IoT Hierarchical Topology Strategy and Intelligentize Evaluation System of Diesel Engine in Complexity Environment

Abstract

:1. Introduction

2. Literature Review

3. Problem Analysis

3.1. Present Situation and Existing Problems in Diesel Engine Enterprise

3.2. Analysis of Uncertain Factors in Production Process

4. The Topology Design Strategy of IIoT Network and Evaluation Model of Intelligentize Manufacturing

4.1. The Topology Design Strategy of IIoT Network

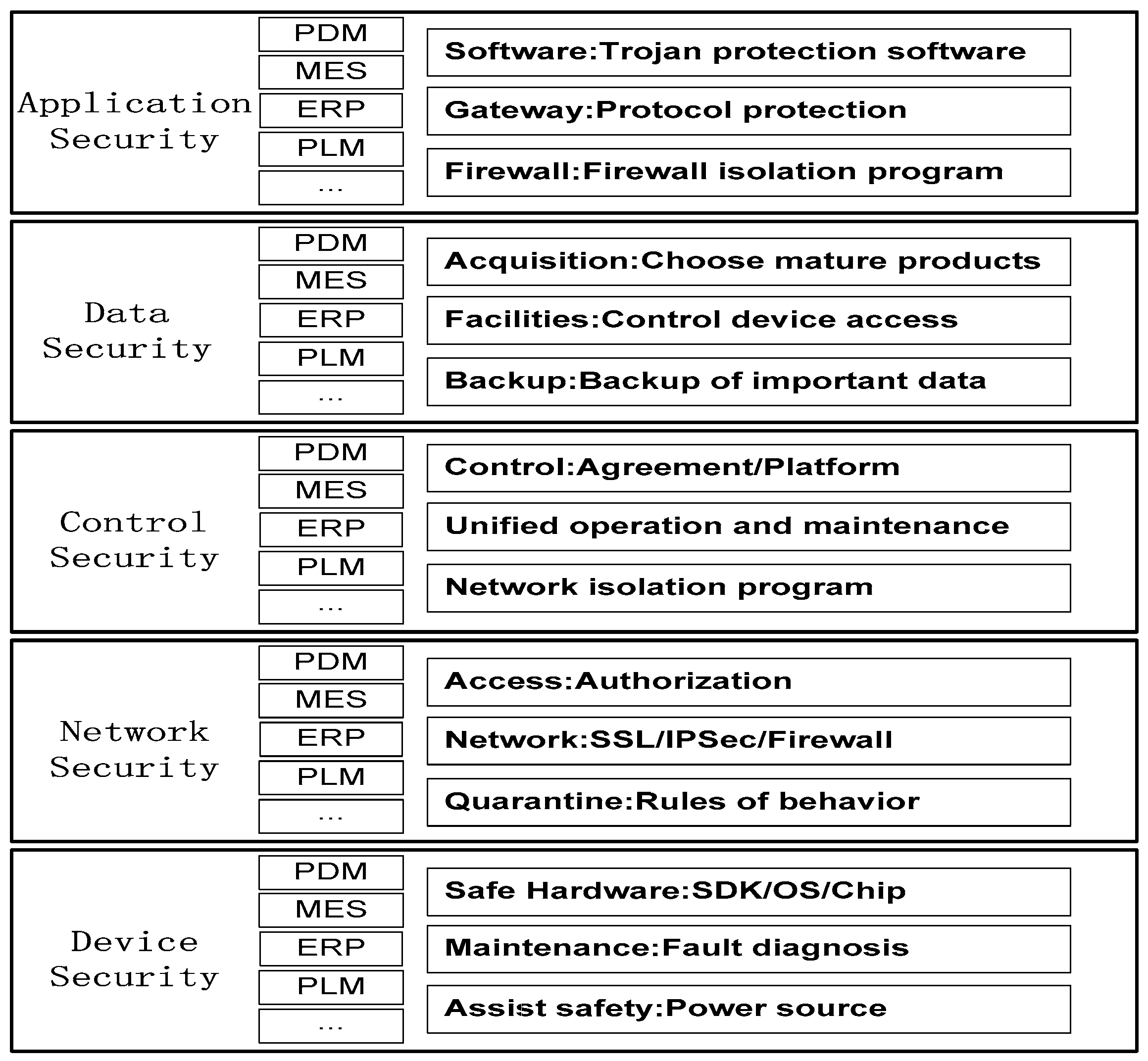

4.2. The Big Data Analysis Model and Security Protection System Oriented IIoT Network

4.3. Weight Coefficient and Evaluation Model of Intelligent Evaluation Index Based on IIoT Network

5. Application of the IIoT Network Topology Design Strategy in Diesel Engine Enterprise Intelligent Manufacturing

5.1. IIoT Network Topology Design for the Foundry Workshop of Diesel Engine

5.2. IIoT Network Topology Design for the Machining Workshop of Diesel Engine

5.3. IIoT Network Topology Design of the Workshop MES in Enterprise

6. A Case of Analysis on Intelligent Evaluation of Diesel Engine Enterprise

6.1. The Establishment of Hierarchical Structure Model of Evaluation System

6.2. Result Analysis

- (i)

- 86 ≤ H < 100, advanced intelligentized enterprise

- (ii)

- 61 ≤ H < 85, intermediate intelligentized enterprise

- (iii)

- 41 ≤ H ≤ 60, Primary intelligentized enterprise

- (iv)

- H ≤ 40, entry intelligentized enterprise (single intelligent application).

7. Conclusions

- (1)

- According to production status, production demands and network characteristics, the topological process and deployment strategy of the IIoT were designed. The network topology design is expansible.

- (2)

- The AHP method was used to establish the intelligent evaluation system for the diesel engine enterprise and the judgment matrix for each evaluation index layer was set up to verify the consistency of them. Finally, the weight coefficients between the evaluation indices of each layer were obtained. The weighted average model of the evaluation system was established to obtain the result of the intelligent evaluation level of the diesel engine enterprise.

Author Contributions

Funding

Conflicts of Interest

References

- Shen, L.Z.; Yang, Y.Z.; Lei, J.L.; Bi, Y.H.; Yan, W.A. A Study on the Performance of Turbocharged and Intercooled Diesel Engine Working in the Different Altitude Regions. Automot. Eng. 2005, 27, 674–677. [Google Scholar]

- Zheng, G.Z.; Yuan, L. A Research on the Effects of Dynamic Characteristics of Connecting Rod on the Piston Slap of Engine. Automot. Eng. 2012, 34, 1119–1124. [Google Scholar]

- Jazdi, N. Cyber physical systems in the context of Industry 4.0. In Proceedings of the IEEE International Conference on Automation, Cluj-Napoca, Romania, 22–24 May 2014; pp. 1–4. [Google Scholar]

- Michalos, G.; Makris, S.; Papakostas, N.; Mourtzis, D.; Chryssolouris, G. Automotive assembly technologies review: Challenges and outlook for a flexible and adaptive approach. CIRP J. Manuf. Sci. Technol. 2010, 2, 81–91. [Google Scholar] [CrossRef]

- Li, S.; Xu, L.D.; Zhao, S. The Internet of Things: A Survey. Inf. Syst. Front. 2015, 17, 243–259. [Google Scholar] [CrossRef]

- Nasr, E.S.A.; Kamrani, A.K. Intelligent Design and Manufacturing; Springer: New York, NY, USA, 2008; pp. 103–125. [Google Scholar]

- Shi, C.; Sun, Z.; Dong, K. Research on Evaluation Model of Financial Core Competence of Listed Companies of Equipment Manufacturing. In Proceedings of the Conference on Knowledge Engineering and Software Engineering, Shenzhen, China, 19–20 December 2009; pp. 75–77. [Google Scholar]

- Li, W.; Wang, B.; Sheng, J.; Dong, K.; Li, Z.; Hu, Y. A Resource Service Model in the Industrial IoT System Based on Transparent Computing. Sensors 2018, 18, 981. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Ma, J.; Lin, L.; Ge, M.; Wang, Q.; Liu, C. Intelligent assembly system for mechanical products and key technology based on internet of things. J. Intell. Manuf. 2017, 28, 271–299. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, Z.; Ning, Y. Design of Compressed Sensing Algorithm for Coal Mine IoT Moving Measurement Data Based on a Multi-Hop Network and Total Variation. Sensors 2018, 18, 1732. [Google Scholar] [CrossRef] [PubMed]

- Ji, C.; Shao, Q.; Sun, J.; Liu, S.; Pan, L.; Wu, L.; Yang, C. Device Data Ingestion for Industrial Big Data Platforms with a Case Study. Sensors 2016, 16, 279–293. [Google Scholar] [CrossRef] [PubMed]

- Fraga-Lamas, P.; Fernández-Caramés, T.M.; Suárez-Albela, M.; Castedo, L.; González-López, M. A Review on Internet of Things for Defense and Public Safety. Sensors 2016, 16, 1644. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.Q.; Zhang, Y.; Jiang, P. RFID based wireless manufacturing for real-time management of job shop WIP inventories. Int. J. Adv. Manuf. Technol. 2008, 36, 752–764. [Google Scholar] [CrossRef]

- Brintru, A. RFID opportunity analysis for leaner manufacturing. Int. J. Prod. Res. 2010, 48, 2745–2764. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.-C.; Deng, D.-J.; Chen, Z.-Y.; Chen, K.-C. Key design of driving industry 4.0: Joint energy efficient deployment and scheduling in group based industrial wireless sensor networks. IEEE Commun. Mag. 2016, 54, 46–52. [Google Scholar] [CrossRef]

- Lin, F.; Chen, C.; He, T.; Ma, K.; Guan, X. A separation principle for resource allocation in industrial wireless sensor networks. Wirel. Netw. 2017, 23, 805–818. [Google Scholar] [CrossRef]

- Liu, Y.; Ota, K.; Zhang, K.; Ma, M.; Xiong, N.; Liu, A.; Long, J. QTSAC: An Energy-Efficient MAC Protocol for Delay Minimization in Wireless Sensor Networks. IEEE Access 2018, 6, 8273–8291. [Google Scholar] [CrossRef]

- Chen, Y.; Lee, J.M.; Shu, L.; Crespi, N. Industrial Internet of Things-Based Collaborative Sensing Intelligence: Framework and Research Challenges. Sensors 2016, 16, 215. [Google Scholar] [CrossRef] [PubMed]

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2018, 101, 1–12. [Google Scholar] [CrossRef]

- Bassi, A.; Bauer, M.; Fiedler, M. Enabling Things of Talk; Springer: Berlin/Heidelberg, Germany, 2013; pp. 163–211. [Google Scholar]

- Kiljander, J.; D’Elia, A.; Morandi, F.; Hyttinen, P.; Takalo-Mattila, J.; Ylisaukko-Oja, A.; Soininen, J.-P.; Cinotti, T.S. Semantic Interoperability Architecture for Pervasive Computing and Internet of Things. IEEE Access 2014, 2, 856–873. [Google Scholar] [CrossRef]

- Li, B.; Hou, B.; Yu, W.; Lu, X.; Yang, C. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Okafor, K.C.; Achumba, I.E.; Chukwudebe, G.A.; Ononiwu, G.C. Leveraging Fog Computing for Scalable IoT Data center Using Spine-Leaf Network Topology. Int. J. Innov. Res. Comput. Commun. Eng. 2017, 10, 1–11. [Google Scholar]

- Li, J.; Chen, M. Multi-objective Topology Optimization Based on Mapping Matrix and NSGA-II for Switched Industrial Internet of Things. IEEE Internet Things J. 2017, 3, 1235–1245. [Google Scholar] [CrossRef]

- Jiang, P.; Xu, Y.; Liu, J. A Distributed and Energy-Efficient Algorithm for Event K-Coverage in Underwater Sensor Networks. Sensors 2017, 17, 186. [Google Scholar] [CrossRef] [PubMed]

- Shao, X.; Chen, Z.; Fu, M.; Gao, L. Multi-objective Topology Optimization of Structures Using NN-OC Algorithms. In Proceedings of the International Symposium on Neural Networks: Advances in Neural Networks, Nanjing, China, 3–7 June 2010; pp. 204–212. [Google Scholar]

- Patel, J.; Choi, S.K. Classification approach for reliability-based topology optimization using probabilistic neural networks. Struct. Multidiscip. Optim. 2012, 45, 529–543. [Google Scholar] [CrossRef]

- Wang, C.; Huang, N.; Bai, Y.; Zhang, S. A method of network topology optimization design considering application process characteristic. Mod. Phys. Lett. B 2018, 32, 1850091. [Google Scholar] [CrossRef]

- Kim, J.R.; Gen, M. Genetic algorithm for solving bicriteria network topology design problem. Congr. Evol. Comput. 2017, 12, 2279. [Google Scholar] [CrossRef]

- Jiang, Z.; Jin, Y.; Liang, J.; Mingcheng, E. Dynamic materials distribution strategy for mixed model assembly lines under uncertainty. Comput. Integr. Manuf. Syst. 2017, 23, 2108–2118. [Google Scholar]

- Bui, N.; Jardak, C.; Magerkurth, C. Internet of Things Architecture; Elsevier: New York, NY, USA, 2013; pp. 1–256. [Google Scholar]

- Squillante, R., Jr.; Filhoa, D.J.S.; Silvab, R.M.D.; Souza, J.A.L.; Junqueira, F.; Miyagi, P.E. A novel safety control hierarchical architecture for prevention and mitigation of critical faults in process industries based on defense-in-depth, reactive systems and safety-diagnosabitity. IFAC Papers OnLine 2015, 48, 1326–1331. [Google Scholar] [CrossRef]

- Lin, Z.; Tao, D.; Wang, Z. Dynamic Construction Scheme for Virtualization Security Service in Software-Defined Networks. Sensors 2017, 17, 920. [Google Scholar] [CrossRef] [PubMed]

- Pidikiti, D.S.; Kalluri, R.; Kumar, R.K.; Bindhumadhava, B.S. SCADA communication protocols vulnerabilities, attacks and possible mitigations. CSI Trans. ICT 2013, 1, 135–141. [Google Scholar] [CrossRef]

- Marchesi, T.R.; Lahuerta, R.D.; Silva, E.C.N.; Tsuzuki, M.S.G.; Martins, T.C.; Barari, A.; Wood, I. Topologically Optimized Diesel Engine Support Manufactured with Additive Manufacturing. IFAC PapersOnLine 2015, 48, 2333–2338. [Google Scholar] [CrossRef]

- Yin, F. Study on Evaluating Indicator System of Smart Manufacturing. Ind. Econ. Rev. 2016, 3, 632–641. [Google Scholar]

- Gong, B.Z. The discussion on evaluation index and the assessment method of intelligent manufacturing. Appl. Electron. Tech. 2015, 41, 6–8. [Google Scholar]

| Name | Status | Problem |

|---|---|---|

| Equipment | Low intelligence, poor network | Information isolated island |

| Product | Multiple Species and Small Batch | Difficult to produce and manage |

| Design | Complex shape and high requirement | Difficult to Synergetic design |

| Schedule | Frequent change plan | Non-dynamic scheduling |

| Production | Complex data | Unable to share information |

| Management | No integration system | No interoperability |

| Target Layer | First-Degree Index | Second-Degree Index |

|---|---|---|

| Intelligent evaluation index U | Decision support U1 | Dynamic scheduling U11 |

| Supply chain management U12 | ||

| Order tracking U13 | ||

| Quality traceability U14 | ||

| Decision support U15 | ||

| Systems engineering U2 | Data definition U21 | |

| Data management U22 | ||

| Model Transfer U23 | ||

| System integration U3 | MES and ERP integration U31 | |

| ERP and PDM integration U32 | ||

| Economic benefit U4 | Production cost U41 | |

| Production efficiency U42 | ||

| Rejection rate U43 |

| Judgment Matrix | Maximum Eigenvalue | Eigenvector | Weight Vector |

|---|---|---|---|

| A1 | 5.15 | (0.33,0.24,0.71,0.56) | (0.18,0.13,0.39,0.30) |

| A21 | 5.17 | (0.41,0.18,0.26,0.85,0.09) | (0.23,0.10,0.15,0.47,0.05) |

| A22 | 3.02 | (0.20,0.35,0.92) | (0.14,0.24,0.62) |

| A23 | 2 | (0.95,0.32) | (0.75,0.25) |

| A24 | 3.11 | (0.22,0.32,0.92) | (0.15,0.22,0.63) |

| Judgment Matrix | CI | RI | CR |

|---|---|---|---|

| A1 | 0.0375 | 0.58 | 0.0646 |

| A21 | 0.0425 | 1.12 | 0.0379 |

| A22 | 0.0100 | 0.58 | 0.0172 |

| A24 | 0.0550 | 0.58 | 0.0948 |

| First-Degree Index | Weight Coefficient | Second-Degree Index | Weight Coefficient |

|---|---|---|---|

| U1 | 0.18 | U11 | 0.23 |

| U12 | 0.10 | ||

| U13 | 0.15 | ||

| U14 | 0.47 | ||

| U15 | 0.05 | ||

| U2 | 0.13 | U21 | 0.14 |

| U22 | 0.24 | ||

| U23 | 0.62 | ||

| U3 | 0.39 | U31 | 0.75 |

| U32 | 0.25 | ||

| U4 | 0.30 | U41 | 0.15 |

| U42 | 0.22 | ||

| U43 | 0.63 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Chen, M.; Yang, T.; Wu, J. IoT Hierarchical Topology Strategy and Intelligentize Evaluation System of Diesel Engine in Complexity Environment. Sensors 2018, 18, 2224. https://doi.org/10.3390/s18072224

Liu J, Chen M, Yang T, Wu J. IoT Hierarchical Topology Strategy and Intelligentize Evaluation System of Diesel Engine in Complexity Environment. Sensors. 2018; 18(7):2224. https://doi.org/10.3390/s18072224

Chicago/Turabian StyleLiu, Jiangshan, Ming Chen, Tangfeng Yang, and Jie Wu. 2018. "IoT Hierarchical Topology Strategy and Intelligentize Evaluation System of Diesel Engine in Complexity Environment" Sensors 18, no. 7: 2224. https://doi.org/10.3390/s18072224

APA StyleLiu, J., Chen, M., Yang, T., & Wu, J. (2018). IoT Hierarchical Topology Strategy and Intelligentize Evaluation System of Diesel Engine in Complexity Environment. Sensors, 18(7), 2224. https://doi.org/10.3390/s18072224