Low-Cost Interrogation Technique for Dynamic Measurements with FBG-Based Devices

Abstract

:1. Introduction

2. Materials and Methods

2.1. Proposed Interrogator Operation Principle

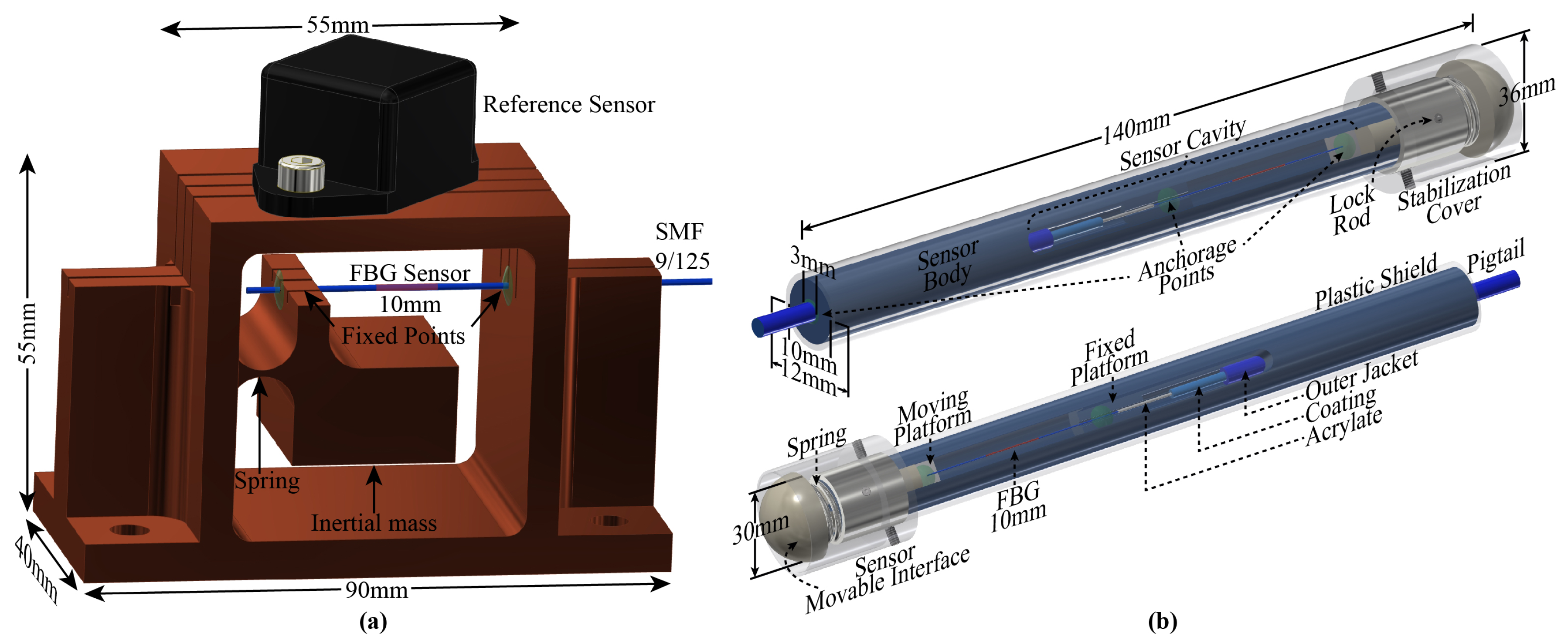

2.2. FBG-Based Sensors Used to Test the Interrogation System

3. Results

3.1. Optical Accelerometer

3.2. Carotid Pulse Waveform FBG-Based Device

3.3. Temperature Cross Sensitivity Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rodríguez, C.A.; Ribeiro, M.R.N.; Frizera-Neto, A.; Castellani, C.E.S.; Pontes, M.J. Envelope-based technique for liquid level sensors using an in-line fiber Mach-Zehnder interferometer. Appl. Opt. 2016, 55, 9803–9809. [Google Scholar] [CrossRef] [PubMed]

- Alberto, N.; Tavares, C.; Domingues, M.F.; Correia, S.F.H.; Marques, C.; Antunes, P.; Pinto, J.L.; Ferreira, R.A.S.; André, P.S. Relative humidity sensing using micro-cavities produced by the catastrophic fuse effect. Opt. Quantum Electron. 2016, 48, 216. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Peng, G.D.; Webb, D.J. Highly sensitive liquid level monitoring system utilizing polymer fiber Bragg gratings. Opt. Express 2015, 23, 6058–6072. [Google Scholar] [CrossRef] [PubMed]

- Domingues, M.F.; Tavares, C.; Leitão, C.; Neto, A.; Alberto, N.; Marques, C.; Radwan, A.; Rodriguez, J.; Postolache, O.; Rocon, E.; et al. Insole optical fiber Bragg grating sensors network for dynamic vertical force monitoring. J. Biomed. Opt. 2017, 22, 091507. [Google Scholar] [CrossRef] [PubMed]

- Antunes, P.; Dias, J.; Paixão, T.; Mesquita, E.; Varum, H.; André, P. Liquid level gauge based in plastic optical fiber. Measurement 2015, 66, 238–243. [Google Scholar] [CrossRef]

- Da Silva Marques, R.; Prado, A.R.; da Costa Antunes, P.F.; de Brito André, P.S.; Ribeiro, M.R.N.; Frizera-Neto, A.; Pontes, M.J. Corrosion resistant FBG-based quasi-distributed sensor for crude oil tank dynamic temperature profile monitoring. Sensors 2015, 15, 30693–30703. [Google Scholar] [CrossRef] [PubMed]

- Culshaw, B. Optical fibre sensors: A current perspective. Open Opt. J. 2013, 7, 21–31. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, Y.H.; Park, K.S.; Eom, J.B.; Kim, M.J.; Rho, B.S.; Choi, H.Y. Interferometric fiber optic sensors. Sensors 2012, 12, 2467–2486. [Google Scholar] [CrossRef] [PubMed]

- Hill, K.O.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Lightw. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Tosi, D. Advanced interrogation of fiber-optic Bragg grating and Fabry–Perot sensors with KLT analysis. Sensors 2015, 15, 27470–27492. [Google Scholar] [CrossRef] [PubMed]

- Othonos, A.; Kalli, K. Fiber Bragg Gratings: Fundamentals and Applications in Telecommunications and Sensing; Artech House: Norwood, MA, USA, 1999. [Google Scholar]

- Holmes, C.; Carpenter, L.G.; Gates, J.C.; Smith, P.G.R. Miniaturization of Bragg-multiplexed membrane transducers. J. Micromech. Microeng. 2012, 22, 025017. [Google Scholar] [CrossRef]

- Holmes, C.; Gates, J.C.; Smith, P. Integrated optical differential pressure transducers achieved using thin buckled silica membranes and direct UV written planar Bragg gratings. Sens. Actuators A 2011, 168, 14–21. [Google Scholar] [CrossRef]

- Tiwari, U.; Thyagarajan, K.; Shenoy, M.R.; Jain, S.C. EDF-based edge-filter interrogation scheme for FBG sensors. IEEE Sens. J. 2013, 13, 1315–1319. [Google Scholar] [CrossRef]

- Sengupta, D.; Kishore, P. Continuous liquid level monitoring sensor system using fiber Bragg grating. Opt. Eng. 2014, 53, 017102. [Google Scholar] [CrossRef]

- Kouroussis, G.; Kinet, D.; Mendoza, E.; Dupuy, J.; Moeyaert, V.; Caucheteur, C. Edge-filter technique and dominant frequency analysis for high-speed railway monitoring with fiber Bragg gratings. Smart Mater. Struct. 2016, 25, 075029. [Google Scholar] [CrossRef]

- Zhao, Y.; Liao, Y. Discrimination methods and demodulation techniques for fiber Bragg grating sensors. Opt. Lasers Eng. 2004, 41, 1–18. [Google Scholar] [CrossRef]

- Alfonso, J.E.; Cárdenas, L.G.; Triana, C.A.; Durán, M.V. Design of an optical sensing interrogator using an edge filter scheme. In Proceedings of the 2013 SBMO/IEEE MTT-S International Microwave & Optoelectronics Conference (IMOC), Rio de Janeiro, Brazil, 4–7 August 22013; pp. 1–5. [Google Scholar]

- Kersey, A.D. Interrogation and multiplexing techniques for fiber Bragg grating strain sensors. In Proceedings of the Optical Tools for Manufacturing and Advanced Automation, Boston, MA, USA, 30 December 1993; Volume 2071, pp. 30–49. [Google Scholar]

- Cui, J.; Hu, Y.; Feng, K.; Li, J.; Tan, J. FBG interrogation method with high resolution and response speed based on a reflective-matched FBG scheme. Sensors 2015, 15, 16516–16535. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Semenova, Y.; Sun, A.; Wang, P.; Farrell, G. High resolution temperature insensitive interrogation technique for FBG sensors. Opt. Laser Technol. 2010, 42, 653–656. [Google Scholar] [CrossRef]

- Roncancio, J.S.; González, N.; Cano, C.C.; Varón, M. Low cost optical interrogation system based on FBG sensors. In Proceedings of the 2015 SBMO/IEEE MTT-S International Microwave and Optoelectronics Conference (IMOC), Porto de Galinhas, Brazil, 3–6 November 2015; pp. 1–5. [Google Scholar]

- Guo, T.; Tam, H.Y.; Albert, J. Chirped and tilted fiber Bragg grating edge filter for in-fiber sensor interrogation. In Proceedings of the CLEO: 2011-Laser Science to Photonic Applications, Baltimore, MD, USA, 1–6 May 2011; p. CThL3. [Google Scholar]

- Fallon, R.; Zhang, L.; Everall, L.; Williams, J.; Bennion, I. All-fibre optical sensing system: Bragg grating sensor interrogated by a long-period grating. Meas. Sci. Technol. 1998, 9, 1969. [Google Scholar] [CrossRef]

- Antunes, P.F.; Domingues, M.F.F.; Alberto, N.J.; André, P. Optical fiber microcavity strain sensors produced by the catastrophic fuse effect. IEEE Photonics Technol. Lett. 2014, 26, 78–81. [Google Scholar] [CrossRef]

- André, P.; Domingues, F.; Alberto, N.; Marques, C.; Antunes, P. Recycling optical fibers for sensing. In Proceedings of the 2016 SPIE, Brussels, Belgium, 3–7 April 2016; Volume 9899, pp. 98991F-1–98991F-5. [Google Scholar]

- Antunes, P.; Varum, H.; André, P. Uniaxial fiber Bragg grating accelerometer system with temperature and cross axis insensitivity. Measurement 2011, 44, 55–59. [Google Scholar] [CrossRef]

- Leitão, C.; Antunes, P.; Bastos, J.M.; André, P.; Pinto, J.L. In the trail of a fiber Bragg grating sensor to assess the central arterial pressure wave profile. In Proceedings of the Fifth European Workshop on Optical Fibre Sensors, Krakow, Poland, 20 May 2013; Volume 8794, pp. 87941C-1–87941C-4. [Google Scholar]

- Leitão, C.; Antunes, P.; André, P.; Pinto, J.L.; Bastos, J.M. Central arterial pulse waveform acquisition with a portable pen-like optical fiber sensor. Blood Press. Monit. 2015, 20, 43–46. [Google Scholar]

- Leitão, C.; Antunes, P.; Pinto, J.; Mesquita Bastos, J.; André, P. Optical fiber sensors for central arterial pressure monitoring. Opt. Quantum Electron. 2016, 48, 218. [Google Scholar] [CrossRef]

- Ikhlef, A.; Hedara, R.; Chikh-Bled, M. Uniform fiber Bragg grating modeling and simulation used matrix transfer method. Int. J. Comput. Sci 2012, 9, 368–374. [Google Scholar]

- André, P.S.; Facâo, M.; Rocha, A.M.; Antunes, P.; Martins, A. Evaluation of the fuse effect propagation in networks infrastructures with different types of fibers. In Proceedings of the 2010 Conference on Optical Fiber Communication (OFC/NFOEC), Collocated National Fiber Optic Engineers, San Diego, CA, USA, 21–25 March 2010; pp. 1–3. [Google Scholar]

- Rocha, A.M.; da Costa Antunes, P.F.; Maria de Fátima, F.D.; Facao, M.; de Brito André, P.S. Detection of fiber fuse effect using FBG sensors. IEEE Sens. J. 2011, 11, 1390–1394. [Google Scholar] [CrossRef]

- Antunes, P.; Lima, H.F.; Alberto, N.J.; Rodrigues, H.; Pinto, P.M.; de Lemos Pinto, J.; Nogueira, R.N.; Varum, H.; Costa, A.G.; de Brito André, P.S. Optical fiber accelerometer system for structural dynamic monitoring. IEEE Sens. J. 2009, 9, 1347–1354. [Google Scholar] [CrossRef]

- Leitão, C.; Antunes, P.; Bastos, M.J.; Pinto, J.L.; André, P. Optical fiber sensors in arterial pulse waveform acquisition. In Proceedings of the Second International Conference on Applications of Optics and Photonics, Aveiro, Portugal, 22 August 2014; Volume 9286, pp. 92864O-1–92864O-4. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz, C.A.R.; Leitão, C.; Marques, C.A.; Domingues, M.F.; Alberto, N.; Pontes, M.J.; Frizera, A.; Ribeiro, M.R.N.; André, P.S.B.; Antunes, P.F.C. Low-Cost Interrogation Technique for Dynamic Measurements with FBG-Based Devices. Sensors 2017, 17, 2414. https://doi.org/10.3390/s17102414

Díaz CAR, Leitão C, Marques CA, Domingues MF, Alberto N, Pontes MJ, Frizera A, Ribeiro MRN, André PSB, Antunes PFC. Low-Cost Interrogation Technique for Dynamic Measurements with FBG-Based Devices. Sensors. 2017; 17(10):2414. https://doi.org/10.3390/s17102414

Chicago/Turabian StyleDíaz, Camilo A. R., Cátia Leitão, Carlos A. Marques, M. Fátima Domingues, Nélia Alberto, Maria José Pontes, Anselmo Frizera, Moisés R. N. Ribeiro, Paulo S. B. André, and Paulo F. C. Antunes. 2017. "Low-Cost Interrogation Technique for Dynamic Measurements with FBG-Based Devices" Sensors 17, no. 10: 2414. https://doi.org/10.3390/s17102414