Lightdrum—Portable Light Stage for Accurate BTF Measurement on Site

Abstract

:1. Introduction

- a novel design and construction of a working prototype of a portable BTF/BRDF measuring device that allows for its positioning against a sample by means of an auto-collimator, thus permitting on site measurement in real life scenarios with high speed and accuracy,

- the first portable device for on site measurements where a viewing direction (two degrees of freedom) to the measured sample can be set continuously and arbitrarily for up to maximum zenith angle 75,

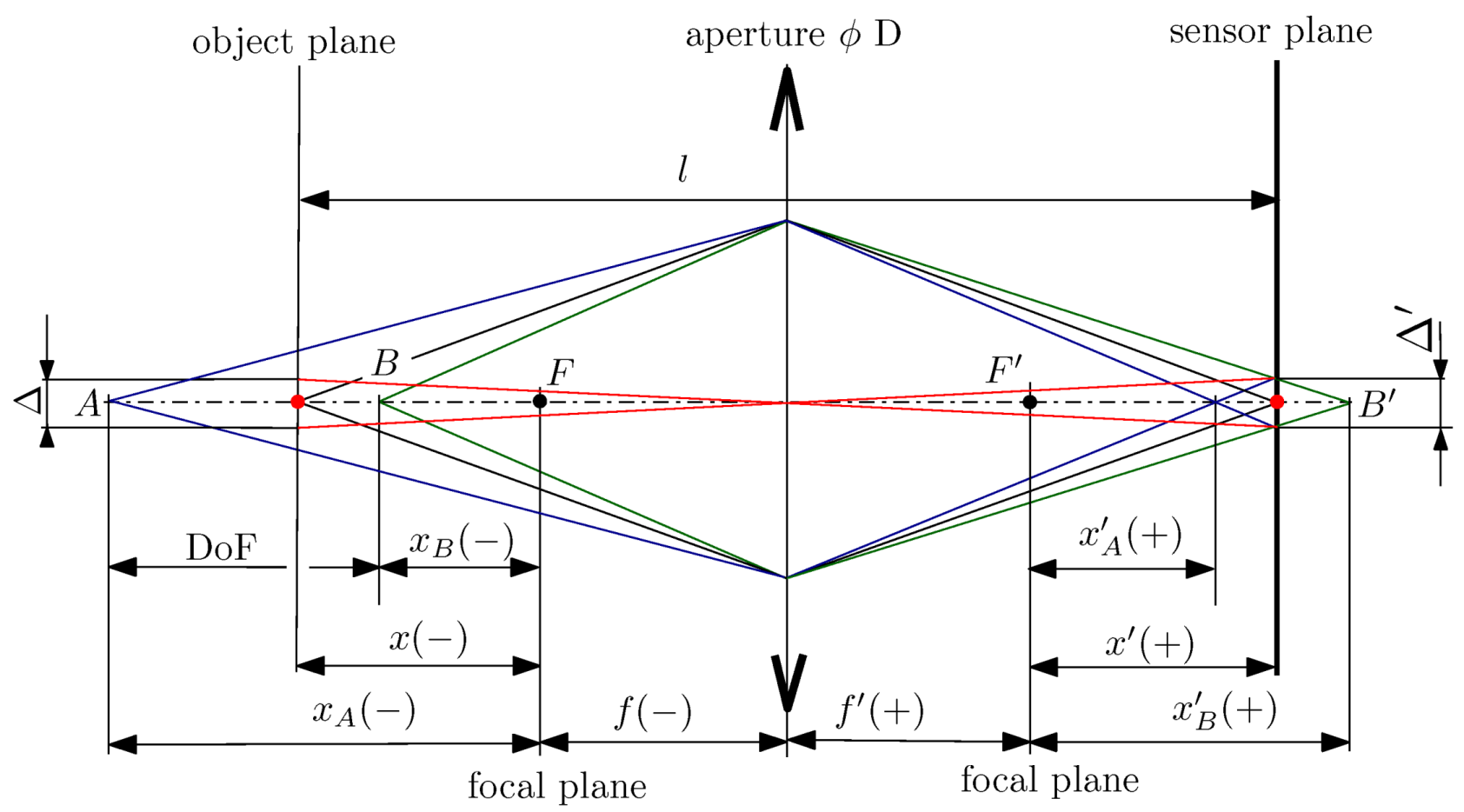

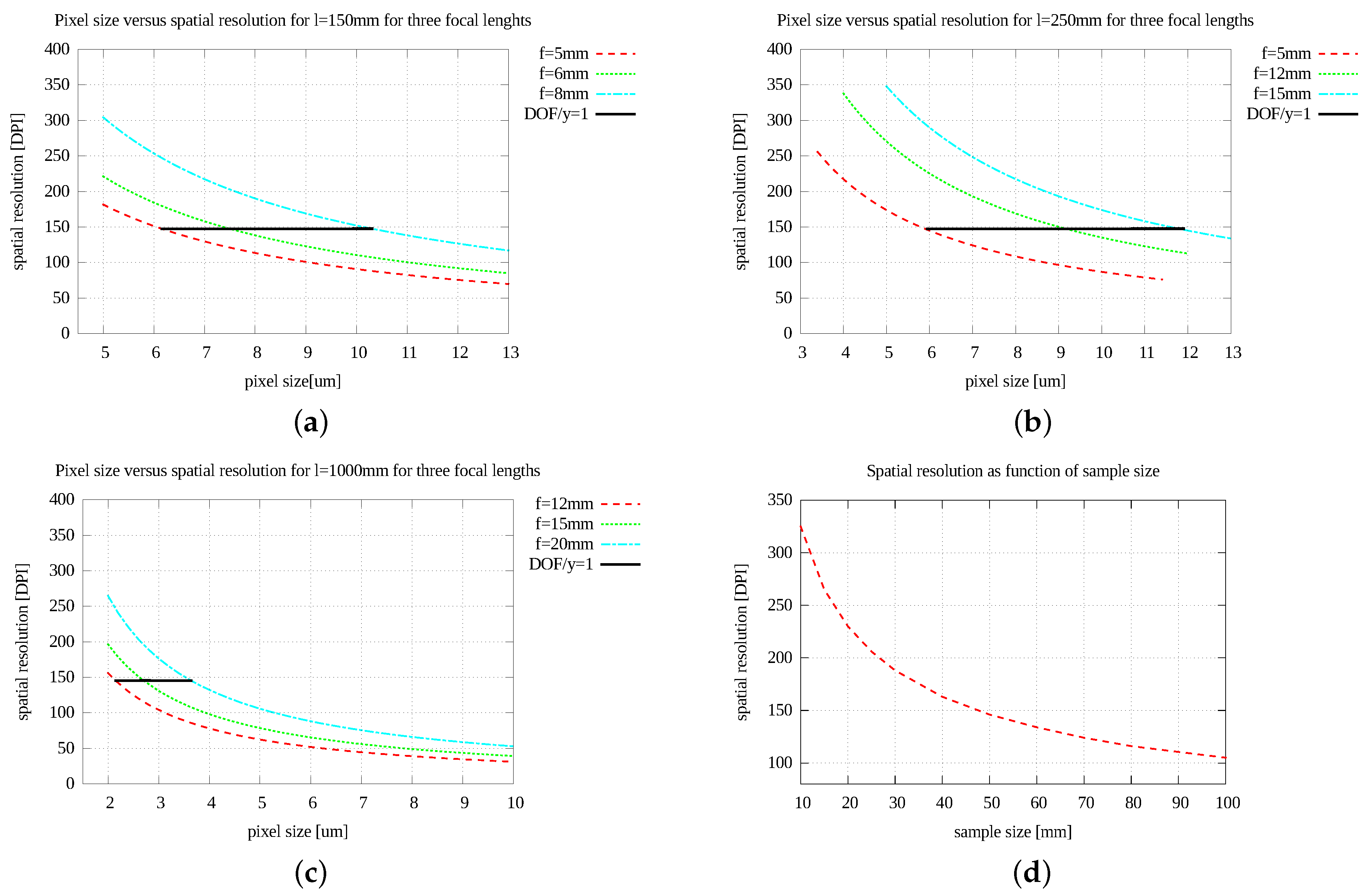

- a description of optical phenomena that limit either the spatial resolution or the size of the sample measured with BTF gantry,

- a marker sticker method for BTF/BRDF data acquisition which is used later in the data processing to align the data measured from the various camera directions,

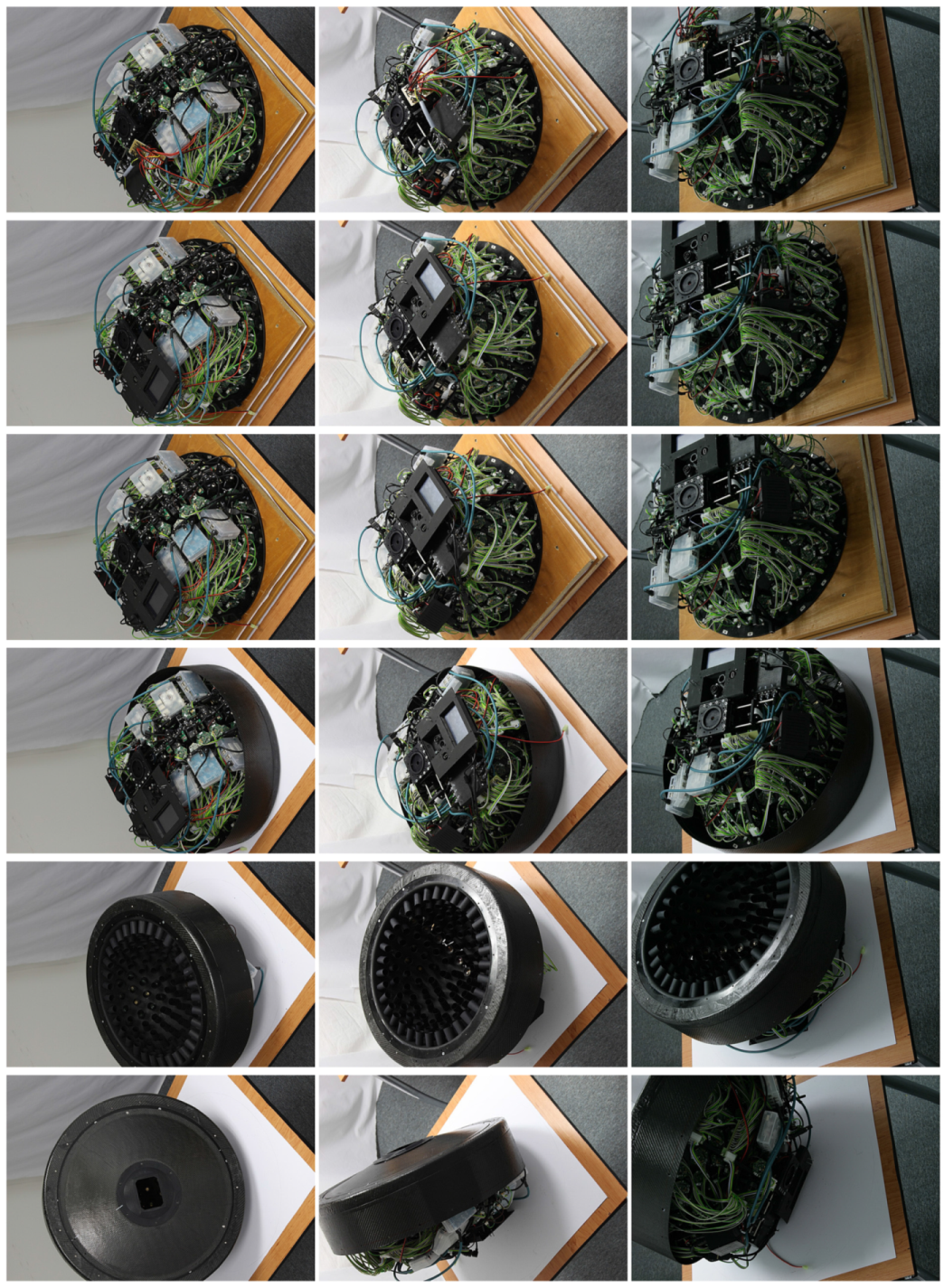

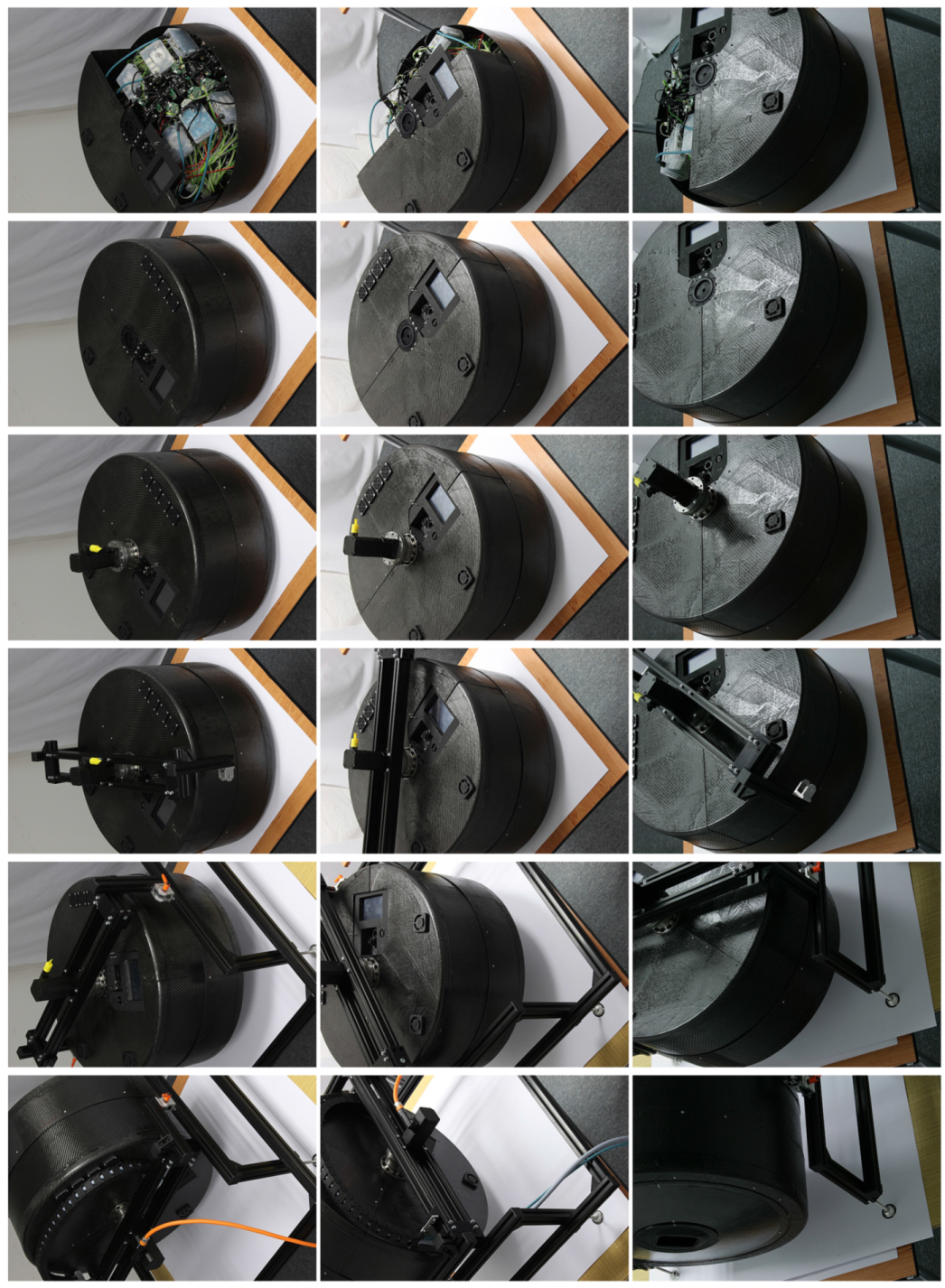

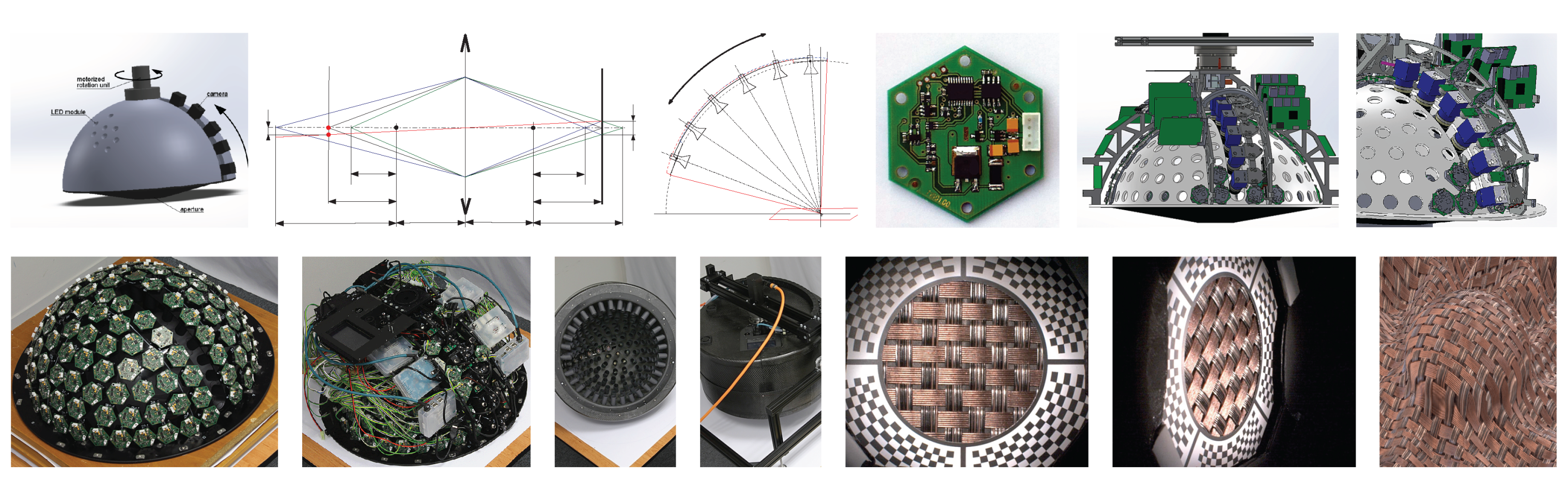

- the documentation of our device construction by photographs of the individual parts and a step-by-step photographic documentation of the prototype assembly.

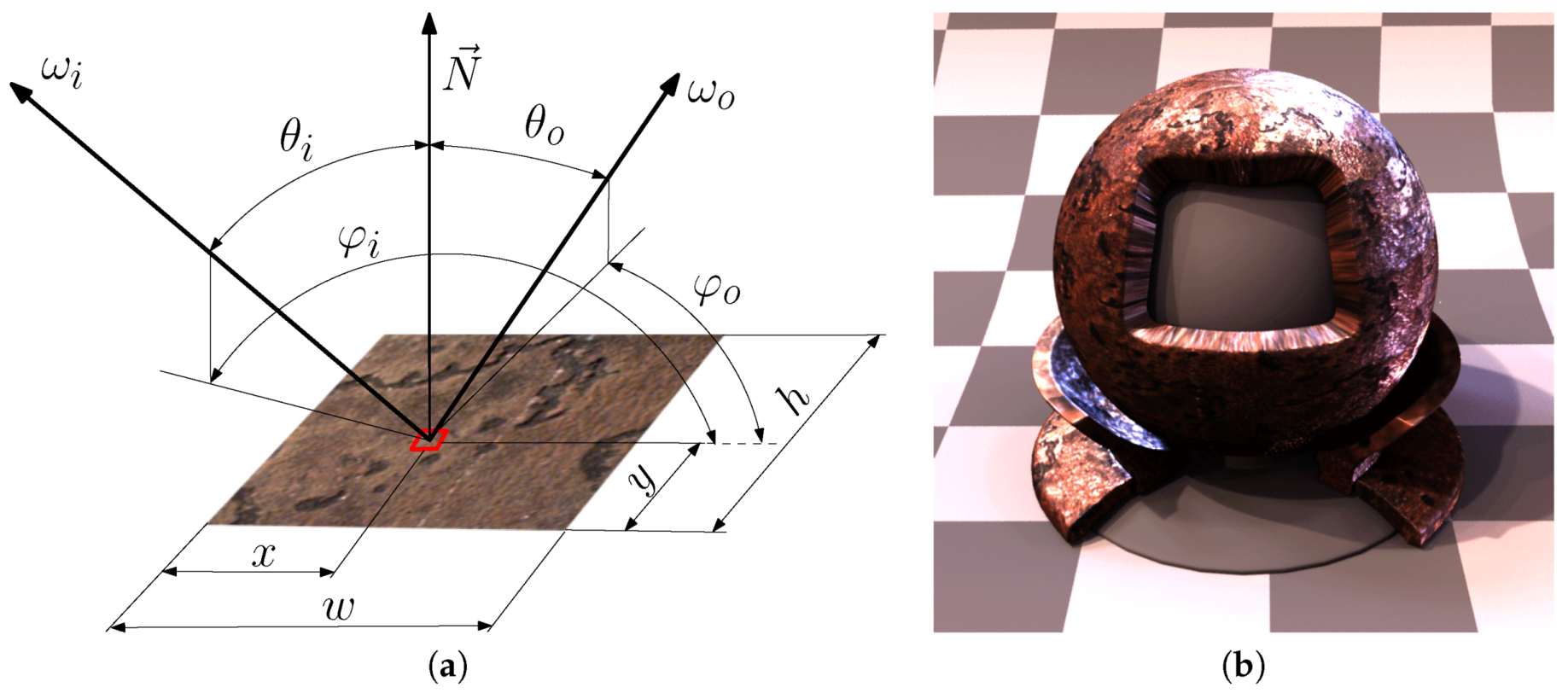

2. Related Work

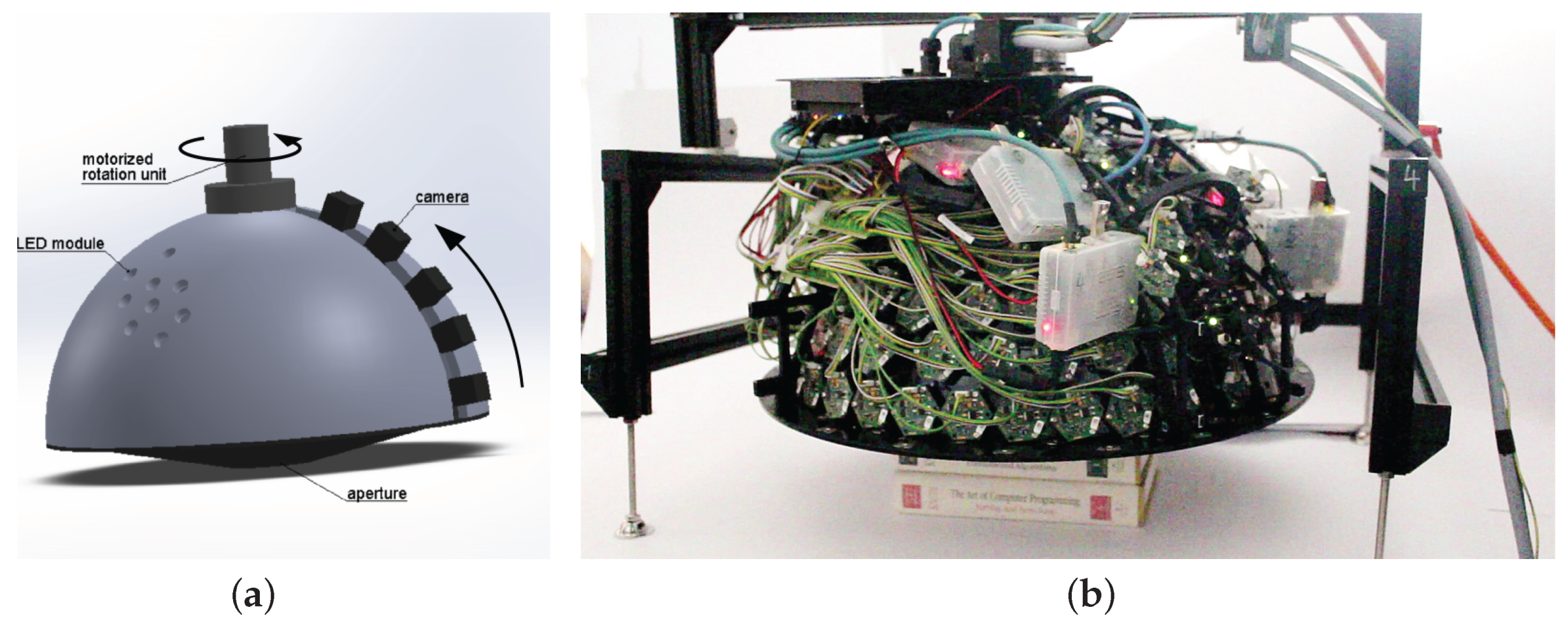

3. Lightdrum Overview

4. Mechanical Design

5. Cameras

5.1. Camera Selection and Optical Design

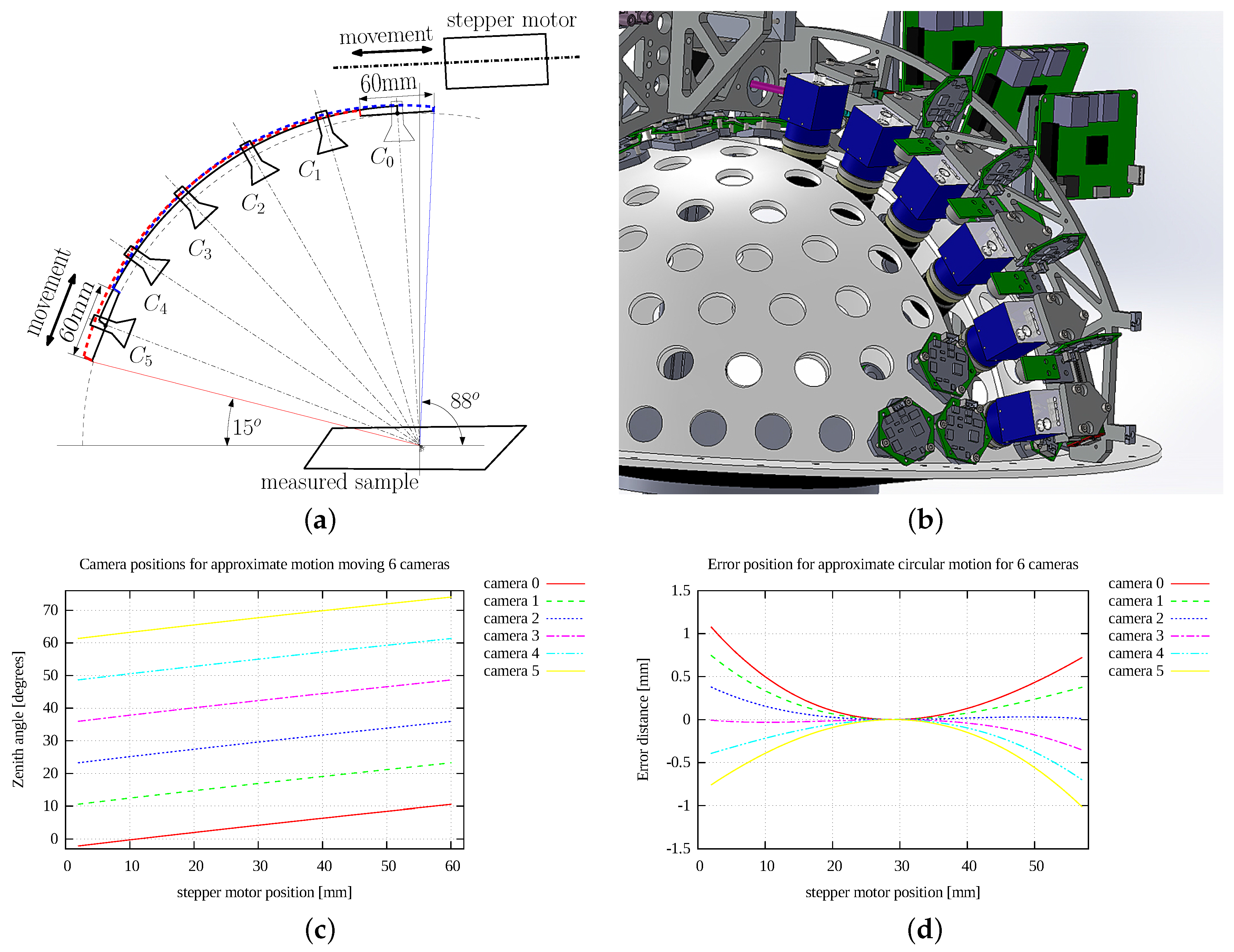

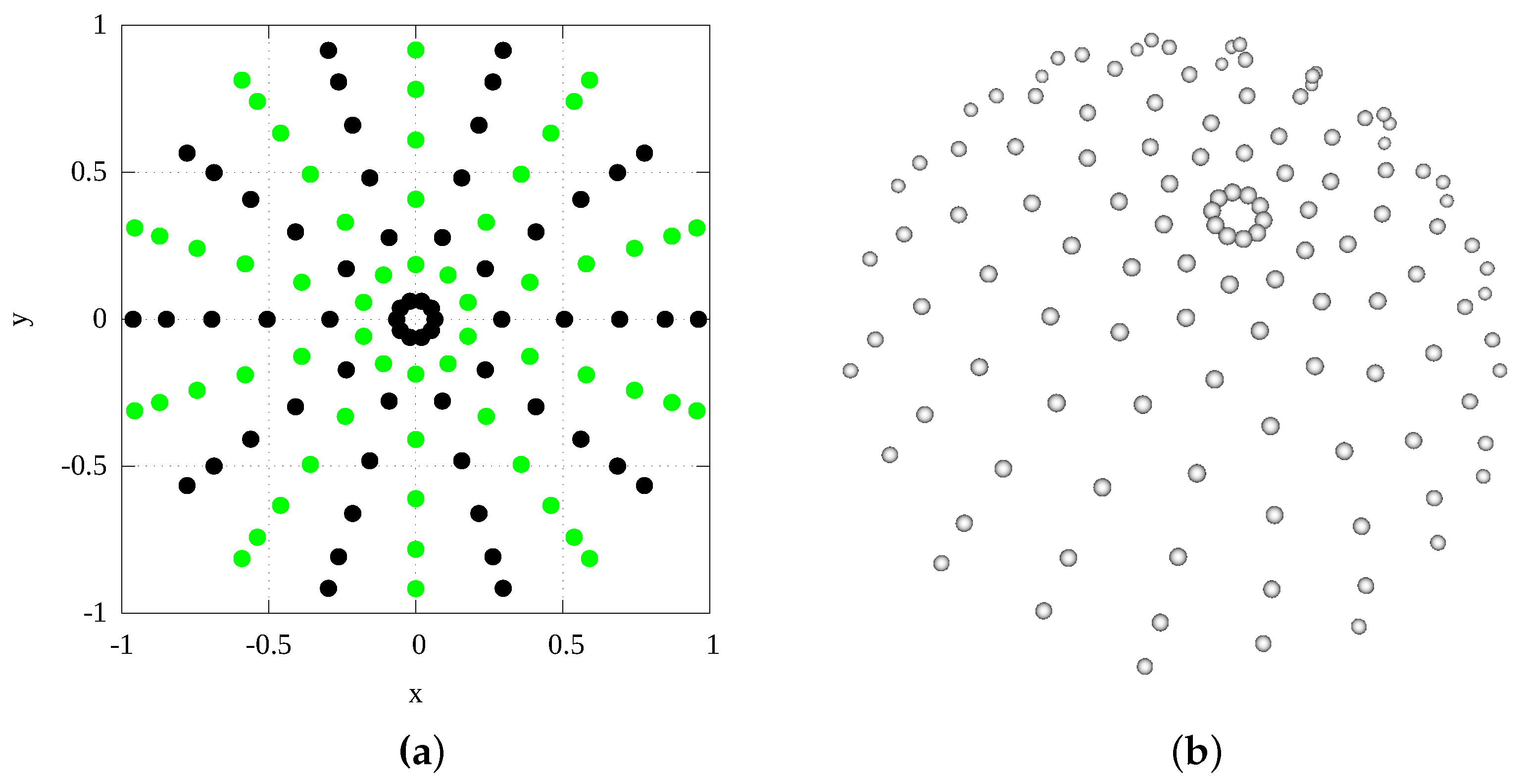

5.2. Camera Positioning

6. Illumination Units

6.1. LED Selection

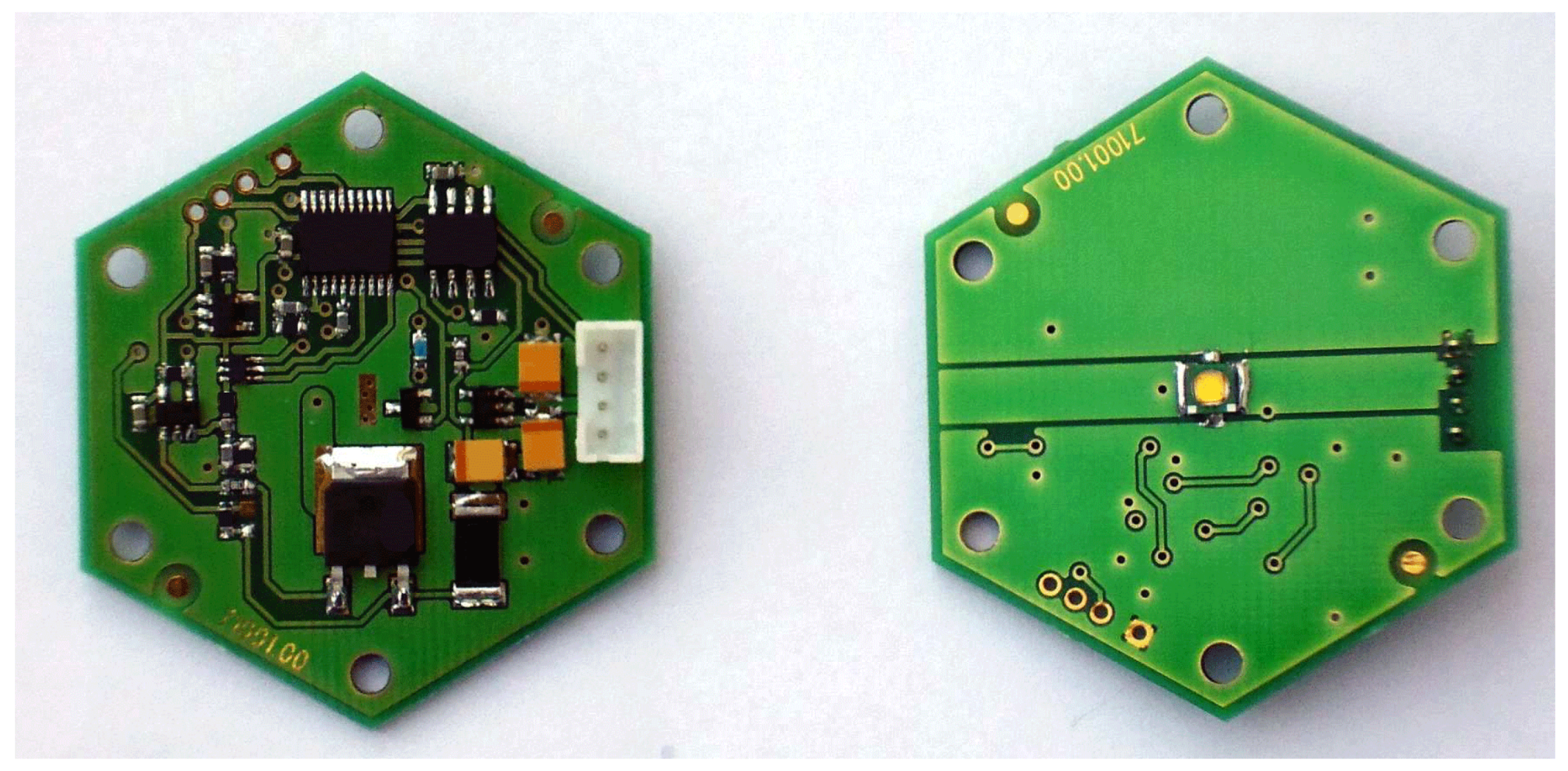

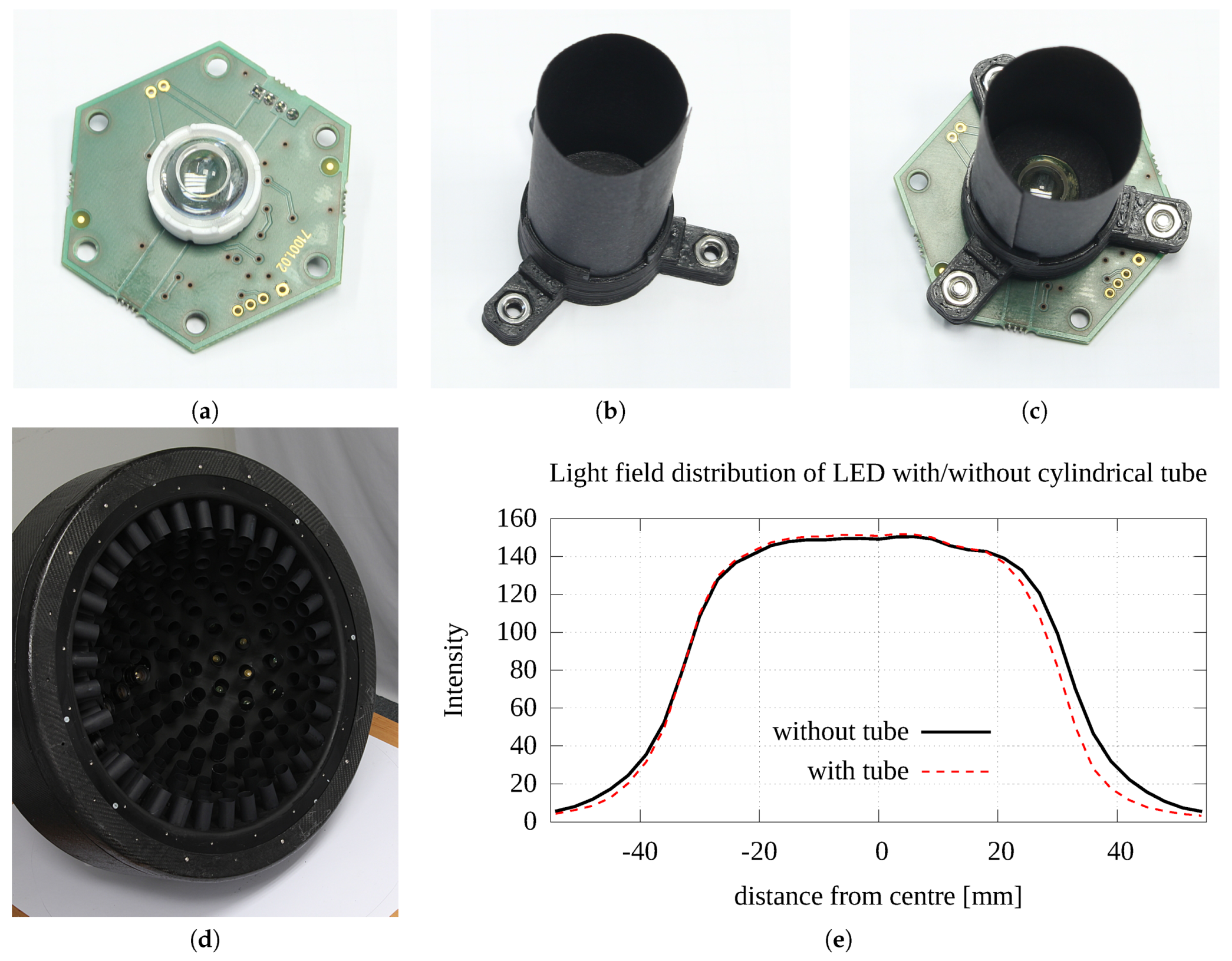

6.2. LED Modules

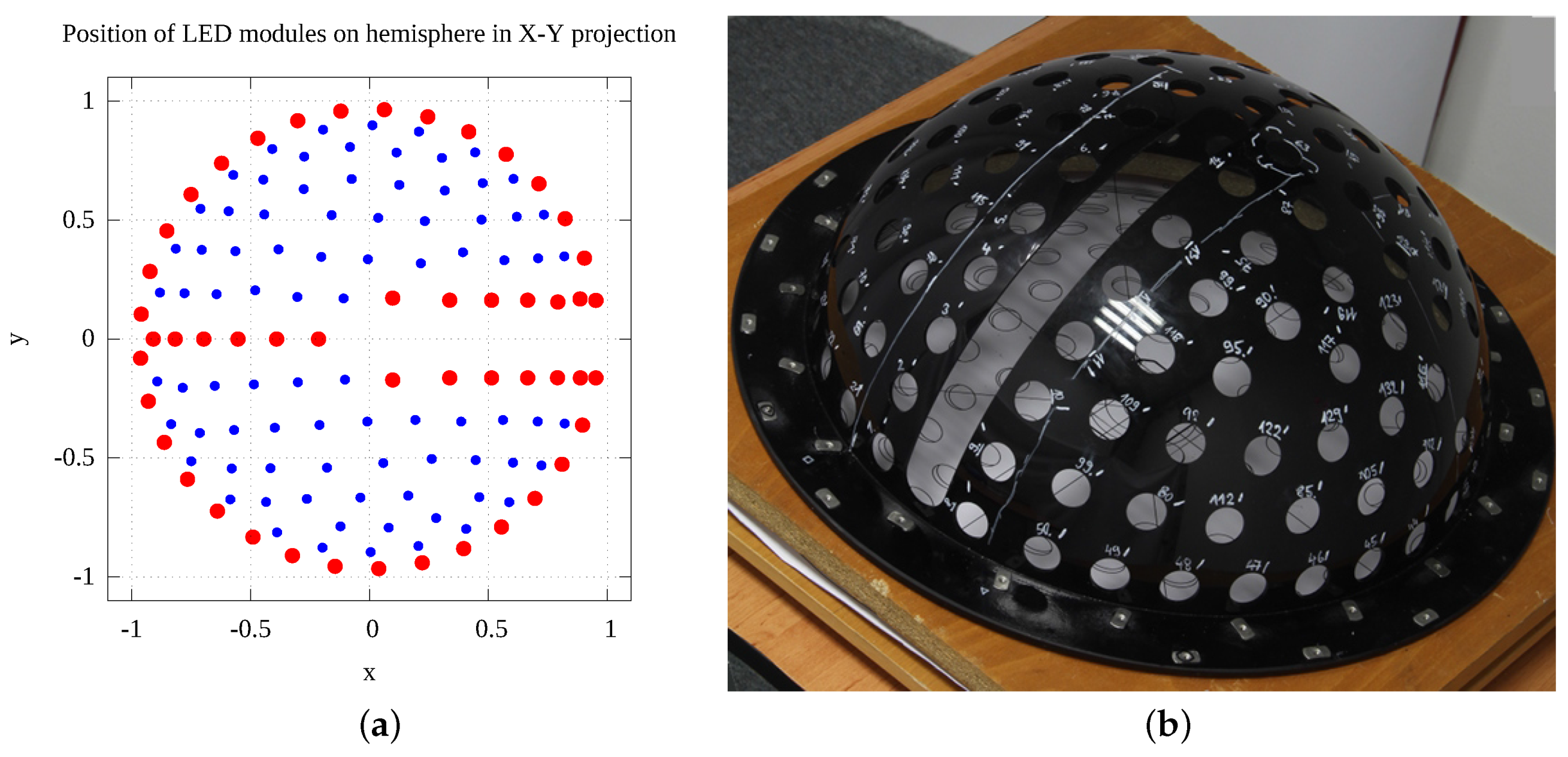

6.3. LED Modules Distribution on Hemispherical Dome

7. Other Measurement Issues

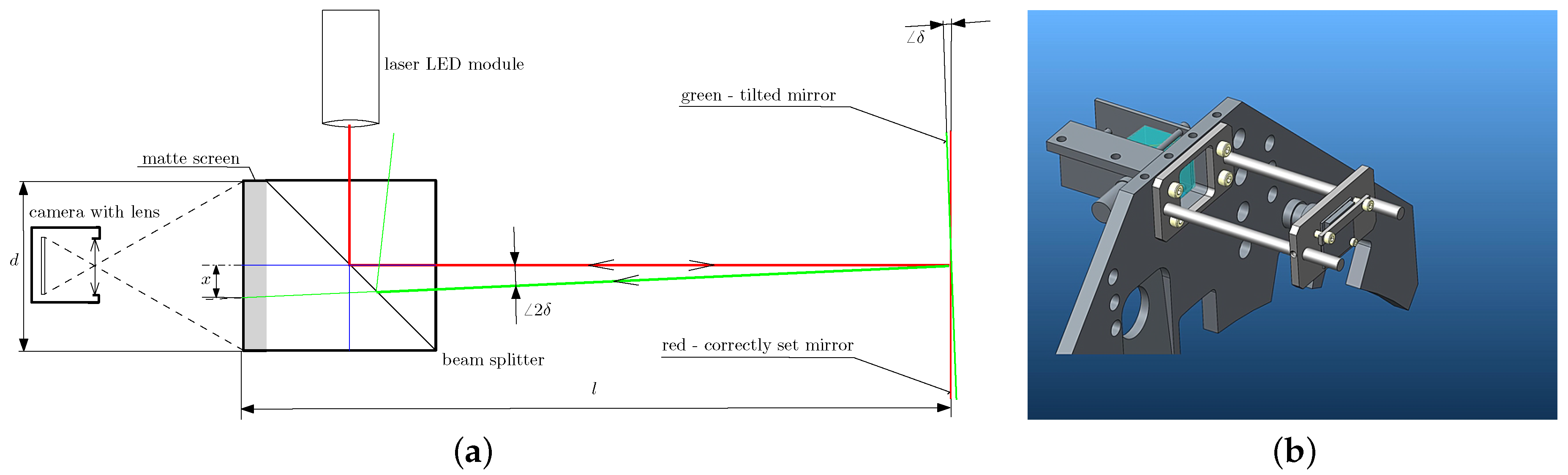

7.1. Auto-Collimator

7.2. Marker Sticker Image Registration Method

7.3. Measurement Setup Procedure

- find a locally flat and appropriate position on the measured surface sample, verify it is accessible by the gantry,

- glue on the marker sticker with a selected orientation that can relate to the structure of the measured surface sample,

- temporarily fasten the mirror (by appropriate means such as power tape) so that the middle of the marker sticker contains the mirror, while the fastener of the mirror can be removed, and the border of the marker sticker with its centring marks is still visible. The 40 mm mirror width allows us to put the mirror at an angle of 45 to the centring marks so that they remain visible.

- position the measurement instrument, adjust both its perpendicularity and position against the sample using the mirror and centring marks on the marker sticker,

- carefully remove the mirror fasteners, and slide the mirror away from the instrument’s measurement aperture. The 500 mm length of the mirror allows for easy manipulation of the mirror upon its removal, before the measurement takes place.

- recheck the position of the instrument against the sample and start the measurement.

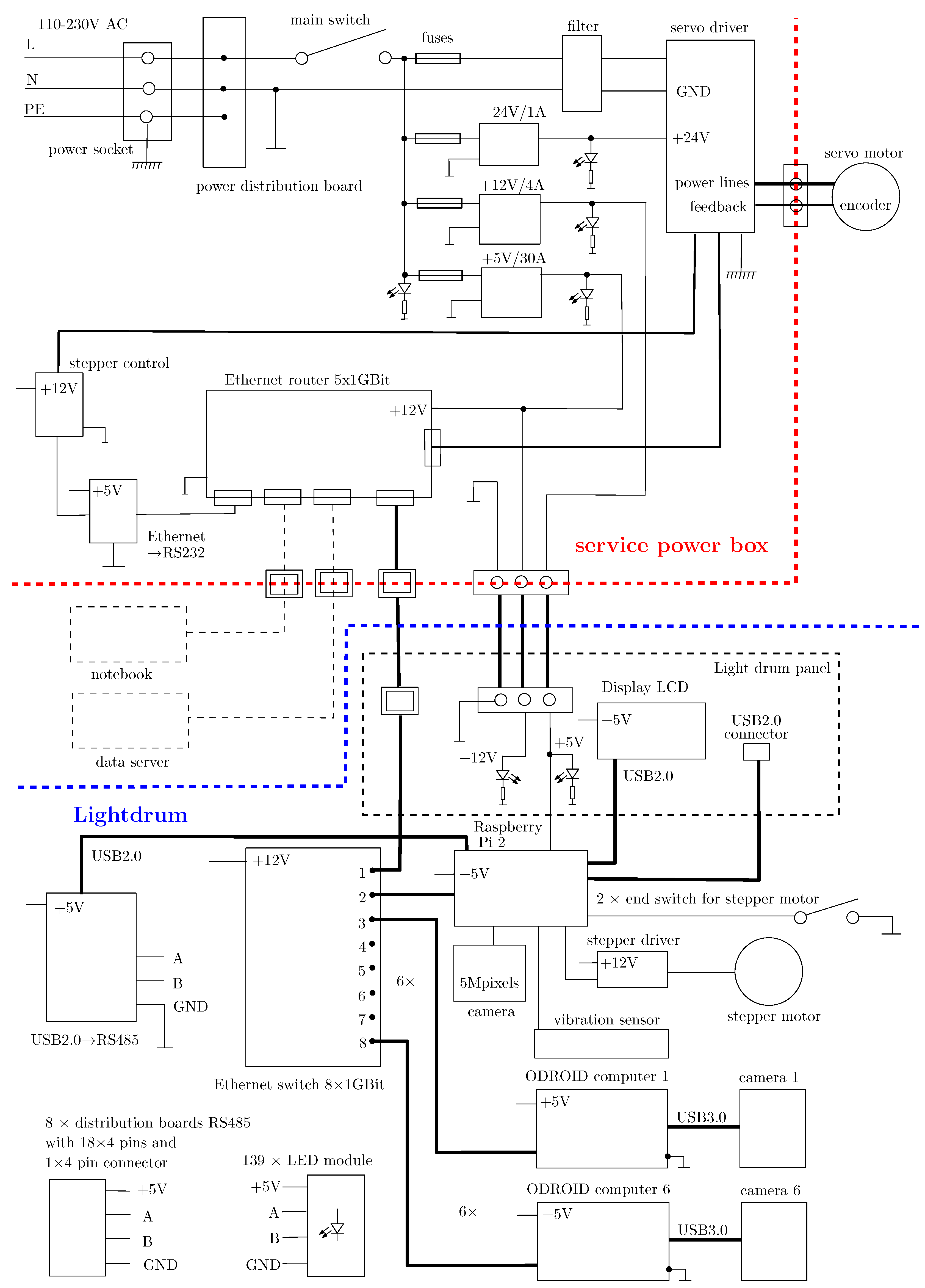

7.4. Electronics

8. Parts Production, Assembly and Debugging

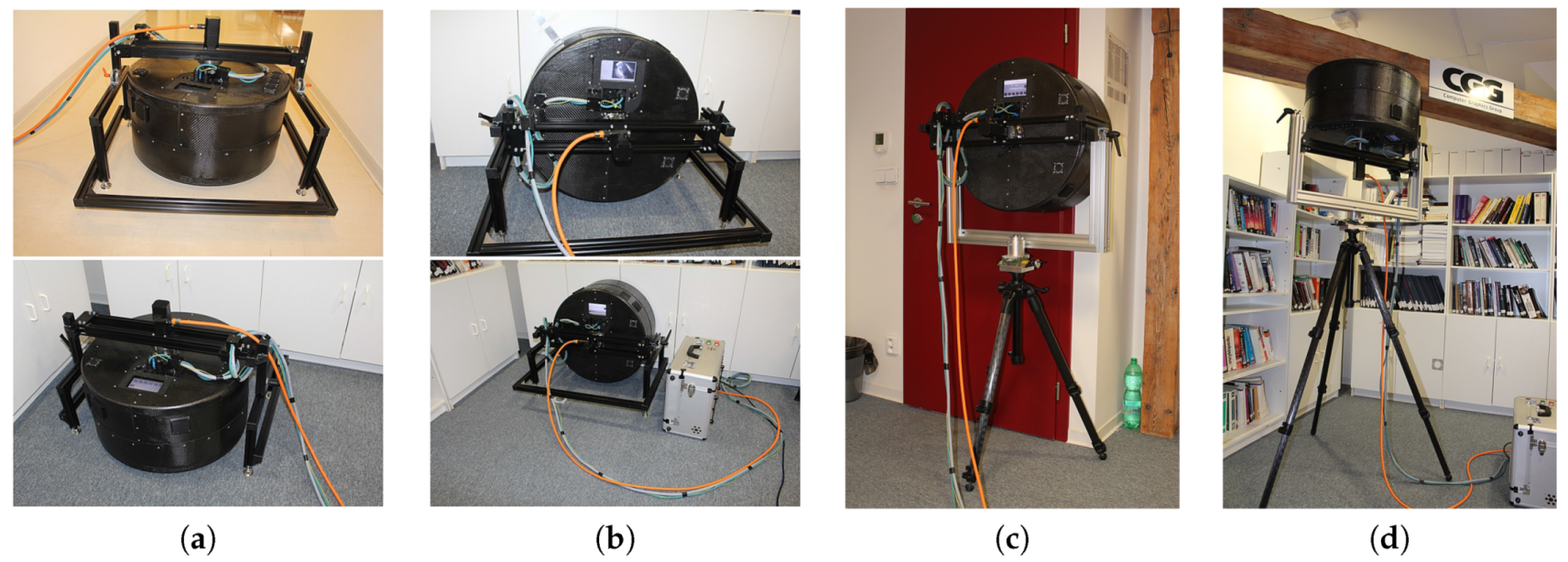

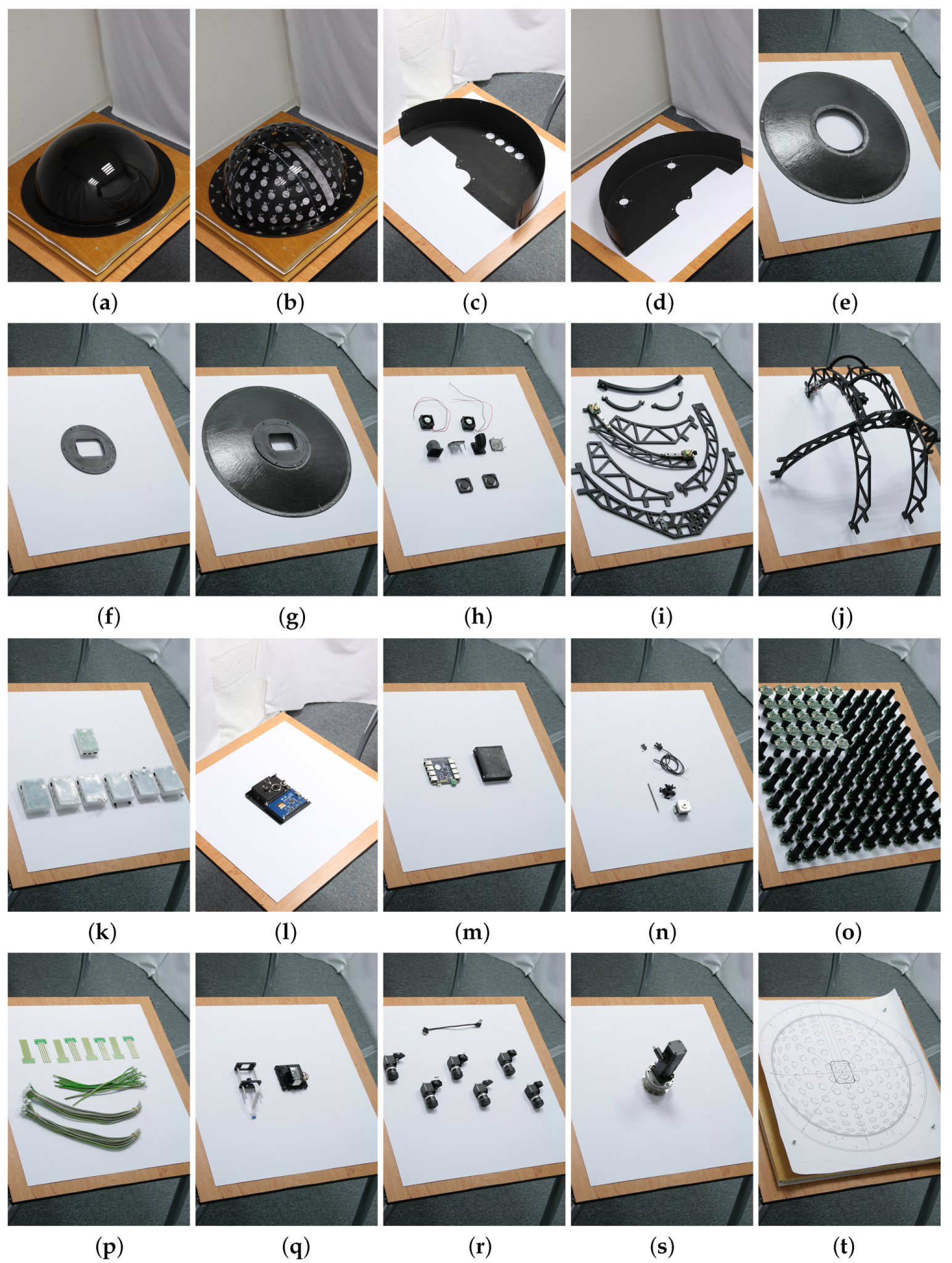

- the holding frame for measurement on the floor or the desk, or the tripod for measurement on the wall or ceiling, shown in Figure 4,

- the aluminium frame with geared servo motor (shown in Figure 16s) on which the lightdrum is mounted,

- the service power box with electronics (power supplies, servo motor drive, and gigabit Ethernet router), shown in Figure 4b,

- the outer carbon cover consisting of three parts, protecting the instrument from damage and disturbing external light, in Figure 16c–g,

- the inner aluminium frame construction that provides mechanical support and is mounted on the servo motor gear output, in Figure 16i,j,

- the PMMA dome mounted on the inner aluminium frame, in Figure 16a,b,

- the six cameras mounted on the approximate circular motion mechanism, in Figure 16r,

- the six embedded microcomputers for operating the cameras (Hardkernel Odroid-XU3), in Figure 16k,

- the additional 5 Mpixel camera connected to the Raspberry Pi 2 and the laser module for the auto-collimator, in Figure 16q,

- the embedded gigabit Ethernet switch and its cover, in Figure 16m,

- the 139 LED modules (in Figure 16o) mounted on the PMMA dome,

- the cables inside the lightdrum; power, RS485 (in Figure 16p), and gigabit Ethernet),

- and the three cables between the external service power box and the lightdrum with the servo motor, shown in Figure 4.

9. Adjustment

10. Data Acquisition and Calibration

10.1. Data Acquisition

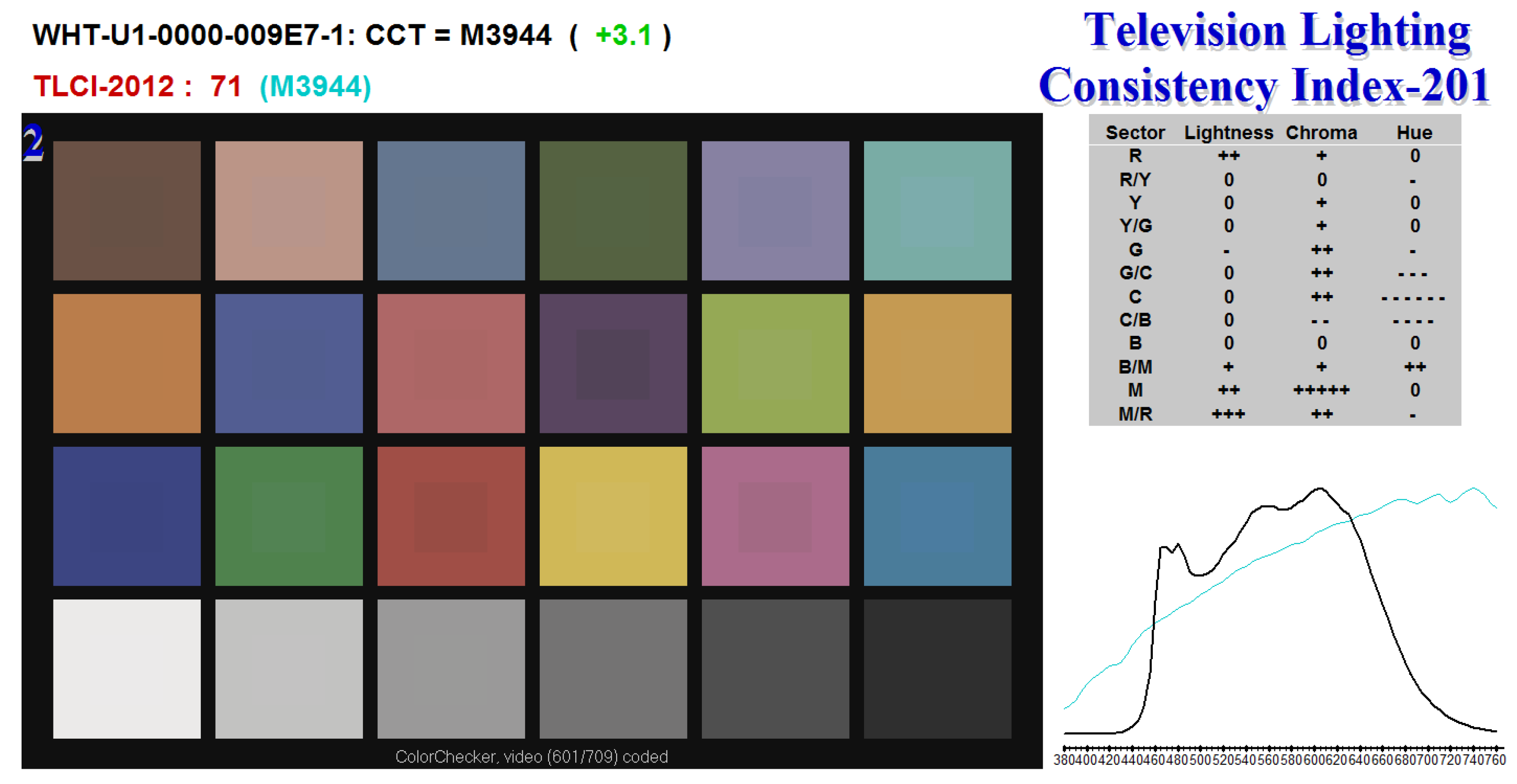

10.2. Radiometric and Colourimetric Calibration

11. Data Processing

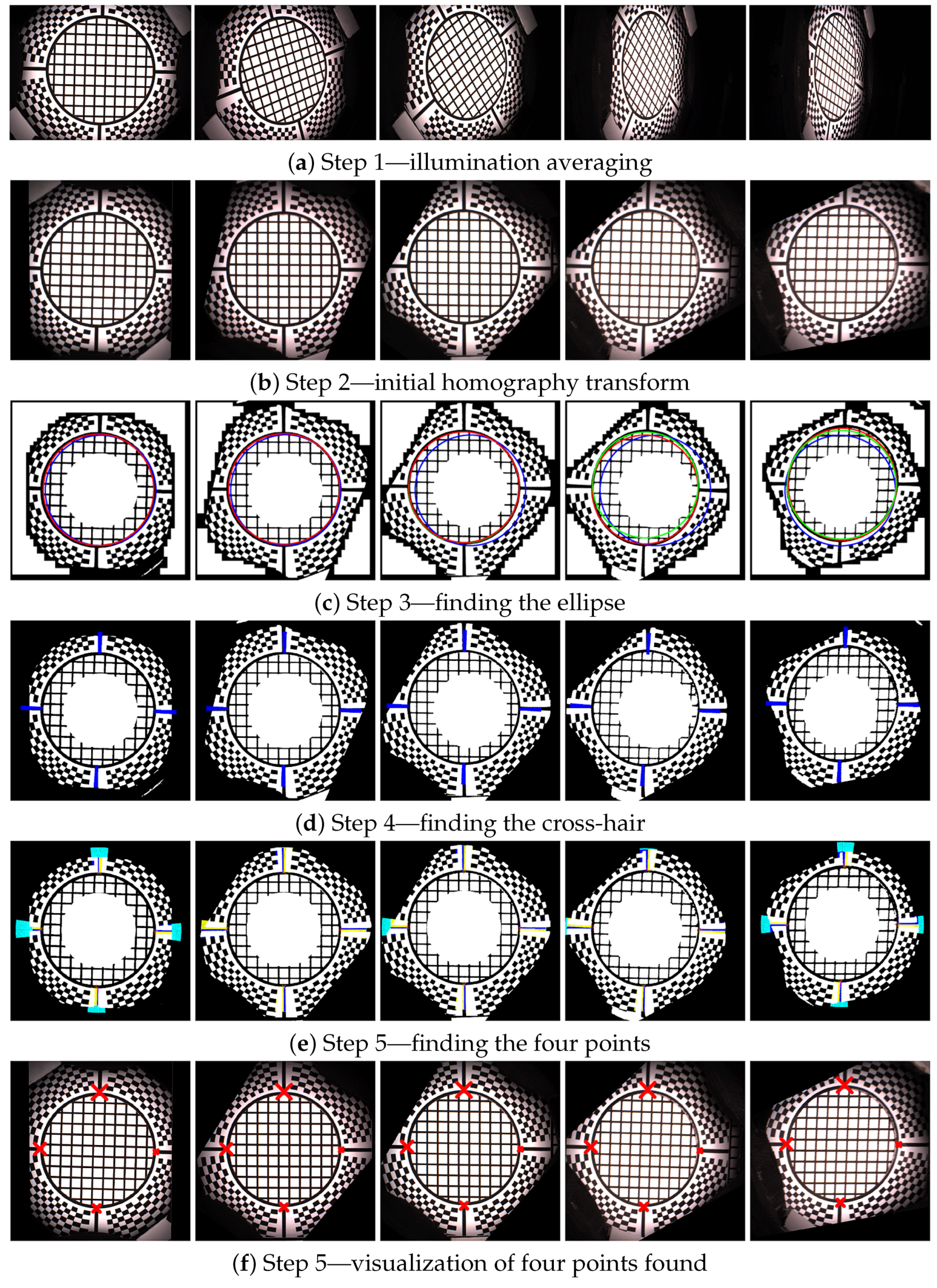

11.1. Step 1—Illumination Averaging

11.2. Step 2—Initial Homography Transform

11.3. Step 3—Ellipse Finding

11.4. Step 4—Cross-Hair Finding

11.5. Step 5—Four Points Location

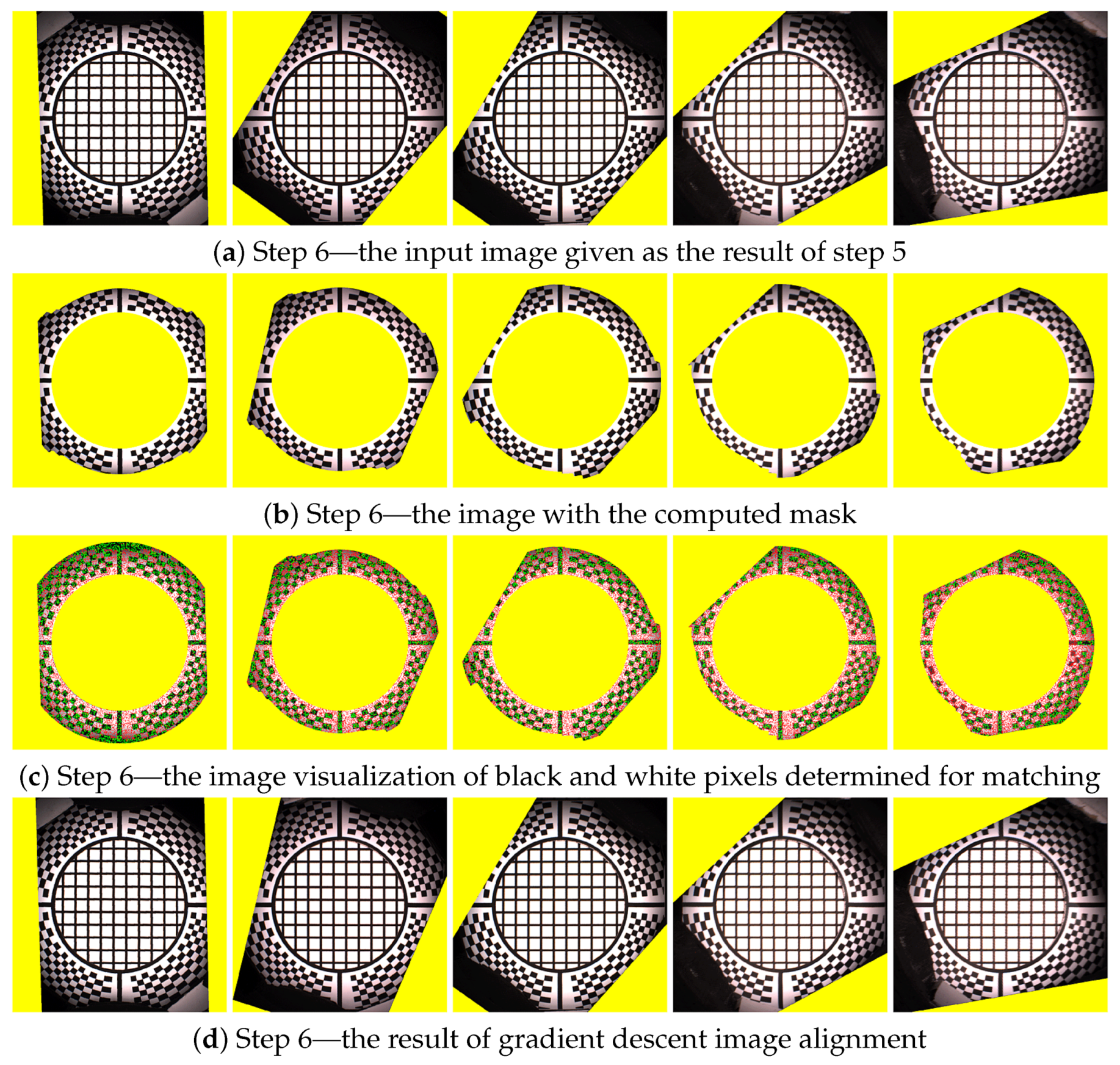

11.6. Step 6—Chequerboard Fitting

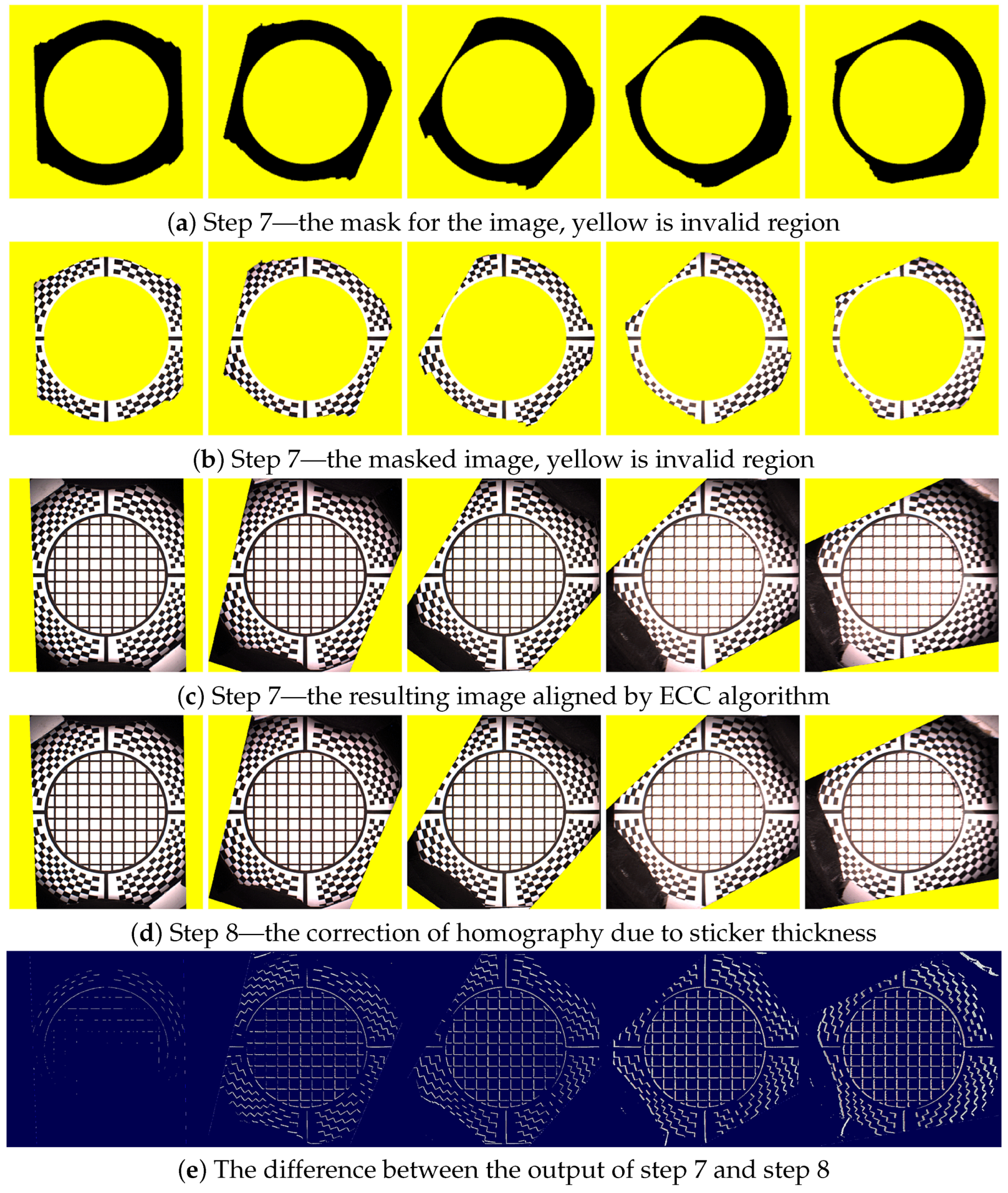

11.7. Step 7—Chequerboard Subpixel Fitting

11.8. Step 8—Marker Sticker Thickness Correction

11.9. Step 9—Data Transform and Processing

12. Results

12.1. Software

12.2. Measurements

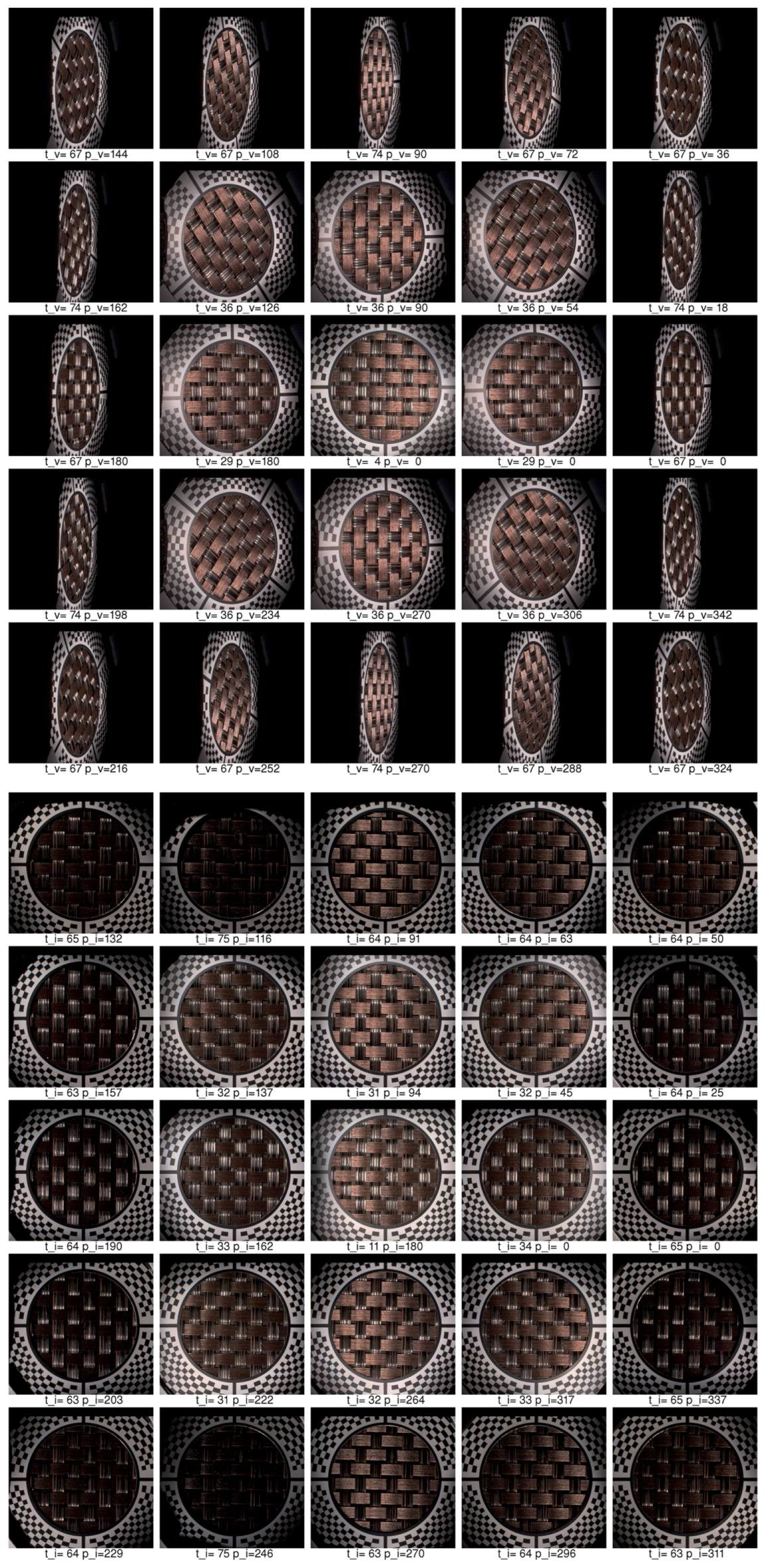

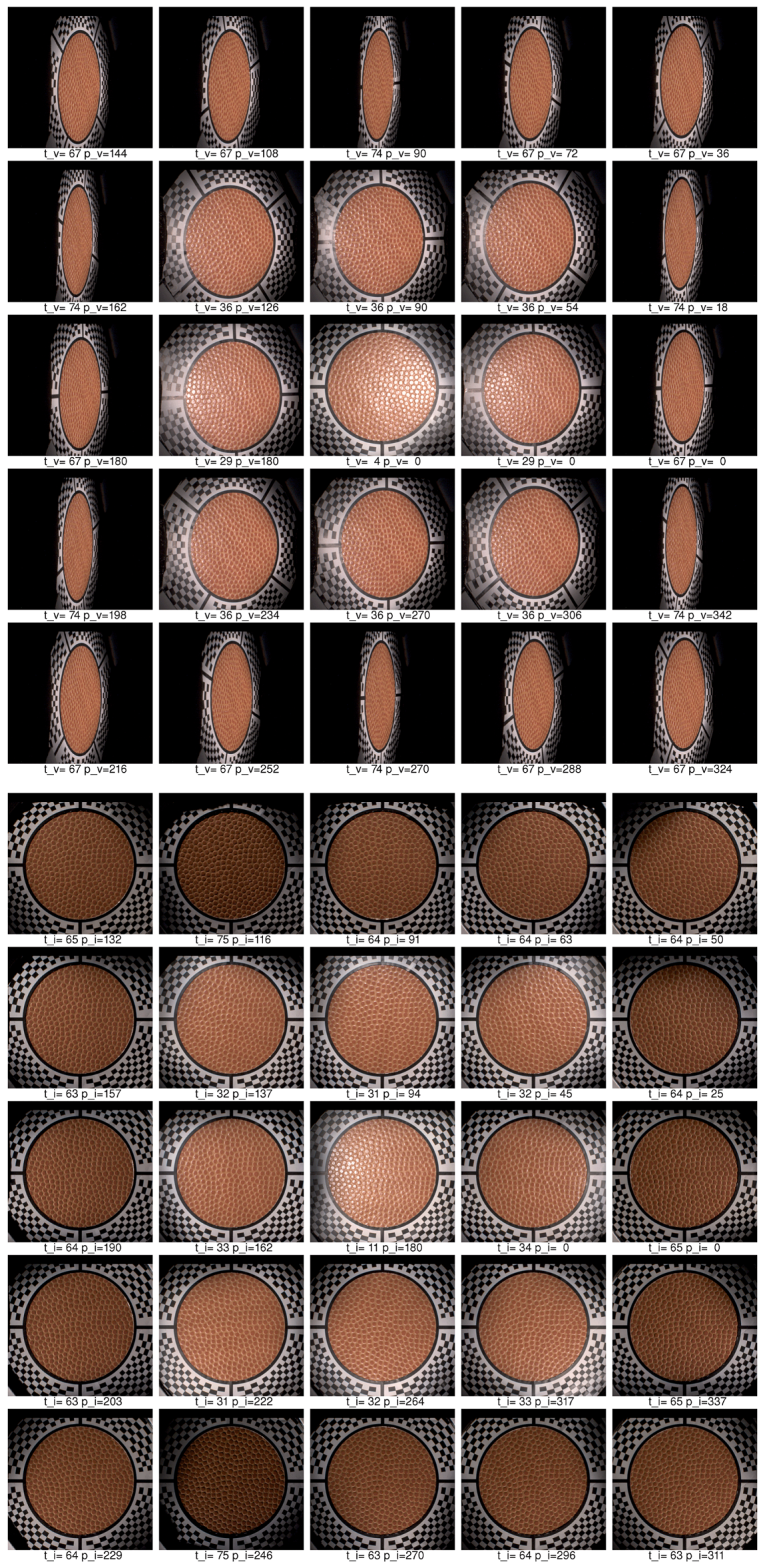

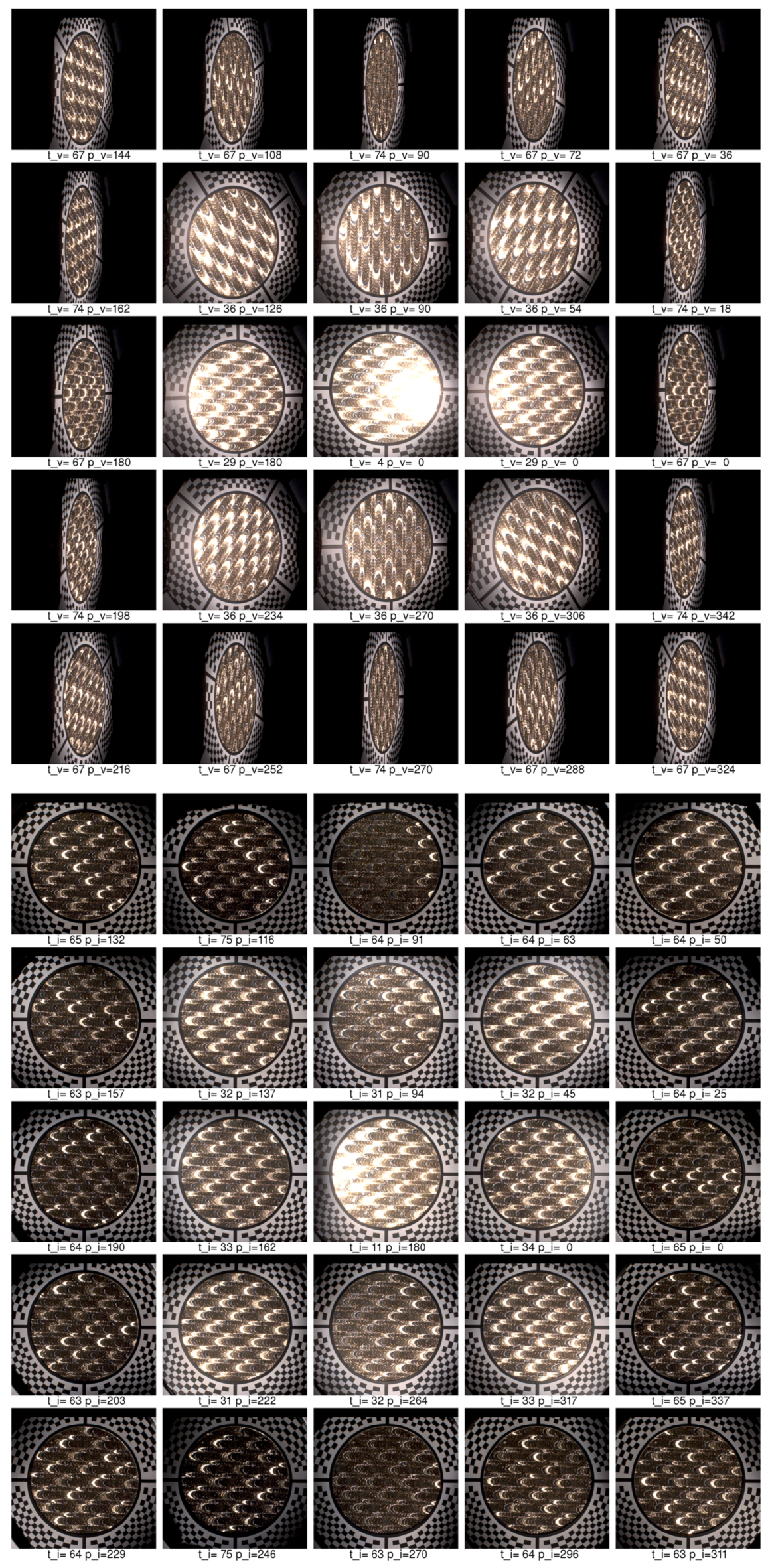

12.3. MAM 2014 Sample Set Measurements

12.4. Data Processing

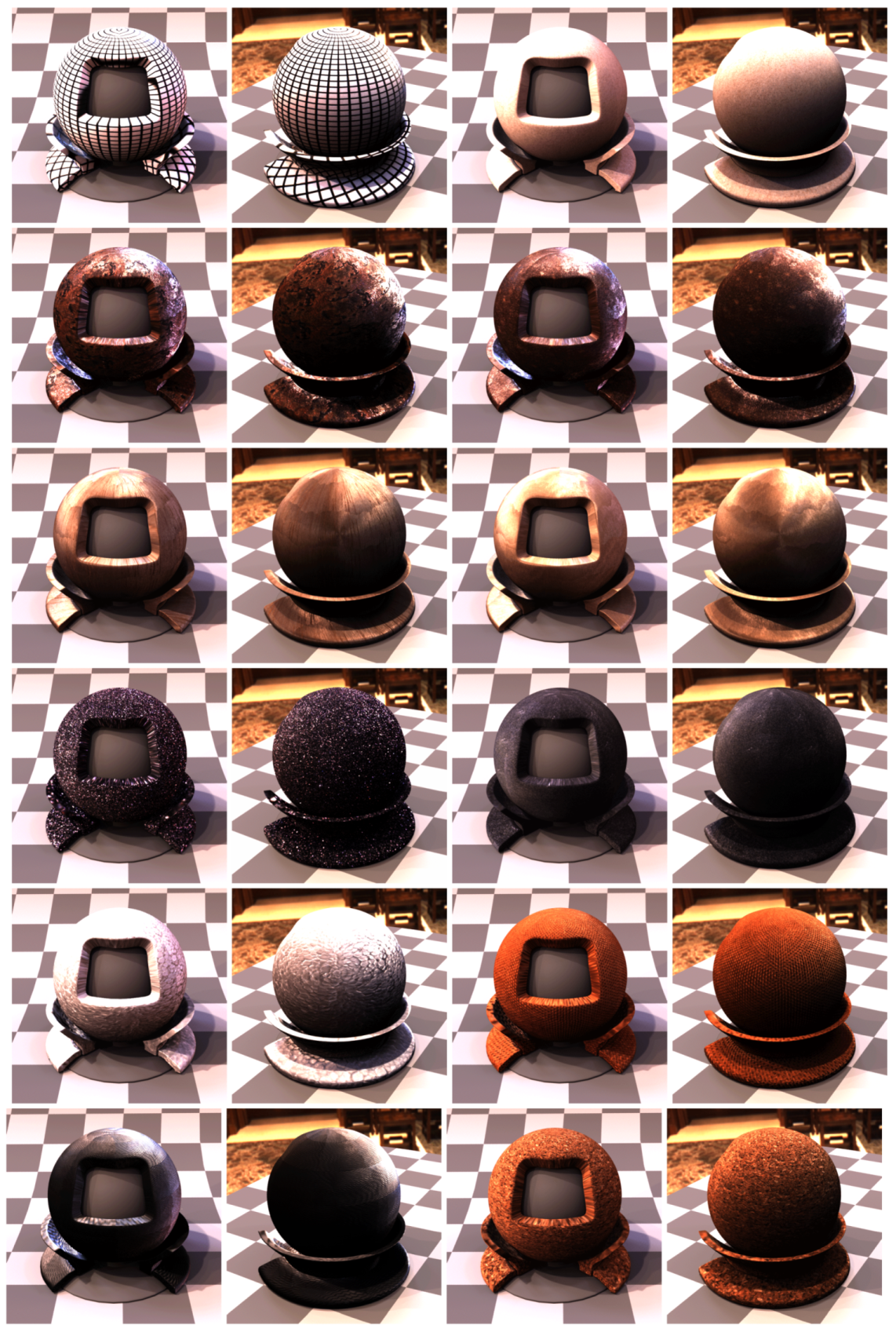

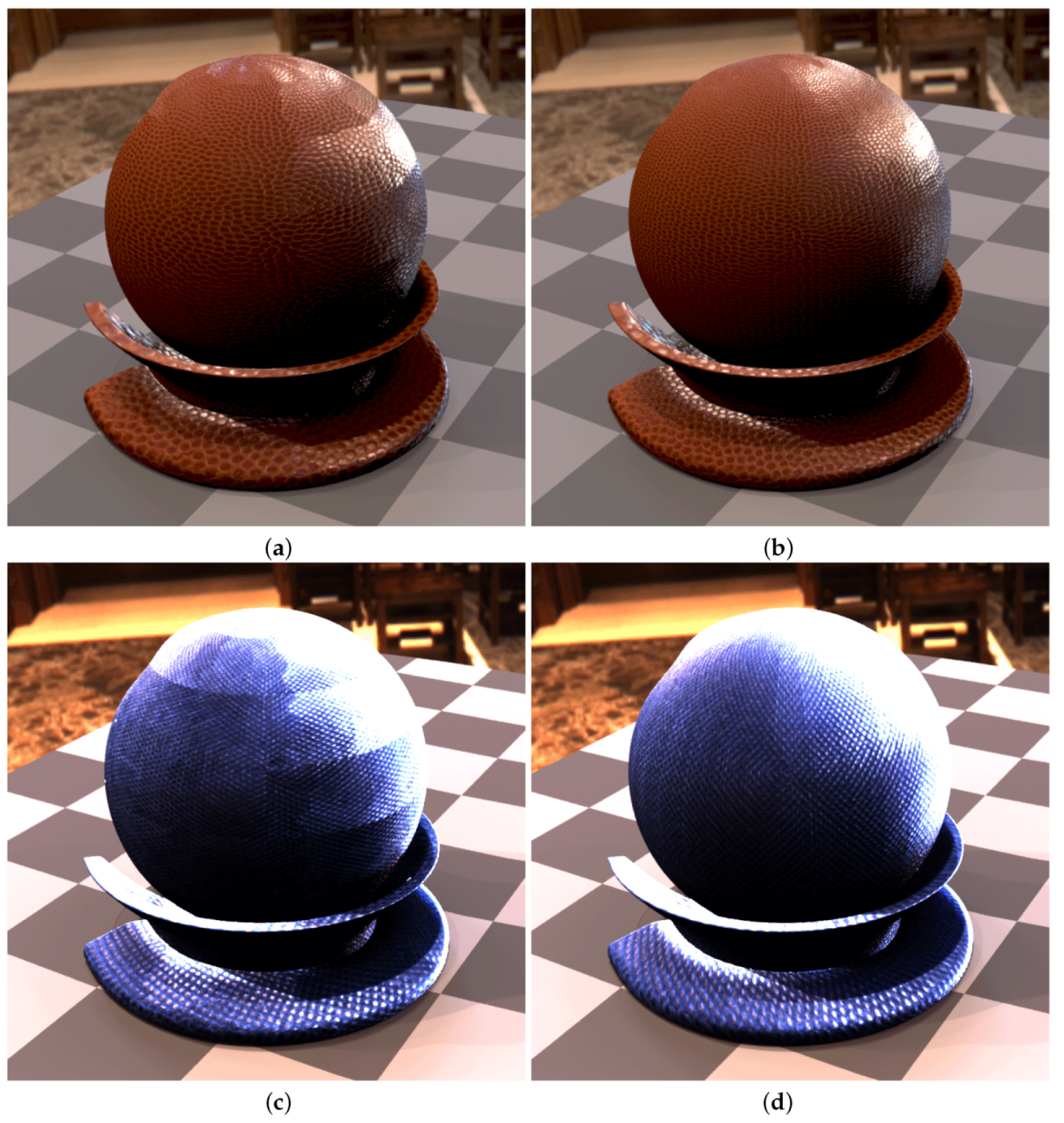

12.5. Rendering

12.6. Comparison

12.7. Data and Videos

13. Limitations

13.1. Optical and Spatial Limitations

13.2. Camera Limitations

13.3. Angular Limitations of Illumination

13.4. Highly Glossy BTF

13.5. Construction and Environmental Limitations

13.6. Other Limitations

14. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. DoF Derivation for BTF Instrument with Thin Lens Imaging

Appendix B. Geometric Uncertainty and Accuracy of Illumination and Cameras

Appendix B.1. Evaluation of Angular Position Uncertainty of Illumination Source

| Illumination Alignment Uncertainty | Meridional Direction | Zonal Direction |

|---|---|---|

| LED chip soldered to the platform | mm | mm |

| LED chip inclination | 0–15 | 0–15 |

| LED chip inclination compensated | ||

| with condenser decentration | 20–2.6 mm | 20–2.6 mm |

| adjustment screws clearance | mm | mm |

| adjustable platform alignment range | ||

| LED chip shift by adjustment | mm | mm |

| liner clearance in the dome hole | mm | mm |

| dome misalignment during machining | mm | mm |

| dome inclination towards sample | ||

| dome misalignment towards sample | mm | mm |

Appendix B.2. Evaluation of Angular Position Uncertainty of Cameras

| Camera Alignment Uncertainty | Meridional Direction | Zonal Direction |

|---|---|---|

| camera mount on adjustable platform | mm | mm |

| adjustment screws clearance | mm | mm |

| adjustable platform alignment range | ||

| camera shift by adjustment | mm | mm |

| fixtures mount on the arm | mm | mm |

| linear guide clearance | - | mm |

| threaded screw axial end play | mm | - |

| frame’s leg mounting position | mm | mm |

| inner aluminium frame misalignment during machining | mm | mm |

| inner aluminium frame inclination towards sample | ||

| inner aluminium frame misalignment towards sample | mm | mm |

Appendix C. Marker Sticker Code Listing in ANSI C++ Language

1 // The source code written by Vlastimil Havran, September 2015 2 #include <cstdlib> 3 #include <iostream> 4 #include <fstream> 5 #include <cmath> 6 #include "Board.h" 7 8 using namespace LibBoard; 9 using namespace std; 10 11 #define MIDCOLOR 0,255,0 12 13 // Positive - printing black on white background 14 #define WHITE 255,255,255 15 #define BLACK 0,0,0 16 #define NOINVERT 1 17 #define HOLE 1 18 19 inline float sqr(float a) { return a*a;} 20 21 // From Libboard library https://github.com/c-koi/libboard by Sebastien Fourey 22 Board board; 23 24 void PutRectangle(float centerx, float centery, float width, float height) 25 { 26 board.fillRectangle(centerx-width/2.0, centery+height/2.0, width, height); 27 } 28 29 int CropPoint(Point &p1, float mSize) 30 { 31 int cnt = 0; 32 float dist = sqrt(p1.x*p1.x + p1.y*p1.y); 33 float maxdist = sqrt(2.0)*mSize; 34 bool crop = false; 35 if (p1.x > mSize) {crop = true;} 36 if (p1.x < -mSize) {crop = true;} 37 if (p1.y > mSize) {crop = true;} 38 if (p1.y < -mSize) {crop = true;} 39 40 if (crop) { // Find the closest point to the center in the square 41 int cnt = 10000; 42 for (int i = cnt; i ; i–) { 43 float mult = (float)i/(float)cnt; 44 Point pp = p1; 45 pp.x *= mult; 46 pp.y *= mult; 47 bool crop2 = false; 48 if (pp.x > mSize) {crop2 = true;} 49 if (pp.x < -mSize) {crop2 = true;} 50 if (pp.y > mSize) {crop2 = true;} 51 if (pp.y < -mSize) {crop2 = true;} 52 if (!crop2) { 53 p1 = pp; 54 return true; // was cropped 55 } 56 } 57 } 58 return false; 59 } 60 61 int CropPointXY1(Point &pp, float mSizeX, float mSizeY) 62 { 63 int cnt = 0; 64 if ((pp.x < mSizeX)&&(pp.y < mSizeY)) 65 cnt++; 66 return cnt; 67 } 68 69 int CropPointXY2(Point &pp, float mSizeX, float mSizeY) 70 { 71 int cnt = 0; 72 if ((pp.x > mSizeX)&&(pp.y < mSizeY)) 73 cnt++; // inside; 74 return cnt; 75 } 76 77 bool CMP(float phi, float endPhi, int q) 78 { 79 if ((q % 2) == 0) 80 return phi < endPhi; 81 return phi > endPhi; 82 } 83 84 template<class T> void Swap(T &x, T &y) { T temp = x; x = y; y = temp;} 85 86 int main(int argc, char *argv[]) 87 { 88 board.clear( Color(WHITE) ); 89 float mSize = 85.f; // mm - size of marker 90 91 board.setLineWidth( 12.5 ).setPenColorRGBi( WHITE ); 92 board.setLineStyle( Shape::SolidStyle ); 93 board.setLineJoin( Shape::MiterJoin ); 94 board.setLineCap( Shape::RoundCap ); 95 96 // Draw a frame around the image - black 97 board.setLineWidth( 4.0 ).setPenColorRGBi( BLACK ); 98 board.drawRectangle(-0.5, 0.5, 1.0, 1.0); 99 // Draw a small frame right bottom 100 board.setLineWidth( 1.5 ).setPenColorRGBi( BLACK ); 101 board.drawRectangle(0.325, -0.43, 0.175, 0.07); 102 // Draw a small frame left bottom 103 board.setLineWidth( 1.5 ).setPenColorRGBi( BLACK ); 104 board.drawRectangle(-0.5, -0.43, 0.092, 0.07); 105 106 // chequerboard pattern in polar coordinates 107 float deltaPhi = 2.9*M_PI/(64.0)/2.0; // radians 108 float deltaRad = 4.3f/mSize/2.0; // mm 109 const float phiStartOffset = 0.1f; 110 const float phiEndOffset = 0.08f; 111 // Each quarter part of radial chequerboard patttern has its own data 112 for (int q = 0; q < 4; q++) { 113 int odd2 = 0; 114 float begPhi, endPhi, stepPhi; 115 // Set initial conditions 116 if (q == 0) { 117 begPhi = phiStartOffset; 118 endPhi = M_PI/2.0 - phiEndOffset; 119 stepPhi = deltaPhi; 120 } 121 if (q == 1) { 122 begPhi = M_PI - phiStartOffset; 123 endPhi = M_PI/2.0f + phiEndOffset; 124 stepPhi = -deltaPhi; 125 } 126 if (q == 2) { 127 begPhi = M_PI + phiStartOffset; 128 endPhi = 3.0/2.0*M_PI - phiEndOffset; 129 stepPhi = deltaPhi; 130 } 131 if (q == 3) { 132 begPhi = 2.0*M_PI - phiStartOffset; 133 endPhi = 3.0/2.0*M_PI + phiEndOffset; 134 stepPhi = -deltaPhi*1.05; 135 } 136 137 // Increasing phi 138 for (float phi = begPhi; CMP(phi+stepPhi, endPhi, q); phi += stepPhi, odd2++) { 139 if (q == 0) 140 stepPhi *= 1.03f; 141 if (q == 1) 142 stepPhi = -deltaPhi*1.3 - deltaPhi*0.3*sin((phi-begPhi)*3.5 + M_PI*2.0f/4.0); 143 if (q == 2) 144 stepPhi = deltaPhi*1.3 + deltaPhi*0.3*sin((phi-begPhi)*5.0 + M_PI*1.25f/4.0); 145 if (q == 3) 146 stepPhi = -deltaPhi*1.3 + deltaPhi*0.3*cos((phi-begPhi)*5.5 + M_PI*1.25f/4.0); 147 int odd = 0; // if to start with black or white region of chequerboard pattern 148 if ((odd2%2) == 0) odd = 1; 149 // Increasing radius by a fixed step 150 for (float rad = 28.5/mSize; rad < 0.61; rad += deltaRad) { 151 int cnt = 0; 152 // 4 corners defining the radial region of the chequerboard pattern element 153 Point p1(rad*cos(phi), rad*sin(phi)); 154 Point p2((rad+deltaRad)*cos(phi), (rad+deltaRad)*sin(phi)); 155 Point p3((rad+deltaRad)*cos(phi+stepPhi), (rad+deltaRad)*sin(phi+stepPhi)); 156 Point p4(rad*cos(phi+stepPhi), rad*sin(phi+stepPhi)); 157 if ((q == 1) || (q==3)) { 158 Swap(p2, p3); 159 Swap(p1, p4); 160 } 161 float maxf = 0.487; 162 cnt += CropPoint(p1, maxf); 163 cnt += CropPoint(p2, maxf); 164 cnt += CropPoint(p3, maxf); 165 cnt += CropPoint(p4, maxf); 166 float phi2 = atan2(p2.y, p2.x); 167 float phi3 = atan2(p3.y, p3.x); 168 169 float th = 0.004f; 170 float maxcheck = 0.48f; 171 if ( (q==0) && (p1.x > maxcheck) && (fabs(p1.x - p2.x) < th) && 172 (fabs(p2.x - p3.x) < th) && (fabs(p4.x - p3.x) < th) ) continue; 173 if ( (q==0) && (p1.y > maxcheck) && (fabs(p1.y - p2.y) < th) && 174 (fabs(p2.y - p3.y) < th) && (fabs(p4.y - p3.y) < th) ) continue; 175 if ( (q==1) && (p1.x < -maxcheck) && (fabs(p1.x - p2.x) < th) && 176 (fabs(p2.x - p3.x) < th) && (fabs(p4.x - p3.x) < th) ) continue; 177 if ( (q==1) && (p1.y > maxcheck) && (fabs(p1.y - p2.y) < th) && 178 (fabs(p2.y - p3.y) < th) && (fabs(p4.y - p3.y) < th) ) continue; 179 if ( (q==2) && (p1.x < -maxcheck) && (fabs(p1.x - p2.x) < th) && 180 (fabs(p2.x - p3.x) < th) && (fabs(p4.x - p3.x) < th) ) continue; 181 if ( (q==2) && (p1.y < -maxcheck) && (fabs(p1.y - p2.y) < th) && 182 (fabs(p2.y - p3.y) < th) && (fabs(p4.y - p3.y) < th) ) continue; 183 if ( (q==3) && (p1.x > maxcheck) && (fabs(p1.x - p2.x) < th) && 184 (fabs(p2.x - p3.x) < th) && (fabs(p4.x - p3.x) < th) ) continue; 185 if ( (q==3) && (p1.y < -maxcheck) && (fabs(p1.y - p2.y) < th) && 186 (fabs(p2.y - p3.y) < th) && (fabs(p4.y - p3.y) < th) ) continue; 187 188 if (cnt < 8) { // We have not cropped the whole region, draw it 189 // Avoid right bottom corner 190 const float bottomDistMarkY1 = -0.43; 191 const float bottomDistMarkX1 = 0.36; 192 int cnt2 = CropPointXY2(p1, bottomDistMarkX1, bottomDistMarkY1); 193 cnt2 += CropPointXY2(p2, bottomDistMarkX1, bottomDistMarkY1); 194 cnt2 += CropPointXY2(p3, bottomDistMarkX1, bottomDistMarkY1); 195 cnt2 += CropPointXY2(p4, bottomDistMarkX1, bottomDistMarkY1); 196 if (cnt2 > 0) { 197 continue; 198 } 199 // Avoid left bottom corner 200 const float bottomDistMarkY2 = -0.43; 201 const float bottomDistMarkX2 = -0.42; 202 cnt2 = 0; 203 cnt2 += CropPointXY1(p1, bottomDistMarkX2, bottomDistMarkY2); 204 cnt2 += CropPointXY1(p2, bottomDistMarkX2, bottomDistMarkY2); 205 cnt2 += CropPointXY1(p3, bottomDistMarkX2, bottomDistMarkY2); 206 cnt2 += CropPointXY1(p4, bottomDistMarkX2, bottomDistMarkY2); 207 if (cnt2 > 0) { 208 odd = !odd; 209 continue; 210 } 211 // Draw a filed polygon of polar chequerboard region in black 212 vector<Point> polyline; 213 // First vertex p1 214 polyline.push_back(p1); 215 cnt2 = 200; // how finely decompose arc to line segments 216 // From p2 to p3 217 float rad1 = sqrt(p2.x*p2.x + p2.y*p2.y); 218 float rad2 = sqrt(p3.x*p3.x + p3.y*p3.y); 219 float phi1 = atan2(p2.y, p2.x); 220 float phi2 = atan2(p3.y, p3.x); 221 int i = 0; 222 if (phi2 > phi1) { 223 for (float p = phi1; p < phi2; p += (phi2-phi1)/(float)cnt2, i++) { 224 float alpha = (float)i/(float)cnt2; 225 float r = rad1*(1.0 - alpha) + rad2*alpha; 226 Point pp(r*cos(p), r*sin(p)); 227 polyline.push_back(pp); 228 } 229 } else { 230 for (float p = phi1; p > phi2; p -= (phi1-phi2)/(float)cnt2, i++) { 231 float alpha = (float)i/(float)cnt2; 232 float r = rad1*(1.0 - alpha) + rad2*alpha; 233 Point pp(r*cos(p), r*sin(p)); 234 polyline.push_back(pp); 235 } // for i 236 } 237 polyline.push_back(p3); 238 // From p4 to p1 239 rad1 = sqrt(p4.x*p4.x + p4.y*p4.y); 240 rad2 = sqrt(p1.x*p1.x + p1.y*p1.y); 241 phi1 = atan2(p4.y, p4.x); 242 phi2 = atan2(p1.y, p1.x); 243 i = 0; 244 if (phi2 > phi1) { 245 for (float p = phi1; p < phi2; p += (phi2-phi1)/(float)cnt2, i++) { 246 float alpha = (float)i/(float)cnt2; 247 float r = rad1*(1.0 - alpha) + rad2*alpha; 248 Point pp(r*cos(p), r*sin(p)); 249 polyline.push_back(pp); 250 } 251 } else { 252 for (float p = phi1; p > phi2; p -= (phi1-phi2)/(float)cnt2, i++) { 253 float alpha = (float)i/(float)cnt2; 254 float r = rad1*(1.0 - alpha) + rad2*alpha; 255 Point pp(r*cos(p), r*sin(p)); 256 polyline.push_back(pp); 257 } // for i 258 } 259 if (odd) // draw only black regions of polar chequerboard pattern 260 board.fillPolyline(polyline, -1); 261 } 262 odd = !odd; // change the order of black and white the next time 263 } // rad 264 } // phi 265 } // for q 266 267 // Add four rectangles to represent cross hair 268 float bw = 0.02; 269 float bh = 0.18; 270 const float offsetMark = 0.40; 271 float kw = 1.0; 272 float kh = 1.0; 273 // top middle 274 PutRectangle(0.0, offsetMark, bw*kw, bh*kh); 275 // bottom middle 276 PutRectangle(0.0, -offsetMark, bw*kw, bh*kh); 277 // right middle 278 PutRectangle(offsetMark, 0, bh*kh, bw*kw); 279 // left middle 280 PutRectangle(-offsetMark, 0, bh*kh, bw*kw); 281 282 const float RADIUS = 23.5; // mm 283 const float RADIUS2 = 20.0; // mm 284 const float RADIUS3 = 51.0/2.0f; // mm 285 // Draw the important circle by black color 286 if (!HOLE) { 287 if (NOINVERT) { 288 // black 289 board.setLineWidth( RADIUS2 ).setPenColorRGBi( BLACK ); 290 board.drawCircle(0, 0, 1.00*RADIUS/mSize, -1); 291 } 292 else { 293 float RADIUS3 = RADIUS + RADIUS2/6.0 + 0.215f; 294 board.setLineWidth(0.f).setPenColorRGBi( BLACK ); 295 board.fillCircle(0, 0, RADIUS3/mSize,-1); 296 } 297 } else { 298 // Make a hole in special color 299 board.setLineWidth( RADIUS2 ).setPenColorRGBi( BLACK ); 300 board.drawCircle(0, 0, 1.00*RADIUS/mSize,-1); 301 board.setLineWidth(0.f).setPenColorRGBi( MIDCOLOR ); 302 board.fillCircle(0, 0, RADIUS3/mSize,-1); 303 } 304 305 // Draw a cross in the middle of the sticker - black 306 if (NOINVERT) { 307 // This makes no sense for a sticker production company 308 board.setLineWidth( 0.5 ).setPenColorRGBi( BLACK ); 309 float deltaCross = 0.04f; 310 board.drawLine( -deltaCross, 0, deltaCross, 0); 311 board.drawLine( 0, -deltaCross, 0, deltaCross); 312 } 313 314 board.setPenColor( Color(BLACK) ).setFont( Fonts::HelveticaBold, 5.5 ) 315 .drawText( -0.488, 0.440, "FEL FSI" ); 316 board.setPenColor( Color(BLACK) ).setFont( Fonts::HelveticaBold, 5.5 ) 317 .drawText( -0.488, 0.466, "CVUT" ); 318 board.setPenColor( Color(BLACK) ).setFont( Fonts::HelveticaBold, 5.5 ) 319 .drawText( 0.380, 0.466, "HAVRAN" ); 320 321 // 85x85mm - final size of EPS/FIG/SVG 322 board.saveEPS("markersticker.eps", mSize, mSize, 0); 323 return 0; 324 }

Appendix D. Gantry Assembly

References

- Nicodemus, F.E.; Richmond, J.C.; Hsia, J.J.; Ginsberg, I.W.; Limperis, T. Geometric Considerations and Nomenclature for Reflectance; Monograph 161, National Bureau of Standards (US); Jones and Bartlett Publishers: Burlington, MA, USA, 1977. [Google Scholar]

- Dana, K.; Van-Ginneken, B.; Nayar, S.; Koenderink, J. Reflectance and Texture of Real World Surfaces. ACM Trans. Graph. 1999, 18, 1–34. [Google Scholar] [CrossRef]

- Dana, K.J.; Nayar, S.K.; van Ginneken, B.; Koenderink, J.J. Reflectance and Texture of Real-World Surfaces. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, San Juan, Puerto Rico, 17–19 June 1997; pp. 151–157.

- Schwartz, C.; Sarlette, R.; Weinmann, M.; Rump, M.; Klein, R. Design and Implementation of Practical Bidirectional Texture Function Measurement Devices Focusing on the Developments at the University of Bonn. Sensors 2014, 14, 7753–7819. [Google Scholar] [CrossRef] [PubMed]

- Filip, J.; Haindl, M. Bidirectional Texture Function Modeling: A State of the Art Survey. IEEE Trans. Pattern Anal. Mach. Intell. 2009, 31, 1921–1940. [Google Scholar] [CrossRef] [PubMed]

- Weyrich, T.; Lawrence, J.; Lensch, H.; Rusinkiewicz, S.; Zickler, T. Principles of Appearance Acquisition and Representation. Found. Trends Comput. Graph. Vis. 2008, 4, 75–191. [Google Scholar] [CrossRef]

- Müller, G.; Meseth, J.; Sattler, M.; Sarlette, R.; Klein, R. Acquisition, Synthesis, and Rendering of Bidirectional Texture Functions. Comput. Graph. Forum 2005, 24, 83–109. [Google Scholar] [CrossRef]

- Weinmann, M.; Klein, R. Advances in Geometry and Reflectance Acquisition (Course Notes). In SIGGRAPH Asia 2015 Courses; ACM: New York, NY, USA, 2015; pp. 1:1–1:71. [Google Scholar]

- Riviere, J.; Peers, P.; Ghosh, A. Mobile Surface Reflectometry. Comput. Graph. Forum 2016, 35, 191–202. [Google Scholar] [CrossRef]

- Aittala, M.; Weyrich, T.; Lehtinen, J. Practical SVBRDF Capture in the Frequency Domain. ACM Trans. Graph. 2013, 32, 110:1–110:12. [Google Scholar] [CrossRef]

- Dana, K. BRDF/BTF Measurement Device. In Proceedings of the Eighth IEEE International Conference on Computer Vision, Vancouver, BC, Canada, 7–14 July 2001; Volume 2, pp. 460–466.

- Han, J.Y.; Perlin, K. Measuring Bidirectional Texture Reflectance with a Kaleidoscope. ACM Trans. Graph. 2003, 22, 741–748. [Google Scholar] [CrossRef]

- Ben-Ezra, M.; Wang, J.; Wilburn, B.; Li, X.; Ma, L. An LED-Only BRDF Measurement Device. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR 2008), Anchorage, AK, USA, 23–28 June 2008; IEEE Computer Society: Los Alamitos, CA, USA, 2008; pp. 1–8. [Google Scholar]

- Debevec, P.; Hawkins, T.; Tchou, C.; Duiker, H.P.; Sarokin, W.; Sagar, M. Acquiring the Reflectance Field of a Human Face. In Proceedings of the 27th Annual Conference on Computer Graphics and Interactive Techniques, Seattle, WA, USA, 14–18 July 1980; ACM Press: New York, NY, USA, 2000; pp. 145–156. [Google Scholar]

- Malzbender, T.; Gelb, D.; Wolters, H. Polynomial Texture Maps. In Proceedings of the 28th Annual Conference on Computer Graphics and Interactive Techniques, Los Angeles, CA, USA, 12–17 August 2001; ACM: New York, NY, USA, 2001; pp. 519–528. [Google Scholar]

- Foo, S.C. A Gonioreflectometer for Measuring the Bidirectional Reflectance of Material for Use in Illumination Computation. Master’s Thesis, Cornell University, Ithaca, NY, USA, August 1997. [Google Scholar]

- Sattler, M.; Sarlette, R.; Klein, R. Efficient and Realistic Visualization of Cloth. In Proceedings of the 14th Eurographics Workshop on Rendering, Leuven, Belgium, 25–26 June 2003; Eurographics Association: Aire-la-Ville, Switzerland, 2003; pp. 167–177. [Google Scholar]

- Huenerhoff, D.; Grusemann, U.; Hope, A. New robot-based gonioreflectometer for measuring spectral diffuse reflection. Metrologia 2006, 43, S11. [Google Scholar] [CrossRef]

- Schwartz, C.; Sarlette, R.; Weinmann, M.; Klein, R. DOME II: A Parallelized BTF Acquisition System. In Proceedings of the Eurographics 2013 Workshop on Material Appearance Modeling, Issues and Acquisition, MAM ’13, Zaragoza, Spain, 19 June 2013; Eurographics Association: Aire-la-Ville, Switzerland, 2013; pp. 25–31. [Google Scholar]

- Köhler, J.; Noll, T.; Reis, G.; Stricker, D. A Full-Spherical Device for Simultaneous Geometry and Reflectance Acquisition. In Proceedings of the 2013 IEEE Workshop on Applications of Computer Vision, Clearwater Beach, FL, USA, 15–17 January 2013; pp. 355–362.

- Filip, J.; Vávra, R.; Krupička, M. Rapid Material Appearance Acquisition Using Consumer Hardware. Sensors 2014, 14, 19785–19805. [Google Scholar] [CrossRef] [PubMed]

- Hošek, J.; Havran, V.; Čáp, J.; Němcová, S.; Macúchová, K.; Bittner, J.; Zicha, J. Realisation of Circular Motion for Portable BTF Measurement Instrument. Romanian Rev. Precis. Mech. Opt. Mechatron. 2015, 48, 252–255. [Google Scholar]

- Tong, X.; Wang, J.; Lin, S.; Guo, B.; Shum, H.Y. Modeling and rendering of quasi-homogeneous materials. ACM Trans. Graph. 2005, 24, 1054–1061. [Google Scholar] [CrossRef]

- CIE 13.3-95. Method of Measuring and Specifying Colour Rendering Properties of Light Sources, Publication 13.3-1995. In A Verbatim Re-Publication of the 1974, 2nd ed.; Commission Internationale de l’Eclairage: Vienna, Austria, 1995. [Google Scholar]

- CIE 177:2007. CIE Technical Report 177:2007, Color Rendering of White LED Light Sources; Commission Internationale de l’Eclairage: Vienna, Austria, 2007. [Google Scholar]

- EBU. TECH 3355—Method for the Assesment of the Colorimetric Properties of Luminaires—The Television Lighting Consistency Index (TLCI-2012); EBU: Geneva, Switzerland, 2014. [Google Scholar]

- Lloyd, S. Least Squares Quantization in PCM. IEEE Trans. Inf. Theory 2006, 28, 129–137. [Google Scholar] [CrossRef]

- Vávra, R.; Filip, J. Registration of Multi-View Images of Planar Surfaces. In Proceedings of the 11th Asian Conference on Computer Vision, ACCV, Daejeon, Korea, 5–9 November 2012.

- Havran, V. Practical Experiences with Using Autocollimator for Surface Reflectance Measurement. In Workshop on Material Appearance Modeling; Klein, R., Rushmeier, H., Eds.; The Eurographics Association: Geneva, Switzerland, 2016. [Google Scholar]

- Billinghurst, M.; Clark, A.; Lee, G. A Survey of Augmented Reality. Found. Trends Hum. Comput. Interact. 2015, 8, 73–272. [Google Scholar] [CrossRef]

- Haindl, M.; Filip, J. Visual Texture. In Advances in Computer Vision and Pattern Recognition; Springer: London, UK, 2013. [Google Scholar]

- Press, W.H.; Teukolsky, S.A.; Vetterling, W.T.; Flannery, B.P. Numerical Recipes in C++; Cambridge University Press: Cambridge, UK, 2002. [Google Scholar]

- Evangelidis, G.D.; Psarakis, E.Z. Parametric Image Alignment Using Enhanced Correlation Coefficient Maximization. IEEE Trans. Pattern Anal. Mach. Intell. 2008, 30, 1858–1865. [Google Scholar] [CrossRef] [PubMed]

- Bradski, G.; Kaehler, A. Learning OpenCV: Computer Vision in C++ with the OpenCV Library, 2nd ed.; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2013. [Google Scholar]

- Rushmeier, H. The MAM2014 Sample Set. In Eurographics Workshop on Material Appearance Modeling; Klein, R., Rushmeier, H., Eds.; The Eurographics Association: Geneva, Switzerland, 2014. [Google Scholar]

- Müller, G.; Meseth, J.; Klein, R. Compression and Real-Time Rendering of Measured BTFs Using Local PCA. In Vision, Modeling and Visualisation 2003; Ertl, T., Girod, B., Greiner, G., Niemann, H., Seidel, H.P., Steinbach, E., Westermann, R., Eds.; Akademische Verlagsgesellschaft Aka GmbH: Berlin, Germany, 2003; pp. 271–280. [Google Scholar]

- Haindl, M.; Hatka, M. A Roller—Fast Sampling-Based Texture Synthesis Algorithm. In Proceedings of the 13th International Conference in Central Europe on Computer Graphics, Visualization and Computer Vision 2005, Bory, Czech Republic, 31 January–4 February 2005; Skala, V., Ed.; University of Western Bohemia: Plzen, Czech Republic, 2005; pp. 80–83. [Google Scholar]

- Jakob, W. Mitsuba Renderer. 2010. Available online: http://www.mitsuba-renderer.org (accessed on 20 May 2016).

- Havran, V.; Neummann, A.; Zotti, G.; Purgathofer, W.; Seidel, H.P. On Cross-Validation and Resampling of BRDF Data Measurements. In Proceedings of the 21st Spring Conference on Computer Graphics (SCCG 2005), Budmerice, Slovakia, 12–14 May 2005; Juettler, B., Ed.; ACM SIGGRAPH and EUROGRAPHICS, 2005; pp. 154–161. [Google Scholar]

- Ruiters, R.; Schwartz, C.; Klein, R. Example-Based Interpolation and Synthesis of Bidirectional Texture Functions. Comput. Graph. Forum 2013, 32, 361–370. [Google Scholar] [CrossRef]

| Parameter/Setup | Dome 1 | Dome 2 | Lightdrum | |

|---|---|---|---|---|

| Configuration (Year) | 2004 | 2008/2011 | 2012 | 2016 |

| dimensions (L × W × H) [mm] | ||||

| distance to sample [mm] | 650 | 1000 | 251 | |

| directions | ||||

| resolution | 9.4 | 9 | 11.1 | |

| resolution | 9.4 | 7.6 | 10.1 | |

| maximum θ | 75 | 75 | 75 | |

| equivalent focal length [mm] | 116 | 104 | 190/95 | 80 |

| focal length [mm] | 16.22 | 22 | 100/50 | 12.5 |

| spatial resolution [DPI] | 235 | 450 | 380/190 | 300/150 |

| dynamic range [dB] | 28/33/33 | 25/44/44 | 32/60/∞ | 60.06/78.06/- |

| spectral bands | RGB | RGB | RGB | |

| camera type | Canon P&S | Industrial CCD | Industrial CMOS | |

| camera sensor size [mm] | ||||

| camera sensor pixel resolution | ||||

| #cameras | 151 | 11 | 6 | |

| camera data | 8 BPP JPEG | 12 BPP raw | 12 BPP raw | |

| light source type | flash | LED | LED | |

| #light sources | 151 | 198 | 139 | |

| measurement size [mm] | ⊘ 51 | |||

| direction variation (field of view) | ||||

| BTF raw/HDR images | 91,204/22,801 | 156,816/52,272 | 66,720/16,680 | |

| saved HDR images resolution | ||||

| equivalent BTF HDR size [GB] | 200 | 764 | 612 | 40 |

| BTF size (disk space) [GB] | 22 | 281 | 918 | 40 |

| BTF time [h] | 1.8 | 4.4–9.7 | 0.28 | |

| HDR speed [Msamples/s] | 10.56 | 40.27 | 6–13.2 | 12.58 |

| radiometric repeatability | - | 7.4 | 0.1 | <0.6 |

| geometric repeatability | - | 0.81 px/0.006 | 0.12 px/0.002 | 1.20 px/0.011 |

| and ±0.05 px/0.002 | ||||

| sample flexibility | none | some; arbitrary | arbitrary , dependent | |

| radiometric calib. procedure | complex | easy | easy | |

| geometric calib. procedure | automatic | automatic | automatic | |

| durability (#measurements) | - | ≈265/>347 | >3650 | >20,000 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Havran, V.; Hošek, J.; Němcová, Š.; Čáp, J.; Bittner, J. Lightdrum—Portable Light Stage for Accurate BTF Measurement on Site. Sensors 2017, 17, 423. https://doi.org/10.3390/s17030423

Havran V, Hošek J, Němcová Š, Čáp J, Bittner J. Lightdrum—Portable Light Stage for Accurate BTF Measurement on Site. Sensors. 2017; 17(3):423. https://doi.org/10.3390/s17030423

Chicago/Turabian StyleHavran, Vlastimil, Jan Hošek, Šárka Němcová, Jiří Čáp, and Jiří Bittner. 2017. "Lightdrum—Portable Light Stage for Accurate BTF Measurement on Site" Sensors 17, no. 3: 423. https://doi.org/10.3390/s17030423

APA StyleHavran, V., Hošek, J., Němcová, Š., Čáp, J., & Bittner, J. (2017). Lightdrum—Portable Light Stage for Accurate BTF Measurement on Site. Sensors, 17(3), 423. https://doi.org/10.3390/s17030423