Assessment of Embedded Conjugated Polymer Sensor Arrays for Potential Load Transmission Measurement in Orthopaedic Implants

Abstract

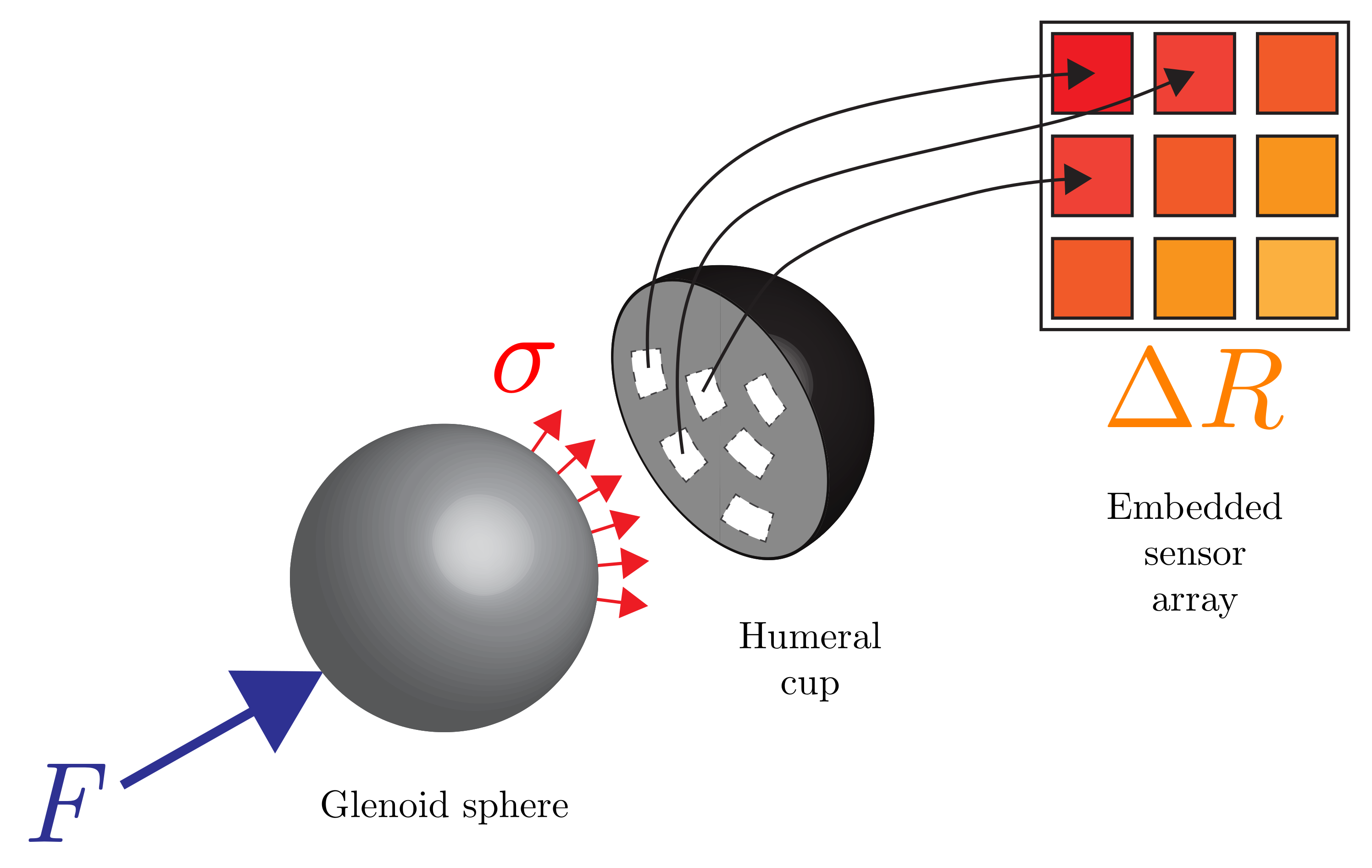

:1. Introduction

2. Materials and Methods

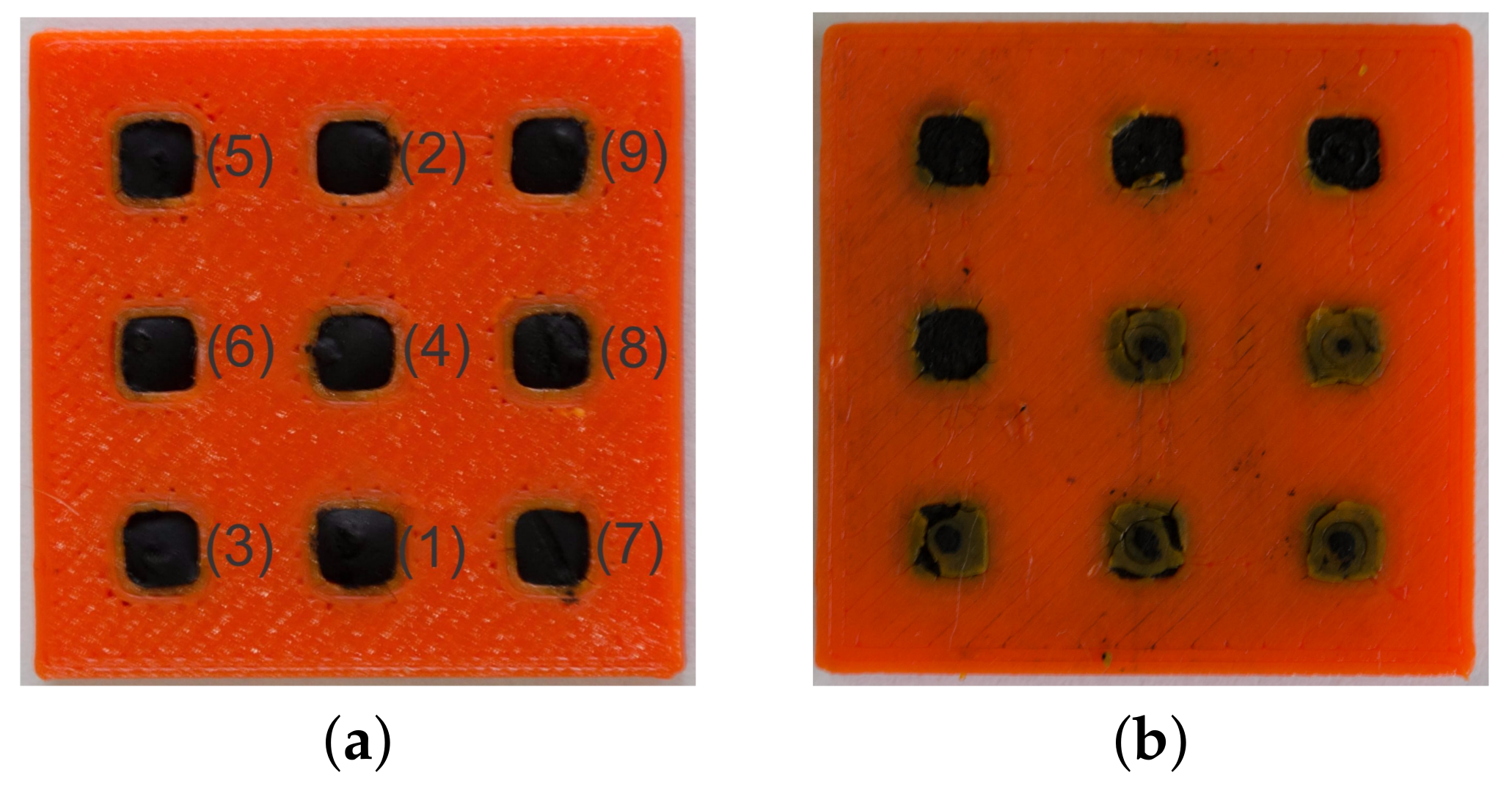

2.1. Design and Fabrication

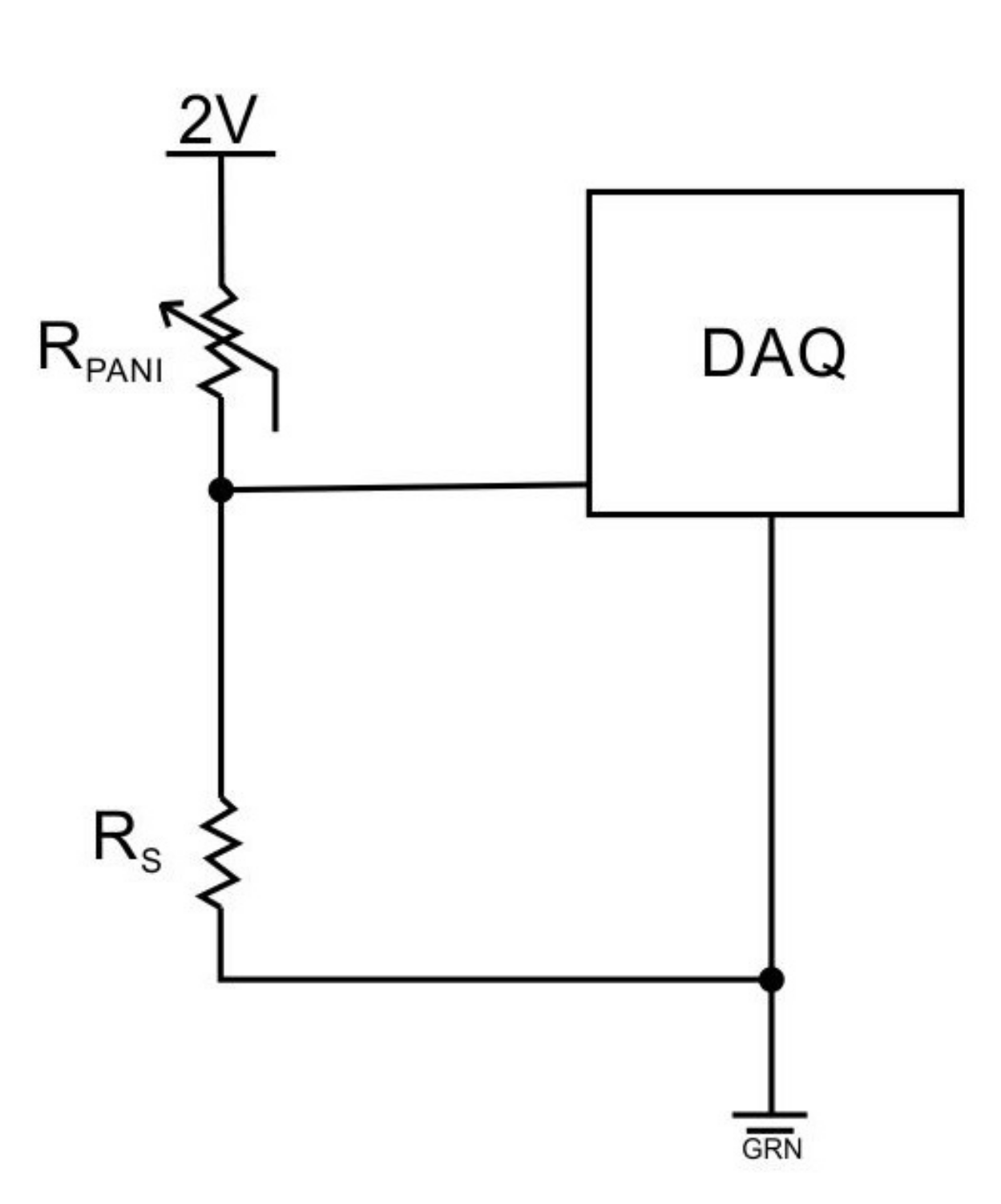

2.2. Signal Acquisition and Processing

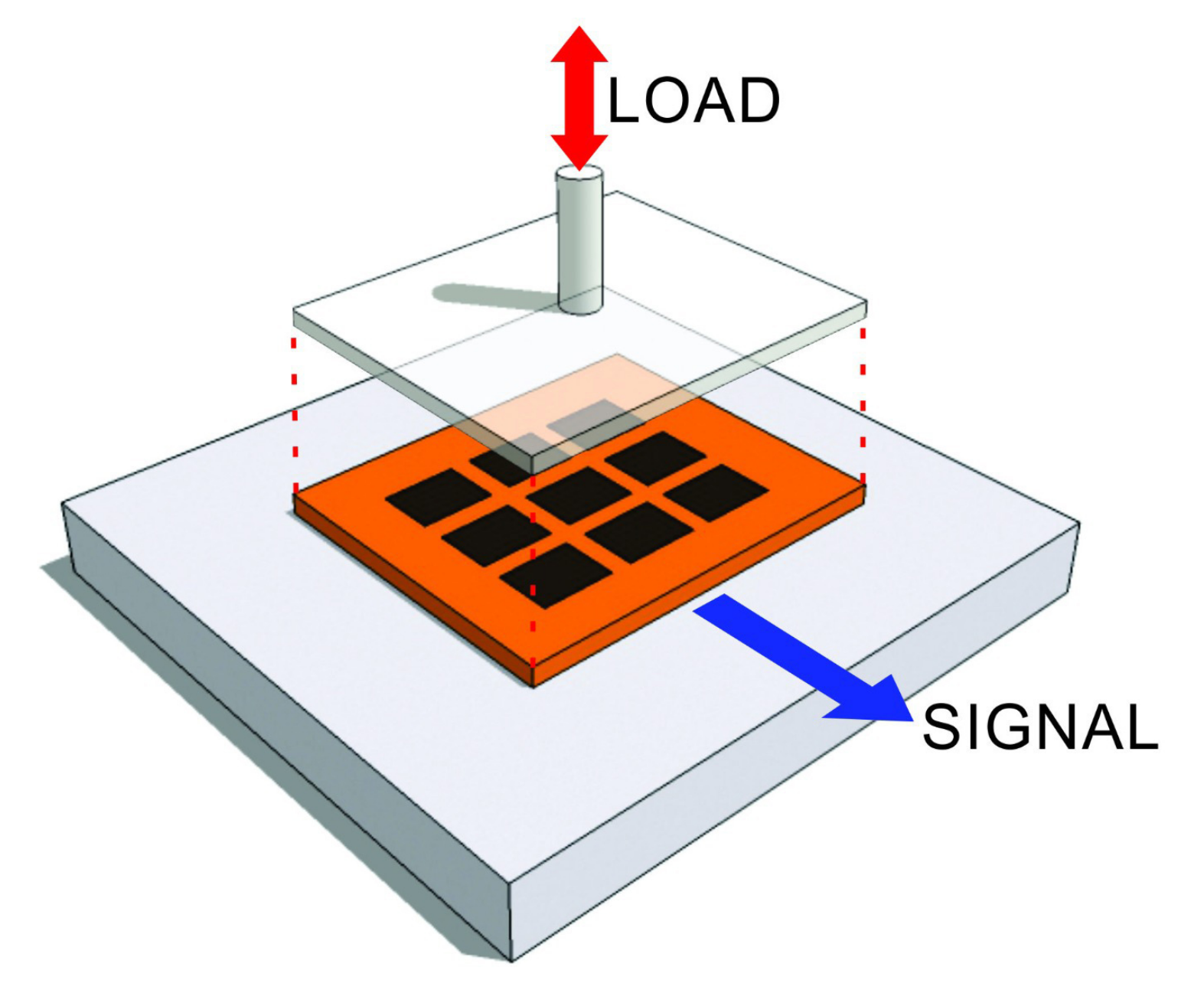

2.3. Calibration Apparatus

2.4. Sensor Array Characterization

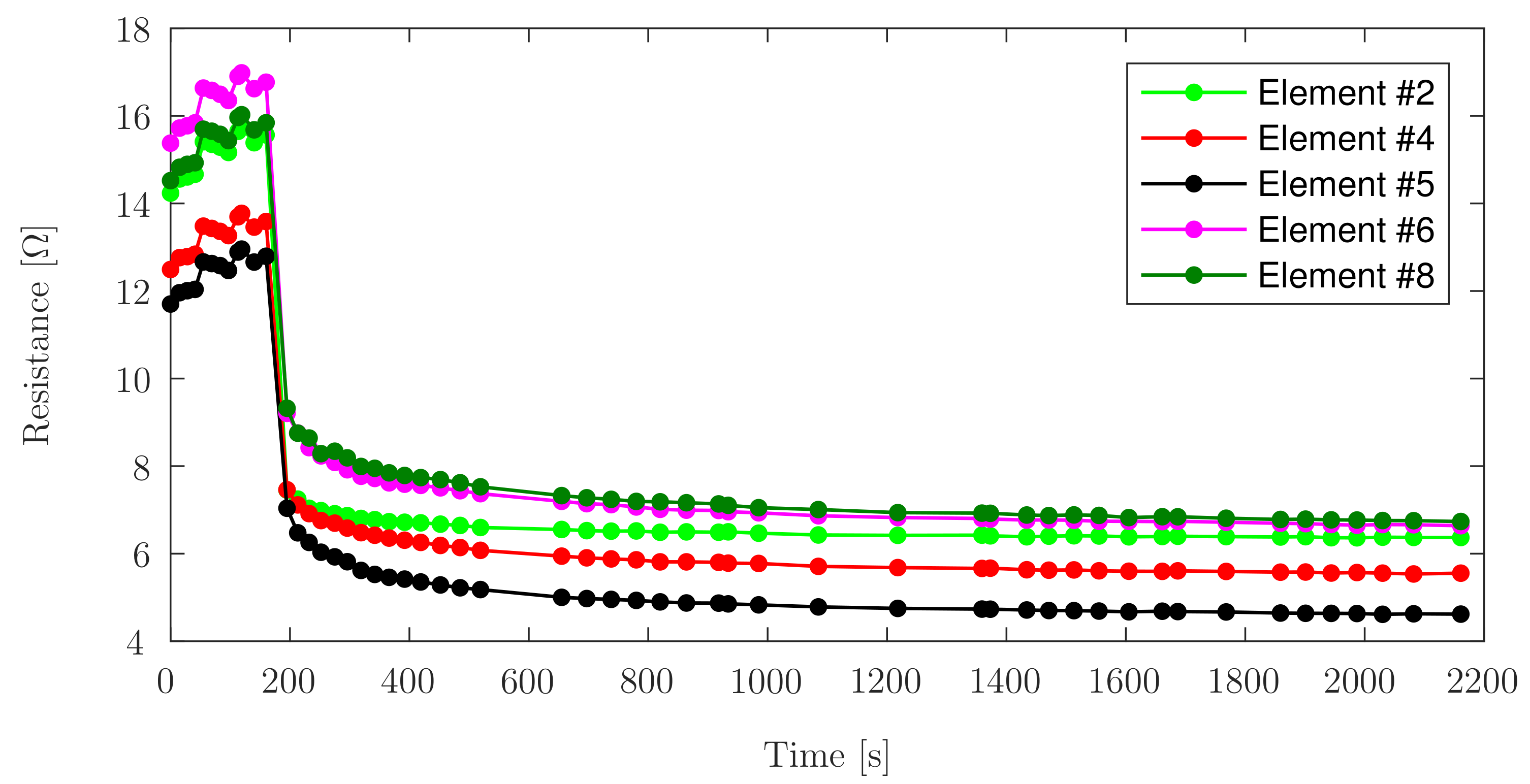

2.4.1. Stability

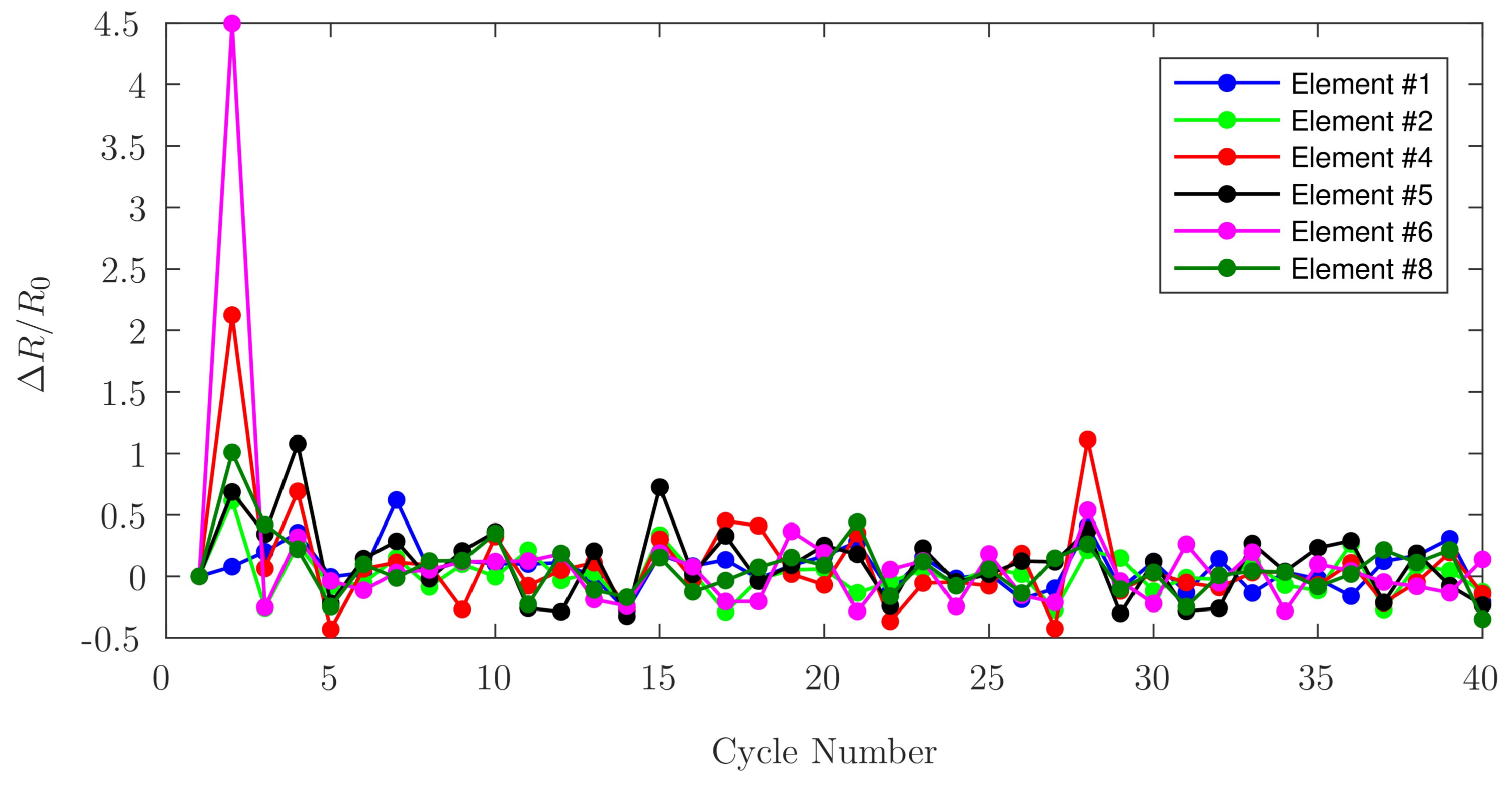

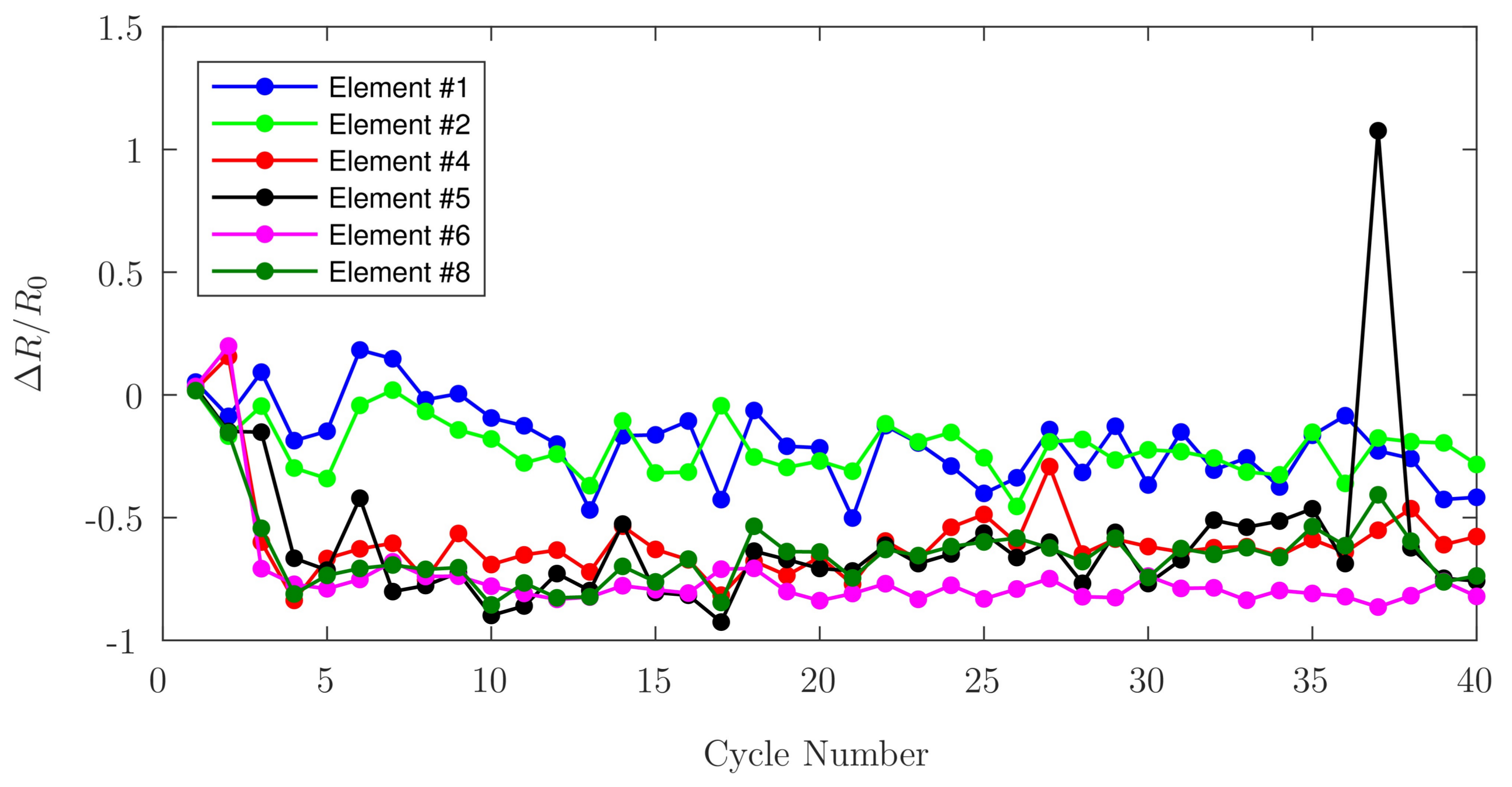

2.4.2. Cycle Loading

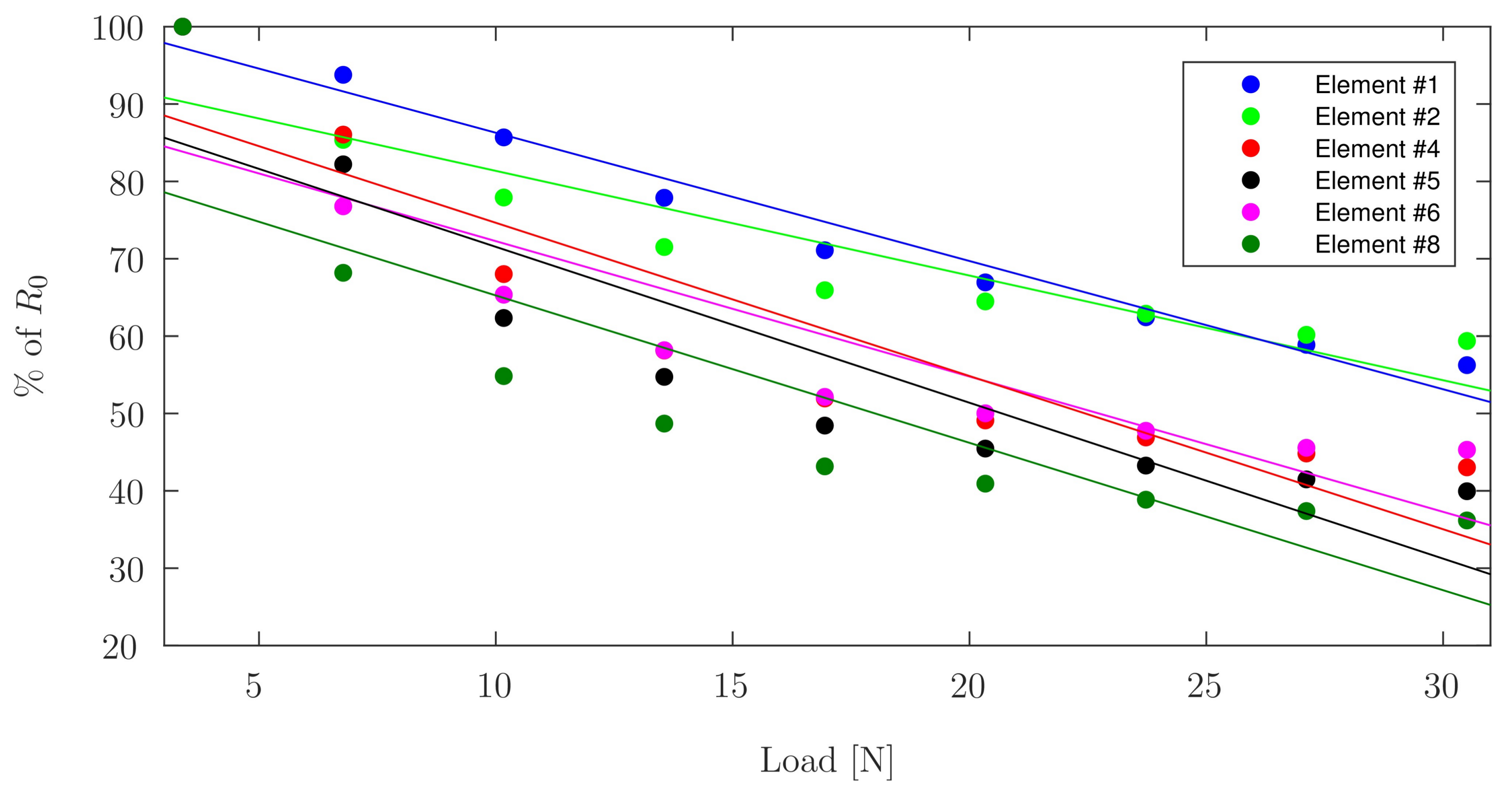

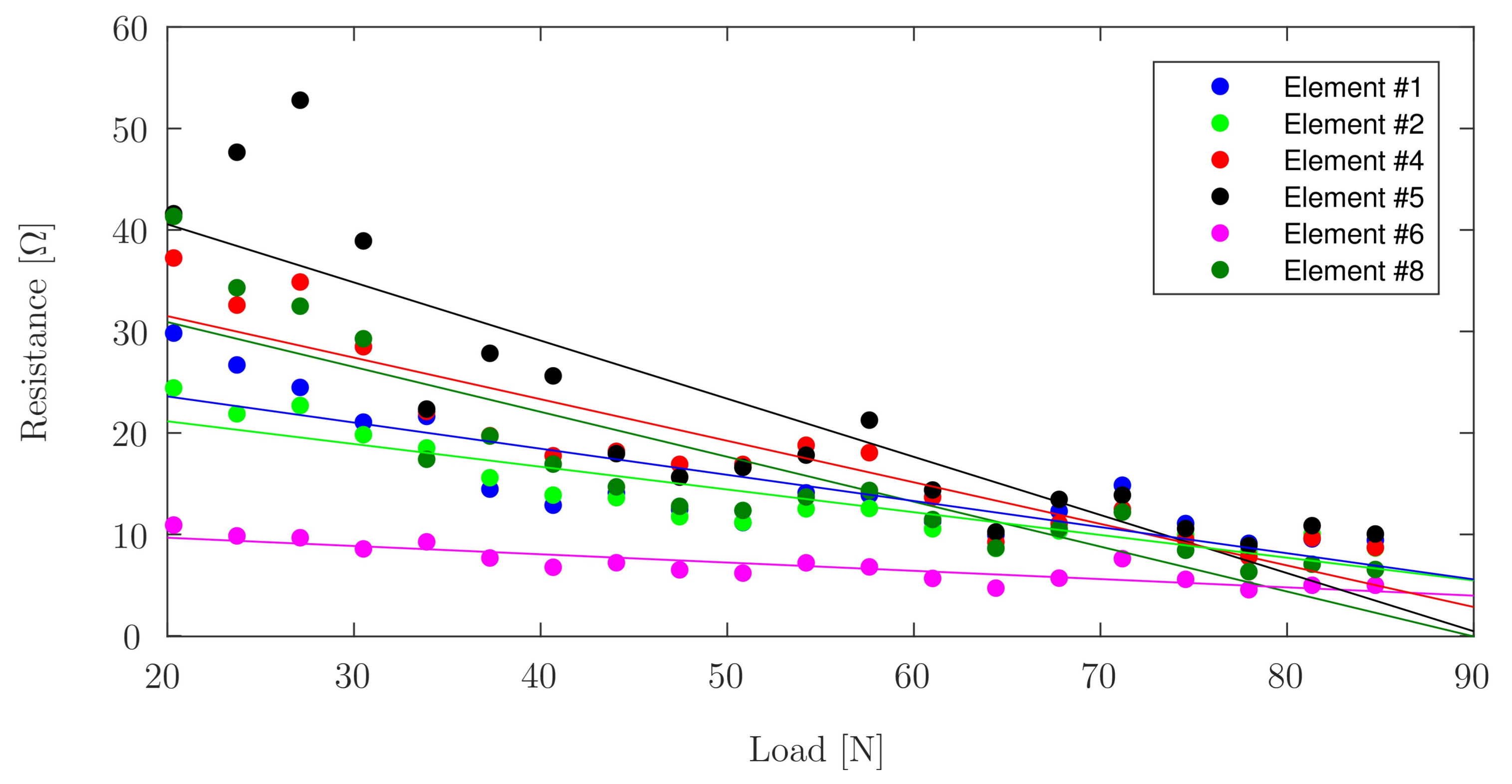

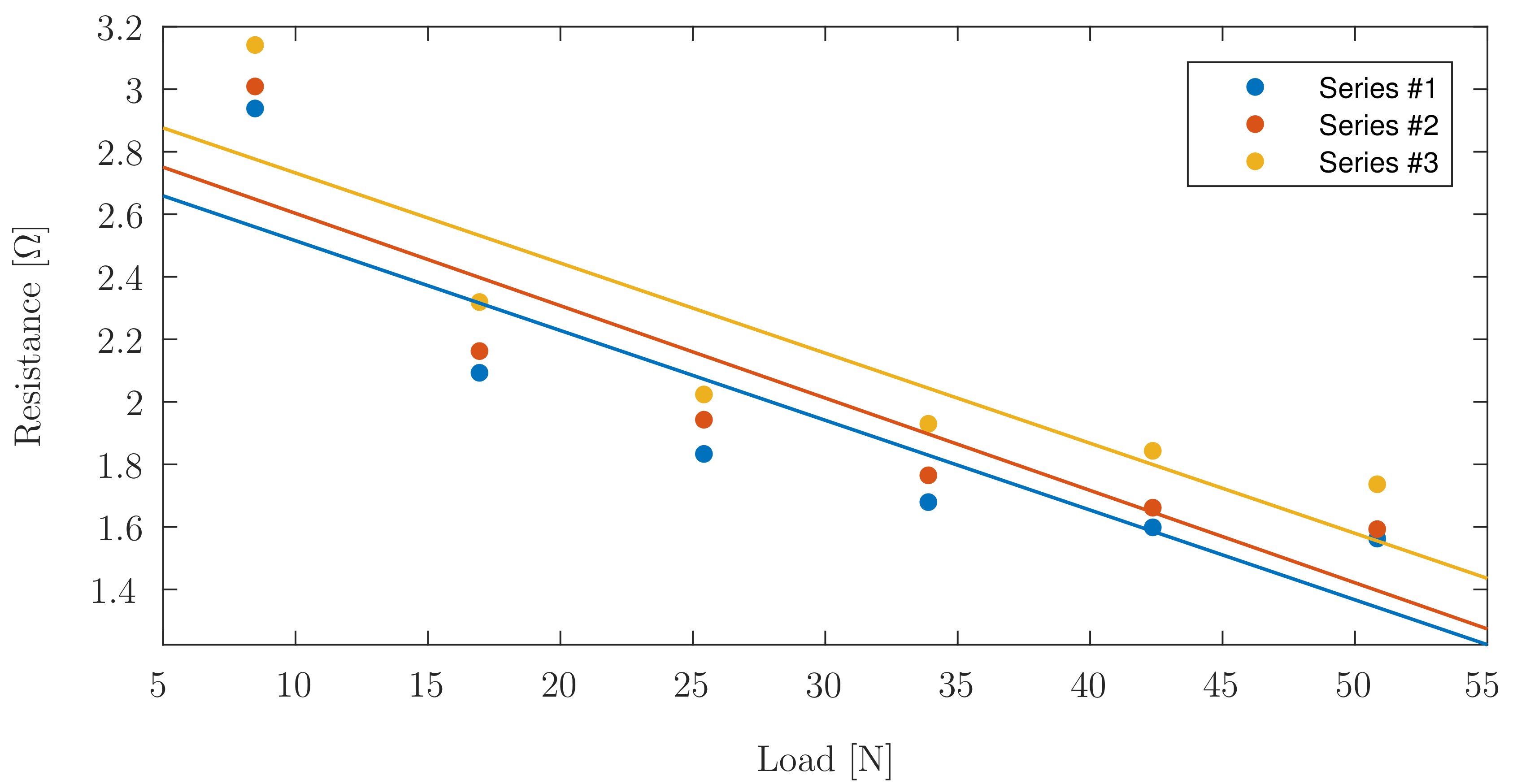

2.4.3. Incremental Loading

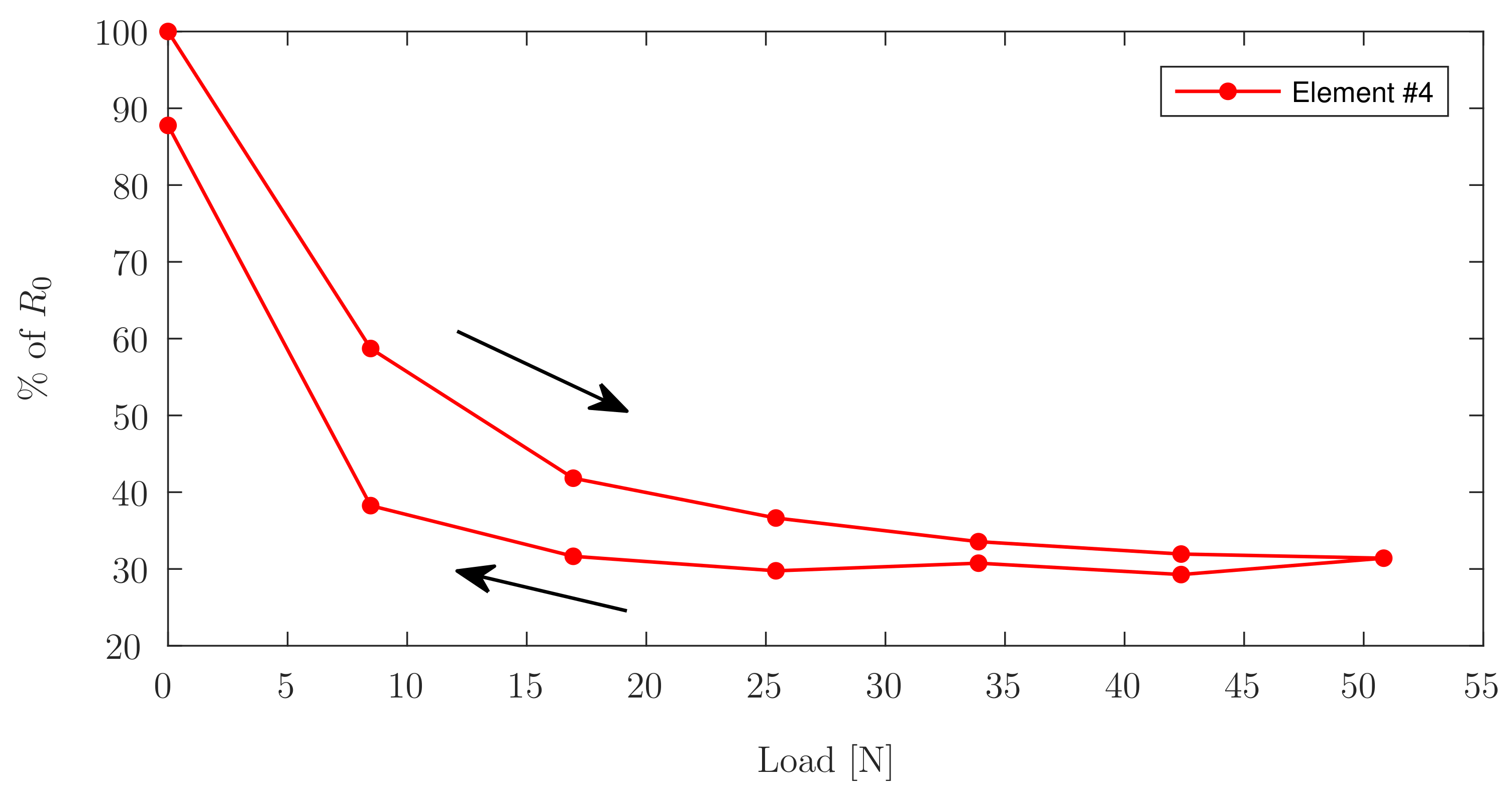

2.4.4. Loading/Unloading Cycle

2.4.5. Repeatability

2.4.6. Accuracy

3. Results

3.1. Design and Fabrication

3.2. Sensor Array Characterization

3.2.1. Stability

3.2.2. Cycle Loading

3.2.3. Incremental Continuous Loading

3.2.4. Incremental Loading: Zero-Breaks

3.2.5. Loading/Unloading Cycle

3.2.6. Repeatability

3.2.7. Accuracy

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lillemose, M.; Spieser, M.; Christiansen, N.O.; Christensen, A.; Boisen, A. Intrinsically conductive polymer thin film piezoresistors. Microelectron. Eng. 2008, 85, 969–971. [Google Scholar] [CrossRef]

- Pereira, J.N.; Vieira, P.; Ferreira, A.; Paleo, A.J.; Rocha, J.G.; Lanceros-Méndez, S. Piezoresistive effect in spin-coated polyaniline thin films. J. Polym. Res. 2012, 19, 9815. [Google Scholar] [CrossRef]

- Della Pina, C.; Zappa, E.; Busca, G.; Sironi, A.; Falletta, E. Electromechanical properties of polyanilines prepared by two different approaches and their applicability in force measurements. Sens. Actuators B Chem. 2014, 201, 395–401. [Google Scholar] [CrossRef]

- Mattioli-Belmonte, M.; Giavaresi, G.; Biagini, G.; Virgili, L.; Giacomini, M.; Fini, M.; Giantomassi, F.; Natali, D.; Torricelli, P.; Giardino, R. Tailoring biomaterial compatibility: In Vivo tissue response versus in vitro cell behavior. Int. J. Artif. Organs 2003, 26, 1077–1085. [Google Scholar] [PubMed]

- Adams, P.N.; Laughlin, P.J.; Monkman, A.P.; Bernhoeft, N. A further step towards stable organic metals. Oriented films of polyaniline with high electrical conductivity and anisotropy. Solid State Commun. 1994, 91, 875–878. [Google Scholar] [CrossRef]

- Bao, Z.X.; Colon, F.; Pinto, N.J.; Liu, C.X. Pressure dependence of the resistance in polyaniline and poly(o-toluidine) at room temperature. Synth. Met. 1998, 94, 211–213. [Google Scholar] [CrossRef]

- Razak, S.I.A.; Dahli, F.N.; Wahab, I.F.; Abdul Kadir, M.R.; Muhamad, I.I.; Yusof, A.H.M.; Adeli, H. A Conductive polylactic acid/polyaniline porous scaffold via freeze extraction for potential biomedical applications. Soft Mater. 2016, 14, 78–86. [Google Scholar] [CrossRef]

- Falletta, E.; Costa, P.; Della Pina, C.; Lanceros-Mendez, S. Development of high sensitive polyaniline based piezoresistive films by conventional and green chemistry approaches. Sens. Actuators A Phys. 2014, 220, 13–21. [Google Scholar] [CrossRef]

- Kang, J.H.; Park, C.; Scholl, J.A.; Brazin, A.H.; Holloway, N.M.; High, J.W.; Lowther, S.E.; Harrison, J.S. Piezoresistive characteristics of single wall carbon nanotube/polyimide nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 994–1003. [Google Scholar] [CrossRef]

- Del Castillo-Castro, T.; Castillo-Ortega, M.M.; Encinas, J.C.; Herrera Franco, P.J.; Carrillo-Escalante, H.J. Piezo-resistance effect in composite based on cross-linked polydimethylsiloxane and polyaniline: Potential pressure sensor application. J. Mater. Sci. 2012, 47, 1794–1802. [Google Scholar] [CrossRef]

- Barra, G.M.O.; Matins, R.R.; Kafer, K.A.; Paniago, R.; Vasques, C.T.; Pires, A.T.N. Thermoplastic elastomer/polyaniline blends: Evaluation of mechanical and electromechanical properties. Polym. Test. 2008, 27, 886–892. [Google Scholar] [CrossRef]

- Holness, F.B.; Price, A.D. Design and fabrication of conductive polyaniline transducers via computer controlled direct ink writing. Proceedings of Electroactive Polymer Actuators and Devices (EAPAD)—SPIE, Portland, OR, USA, 25–29 March 2017; Volume 10163, p. 101632O. [Google Scholar]

- Guery, J.; Favard, L.; Sirveaux, F.; Oudet, D.; Mole, D.; Walch, G. Reverse total shoulder arthroplasty. Survivorship analysis of eighty replacements followed for five to ten years. J. Bone Jt. Surg. Am. Vol. 2006, 88, 1742–1747. [Google Scholar] [CrossRef] [PubMed]

- Cheung, E.; Willis, M.; Walker, M.; Clark, R.; Frankle, M.A. Complications in reverse total shoulder arthroplasty. J. Am. Acad. Orthop. Surg. 2011, 19, 439–449. [Google Scholar] [CrossRef] [PubMed]

- Kwon, Y.W.; Forman, R.E.; Walker, P.S.; Zuckerman, J.D. Analysis of reverse total shoulder joint forces and glenoid fixation. Bull. NYU Hosp. Jt. Dis. 2010, 68, 273–280. [Google Scholar] [PubMed]

- Bohsali, K.I. Complications of total shoulder arthroplasty. J. Bone Jt. Surg. Am. 2006, 88, 2279. [Google Scholar]

- Giles, J.W.; Langohr, G.D.G.; Johnson, J.A.; Athwal, G.S. Implant design variations in reverse total shoulder arthroplasty influence the required deltoid force and resultant joint load. Clin. Orthop. Relat. Res. 2015, 473, 3615–3626. [Google Scholar] [CrossRef] [PubMed]

- Terrier, A.; Reist, A.; Merlini, F.; Farron, A. Simulated joint and muscle forces in reversed and anatomic shoulder prostheses. Bone Jt. J. 2008, 90-B, 751–756. [Google Scholar] [CrossRef] [PubMed]

- Langohr, G.D.G.; Willing, R.; Medley, J.B.; Athwal, G.S.; Johnson, J.A. Contact mechanics of reverse total shoulder arthroplasty during abduction: The effect of neck-shaft angle, humeral cup depth, and glenosphere diameter. J. Shoulder Elb. Surg. 2016, 25, 589–597. [Google Scholar] [CrossRef] [PubMed]

- Hong, J.; Pan, Z.; Yao, M.; Chen, J.; Zhang, Y. A large-strain weft-knitted sensor fabricated by conductive UHMWPE/PANI composite yarns. Sens. Actuators A Phys. 2016, 238, 307–316. [Google Scholar] [CrossRef]

- Smith, S.; Li, B.; Buniya, A.; Lin, S.H.; Scholes, S.; Johnson, G.; Joyce, T. In vitro wear testing of a contemporary design of reverse shoulder prosthesis. J. Biomech. 2015, 48, BMD1500176. [Google Scholar] [CrossRef] [PubMed]

- Matsen, F.A.; Clinton, J.; Lynch, J.; Bertelsen, A.; Richardson, M.L. Glenoid component failure in total shoulder arthroplasty. J. Bone Jt. Surg. 2008, 90, 885–896. [Google Scholar] [CrossRef] [PubMed]

- Nam, D.; Kepler, C.K.; Nho, S.J.; Craig, E.V.; Warren, R.F.; Wright, T.M. Observations on retrieved humeral polyethylene components from reverse total shoulder arthroplasty. J. Shoulder Elb. Surg. 2010, 19, 1003–1012. [Google Scholar] [CrossRef] [PubMed]

- Berhouet, J.; Garaud, P.; Favard, L. Evaluation of the role of glenosphere design and humeral component retroversion in avoiding scapular notching during reverse shoulder arthroplasty. J. Shoulder Elb. Surg. 2014, 23, 151–158. [Google Scholar] [CrossRef] [PubMed]

- Holness, F.B.; Price, A.D. Robotic extrusion processes for direct ink writing of 3D conductive polyaniline structures. Proceedings of Electroactive Polymer Actuators and Devices (EAPAD)—SPIE, Las Vegas, NV, USA, 20–24 March 2016; Volume 9798, p. 97981G. [Google Scholar]

- Holness, F.B.; Price, A.D. Direct ink writing of 3D conductive polyaniline structures and rheological modelling. Smart Mater. Struct. 2017, 27, 015006. [Google Scholar] [CrossRef]

- Blythe, A. Electrical resistivity measurements of polymer materials. Polym. Test. 1984, 4, 195–209. [Google Scholar] [CrossRef]

| Element #1 | Element #2 | Element #4 | Element #5 | Element #6 | Element #8 | |

|---|---|---|---|---|---|---|

| Series 1 | 0.81 | 0.85 | 0.76 | 0.79 | 0.78 | 0.81 |

| Series 2 | 0.86 | 0.68 | 0.79 | 0.80 | 0.64 | 0.81 |

| Series 3 | 0.84 | 0.68 | 0.78 | 0.78 | 0.71 | 0.82 |

| Load [N] | Element #1 | Element #2 | Element #4 | Element #5 | Element #6 | Element #8 |

|---|---|---|---|---|---|---|

| 8.47 | 5.47% | 7.19% | 2.78% | 0.66% | 5.90% | 4.88% |

| 16.95 | 6.27% | 5.19% | 4.32% | 1.99% | 7.97% | 5.00% |

| 25.42 | 4.99% | 4.49% | 4.03% | 2.86% | 1.65% | 4.41% |

| 33.89 | 6.01% | 5.49% | 5.80% | 5.24% | 4.40% | 3.35% |

| 42.36 | 4.53% | 2.71% | 6.10% | 6.34% | 4.42% | 2.98% |

| 50.84 | 2.98% | 7.28% | 4.65% | 5.21% | 6.51% | 4.47% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Micolini, C.; Holness, F.B.; Johnson, J.A.; Price, A.D. Assessment of Embedded Conjugated Polymer Sensor Arrays for Potential Load Transmission Measurement in Orthopaedic Implants. Sensors 2017, 17, 2768. https://doi.org/10.3390/s17122768

Micolini C, Holness FB, Johnson JA, Price AD. Assessment of Embedded Conjugated Polymer Sensor Arrays for Potential Load Transmission Measurement in Orthopaedic Implants. Sensors. 2017; 17(12):2768. https://doi.org/10.3390/s17122768

Chicago/Turabian StyleMicolini, Carolina, Frederick Benjamin Holness, James A. Johnson, and Aaron David Price. 2017. "Assessment of Embedded Conjugated Polymer Sensor Arrays for Potential Load Transmission Measurement in Orthopaedic Implants" Sensors 17, no. 12: 2768. https://doi.org/10.3390/s17122768

APA StyleMicolini, C., Holness, F. B., Johnson, J. A., & Price, A. D. (2017). Assessment of Embedded Conjugated Polymer Sensor Arrays for Potential Load Transmission Measurement in Orthopaedic Implants. Sensors, 17(12), 2768. https://doi.org/10.3390/s17122768