A Through-Hole Lead Connection Method for Thin-Film Thermocouples on Turbine Blades

Abstract

:1. Introduction

2. Design and Fabrication of the Through-Hole Lead Connection

2.1. Design of the Through-Hole Lead Connection

2.2. Fabrication of the Through-Hole Lead Connection

2.2.1. Surface Treatment and Processing

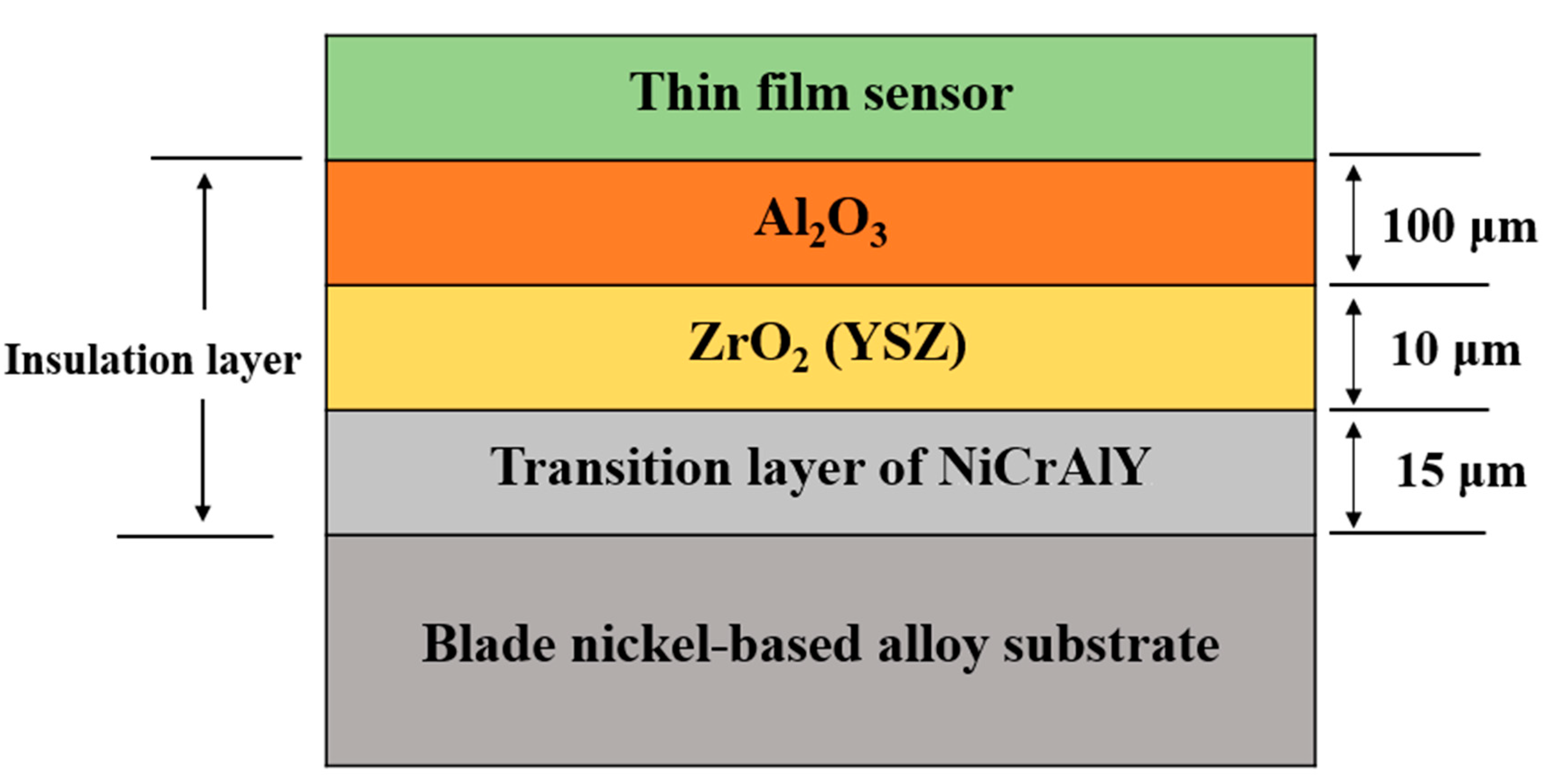

2.2.2. Insulation Layer Preparation

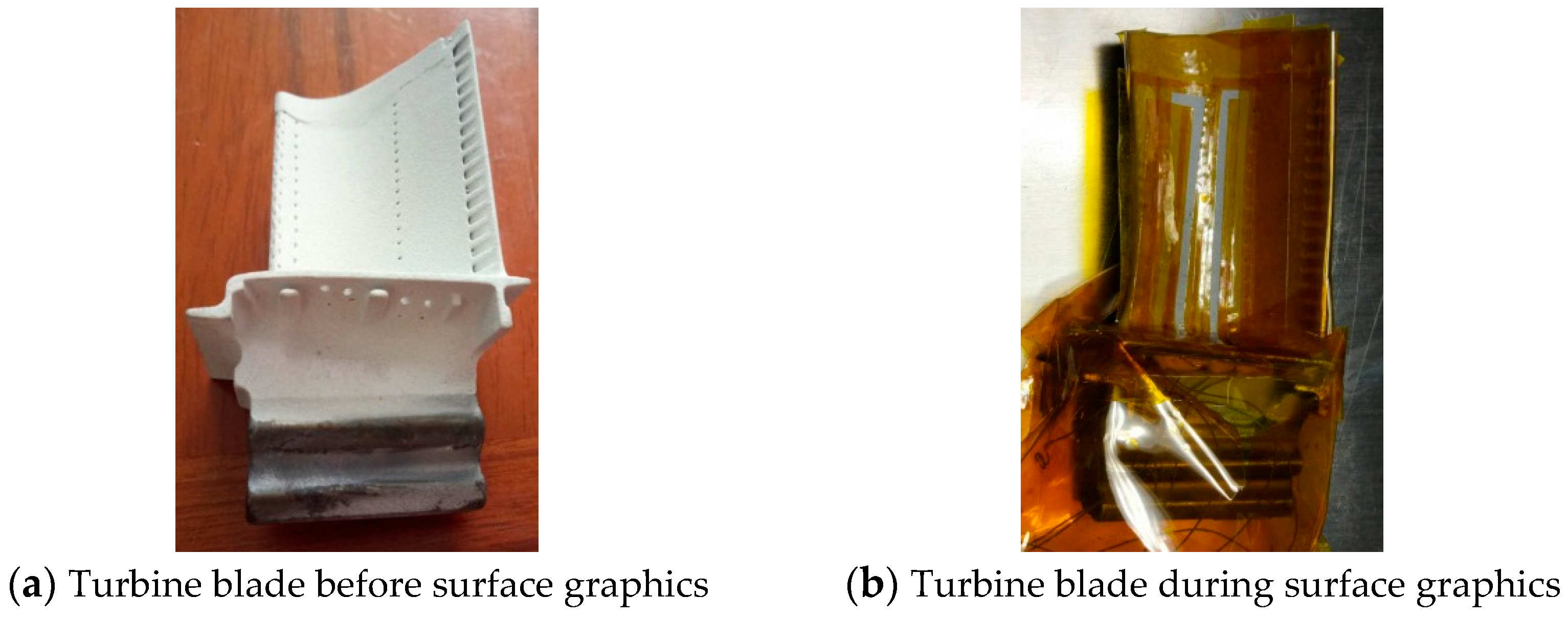

2.2.3. Surface Graphics

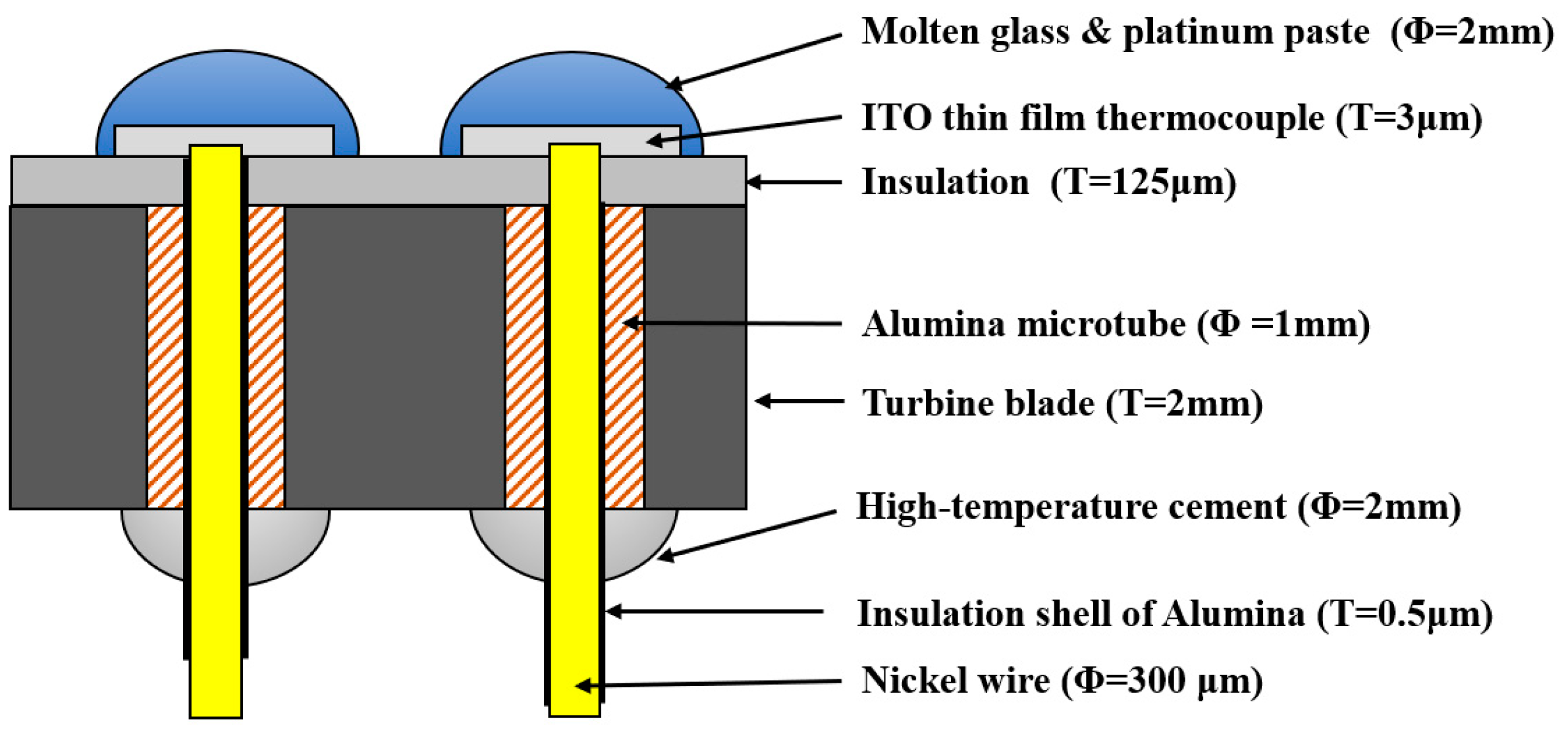

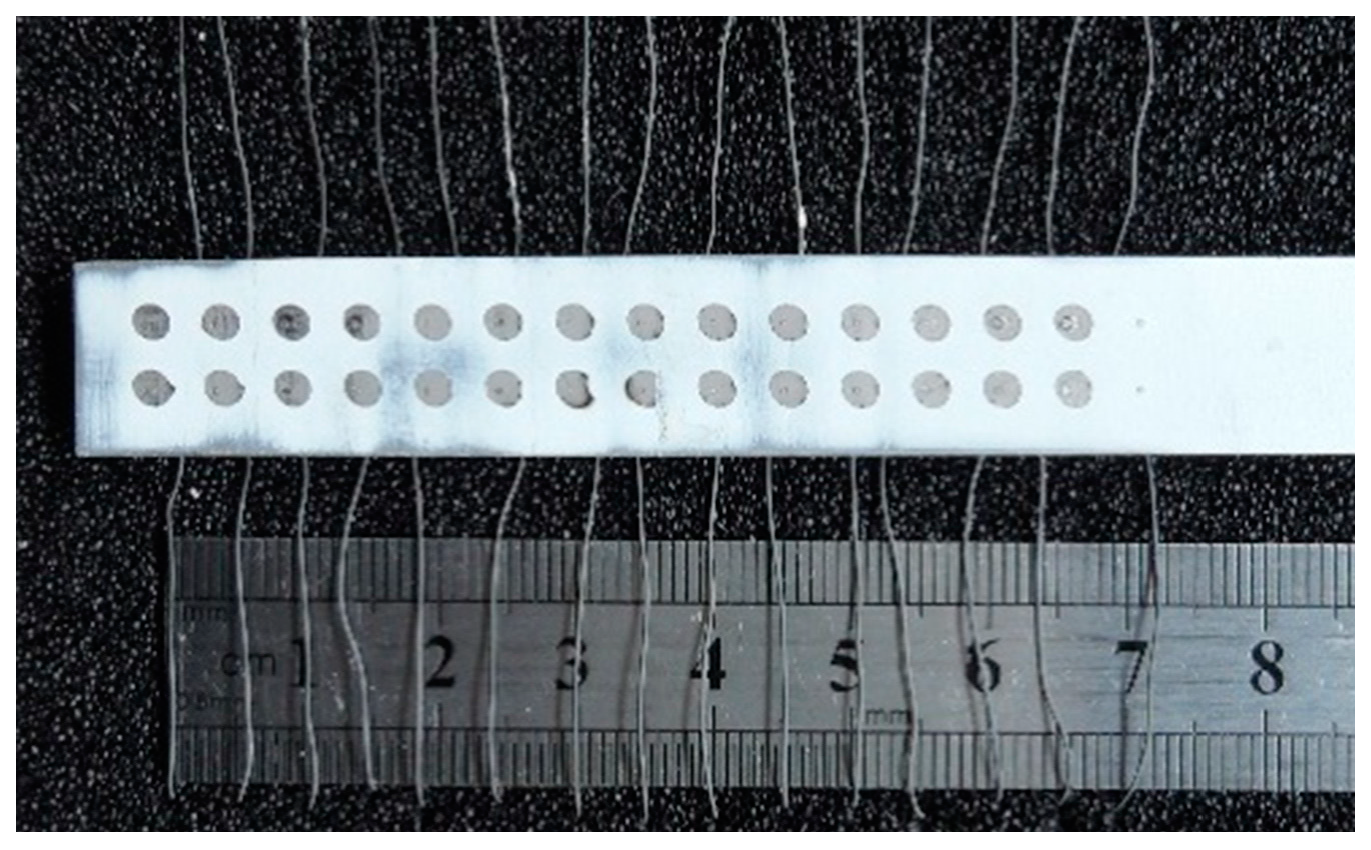

2.2.4. Lead Connection

3. Lead Connection Feature Experiments

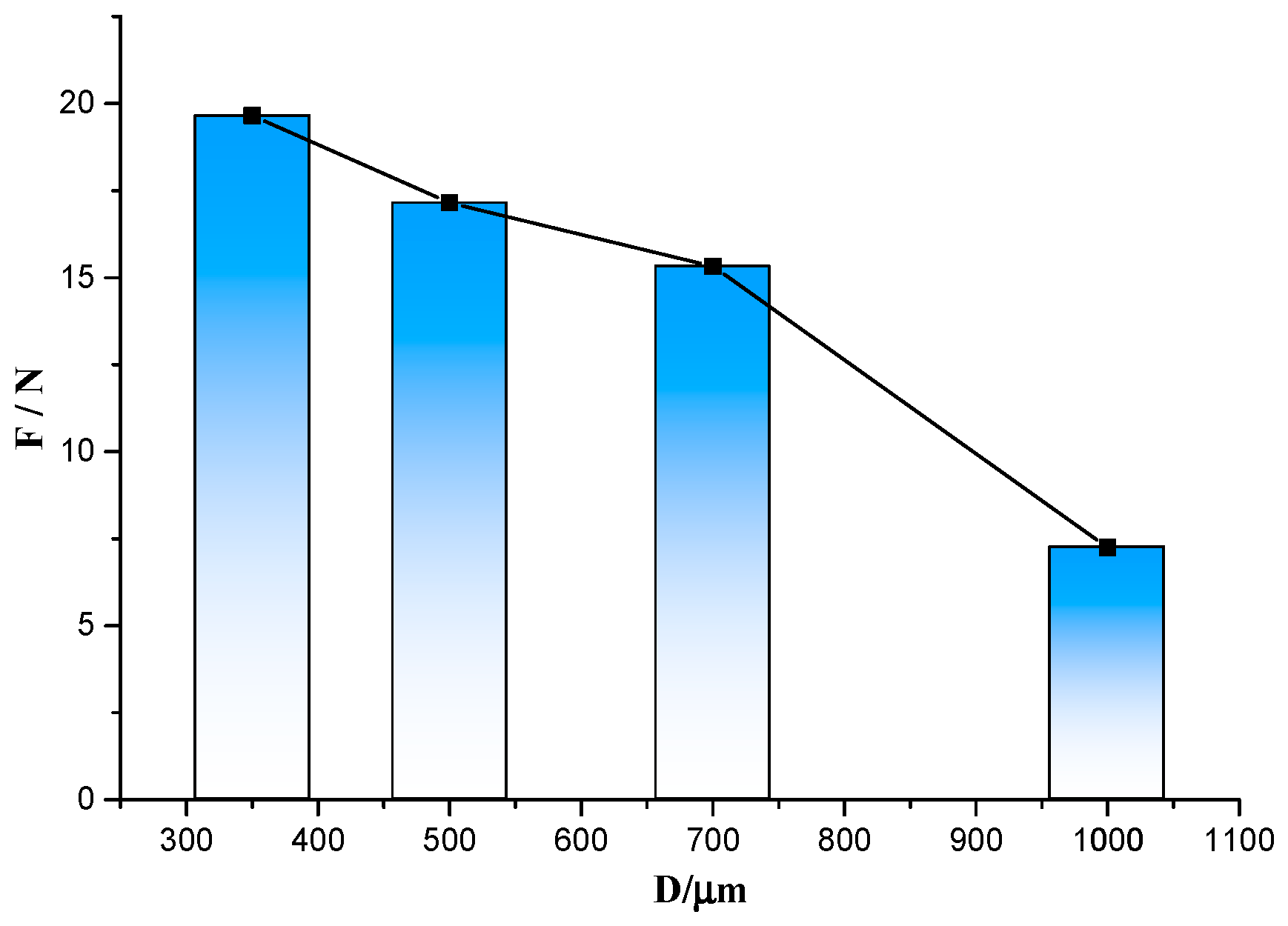

3.1. Lead Connection Strength Experiment

3.2. Studies on the Influence of the Insulation Surface Roughness on Contact Resistance

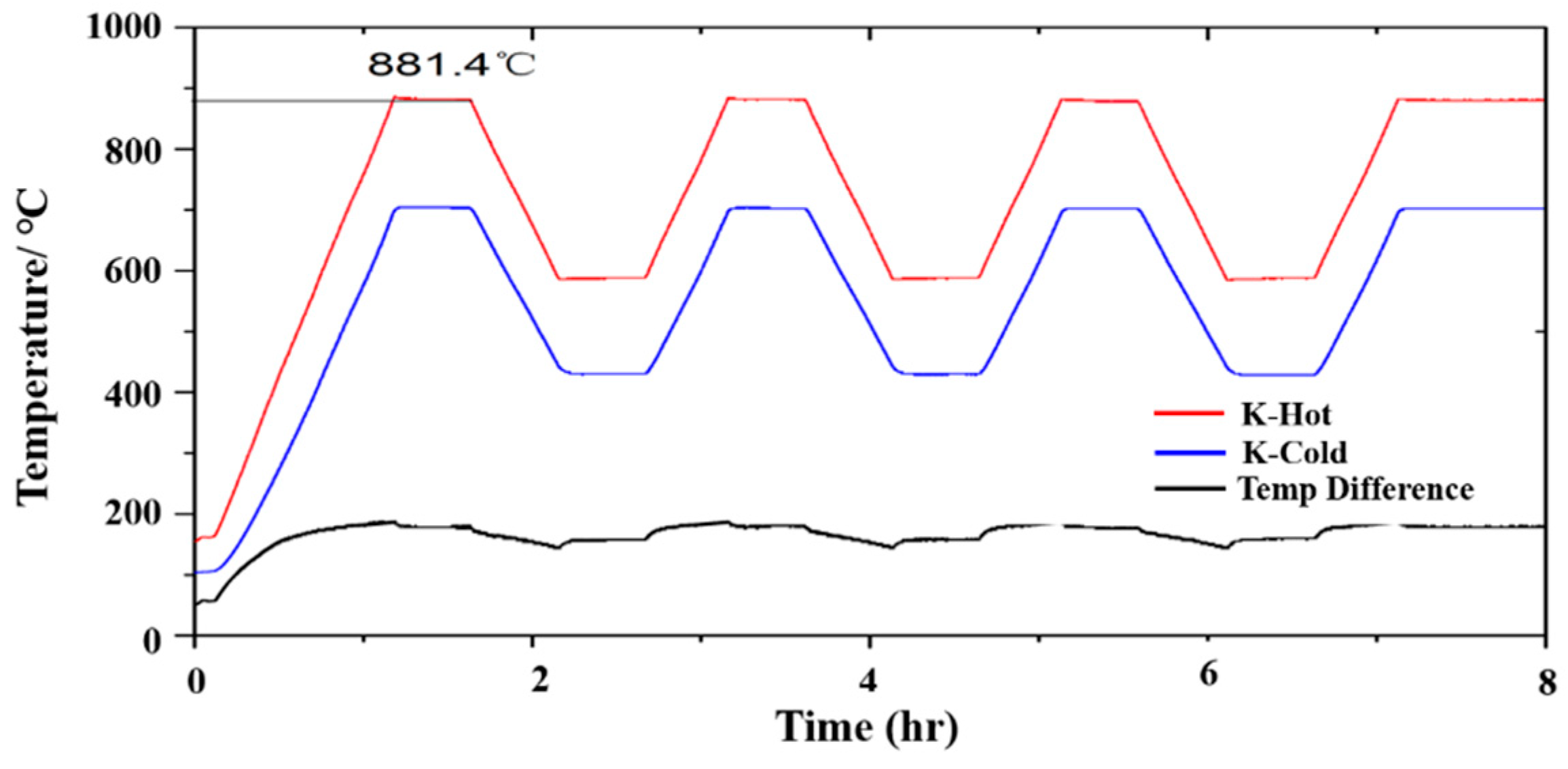

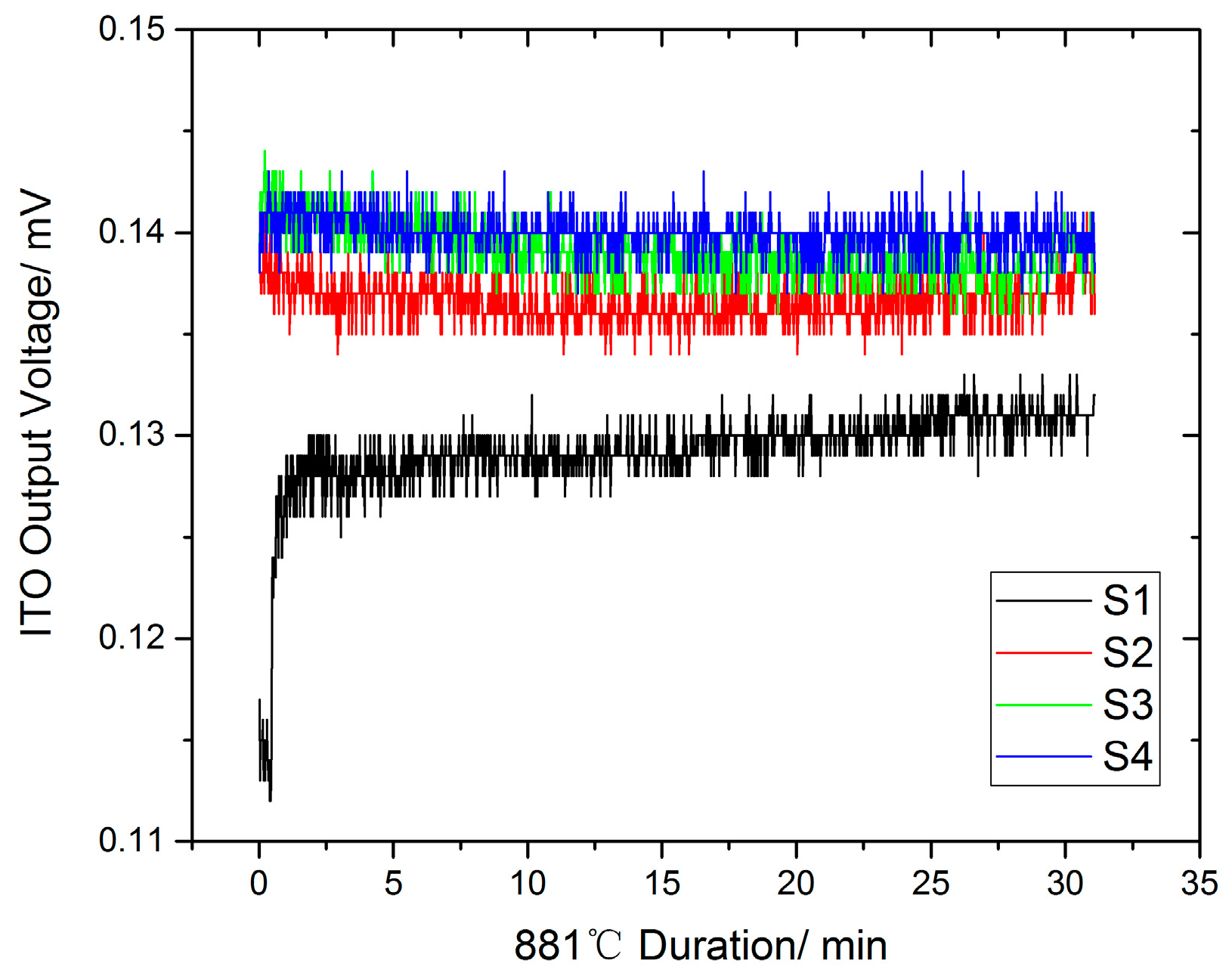

4. High Temperature Static Experiment

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, Y.; Li, Z.; Xiong, B.; Xiong, Q. Current Status and Development of Aeroengine Turbine Blade Temperature Measurement Technology. In Proceedings of the Symposium on Aero Engine Design, Manufacturing and Application Technology of China Association of Science and Technology, Guiyang, China, 25 May 2013. [Google Scholar]

- Cai, J.; Yang, Y.; Zhao, J. The measure method of surface temperature in aero-engine. Meas. Technol. 2008, 28, 46–48. [Google Scholar]

- Marr, M.A.; Wallace, J.S.; Chandra, S. A fast response thermocouple for internal combustion engine surface temperature measurements. Exp. Thermal Fluid Sci. 2010, 34, 183–189. [Google Scholar] [CrossRef]

- Martin, L.C. Testing of Thin Film Thermocouples in Rocket Engine Environments. In Advanced Earth-to-Orbit Propulsion Technology; NASA CP–3282; NASA: Washington, DC, USA, 1994. [Google Scholar]

- Liu, H.; Jia, Y.; Zeng, Q. Design of Rocket Engine Combustion Temperature Test Sensor. J. Test Meas. Technol. 2017, 31, 346–351. [Google Scholar]

- Zhang, S. Development and Application of High Temperature Film Pressure Sensor. In Proceedings of the Sensitive Components and Sensors Conference, Beijing, China, 16 November 2003. [Google Scholar]

- Bhatt, H.D.; Vedula, R.; Desu, S.B.; Fralick, G.C. Thin film TiC/TaC thermocouples. Thin Solid Films 1999, 342, 214–220. [Google Scholar] [CrossRef]

- Chen, X.; Gregory, O.J.; Amani, M. Thin-Film Thermocouples Based on the System In2O3-SnO2. J. Am. Cream. Soc. 2011, 94, 854–860. [Google Scholar] [CrossRef]

- Wrbanek, J.D.; Fralick, G.C.; Farmer, S.C. Development of Thin Film Ceramic Thermocouples for High Temperature Environments; NASA/TM; NASA: Washington, DC, USA, 2004.

- Gregory, O.J.; You, T. Ceramic temperature sensors for harsh environments. Sens. J. 2005, 5, 833–838. [Google Scholar] [CrossRef]

- Gregory, O.J.; Busch, E.; Fralick, G.C. Preparation and characterization of ceramic thin film thermocouples. Thin Solid Films 2010, 518, 6093–6098. [Google Scholar] [CrossRef]

- Grant, H.P.; Przybyszewski, J.S.; Claing, R.G. Turbine Blade Temperature Measurements Using Thin Film Temperature Sensors; NASA Technical Reports Server: East Hartford, CT, USA, 1981.

- Grant, H.P.; Przybyszewski, J.S.; Claing, R.G. Thin Film Temperature Sensors, Phase 2; NASA Sti/recon Technical Report N; NASA: Cleveland, OH, USA, 1982.

- Holanda, R.; Kim, W.S.; Pencil, E. Attachment of lead wires to thin film thermocouples mounted on high temperature materials using the parallel gap welding process. In Proceedings of the Meeting of the Electrochemical Society, Montreal, QC, Canada, 6 May 1990. [Google Scholar]

- Fendrock, J.J.; Hong, L.M. Parallel-gap welding to very-thin metallization for high temperature microelectronic interconnects. IEEE Trans. Compon. Hybrids Manuf. Technol. 1990, 13, 376–382. [Google Scholar] [CrossRef]

- Lei, J.F.; Kiser, J.D.; Singh, M. Durability Evaluation of a Thin Film Sensor System with Enhanced Lead Wire Attachments on SiC/SiC Ceramic Matrix Composites; NASA Glenn Research Center: Cleveland, OH, USA, 2000.

| Diameter of Through-Hole, D (mm) | Surface Roughness, Ra (μm) | Drying Temperature, T (°C) |

|---|---|---|

| 0.35 | 0.84 | 80 |

| 0.5 | 1.19 | 120 |

| 0.7 | 1.97 | 160 |

| 1.0 | 2.24 | 200 |

| Group | Diameter of Through-Hole, D (mm) | Surface Roughness, Ra (μm) | Drying Temperature, T (°C) | Tensile Strength, Fs (N) |

|---|---|---|---|---|

| 1 | 350 | 0.85 | 80 | 29.9 |

| 2 | 350 | 1.19 | 120 | 5.5 |

| 3 | 350 | 1.97 | 160 | 28.6 |

| 4 | 350 | 2.24 | 200 | 14.6 |

| 5 | 500 | 0.84 | 160 | 18.7 |

| 6 | 500 | 1.19 | 200 | 16.5 |

| 7 | 500 | 1.97 | 80 | 18.3 |

| 8 | 500 | 2.24 | 120 | 15.1 |

| 9 | 700 | 0.84 | 200 | 17.4 |

| 10 | 700 | 1.19 | 160 | 17 |

| 11 | 700 | 1.97 | 120 | 12.3 |

| 12 | 700 | 2.24 | 80 | 14.6 |

| 13 | 1000 | 0.84 | 120 | 14.2 |

| 14 | 1000 | 1.19 | 80 | 6.7 |

| 15 | 1000 | 1.97 | 200 | 4.9 |

| 16 | 1000 | 2.24 | 160 | 3.2 |

| Factor | Sum of Squares | F | Significance |

|---|---|---|---|

| D | 345.262 | 2.548 | * |

| Ra | 196.007 | 1.447 | * |

| T | 86.347 | 0.637 | - |

| Error | 135.485 |

| Group | Roughness, Ra (μm) | First Resistance Value (Ω) | Second Resistance Value (Ω) | Third Resistance Value (Ω) |

|---|---|---|---|---|

| R1 | 2.03 | 873.6 | 872.7 | 873.3 |

| R2 | 1.25 | 619.5 | 619.7 | 619.5 |

| R3 | 0.84 | 352.4 | 352.5 | 350.2 |

| R4 | 0.46 | 98.95 | 99.16 | 98.85 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, J.; Wang, W.; Hui, L.; Zhang, J.; Jin, X. A Through-Hole Lead Connection Method for Thin-Film Thermocouples on Turbine Blades. Sensors 2019, 19, 1155. https://doi.org/10.3390/s19051155

Deng J, Wang W, Hui L, Zhang J, Jin X. A Through-Hole Lead Connection Method for Thin-Film Thermocouples on Turbine Blades. Sensors. 2019; 19(5):1155. https://doi.org/10.3390/s19051155

Chicago/Turabian StyleDeng, Jinjun, Weihua Wang, Liuan Hui, Jietong Zhang, and Xinhang Jin. 2019. "A Through-Hole Lead Connection Method for Thin-Film Thermocouples on Turbine Blades" Sensors 19, no. 5: 1155. https://doi.org/10.3390/s19051155