The Limpet: A ROS-Enabled Multi-Sensing Platform for the ORCA Hub

Abstract

1. Introduction

1.1. Challenges Facing Offshore Industries

1.2. Application of Robotics in Offshore Industries

1.3. Offshore Robotics for Certification of Assets (ORCA Hub)

1.4. Offshore Robotics (Current-State-of-the-Art and Challenges)

1.5. Fault Detection and Condition Monitoring Systems

1.6. The Limpet

2. Design and Fabrication of the Limpet

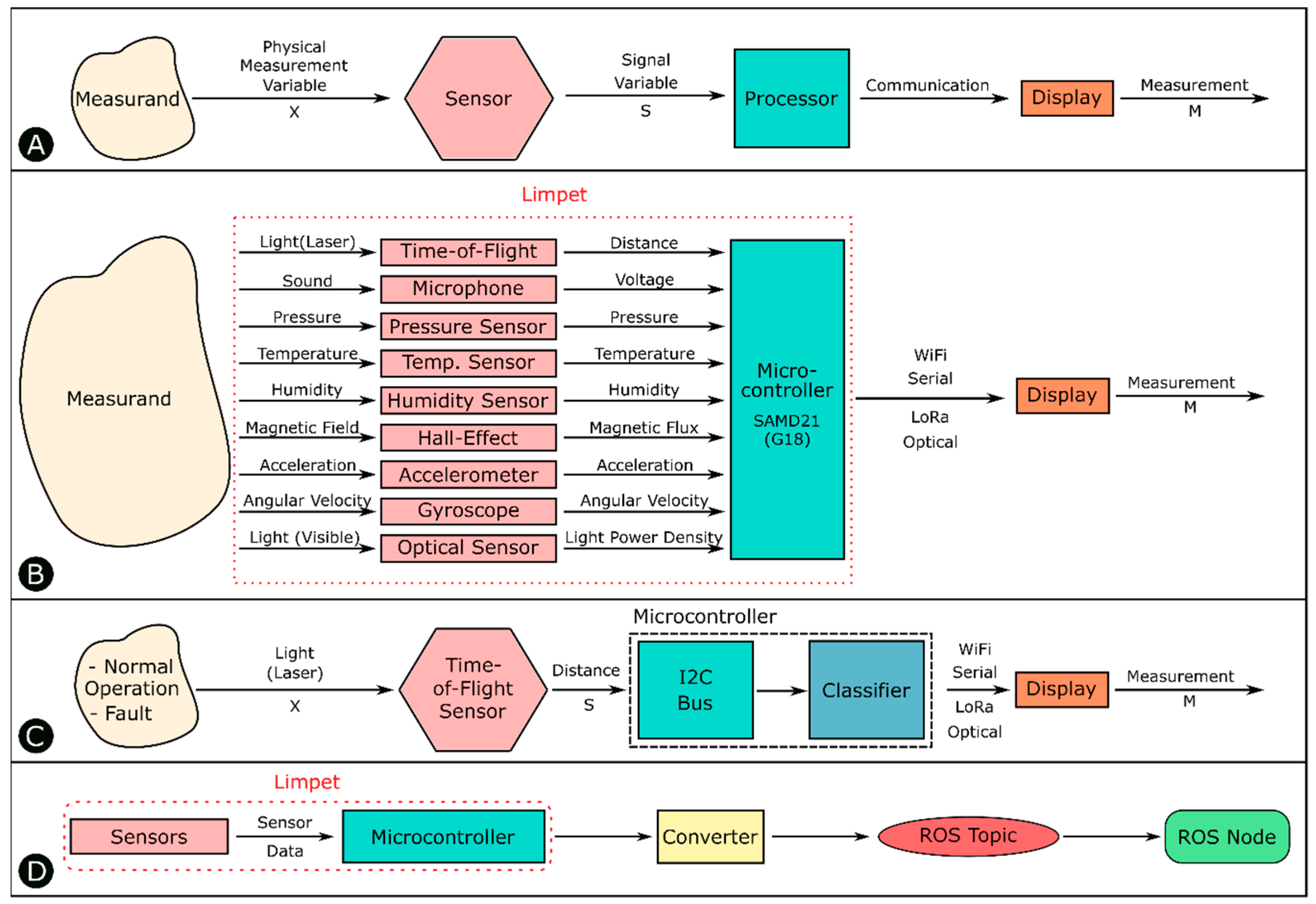

2.1. Instrument Model

2.2. Design of the Limpet

2.2.1. System Design

2.2.2. Electrical Design

2.2.3. Mechanical Design

2.3. ROS Interface

3. Experimental Design

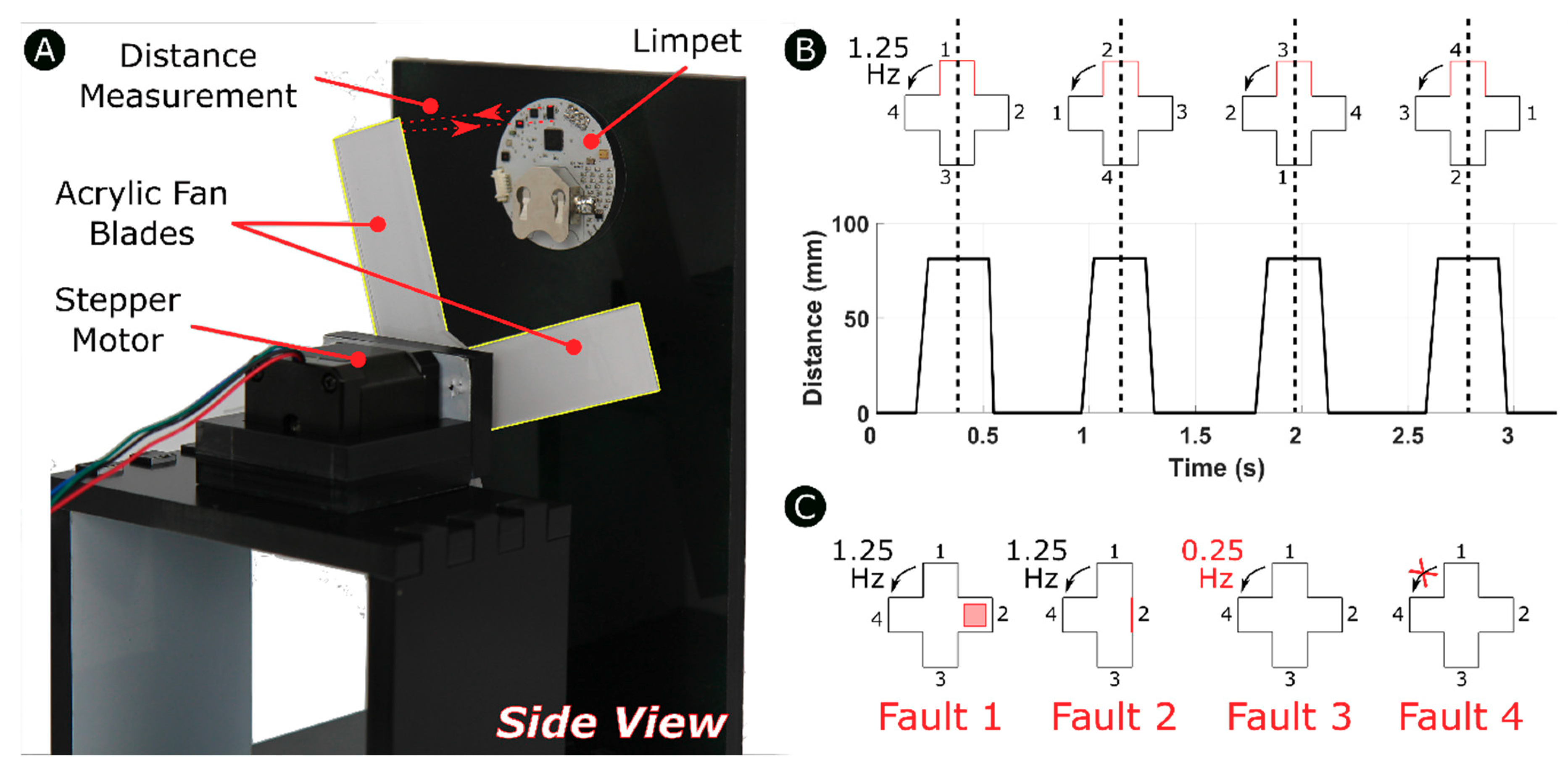

3.1. Design of the Distance-Based Fault Detection Experimental Setup

- Fault 1: We attach an object of 15 mm thickness to one of the four blades.

- Fault 2: We remove one of the four blades of the fan.

- Fault 3: We reduce the frequency of detection of a fan blade from 1.25 Hz to 0.25 Hz.

- Fault 4: We immobilize the rotation of the fan for a certain period during its normal operation.

3.2. Design of the Offline Classification Experiments

3.3. Design of the Online Classification Experiments

3.4. Overview of the Communication

3.5. Overview of the Classification Techniques

3.5.1. Signal-Processing Tools

3.5.2. Analysis Tools

4. Results

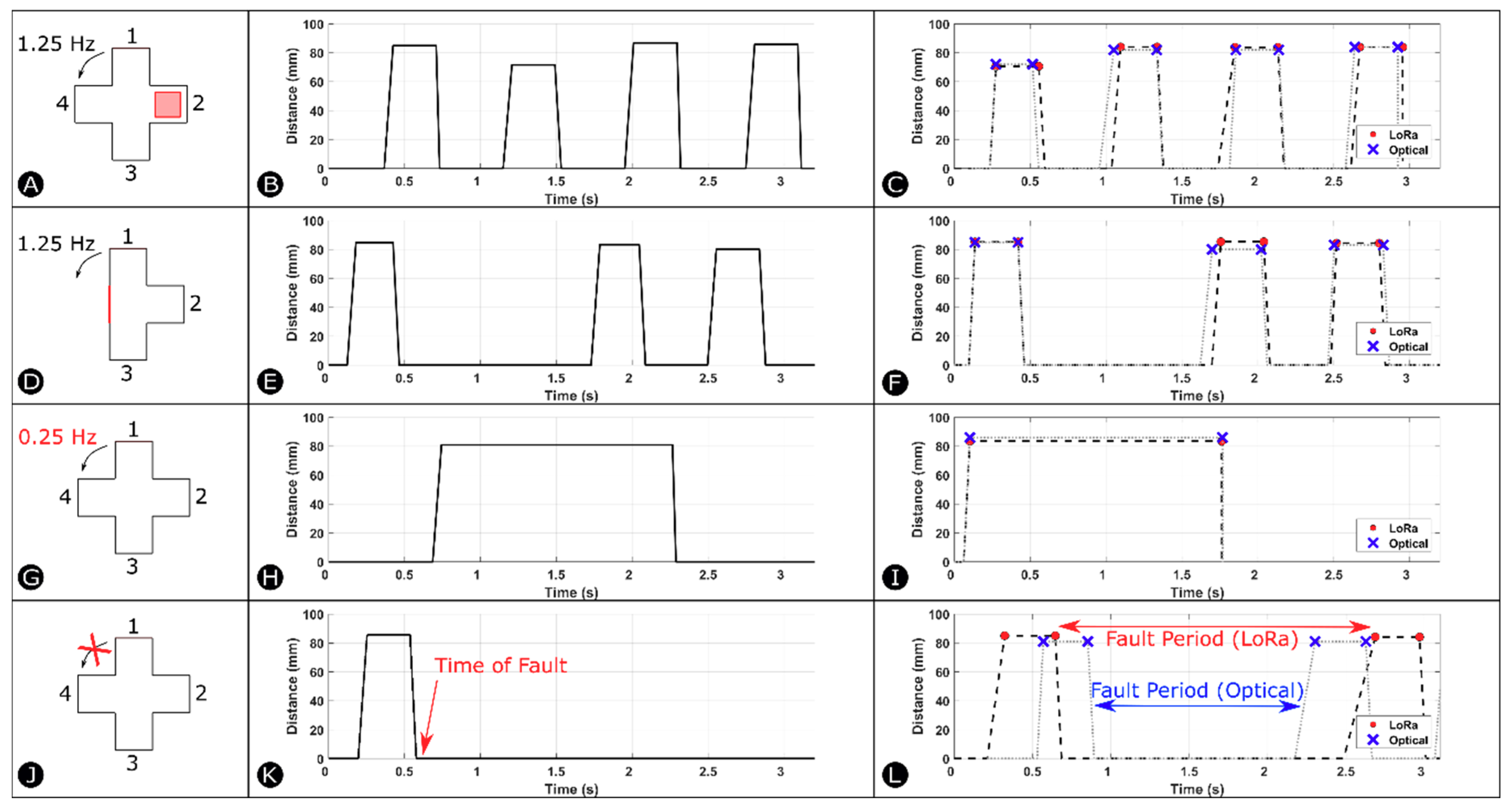

Distance-Based Fault Detection

5. Discussion

5.1. Applicability to Other Faults

5.2. Applicability to Other Sensors

5.3. On-Board Data Processing vs. Offline Processing

5.4. Mitigation of Interferences

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hastie, H.; Lohan, K.; Chantler, M.; Robb, D.A.; Ramamoorthy, S.; Petrick, R.; Vijayakumar, S.; Lane, D. The ORCA Hub: Explainable Offshore Robotics through Intelligent Interfaces. In Proceedings of the 13th Annual ACM/IEEE International Conference on Human Robot Interaction, Chicago, IL, USA, 5–8 March 2018. [Google Scholar]

- Griggs, J.W. BP Gulf of Mexico oil spill. Energy Law J. 2011, 32, 57. [Google Scholar]

- Shukla, A.; Karki, H. Application of robotics in offshore oil and gas industry—A review Part II. Robot. Auton. Syst. 2016, 75, 508–524. [Google Scholar] [CrossRef]

- Chen, H.; Stavinoha, S.; Walker, M.; Zhang, B.; Fuhlbrigge, T. Opportunities and Challenges of Robotics and Automation in Offshore Oil & Gas Industry. Intell. Control Autom. 2014, 5, 136–145. [Google Scholar]

- Mois, G.; Folea, S.; Sanislav, T. Analysis of Three IoT-Based Wireless Sensors for Environmental Monitoring. IEEE Trans. Instrum. Meas. 2017, 66, 2056–2064. [Google Scholar] [CrossRef]

- Yuh, J.; Lakshmi, R. An intelligent control system for remotely operated vehicles. IEEE J. Ocean. Eng. 1993, 18, 55–62. [Google Scholar] [CrossRef]

- Elvander, J.; Hawkes, G. ROVs and AUVs in support of marine renewable technologies. In Proceedings of the 2012 Oceans, Hampton Roads, VA, USA, 14–19 October 2012; pp. 1–6. [Google Scholar]

- Raine, G.A.; Lugg, M.C. ROV Inspection of Welds—A Reality; Underwater Intervention: Houston, TX, USA, 1995. [Google Scholar]

- Whitcomb, L.L. Underwater robotics: Out of the research laboratory and into the field. In Proceedings of the 2000 IEEE International Conference on Robotics and Automation (ICRA), San Francisco, CA, USA, 24–28 April 2000; Volume 1, pp. 709–716. [Google Scholar]

- Bessa, M.S.W. Controlling the dynamic positioning of a ROV. In Proceedings of the Oceans 2003, San Diego, CA, USA, 22–26 September 2003; Volume 2. [Google Scholar]

- Hagen, P.E.; Fossum, T.G.; Hansen, R.E. Applications of AUVs with SAS. In Proceedings of the OCEANS 2008, Quebec City, QC, Canada, 15–18 September 2008; pp. 1–4. [Google Scholar]

- Costa, M.J.; Goncalves, P.; Martins, A.; Silva, E. Vision-based assisted teleoperation for inspection tasks with a small ROV. In Proceedings of the 2012 Oceans, Hampton Roads, VA, USA, 14–19 October 2012; pp. 1–8. [Google Scholar]

- Bengel, M.; Pfeiffer, K. Mimroex Mobile Maintenance and Inspection Robot for Process Plants; Fraunhofer Institute for Manufacturing Engineering and Automation IPA: Stuttgart, Germany, 2007. [Google Scholar]

- NREC/CMU. Sensabot: A Safe and Cost-Effective Inspection Solution. J. Pet. Technol. 2012, 64, 32–34. [Google Scholar] [CrossRef]

- Kyrkjebo, E.; Liljebäck, P.; Transeth, A.A. A Robotic Concept for Remote Inspection and Maintenance on Oil Platforms. In Proceedings of the ASME 28th International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009; pp. 667–674. [Google Scholar]

- Galassi, M.; Røyrøy, A.; Carvalho, G.; Freitas, G.; From, P.J.; Costa, R.R.; Lizarralde, F.; Hsu, L.; de Carvalho, G.H.; de Oliveira, J.F. DORIS—A Mobile Robot for Inspection and Monitoring of Offshore Facilities. In Proceedings of the Congresso Brasileiro de Automática, Belo Horizonte, Brazil, 20–24 September 2014. [Google Scholar]

- Moghaddam, A.F.; Lange, M.; Mirmotahari, O.; Høvin, M. Novel Mobile Climbing Robot Agent for Offshore Platforms. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2012, 6, 1353–1359. [Google Scholar]

- Bengel, M.; Pfeiffer, K.; Graf, B.; Bubeck, A.; Verl, A. Mobile robots for offshore inspection and manipulation. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 11–15 October 2009; pp. 3317–3322. [Google Scholar]

- Nichols, J.M. Structural health monitoring of offshore structures using ambient excitation. Appl. Ocean Res. 2003, 25, 101–114. [Google Scholar] [CrossRef]

- Hillis, A.J.; Courtney, C.R.P. Structural health monitoring of fixed offshore structures using the bicoherence function of ambient vibration measurements. J. Sound Vib. 2011, 330, 1141–1152. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Wilkinson, M.R. Condition monitoring and fault diagnosis of a wind turbine synchronous generator drive train. IET Renew. Power Gener. 2009, 3, 1–11. [Google Scholar] [CrossRef]

- Kryter, R.C.; Haynes, H.D. Condition monitoring of machinery using motor current signature analysis. In Proceedings of the Power Plant Dynamics, Control and Testing Symposium, Knoxville, TN, USA, 15–17 May 1989; Volume 20. [Google Scholar]

- Cardoso, A.J.M.; Saraiva, E.S. Computer-aided detection of airgap eccentricity in operating three-phase induction motors by Park’s vector approach. IEEE Trans. Ind. Appl. 1993, 29, 897–901. [Google Scholar] [CrossRef]

- Hameed, Z.; Hong, Y.S.; Cho, Y.M.; Ahn, S.H.; Song, C.K. Condition monitoring and fault detection of wind turbines and related algorithms: A review. Renew. Sustain. Energy Rev. 2009, 13, 1–39. [Google Scholar] [CrossRef]

- Lu, B.; Li, Y.; Wu, X.; Yang, Z. A review of recent advances in wind turbine condition monitoring and fault diagnosis. In Proceedings of the 2009 IEEE Power Electronics and Machines in Wind Applications, Lincoln, NE, USA, 24–26 June 2009; pp. 1–7. [Google Scholar]

- Shin, S.-H.; Kim, S.; Seo, Y.-H.; Shin, S.-H.; Kim, S.; Seo, Y.-H. Development of a Fault Monitoring Technique for Wind Turbines Using a Hidden Markov Model. Sensors 2018, 18, 1790. [Google Scholar] [CrossRef] [PubMed]

- Yuji, T.; Bouno, T.; Hamada, T. Suggestion of Temporarily for Forecast Diagnosis on Blade of Small Wind Turbine. IEEJ Trans. Power Energy 2006, 126, 710–711. [Google Scholar] [CrossRef]

- Buono, T.; Yuji, T.; Hamada, T.; Hideaki, T. Failure Forecast Diagnosis of Small Wind Turbine using Acoustic Emission Sensor. KIEE Int. Trans. Electr. Mach. Energy Convers. Syst. 2005, 5, 78–83. [Google Scholar]

- Schroeder, K.; Ecke, W.; Apitz, J.; Lembke, E.; Lenschow, G. A fibre Bragg grating sensor system monitors operational load in a wind turbine rotor blade. Meas. Sci. Technol. 2006, 17, 1167–1172. [Google Scholar] [CrossRef]

- Tian, S.; Yang, Z.; Chen, X.; Xie, Y. Damage Detection Based on Static Strain Responses Using FBG in a Wind Turbine Blade. Sensors 2015, 15, 19992–20005. [Google Scholar] [CrossRef] [PubMed]

- Oh, K.-Y.; Park, J.-Y.; Lee, J.-S.; Epureanu, B.I.; Lee, J.-K. A Novel Method and Its Field Tests for Monitoring and Diagnosing Blade Health for Wind Turbines. IEEE Trans. Instrum. Meas. 2015, 64, 1726–1733. [Google Scholar] [CrossRef]

- Ruan, J.; Ho, S.C.M.; Patil, D.; Song, G. Structural health monitoring of wind turbine blade using piezoceremic based active sensing and impedance sensing. In Proceedings of the 11th IEEE International Conference on Networking, Sensing and Control, Miami, FL, USA, 7–9 April 2014; pp. 661–666. [Google Scholar]

- Marshall, D.J.; Hodgson, A.N. Structure of the Cephalic Tentacles of Some Species of Prosobranch Limpet (Patellidae and Fissurellidae). J. Molluscan Stud. 1990, 56, 415–424. [Google Scholar] [CrossRef]

- Webster, J.G. The Measurement, Instrumentation and Sensors Handbook, 1st ed.; CRC Press LLC: Boca Raton, FL, USA, 1999; Volume 104. [Google Scholar]

- Farrow, N.; Klingner, J.; Reishus, D.; Correll, N. Miniature six-channel range and bearing system: Algorithm, analysis and experimental validation. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 6180–6185. [Google Scholar]

- Nemitz, M.P.; Stokes, A.A.; Marcotte, R.J.; Sayed, M.E.; Ferrer, G.; Hero, A.O.; Olson, E.B. Multi-Functional Sensing for Swarm Robots Using Time Sequence Classification: HoverBot, an Example. Front. Robot. AI 2018, 5, 55. [Google Scholar] [CrossRef]

- Light, R.A. Mosquitto: Server and client implementation of the MQTT protocol. J. Open Source Softw. 2017, 2, 265. [Google Scholar] [CrossRef]

- Sornin, N.; Luis, M.; Eirich, T.; Kramp, T.; Hersent, O. LoRaWAN Specification; LoRa Alliance: Fremont, CA, USA, 2015. [Google Scholar]

- Nemitz, M.P.; Sayed, M.E.; Mamish, J.; Ferrer, G.; Teng, L.; McKenzie, R.M.; Hero, A.O.; Olson, E.; Stokes, A.A. HoverBots: Precise Locomotion Using Robots That Are Designed for Manufacturability. Front. Robot. AI 2017, 4, 55. [Google Scholar] [CrossRef]

- Wang, J.; Wang, R.; Li, T. Analysis of the data streams trend in sensor network based on sliding window. In Proceedings of the 2012 IEEE International Conference on Computer Science and Automation Engineering (CSAE), Zhangjiajie, China, 25–27 May 2012; pp. 224–228. [Google Scholar]

- Vafaeipour, M.; Rahbari, O.; Rosen, M.A.; Fazelpour, F.; Ansarirad, P. Application of sliding window technique for prediction of wind velocity time series. Int. J. Energy Environ. Eng. 2014, 5, 105. [Google Scholar] [CrossRef]

- Dennis, L.A.; Fisher, M.; Aitken, J.M.; Veres, S.M.; Gao, Y.; Shaukat, A.; Burroughes, G. Reconfigurable Autonomy. KI Künstliche Intelligenz 2014, 28, 199–207. [Google Scholar] [CrossRef]

- Adelantado, F.; Vilajosana, X.; Tuset-Peiro, P.; Martinez, B.; Melia-Segui, J.; Watteyne, T. Understanding the Limits of LoRaWAN. IEEE Commun. Mag. 2017, 55, 34–40. [Google Scholar] [CrossRef]

- Jin, M.H.-C.; Pierce, J.M.; Lambiotte, J.C.; Fite, J.D.; Marshall, J.S.; Huntley, M.A. Underwater Free-Space Optical Power Transfer: An Enabling Technology for Remote Underwater Intervention. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar]

- Benbouzid, M.E.H. A review of induction motors signature analysis as a medium for faults detection. IEEE Trans. Ind. Electron. 2000, 47, 984–993. [Google Scholar] [CrossRef]

- Pineda-Sanchez, M.; Puche-Panadero, R.; Martinez-Roman, J.; Sapena-Bano, A.; Riera-Guasp, M.; Perez-Cruz, J. Partial Inductance Model of Induction Machines for Fault Diagnosis. Sensors 2018, 18, 2340. [Google Scholar] [CrossRef] [PubMed]

| Sensor | Physical Measurement Variable | Signal Variable | Measurands |

|---|---|---|---|

| Accelerometer | Acceleration | Acceleration | Inclination, Collision, Vibration, Free-Fall Detection, Movement Acceleration |

| Gyroscope | Angular Velocity | Angular Velocity | Tilt Detection, Orientation |

| Temperature | Temperature | Temperature | Ambient Temperature, Over-heating, Fire Detection |

| Humidity | Humidity | Humidity | Relative Humidity |

| Microphone | Sound | Voltage | Speech Recognition, Noise Cancellation, Audible Fault Detection |

| Pressure | Pressure | Pressure | Ambient Pressure |

| Hall-Effect | Magnetic Field | Magnetic Flux Density | Locating Pipelines, Corrosion Detection |

| Optical | Light (Visible) | Distance | Ambient Light Intensity, Local Communication, Color Detection |

| Distance (Time-of-Flight) | Light (Laser) | Distance | Fault Detection, Proximity, Collision Detection, Object Identification |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayed, M.E.; Nemitz, M.P.; Aracri, S.; McConnell, A.C.; McKenzie, R.M.; Stokes, A.A. The Limpet: A ROS-Enabled Multi-Sensing Platform for the ORCA Hub. Sensors 2018, 18, 3487. https://doi.org/10.3390/s18103487

Sayed ME, Nemitz MP, Aracri S, McConnell AC, McKenzie RM, Stokes AA. The Limpet: A ROS-Enabled Multi-Sensing Platform for the ORCA Hub. Sensors. 2018; 18(10):3487. https://doi.org/10.3390/s18103487

Chicago/Turabian StyleSayed, Mohammed E., Markus P. Nemitz, Simona Aracri, Alistair C. McConnell, Ross M. McKenzie, and Adam A. Stokes. 2018. "The Limpet: A ROS-Enabled Multi-Sensing Platform for the ORCA Hub" Sensors 18, no. 10: 3487. https://doi.org/10.3390/s18103487

APA StyleSayed, M. E., Nemitz, M. P., Aracri, S., McConnell, A. C., McKenzie, R. M., & Stokes, A. A. (2018). The Limpet: A ROS-Enabled Multi-Sensing Platform for the ORCA Hub. Sensors, 18(10), 3487. https://doi.org/10.3390/s18103487