Reaction Force/Torque Sensing in a Master-Slave Robot System without Mechanical Sensors

Abstract

:1. Introduction

2. Working Mechanism

3. Experimental Study

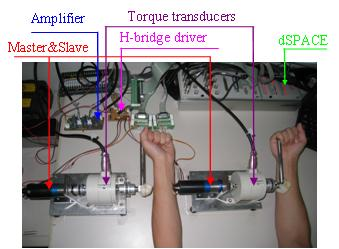

3.1. Experimental Platform

3.2. Calibration Test

3.3. Frequency Response Test

3.4. Resistant and Assistant Force Sensing Test

4. Discussion

5. Conclusions

Acknowledgments

References and Notes

- Banz, R; Bolliger, M; Müller, S; Santelli, C; Riener, R. A method of estimating the degree of active participation during stepping in a driven gait orthosis based on actuator force profile matching. IEEE Trans. Neural Syst. Reh. En 2009, 17, 15–22. [Google Scholar]

- Rashedi, E; Mirbagheri, A; Taheri, B; Farahmand, F; Vossoughi, G; Parnianpour, M. Design and development of a hand robotic rehabilitation device for post stroke patients. Proceedings of the 31st Annual International Conference of the IEEE Engineering in Medicine and Biology Society: Engineering the Future of Biomedicine, Hilton Minneapolis, MN, USA, September 2–6, 2009.

- Gupta, A; O'Malley, MK; Patoglu, V; Burgar, C. Design, control and performance of RiceWrist: A force feedback wrist exoskeleton for rehabilitation and training. Int. J. Robot. Res 2008, 27, 233–251. [Google Scholar]

- Dovat, L; Lambercy, O; Gassert, R; Maeder, T; Milner, T; Leong, TC; Burdet, E. HandCARE: A cable-actuated rehabilitation system to train hand function after stroke. IEEE Trans. Neural Syst. Reh. En 2008, 16, 582–591. [Google Scholar]

- Wolbrecht, ET; Reinkensmeyer, DJ; Bobrow, JE. Pneumatic control of robots for rehabilitation. Int. J. Robot. Res 2010, 29, 23–38. [Google Scholar]

- Komada, S; Hashimoto, Y; Okuyama, N; Hisada, T; Hirai, J. Development of a biofeedback therapeutic-exercise-supporting manipulator. IEEE Trans. Ind. Electron 2009, 56, 914–3920. [Google Scholar]

- King, CH; Culjat, MO; Franco, ML; Lewis, CE; Dutson, EP; Grundfest, WS; Bisley, JW. Tactile feedback induces reduced grasping force in robot-assisted surgery. IEEE Trans. Haptics 2009, 2, 103–110. [Google Scholar]

- Hagn, U; Konietschke, R; Tobergte, A; Nickl, M; Jörg, S; Kübler, B; Passig, G; Gröger, M; Fröhlich, F; Seibold, U; Le-Tien, L; Albu-Schäffer, A; Nothhelfer, A; Hacker, F; Grebenstein, M; Hirzinger, G. DLR MiroSurge: A versatile system for research in endoscopic telesurgery. Int. J. Comp. Assist. Radio. Surg 2010, 5, 183–193. [Google Scholar]

- Akinbiyi, T; Reiley, CE; Saha, S; Burschka, D; Hasser, CJ; Yuh, DD; Okamura, AM. Dynamic augmented reality for sensory substitution in robot-assisted surgical systems. Proceedings of International Conference of the IEEE Engineering in Medicine and Biology Society, New York City, NY, USA, August 30–September 3, 2006.

- Kitagawa, M; Dokko, D; Okamura, AM; Yuh, DD. Effect of sensory substitution on suture-manipulation forces for robotic surgical systems. J. Thorac. Cardiovasc. Surg 2005, 129, 151–158. [Google Scholar]

- Kokes, R; Lister, K; Gullapalli, R; Zhang, B; MacMillan, A; Richard, H; Desai, JP. Towards a teleoperated needle driver robot with haptic feedback for RFA of breast tumors under continuous MRI. Med. Image Anal 2009, 13, 445–455. [Google Scholar]

- Zeb, J; Rashid, F; Iqbal, N; Ahmad, N. Wipe testing of sealed radiation sources using a radiation protection assistant robot. Nucl Tech. Radiat. Prot 2009, 24, 152–155. [Google Scholar]

- Izard, JB; Gargiulo, L; Keller, D; Perrot, Y. Hardening inspection devices to ultra-high vacuum, temperature and high magnetic field. IEEE Trans Appl Superconduct 2010, in press. [Google Scholar]

- Ando, N; Korondi, P; Hashimoto, H. Development of micromanipulator and haptic interface for networked micromanipulation. IEEE-ASME Trans. Mechatron 2001, 6, 417–427. [Google Scholar]

- Zareinejad, M; Rezaei, SM; Abdullah, A; Ghidary, SS. Development of a piezo-actuated micro-teleoperation system for cell manipulation. Int. J. Med. Robot. Comput. Assist. Surg 2009, 5, 66–76. [Google Scholar]

- Floyd, S; Pawashe, C; Sitti, M. Two-dimensional contact and noncontact micromanipulation in liquid using an untethered mobile magnetic microrobot. IEEE Trans. Robot 2009, 25, 1332–1342. [Google Scholar]

- Zhang, Y; Chen, BK; Liu, X; Sun, Y. Autonomous robotic pick-and-place of microobjects. IEEE Trans. Robot 2010, 26, 200–207. [Google Scholar]

- Zhang, YL; Han, ML; Vidyalakshmi, J; Shee, CY; Ang, WT. Automatic control of mechanical forces acting on cell biomembranes using a vision-guided microrobotic system in computer microscopy. J. Microsc 2009, 236, 70–78. [Google Scholar]

- Johnson, MJ; Van Der Loos, HFM; Burgar, CG; Shor, P; Leifer, LJ. Experimental results using force-feedback cueing in robot-assisted stroke therapy. IEEE Trans. Neural Syst. Reh. En 2005, 13, 335–348. [Google Scholar]

- Park, HS; Peng, Q; Zhang, LQ. A portable telerehabilitation system for remote evaluations of impaired elbows in neurological disorders. IEEE Trans. Neural Syst. Reh. En 2008, 16, 245–254. [Google Scholar]

- Park, HS; Peng, Q; Zhang, LQ. Causality-Based Portable Control System Design for Tele-Assessment of Elbow Joint Spasticity. Proceedings of the IEEE 9th International Conference on Rehabilitation Robotics, Northwestern Memorial Hospital’s (NMH), Feinberg Pavilion Conference Center, Chicago, IL, USA, June 28–July 1, 2005.

- Guo, S; Song, Z. VR-based A Novel Active Rehabilitation System for Upper Limbs. Proceedings of IEEE International Conference on Mechatronics and Automation, Sunport Takamatsu, 1 Sunport, Takamatsu, Japan, August 05–08, 2008.

- Li, C; Liu, T; Shibata, K; Inoue, Y. A Master-Slave Control System with Energy Recycling and Force Sensing for upper Limb Rehabilitation Robots. Proceedings of IEEE/ASME International Conference on Advanced Intelligent Mechatronics, AIM, SUNTEC City Convention Center Singapore, Singapore, July 14–17, 2009; pp. 36–41.

- Li, C; Inoue, Y; Liu, T; Shibata, K; Oka, K. Design and implementation of a compact master-slave robotic system with force feedback and energy recycling. J. Syst. Des. Dyn 2010, 4, 13–25. [Google Scholar]

- Lum, PS; Burgar, CG; Van Der Loos, M; Shor, PC; Majmundar, M; Yap, R. MIME robotic device for upper-limb neurorehabilitation in subacute stroke subjects: A follow-up study. J. Rehabil. Res. Dev 2006, 43, 631–642. [Google Scholar]

- Lum, PS; Burgar, CG; Shor, PC. Evidence for improved muscle activation patterns after retraining of reaching movements with the MIME robotic system in subjects with post-stroke hemiparesis. IEEE Trans. Neural Syst. Reh. En 2004, 12, 186–194. [Google Scholar]

- Eng, K; Siekierka, E; Pyk, P; Chevrier, E; Hauser, Y; Cameirao, M; Holper, L; Hägni, K; Zimmerli, L; Duff, A; Schuster, C; Bassetti, C; Verschure, P; Kiper, D. Interactive visuo-motor therapy system for stroke rehabilitation. Med. Biol. Eng. Comput 2007, 45, 901–907. [Google Scholar]

- Ueki, S; Nishimoto, Y; Abe, M; Kawasaki, H; Ito, S; Ishigure, Y; Mizumoto, J; Ojika, T. Development of virtual reality exercise of hand motion assist robot for rehabilitation therapy by patient self-motion control. Proceedings of International Conference of the IEEE Engineering in Medicine and Biology Society, Vancouver Convention & Exhibition Centre, Vancouver, BC, Canada, August 20–24, 2008.

- Daluja, S; Golenberg, L; Cao, A; Pandya, AK; Auner, GW; Klein, MD. An integrated movement capture and control platform applied towards autonomous movements of surgical robots. Stud. Health Tech. Inform 2009, 142, 62–67. [Google Scholar]

- Seifabadi, R; Rezaei, SM; Ghidary, SS; Zareinejad, M; Saadat, M. To enhance transparency of a piezo-actuated tele-micromanipulator using passive bilateral control. Robotica 2009, 1–15. [Google Scholar] [CrossRef]

- Hesse, S; Schmidt, H; Werner, C. Machines to support motor rehabilitation after stroke: 10 Years of experience in Berlin. J. Rehabil. Res. Dev 2006, 43, 671–678. [Google Scholar]

© 2010 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Liu, T.; Li, C.; Inoue, Y.; Shibata, K. Reaction Force/Torque Sensing in a Master-Slave Robot System without Mechanical Sensors. Sensors 2010, 10, 7134-7145. https://doi.org/10.3390/s100807134

Liu T, Li C, Inoue Y, Shibata K. Reaction Force/Torque Sensing in a Master-Slave Robot System without Mechanical Sensors. Sensors. 2010; 10(8):7134-7145. https://doi.org/10.3390/s100807134

Chicago/Turabian StyleLiu, Tao, Chunguang Li, Yoshio Inoue, and Kyoko Shibata. 2010. "Reaction Force/Torque Sensing in a Master-Slave Robot System without Mechanical Sensors" Sensors 10, no. 8: 7134-7145. https://doi.org/10.3390/s100807134