1. Introduction

Over the past few decades, moving-base gravity gradiometers have been recognized as a viable solution for geodetic surveys [

1,

2], resource exploration [

2,

3,

4,

5], and inertial navigation [

6,

7,

8]. The basic configuration of the rotating gravity gradiometer instrument (GGI) is an accelerometer complement consisting of two pairs of accelerometers. Their sensitive axes are tangential to the rotary disk. Each pair of accelerometers is set diametrically opposite to the other, in order to reject the common-mode linear acceleration perpendicular to the rotating axis, and to double the gradient signal. The two pairs of accelerometers are mounted orthogonally to each other. Their summed outputs are subtracted to suppress the angular acceleration around the rotating axis, and to double the gradient signal again. However, the performance of common-mode acceleration suppression depends on the precise matching of the accelerometers [

4,

5,

9,

10]. In terms of the need to maintain consistency of the sensitivities of state-of-the-art accelerometers, lack of online adjustment makes it difficult to meet such strict requirements [

4,

10]. In addition, the matching of the accelerometers is difficult to maintain for an extended period because of material aging, temperature variance, and electronic component instabilities, etc. The dynamic adjustment method for each configured accelerometer is a basic and necessary technology for GGI development.

In our previous experiment, we developed a quartz-flexure accelerometer with a high-performance electrostatic servo-controlled actuator. The electrostatic accelerometer adjusts the scale factor by trimming the electrostatic bias voltages [

10]. This method has the advantage of ease of operation, and no extra trimming assembly process is needed. However, the input range of the electrostatic accelerometer is about 10 mg (1 g ≈ 9.8 m/s

2), which is too small for a full tensor gradient measurement. When considering the full tensor measurement application, using magnetic force to rebalance the accelerometer with a large measuring range might be a better choice. The modified Model VII accelerometer used in Bell’s GGI is one specific application [

4,

5]. To adjust the scale factor dynamically, the accelerometer is disassembled, and an additional trimming coil is wound around the permanent magnet [

11,

12]. An appropriate current is calculated, which flows through the trimming coil to change the strength of the magnetic field acting on the torque coil. Thus, the scale factor can be adjusted. However, imperfect assembly will cause more nonlinear and cross-coupling effects, and the current in the trimming coil may cause extra unwanted heat effects, which will affect the relative permeability of the magnet. Hence, the stability of the magnetic field in the feedback loop will deteriorate.

By combining the advantages of the aforementioned methods, we propose a scale factor trimming method for a magnetic force rebalance accelerometer. An additional trimming current proportional to the feedback current is injected into the torque coil. The scale factor varies with that proportional coefficient, and the calibration results verify the validity of the trimming method. The method trims the feedback current instead of changing the strength of the magnet; hence, it needs no extra assembly and is easy to operate.

2. The Principle of the Scale Factor Adjustment Method by Trimming the Feedback Current

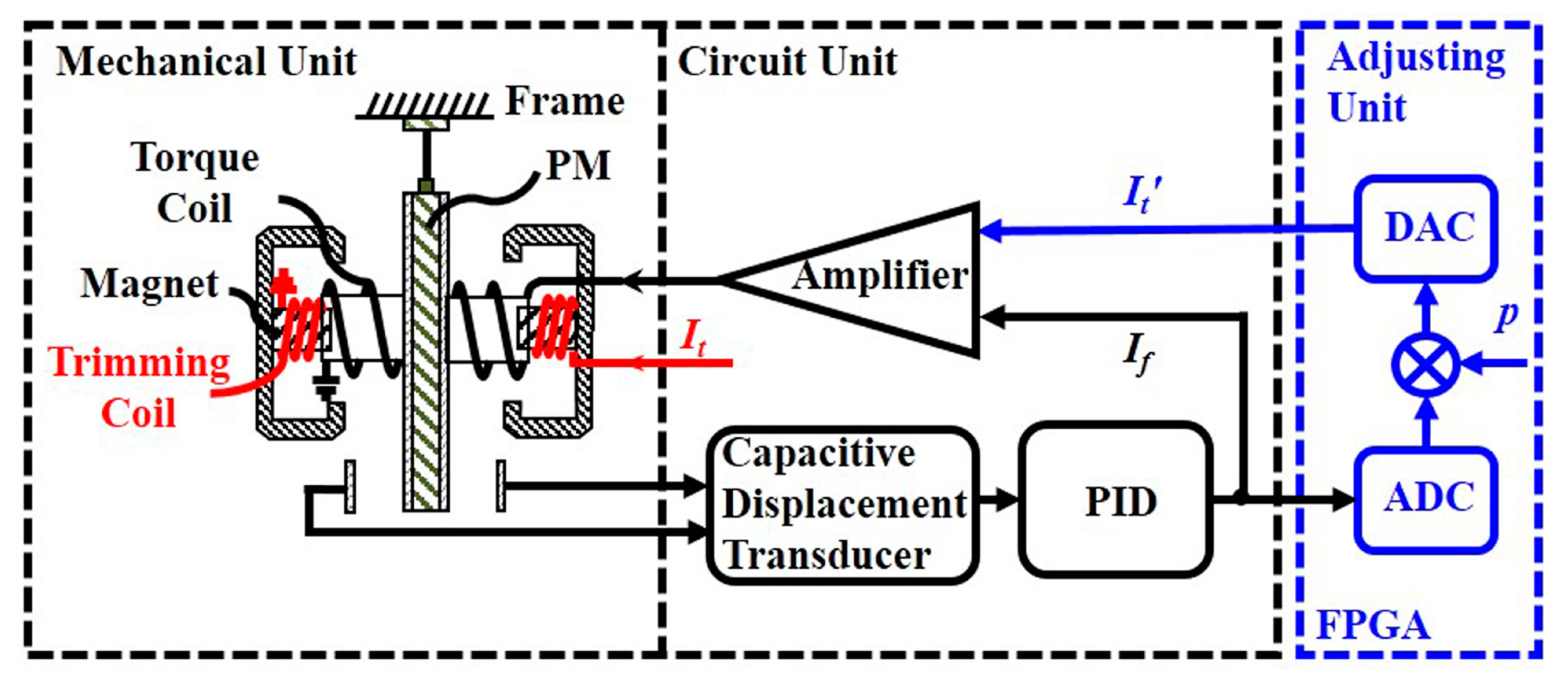

The diagram of a magnetic force rebalance accelerometer with scale factor trimming is illustrated in

Figure 1. The magnetic force rebalance accelerometer consists of two units: the mechanical unit and the circuit unit. In the mechanical unit, the proof mass (PM) is suspended by a thin cantilever spring within a homogeneous magnetic field. The PM, which is coated with gold, works as a moving capacitive plate. The moving capacitive plate and the two fixed plates form a pair of differential capacitors. A couple of torque coils are distributed symmetrically on the PM. A permanent magnet is mounted in each fixed plate. Due to external acceleration, the PM will move with respect to the frame. The motion of the PM is sensed by the capacitive displacement transducer [

10,

13]. In the feedback path, a digital proportional integral differential (PID) controller provides a current

If related to the movement of the PM. The current

If flows through the torque coil and generates an equal and opposite force to compensate the movement. The related signal

If is therefore taken as the output of the accelerometer.

The force rebalance equation of the accelerometer is given by

where

m is the mass of the PM,

a is the input acceleration,

N is the number of turns of the torque coil,

B0 is the strength of the permanent magnet, and

L is the circumference of the torque coil. The physical parameters of the accelerometer appears in

Table 1.

Thus, the transfer function from acceleration to feedback current, called the scale factor, can be derived to be

In Bell’s scheme (red,

Figure 1), an additional trimming coil is wound around the permanent magnet to adjust the scale factor. The current

It flowing through the trimming coil generates an additional magnetic strength ∆

B. Hence, the magnetic field in which the torque coil acts is strengthened or weakened. Therefore, the force rebalance equation varies with the strength of the magnetic field, and the feedback force is given by

Substituting the initial scale factor

Ki0 into the Equation (3), the trimmed scale factor

Ki has the following relationship

From Equation (4), the scale factor varies with ΔB, thus it is adjusted by varying It.

Bell’s scale factor adjustment method requires the disassembly of the mechanical unit so an additional trimming coil can be wound around the permanent magnet. To meet the gradient measurement requirement, the assembly of the accelerometer also needs to achieve a high degree of precision. The distance between the moving plate and fixed plates needs to be controlled with a precision greater than 100 μm [

4]. Therefore, every single piece of the assembly process is very delicate. Imperfect assembly will generate nonlinear and cross-coupling output components, thus degrading the performance of the accelerometer.

By combining the advantages of the scale factor adjustment method of the electrostatic accelerometer used in our previous experiment [

10] and the magnetic force rebalance accelerometer in Bell’s scheme [

4,

12], we can provide the adjustment principle as highlighted in the blue box in

Figure 1. The output current

If is acquired with an Analog-Digital-Converter (ADC), multiplied by a scale proportionality coefficient

p provided by the Field Programmable Gate Array (FPGA) according to the actual requirement, and subsequently transferred to analog current

with a Digital–Analog Converter (DAC). The adjustment current

and the feedback current

If are summed and injected into the torque coil to rebalance the PM. The adjusting current

and the feedback current

If satisfy the relationship

Thus, the total current

Itot injected into the torque coil consists of two parts,

If and

, and they satisfy the relationship given by

Then, the feedback force will be given by

In this case, the scale factor

and proportionality coefficient

p satisfies the following relationship,

where

Ki’ is the scale factor after trimming the feedback current. It can be seen from the expressions that the acceleration-to-current transfer function varies with the coefficient

p. Comparing Equation (8) with Equation (4), we find that these two methods have similar formulas for the scale factor and are adjustable in common.

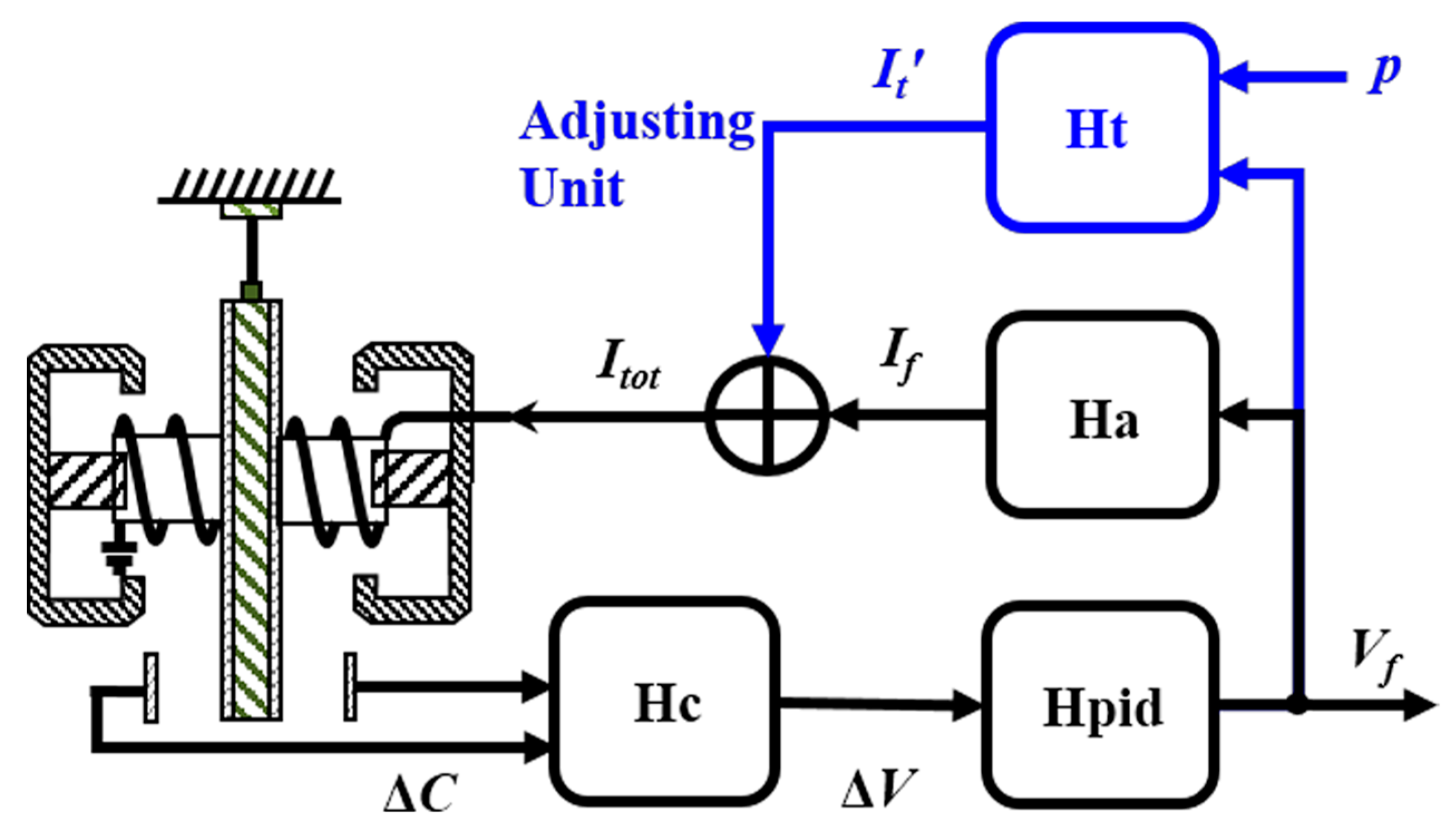

The block of the trimmed accelerometer, as shown in

Figure 2, clearly demonstrates the changes in the circuit unit. The transfer functions of the capacitive displacement transducer, PID, the gain of the feedback voltage-to-current (V-I) amplifier and the adjusting V-I amplifier are written as

Hc,

Hpid,

Ha and

Ht, respectively. The gain of

Ht is adjustable by FPGA, and must satisfy the relationship

Ht =

p ×

Ha to ensure that Equation (5) is satisfied. After that, the adjusting current

and the output current

If are summed as

Itot and injected into the torque coil. To trim the scale factor of the accelerometer, all that needs to be done is to change the proportional coefficient

p in FPGA.

3. Experimental Verification

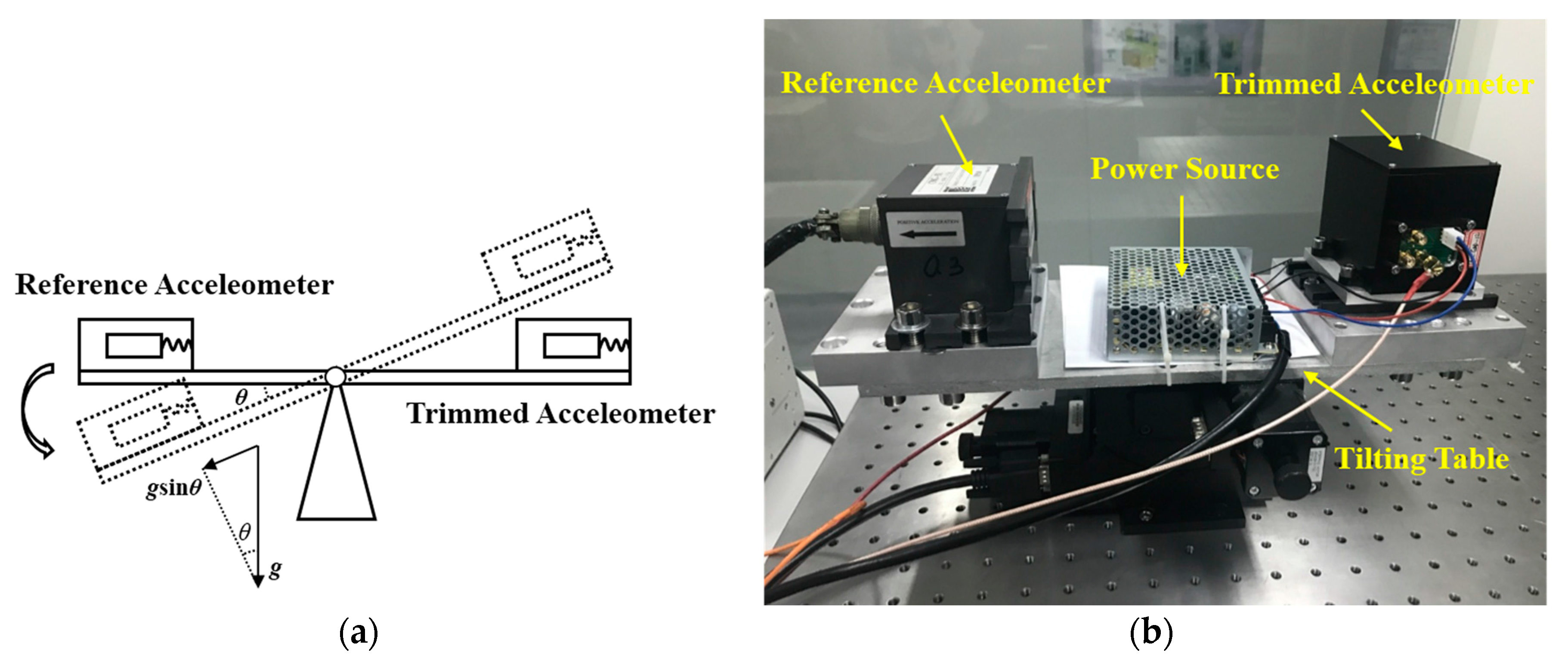

To verify the effectiveness of the scale factor adjustment method by trimming the feedback current, the accelerometers are calibrated by tilting their sensitive axes in a local gravity field with a commercial accelerometer as reference [

13,

14]. Both of the two accelerometers were mounted on a tilt table with their sensitive axes perpendicular to the tilt axis, as shown in

Figure 3. The input axes of the accelerometers were changed relative to the gravity vector, with a series of different tilt angles

èi. The adjustment unit (blue,

Figure 1) consists of a digital circuit with a high-precision, 20-bit ADC AD7703, FPGA, and 20-bit DAC AD5791.

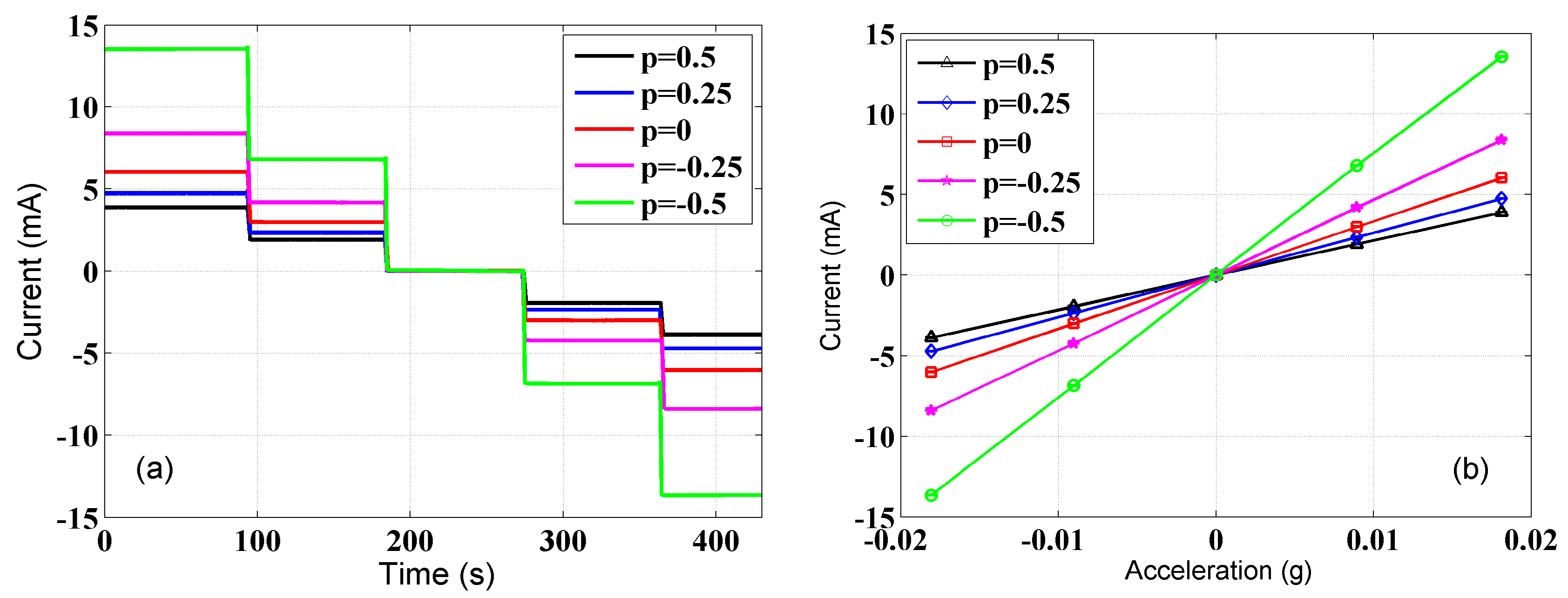

The data of the trimmed accelerometer and reference accelerometer were not collected until the system established temperature equilibrium with the environment and the sensors settled down in their positions. To calibrate the accelerometer, the input acceleration and the output current of the trimmed accelerometer need to be recorded at the same time. The input acceleration can be calculated based on the output voltage and the scale factor of the reference accelerometer given by

ain =

Vout/

K, where

Vout and

K are the output voltage and the scale factor of the reference accelerometer respectively. The scale factor of the reference accelerometer used was 100 V/g. The tilt table was inclined an additional angle of about 9 mrad each time, and was kept still for about 90 s at each position to record the data. The calibration results are shown in

Figure 4. The output currents of the trimmed accelerometer with different proportional coefficient

p vary with time, as shown in

Figure 4a. When taking the input acceleration derived from the output of the reference accelerometer as the

x-axis and the output current of the trimmed accelerometer as the

y-axis, accordingly, the slope of the line is the scale factor of the trimmed accelerometer, as shown in

Figure 4b.

To verify the new adjustment method directly, Equation (8) is transformed to

, and we plot the ratio of

varying with the coefficient

p, as shown in

Figure 5. We find that the point where

p = 0 corresponds to the initial scale factor

Ki0 of the accelerometer. By a least-squares linear fitting, the result is

, which results in good agreement with the expected value. The fitting results verify the proposed scale factor adjustment method. The changes of the scale factor are 33% smaller at

p = 0.5 and 100% larger at

p = −0.5 than the original one, which is in perfectly experimental agreement with Equation (8). In general cases of GGI, the scale factors of the accelerometers are able to achieve a consistency of ±10%, which corresponds to the range of

p from +0.11 to −0.09. The scale factor balance loop would be able to calculate an appropriate coefficient

p for each accelerometer in the GGI automatically [

10]. Thus, this method would meet the requirement to expediently adjust the scale factor of the accelerometers in the development of the GGI.

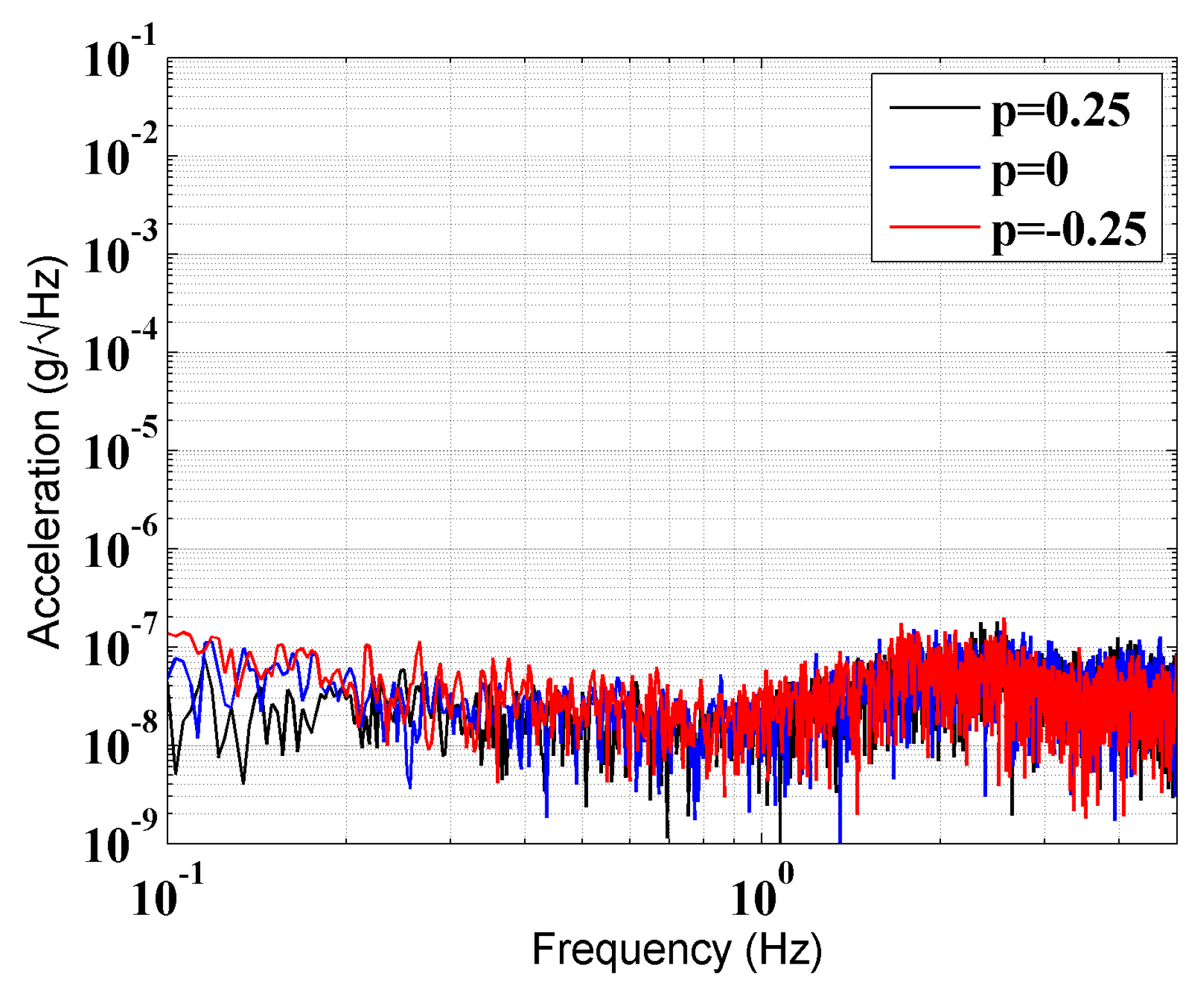

The noise level of the accelerometer is one of the key features of the GGI. However, the adjustment unit may introduce additional noise into the close-loop transfer function of the accelerometer. To determine whether the adjustment unit would deteriorate the noise level of the accelerometer, a static noise test was done. The trimmed accelerometer was mounted in our cave laboratory, where the vibration of the floor is relatively low, and the fluctuation of the temperature is lower than 0.03 K/day [

15]. The acceleration spectral density (ASD) with different

p was as shown in

Figure 6. No obvious change in the noise level was observed in the frequency range from 0.2 to 1 Hz, in which the accelerometers would be kept rotating in the GGI.