Lagging-Domain Model for Compensation of Hysteresis of xMR Sensors in Positioning Applications

Abstract

:1. Introduction

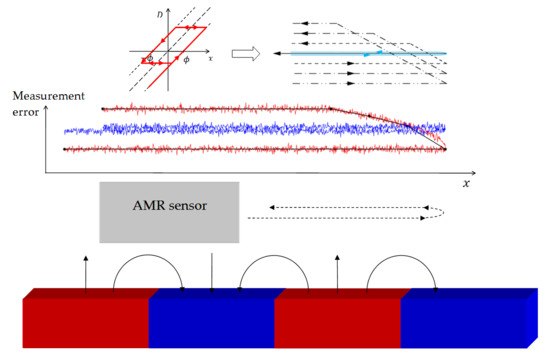

2. The Lagging-Domain Model

2.1. Calibration

2.2. Compensation

3. Experiment and Results

4. Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

| Product Name/Mark | Company | Electrical Period [μm] | HME Before Compensation [°] | HME After Compensation [°] | HME Before Compensation [μm] | HME After Compensation [μm] | Relative Improvement |

|---|---|---|---|---|---|---|---|

| 5B | Under NDA 1 | 2000 | 1.727 | 0.333 | 9.594 | 1.848 | 81% |

| 2000 | 1.680 | 0.333 | 9.332 | 1.852 | 80% | ||

| 2000 | 7.507 | 0.864 | 41.708 | 4.800 | 88% | ||

| 2000 | 0.427 | 0.133 | 2.373 | 0.738 | 69% | ||

| A5 | Under NDA | 2000 | 0.540 | 0.244 | 3.001 | 1.358 | 55% |

| SM2L [44] #1 | iC Haus | 2000 | 0.761 | 0.268 | 4.226 | 1.489 | 65% |

| 2000 | 2.109 | 0.445 | 11.714 | 2.471 | 79% | ||

| 2000 | 0.416 | 0.196 | 2.314 | 1.087 | 53% | ||

| 2000 | 1.081 | 0.366 | 6.007 | 2.035 | 66% | ||

| W3_2 | Under NDA | 2000 | 1.359 | 0.166 | 7.550 | 0.921 | 88% |

| 2000 | 0.159 | 0.056 | 0.881 | 0.310 | 65% | ||

| W3_1 | Under NDA | 2000 | 0.552 | 0.137 | 3.067 | 0.760 | 75% |

| 2000 | 0.178 | 0.070 | 0.987 | 0.389 | 61% | ||

| W5_8 | Under NDA | 2000 | 0.653 | 0.096 | 3.625 | 0.533 | 85% |

| 2000 | 1.225 | 0.232 | 6.806 | 1.290 | 81% | ||

| 2000 | 0.217 | 0.070 | 1.207 | 0.388 | 68% | ||

| W5_3 | Under NDA | 2000 | 0.595 | 0.145 | 3.306 | 0.805 | 76% |

| 2000 | 3.578 | 0.362 | 19.876 | 2.014 | 90% | ||

| 7A | Under NDA | 2000 | 1.759 | 0.194 | 9.770 | 1.077 | 89% |

| 2000 | 0.531 | 0.111 | 2.952 | 0.614 | 79% | ||

| 2C | Under NDA | 2000 | 10.829 | 1.242 | 60.163 | 6.902 | 89% |

| 2000 | 5.835 | 0.420 | 32.418 | 2.334 | 93% | ||

| SM2L [44] #2 | iC Haus | 2000 | 0.840 | 0.245 | 4.669 | 1.358 | 71% |

| 2000 | 0.144 | 0.101 | 0.799 | 0.561 | 30% |

| Product Name/Mark | Company | Electrical Period [μm] | HME Before Compensation [°] | HME After Compensation [°] | HME Before Compensation [μm] | HME After Compensation [μm] | Relative Improvement |

|---|---|---|---|---|---|---|---|

| TL912 z [45] | Sensitec | 1000 | 6.497 | 3.152 | 18.046 | 8.755 | 51% |

| 1000 | 4.908 | 2.940 | 13.634 | 8.167 | 40% | ||

| 1000 | 12.179 | 4.022 | 33.830 | 11.172 | 67% | ||

| 1000 | 0.548 | 0.358 | 1.524 | 0.996 | 35% | ||

| 1000 | 2.392 | 1.589 | 6.644 | 4.413 | 34% | ||

| 1000 | 0.155 | 0.146 | 0.430 | 0.406 | 6% | ||

| MDT TMR40xx package [46] | Multi Dimension Technology (MDT) | 1200 | 0.030 | 0.021 | 0.100 | 0.070 | 30% |

| MDT TMR40xx custom design | Multi Dimension Technology (MDT) | 1200 | 1.050 | 0.150 | 3.500 | 0.500 | 86% |

| 1200 | 0.420 | 0.090 | 1.400 | 0.300 | 79% | ||

| 1200 | 0.600 | 0.240 | 2.000 | 0.800 | 60% | ||

| 1200 | 0.390 | 0.210 | 1.300 | 0.700 | 46% | ||

| TMR4012 [47] | Multi Dimension Technology (MDT) | 1200 | 1.500 | 0.450 | 5.000 | 1.500 | 70% |

| MIS6301 [48] | Multi Dimension Technology (MDT) | 2000 | 1.440 | 0.720 | 8.000 | 4.000 | 50% |

| 2000 | 0.900 | 0.450 | 5.000 | 2.500 | 50% | ||

| 2000 | 3.600 | 0.900 | 20.000 | 5.000 | 75% | ||

| 2000 | 2.700 | 0.900 | 15.000 | 5.000 | 67% | ||

| 2000 | 10.800 | 3.060 | 60.000 | 17.000 | 72% | ||

| TL912 [45] c | Sensitec | 1000 | 9.000 | 2.520 | 25.000 | 7.000 | 72% |

| 1000 | 7.200 | 1.800 | 20.000 | 5.000 | 75% |

References

- Bolandi, H.; Riahi, N.; Esmaeilzadeh, M.; Abedi, M.; Ghorbani, B. Implementation of an AMR magnetic sensor by means of a microcontroller to achieve more accurate response. In Proceedings of the 21st Iranian Conference on Electrical Engineering, ICEE, Mashhad, Iran, 14–16 May 2013. [Google Scholar]

- Tran, T.-H.; Chao, P.; Chien, P.-C. The Front-End Readout as an Encoder IC for Magneto-Resistive Linear Scale Sensors. Sensors 2016, 16, 1416. [Google Scholar] [CrossRef] [PubMed]

- Haji-Sheikh, M.J.; Michael, J. Commercial Magnetic Sensors (Hall and Anisotropic Magnetoresistors). Lect. Notes Electr. Eng. 2008, 1, 23–43. [Google Scholar] [CrossRef]

- Thomson, W. On the Electro-Dynamic Qualities of Metals—Effects of Magnetization on the Electric Conductivity of Nickel and of Iron. Proc. R. Soc. Lond. 1857, 8, 546–550. [Google Scholar] [CrossRef]

- Smit, J. Magnetoresistance of ferromagnetic metals and alloys at low temperature. Physica 1951, 17, 612–627. [Google Scholar] [CrossRef]

- Jan, J.P. Galvanometric and thermomagnetic effects in metals. Solid State Phys. 1957, 5. [Google Scholar] [CrossRef]

- McGuire, R.I.; Potter, T.R. Anisotropic magnetoresistance in ferromagnetic 3d alloys. IEEE Trans. Magn. 1975, 11, 1018–1038. [Google Scholar] [CrossRef]

- Kondo, J. Anomalus Hall effect and magnetoresistance of ferromagnetic metals. Progr. Theor. Phys. 1962, 27, 772–792. [Google Scholar] [CrossRef]

- Berger, L. Influence of spin-orbit interaction on the transport processes in ferromagnetic nickel alloys, in the presence of a degeneracy of the 3d band. J. Appl. Phys. 1963. [Google Scholar] [CrossRef]

- Ky, V.D. Theory of the anisotropy of resistance in ferromagnetic metals. Sov. Phys. JETP 1967, 24, 995–999. [Google Scholar]

- Campbell, I.A.; Fert, A.; Jaoul, O. The spontaneous resistivity anisotropy in Ni-based alloys. J. Phys. C 1970, 3, S95. [Google Scholar] [CrossRef]

- Julliere, M. Tunneling between ferromagnetic films. Phys. Lett. A 1975, 54, 225–226. [Google Scholar] [CrossRef]

- Baibich, M.N.; Broto, J.M.; Fert, A.; Nguyen Van Dau, F.; Petroff, F.; Eitenne, P.; Creuzet, G.; Friedrich, A.; Chazelas, J. Giant Magnetoresistance of (001)Fe/(001)Cr Magnetic Superlattices. Phys. Rev. Lett. 1988, 61, 2472–2475. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Binasch, G.; Grünberg, P.; Saurenbach, F.; Zinn, W. Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange. Phys. Rev. B 1989, 39, 4828–4830. [Google Scholar] [CrossRef]

- Tumanski, S. Thin Film Magnetoresistive Sensors; CRC Press: Boca Raton, FL, USA, 2001; ISBN 9781420033243. [Google Scholar]

- Jogschies, L.; Klaas, D.; Kruppe, R.; Rittinger, J.; Taptimthong, P.; Wienecke, A.; Rissing, L.; Wurz, M. Recent Developments of Magnetoresistive Sensors for Industrial Applications. Sensors 2015, 15, 28665–28689. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Podhraški, M.; Trontelj, J. A differential monolithically integrated inductive linear displacement measurement microsystem. Sensors 2016, 16, 384. [Google Scholar] [CrossRef] [PubMed]

- Xie, F.; Weiss, R.J. Hysteresis Compensation Based on Controlled Current Pulses for Magnetoresstive Sensors. IEEE Trans. Ind. Electron. 2015, 62, 7804–7809. [Google Scholar] [CrossRef]

- Maček, M.; Oblak, A. Ni-Fe alloy thin films for AMR sensors. Mater. Tehnol. 2017, 51, 499–501. [Google Scholar] [CrossRef]

- Stoner, E.C.; Wohlfarth, E.P. A mechanism of magnetic hysteresis in heterogeneous alloys. Phil. Trans. R. Soc. Lond. A 1948, 240, 599–642. [Google Scholar] [CrossRef]

- Jiles, D.; Atherton, D. Ferromagnetic hysteresis. IEEE Trans. Magn. 1983, 19, 2183–2185. [Google Scholar] [CrossRef]

- Jiles, D.C.; Thoelke, J.B. Theory of ferromagnetic hysteresis: Determination of model parameters from experimental hysteresis loops. IEEE Trans. Magn. 1989, 25, 3928–3930. [Google Scholar] [CrossRef]

- Jiles, D.C.C.; Atherton, D.L.L. Theory of ferromagnetic hysteresis. J. Appl. Phys. 1984, 55, 48–60. [Google Scholar] [CrossRef]

- Jiang, W.; Shi, Y.; Zhao, W.; Wang, X. Parameters identification of fluxgate magnetic core adopting the Biogeography-Based Optimization algorithm. Sensors 2016, 16, 979. [Google Scholar] [CrossRef] [PubMed]

- Haumer, H.; Hauser, D.P. Bajalan: Hysteresis modeling of Thin Permalloy Films and Parameter Interpretation. IEEE Trans. Magn. 2004, 40, 2745–2747. [Google Scholar] [CrossRef]

- Gu, G.Y.; Zhu, L.M.; Su, C.Y.; DIng, H.; Fatikow, S. Modeling and control of piezo-actuated nanopositioning stages: A survey. IEEE Trans. Autom. Sci. Eng. 2016, 13, 313–332. [Google Scholar] [CrossRef]

- Macki, J.W.; Nistri, P.; Zecca, P. Mathematical Models for Hysteresis. IEEE Trans. Magn. 1993, 35, 94–123. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.-S.; Kim, G.-W. Hysteresis Compensation of Piezoresistive Carbon Nanotube/Polydimethylsiloxane Composite-Based Force Sensors. Sensors 2017, 17, 229. [Google Scholar] [CrossRef] [PubMed]

- Su, C.-Y.; Stepanenko, Y.; Svoboda, J.; Leung, T.P. Robust adaptive control of a class of nonlinear systems with unknown backlash-like hysteresis. IEEE Trans. Autom. Contr. 2000, 45, 2427–2432. [Google Scholar] [CrossRef]

- Zhao, X.; Tan, Y. Modeling hysteresis and its inverse model using neural networks based on expanded input space method. IEEE Trans. Contr. Syst. Technol. 2008, 16, 484–490. [Google Scholar] [CrossRef]

- Lin, J.-H.; Chiang, M.-H. Tracking Control of a Magnetic Shape Memory Actuator Using an Inverse Preisach Model with Modified Fuzzy Sliding Mode Control. Sensors 2016, 16, 1368. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Wong, P.K. Hysteresis modeling and compensation of a piezostage using least squares support vector machines. Mechatronics 2011, 21, 1239–1251. [Google Scholar] [CrossRef]

- Jedlicska, I.; Weiss, R.; Weigel, R. Linearizing the output characteristic of GMR current sensors through hysteresis modeling. IEEE Trans. Ind. Electron. 2010, 57, 1728–1734. [Google Scholar] [CrossRef]

- Jedlicska, I.; Weiss, R.; Weigel, R. Increasing the measurement accuracy of GMR current sensors through hysteresis modeling. In Proceedings of the IEEE International Symposium on Industrial Electronics, Cambridge, UK, 30 June–2 July 2008. [Google Scholar]

- Han, J.; Hu, J.; Ouyang, Y.; Wang, S.X.; He, J. Hysteretic modeling of output characteristics of giant magnetoresistive current sensors. IEEE Trans. Ind. Electron. 2015, 62, 512–524. [Google Scholar] [CrossRef]

- Preisach, F. Über die magnetische Nachwirkung. Z. Phys. 1935, 94, 277–302. [Google Scholar] [CrossRef]

- Mayergoyz, I.D. Vector Preisach hysteresis models. J. Appl. Phys. 1988, 63, 2995–3000. [Google Scholar] [CrossRef]

- Sánchez-Durán, J.A.; Vidal-Verdú, F.; Oballe-Peinado, Ó.; Castellanos-Ramos, J.; Hidalgo-López, J.A. A new model based on adaptation of the external loop to compensate the hysteresis of tactile sensors. Sensors 2015, 15, 26170–26197. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Yu, P.; Wang, F.; Chan, H.Y.; Zhou, L.; Dong, Z.; Liu, L.; Li, W.J. Improving atomic force microscopy imaging by a direct inverse asymmetric PI hysteresis model. Sensors 2015, 15, 3409–3425. [Google Scholar] [CrossRef] [PubMed]

- Hassani, V.; Tjahjowidodo, T.; Do, T.N. A survey on hysteresis modeling, identification and control. Mech. Syst. Signal Process. 2014, 49, 209–233. [Google Scholar] [CrossRef]

- Bobbio, S.; Miano, G.; Serpico, C.; Visone, C. Models of magnetic hysteresis based on play and stop hysterons. IEEE Trans. Magn. 1997, 33, 4417–4426. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, Y. Modeling of rate-dependent hysteresis using a GPO-Based adaptive filter. Sensors 2016, 16, 205. [Google Scholar] [CrossRef] [PubMed]

- Galinaitis, W.S. Two Methods for Modeling Scalar Hysteresis and Their Use in Controlling Actuators with Hysteresis; Virginia Tech: Blacksburg, VA, USA, 1999. [Google Scholar]

- iC-Haus Homepage—Product: IC-SM2L. Available online: http://www.ichaus.de/iC-SM2L (accessed on 28 June 2018).

- Evaluation Boards Sensitec GmbH. Available online: https://www.sensitec.com/products-solutions/angle-and-length-measurement/evaluation-boards (accessed on 26 June 2018).

- TMR Gear Speed Sensors—Sensors—MultiDimension Technology, The Leading Supplier of TMR Magnetic Sensors. Available online: http://www.dowaytech.com/en/sensor/gear_speed_sensors.html (accessed on 27 June 2018).

- TMR4012—TMR Gear Speed Sensors—Sensors—MultiDimension Technology, The Leading Supplier of TMR Magnetic Sensors—MultiDimension Technology Co., Ltd. Available online: http://www.dowaytech.com/en/1961.html (accessed on 27 June 2018).

- MIS6301—Magnetic Image Sensors—Modules—MultiDimension Technology, The Leading Supplier of TMR Magnetic Sensors—MultiDimension Technology Co., Ltd. Available online: http://www.dowaytech.com/en/1724.html (accessed on 27 June 2018).

| Symbol | Meaning | Unit |

|---|---|---|

| Number of mathematical domains | / | |

| Domain function-play operator | ° | |

| Magnetic flux density | mT | |

| Domain lags-parameters for play operators | ° | |

| Current domain orientation angles | ° | |

| Weights | / | |

| Actual angle of in x-y plane, measured by a reference encoder | ° | |

| Measured angle of ; encoder’s output, affected by hysteresis | ° | |

| Error of measured angle | ° | |

| Estimated error | ° | |

| Time | s | |

| Time step | / |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domajnko, D.; Križaj, D. Lagging-Domain Model for Compensation of Hysteresis of xMR Sensors in Positioning Applications. Sensors 2018, 18, 2281. https://doi.org/10.3390/s18072281

Domajnko D, Križaj D. Lagging-Domain Model for Compensation of Hysteresis of xMR Sensors in Positioning Applications. Sensors. 2018; 18(7):2281. https://doi.org/10.3390/s18072281

Chicago/Turabian StyleDomajnko, Dora, and Dejan Križaj. 2018. "Lagging-Domain Model for Compensation of Hysteresis of xMR Sensors in Positioning Applications" Sensors 18, no. 7: 2281. https://doi.org/10.3390/s18072281