Mechanical Structural Design of a MEMS-Based Piezoresistive Accelerometer for Head Injuries Monitoring: A Computational Analysis by Increments of the Sensor Mass Moment of Inertia †

Abstract

:1. Introduction

2. Theory and Method

2.1. Theory of Operations

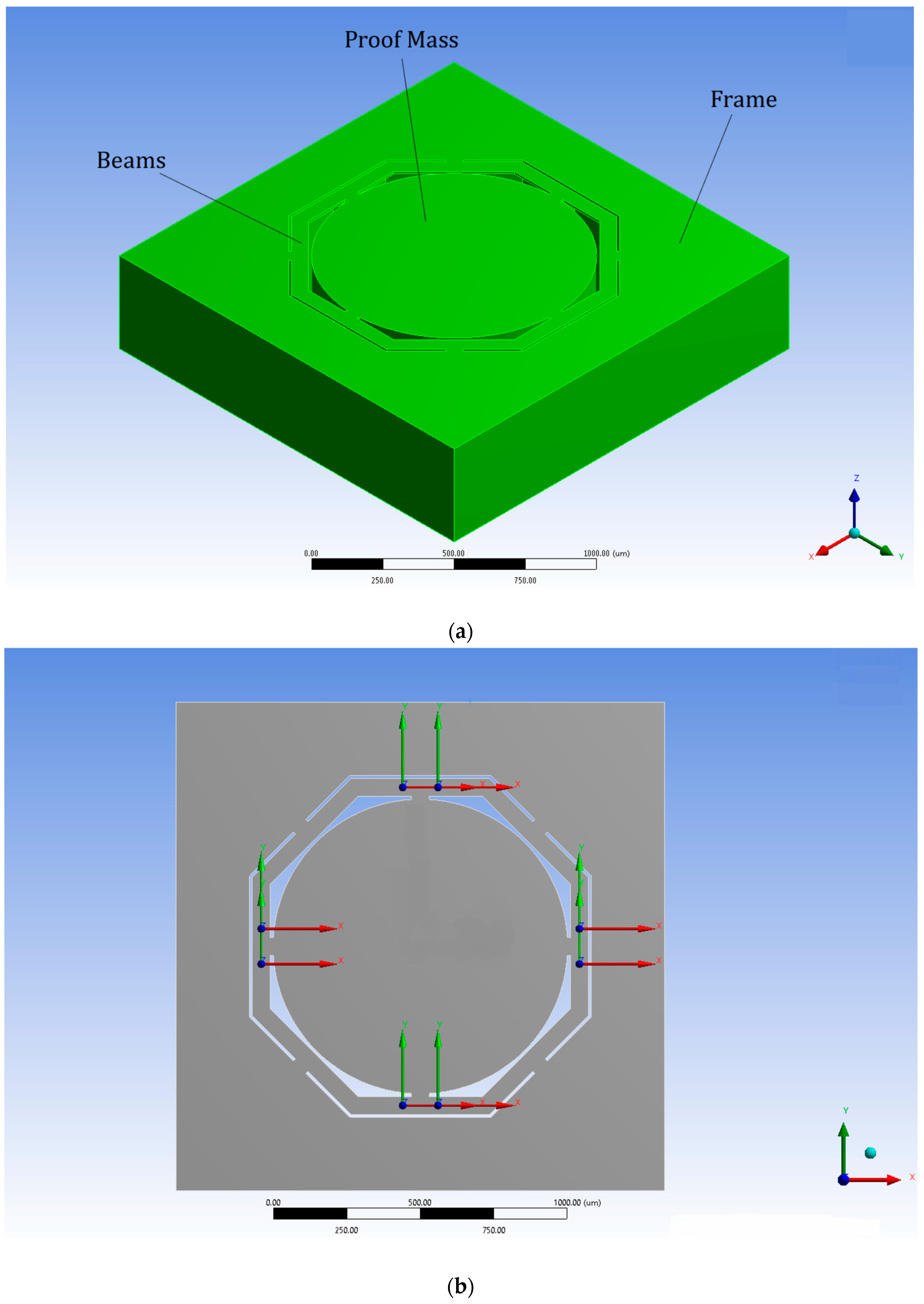

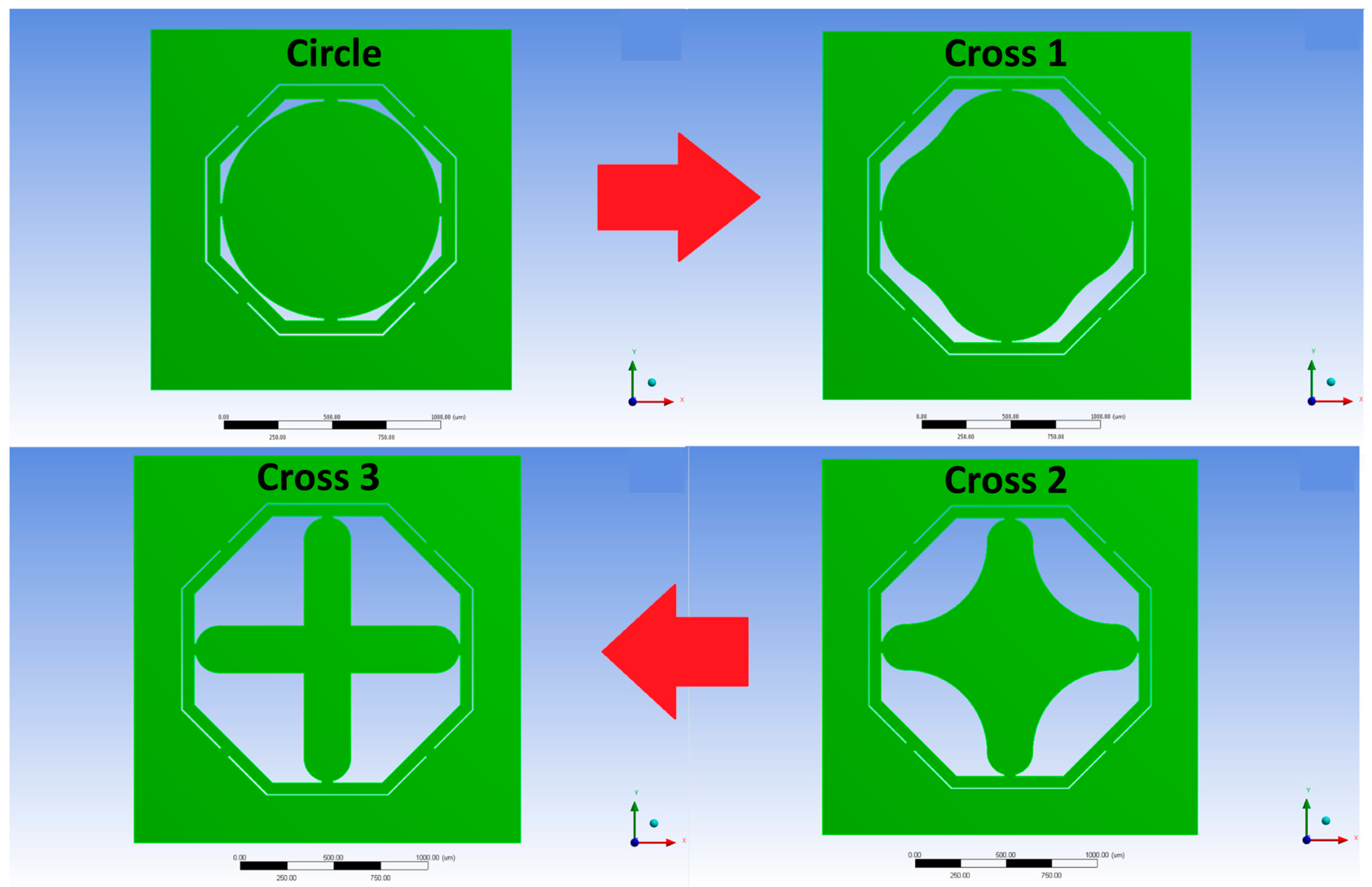

2.2. Design, Modelling, and Optimization

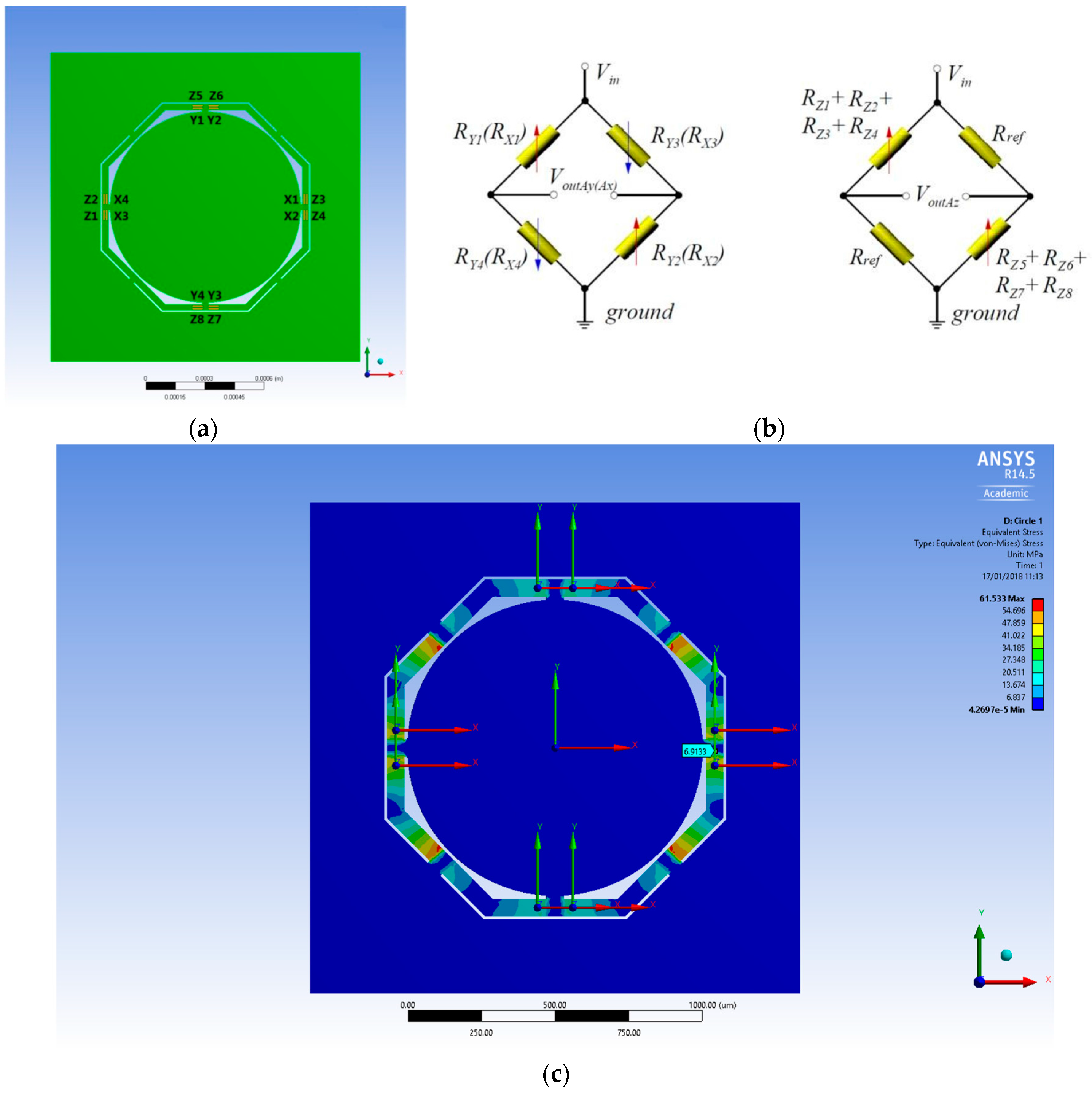

2.3. Measurement Circuit

2.4. Electrical Sensitivity and Cross-Axis Sensitivity

3. Results

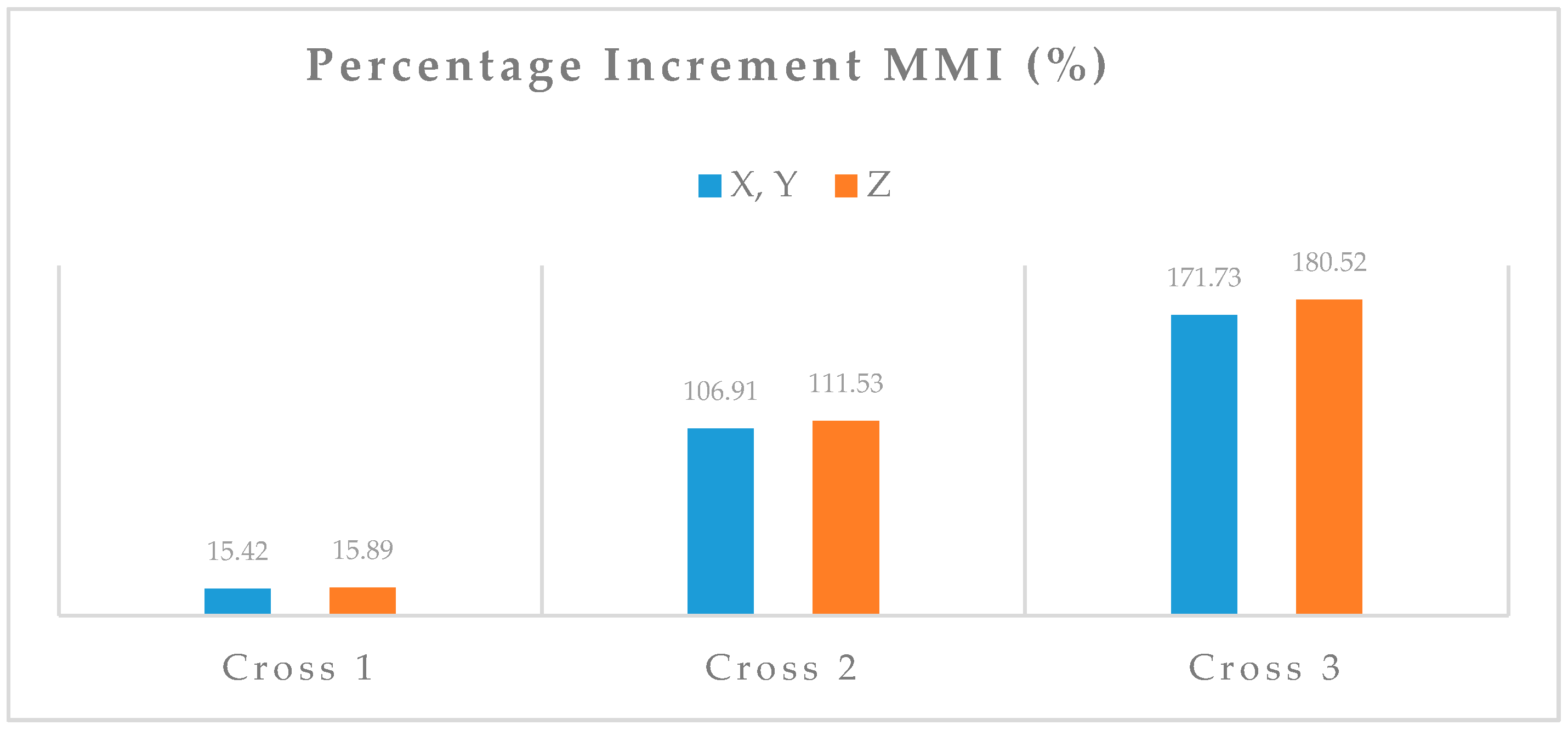

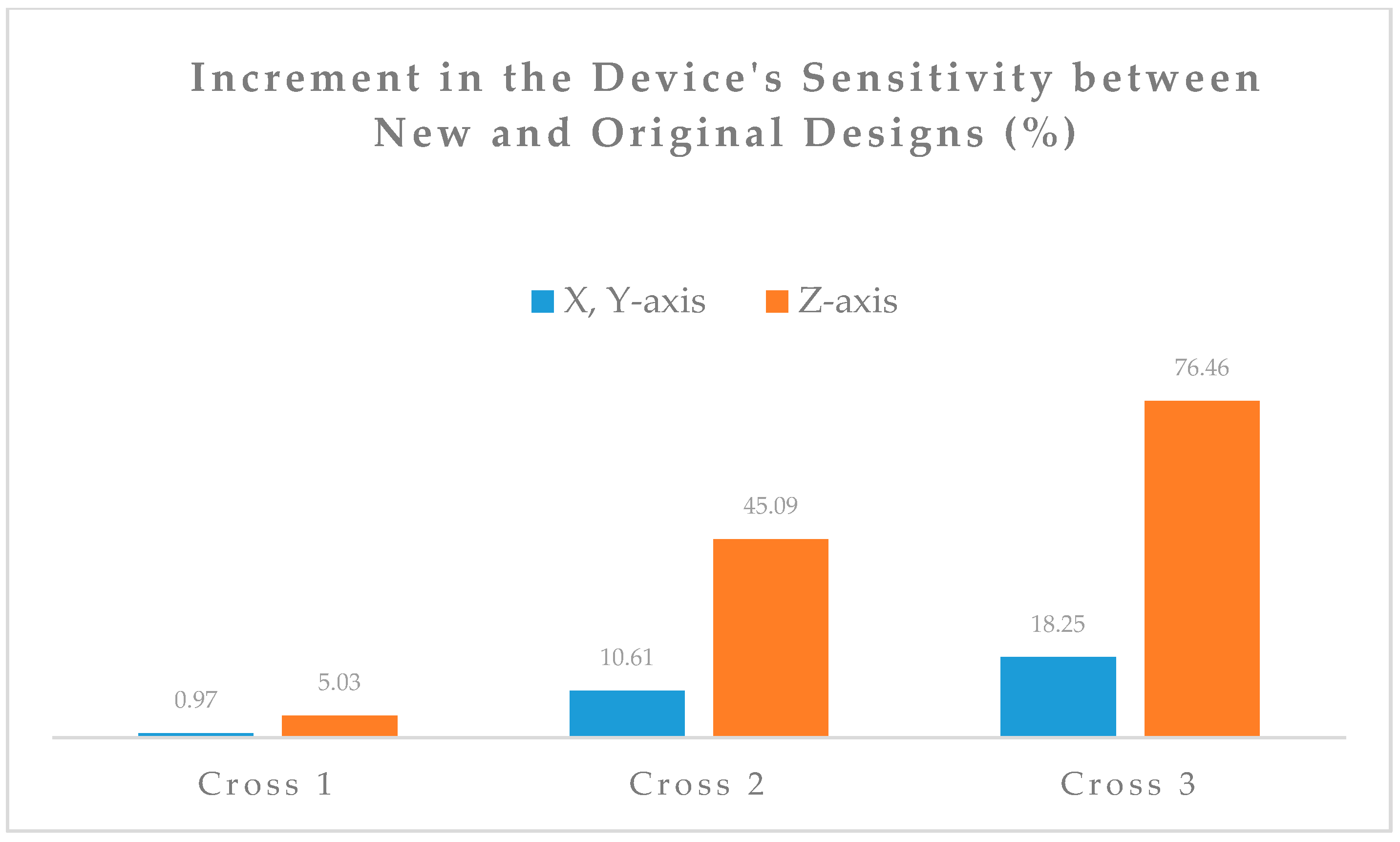

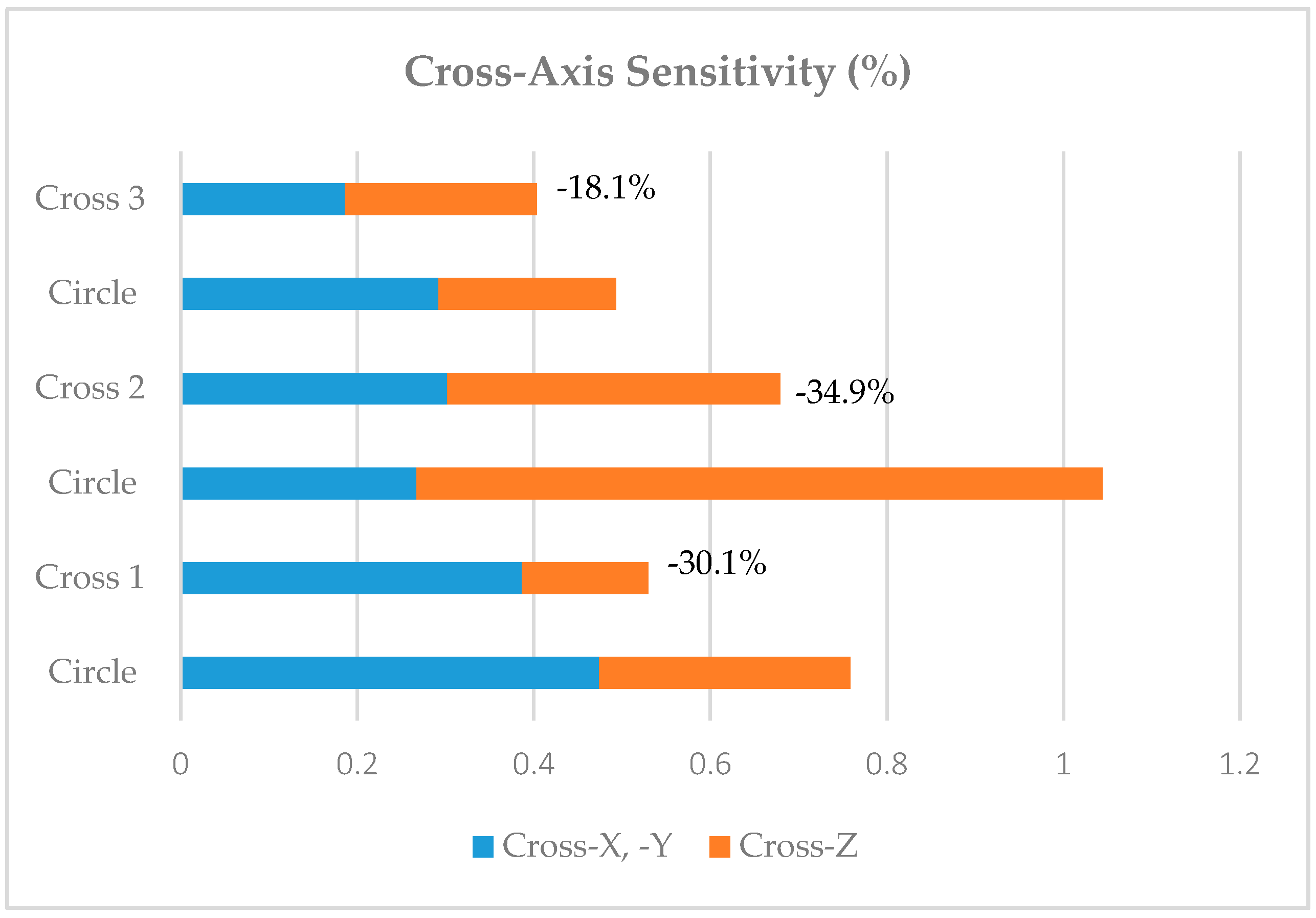

Performance Calculation

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nakamura, K.; Isono, Y.; Toriyama, T. First-Principles Study on Piezoresistance Effect in Silicon Nanowires. Jpn. J. Appl. Phys. 2008, 47, 5132. [Google Scholar] [CrossRef]

- Sasaki, S.; Seki, T.; Imanaka, K.; Kimata, M.; Toriyama, T.; Miyano, T.; Sugiyama, S. Batteryless-Wireless Mems Sensor System with a 3d Loop Antenna. In Proceedings of the 2007 IEEE Sensors, Atlanta, GA, USA, 28–31 October 2007. [Google Scholar]

- Bishop, P.J. Dynamic Response Criteria for Ice Hockey Helmet Design. In Biomechanics; University Park Press: Baltimore, MD, USA, 1976; Volume V-B, pp. 299–305. [Google Scholar]

- Bishop, P.J.; Norman, R.W.; Pierrynowski, M.; Kozey, J. The Ice Hockey Helmet: How Effective Is It. Phys. Sportsmed. 1979, 7, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Bishop, P.J.; Norman, R.W.; Wells, R.; Ranney, D.; Skleryk, B. Changes in the Centre of Mass and Moment of Inertia of a Headform Induced by a Hockey Helmet and Face Shield. Can. J. Appl. Sport Sci. 1983, 8, 19–25. [Google Scholar] [PubMed]

- Gurdjian, E.S.; Roberts, V.L.; Thomas, L.M. Tolerance Curves of Acceleration and Intracranial Pressure and Protective Index in Experimental Head Injury. J. Trauma Acute Care Surg. 1966, 6, 600–604. [Google Scholar] [CrossRef]

- Hodgson, V.R. Biomechanical Study of Football Head Impacts Using a Human Head Model: A Final Report Prepared for Nocsae; National Operating Committee on Standards for Athletic Equipment (NOCSAE): Overland Park, KS, USA, 1973. [Google Scholar]

- Myers, T.J.; Yoganandan, N.; Anthony, S., Jr.; Pintar, F.A.; Reinartz, J.; Battocletti, J.H. Energy Absorption Characteristics of Football Helmets under Low and High Rates of Loading. Bio-Med. Mater. Eng. 1993, 3, 15–24. [Google Scholar]

- Naunheim, R.S.; Ryden, A.; Standeven, J.; Genin, G.; Lewis, L.; Thompson, P.; Bayly, P. Does Soccer Headgear Attenuate the Impact When Heading a Soccer Ball? Acad. Emerg. Med. 2003, 10, 85–90. [Google Scholar] [CrossRef] [PubMed]

- Gurdjian, E.S.; Lissner, H.R.; Evans, F.G.; Patrick, L.M.; Hardy, W.G. Intracranial Pressure and Acceleration Accompanying Head Impacts in Human Cadavers. Surg. Gynecol. Obstet. 1961, 113, 185. [Google Scholar] [PubMed]

- Lewis, L.M.; Naunheim, R.; Standeven, J.; Lauryssen, C.; Richter, C.; Jeffords, B. Do Football Helmets Reduce Acceleration of Impact in Blunt Head Injuries? Acad. Emerg. Med. 2001, 8, 604–609. [Google Scholar] [CrossRef] [PubMed]

- Lewis, L.M.; Naunheim, R.S.; Richter, C.J.; Standeven, J.W. Are Helmets Protective in High Impact Collisions? Acad. Emerg. Med. 2000, 7, 437. [Google Scholar]

- Higgins, M.; Halstead, P.D.; Snyder-Mackler, L.; Barlow, D. Measurement of Impact Acceleration: Mouthpiece Accelerometer Versus Helmet Accelerometer. J. Athl. Train. 2007, 42, 5. [Google Scholar] [PubMed]

- Knox, T. Validation of Earplug Accelerometers as a Means of Measuring Head Motion; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Olvey, S.E.; Knox, T.; Cohn, K.A. The Development of a Method to Measure Head Acceleration and Motion in High-Impact Crashes. Neurosurgery 2004, 54, 672–677. [Google Scholar] [CrossRef] [PubMed]

- Corporation, D. Delphi’s Innovative Earpiece Sensor System Becomes Safety Requirement for Indy Racing League Drivers. Available online: http://www.prnewswire.com/news-releases/delphis-innovative-earpiece-sensor-system-becomes-safety-requirement-for-indy-racing-league-drivers-74498057.html (accessed on 18 January 2018).

- Begeman, P.; Melvin, J.; Troxel, T.; Mellor, A. Frequency Response and Coupling of Earpiece Accelerometers in the Human Head; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Salzar, R.S.; Cameron, R.; Pellettiere, J.A. Improving Earpiece Accelerometer Coupling to the Head. SAE Int. J. Passeng. Cars Mech. Syst. 2008, 1, 1367–1381. [Google Scholar] [CrossRef]

- Knox, T.; Pellettiere, J.; Perry, C.; Plaga, J.; Bonfeld, J. New Sensors to Track Head Acceleration During Possible Injurious Events. SAE Int. J. Passeng. Cars Electron. Electr. Syst. 2009, 1, 652–663. [Google Scholar] [CrossRef]

- Messina, M. Design and Optimization of a Novel Tri-Axial Miniature Ear-Plug Piezoresistive Accelerometer with Nanoscale Piezoresistors. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2013. [Google Scholar]

- Messina, M.; Njuguna, J. Potential of Silicon Nanowires Structures as Nanoscale Piezoresistors in Mechanical Sensors. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Miskolc-Lillafüred, Hungary, 8–12 October 2012. [Google Scholar]

- Messina, M.; Njuguna, J.; Dariol, V.; Pace, C.; Angeletti, G. Design and Simulation of a Novel Biomechanic Piezoresistive Sensor with Silicon Nanowires. IEEE/ASME Trans. Mechatron. 2013, 18, 1201–1210. [Google Scholar] [CrossRef] [Green Version]

- Messina, M.; Njuguna, J. High Performance Tri-Axial Piezoresistive Accelerometer. Patent EP2741088A1, 2014. [Google Scholar]

- Barlian, A.A.; Park, W.-T.; Mallon, J.R.; Rastegar, A.J.; Pruitt, B.L. Review: Semiconductor Piezoresistance for Microsystems. Proc. IEEE 2009, 97, 513–552. [Google Scholar] [CrossRef] [PubMed]

- Kanda, Y. A Graphical Representation of the Piezoresistance Coefficients in Silicon. IEEE Tran. Electron Devices Soc. 1982, 29, 64–70. [Google Scholar] [CrossRef]

- Wilson, J.S. Sensor Technology Handbook; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Mason, W.P.; Forst, J.J.; Tornillo, L.M. Recent Developments in Semiconductor Strain Transducers. In Semiconductor and Conventional Strain Gauges; Academic Press: New York, NY, USA, 1962. [Google Scholar]

- Amarasinghe, R.; Dao, D.V.; Dau, V.T.; Tung, B.T.; Sugiyama, S. Sensitivity Enhancement of Piezoresistive Micro Acceleration Sensors with Nanometer Stress Concentration Regions on Sensing Elements. In Proceedings of the Solid-State Sensors, Actuators and Microsystems Conference, Denver, CO, USA, 21–25 June 2009. [Google Scholar]

- Smith, C.S. Piezoresistance Effect in Germanium and Silicon. Phys. Rev. 1954, 94, 42. [Google Scholar] [CrossRef]

- Bardeen, J.; Shockley, W. Deformation Potentials and Mobilities in Non-Polar Crystals. Phys. Rev. 1950, 80, 72. [Google Scholar] [CrossRef]

- Herring, C. Transport Properties of a Many-Valley Semiconductor. Bell Labs Tech. J. 1955, 34, 237–290. [Google Scholar] [CrossRef]

- Herring, C.; Vogt, E. Transport and Deformation-Potential Theory for Many-Valley Semiconductors with Anisotropic Scattering. Phys. Rev. 1956, 101, 944. [Google Scholar] [CrossRef]

- Maluf, N. An Introduction to Microelectromechanical Systems Engineering; IOP Publishing: Bristol, UK, 2002. [Google Scholar]

- Tufte, O.N.; Stelzer, E.L. Piezoresistive Properties of Silicon Diffused Layers. J. Appl. Phys. 1963, 34, 313–318. [Google Scholar] [CrossRef]

- Kazuji, Y.; Nishihara, M.; Shimada, S.; Tanabe, M.; Shimazoe, M.; Matsuoka, Y. Nonlinearity of the Piezoresistance Effect of P-Type Silicon Diffused Layers. IEEE Trans. Electron Devices 1982, 29, 71–77. [Google Scholar]

- Kerr, D.R.; Milnes, A.G. Piezoresistance of Diffused Layers in Cubic Semiconductors. J. Appl. Phys. 1963, 34, 727–731. [Google Scholar] [CrossRef]

- Senturia, S.D. Microsystem Design; Springer Science & Business Media: New York, NY, USA, 2007. [Google Scholar]

- Harkey, J.A.; Kenny, T.W. 1/F Noise Considerations for the Design and Process Optimization of Piezoresistive Cantilevers. J. Microelectromech. Syst. 2002, 9, 226–235. [Google Scholar] [CrossRef]

- Marian, B.; Ilie, I.; Lupu, B.; Comes, M. Signal Conditioner for Piezoelectric Sensors. In Proceedings of the 31st International Spring Seminar on Electronics Technology, Budapest, Hungary, 7–11 May 2008. [Google Scholar]

- Hunter, C.S. The Bakerian Lecture: Experimental Determination of the Laws of Magneto-Electric Induction in Different Masses of the Same Metal, and of Its Intensity in Different Metals. Philos. Trans. R. Soc. Lond. 1833, 123, 95–142. [Google Scholar]

- Viet, D.D.; Okada, S.; Dau, V.T.; Toriyama, T.; Sugiyama, S. Development of a 3-Dof Silicon Piezoresistive Micro Accelerometer. In Proceedings of the 2004 International Symposium on Micro-Nanomechatronics and Human Science, 2004 and The Fourth Symposium Micro-Nanomechatronics for Information-Based Society, Nagoya, Japan, 31 October–3 November 2004. [Google Scholar]

- Freescale Semiconductor. Accelerometer Terminology Guide (2017). Available online: http://cache.freescale.com/files/sensors/doc/support_info/SENSORTERMSPG.pdf (accessed on 18 January 2018).

- Craig, L.; Desmulliez, M.P.Y.; Hoff, L.; Elle, O.J.; Fosse, E. Mems Three-Axis Accelerometer: Design, Fabrication and Application of Measuring Heart Wall Motion. In Proceedings of the 2009 Symposium on Design, Test, Integration & Packaging of MEMS/MOEMS, Rome, Italy, 1–3 April 2009. [Google Scholar]

- Woo-Tae, P.; O’Connor, K.N.; Chen, K.; Mallon, J.R.; Maetani, T.; Dalal, P.; Candler, R.N.; Ayanoor-Vitikkate, V.; Roberson, J.B.; Puria, S. Ultraminiature Encapsulated Accelerometers as a Fully Implantable Sensor for Implantable Hearing Aids. Biomed. Microdevices 2007, 9, 939–949. [Google Scholar]

| Piezoresistive Coefficient (10−11 Pa−1) | n-Type (Resistivity = 11.7 Ω-cm) | p-Type (Resistivity = 7.8 Ω-cm) |

|---|---|---|

| π11 | −102.2 | 6.6 |

| π12 | 53.4 | −1.1 |

| π44 | −13.6 | 138.1 |

| Direction of Strain | Direction of Current | Configuration | Piezoresistive Coefficient |

|---|---|---|---|

| <100> | <100> | Longitudinal | π11 |

| <100> | <010> | Transversal | π12 |

| <110> | <110> | Longitudinal | (π11 + π12 + π44)/2 |

| <110> | <110> | Transversal | (π11 + π12 − π44)/2 |

| <111> | <111> | Longitudinal | (π11 + 2π12 + π44)/2 |

| Parameter | Cross 3 (This Work) | ADXL377 | H3LIS331DL |

|---|---|---|---|

| Measurement Range (G) | ±500 | ±200 | ±400 |

| Sensitivity (mV/G) | 0.22 | 6.50 | - |

| Cross-axis sensitivity (%FS) | <±1 | ±1.4 | ±2 |

| Size (mm2) | 1.5 × 1.5 | 3 × 3 | 3 × 3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Messina, M.; Njuguna, J.; Palas, C. Mechanical Structural Design of a MEMS-Based Piezoresistive Accelerometer for Head Injuries Monitoring: A Computational Analysis by Increments of the Sensor Mass Moment of Inertia. Sensors 2018, 18, 289. https://doi.org/10.3390/s18010289

Messina M, Njuguna J, Palas C. Mechanical Structural Design of a MEMS-Based Piezoresistive Accelerometer for Head Injuries Monitoring: A Computational Analysis by Increments of the Sensor Mass Moment of Inertia. Sensors. 2018; 18(1):289. https://doi.org/10.3390/s18010289

Chicago/Turabian StyleMessina, Marco, James Njuguna, and Chrysovalantis Palas. 2018. "Mechanical Structural Design of a MEMS-Based Piezoresistive Accelerometer for Head Injuries Monitoring: A Computational Analysis by Increments of the Sensor Mass Moment of Inertia" Sensors 18, no. 1: 289. https://doi.org/10.3390/s18010289