Tip-Clearance Measurement in the First Stage of the Compressor of an Aircraft Engine

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sensor Design

2.2. Experimental Set-up

3. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vakhtin, A.B.; Chen, S.J.; Massick, S.M. Optical probe for monitoring blade tip clearance. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009.

- Wisler, D.C. Loss reduction in axial-flow compressors through low-speed model testing. J. Eng. Gas Turbines Power 1985, 107, 354–363. [Google Scholar] [CrossRef]

- Kempe, A.; Schlamp, S.; Rösgen, T.; Haffner, K. Spatial and temporal high-resolution optical tip-clearance probe for harsh environments. In Proceedings of the 13th International Symposium on Applications of Laser Techniques to Fluid Mechanics, Lisbon, Portugal, 26–29 June 2006.

- Guo, O.A. Active Turbine Tip Clearance Control Research. Available online: http://www.grc.nasa.gov/WWW/cdtb/aboutus/workshop2015/ACC_2_Guo.pdf (accessed on 8 August 2016).

- Lattime, S.B.; Steinetz, B.M.; Robbie, M.G. Test rig for evaluating active turbine blade tip clearance control concepts. J. Propuls. Power 2005, 21, 552–563. [Google Scholar] [CrossRef]

- Geisheimer, J.L.; Holst, T.A. Metrology considerations for calibrating turbine tip clearance sensors. In Proceedings of the XIX Biannual Symposium on Measuring Techniques in Turbomachinery Transonic and Supersonic Flow in Cascades and Turbomachines, Rhodes-St-Genèse, Belgium, 7–8 April 2007.

- Guo, H.; Duan, F.; Wu, G.; Zhang, J. Blade tip clearance measurement of the turbine engines based on a multi-mode fiber coupled laser ranging system. Rev. Sci. Instrum. 2014, 85, 115105. [Google Scholar] [CrossRef] [PubMed]

- Sheard, A.G. Blade by blade tip clearance measurement. Int. J. Rotating Mach. 2011, 2011, 516128. [Google Scholar] [CrossRef]

- Haase, W.C.; Haase, Z.S. High-Speed, capacitance-based tip clearance sensing. In Proceedings of the Aerospace Conference, Big Sky, MT, USA, 2–9 March 2013.

- Ye, D.C.; Duan, F.J.; Guo, H.T.; Li, Y.; Wang, K. Turbine blade tip clearance measurement using a skewed dual-beam fiber optic sensor. Opt. Eng. 2012, 51, 081514. [Google Scholar] [CrossRef]

- Schicht, A.; Schwarzer, S.; Schmidt, L.P. Tip clearance measurement technique for stationary gas turbines using an autofocusing millimeter-wave synthetic aperture radar. IEEE Trans. Instrum. Meas. 2012, 61, 1778–1785. [Google Scholar] [CrossRef]

- Violetti, M.; Skrivervik, A.K.; Xu, Q.; Hafner, M. New microwave sensing system for blade tip clearance measurement in gas turbines. In Proceedings of the 2012 IEEE Sensors, Taipei, Taiwan, 28–31 October 2012.

- Szczepanik, R.; Przysowa, R.; Spychała, J.; Rokicki, E.; Kaźmierczak, K.; Majewski, P. Application of Blade-Tip Sensors to Blade-Vibration Monitoring in Gas Turbines; INTECH Open Access Publisher: Rijeka, Croatia, 2012. [Google Scholar]

- Du, L.; Zhu, X.; Zhe, J. A high sensitivity inductive sensor for blade tip clearance measurement. Smart Mater. Struct. 2014, 23, 065018. [Google Scholar] [CrossRef]

- Cao, S.Z.; Duan, F.J.; Zhang, Y.G. Measurement of rotating blade tip clearance with fiber-optic probe. J. Phys. Confer. Ser. 2006, 48, 873–877. [Google Scholar] [CrossRef]

- López-Higuera, J.M. Handbook of Optical Fiber Sensing Technology; Wiley and Sons: Chichester, West Sussex, UK, 2002. [Google Scholar]

- García, I.; Zubia, J.; Durana, G.; Aldabaldetreku, G.; Illarramendi, M.A.; Villatoro, J. Optical Fiber Sensors for Aircraft Structural Health Monitoring. Sensors 2015, 15, 15494–15519. [Google Scholar] [CrossRef] [PubMed]

- Davinson, I. Use of optical sensors and signal processing in gas turbine engines. In Proceedings of the SPIE 1374, Integrated Optics and Optoloelectronics II, San José, CA, USA, 17–19 September 1990.

- Durana, G.; Kirchhof, M.; Luber, M.; de Ocáriz, I.S.; Poisel, H.; Zubia, J.; Vázquez, C. Use of a novel fiber optical strain sensor for monitoring the vertical deflection of an aircraft flap. IEEE Sens. J. 2009, 9, 1219–1225. [Google Scholar] [CrossRef]

- García, I.; Beloki, J.; Zubia, J.; Aldabaldetreku, G.; Illarramendi, M.A.; Jiménez, F. An Optical Fiber Bundle Sensor for Tip Clearance and Tip Timing Measurements in a Turbine Rig. Sensors 2013, 13, 7385–7398. [Google Scholar] [CrossRef] [PubMed]

- Pfister, T.; Büttner, L.; Czarske, J.; Krain, H.; Schodl, R. Turbo machine tip clearance and vibration measurements using a fiber optic laser Doppler position sensor. Meas. Sci. Technol. 2006, 17, 1693. [Google Scholar] [CrossRef]

- Kempe, A.; Schlamp, S.; Rösgen, T.; Haffner, K. Low-coherence interferometric tip-clearance probe. Opt. Lett. 2003, 28, 1323–1325. [Google Scholar] [CrossRef] [PubMed]

- Suganuma, F.; Shimamoto, A.; Tanaka, K. Development of a differential optical-fiber displacement sensor. Appl. Opt. 1999, 38, 1103–1109. [Google Scholar] [CrossRef] [PubMed]

- Trudel, V.; St-Amant, Y. One-dimensional single-mode fiber-optic displacement sensors for submillimeter measurements. Appl. Opt. 2009, 48, 4851–4857. [Google Scholar] [CrossRef] [PubMed]

- Cook, R.O.; Hamm, C.W. Fiber optic lever displacement transducer. Appl. Opt. 1979, 18, 3230–3241. [Google Scholar] [CrossRef] [PubMed]

- Qing-Bin, T.; Hui-Ping, M.; Li-Hua, L.; Xiao-Dong, Z.; Gui-Bin, L. Measurements of radiation vibrations of turbomachine blades using an optical-fiber displacement-sensing system. J. Russ. Laser Res. 2011, 32, 216–229. [Google Scholar] [CrossRef]

- Yu-zhen, M.; Yong-kui, Z.; Guo-ping, L.; Hua-guan, L. Tip clearance optical measurement for rotating blades. In Proceedings of the 2011 International Conference on Management Science and Industrial Engineering (MSIE), Harbin, China, 8–11 January 2011; IEEE: New York, NY, USA, 2011; pp. 1206–1208. [Google Scholar]

- García, I.; Zubia, J.; Beloki, J.; Aldabaldetreku, G.; Durana, G.; Illaramendi, M.A. Optical tip clearance measurements for rotating disk characterization. In Proceedings of the 17th International Conference on Transparent Optical Networks (ICTON), Budapest, Hungary, 5–9 July 2015.

- García, I.; Zubia, J.; Berganza, A.; Beloki, J.; Arrue, J.; Illarramendi, M.A.; Mateo, J.; Vázquez, C. Different configurations of a reflective intensity-modulated optical sensor to avoid modal noise in tip-clearance measurements. J. Lightwave Technol. 2015, 33, 2663–2669. [Google Scholar] [CrossRef]

- García, I.; Przysowa, R.; Zubia, J.; Mateo, J.; Vázquez, C. Tip timing measurements for structural health monitoring in the first stage of the compressor of an aircraft engine. In Proceedings of the 18th International Conference on Transparent Optical Networks (ICTON), Trento, Italy, 10–14 July 2016.

- Cao, H.; Chen, Y.; Zhou, Z.; Zhang, G. Theoretical and experimental study on the optical fiber bundle displacement sensors. Sens. Actuators A Phys. 2007, 136, 580–587. [Google Scholar] [CrossRef]

- Shimamoto, A.; Tanaka, K. Geometrical analysis of an optical fiber bundle displacement sensor. Appl. Opt. 1996, 35, 6767–6774. [Google Scholar] [CrossRef] [PubMed]

- Harun, S.W.; Yang, H.Z.; Yasin, M.; Ahmad, H. Theoretical and experimental study on the fiber optic displacement sensor with two receiving fibers. Microw. Opt. Technol. Lett. 2010, 52, 373–375. [Google Scholar] [CrossRef]

| V2/V1 | Simulation Distance (mm) | Experimental Distance (mm) | Difference (mm) |

|---|---|---|---|

| 20 | 2.575 | 2.55 | 0.025 (1%) |

| 30 | 2.775 | 2.78 | −0.005 (−0.2%) |

| 40 | 2.97 | 3 | −0.03 (−1%) |

| 50 | 3.15 | 3.175 | −0.025 (−1.1) |

| 60 | 3.325 | 3.375 | −0.05 (−1.5%) |

| 70 | 3.5 | 3.6 | −0.1 (−2.8%) |

| 80 | 3.7 | 3.875 | −0.175 (−4.37%) |

| 90 | 3.9 | 4.325 | −0.425 (−10.9%) |

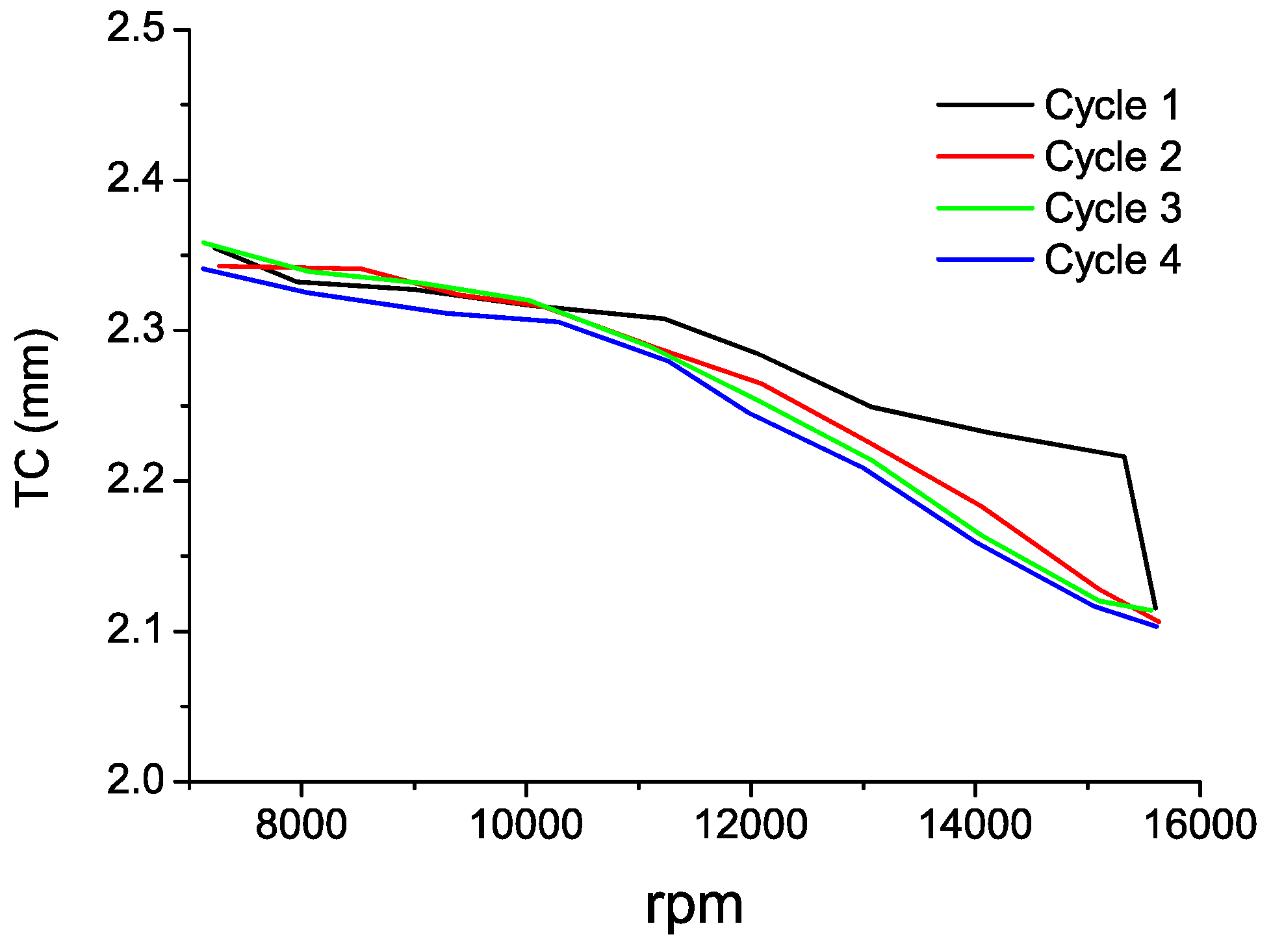

| rpm | TC Cycle 1 (mm) | rpm | TC Cycle 3 (mm) |

|---|---|---|---|

| 7226 | 2.355 | 7126 | 2.359 |

| 7960 | 2.332 | 8060 | 2.339 |

| 9003 | 2.327 | 9072 | 2.331 |

| 10,025 | 2.317 | 10,025 | 2.320 |

| 11,229 | 2.308 | 11,078 | 2.290 |

| 12,041 | 2.285 | 12,089 | 2.253 |

| 13,064 | 2.249 | 13,080 | 2.213 |

| 14,112 | 2.232 | 14,059 | 2.163 |

| 15,321 | 2.216 | 15,098 | 2.120 |

| 15,603 | 2.115 | 15,567 | 2.114 |

| rpm | TC Cycle 2 (mm) | rpm | TC Cycle 4 (mm) |

|---|---|---|---|

| 7265 | 2.343 | 7124 | 2.341 |

| 8533 | 2.341 | 8051 | 2.325 |

| 9406 | 2.323 | 9293 | 2.311 |

| 10,147 | 2.316 | 10,284 | 2.306 |

| 11,174 | 2.288 | 11,259 | 2.280 |

| 12,092 | 2.265 | 11,980 | 2.245 |

| 13,068 | 2.225 | 12,997 | 2.209 |

| 14,055 | 2.183 | 14,006 | 2.159 |

| 15,096 | 2.128 | 15,047 | 2.117 |

| 15,635 | 2.106 | 15,617 | 2.103 |

| rpm | TC Cycle 1 (mm) | rpm | TC Cycle 2 (mm) |

| 14,998 | 2.139 | 15,049 | 2.116 |

| 14,001 | 2.171 | 14,039 | 2.152 |

| 13,030 | 2.207 | 13,028 | 2.203 |

| 12,050 | 2.253 | 12,009 | 2.256 |

| 10,941 | 2.293 | 10,996 | 2.283 |

| 10,028 | 2.317 | 10,006 | 2.315 |

| 9006 | 2.331 | 9024 | 2.342 |

| 8069 | 2.347 | 8004 | 2.354 |

| 7281 | 2.359 | 7226 | 2.358 |

| rpm | TC Cycle 3 (mm) | rpm | TC Cycle 4 (mm) |

| 15,055 | 2.117 | 15,039 | 2.117 |

| 14,007 | 2.151 | 14,028 | 2.151 |

| 13,022 | 2.192 | 13,043 | 2.202 |

| 11,997 | 2.245 | 11,997 | 2.240 |

| 11,014 | 2.274 | 10,980 | 2.273 |

| 10,006 | 2.317 | 10,006 | 2.315 |

| 9005 | 2.323 | 8942 | 2.321 |

| 8019 | 2.340 | 7962 | 2.336 |

| 6990 | 2.357 | 7011 | 2.351 |

| rpm | Mean TC (mm) | Mean TC (mm) * | Standard Deviation (µm) | Standard Deviation (µm) * |

|---|---|---|---|---|

| 7000 | 2.353 | 2.351 | 7 | 8 |

| 8000 | 2.339 | 2.339 | 9 | 9 |

| 9000 | 2.326 | 2.325 | 9 | 10 |

| 10,000 | 2.315 | 2.315 | 4 | 5 |

| 11,000 | 2.286 | 2.281 | 11 | 7 |

| 12,000 | 2.255 | 2.251 | 14 | 9 |

| 13,000 | 2.212 | 2.207 | 18 | 11 |

| 14,000 | 2.170 | 2.160 | 27 | 12 |

| 15,000 | 2.134 | 2.119 | 34 | 5 |

| 15,600 | 2.110 | 2.108 | 6 | 6 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García, I.; Przysowa, R.; Amorebieta, J.; Zubia, J. Tip-Clearance Measurement in the First Stage of the Compressor of an Aircraft Engine. Sensors 2016, 16, 1897. https://doi.org/10.3390/s16111897

García I, Przysowa R, Amorebieta J, Zubia J. Tip-Clearance Measurement in the First Stage of the Compressor of an Aircraft Engine. Sensors. 2016; 16(11):1897. https://doi.org/10.3390/s16111897

Chicago/Turabian StyleGarcía, Iker, Radosław Przysowa, Josu Amorebieta, and Joseba Zubia. 2016. "Tip-Clearance Measurement in the First Stage of the Compressor of an Aircraft Engine" Sensors 16, no. 11: 1897. https://doi.org/10.3390/s16111897

APA StyleGarcía, I., Przysowa, R., Amorebieta, J., & Zubia, J. (2016). Tip-Clearance Measurement in the First Stage of the Compressor of an Aircraft Engine. Sensors, 16(11), 1897. https://doi.org/10.3390/s16111897