Motion Sequence Decomposition-Based Hybrid Entropy Feature and Its Application to Fault Diagnosis of a High-Speed Automatic Mechanism

Abstract

:1. Introduction

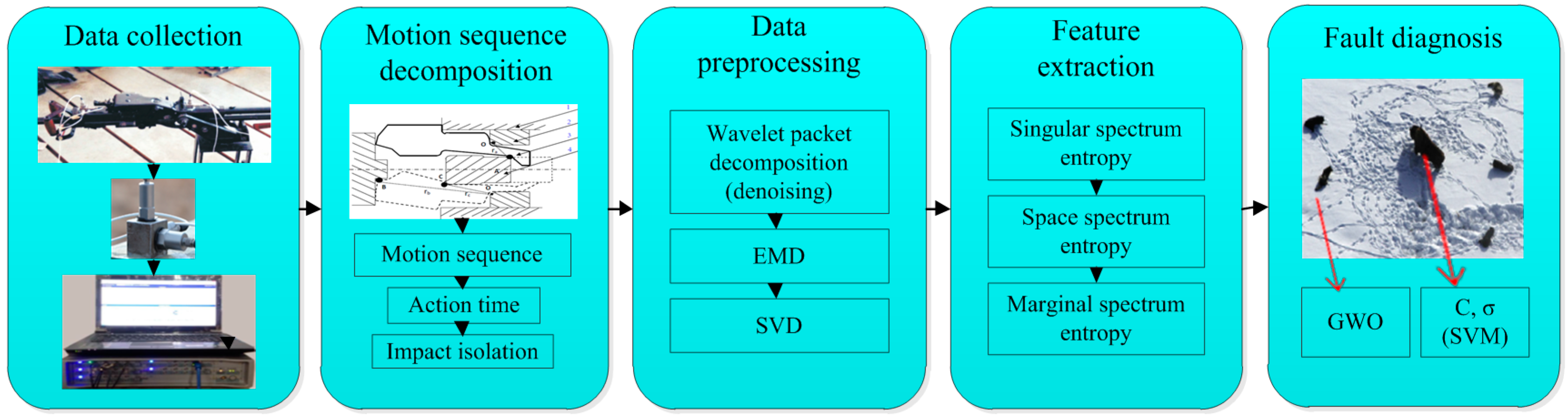

2. Methods

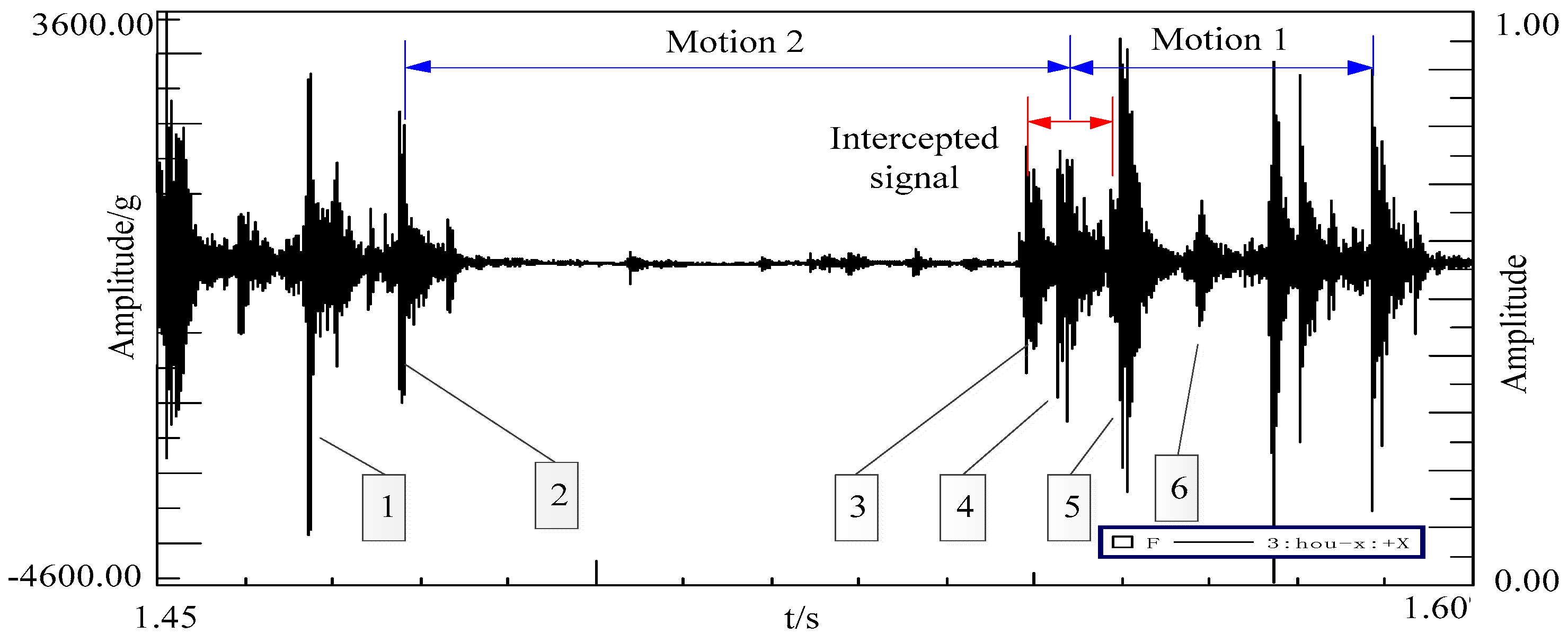

2.1. Motion Sequence Decomposition

2.2. Hybrid Information Entropy

2.3. Fault Diagnosis of a High-Speed Automatic Mechanism

2.3.1. Support Vector Machine

2.3.2. Gray-Wolf Optimization Algorithm

| Parameters setting (e.g., population size, number of iterations) and gray wolf population initialization |

| Initialize the best position vectors: , , |

| Calculate the fitness of each search agent |

| When t < M (maximum number of iterations) |

| For each agent |

| Take the parameters σ and as the search agent and training SVM model, respectively, by using training data |

| Calculate the fitness (training accuracy) of each search agent |

| Update the optimal search agents σ and |

| End for |

| Update |

| T = t + 1 |

| End while |

| Get the optimal parameters σ and and test the trained SVM by using testing data |

3. Experiments and Results

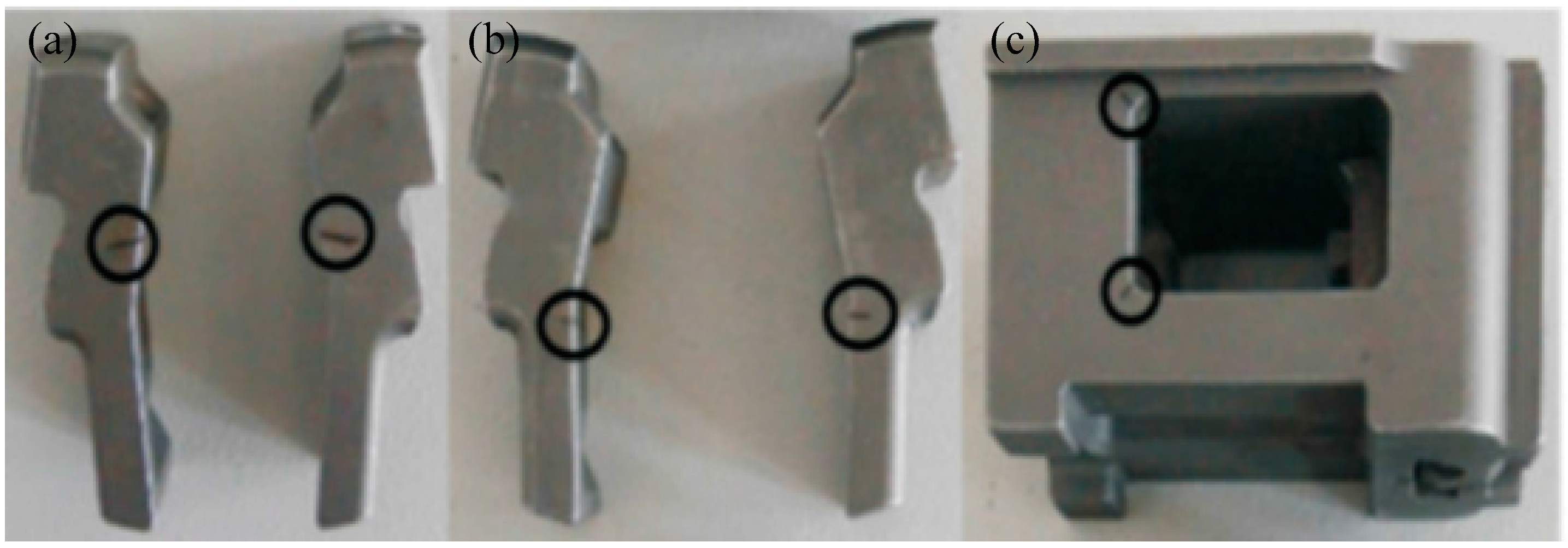

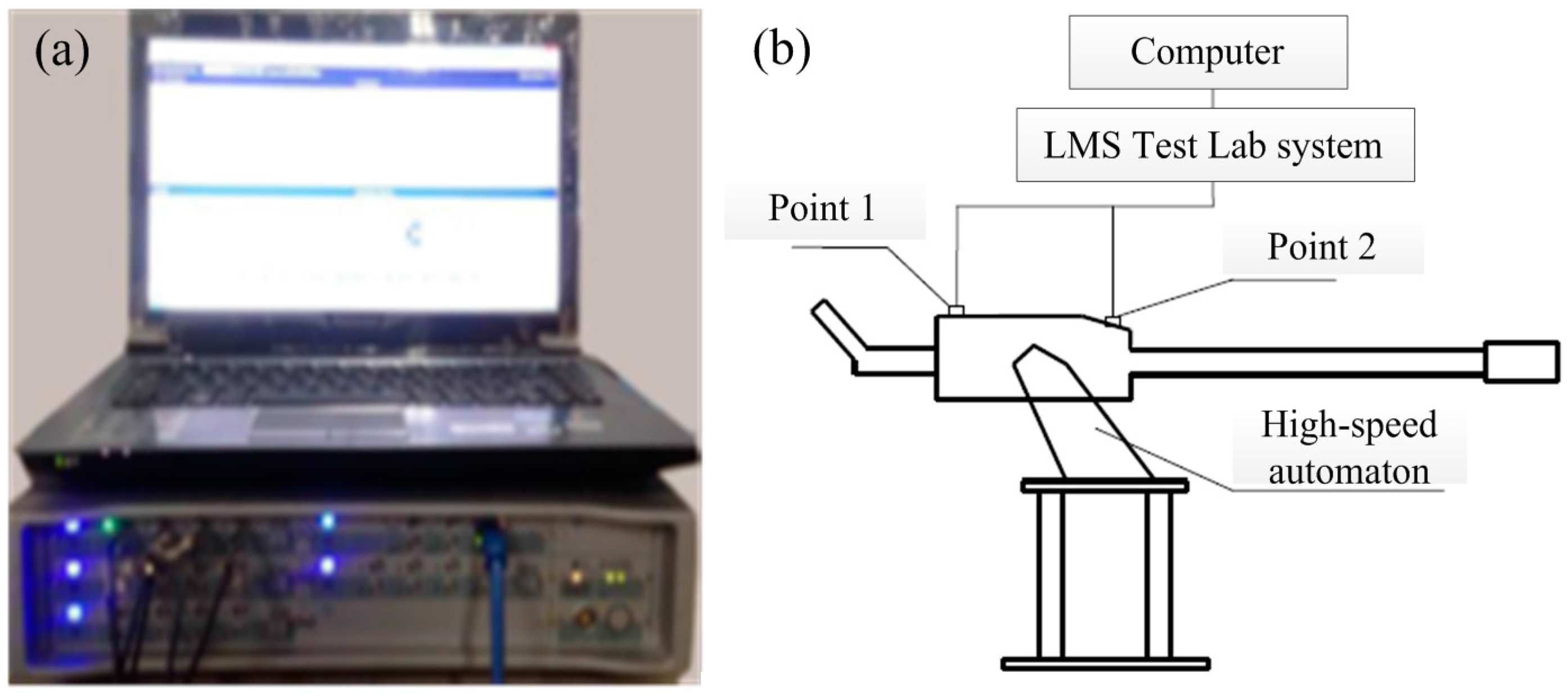

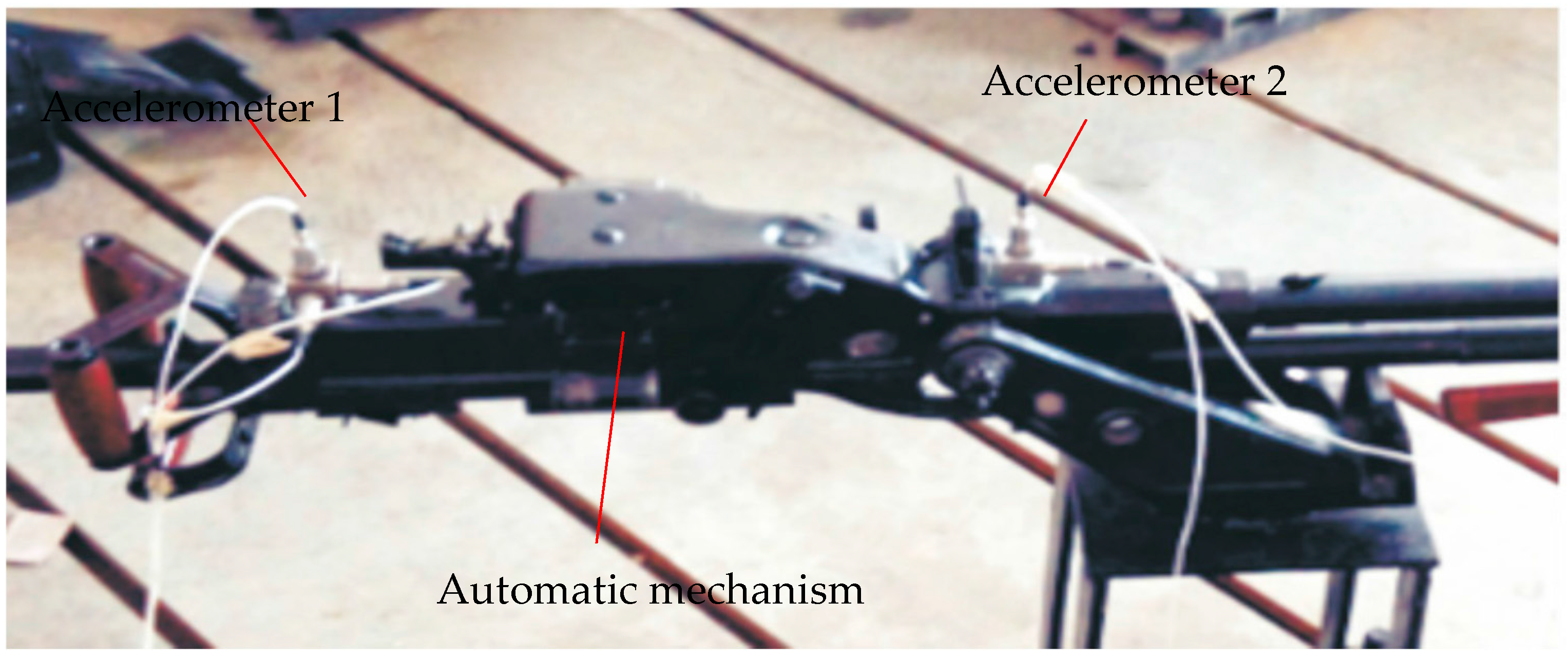

3.1. Experimental Setup

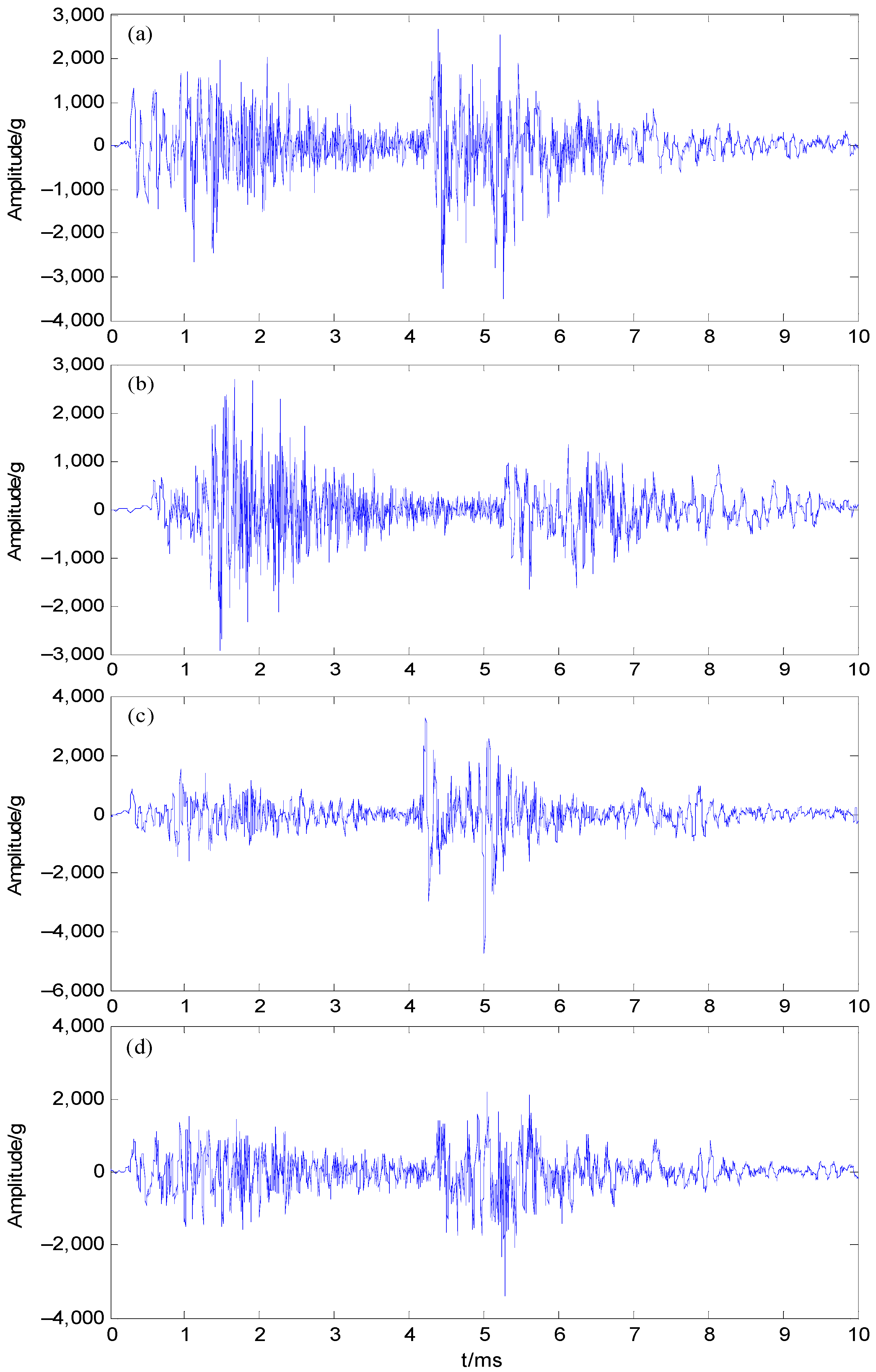

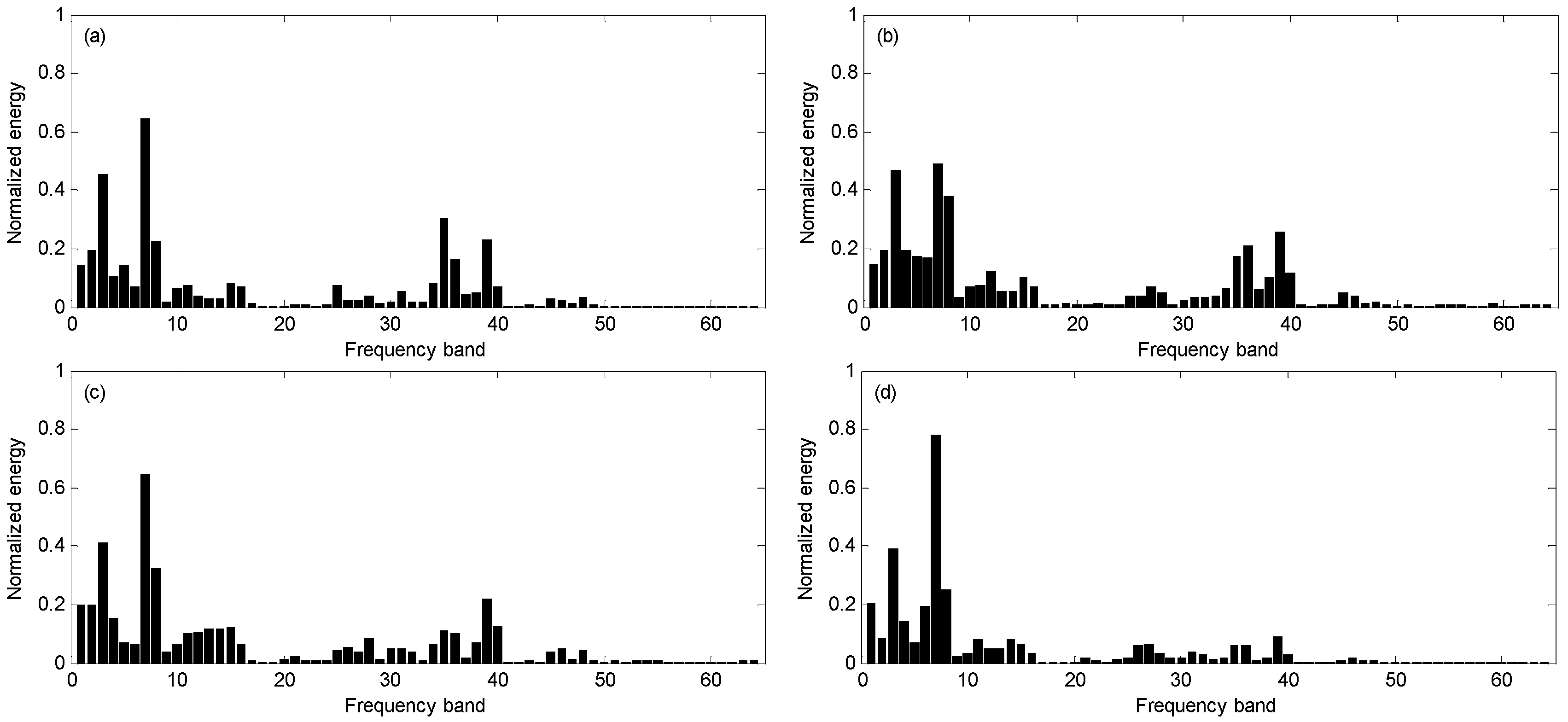

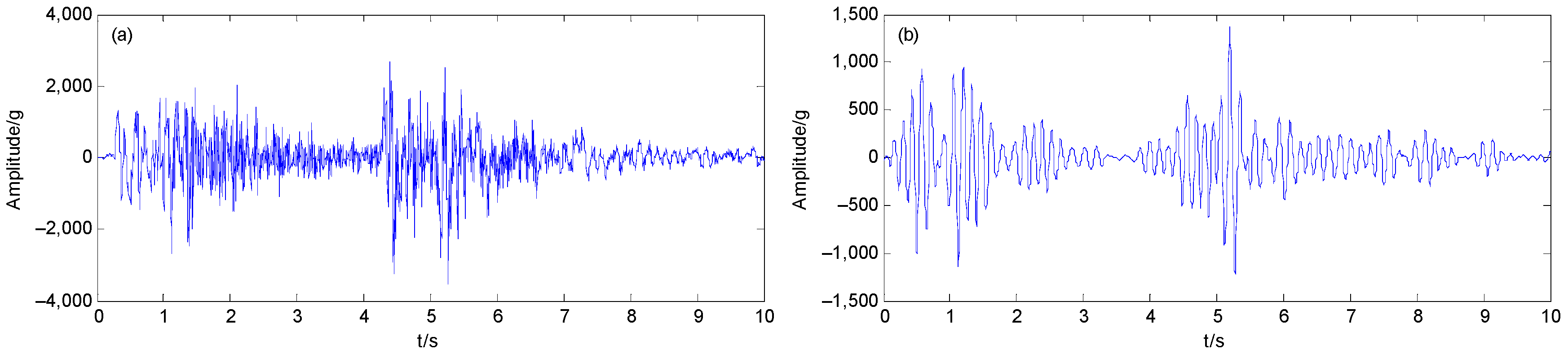

3.2. Experimental Results

4. Discussion

- (1)

- It is possible to accurately estimate the state of non-rotating components in a high-speed automaton by dealing with the vibration signal recorded from the shooting experiment. The result obtained above reveals the effectiveness of the proposed work to diagnose the state of an automaton. At present, many published works have been presented for fault diagnosis of rotating machinery, such as rolling bearing, gearbox, etc. Researchers have paid little attention to fault diagnosis of non-rotating machinery. It is worth pointing out that, to the best of our knowledge, no published works using a hybrid entropy feature have approached the issue of distinguishing the states of high-speed automaton based only on impact signal.

- (2)

- Motion sequence decomposition is an efficient approach to fault diagnosis in high-speed automatic mechanisms. Also, it is of great significance for fault diagnosis of non-rotating machinery. From Section 2, we understand that the impact signal of high-speed mechanism shows a specific characteristic different from common signals. Moreover, a shooting action comprises 19 motion travels, and the impact signal that is sampled includes superposed signals coming from these travels as well as components involved. In addition, due to the “three-high” working condition, extraction of the fault features is more complicated in practical applications. That is, this paper accomplishes a challenging task.

- (3)

- As displayed in Table 4, for each fault, we find that the feature indexes are unstable. This presents a great challenge to fault diagnosis of a high-speed automaton. The main reason may lie in the fact that the mass of dynamics system (automaton) tends to decrease along the shooting time. That is, the shooting experiment starts with five bullets, while the mass of the system varies during the five shootings. Moreover, the amount of gunpowder in each bullet is different, which also affects the response of the dynamic system.

- (4)

- GWO is introduced to improve the performance of SVM in the fault identification of an automaton. Experimental results confirm that GWO has a stronger ability to avoid local optima while exploring the best performance of SVM compared with the widely used algorithms GA and PSO (Table 2). Although GWO fails to show obvious superiority, it provides a competitive diagnosis result in this study (Table 3). It can be used as a potential alternative for parameter optimization.

5. Conclusions

- (1)

- The proposed work in this paper is effective for fault diagnosis of a high-speed automatic mechanism and the results obtained are satisfactory.

- (2)

- This paper demonstrates that the information entropy feature can be used as an efficient measure of fault information to recognize faults in automatic mechanisms.

- (3)

- The gray-wolf optimization (GWO) algorithm is used to improve the classification accuracy of SVM. Although GWO fails to indicate obvious superiority, it provides a competitive diagnosis result compared with GA and PSO.

- (4)

- The proposed work is of great significance for fault diagnosis of non-rotary mechanical parts. Fault diagnosis of a high-speed automaton is a challenging task in real life, so this subject needs more attention, as well as broader views.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lu, C.; Chen, J.; Hong, R.; Feng, Y.; Li, Y. Degradation trend estimation of slewing bearing based on LSSVM model. Mech. Syst. Signal Process. 2016, 76, 353–366. [Google Scholar] [CrossRef]

- Cui, H.; Qiao, Y.; Yin, Y.; Hong, M. An investigation of rolling bearing early diagnosis based on high-frequency characteristics and self-adaptive wavelet de-noising. Neurocomputing 2016, 216, 649–656. [Google Scholar] [CrossRef]

- Liu, Z.; He, Z.; Guo, W.; Tang, Z. A hybrid fault diagnosis method based on second generation wavelet de-noising and local mean decomposition for rotating machinery. ISA Trans. 2016, 61, 211–220. [Google Scholar] [CrossRef] [PubMed]

- Tabrizi, A.; Garibaldi, L.; Fasana, A.; Marchesiello, S. Early damage detection of roller bearings using wavelet packet decomposition, ensemble empirical mode decomposition and support vector machine. Meccanica 2015, 50, 865–874. [Google Scholar] [CrossRef]

- Wang, D. An extension of the infograms to novel Bayesian inference for bearing fault feature identification. Mech. Syst. Signal Process. 2016, 80, 19–30. [Google Scholar] [CrossRef]

- Wang, D.; Tsui, K.L. Dynamic Bayesian wavelet transform: New methodology for extraction of repetitive transients. Mech. Syst. Signal Process. 2017, 88, 137–144. [Google Scholar] [CrossRef]

- Antoni, J. The infogram: Entropic evidence of the signature of repetitive transients. Mech. Syst. Signal Process. 2016, 74, 73–94. [Google Scholar] [CrossRef]

- Asr, M.Y.; Ettefagh, M.M.; Hassannejad, R.; Razavi, S.N. Diagnosis of Combined Faults in Rotary Machinery by Non-Naive Bayesian Approach. Mech. Syst. Signal Process. 2017, 85, 56–70. [Google Scholar] [CrossRef]

- Yang, Z.X.; Zhong, J.H. A hybrid EEMD-based sampEn and SVD for acoustic signal processing and fault diagnosis. Entropy 2016, 18. [Google Scholar] [CrossRef]

- Li, Y.; Xu, M.; Wang, R.; Huang, W. A fault diagnosis scheme for rolling bearing based on local mean decomposition and improved multiscale fuzzy entropy. J. Sound Vib. 2016, 360, 277–299. [Google Scholar] [CrossRef]

- Liu, H.; Han, M. A fault diagnosis method based on local mean decomposition and multi-scale entropy for roller bearings. Mech. Mach. Theory 2014, 75, 67–78. [Google Scholar] [CrossRef]

- Qian, Y.; Yan, R.; Hu, S. Bearing degradation evaluation using recurrence quantification analysis and Kalman filter. IEEE Trans. Instrum. Meas. 2014, 63, 2599–2610. [Google Scholar] [CrossRef]

- Kang, M.; Kim, J.M. Singular value decomposition based feature extraction approaches for classifying faults of induction motors. Mech. Syst. Signal Process. 2013, 41, 348–356. [Google Scholar] [CrossRef]

- Muruganatham, B.; Sanjith, M.A.; Krishnakumar, B.; Murty, S.A.V.S. Roller element bearing fault diagnosis using singular spectrum analysis. Mech. Syst. Signal Process. 2013, 35, 150–166. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, H.; Bai, F. Classification of fault location and performance degradation of a roller bearing. Measurement 2013, 46, 1178–1189. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, J.; Dong, G.; Wang, R. Detection and diagnosis of bearing faults using shift-invariant dictionary learning and hidden Markov model. Mech. Syst. Signal Process 2016, 72, 65–79. [Google Scholar] [CrossRef]

- Tian, Y.; Ma, J.; Lu, C.; Wang, Z. Rolling bearing fault diagnosis under variable conditions using LMD-SVD and extreme learning machine. Mech. Mach. Theory 2015, 90, 175–186. [Google Scholar] [CrossRef]

- Feng, J.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Process 2016, 72, 303–315. [Google Scholar]

- Ao, H.; Cheng, J.; Yang, Y.; Truong, T.K. The support vector machine parameter optimization method based on artificial chemical reaction optimization algorithm and its application to roller bearing fault diagnosis. J. Vib. Control 2015, 21, 2434–2445. [Google Scholar] [CrossRef]

- Cerrada, M.; Zurita, G.; Cabrera, D.; Sánchez, R.V.; Artés, M.; Li, C. Fault diagnosis in spur gears based on genetic algorithm and random forest. Mech. Syst. Signal Process. 2016, 70, 87–103. [Google Scholar] [CrossRef]

- Grasso, M.; Chatterton, S.; Pennacchi, P.; Colosimo, B.M. A data-driven method to enhance vibration signal decomposition for rolling bearing fault analysis. Mech. Syst. Signal Process. 2016, 81, 126–147. [Google Scholar] [CrossRef]

- Liu, Z.; Cao, H.; Chen, X.; He, Z.; Shen, Z. Multi-fault classification based on wavelet SVM with PSO algorithm to analyze vibration signals from rolling element bearings. Neurocomputing 2013, 99, 399–410. [Google Scholar] [CrossRef]

- Xu, H.; Chen, G. An intelligent fault identification method of rolling bearings based on LSSVM optimized by improved PSO. Mech. Syst. Signal Process. 2013, 35, 167–175. [Google Scholar] [CrossRef]

- Yang, D.; Liu, Y.; Li, S.; Li, X.; Ma, L. Gear fault diagnosis based on support vector machine optimized by artificial bee colony algorithm. Mech. Mach. Theory 2015, 90, 219–229. [Google Scholar] [CrossRef]

- Seyedali, M.; Mirjalili, S.M.; Lewis, A. Grey wolf optimizer. Adv. Eng. Soft. 2014, 69, 46–61. [Google Scholar]

- Yu, J. Health condition monitoring of machines based on hidden Markov model and contribution analysis. IEEE Trans. Instr. Meas. 2012, 61, 2200–2211. [Google Scholar] [CrossRef]

- Yu, J. Local and nonlocal preserving projection for bearing defect classification and performance assessment. IEEE Trans. Ind. Electron. 2012, 59, 2363–2376. [Google Scholar] [CrossRef]

- Chang, C.C.; Lin, C.J. LIBSVM: A library for support vector machines. ACM Trans. Intel. Sys. Tech. 2011, 2. [Google Scholar] [CrossRef]

| Method | Training Samples | Testing Samples | Optimal Fitness (%) |

|---|---|---|---|

| GA-SVM | 8 | 16 | 75 |

| PSO-SVM | 8 | 16 | 75 |

| GWO-SVM | 8 | 16 | 87.5 |

| Method | Training Accuracy (%) | Testing Accuracy (%) |

|---|---|---|

| GA-SVM | 100 | 81.25 |

| PSO-SVM | 87.5 | 87.5 |

| GWO-SVM | 100 | 87.5 |

| State | |||

|---|---|---|---|

| Normal conditions | 8.1267 | 7.6934 | 1.5944 |

| 7.8538 | 7.5349 | 1.5688 | |

| 8.1505 | 7.7227 | 1.8123 | |

| 7.8150 | 7.5249 | 1.3778 | |

| Fault 1 | 7.2681 | 6.9814 | 1.1907 |

| 7.5189 | 7.2021 | 1.2030 | |

| 7.2469 | 7.0287 | 0.9091 | |

| 7.2067 | 7.0129 | 0.8338 | |

| Fault 2 | 7.9746 | 7.3326 | 0.8424 |

| 7.8506 | 7.1696 | 0.7401 | |

| 7.8968 | 7.4239 | 1.1333 | |

| 7.8181 | 7.1364 | 0.7521 | |

| Fault 3 | 7.9501 | 7.7056 | 1.8466 |

| 8.1020 | 7.6833 | 1.7437 | |

| 8.0773 | 7.7977 | 2.2783 | |

| 8.0250 | 7.6825 | 1.5842 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Pan, H.; Du, H. Motion Sequence Decomposition-Based Hybrid Entropy Feature and Its Application to Fault Diagnosis of a High-Speed Automatic Mechanism. Entropy 2017, 19, 86. https://doi.org/10.3390/e19030086

Wang B, Pan H, Du H. Motion Sequence Decomposition-Based Hybrid Entropy Feature and Its Application to Fault Diagnosis of a High-Speed Automatic Mechanism. Entropy. 2017; 19(3):86. https://doi.org/10.3390/e19030086

Chicago/Turabian StyleWang, Baoxiang, Hongxia Pan, and Heng Du. 2017. "Motion Sequence Decomposition-Based Hybrid Entropy Feature and Its Application to Fault Diagnosis of a High-Speed Automatic Mechanism" Entropy 19, no. 3: 86. https://doi.org/10.3390/e19030086