. [Google Scholar] [CrossRef]

- Shau, R.; Ortsiefer, M.; Rosskopf, J.; Boehm, G.; Lauer, C.; Maute, M.; Amann, M.-C. Long-wavelength InP-based VCSELs with buried tunnel junction: Properties and applications. In Proceedings of the Integrated Optoelectronic Devices 2004, San Jose, CA, USA, 26–29 January 2004; Volume 5364. [Google Scholar] [CrossRef]

- Ortsiefer, M.; Shau, R.; Boehm, G.; Koehler, F.; Rosskopf, J.; Amann, M.-C. Thermal Conductivity Analysis and Device Performance of 1.55 μm InGaAlAs/InP Buried Tunnel Junction VCSELs. Phys. Status Solidi A 2001, 188, 913–919. [Google Scholar] [CrossRef]

- Boehm, G.; Ortsiefer, M.; Shau, R.; Koehler, F.; Meyer, R.; Amann, M.-C. AlGaInAs/InP-epitaxy for long wavelength vertical-cavity surface-emitting lasers. J. Cryst. Growth 2001, 227–228, 319–323. [Google Scholar] [CrossRef]

- Hofmann, W. InP-Based Long-Wavelength VCSELs and VCSELs Arrays for High-Speed Optical Communication. Ph.D. Thesis, Technical University, München, Germany, 2009; p. 60. Available online: https://mediatum.ub.tum.de/node?id=679286 (accessed on 21 February 2023).

- Spiga, S.; Soenen, W.; Andrejew, A.; Schoke, D.M.; Yin, X.; Bauwelinck, J.; Boehm, G.; Amann, M.-C. Single-Mode High-Speed 1.5-μm VCSELs. J. Light. Technol. 2017, 35, 727–733. [Google Scholar] [CrossRef]

- Meyer, R.; Meissner, P.; Amann, M.-C.; Zogal, K.; Nagel, R.D.; Gruendl, T.; Geiger, K.; Grasse, C.; Ortsiefer, M.; Mueller, M.; et al. High-Speed and high-power vertical-cavity surface-emitting lasers based on InP suitable for telecommunication and gas sensing. In Proceedings of the SPIE Remote Sensing 2010, Toulouse, France, 20–23 September 2010; Volume 7828, p. 782807. [Google Scholar] [CrossRef]

- Boehm, G.; Ortsiefer, M.; Shau, R.; Rosskopf, J.; Lauer, C.; Maute, M.; Köhler, F.; Mederer, F.; Meyer, R.; Amann, M.-C. InP-based VCSEL technology covering the wavelength range from 1.3 to 2.0 μm. J. Cryst. Growth 2003, 251, 748–753. [Google Scholar] [CrossRef]

- Spiga, S.; Muller, M.; Amann, M.-C. Energy-efficient high-speed InP-based 1.3 μm short-cavity VCSELs. In Proceedings of the 2013 15th International Conference on Transparent Optical Networks (ICTON), Cartagena, Spain, 23–27 June 2013. [Google Scholar] [CrossRef]

- Tian, S.-C.; Mansoor, A.; Bimberg, D. Progress in Energy-efficient High-Speed Vertical-Cavity Surface-Emitting Lasers for data communication. Photonics 2023. invited paper. in print, same issue. [Google Scholar]

- Tian, S.-C.; Ahamed, M.; Larisch, G.; Bimberg, D. Novel energy-efficient designs of vertical-cavity surface emitting lasers for the next generations of photonic systems. Jpn. J. Appl. Phys. 2022, 61, SK0801. [Google Scholar] [CrossRef]

- Rao, Y.; Yang, W.; Chase, C.; Huang, M.C.Y.; Worland, D.D.P.; Khaleghi, S.; Chitgarha, M.R.; Ziyadi, M.; Willner, A.E.; Chang-Hasnain, C.J. Long-Wavelength VCSEL Using High-Contrast Grating. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1701311. [Google Scholar] [CrossRef]

- Chung, I.-S.; Iakovlev, V.; Sirbu, A.; Mereuta, A.; Caliman, A.; Kapon, E.; Mork, J. Broadband MEMS-Tunable High-Index-Contrast Subwavelength Grating Long-Wavelength VCSEL. IEEE J. Quantum Electron. 2010, 46, 1245–1253. [Google Scholar] [CrossRef]

- Han, Y.; Li, Z.; Wu, L.; Mai, S.; Xing, X.; Fu, H.Y. High-Speed Two-Dimensional Spectral-Scanning Coherent LiDAR System Based on Tunable VCSEL. J. Lightwave Technol. 2023, 41, 412–419. [Google Scholar] [CrossRef]

- Markowski, K.; Bojarczuk, J.; Araszkiewicz, P.; Cybulski, R.; Gaska, M.; Golaszewski, A. Analysis of the Performance of WDM-CDM Bragg Grating Interrogation System with High-Contrast Grating VCSEL. J. Light. Technol. 2023, 1–12. [Google Scholar] [CrossRef]

- Zou, J.; Al Houri, M.; Chen, H.-K.; Eiselt, M. Remote Wavelength Tracking of Strongly Chirped Tunable 10G MEMS-VCSEL for Port-Agnostic WDM Fronthaul. In Proceedings of the 2019 Optical Fiber Communication Conference (OFC), San Diego, CA, USA, 3–7 March 2019. [Google Scholar] [CrossRef]

- Chase, C.; Rao, Y.; Huang, M.; Chang-Hasnain, C. Tunable 1550 nm VCSELs using high-contrast grating for next-generation networks. In Proceedings of the SPIE OPTO, San Francisco, CA, USA, 1–6 February 2014; Volume 9008, p. 900807. [Google Scholar] [CrossRef]

- Paul, S.; Gierl, C.; Cesar, J.; Le, Q.T.; Malekizandi, M.; Kogel, B.; Neumeyr, C.; Ortsiefer, M.; Kuppers, F. 10-Gb/s Direct Modulation of Widely Tunable 1550-nm MEMS VCSEL. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 436–443. [Google Scholar] [CrossRef]

- Zhang, J.; Hao, C.; Zheng, W.; Bimberg, D.; Liu, A. Demonstration of electrically injected vertical-cavity surface-emitting lasers with post-supported high-contrast gratings. Photonics Res. 2022, 10, 1170–1176. [Google Scholar] [CrossRef]

- Chang-Hasnain, C.; Wang, J.; Shen, C.; Ji, Y.; Kapraun, J. Recent Advances in VCSELs for Datacom and Sensing Applications. In Proceedings of the 2022 28th International Semiconductor Laser Conference (ISLC), Matsue, Japan, 16–19 October 2022. [Google Scholar] [CrossRef]

- Chang-Hasnain, C.J. High-Contrast Grating VCSELs. In VCSELs Fundamentals, Technology and Applications of Vertical-Cavity Surface-Emitting Lasers; Michalzik, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 291–317. [Google Scholar] [CrossRef]

- Mateus, C.F.R.; Huang, M.C.Y.; Chen, L.; Chang-Hasnain, C.J.; Suzuki, Y. Broad-Band Mirror (1.12–1.62µm) Using a Subwavelength Grating. IEEE Photonics Technol. Lett. 2004, 16, 1676–1678. [Google Scholar] [CrossRef]

- Mateus, C.F.R.; Huang, M.C.Y.; Deng, Y.; Neureuther, A.R.; Chang-Hasnain, C.J. Ultrabroadband Mirror Using Low-Index Cladded Subwavelength Grating. IEEE Photonics Technol. Lett. 2004, 16, 518–520. [Google Scholar] [CrossRef]

- Karagodsky, V.; Pesala, B.; Chase, C.; Hofmann, W.; Koyama, F.; Chang-Hasnain, C.J. Monolithically integrated multi-wavelength VCSEL arrays using high-contrast gratings. Opt. Express 2010, 18, 694–699. [Google Scholar] [CrossRef] [PubMed]

- Chase, C.; Zhou, Y.; Chang-Hasnain, C.J. Size effect of high contrast gratings in VCSELs. Opt. Express 2009, 17, 24002–24007. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.C.Y.; Zhou, Y.; Chang-Hasnain, C.J. A nanoelectromechanical tunable laser. Nat. Photonics 2008, 2, 180–184. [Google Scholar] [CrossRef]

- Qiao, P.; Cook, K.T.; Li, K.; Chang-Hasnain, C.J. Wavelength-Swept VCSELs. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 1700516. [Google Scholar] [CrossRef]

- Moser, P. Energy-Efficient VCSELs for Optical Interconnects. In Springer Theses; Lahee, A., Ed.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Ellafi, D.; Yang, M.; Chen, H.K.; Kim, S.S.; Bandyopadhyay, N.; Cheng, S.; Hasnain, G.; Huang, M.; Chase, C. MEMs-HCG VCSELs for emerging sensing and datacoms applications. In Proceedings of the SPIE OPTO, San Francisco, CA, USA, 1–6 February 2020; Volume 11300, p. 113000R. [Google Scholar] [CrossRef]

- Cesar, J.; Paul, S.; Kuppers, F.; Kusserow, T. SiC-SiO2 MEMS-DBR Based Widely Tunable Optical Filters Around 1550 nm with Narrow FWHM. In Proceedings of the 2019 Conference on Lasers and Electro-Optics Europe & European Quantum Electronics Conference (CLEO/Europe-EQEC), Munich, Germany, 23–27 June 2019. [Google Scholar] [CrossRef]

- Cesar, J. SiOx-SiCz MEMS-DBR-Based Tunable Optical Devices. Ph.D. Thesis, Technische Universität, Darmstadt, Germany, 17 March 2020. [Google Scholar] [CrossRef]

- Reddy, M.H.M.; Feezell, D.; Asano, T.; Buell, D.A.; Huntington, A.S.; Koda, R.; Coldren, L.A. Selectively etched tunnel junction for lateral current and optical confinement in InP-based vertical cavity lasers. J. Electron. Mater. 2004, 33, 118–122. [Google Scholar] [CrossRef]

- Kapon, E.; Sirbu, A. Power-efficient answer. Nat. Photonics 2009, 3, 27–29. [Google Scholar] [CrossRef]

- Ortsiefer, M.; Hofmann, W.; Rosskopf, J.; Amann, M.-C. Long-Wavelength VCSELs with Buried Tunnel Junction. In VCSELs. Springer Series in Optical Sciences; Michalzik, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 321–351. [Google Scholar] [CrossRef]

- Ortsiefer, M.; Shau, R.; Böhm, G.; Köhler, F.; Abstreiter, G.; Amann, M.-C. Low-resistance InGa(Al)As Tunnel Junctions for Long Wavelength Vertical-cavity Surface-emitting Lasers. Jpn. J. Appl. Phys. 2000, 39, 1727–1729. [Google Scholar] [CrossRef]

- Ortsiefer, M.; Shau, R.; Böhm, G.; Köhler, F.; Zigldrum, M.; Rosskopf, J.; Amann, M.-C. Index-guided long-wavelength InGaAIAs/InP vertical-cavity surface-emitting lasers. Adv. Solid State Phys. 2007, 40, 577–586. [Google Scholar] [CrossRef]

- Ortsiefer, M.; Shau, R.; Mederer, F.; Michalzik, R.; Rosskopf, J.; Böhm, G.; Köhler, F.; Lauer, C.; Maute, M.; Amann, M.-C. High-speed modulation up to 10 Gbit/s with 1.55 μm wavelength InGaAlAs VCSELs. Electron. Lett. 2002, 38, 1180–1181. [Google Scholar] [CrossRef]

- Gierl, C.; Gruendl, T.; Debernardi, P.; Zogal, K.; Grasse, C.; Davani, H.A.; Böhm, G.; Jatta, S.; Küppers, F.; Meißner, P.; et al. Surface micromachined tunable 1.55 μm-VCSEL with 102 nm continuous single-mode tuning. Opt. Express 2011, 19, 17336–17343. [Google Scholar] [CrossRef] [PubMed]

- Debernardi, P.; Kogel, B.; Zogal, K.; Meissner, P.; Maute, M.; Ortsiefer, M.; Bohm, G.; Amann, M.-C. Modal Properties of Long-Wavelength Tunable MEMS-VCSELs With Curved Mirrors: Comparison of Experiment and Modeling. IEEE J. Quantum Electron. 2008, 44, 391–399. [Google Scholar] [CrossRef]

- Bell, G.R.; Kaijaks, N.S.; Dixon, R.J.; McConville, C.F. Atomic hydrogen cleaning of polar III–V semiconductor surfaces. Surf. Sci. 1998, 401, 125–137. [Google Scholar] [CrossRef]

- Seidel, U.; Schimper, H.-J.; Kollonitsch, Z.; Möller, K.; Schwarzburg, K.; Hannappel, T. Growth of an InGaAs/GaAsSb tunnel junction for an InP-based low band gap tandem solar cell. J. Cryst. Growth 2007, 298, 777–781. [Google Scholar] [CrossRef]

- RF Plasma Source for Hydrogen—RF-H 600. Available online: https://www.riber.com/product/rf-plasma-source-for-hydrogen-rf-h-600/ (accessed on 23 January 2023).

- Atom-H Source. For High-Temperature Production of Atomic H for MBE Growth. Available online: https://www.veeco.com/products/atom-h-source/ (accessed on 23 January 2023).

- Blokhin, S.; Babichev, A.; Gladyshev, A.; Karachinsky, L.; Novikov, I.; Blokhin, A.; Rochas, S.; Denisov, D.; Voropaev, K.; Ionov, A.; et al. Wafer-fused 1300 nm VCSELs with an active region based on superlattice. Electron. Lett. 2021, 57, 697–698. [Google Scholar] [CrossRef]

- Blokhin, S.A.; Babichev, A.V.; Gladyshev, A.G.; Novikov, I.I.; Blokhin, A.A.; Bobrov, M.A.; Maleev, N.A.; Andryushkin, V.V.; Denisov, D.V.; Voropaev, K.O.; et al. 20-Gbps 1300-nm range wafer-fused vertical-cavity surface-emitting lasers with InGaAs/InAlGaAs superlattice-based active region. Opt. Eng. 2022, 61, 096109. [Google Scholar] [CrossRef]

- Arzberger, M.; Lohner, M.; Böhm, G.; Amann, M.-C. Low-resistivity p-side contacts for InP-based devices using buried InGaAs tunnel junction. Electron. Lett. 2000, 36, 87–88. [Google Scholar] [CrossRef]

- Muller, M.; Debernardi, P.; Grasse, C.; Grundl, T.; Amann, M.-C. Tweaking the Modal Properties of 1.3-μm Short-Cavity VCSEL—Simulation and Experiment. IEEE Photonics Technol. Lett. 2013, 25, 140–143. [Google Scholar] [CrossRef]

- Chase, C.; Rao, Y.; Hofmann, W.; Chang-Hasnain, C.J. 1550 nm high contrast grating VCSEL. Opt. Express 2010, 18, 15461–15466. [Google Scholar] [CrossRef]

- Rao, Y.; Chase, C.; Huang, M.C.Y.; Khaleghi, S.; Chitgarha, M.R.; Ziyadi, M.; Worland, D.P.; Willner, A.E.; Chang-Hasnain, C.J. Tunable 1550-nm VCSEL using high contrast gratings. In Proceedings of the IEEE Photonics Conference 2012, Burlingame, CA, USA, 23–27 September 2012. [Google Scholar] [CrossRef]

- Boucart, J.; Starck, C.; Gaborit, F.; Plais, A.; Bouche, N.; Derouin, E.; Remy, J.C.; Bonnet-Gamard, J.; Goldstein, L.; Fortin, C.; et al. Metamorphic DBR and tunnel-junction injection. A CW RT monolithic long-wavelength VCSEL. IEEE J. Sel. Top. Quantum Electron. 1999, 5, 520–529. [Google Scholar] [CrossRef]

- Streubel, K. Novel technologies for 1.55-μm vertical cavity lasers. Opt. Eng. 2000, 39, 488–497. [Google Scholar] [CrossRef]

- Wilmsen, C.; Temkin, H.; Coldren, L.A. Vertical-Cavity Surface-Emitting Lasers, design, fabrication, characterization and applications. In Cambridge Studies in Modern Optics; Knight, P.L., Miller, A., Eds.; Cambridge University Press: Cambridge, UK, 2001; Volume 24, p. 474. Available online: https://www.cambridge.org/af/academic/subjects/physics/optics-optoelectronics-and-photonics/vertical-cavity-surface-emitting-lasers-design-fabrication-characterization-and-applications (accessed on 23 January 2023).

- Grasse, C.; Mueller, M.; Gruendl, T.; Boehm, G.; Roenneberg, E.; Wiecha, P.; Rosskopf, J.; Ortsiefer, M.; Meyer, R.; Amann, M.-C. AlGaInAsPSb-based high-speed short-cavity VCSEL with single-mode emission at 1.3 μm grown by MOVPE on InP substrate. J. Cryst. Growth 2013, 370, 217–220. [Google Scholar] [CrossRef]

- Linnik, M.; Christou, A. Vertical cavity surface emitting laser with AlGaInAs/InP Bragg mirrors fabricated for operation at 1.55 μm. In Proceedings of the 2000 IEEE International Symposium on Compound Semiconductors. Proceedings of the IEEE Twenty-Seventh International Symposium on Compound Semiconductors (Cat. No.00TH8498), Monterey, CA, USA, 2–5 October 2000; pp. 383–388. [Google Scholar] [CrossRef]

- Linnik, M.; Christou, A. Vertical cavity surface emitting laser for operation at 1.5 μm with integral AlGaInAs/InP Bragg mirrors. In Proceedings of the IEEE/LEOS Summer Topi All-Optical Networking: Existing and Emerging Architecture and Applications/Dynamic Enablers of Next-Generation Optical Communications Systems/Fast Optical Processing in Optical, Mont Tremblant, QC, Canada, 15–17 July 2002; p. WG2. [Google Scholar] [CrossRef]

- Park, M.-R.; Kwon, O.-K.; Han, W.-S.; Lee, K.-H.; Park, S.-J.; Yoo, B.-S. All-epitaxial InAlGaAs-InP VCSELs in the 1.3–1.6-μm wavelength range for CWDM band applications. IEEE Photonics Technol. Lett. 2006, 18, 1717–1719. [Google Scholar] [CrossRef]

- Song, H.-W.; Han, W.S.; Kim, J.-H.; KoPark, S.-H. Long-wavelength InAlGaAs VCSELs with Al2O3 embedded current-confinement apertures. Electron. Lett. 2006, 42, 808–809. [Google Scholar] [CrossRef]

- Pasquariello, D.; Bjorlin, E.S.; Lasaosa, D.; Chiu, Y.-J.; Piprek, J.; Bowers, J.E. Selective undercut etching of InGaAs and InGaAsP quantum wells for improved performance of long-wavelength optoelectronic devices. J. Light. Technol. 2006, 24, 1470–1477. [Google Scholar] [CrossRef]

- Ustinov, V.M.; Zhukov, A.E.; Egorov, A.Y.; Maleev, N.A. Quantum Dot Lasers. In Series on Semiconductor Science and Technology; Oxford University Press: Oxford, UK, 2003. [Google Scholar] [CrossRef]

- Yu, H.C.; Wang, J.S.; Su, Y.K.; Chang, S.J.; Lai, F.I.; Chang, Y.H.; Kuo, H.C.; Sung, C.P.; Yang, H.P.D.; Lin, K.F.; et al. 1.3-μm InAs-InGaAs quantum-dot vertical-cavity surface-emitting laser with fully doped DBRs grown by MBE. IEEE Photonics Technol. Lett. 2006, 18, 418–420. [Google Scholar] [CrossRef]

- Ledentsov, N.N.; Hopfer, F.; Mutig, A.; Shchukin, V.A.; Savel’ev, A.V.; Fiol, G.; Kuntz, M.; Haisler, V.A.; Warming, T.; Stock, E.; et al. Novel concepts for ultrahigh-speed quantum-dot VCSELs and edge-emitters. In Proceedings of the Integrated Optoelectronic Devices 2007, San Jose, CA, USA, 20–25 January 2007; Volume 6468, p. 64681O. [Google Scholar] [CrossRef]

- Westbergh, P.; Söderberg, E.; Gustavsson, J.S.; Modh, P.; Larsson, A.; Zhang, Z.; Berggren, J.; Hammar, M. Single mode 1.3 μm InGaAs VCSELs for access network applications. Proc. SPIE. In Proceedings of the SPIE Photonics Europe, 2008, Strasbourg, France, 7–11 April 2008; Volume 6997, p. 69970Y. [Google Scholar] [CrossRef]

- Westbergh, P.; Gustavsson, J.S.; Larsson, A.; Zhang, Z.; Berggren, J.; Hammar, M.; Söderberg, E. Noise, distortion and dynamic range of single mode 1.3 µm InGaAs vertical cavity surface emitting lasers for radio-over-fibre links. IET Optoelectron. 2008, 2, 88–95. [Google Scholar] [CrossRef]

- Soderberg, E.; Gustavsson, J.S.; Modh, P.; Larsson, A.; Zhang, Z.; Berggren, J.; Hammar, M. High-Temperature Dynamics, High-Speed Modulation, and Transmission Experiments Using 1.3-μm InGaAs Single-Mode VCSELs. J. Lightwave Technol. 2007, 25, 2791–2798. [Google Scholar] [CrossRef]

- Marcks von Würtemberg, R.; Yu, X.; Hammar, M.; Berggren, J. Performance optimisation of epitaxially regrown 1.3-μm vertical-cavity surface-emitting lasers. IET Optoelectron. 2009, 3, 112–121. [Google Scholar] [CrossRef]

- Takeda, K.; Miyamoto, T.; Kondo, T.; Uchiyama, Y.; Kitabayashi, N.; Uchida, T.; Matsutani, A.; Koyama, F. Wavelength Extension Effect on Lasing Characteristics of Highly-Strained GaInAs/GaAs Vertical-Cavity Surface-Emitting Lasers with Cavity Detuning. Jpn. J. Appl. Phys. 2006, 45, 6691–6696. [Google Scholar] [CrossRef]

- Kuo, H.-C.; Chang, Y.-A.; Chang, Y.-H.; Chu, J.-T.; Tsai, M.-Y.; Wang, S.-C. Single mode 1.27-μm InGaAs:Sb-GaAs-GaAsP quantum-well vertical-cavity surface-emitting lasers. In Proceedings of the Integrated Optoelectronic Devices 2005, San Jose, CA, USA, 22–27 January 2005; Volume 5737. [Google Scholar] [CrossRef]

- Harmand, J.C.; Li, L.H.; Patriarche, G.; Travers, L. GaInAs/GaAs quantum-well growth assisted by Sb surfactant: Toward 1.3 μm emission. Appl. Phys. Lett. 2004, 84, 3981–3983. [Google Scholar] [CrossRef]

- Lao, Y.-F.; Cao, C.-F.; Wu, H.-Z.; Cao, M.; Gong, Q. InAsP/InGaAsP quantum-well 1.3 μm vertical-cavity surface-emitting lasers. Electron. Lett. 2009, 45, 105–107. [Google Scholar] [CrossRef]

- Yamada, M.; Anan, T.; Kurihara, K.; Nishi, K.; Tokutome, K.; Kamei, A.; Sugou, S. Room temperature low-threshold CW operation of 1.23 μm GaAsSb VCSELs on GaAs substrates. Electron. Lett. 2000, 36, 637–638. [Google Scholar] [CrossRef]

- Anan, T.; Yamada, M.; Nishi, K.; Kurihara, K.; Tokutome, K.; Kamei, A.; Sugou, S. Continuous-wave operation of 1.30 μm GaAsSb/GaAs VCSELs. Electron. Lett. 2001, 37, 566–567. [Google Scholar] [CrossRef]

- Thompson, L.R.; Chirovsky, L.M.F.; Jackson, A.W.; Naone, R.L.; Galt, D.; Prakash, S.R.; Feld, S.A.; Crom, M.V.; Wasserbauer, J.G.; Lange, M.D.; et al. Performance of monolithic 1.3 μm VCSELs in telecom applications. In Proceedings of the Symposium on Integrated Optoelectronic Devices, 2002, San Jose, CA, USA, 19–25 January 2002; Volume 4649. [Google Scholar] [CrossRef]

- Graham, L.A.; Jewell, J.L.; Maranowski, K.D.; Crom, M.V.; Feld, S.A.; Smith, J.M.; Beltran, J.G.; Fanning, T.R.; Schnoes, M.; Gray, M.H.; et al. LW VCSELs for SFP+ applications. In Proceedings of the Integrated Optoelectronic Devices 2008, San Jose, CA, USA, 12 February 2008; Volume 6808, p. 690802. [Google Scholar] [CrossRef]

- Graham, L.A.; Schnoes, M.; Maranowski, K.D.; Fanning, T.R.; Crom, M.V.; Feld, S.A.; Gray, M.H.; Bowers, K.; Silva, S.L.; Cook, K.; et al. New developments in 850 and 1300 nm VCSELs at JDSU. In Proceedings of the SPIE OPTO: Integrated Optoelectronic Devices, 2009, San Jose, CA, USA, 6 February 2009; Volume 7229, p. 72290B. [Google Scholar] [CrossRef]

- Riechert, H.; Ramakrishnan, A.; Steinle, G. Development of InGaAsN-based 1.3 μm VCSELs. Semicond. Sci. Technol. 2002, 17, 892–897. [Google Scholar] [CrossRef]

- Onishi, Y.; Saga, N.; Koyama, K.; Doi, H.; Ishizuka, T.; Yamada, T.; Fujii, K.; Mori, H.; Hashimoto, J.; Shimazu, M.; et al. Long-Wavelength GaInNAs Vertical-Cavity Surface-Emitting Laser with Buried Tunnel Junction. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 838–843. [Google Scholar] [CrossRef]

- Jewell, J.; Graham, L.; Crom, M.; Maranowski, K.; Smith, J.; Fanning, T.; Schnoes, M. Commercial GaInNAs VCSELs grown by MBE. Phys. Status Solidi C 2008, 5, 2951–2956. [Google Scholar] [CrossRef]

- Naone, R.L.; Jackson, A.W.; Feld, S.A.; Galt, D.; Malone, K.J.; Hindi, J.J. Monolithic GaAs-based 1.3 μm VCSEL directly-modulated at 10 Gb/s. In Proceedings of the Technical Digest. Summaries of papers presented at the Conference on Lasers and Electro-Optics, Postconference Technical Digest (IEEE Cat. No. 01CH37170). Baltimore, MD, USA, 11 May 2001. [Google Scholar] [CrossRef]

- 10 Gbps 1300 nm PBG-VCSEL for 10 Gigabit Ethernet Transmission up to 10 km Reach. Available online: https://www.alight.dk/index.htm?id=3 (accessed on 23 January 2023).

- Gambin, V.; Ha, W.; Wistey, M.; Yuen, H.; Bank, S.R.; Kim, S.M.; Harris, J.S. GaInNAsSb for 1.3–1.6-μm-long wavelength lasers grown by molecular beam epitaxy. IEEE J. Sel. Top. Quantum Electron. 2002, 8, 795–800. [Google Scholar] [CrossRef]

- Blume, G.; Hild, K.; Marko, I.P.; Hosea, T.J.C.; Yu, S.-Q.; Chaparro, S.A.; Samal, N.; Johnson, S.R.; Zhang, Y.-H.; Sweeney, S.J. Cavity mode gain alignment in GaAsSb-based near-infrared vertical cavity lasers studied by spectroscopy and device measurements. J. Appl. Phys. 2012, 112, 033108. [Google Scholar] [CrossRef]

- Wistey, M.A.; Bank, S.R.; Yuen, H.B.; Goddard, L.L.; Harris, J.S. Monolithic, GaInNAsSb VCSELs at 1.46 μm on GaAs by MBE. Electron. Lett. 2003, 39, 1822–1823. [Google Scholar] [CrossRef]

- Harris, J.S.; Bae, H.; Sarmiento, T. GaInNAs(Sb) Long-Wavelength VCSELs. In VCSELs Fundamentals, Technology and Applications of Vertical-Cavity Surface-Emitting Lasers; Rainer Michalzik, R., Ed.; Part of the Book Series: Springer Series in Optical Sciences; Springer: Berlin/Heidelberg, Germany, 2013; Volume 166, pp. 353–377. [Google Scholar] [CrossRef]

- Wistey, M.A.; Bank, S.R.; Bae, H.P.; Yuen, H.B.; Pickett, E.R.; Goddard, L.L.; Harris, J.S. GaInNAsSb/GaAs vertical cavity surface emitting lasers at 1534 nm. Electron. Lett. 2006, 42, 282–283. [Google Scholar] [CrossRef]

- Sarmiento, T.; Bae, H.P.; O’Sullivan, T.D.; Harris, J.S. GaAs-based 1.53 μm GaInNAsSb vertical cavity surface emitting lasers. Electron. Lett. 2009, 45, 978–979. [Google Scholar] [CrossRef]

- Sarmiento, T.; Zhao, L.; Moser, P.; Li, T.; Huo, Y.; Harris, J.S. Continuous-Wave Operation of GaAs-Based 1.5-μm GaInNAsSb VCSELs. IEEE Photonics Technol. Lett. 2019, 31, 1607–1610. [Google Scholar] [CrossRef]

- Babichev, A.V.; Pirogov, E.V.; Sobolev, M.S.; Denisov, D.V.; Fominykh, N.A.; Baranov, A.I.; Gudovskikh, A.S.; Melnichenko, I.A.; Yunin, P.A.; Nevedomsky, V.N.; et al. Investigation of active regions based on multiperiod GaAsN/InAs superlattices. Semiconductors 2022, 56, 782–790. Available online: https://journals.ioffe.ru/articles/54909?jaccess=63eac4032903b4.15850587 (accessed on 21 February 2023). [CrossRef]

- Albrecht, M.; Grillo, V.; Remmele, T.; Strunk, H.P.; Egorov, A.Y.; Dumitras, G.; Riechert, H.; Kaschner, A.; Heitz, R.; Hoffmann, A. Effect of annealing on the In and N distribution in InGaAsN quantum wells. Appl. Phys. Lett. 2002, 81, 2719–2721. [Google Scholar] [CrossRef]

- RayCan Optoelectronic Next 850 nm/1310 nm/1550 nm VCSEL. Available online: http://raycan.koreasme.com/ (accessed on 23 January 2023).

- Products. Available online: https://www.bandwidth10.com/product/ (accessed on 23 January 2023).

- Park, M.-R.; Kwon, O.-K.; Han, W.-S.; Lee, K.-H.; Park, S.-J.; Yoo, B.-S. All-Monolithic 1.55 µm InAlGaAs/InP Vertical Cavity Surface Emitting Lasers Grown by Metal Organic Chemical Vapor Deposition. Jpn. J. Appl. Phys. 2005, 45, L8. [Google Scholar] [CrossRef]

- Deng, L.; Zhao, Y.; Pang, X.; Tang, M.; Shum, P.; Liu, D. All-VCSEL Transmitters with Remote Optical Injection for WDM-OFDM-PON. IEEE Photonics Technol. Lett. 2014, 26, 461–464. [Google Scholar] [CrossRef]

- Rhew, K.H.; Jeon, S.C.; Lee, D.H.; Yoo, B.-S.; Yun, I. Reliability assessment of 1.55-μm vertical cavity surface emitting lasers with tunnel junction using high-temperature aging tests. Microelectron. Reliab. 2009, 49, 42–50. [Google Scholar] [CrossRef]

- Shin, B.; Jeong, J.; Yoon, W.-S.; Lee, J. 1550 nm VCSEL-based 10 Gb/s optical NRZ signal transmission over 20 km SMF using RSOA gain saturation. Opt. Fiber Technol. 2017, 36, 222–226. [Google Scholar] [CrossRef]

- Hofmann, W. High-Speed Buried Tunnel Junction Vertical-Cavity Surface-Emitting Lasers. IEEE Photonics J. 2010, 2, 802–815. [Google Scholar] [CrossRef]

- Hofmann, W.; Amann, M.-C. Long-wavelength vertical-cavity surface-emitting lasers for high-speed applications and gas sensing. IET Optoelectron. 2008, 2, 134–142. [Google Scholar] [CrossRef]

- Hofmann, W.; Muller, M.; Bohm, G.; Ortsiefer, M.; Amann, M.-C. 1.55-μm VCSEL With Enhanced Modulation Bandwidth and Temperature Range. IEEE Photonics Technol. Lett. 2009, 21, 923–925. [Google Scholar] [CrossRef]

- Muller, M.; Hofmann, W.; Bohm, G.; Amann, M.-C. Short-Cavity Long-Wavelength VCSELs With Modulation Bandwidths in Excess of 15 GHz. IEEE Photonics Technol. Lett. 2009, 21, 1615–1617. [Google Scholar] [CrossRef]

- Hofmann, W.; Müller, M.; Wolf, P.; Mutig, A.; Gründl, T.; Böhm, G.; Bimberg, D.; Amann, M.-C. 40 Gbit/s modulation of 1550 nm VCSEL. Electron. Lett. 2011, 47, 270–271. [Google Scholar] [CrossRef]

- Grundl, T.; Debernardi, P.; Muller, M.; Grasse, C.; Ebert, P.; Geiger, K.; Ortsiefer, M.; Bohm, G.; Meyer, R.; Amann, M.-C. Record Single-Mode, High-Power VCSELs by Inhibition of Spatial Hole Burning. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1700913. [Google Scholar] [CrossRef]

- Müller, M.; Wolf, P.; Grasse, C.; Dias, M.P.I.; Ortsiefer, M.; Böhm, G.; Wong, E.; Hofmann, W.; Bimberg, D.; Amann, M.-C. 1.3 μm short-cavity VCSELs enabling error-free transmission at 25 Gbit/s over 25 km fibre link. Electron. Lett. 2012, 48, 1487–1489. [Google Scholar] [CrossRef]

- Muller, M.; Grasse, C.; Amann, M.C. InP-based 1.3 μm and 1.55 μm short-cavity VCSELs suitable for telecom- and datacom-applications. In Proceedings of the 2012 14th International Conference on Transparent Optical Networks (ICTON), Coventry, UK, 2–5 July 2012. [Google Scholar] [CrossRef]

- Muller, M.; Wolf, P.; Grundl, T.; Grasse, C.; Rosskopf, J.; Hofmann, W.; Bimberg, D.; Amann, M.-C. Energy-efficient 1.3 μm short-cavity VCSELs for 30 Gb/s error-free optical links. In Proceedings of the ISLC 2012 International Semiconductor Laser Conference, San Diego, CA, USA, 7–10 October 2012. [Google Scholar] [CrossRef]

- Müller, M.; Grasse, C.; Saller, K.; Gründl, T.; Böhm, G.; Ortsiefer, M.; Amann, M.C. 1.3 μm High-Power Short-Cavity VCSELs for High-Speed Applications. In Proceedings of the Conference on Lasers and Electro-Optics 2012, San Jose, CA, USA, 6–11 May 2012; p. CW3N-2. [Google Scholar] [CrossRef]

- Malacarne, A.; Neumeyr, C.; Soenen, W.; Falconi, F.; Porzi, C.; Aalto, T.; Rosskopf, J.; Bauwelinck, J.; Bogoni, A. Optical Transmitter Based on a 1.3-μm VCSEL and a SiGe Driver Circuit for Short-Reach Applications and Beyond. J. Lightwave Technol. 2018, 36, 1527–1536. [Google Scholar] [CrossRef]

- Breyne, L.; Verplaetse, M.; Neumeyr, C.; De Keulenaer, T.; Soenen, W.; Yin, X.; Ossieur, P.; Torfs, G.; Bauwelinck, J. DSP-Free and Real-Time NRZ Transmission of 50 Gb/s Over 15-km SSMF and 64 Gb/s Back-to-Back With a 1.3-μm VCSEL. J. Lightwave Technol. 2019, 37, 170–177. [Google Scholar] [CrossRef]

- Salomonsson, F.; Streubel, K.; Bentell, J.; Hammar, M.; Keiper, D.; Westphalen, R.; Piprek, J.; Sagalowicz, L.; Rudra, A.; Behrend, J. Wafer fused p-InP/p-GaAs heterojunctions. J. Appl. Phys. 1998, 83, 768–774. [Google Scholar] [CrossRef]

- Rapp, S.; Salomonsson, F.; Streubel, K.; Mogg, S.; Wennekes, F.; Bentell, J.; Hammar, M. All-Epitaxial Single-Fused 1.55 µm Vertical Cavity Laser Based on an InP Bragg Reflector. Jpn. J. Appl. Phys. 1999, 38, 1261. [Google Scholar] [CrossRef]

- Jin-Phillipp, N.Y.; Sigle, W.; Black, A.; Babic, D.; Bowers, J.E.; Hu, E.L.; Rühle, M. Interface of directly bonded GaAs and InP. J. Appl. Phys. 2001, 89, 1017–1024. [Google Scholar] [CrossRef]

- Dudley, J.J.; Babić, D.I.; Mirin, R.; Yang, L.; Miller, B.I.; Ram, R.J.; Reynolds, T.; Hu, E.L.; Bowers, J.E. Low threshold, wafer fused long wavelength vertical cavity lasers. Appl. Phys. Lett. 1994, 64, 1463–1465. [Google Scholar] [CrossRef]

- Babić, D.I.; Dudley, J.J.; Streubel, K.; Mirin, R.P.; Bowers, J.E.; Hu, E.L. Double-fused 1.52-μm vertical-cavity lasers. Appl. Phys. Lett. 1995, 66, 1030–1032. [Google Scholar] [CrossRef]

- Syrbu, A.V.; Fernandez, J.; Behrend, J.; Berseth, C.A.; Carlin, J.F.; Rudra, A.; Kapon, E. InGaAs/InGaAsP/InP edge emitting laser diodes on p-GaAs substrates obtained by localised wafer fusion. Electron. Lett. 1997, 33, 866–868. [Google Scholar] [CrossRef]

- Sagalowicz, L.; Rudra, A.; Kapon, E.; Hammar, M.; Salomonsson, F.; Black, A.; Jouneau, P.-H.; Wipijewski, T. Defects, structure, and chemistry of InP–GaAs interfaces obtained by wafer bonding. J. Appl. Phys. 2000, 87, 4135–4146. [Google Scholar] [CrossRef]

- Syrbu, A.V.; Iakovlev, V.P.; Berseth, C.-A.; Dehaese, O.; Rudra, A.; Kapon, E.; Jacquet, J.; Boucart, J.; Stark, C.; Gaborit, F.; et al. 30 °C CW operation of 1.52 μm InGaAsP/AlGaAs vertical cavity lasers with in situ built-in lateral current confinement by localised fusion. Electron. Lett. 1998, 34, 1744–1745. [Google Scholar] [CrossRef]

- Black, A.; Hawkins, A.R.; Margalit, N.M.; Babic, D.I.; Holmes, A.L.; Chang, Y.-L.; Abraham, P.; Bowers, J.E.; Hu, E.L. Wafer fusion: Materials issues and device results. IEEE J. Sel. Top. Quantum Electron. 1997, 3, 943–951. [Google Scholar] [CrossRef]

- Black, K.A.; Abraham, P.; Margalit, N.M.; Hegblom, E.R.; Chiu, Y.-J.; Piprek, J.; Bowers, J.E.; Hu, E.L. Double-fused 1.5 μm vertical cavity lasers with record high To of 132 K at room temperature. Electron. Lett. 1998, 34, 1947–1949. [Google Scholar] [CrossRef]

- Margalit, N.M.; Piprek, J.; Zhang, S.; Babic, D.I.; Streubel, K.; Mirin, R.P.; Wesselmann, J.R.; Bowers, J.E. 64 °C continuous-wave operation of 1.5-μm vertical-cavity laser. IEEE J. Sel. Top. Quantum Electron. 1997, 3, 359–365. [Google Scholar] [CrossRef]

- Karim, A.; Abraham, P.; Lofgreen, D.; Chiu, Y.-J.; Piprek, J.; Bowers, J. Wafer bonded 1.55 μm vertical-cavity lasers with continuous-wave operation up to 105 °C. Appl. Phys. Lett. 2001, 78, 2632–2633. [Google Scholar] [CrossRef]

- Karim, A.; Black, K.A.; Abraham, P.; Lofgreen, D.; Chiu, Y.J.; Piprek, J.; Bowers, J.E. Superlattice barrier 1528-nm vertical-cavity laser with 85 °C continuous-wave operation. IEEE Photonics Technol. Lett. 2000, 12, 1438–1440. [Google Scholar] [CrossRef]

- Syrbu, A.; Mircea, A.; Mereuta, A.; Caliman, A.; Berseth, C.-A.; Suruceanu, G.; Iakovlev, V.; Achtenhagen, M.; Rudra, A.; Kapon, E. 1.5-mW Single-Mode Operation of Wafer-Fused 1550-nm VCSELs. IEEE Photonics Technol. Lett. 2004, 16, 1230–1232. [Google Scholar] [CrossRef]

- Jayaraman, V.; Mehta, M.; Jackson, A.W.; Wu, S.; Okuno, Y.; Piprek, J.; Bowers, J.E. High-power 1320-nm wafer-bonded VCSELs with tunnel junctions. IEEE Photonics Technol. Lett. 2003, 15, 1495–1497. [Google Scholar] [CrossRef]

- Mutter, L.; Iakovlev, V.; Caliman, A.; Mereuta, A.; Sirbu, A.; Kapon, E. 1.3 μm-wavelength phase-locked VCSEL arrays incorporating patterned tunnel junction. Opt. Express 2009, 17, 8558–8566. [Google Scholar] [CrossRef] [PubMed]

- Mereuta, A.; Suruceanu, G.; Caliman, A.; Iacovlev, V.; Sirbu, A.; Kapon, E. 10-Gb/s and 10-km error-free transmission up to 100 °C with 1.3-μm wavelength wafer-fused VCSELs. Opt. Express 2009, 17, 12981–12986. [Google Scholar] [CrossRef] [PubMed]

- Sirbu, A.; Iakovelv, V.; Mereuta, A.; Caliman, A.; Suruceanu, G.; Kapon, E. Wafer-fused heterostructures: Application to vertical cavity surface-emitting lasers emitting in the 1310 nm band. Semicond. Sci. Technol. 2010, 26, 014016. [Google Scholar] [CrossRef]

- Sirbu, A.; Suruceanu, G.; Iakovlev, V.; Mereuta, A.; Mickovic, Z.; Caliman, A.; Kapon, E. Reliability of 1310 nm Wafer Fused VCSELs. IEEE Photonics Technol. Lett. 2013, 25, 1555–1558. [Google Scholar] [CrossRef]

- Volet, N.; Czyszanowski, T.; Walczak, J.; Mutter, L.; Dwir, B.; Micković, Z.; Gallo, P.; Caliman, A.; Sirbu, A.; Mereuta, A.; et al. Transverse mode discrimination in long-wavelength wafer-fused vertical-cavity surface-emitting lasers by intra-cavity patterning. Opt. Express 2013, 21, 26983–26989. [Google Scholar] [CrossRef]

- Long, C.M.; Mickovic, Z.; Dwir, B.; Caliman, A.; Iakovlev, V.; Mereuta, A.; Sirbu, A.; Kapon, E. Polarization mode control of long-wavelength VCSELs by intracavity patterning. Opt. Express 2016, 24, 9715–9722. [Google Scholar] [CrossRef]

- Mereuta, A.; Sirbu, A.; Caliman, A.; Suruceanu, G.; Iakovlev, V.; Mickovic, Z.; Kapon, E. Fabrication and performance of 1.3-μm 10-Gb/s CWDM wafer-fused VCSELs grown by MOVPE. J. Cryst. Growth 2015, 414, 210–214. [Google Scholar] [CrossRef]

- Mereuta, A.; Caliman, A.; Sirbu, A.; Iakovlev, V.; Mickovic, Z.; Suruceanu, G.; Kapon, E. Increasing single mode power of 1.3-μm VCSELs by output coupling optimization. Opt. Express 2015, 23, 10900–10904. [Google Scholar] [CrossRef] [PubMed]

- Ellafi, D.; Iakovlev, V.; Sirbu, A.; Grigore, S.; Mickovic, Z.; Caliman, A.; Mereuta, A.; Kapon, E. Effect of Cavity Lifetime Variation on the Static and Dynamic Properties of 1.3-μm Wafer-Fused VCSELs. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 414–422. [Google Scholar] [CrossRef]

- Caliman, A.; Mereuta, A.; Wolf, P.; Sirbu, A.; Iakovlev, V.; Bimberg, D.; Kapon, E. 25 Gbps direct modulation and 10 km data transmission with 1310 nm waveband wafer fused VCSELs. Opt. Express 2016, 24, 16329–16335. [Google Scholar] [CrossRef]

- Wolf, P.; Li, H.; Caliman, A.; Mereuta, A.; Iakovlev, V.; Sirbu, A.; Kapon, E.; Bimberg, D. Spectral Efficiency and Energy Efficiency of Pulse-Amplitude Modulation Using 1.3 μm Wafer-Fusion VCSELs for Optical Interconnects. ACS Photonics 2017, 4, 2018–2024. [Google Scholar] [CrossRef]

- Ishikawa, T.; Bowers, J.E. Band lineup and in-plane effective mass of InGaAsP or InGaAlAs on InP strained-layer quantum well. IEEE J. Quantum Electron. 1994, 30, 562–570. [Google Scholar] [CrossRef]

- Kim, J.M.; Park, C.Y.; Lee, Y.T.; Song, J.D. MBE growth and optical properties of highly tensile-strained In1−xGaxAs/In0.52(Ga0.4Al0.6)0.48As multi-quantum-wells using digital alloy. J. Cryst. Growth 2006, 297, 52–56. [Google Scholar] [CrossRef]

- Bae, S.-J.; Lee, Y.-T. Tensile-strained 1.3 μm InGaAs/InGaAlAs quantum well structure of high temperature characteristics. Opt. Quantum Electron. 2008, 40, 749–756. [Google Scholar] [CrossRef]

- Blokhin, S.A.; Ledentsov, N.; Rochas, S.S.; Babichev, A.V.; Gladyshev, A.G.; Chorchos, L.; Makarov, O.Y.; Karachinsky, L.Y.; Novikov, I.I.; Blokhin, A.A.; et al. 1300-nm wafer-fused VCSELs with InGaAs/InAlGaAs superlattice-based active region. In Proceedings of the SPIE OPTO, 2022, San Francisco, CA, USA, 22 January–28 February 2022; Volume 12020, p. 120200K. [Google Scholar] [CrossRef]

- Kryzhanovskaya, N.V.; Likhachev, A.I.; Blokhin, S.A.; Blokhin, A.A.; Pirogov, E.V.; Sobolev, M.S.; Babichev, A.V.; Gladyshev, A.G.; Karachinsky, L.Y.; Novikov, I.I.; et al. 1.3 μm optically-pumped monolithic VCSEL based on GaAs with InGa(Al)As superlattice active region. Laser Phys. Lett. 2022, 19, 075801. [Google Scholar] [CrossRef]

- Karachinsky, L.Y.; Novikov, I.I.; Babichev, A.V.; Gladyshev, A.G.; Kolodeznyi, E.S.; Rochas, S.S.; Kurochkin, A.S.; Bobretsova, Y.K.; Klimov, A.A.; Denisov, D.V.; et al. Optical Gain in Laser Heterostructures with an Active Area Based on an InGaAs/InGaAlAs Superlattice. Opt. Spectrosc. 2019, 127, 1053–1056. [Google Scholar] [CrossRef]

- Blokhin, S.A.; Bobrov, M.A.; Blokhin, A.A.; Maleev, N.A.; Kuzmenkov, A.G.; Vasiliev, A.P.; Rochas, S.S.; Babichev, A.V.; Novikov, I.I.; Karachinsky, L.Y.; et al. Impact of transverse optical confinment on performance of 1.55 µm vertical-cavity surface-emitting lasers with a buried tunnel junction. Tech. Phys. Lett. 2022, 48, 46–50. Available online: https://journals.ioffe.ru/articles/55117 (accessed on 24 February 2023). [CrossRef]

- Arafin, S.; Bachmann, A.; Amann, M.C. Transverse-mode characteristics of GaSb-based VCSELs with buried-tunnel junctions. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 1576–1583. [Google Scholar] [CrossRef]

- Hadley, G.R. Effective index model for vertical-cavity surface-emitting lasers. Opt. Lett. 1995, 20, 1483–1485. [Google Scholar] [CrossRef] [PubMed]

- Deppe, D.G.; Leshin, J.; Leshin, J.; Eifert, L.; Tucker, F.; Hillyer, T. Transverse mode confinement in lithographic VCSELs. Electron. Lett. 2017, 53, 1598–1600. [Google Scholar] [CrossRef]

- Ortsiefer, M.; Shau, R.; Böhm, G.; Köhler, F.; Amann, M.-C. Low-threshold index-guided 1.5 μm long-wavelength vertical-cavity surface-emitting laser with high efficiency. Appl. Phys. Lett. 2000, 76, 2179–2181. [Google Scholar] [CrossRef]

- Caliman, A.; Mereuta, A.; Suruceanu, G.; Iakovlev, V.; Sirbu, A.; Kapon, E. 8 mW fundamental mode output of wafer-fused VCSELs emitting in the 1550-nm band. Opt. Express 2011, 19, 16996. [Google Scholar] [CrossRef]

- Sirbu, A.; Caliman, A.; Mereuta, A.; Iakovlev, V.; Suruceanu, G.; Kapon, E. Recent progress in wafer-fused VCSELs emitting in the 1550-nm band. In Proceedings of the 2011 13th International Conference on Transparent Optical Networks, Stockholm, Sweden, 26–30 June 2011. [Google Scholar] [CrossRef]

- Ellafi, D.; Iakovlev, V.; Sirbu, A.; Suruceanu, G.; Mickovic, Z.; Caliman, A.; Mereuta, A.; Kapon, E. Control of cavity lifetime of 1.5 µm wafer-fused VCSELs by digital mirror trimming. Opt. Express 2014, 22, 32180–32187. [Google Scholar] [CrossRef]

- Babichev, A.V.; Karachinsky, L.Y.; Novikov, I.I.; Gladyshev, A.G.; Blokhin, S.A.; Mikhailov, S.; Iakovlev, V.; Sirbu, A.; Stepniak, G.; Chorchos, L.; et al. 6-mW Single-Mode High-Speed 1550-nm Wafer-Fused VCSELs for DWDM Application. IEEE J. Quantum Electron. 2017, 53, 1–8. [Google Scholar] [CrossRef]

- Babichev, A.V.; Karachinsky, L.Y.; Novikov, I.I.; Gladyshev, A.G.; Mikhailov, S.; Iakovlev, V.; Sirbu, A.; Stepniak, G.; Chorchos, L.; Turkiewicz, J.P.; et al. Continuous wave and modulation performance of 1550 nm band wafer-fused VCSELs with MBE-grown InP-based active region and GaAs-based DBRs. In Proceedings of the SPIE OPTO, 2017, San Francisco, CA, USA, 28 January–2 February 2017; Volume 10122, p. 1012208. [Google Scholar] [CrossRef]

- Kolodeznyi, E.S.; Rochas, S.S.; Kurochkin, A.S.; Babichev, A.V.; Novikov, I.I.; Gladyshev, A.G.; Karachinskii, L.Y.; Denisov, D.V.; Bobretsova, Y.K.; Klimov, A.A.; et al. Optical Gain of 1550-nm Range Multiple-Quantum-Well Heterostructures and Limiting Modulation Frequencies of Vertical-Cavity Surface-Emitting Lasers Based on Them. Opt. Spectrosc. 2018, 125, 238–242. [Google Scholar] [CrossRef]

- Blokhin, S.A.; Bobrov, M.A.; Blokhin, A.A.; Kuzmenkov, A.G.; Maleev, N.A.; Ustinov, V.M.; Kolodeznyi, E.S.; Rochas, S.S.; Babichev, A.V.; Novikov, I.I.; et al. Influence of Output Optical Losses on the Dynamic Characteristics of 1.55-μm Wafer-Fused Vertical-Cavity Surface-Emitting Lasers. Semiconductors 2019, 53, 1104–1109. [Google Scholar] [CrossRef]

- Larisch, G.; Moser, P.; Lott, J.A.; Bimberg, D. Impact of Photon Lifetime on the Temperature Stability of 50 Gb/s 980 nm VCSELs. IEEE Photonics Technol. Lett. 2016, 28, 2327–2330. [Google Scholar] [CrossRef]

- Bimberg, D.; Larisch, G.; Lott, J.A. Vertical Surface Emitting Laser. Patents issued a. U.S. Patent No.: US 9979158; issued 22 May 2018. b. Europe EP No. 187013990, c. China No.: ZL1880005246.4 issued 18 June 2021, Available online: https://patentimages.storage.googleapis.com/f8/93/eb/7ba0d290723a32/US9979158.pdf (accessed on 1 March 2023).

- Spiga, S.; Schoke, D.; Andrejew, A.; Boehm, G.; Amann, M.C. Effect of cavity length, strain, and mesa capacitance on 1.5-μm VCSELs performance. J. Lightwave Technol. 2017, 35, 3130–3141. [Google Scholar] [CrossRef]

- Arafin, S.; Bachmann, A.; Vizbaras, K.; Hangauer, A.; Gustavsson, J.; Bengtsson, J.; Larsson, A.; Amann, M.C. Comprehensive analysis of electrically-pumped GaSb-based VCSELs. Opt. Express 2011, 19, 17267–17282. [Google Scholar] [CrossRef] [PubMed]

- Eiselt, N.; Griesser, H.; Wei, J.; Hohenleitner, R.; Dochhan, A.; Ortsiefer, M.; Eiselt, M.H.; Neumeyr, C.; Olmos, J.J.V.; Monroy, I.T. Experimental demonstration of 84 Gb/s PAM-4 over up to 1.6 km SSMF using a 20-GHz VCSEL at 1525 nm. J. Lightwave Technol. 2017, 35, 1342–1349. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babichev, A.; Blokhin, S.; Kolodeznyi, E.; Karachinsky, L.; Novikov, I.; Egorov, A.; Tian, S.-C.; Bimberg, D. Long-Wavelength VCSELs: Status and Prospects. Photonics 2023, 10, 268. https://doi.org/10.3390/photonics10030268

Babichev A, Blokhin S, Kolodeznyi E, Karachinsky L, Novikov I, Egorov A, Tian S-C, Bimberg D. Long-Wavelength VCSELs: Status and Prospects. Photonics. 2023; 10(3):268. https://doi.org/10.3390/photonics10030268

Chicago/Turabian StyleBabichev, Andrey, Sergey Blokhin, Evgenii Kolodeznyi, Leonid Karachinsky, Innokenty Novikov, Anton Egorov, Si-Cong Tian, and Dieter Bimberg. 2023. "Long-Wavelength VCSELs: Status and Prospects" Photonics 10, no. 3: 268. https://doi.org/10.3390/photonics10030268

APA StyleBabichev, A., Blokhin, S., Kolodeznyi, E., Karachinsky, L., Novikov, I., Egorov, A., Tian, S. -C., & Bimberg, D. (2023). Long-Wavelength VCSELs: Status and Prospects. Photonics, 10(3), 268. https://doi.org/10.3390/photonics10030268