1. Introduction

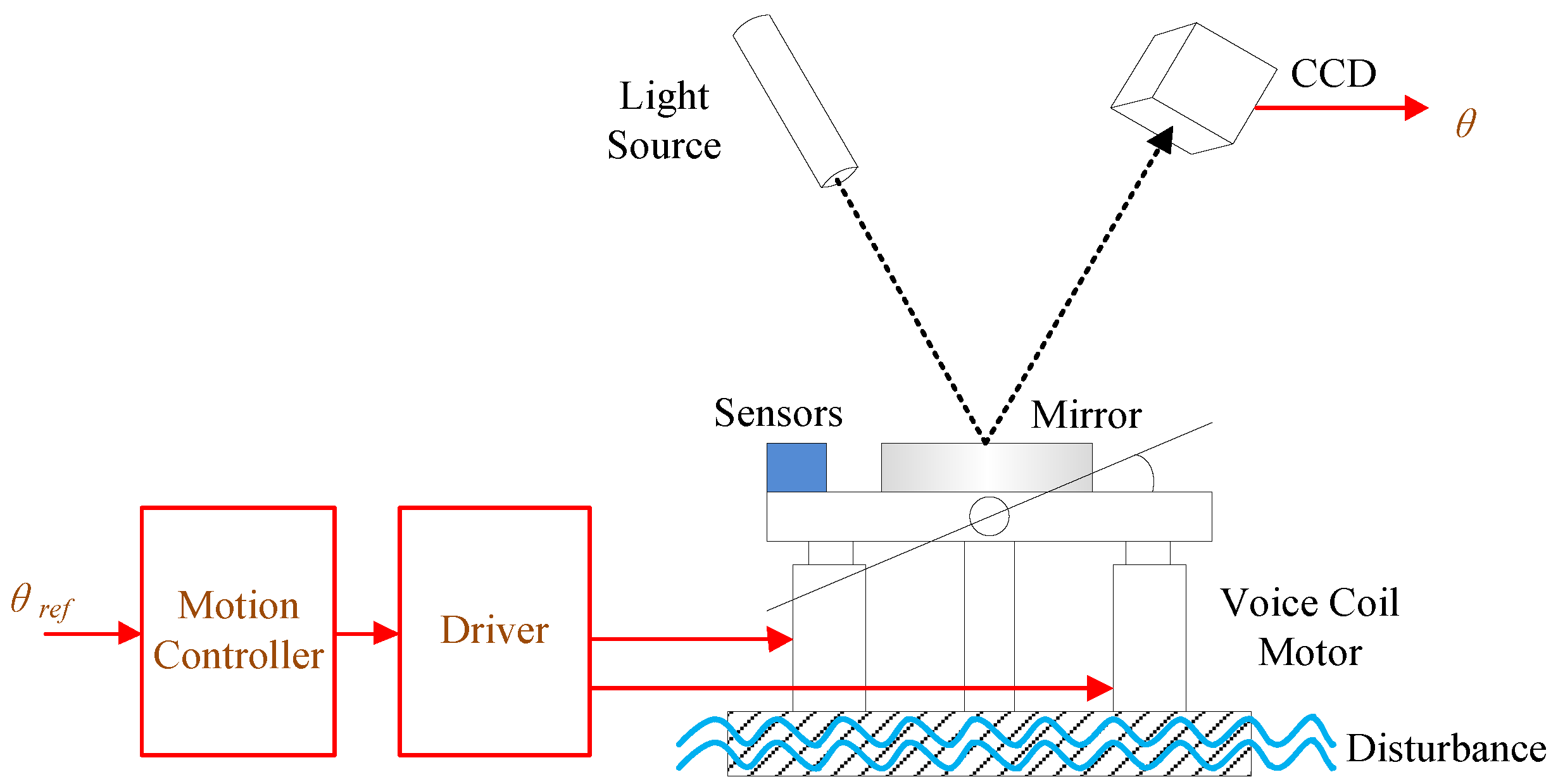

The fast steering mirrors (FSMs) play a critical role in optical fine tracking control systems, such as for adaptive optics, long-distance laser communication, line-of-sight (LOS) stabilization, which are increasingly mounted on vehicles, airplanes, spacecraft and other moving platforms [

1,

2,

3,

4]. In the classical FSM control system, the fiber-optic gyroscopes (FOGs) and charge-coupled devices (CCDs) are generally used to implement a dual closed-loop control to stabilize LOS [

5,

6]. High closed-loop bandwidth facilitates good closed-loop performance. However, the control bandwidth is limited mainly by mechanical resonances, time delay, and also the sensors’ noise.

With the development of the MEMS industry in recent years, the performance of micro-electro-mechanical system (MEMS) inertial sensors, including accelerometers and gyroscopes, have been rapidly improved [

7,

8]. Considering the installation position of the sensors limited to the narrow spaces of the reverse side of the mirror, both MEMS accelerometer and gyroscope can be mounted on the frame of FSM due to the relatively small size and low weight [

7,

8,

9,

10]. Usually, the bandwidth of MEMS gyroscopes with low noise is generally less than 100 Hz, which limits the bandwidth of the velocity closed-loop and the disturbance suppression ability; nevertheless, the bandwidth of MEMS accelerometers exceeds 800 Hz. Thus, the high bandwidth acceleration feedback loop implemented by two linear MEMS accelerometers can be used to improve the disturbance suppression ability of FSM control system [

7,

9].

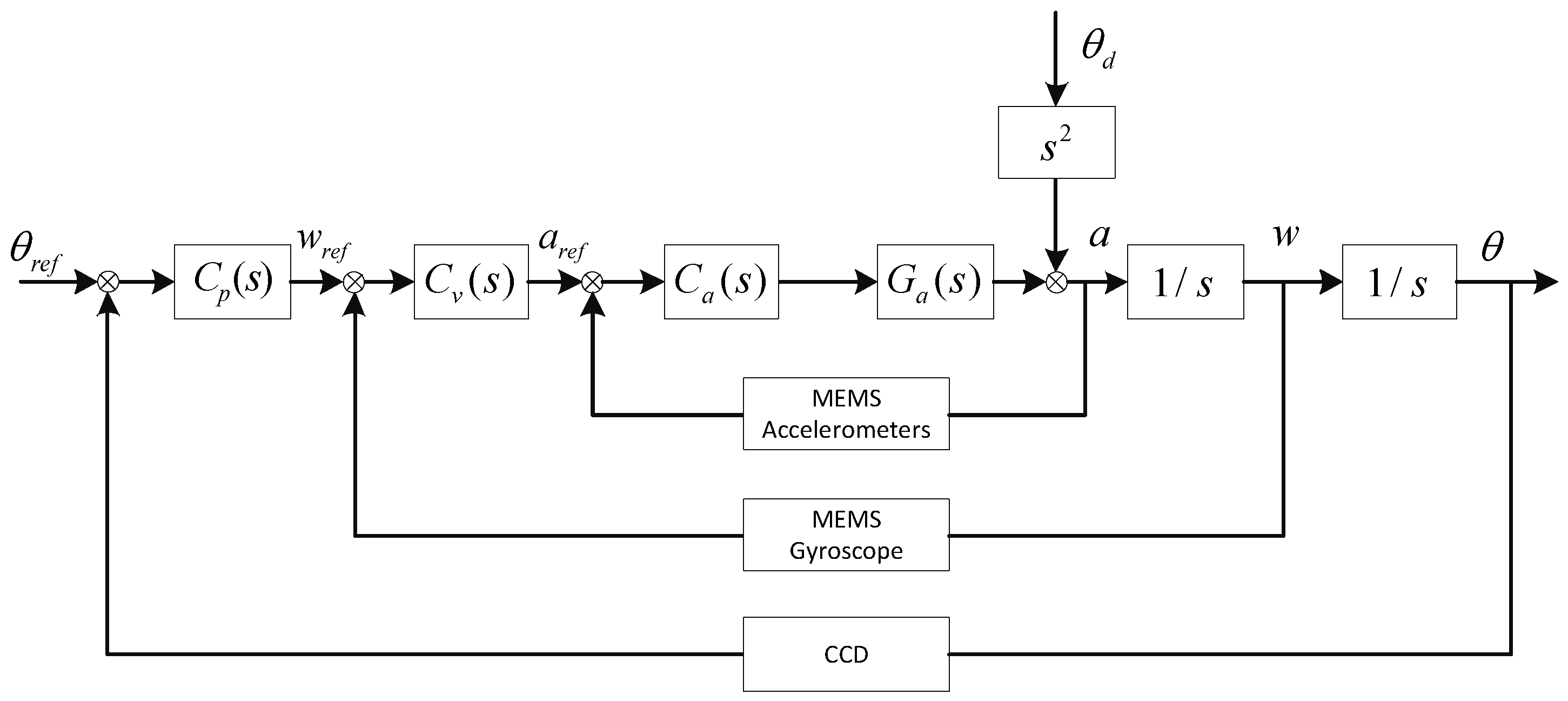

The acceleration feedback control (AFC) is a kind of high-precision robust control method to form multi-loop feedback control (MFC), which has been widely used in some high precision systems such as telescopes, missiles and robots [

11,

12,

13]. In FSM systems, the acceleration closed loop can improve the stiffness of the system. In previous works, some researchers focused on how to design the acceleration controller because of the quadratic differential in the FSM transfer model. To avoid the saturation of double integration, Tang designed the controller as a band-pass filter and combined a CCD and accelerometers to implement dual closed-loop control [

14]. Tian used a CCD, gyroscopes and accelerometers to implement a three-closed-loop control model, and a lag controller was used to accomplish acceleration control, which improved the disturbance suppression performance powerfully [

9,

15]. But the error rejection ability of the FSM system is still not adequate when suffering some uncertain disturbances, because of the mechanical resonances, CCD time delay and the drift noise in MEMS inertial sensors [

14].

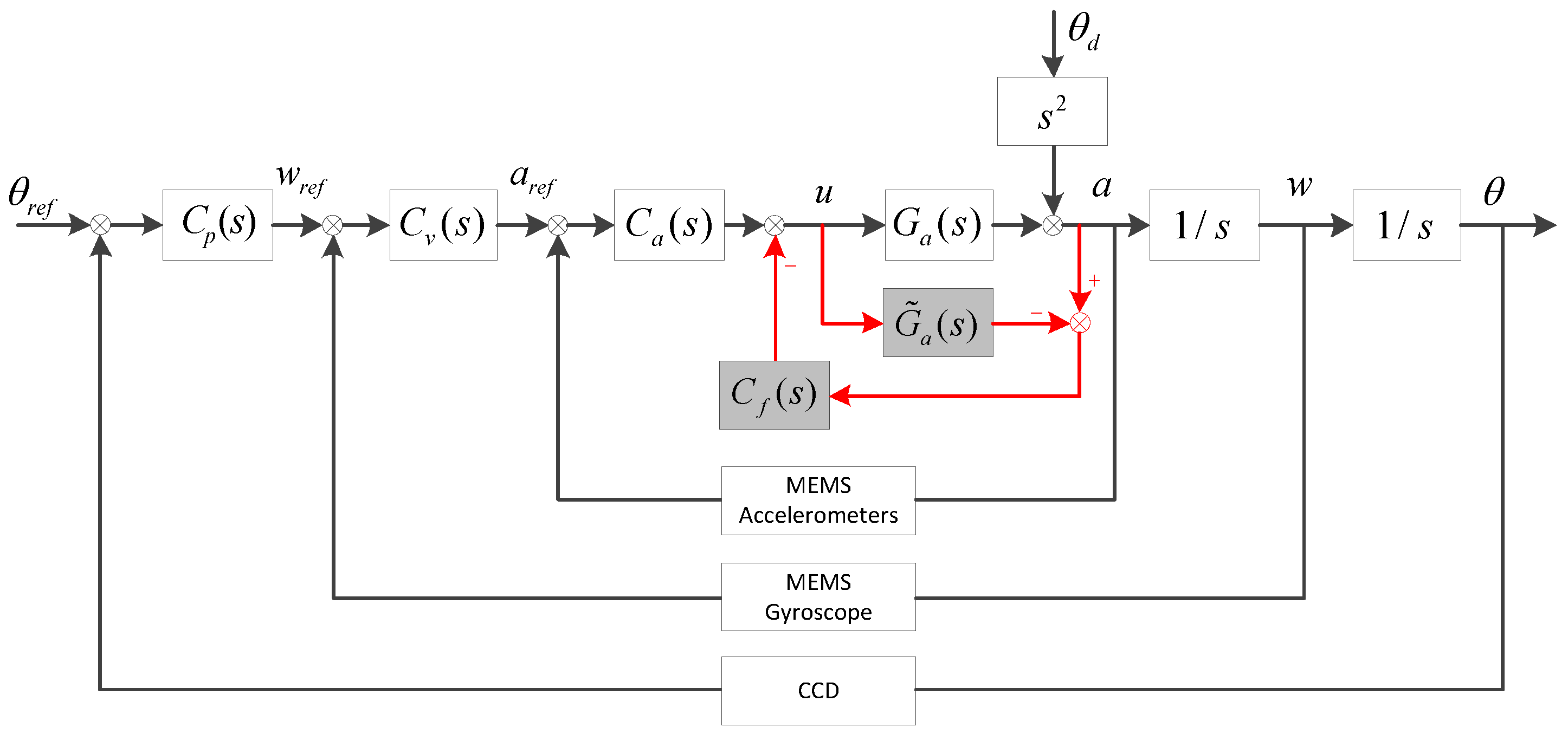

In this paper, to further enhance the stabilization performance, we proposed a new FSM stabilization control method, which combines the MFC with the disturbance observation and compensation (DOC) method. The MFC can be used to improve the stiffness of the FSM, and the DOC is utilized to estimate and compensate the outer base disturbance [

16,

17,

18,

19,

20]. The compensating precision of DOC mostly depends on the mathematical model of the controlled plant [

16,

17]. In FSM control systems, the acceleration response mathematical model can be achieved in high accuracy by a spectral analyzer, which is conducive to DOC fulfillment in practical systems. As a consequence, a detailed introduction to the model of the FSM is presented in

Section 2. And then the theory analysis and the controller design are shown in

Section 3 and

Section 4. The verification experiment is discussed in

Section 5. Concluding remarks are presented in

Section 6.

3. Performance Analysis

From the above derivation, the disturbance rejection characteristics of the MFC and the MFC enhanced by DOC are given clearly.

The disturbance rejection characteristics of the MFC can be presented as follows:

And the disturbance rejection characteristics of the MFC-DOC can be presented as follows:

where

is the controlled plant, while

is the approximate model of the controlled plant, which can be obtained by fitting the measured acceleration transfer function. By a spectral analyzer, the acceleration response of the FSM can be obtained in a high accuracy. Thus, we can easily get

, and it is clear that:

So, the denominators of

and

are almost equal, moreover, the denominators show the stability of the system, which means that the introduction of DOC method has an almost minimal effect on the stability of system. Spontaneously, when comparing with MFC, the disturbance rejection characteristics of MFC-DOC can be simplified as follows:

According to Equation (15), the disturbance compensation controller

is of great concern for the effect of DOC, and a zero error remain will be achieved in theory if the controller is designed to an ideal controller as follows:

The ideal DOC controller is the inverse transfer function of

, which can compensate disturbances in all frequencies in theory. As depicted in

Figure 3, the input of

is the estimate of disturbance force and the purpose of

is to convert the estimated disturbance force into the driver input, by which the disturbance compensation can be completed. After getting

, the ability of disturbance compensation depends primarily on the

design. The ideal DOC controller of FSM can be presented as follows:

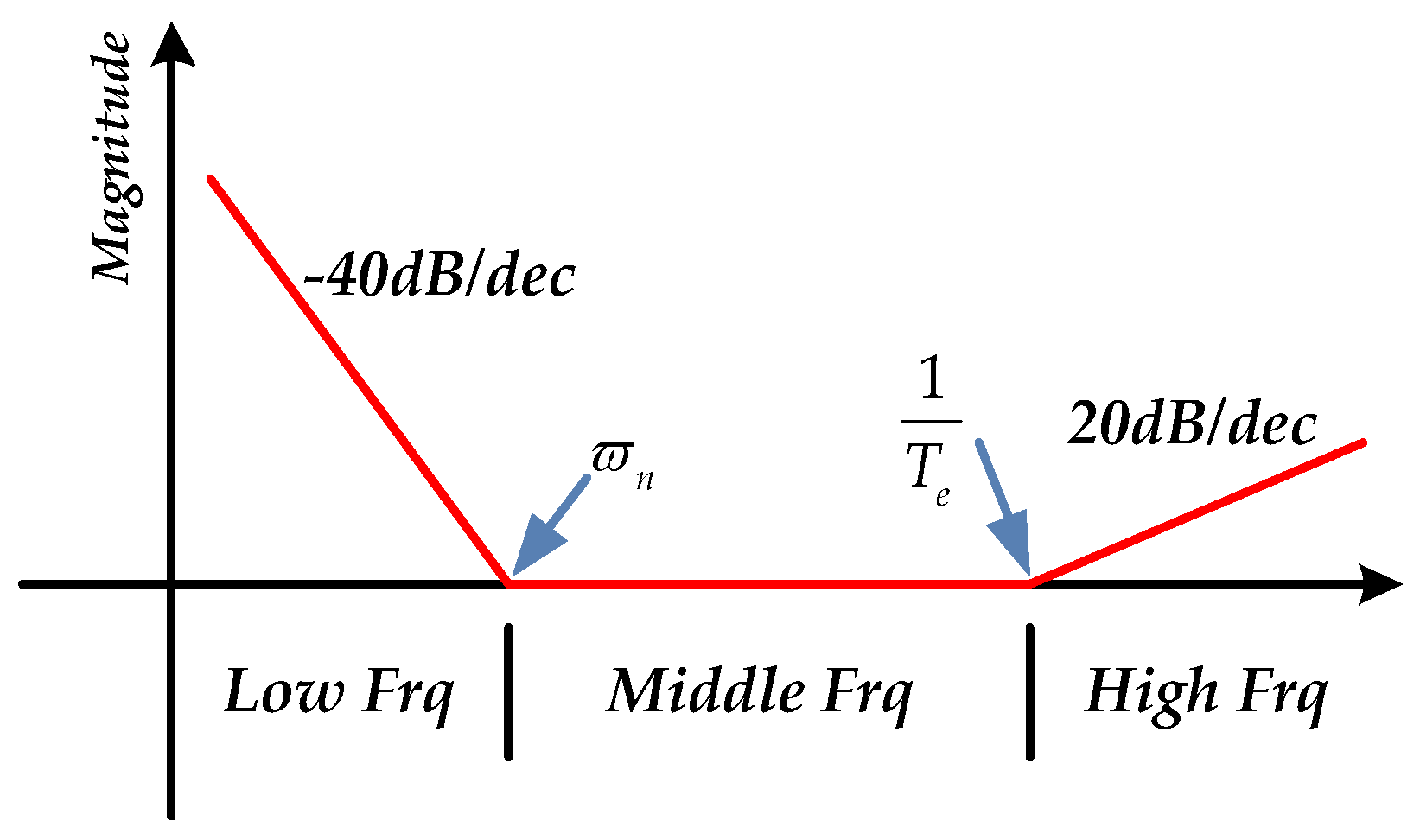

The open loop natural frequency of FSM

is approximately between several Hz to tens of Hz, and the damping factor

is much smaller than 1 [

1,

21]. Due to the high sampling frequency in FSM system, the electrical lag factor

is also much smaller than 1. Thus, it is easy to depict the diagrammatic sketch of the ideal DOC controller in frequency domain as shown in

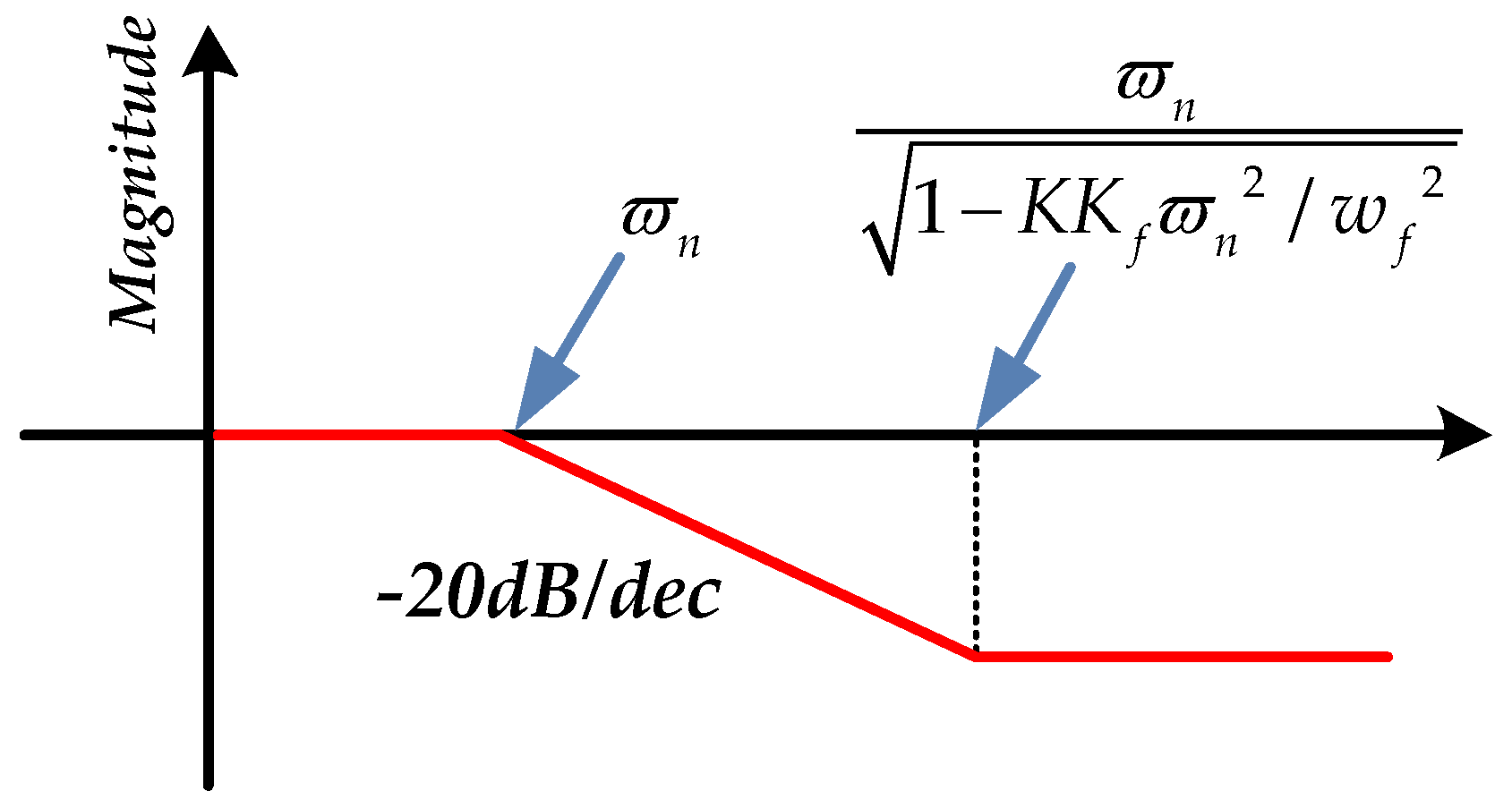

Figure 4.

The full frequency range is divided into three parts in

Figure 4, including low frequency, middle frequency and high frequency. Due to the double integration

and the second-order element, the DOC controller decreases in a slope to −40 dB at low frequency and remains constant at middle frequency. Because of the

element, it rises in a slope to 20 dB at high frequency. However, because of the low sensitivity of accelerometers at low frequency, the right estimated disturbance force is partly submerged in the noise, which causes the DOC controller to become saturated as a result of the quadratic integration influence. At high frequency, the disturbance effect is mostly restrained by the passive disturbance suppression of FSM platform. As the DOC controller can be regarded as a proportional controller at middle frequency, it is easy to realize it by a low-pass filter. Thus, to take advantage of the middle frequency, the DOC controller is designed in Equation (19):

where

is used to compensate phase lag. The second-order resonance element is used to filter the high-frequency noise of accelerometers and compensate the quadratic integration partly. Substituting Equations (1) and (19) into Equation (15), the disturbance rejection transfer function of MFC-DOC is presented as follows:

The damping factor

is much smaller than 1. The designed value of

should be much bigger than

, otherwise the bandwidth of the controller will be too low. Thus, the

can be simplified as follows:

In Equation (21), the disturbance rejection transfer function of MFC-DOC can be designed into a lead-lag corrector form, the diagrammatic sketch of which is depicted in

Figure 5.

As is shown in

Figure 5, the compensation at low frequency could be neglected because of the low sensitivity of accelerometers at low frequency. But when the FSM system is suffering middle or high frequency disturbance, it substantially improves the disturbance rejection ability. So without doubt, there will be:

It indicates that depending on the lead-lag controller design, the MFC-DOC method has a stronger disturbance rejection ability than the only MFC method; in other words, the system will suffer less influence from the outer disturbance and the remainder error of LOS reduces further.

With MFC-DOC, the sensitivity function of FSM becomes:

According to the previous demonstration, if the DOC controller is designed as Equation (19),

can be obtained [

9], which means that the introduction of DOC can also improve the robustness of the traditional MFC system. If the controlled model of the system changes substantially, the stability of the velocity loop with DOC will suffer less than that with MFC.

4. Controller Design

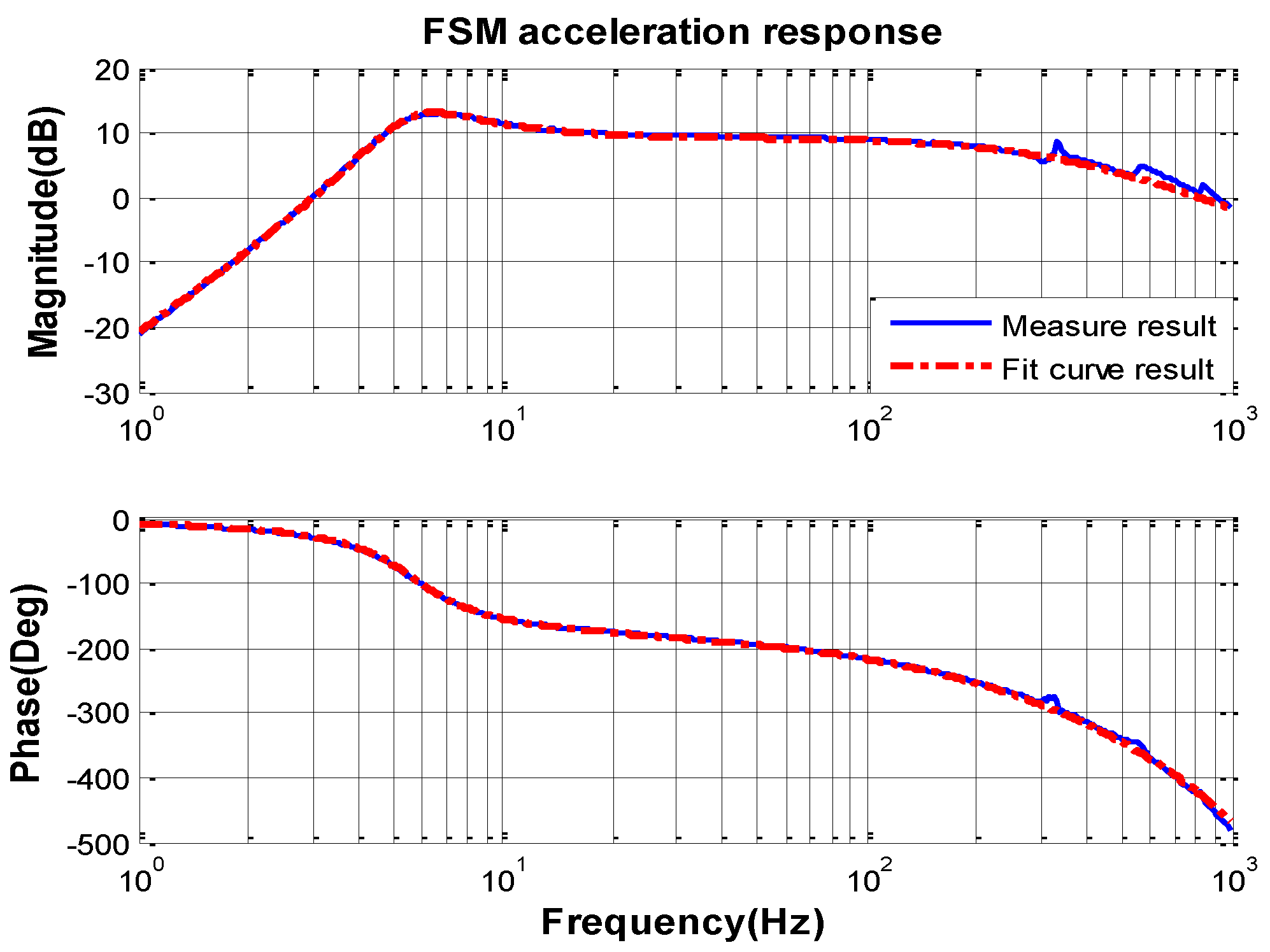

The opened loop characteristic of FSM acceleration response measured by spectral analyzer from 1 Hz to 1000 Hz is shown in

Figure 6.

Because of the high bandwidth of the MEMS accelerometer KXR94-2050 (Kionix, New York, NY, USA) [

24], the frequency characteristic can be measured to 1000 Hz. By the curve-fitting method and transfer function identification, the mathematic transfer function model of the FSM acceleration response can be obtained as follows:

It is obvious that the open loop natural frequency of FSM system

is about 6 Hz and the damping factor

is about 0.057. According to the previous analysis, the DOC controller can be designed as Equation (23). The natural frequency

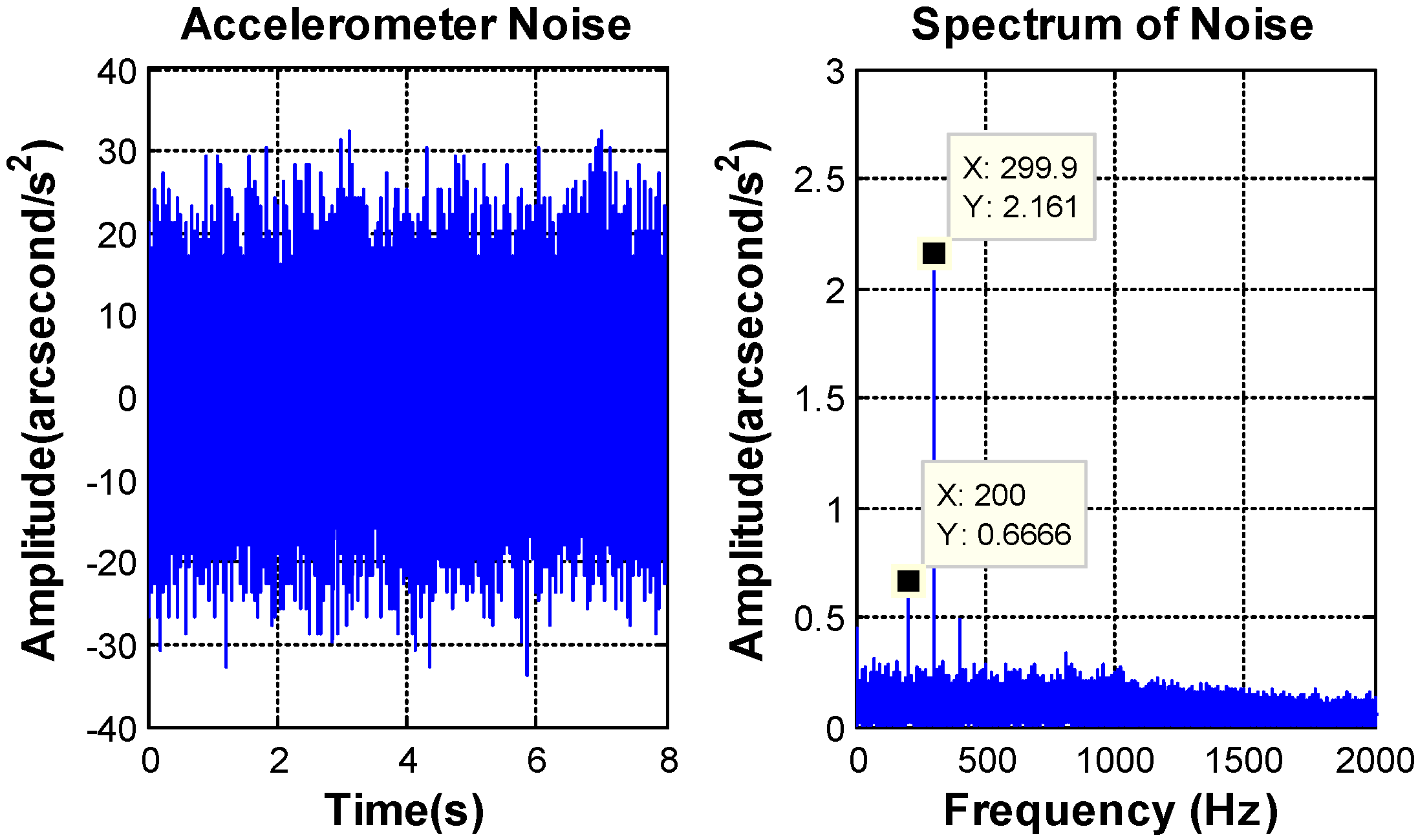

, which decides the bandwidth of the filter is chosen by the characteristics of the sensors noise. The bandwidth of the accelerometer is above 800 Hz and the characteristics of the accelerometer noise are depicted in

Figure 7.

The peak value of the MEMS accelerometer transformed noise is equal to 0.0097°/s

2, and the RMS value is about 0.0022°/s

2. Besides some “spikes”, the amplitude value of amplitude-frequency curve is smooth and the “spikes” are some high frequency noise, which could be filter out by the DOC controller. Considering the noise and the lag of filter, the bandwidth of DOC controller is designed at 40 Hz.

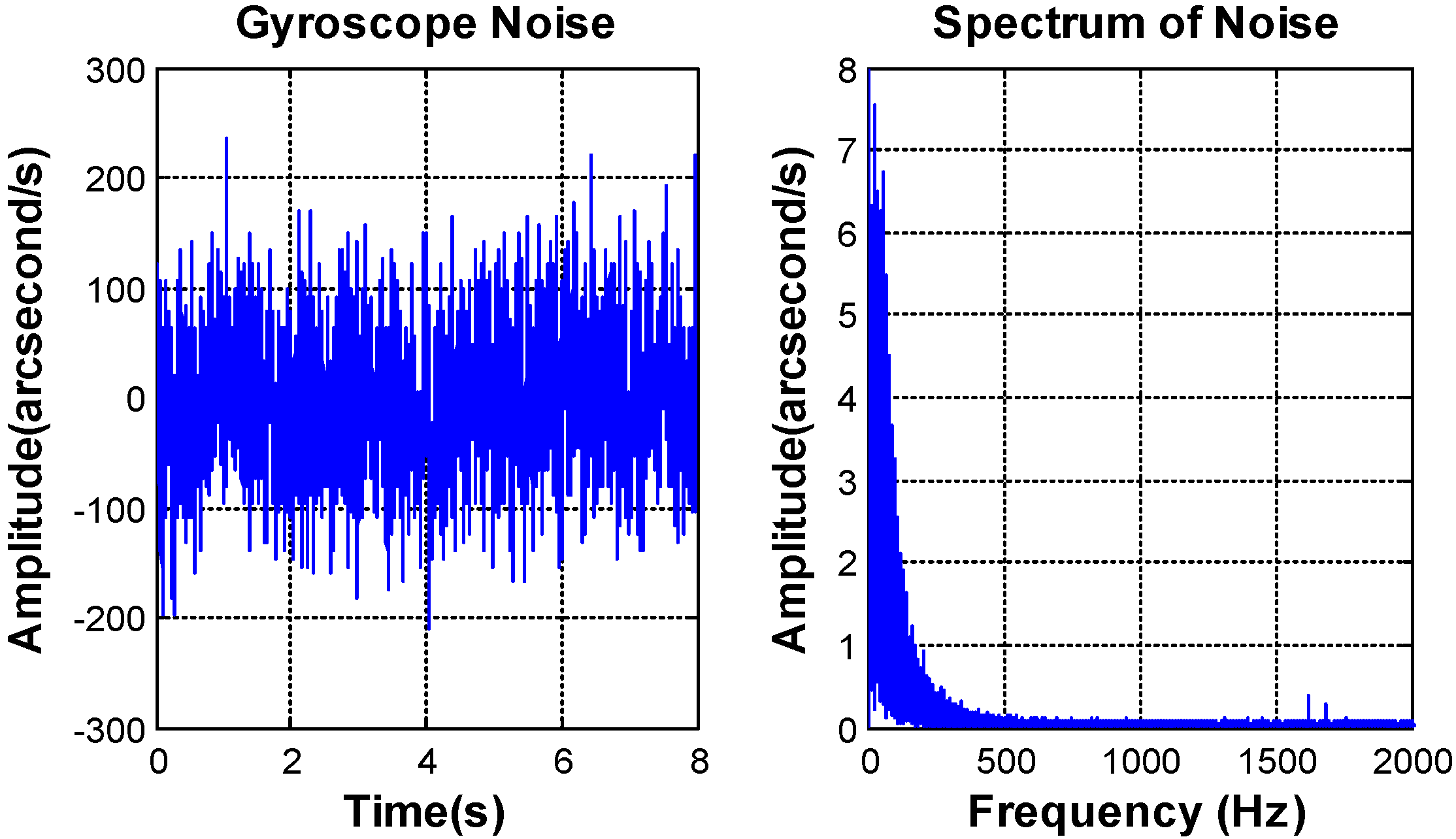

Figure 8 shows the characteristics of the MEMS gyroscope noise.

The bandwidth of the MEMS gyroscope SCR1100-D02 (Murata Manufacturing, Nagaokakyo, Kyoto) [

25] is less than 100 Hz. The noise mainly focuses on the frequencies ranging from 0 to 200 Hz. The peak value of the MEMS gyroscope noise is equal to 0.069°/s

2, and the RMS value is about 0.016°/s

2, which satisfy the requirement of the control system.

Thus, the DOC controller can be designed as follows:

where the damping factor

and the natural frequency

, which are both configured by the noise of sensors. To avoid the inaccurate control in acceleration closed loop, the acceleration controller is designed as follows [

15]:

With the completion of loop acceleration, the model of the FSM has been simplified. Therefore, the traditional PI controller can meet the velocity closed-loop and also the position closed-loop [

15].

5. Experimental Verification

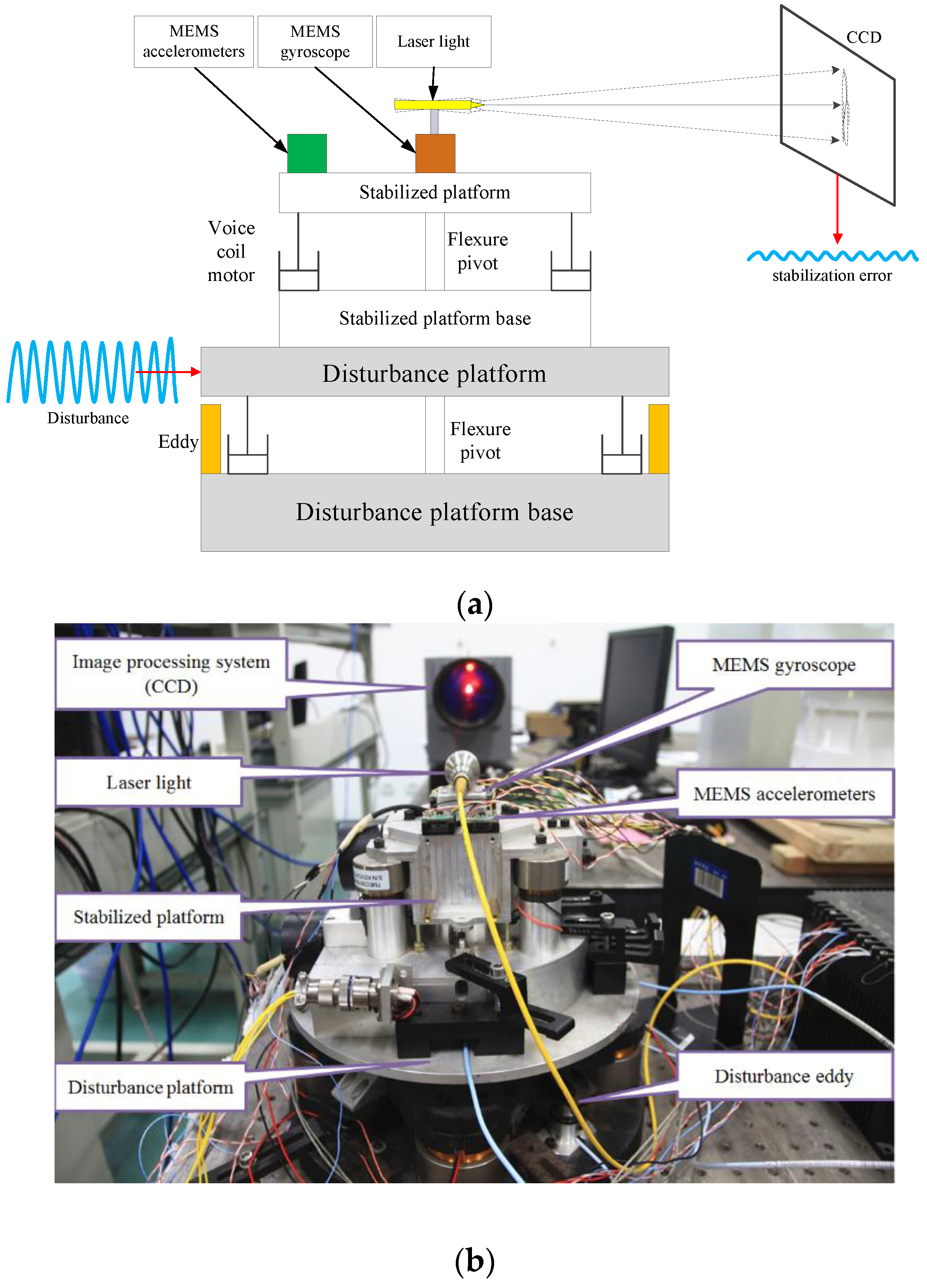

As shown in

Figure 9a, an apparatus constructed by two superimposed FSM systems is used to test and verify the previous analysis. One is used to stabilize the LOS; the other is used to simulate disturbance. The stabilized platform is mounted on the disturbance platform and the laser light is fastened on the top of stabilized platform directly as a reference of LOS. Both of the platforms are driven by the voice coil motors. The eddy sensors in the disturbance platform are used to measure the disturbance input of the stabilized platform and the CCD is used to obtain the stabilization error. Four MEMS linear accelerometers and one MEMS gyroscope are set on the stabilized platform to measure the angular acceleration and angular velocity, respectively. In the experiment, all of the MEMS inertial sensors and the disturbance eddies are at 5000 Hz sampling frequency, moreover, the CCD has only 100 Hz working frequency and 20 ms (two frames) time delay in addition.

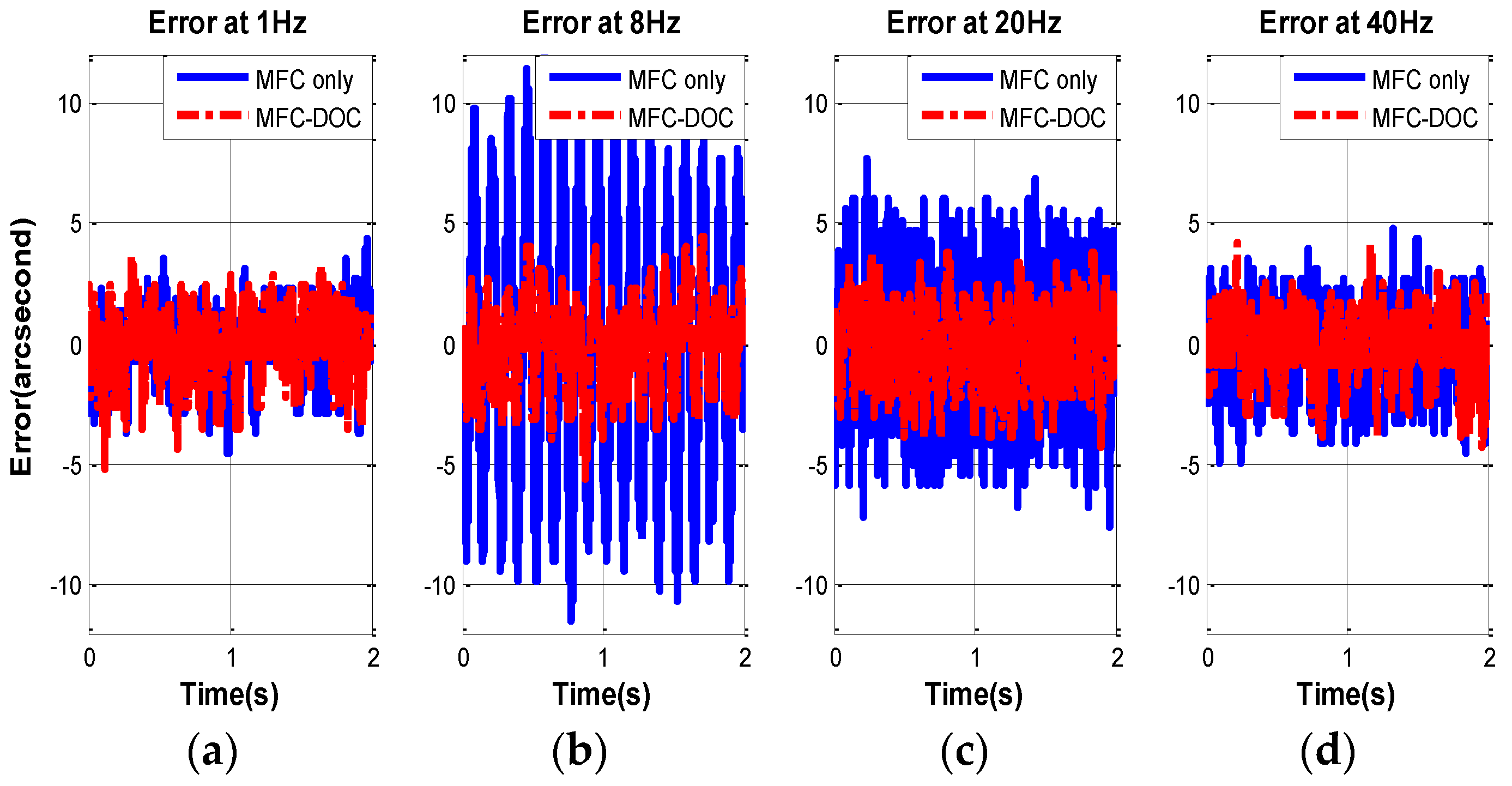

The disturbance suppression of FSM system is measured when the stabilized platform control is closed and the disturbance platform is opened. Then, four experiments in different frequency disturbance are compared as follows, and the error of MFC and MFC-DOC are given in

Figure 10 and

Table 1.

It is obvious that the disturbance suppression performance of MFC-DOC is almost equal to the MFC method at 1 Hz; however, it is improved heavily at 8 Hz and 20 Hz. Due to the passive disturbance suppression characteristics of the FSM platform, the disturbance effect has been mostly restrained, thus, it is the improvement at above 40 Hz is unapparent.

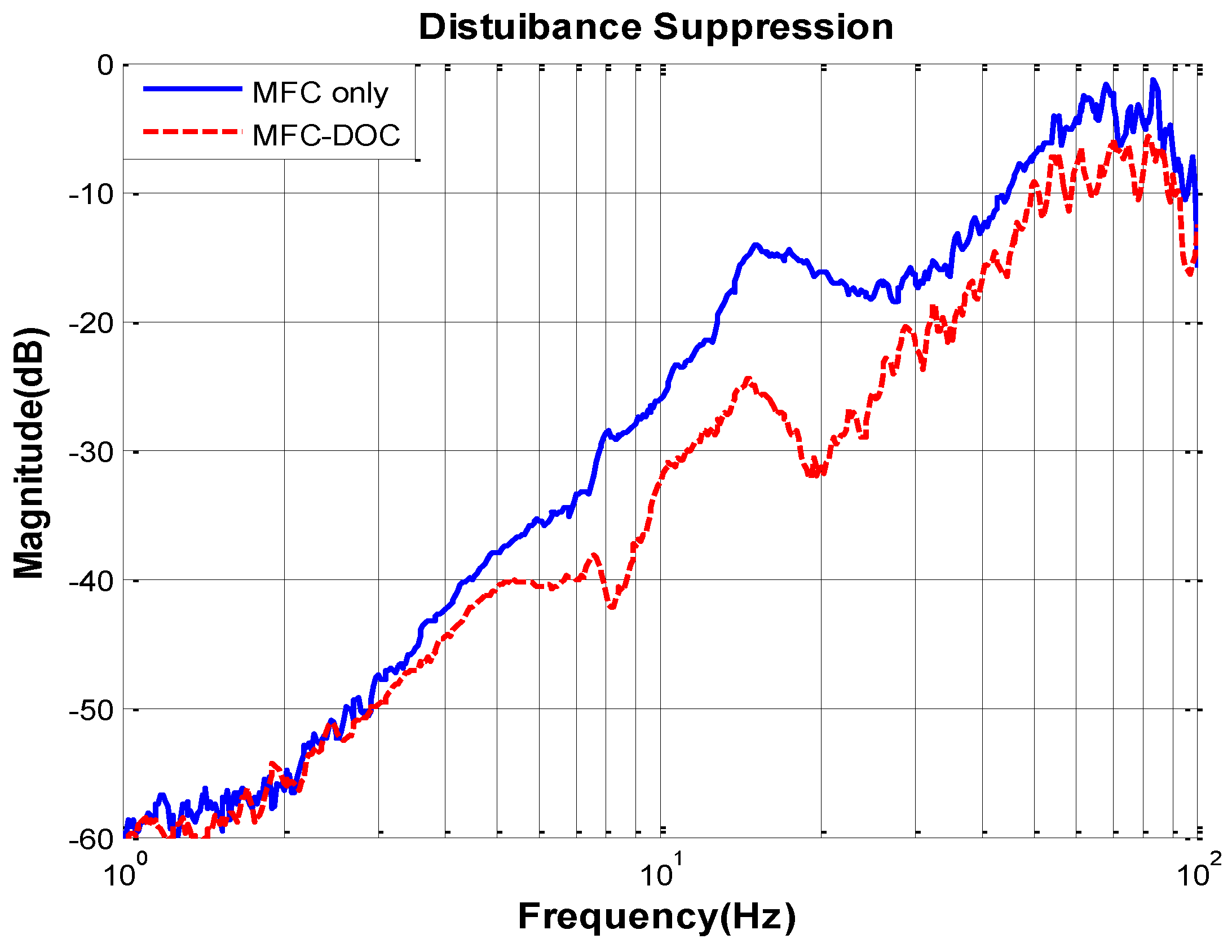

Simultaneously, the total disturbance suppression characteristic of the two methods, shown in

Figure 11, can be obtained. It can be clearly seen that the disturbance suppression of the FSM system has been improved heavily by DOC at middle frequency, while it almost has no effect at low frequency, which proves the previous analysis.

6. Conclusions

The disturbance rejection of LOS is the main purpose of the stabilization of the FSM control system. MEMS inertial sensors have been tried to use in the FSM system because of their relatively small size, low weight and low power consumption. In order to enhance the stabilization performance, the MFC is recommended to raise the stiffness of the FSM system and make stronger disturbance rejection. In this paper, to make further improvement of the stabilization performance, the optimization for MFC with DOC is proposed. The structure of this method is discussed and compared with only the MFC method, which has proved its advantages in theory. Simultaneously, the analysis of stabilization accuracy of this method is presented by contrasting experiments. A series of comparative experimental results show that the disturbance suppression performance of the FSM control system based on the MEMS inertial sensors can be effectively improved by the proposed method.

Future work will concentrate on improving the error attenuation performance of the LOS at low frequency. The use of gyroscopes may be an effective method to estimate the low frequency disturbance, which will be our next work. The sensor fusion of accelerometers and gyroscopes can also be under review.