1. Introduction

Combustion processes are in the heart of many modern industrial activities that are key for productive sectors and economic development. For example, in the petroleum, forestry and steel industries, more than 90% of the heat and steam production is based on combustion [

1]. At the same time, due to the accelerated pace of industrialization and urbanization in recent decades and omission of their side effects, combustion processes have also become a major contributor to the global greenhouse gas (GHG) emissions [

2,

3]. An important source of pollution derived from modern combustion processes relates to the release of particulate matter (PM) to the atmosphere, a combustion by-product [

4,

5]. Recent studies place PM as a major contributor to global warming and climate change, just after carbon dioxide (CO

) emissions [

4]. PM alters the radiative properties of the atmosphere and has a negative global effect on temperature and climate. Moreover, PM emissions affect the population’s health, being responsible for respiratory system diseases and the subsequent increase in morbidity and mortality rates [

4,

6,

7]. Consequently, because of increasing public awareness about negative environmental effects and the rise of more strict regulations regarding GHG emissions, there is an imperative need for developing more effective diagnostic and control methods for improving the efficiency of industrial combustion processes.

Recent studies show a direct relation between PM emissions and soot formation in flames [

8,

9]. Analysis of soot in flames is typically made through

soot propensity analysis, which denotes the competition between the processes of soot formation (

) and soot oxidation (

) occurring within a flame [

10,

11]. The most common method for analyzing the sooting propensity of a fuel or a mixture is the Smoke Point Height (SPH) approach [

9,

12,

13], which relates the height of a diffusion flame to an operational point where the process reaches a certain threshold value of the fuel flow rate. Usually, the transition from a non-sooting to a sooting regime surpassing the SPH threshold is the result of an increase in both the

/

ratio and the residence time of soot particles inside the flame [

8]. Once the SPH threshold is surpassed, the flame manifests morphological changes in its tip, which breaks open and shows wings. This marks the moment at which the release of soot particles and emissions of PM from the combustion process increase drastically [

14].

The current literature in combustion diagnostics reports two main methods for detecting the SPH: (i) direct visual inspection, and (ii) Line-of-sight attenuation (LOSA) measurements. The quality of the estimations of SPH from direct visual inspection depends on the expertise of the observer for noticing faint morphological variations in the flame that are not always perceptible for the human eye, which leads to high bias and poor repeatibility of the results. In contrast, the LOSA method provides a systematic and robust estimation of the sooting behavior of a diffusion flame; however, LOSA has limited utility in practical combustion systems due to the complexity of the observed phenomena, high sensitivity to signal attenuation, and requirement of especialized and expensive equipment (laser sources, pattern light source, etc.) [

10,

11,

14]. In practice, estimating the SPH of a flame in real-world settings is a challenging task, and current approaches suffer from a high sensitivity to the experimental setup that prevents proper comparison and practical validation of the results.

This paper presents a comparative evaluation of two novel approaches for performing soot propensity analysis using techniques for video magnification over flame images. We propose using Eulerian Video Magnification (EVM) and Phase-based Video Magnification (PVM) to amplify subtle morphological variations in a sequence of flame images, facilitating detection of the point at which wings in the tip of flame appear and release of soot to the atmosphere begins. Using these techniques, we performed sooting propensity analysis on an ethylene diffusion flame using oxygen indexes that ranged from 19% to 35%, and compared the results to reference measurements obtained by LOSA. The experiments validate the effectiveness of video magnification techniques for obtaining quick and in situ estimations of PM emissions using sequences of flame images. These model-free methods have the potential to provide the foundation for low-cost and non-invasive procedures for estimating emissions using cameras that may be already present in typical industrial combustion settings. In addition, with the adequate computational support for fast image processing, the proposed method could overcome the limitations related to the inherent delay in the readings obtained from traditional gas chromatographs and other model-based methods, paving the way for advanced control strategies for combustion process [

1,

15,

16].

The rest of the paper is organized as follows:

Section 2 summarizes relevant related work to the monitoring of pollutants emissions in combustion processes.

Section 3 summarizes the theoretical background of soot propensity by LOSA and and an overview of video magnification by Eulerian and Phase-based methods.

Section 4 describes the proposed experimental setup and methodology.

Section 5 reports experimental results and analysis for sooting property using both LOSA and the proposed image-based methods using EVM and PVM. Finally,

Section 6 concludes the paper.

2. Related Work

The literature reports a fair amount of works dealing with the estimation of pollutants emissions based on data-based models [

17,

18,

19] or first principles models [

20]. Unfortunately, any model-based approach depends on the intrinsic error of the model, availability of field sensors to record a referential data set, and the presence of hidden data outliers given by sensor failures or decalibration [

21]. As an attempt to compensate for these limitations, some authors propose mechanisms for online model parameters update, incorporating in situ measurements of process variables to estimate the concentrations of pollutants such as NO

[

15,

22] and CO [

23], and the O

content of the combustion products [

24]. However, despite some improvements in specific applications, the intrinsic limitations of model-based approaches still remain.

Soot propensity analysis is a method for estimating PM emissions from combustion processes by observing the flame, which can overcome the intrinsic delay of conventional direct measurements of emissions using gas chromatographs. LOSA provides a systematic method to perform soot propensity analysis, removing the high-bias of estimations obtained from traditional visual inspection of the flame [

10,

25]. The LOSA technique obtains soot volume fractions by measuring the attenuation of a beam of known light intensity and frequency as it passes through the flame. The intensity of the light reaching the detector at the opposite side of the flame is attenuated due to the presence of the soot particle cloud within the flame, which scatters and absorbs part of the beam. Using Beer-Lambert’s law, the extinction coefficient is correlated to the soot volume fraction [

8,

10]. In practice, the LOSA method presents some drawbacks that limit its applicability at industrial scale facilities, including (i) high sensitivity of the method to variations in the refractive index of the flame along the optical path; (ii) strong difficulties in carrying out measurements in non-symmetrical or unsteady flames; (iii) inability to perform measurements when the the soot volume fractions are of the order of ppb or lower; (iv) inability to characterize fuel mixtures typically used in industrial boilers [

5,

26,

27]; (v) requirement of specialized equipment; and (vi) high-computational cost for processing the collected data [

10,

28]. Note that the method presented in this article can account for variations in the soot volume fractions along the optical path. This can be accomplished for laminar, steady and axisymmetric flames. In the case of turbulent flames, which are typical of industrial settings, the LOSA method can be used under the assumption that the soot volume fraction is uniform along the optical path.

Rapid advances in optical sensors and computational support for data capturing and processing have triggered interest in alternative non-invasive sensing for combustion diagnostics using optical measurements. Recent work reports effective approaches based on optical sensors for identification of conversion zones in a combustion chamber (drying, devolatilization and char oxidation) [

29], estimating the radiation emitted by a flame [

30,

31,

32], and reconstructing the temperature of a volumetric representation of a flame [

33]. While these methods focus on energy measurements, they do not address directly the challenges associated to reducing the environmental impact of combustion-based processes.

This work describes a setup and methodology for a model-free estimation of the SPH of a flame using digital images. The proposed approach relies on video magnification techniques to amplify subtle morphological changes in a sequence of images. Several works have shown the effectivity of video magnification in applications such as the detection of heart rate and blood pressure by visible or thermal images [

34,

35], identification of resonant frequencies, damping ratios of a structure and small undesirable movements in a structure [

36,

37], or calculation of material properties through visual vibrometry [

38]. This work builds upon preliminary proof of concept [

39], by comparing the error of two different methods for video magnification (EVM and PVM) applied for soot propensity. The comparison of EVM and PVM regards by the analysis of the overall accuracy in the obtained relation between the SPH and the fuel flow rate for soot propensity, through the calculation of average root-mean-square-error, and the confidence interval for a fixed uncertainty, which represents the systematic and random error respectively.

3. Proposed Approach for Smoke Point Detection and Background on Video Magnification

In general, combustion processes are controlled by manipulating the flows of fuel and oxygen. If the fuel flow rate is increased while keeping the oxygen flow constant, then the process will reach an operation point at which the soot formation reaction rates within the flame are large enough to overcome the soot oxidation reactions. The smoke point occurs when the threshold fuel flow rate is reached and soot particles flow outside the flame in the form of black smoke. Considering that the heat release and flame height are proportional to the fuel flow rate [

13], the SPH method relates the critical point at which the flame starts releasing smoke with morphological changes in the flame

Figure 1 shows morphological properties observed in an axisymmetric diffusion laboratory-scale flame under different levels of fuel flow for a constant oxygen flow. Under SPH (USPH) condition represents the points where the fuel flow rate lies below the threshold value, and the flame has a candle-like shape without releasing smoke. The equal SPH (ESPH) condition corresponds to the critical point when the fuel flow rate reaches the threshold and the tip of the flame shows subtle wings and starts releasing smoke. If the fuel flow rate keeps increasing, then the process enters the above SPH (ASPH) condition, where the wings on the tip become more evident and PM emissions increase drastically [

14].

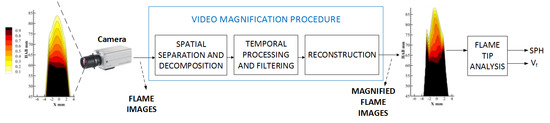

Figure 2 shows an overview of the proposed processing flow for performing soot propensity analysis by detecting the smoke point of a flame in a combustion process. The system considers a digital camera that captures a sequence of flame images. The core of the system is the video magnification procedure that takes a stream of images from the camera and produces a new sequence that magnifies variations between consecutive images. We expect the magnified image sequence to reveal information about the subtle morphological changes in the tip of the flame that occur at the smoke point.

To validate the SPH results obtained through video magnification methods, we compare them to estimations obtained from LOSA in the same scenario [

8,

10], which consists in the calculation of the radially integrated soot volume fraction

within the flame, defined as in Equation (

1):

where

r is the distance from the flame’s symmetry axis,

is a discretization index for numerical integration, and

is the local soot volume fraction calculated as [

10]:

The local soot volume fraction

is a function of the absorption function

and the spectral absorption coefficient

. The absorption function

is calculated as:

where

and

are the real and complex part of soot’s refractive index, whose values can be evaluated using correlations obtained by Chang and Charalampopoulos correlations [

40]. On the other hand, the spectral absorption coefficient

can be obtained from its relation with the total fraction of light transmitted through the flame (

), retrieved from the LOSA measurements [

41] and the Beer-Lambert’s law according to the following equation:

where

is the flame radius.

Finally, the SPH referential value is obtained through the radially-integrated soot volume fraction

, evaluated according to Equation (

1) [

28].

is evaluated as a function of the dimensionless axial coordinate (i.e., height above the burner base)

, in order to compare the integrated soot volume fraction for different fuel flow rates [

28]; where

z is the axial position where

is calculated,

is the volumetric fuel flow rate in sccs, and

is the diffusion coefficient (a value of

cm

/s is considered [

28]).

3.1. Fundamentals of Eulerian Video Magnification

EVM combines spatial and temporal processing to amplify subtle variations in sequences of images using a three-stage approach [

42,

43]. The first stage corresponds to the spatial decomposition of the original video input into a set of different spatial bands, to recognize the contour of the different shapes in the video [

44] and increase the temporal signal-to-noise ratio by pooling multiple pixels [

43]. The second stage performs temporal processing on each spatial band separately, by considering a pixel as a time series. Here, a bandpass filter is applied to retain the frequency bands of interest, according to the specific study phenomenon. Then, the filtered bandpass signal is multiplied by a magnification factor

to enhance the desired variations. Finally, in the third stage, the magnified signal is added to the original signal and the spatial pyramid is collapsed to obtain the final amplified output.

is the intensity of a particular pixel

x recorded in the image at a given time

t. Since the image is in translational motion, the intensity of a certain pixel can be expressed in terms of an arbitrary spatial displacement function

:

Then with Equation (

5), we could have

We are interested on obtain the time series of pixel variations at each pixel

x in the form

. Then, by using a first-order Taylor expansion with respect to

x in Equation (

5), the pixel intensity at time

t can be approximated as:

If

is the result of applying a broadband temporal band-pass filter on the signal

at every position

x to isolate the term proportional to the displacement function

, and taking

with

, then we have:

This is the first order approximation to the brightness constancy equation in optical flow [

42], where the intensity variation at a pixel

x is the negative of the product between the spatial displacement

and the spatial gradient

. The filtered band-pass signal

is subsequently amplified by the amplification factor

and added back into Equation (

6), resulting in the processed signal

[

42]:

where the amplification factor

determining the amplification of subtle color variations, which is obtained according to the specific application. However, an upper bound of amplification factor

could be obtained [

43], which is compatible with accurate motion magnification of the unknown spatial displacement function

and cut-off frequency

, given by

[

43]. By combining Equations (

6)–(

8), we obtain the following result for the pixel intensity:

Assuming that the amplified larger perturbation

can be approximated through a first-order Taylor expansion, then the amplification of the temporally band-passed signal is related to the magnification of tiny motion from the original image source [

42]. The processed output in the final stage is then expressed as:

where the spatial displacement

has been amplified

times. In summary, the term

defines the amplification factor applied in the video magnification sequence according to the specific application. On the other hand, the term

describes the upper bound of the amplification factor

and the term

defines how many times the spatial displacement function

is truly amplified.

3.2. Fundamentals of Phase Based Video Magnification

PVM modifies local motions in a sequence using a processing flow similar to EVM, but changing the representation from pixel intensities to local spatial phases [

42]. In this case, the input image sequence is projected into a basis of complex functions to amplify the phase differences between all independent corresponding basis elements.

Let us reconsider Equation (

5), where the intensity of a pixel is expressed in terms of another spatial displacement function,

. We want to obtain a sequence with modified motion as previously defined in Equation (

10) for some magnification factor

, but now considering a Fourier basis. Let us rewrite the displaced image profile from Equation (

5) as a sum of complex sinusoids as:

where each band corresponds to a single frequency

[

45].

From Equation (

11), the band for a certain frequency

is the complex sinusoidal function

described as:

Considering that two consecutive frames in a video sequence are normally slight translations of each other, each coefficient has a slight phase difference in the steerable pyramid representation of motion. Here, the phase term

contains motion information. Using the Fourier shift theorem, we can manipulate the motion between frames by modifying the phase of the signal. Assuming that a DC filter removes the DC component of

, we can obtain the term

, which is proportional to the translation. By multiplying the phase shift by

, we obtain an increased phase of sub-band

as:

where

represents a complex sinusoid motion exactly

times the original value. Finally, by shifting the Fourier coefficients we obtain [

42]:

where the two consecutive frames are slight translations of each other, and they have a phase difference given by

, which is amplified by a factor

. Finally, the new frames are reconstructed by multiplying the phase shift and a basis function (usually an amplitude weighted Gaussian kernel [

42]). Then, the real part of the new shifted frames is added to get new frames, where the translations and therefore the motions in the flame images are amplified.

3.3. Comparing EVM and PVM

It is important to note that the Eulerian perspective of video magnification uses a fixed reference frame and characterizes properties over time at each fixed location [

42]. EVM targets the magnification of small variations in consecutive images, and thus certain features that remain mostly stable between images (e.g., height and width of the flame) should remain unaffected. This is a very important property for our specific target application, as SPH analysis requires an accurate value of the flame height at the instant when the flame morphology changes from a non-sooting to a sooting behavior. Unfortunately, since EVM relies on a first-order Taylor expansion, the motion amplification will go out of range if the input motion or the amplification factor is too large [

42]. Besides, as a linear motion magnification tool, EVM also tends to amplify the measurement noise. If the original input noise has a high amplitude, then the output image with amplified variations will have a value of

[

42].

PVM amplifies phase differences rather than pixel intensities, which presents two main advantages: (i) it supports larger amplification factors than EVM, (ii) PVM is less sensitive to noise, because the noise amplitude is not amplified [

42]. Unfortunately, PVM presents oversmoothing effects that can shape white noise into a false motion signal. Besides, PVM recovers tiny motions at frequencies lower than the temporal Nyquist frequency of the field camera. Thus, if motions are too fast, such as in the case of the flame images, only an aliased version of the motion will be amplified [

42].

5. Experimental Results and Analysis

5.1. Referential Soot Propensity Analysis by LOSA

To obtain reference values for SPH analysis using LOSA, we calculated the integrated soot volume fraction (

) using Equation (

1). To calculate

, we evaluate soot volume fraction profiles at different flame heights above burner (HAB) for each of the fuel flow conditions in

Table 1.

Figure 4 shows the calculated

as function of the normalized height fuel flow

for different fuel flow rates and OI = 21%. In particular, the plot shows the results of the integrated soot volume fraction for a flame USPH and ASPH, where a sooting flame is verified if the soot volume fraction

does not reach zero value when

increases and approaches the flame height. Otherwise, if the flame does not release soot, then

approaches zero when

increases. This analysis is repeated for the tested oxygen indices between 19% and 35% as shown on

Table 1 to obtain referential SPHs and fuel flow rates at SPH

for each experimental condition.

5.2. Soot Propensity Analysis Using EVM and PVM

Figure 5 and

Figure 6 show the processed flame images at OI = 21% for a non-sooting condition when SPH is reached and for a sooting condition when SPH is surpassed, respectively. Color scale defines the normalized intensity of the flame images.

To quantify the effects of using video magnification, we calculate a differential image corresponding to the pixel difference

, where

represents the pixel intensity of the original flame image measured with the camera and

is the pixel intensity of the magnified image.

Figure 7 shows the absolute values of the pixel differences when the sooting condition of SPH is reached as in

Figure 5 (OI = 21%). Following a similar scheme,

Figure 8 and

Figure 9 show the processed flame images at OI = 35%, for the different conditions respect to the SPH, and

Figure 10 shows the absolute values of the pixel differences when the sooting condition of SPH is reached as in

Figure 8. The plots of the pixel difference between amplified and original image clearly show that EVM produces a stronger magnification of the flame tip than PVM for the same amplification factor of

.

Figure 11a,b present a soot propensity analysis in terms of the SPH and volumetric fuel flow rate at the SPH

, respectively. The analysis is presented as a function of the OI, which defines the experimental testing condition summarized in

Table 1. To estimate the uncertainty of the analysis in terms of SPH and

, 100 samples are taken to obtain the average and variance of each indicator. These plots also present the referential values of SPH and

obtained through the LOSA method by

, as described in

Figure 4. It is clear that the EVM method yields results which are closer to the reference LOSA values. Note that the error bars of the EVM method are larger than those of the PVM method, which can be explained by the amplification of the input noise which is carried out by the EVM analysis.

5.3. Analysis and Discussion

Figure 5 and

Figure 8 show the results of the application of video magnification to an image of a flame that has reached the SPH at OI = 21% and OI = 35%. Through simple direct visual inspection, We observe that EVM provides a stronger enhancement of relevant morphological changes when the flame tip begins to open (see

Figure 5a and

Figure 8a) compared to PVM for the same amplification factor. Similarly, experimental results for ASPH conditions (

Figure 6 and

Figure 9) show that EVM is again more effective than PVM when enhancing the morphological characteristics when the flame tip is open and soot is being released. The quantitive analysis of the differences between the original and amplified images presented in

Figure 7 and

Figure 10 clearly shows that EVM has a larger intensity difference around the tip of the flame, while PVM produces greater amplification at mid-flame height. In this context, EVM produces more useful results than PVM in terms of facilitating the identification the operational conditions of SPH and subsequently

in a more precise way.

One problem with using EVM is that it relies in a linear amplification of subtle changes between consecutive images, and therefore amplifies the noise in the image. Consequently, images amplified through EVM tend to have more noise than the ones with PVM. From our experiments, we observed that the following factors affect the accuracy of the procedures for video magnification: With respect to uncertainties identified in the video magnification process, we observe that the following factors affect the accuracy of the procedures evaluated in our experiments:

Lighting: measurements for soot propensity consider the same light applied to the CCD camera, corresponding to the flame chemiluminescence. Then, both EVM and PVM amplify pixel intensities that cannot be observed by the naked eye in the original flame image.

Camera angle and position: If the camera angle and position are not fixed when capturing the sequence of flame images, movements from the camera can generate false image variations that will be added to the video magnification results [

42]. This can seriously affect the accuracy of the SPH detection.

Noise: measurements using optical instruments are subject to additive random variables related to the spurious noise and noise factor according to the camera type: CCD, ICCD or EMCCD [

52]. Also, we can consider the presence of electronic noise on the video magnification block when the electronic devices are exposed to external perturbations.

The setup for our laboratory scale experiments considered configurations that reduced the sources of added noise in the captured videos of the flame under observation. Still, to reduce potential bias from remaining noise sources, we performed uncorrelated experiments to obtain average values of and . However, in industrial settings it may not be possible to completely eliminate these sources of noise, posing an extra challenge in the application of these techniques in practical combustion systems.

From SPH results obtained according to the experimental conditions described in

Table 1, we observe that EVM presents better than PVM, in terms of its accuracy with respect to the target soot propensity analysis by LOSA. Unfortunately, a slightly larger uncertainty is obtained with EVM with respect to PVM, because of the inherent noise amplification of EVM.

When performing a quantitative evaluation of the uncertainty analysis for SPH, we obtained the following results:

- (i)

Average root-mean-square-error of EVM with respect to LOSA, mm equivalent to 8%. This is more accurate than the average root-mean-square-error of PVM mm equivalent to 25%.

- (ii)

Maximum uncertainty (calculated for 95% confidence interval) for EVM and PVM are mm and mm and equivalent to and , respectively.

For results, EVM also reveals a slightly larger uncertainty than the PVM method because of the noise amplification:

- (i)

Average root-mean-square-error of EVM cm3/s equivalent to 14%, more accurate compared to the average root-mean-square-error of PVM with respect to LOSA cm3/s equivalent to 26%.

- (ii)

Maximum uncertainty (calculated for 95% confidence interval) for EVM and PVM are cm/s and cm/s and equivalent to and , respectively.

With the overall uncertainty analysis, we verify that sooting propensity analysis by EVM presents an improved average performance, in terms of the and results, in comparison to the results obtained through PVM. Concerning the random error for SPH and , we observe that slightly smaller values are obtained with PVM, because of the noise amplification of EVM.

6. Conclusions

This paper presents novel methods for soot propensity analysis of combustion processes based on the amplification of the morphological changes recorded in a video sequence of a flame. The evaluated methodologies are based on EVM and PVM methods for video magnification. The results show that both techniques are able to magnify subtle changes in flame morphology that occur at the SPH, which facilitates detecting the point at which the flame starts releasing particulate matter.

Results of soot propensity analysis performed using EVM and PVM are benchmarked with reference results obtained through LOSA. The proposed techniques report acceptable average and random error, taking as key metrics for the evaluation the smoke point height (SPH) and volumetric fuel flow rate where SPH is reached. EVM presents the best results in terms of average error, but slightly higher random uncertainty with respect to PVM results, mainly given by the inherent amplification of noise of the EVM technique.

The results of this work are encouraging, showing the feasibility of performing soot propensity analysis for detecting emissions of particulate matter to the environment using flame images. The proposed technique can overcome the intrinsic delay of direct measurements of PM emissions in industrial settings using gas chromatographs. Moreover, the main component of the methods is an image acquisition device that may be already present in industrial settings for monitoring purposes. This makes it a simpler and cheaper alternative to LOSA, which requires expensive equipment that is normally unsuitable for conventional industrial combustion facilities. Nevertheless, there are still several practical challenges to be solved, including accounting for sources of signal noise in industrial settings and working with turbulent, unsteady flames which are typically found in combustion chambers.

From previous results, unified behavioral analysis for axisymmetric or co-flow diffusion flames was proposed for different fuels [

11]. This analysis concerns the smoke point height (SPH), volumetric fuel flow rate

where SPH is reached, and soot volume fraction within the flame

, when the oxygen index, flow conditions and the dominance of soot formation over oxidation varying. Then, this model-free soot propensity analysis approach based on video magnification could be used for different fuels, because it is strictly based on measurement conditions of flame images, and

by LOSA as reference.

Future work considers the detailed characterization of the computational cost for the processing flow based on EVM, and the deployment of a prototype as an embedded platform for real-time estimations to be tested in both laboratory scale experiments and industrial settings. The final objective is to validate our findings and evaluate their effective utility on the development of novel instrumentation for cleaner combustion processes.