Effect of Gamma-Ray Irradiation on the Growth of Au Nano-Particles Embedded in the Germano-Silicate Glass Cladding of the Silica Glass Fiber and its Surface Plasmon Resonance Response

Abstract

1. Introduction

2. Experiments

2.1. Optical Fiber for Surface Plasmon Resonance Sensor

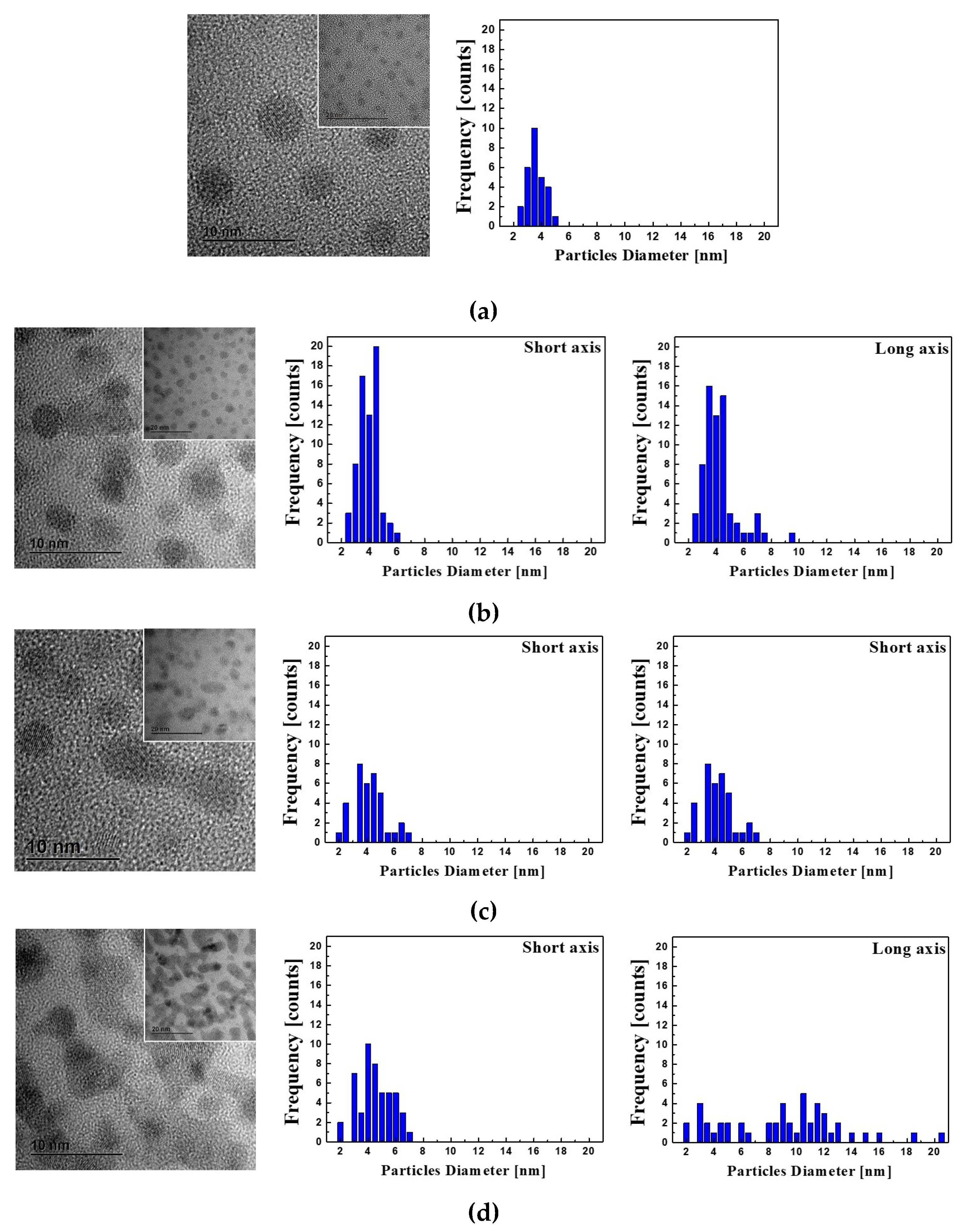

2.2. Verification of Existence and Morphology of Au Nano-Particles

2.3. Surface Palsmon Resonance Measurement

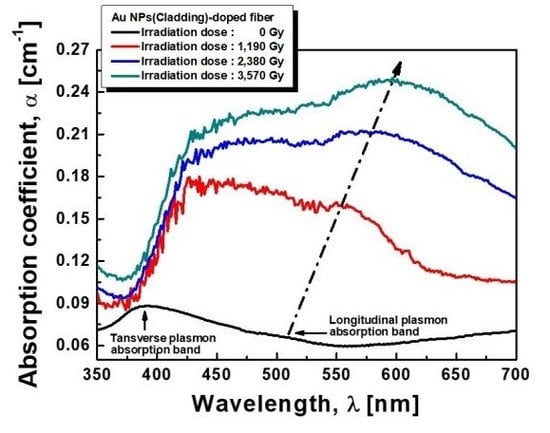

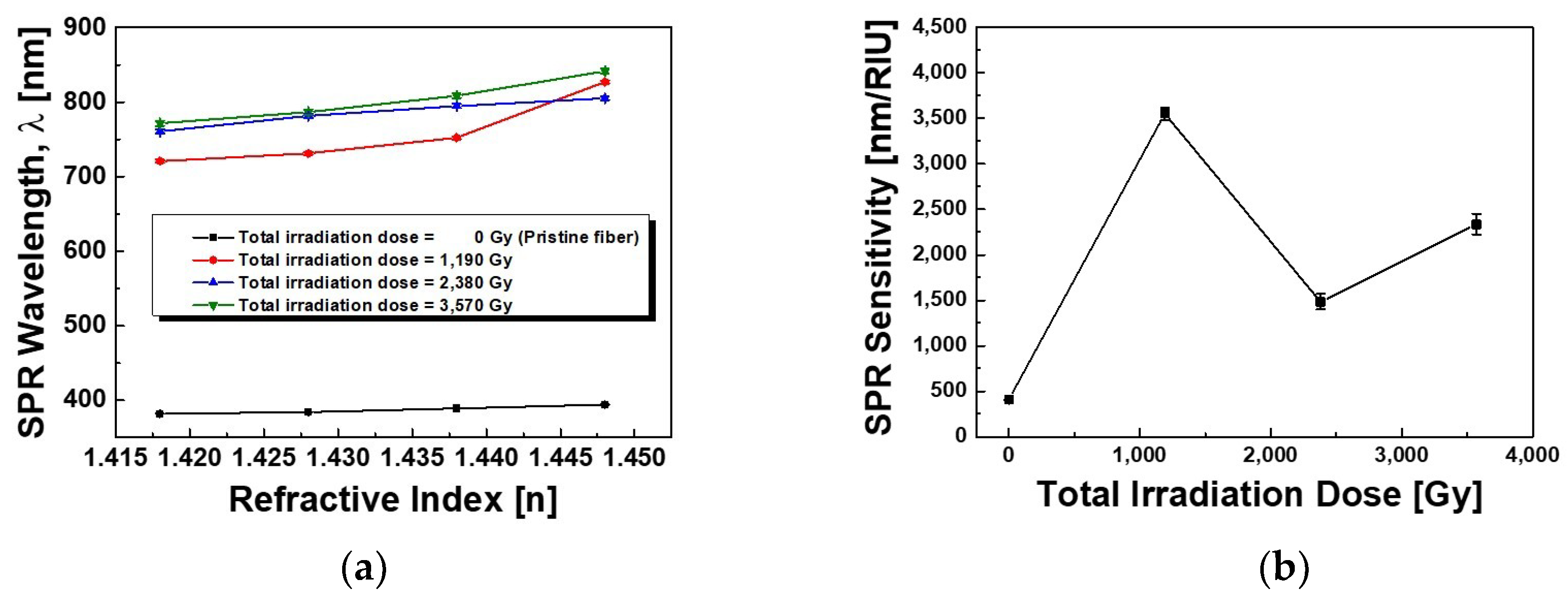

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Homola, J.; Yee, S.S.; Gauglitz, G. Surface plasmon resonance sensors: Review. Sens. Actuators B 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Yonzon, C.R.; Jeoung, E.; Zou, S.; Schatz, G.C.; Mrksich, M.; Duyne, R.P.V. A comparative analysis of localized and propagating surface plasmon resonance sensors: The binding of concanavalin A to a monosaccharide functionalized self-assembled monolayer. J. Am. Chem. Soc. 2004, 126, 12669–12676. [Google Scholar] [CrossRef] [PubMed]

- Nath, N.; Chilkoti, A. Label-free biosensing by surface plasmon resonance of nanoparticles on glass: Optimization of nanoparticle size. Anal. Chem. 2004, 76, 5370–5378. [Google Scholar] [CrossRef]

- Yu, F.; Ahl, S.; Caminade, A.-M.; Majoral, J.-P.; Knoll, W.; Erlebacher, J. Simultaneous excitation of propagating and localized surface plasmon resonance in nanoporous gold membranes. Anal. Chem. 2006, 78, 7346–7350. [Google Scholar] [CrossRef] [PubMed]

- Garcia, M.A. Corrigendum: Surface plasmons in metallic nanoparticles: Fundamentals and applications. J. Phys. D Appl. Phys. 2012, 45, 389501. [Google Scholar] [CrossRef]

- Peng, T.-C.; Lin, W.-C.; Chen, C.-W.; Tsai, D.P.; Chiang, H.-P. Enhanced sensitivity of surface plasmon resonance phase-interrogation biosensor by using silver nanoparticles. Plasmonics 2011, 6, 29–34. [Google Scholar] [CrossRef]

- Lee, K.-S.; El-Sayed, M.A. Gold and silver nanoparticles in sensing and imaging: Sensitivity of plasmon response to size, shape, and metal composition. J. Phys. Chem. B 2006, 110, 19220–19225. [Google Scholar] [CrossRef]

- Sönnichsen, C.; Reinhard, B.M.; Liphardt, J.; Alivisatos, A.P. A molecular ruler based on plasmon coupling of single gold and silver nanoparticles. Nat. Biotechnol. 2005, 23, 741–745. [Google Scholar]

- Luther, J.M.; Jain, P.K.; Ewers, T.; Alivisatos, A.P. Localized surface plasmon resonances arising from free carriers in doped quantum dots. Nat. Mater. 2011, 10, 361–366. [Google Scholar] [CrossRef]

- Mohamed, M.B.; Volkov, V.; Link, S.; El-Sayed, M.A. The ‘lighting’ gold nanorods: Fluorescence enhancement of over a million compared to the gold metal. Chem. Phys. Lett. 2000, 317, 517–523. [Google Scholar] [CrossRef]

- Jiang, Z.; Wen, G.; Luo, Y.; Zhang, X.; Liu, Q.; Liang, A. A new silver nanorod SPR probe for detection of trace benzoyl peroxide. Sci. Rep. 2014, 4, 5323. [Google Scholar] [CrossRef]

- Link, S.; El-Sayed, M.A. Optical properties and ultrafast dynamics of metallic nanocrystals. Annu. Rev. Phys. Chem. 2003, 54, 331–366. [Google Scholar] [CrossRef]

- Dawi, E.A.; Rizza, G.; Mink, M.P.; Vredenderg, A.M.; Habraken, F.H.P.M. Ion beam shaping of Au nanoparticles in silica: Particle size and concentration dependence. J. Appl. Phys. 2009, 105, 074305. [Google Scholar] [CrossRef]

- Kabashin, A.V.; Evans, P.; Pastkovsky, S.; Hendren, W.; Wurtz, G.A.; Atkinson, R.; Pollard, R.; Podolskiy, V.A.; Zayats, A.V. Plasmonic nanorod metamaterials for biosensing. Nat. Mater. 2009, 8, 867–871. [Google Scholar] [CrossRef]

- Singh, S.; Gupta, B.D. Simulation of a surface plasmon resonance-based fiber-optic sensor for gas sensing in visible range using films of nanocomposites. Meas. Sci. Technol. 2010, 21, 115202. [Google Scholar] [CrossRef]

- Jorgenson, R.C.; Yee, S.S. A fiber-optic chemical sensor based on surface plasmon resonance. Sens. Actuators B Chem. 1993, 12, 213–220. [Google Scholar] [CrossRef]

- Matsubara, K.; Kawata, S.; Minami, S. Optical chemical sensor based on surface plasmon measurement. Appl. Opt. 1998, 27, 1160–1163. [Google Scholar] [CrossRef]

- Liedberg, B.; Nylander, C.; Lunström, I. Surface plasmon resonance for gas detection and biosensing. Sens. Actuators 1983, 4, 299–304. [Google Scholar] [CrossRef]

- Sharma, S.K.; Gupta, B.D. Simulation of a localized surface-plasmon-resonance-based fiber optic temperature sensor. Opt. Soc. Am. A 2010, 27, 1743–1749. [Google Scholar]

- Homola, J. Present and future of surface plasmon resonance biosensors. Anal. Bioanal. Chem. 2003, 377, 528–539. [Google Scholar] [CrossRef]

- Haes, A.J.; Hall, W.P.; Chang, L.; Klein, W.L.; Van Duyne, R.P. A localized surface plasmon resonance biosensor: First steps toward an assay for Alzheimer’s disease. NANO Lett. 2004, 4, 1029–1034. [Google Scholar] [CrossRef]

- Lin, Y.; Zou, Y.; Lindquist, R.G. A reflection-based localized surface plasmon resonance fiber-optic probe for biochemical sensing. Biomed. Opt. Express 2011, 2, 478–484. [Google Scholar] [CrossRef]

- Anker, J.N.; Hall, W.P.; Lyandres, O.; Shan, N.C.; Zhao, J.; Duyne, R.P.V. Biosensing with plasmonic nanosensors. Nat. Mater. 2008, 7, 442–453. [Google Scholar] [CrossRef]

- Chung, P.-Y.; Lin, T.-H.; Schultz, G.; Batich, C.; Jiang, P. Nanopyramid surface plasmon resonance sensors. Appl. Phys. Lett. 2010, 96, 261108. [Google Scholar] [CrossRef]

- Zhang, Y.; Yuwono, A.H.; Li, J.; Wang, J. Highly dispersed gold nanoparticles assembled in mesoporous titania films of cubic configuration. Microporous Mesoporous Mater. 2008, 110, 242–249. [Google Scholar] [CrossRef]

- Jensen, T.R.; Schatz, G.C.; Van Duyne, R.P. Nanosphere lithography: Surface plasmon resonance spectrum of a periodic array of silver nanoparticles by ultraviolet-visible extinction spectroscopy and electrodynamic modeling. J. Phys. Chem. B 1999, 103, 2394–2401. [Google Scholar] [CrossRef]

- Chang, S.H.; Gray, S.K.; Schatz, G.C. Surface plasmon generation and light transmission by isolated nanoholes and arrays of nanoholes in thin metal films. Opt. Express 2005, 13, 3150–3165. [Google Scholar] [CrossRef]

- Aizpurua, J.; Hanarp, P.; Sutherland, D.S.; Kall, M.; Bryant, G.W.; de Abajo, F.J.G. Optical properties of gold nanorings. Phys. Rev. Lett. 2003, 90, 057401. [Google Scholar] [CrossRef]

- Fu, J.; Park, B.; Zhao, Y. Nanorod-mediated surface plasmon resonance sensor based on effective medium theory. App. Opt. 2009, 48, 4637–4649. [Google Scholar] [CrossRef]

- Kim, J.; Liu, G.L.; Lu, Y.; Lee, L.P. Spectral tuning of localised surface plasmon-polariton resonance in metallic nano-crescents. IEE Proc.-Nanobiotechnol. 2006, 153, 42–46. [Google Scholar] [CrossRef][Green Version]

- Liu, Z.W.; Wei, Q.H.; Zhang, X. Surface plasmon interference nanolithography. Nano. Lett. 2005, 5, 957–961. [Google Scholar] [CrossRef]

- Halas, N. Playing with plasmons: Tuning the optical resonant properties of metallic nanoshells. MRS Bull. 2005, 30, 362–367. [Google Scholar] [CrossRef]

- Khlebtsov, N.G. Optics and biophotonics of nanoparticles with a plasmon resonance. Quantum Electron. 2008, 38, 504–529. [Google Scholar] [CrossRef]

- Takahata, R.; Yamazoe, S.; Koyasu, K.; Tsukuda, T. Surface plasmon resonance in gold ultrathin nanorods and nanowires. J. Am. Chem. Soc. 2014, 136, 8489–8491. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, Y.; Guo, S.; Goebl, J.; Yin, Y. Seeded growth of uniform Ag nanoplates with high aspect ratio and widely tunable surface plasmon bands. Nano Lett. 2010, 10, 5037–5042. [Google Scholar] [CrossRef]

- Zhu, J.; Deng, X.-C. Improve the refractive index sensitivity of gold nanotube by reducing the restoring force of localized surface plasmon resonance. Sens. Actuators B Chem. 2011, 155, 843–847. [Google Scholar] [CrossRef]

- Mahmoud, M.A.; El-Sayed, M.A. Time dependence and signs of the shift of the surface plasmon resonance frequency in nanocages elucidate the nanocatalysis mechanism in hollow nanoparticles. Nano Lett. 2011, 11, 946–953. [Google Scholar] [CrossRef]

- Ringe, E.; McMahon, J.M.; Sohn, K.; Cobley, C.; Xia, Y.; Huang, J.; Schatz, G.C.; Marks, L.D.; Van Duyne, R.P. Unraveling the effects of size, composition, and substrate on the localized surface plasmon resonance frequencies of gold and silver nanocubes: A systematic single-particle approach. J. Phys. Chem. C 2010, 114, 12511–12516. [Google Scholar] [CrossRef]

- Zeng, S.; Yu, X.; Law, W.-C.; Zhang, Y.; Hu, R.; Dinh, X.-Q.; Ho, H.-P.; Yong, K.-T. Size dependence of Au NP-enhanced surface plasmon resonance based on differential phase measurement. Sensor. Actuat. B Chem. 2013, 176, 1128–1133. [Google Scholar] [CrossRef]

- Kwon, M.J.; Lee, J.; Wark, A.W.; Lee, H.J. Nanoparticle-enhanced surface plasmon resonance detection of proteins at Attomolarc: Comparing different nanoparticle shapes and sizes. Anal. Chem. 2012, 84, 1702–1707. [Google Scholar] [CrossRef]

- Chen, C.-D.; Cheng, S.-F.; Chau, L.-K.; Wang, C.R.C. Sensing capability of the localized surface plasmon resonance of gold nanorods. Biosens. Bioelectron. 2007, 22, 926–932. [Google Scholar] [CrossRef]

- Muskens, O.L.; Bachelier, G.; Fatti, N.D.; Vallée, F.; Brioude, A.; Jiang, X.; Pileni, M.-P. Quantitative absorption spectroscopy of a single gold nanorod. J. Phys. Chem. C 2008, 112, 8917–8921. [Google Scholar] [CrossRef]

- Mallick, K.; Wang, Z.L.; Pal, T. Seed-mediated successive growth of gold particles accomplished by UV irradiation: A photochemical approach for size-controlled synthesis. J. Photochem. Photobiol. A Chem. 2001, 140, 75–80. [Google Scholar] [CrossRef]

- Stamplecoskie, K.G.; Scaiano, J.C. Light emitting diode irradiation can control the morphology and optical properties of silver nanoparticles. J. Am. Chem. Soc. 2010, 132, 1825–1827. [Google Scholar] [CrossRef]

- Stellacci, F.; Bauer, C.A.; Meyer-Friedrichsen, T.; Wenseleers, W.; Alain, V.; Kuebler, S.M.; Pond, S.J.K.; Zhang, Y.; Marder, S.R.; Perry, J.W. Laser and electron-beam induced growth of nanoparticles for 2D and 3D metal patterning. Adv. Mater. 2002, 14, 194–198. [Google Scholar] [CrossRef]

- Abid, J.P.; Wark, A.W.; Brevet, P.F.; Girault, H.H. Preparation of silver nanoparticles in solution from a silver salt by laser irradiation. Chem. Commun. 2002, 7, 792–793. [Google Scholar] [CrossRef]

- Mishra, Y.K.; Avasthi, D.K.; Kulriya, P.K.; Singh, F.; Kabiraj, D.; Tripathi, A.; Pivin, J.C.; Bayer, I.S.; Biswas, A. Controlled growth of gold nanoparticles induced by ion irradiation: An in situ x-ray diffraction study. Appl. Phys. Lett. 2007, 91, 073110. [Google Scholar] [CrossRef]

- Valentin, E.; Bernas, H.; Ricolleau, C.; Creuzet, F. Ion Beam “Photography”: Decoupling nucleation and growth of metal clusters in glass. Phys. Rev. Lett. 2001, 86, 99–102. [Google Scholar] [CrossRef]

- Chen, P.; Song, L.; Liu, Y.; Fang, Y. Synthesis of silver nanoparticles by γ-ray irradiation in acetic water solution containing chitosan. Radiat. Phys. Chem. 2007, 76, 1165–1168. [Google Scholar] [CrossRef]

- Yokan, R.; Chirachanchai, S. Silver nanoparticles dispersing in chitosan solution: Preparation by γ-ray irradiation and their antimicrobial activities. Mater. Chem. Phys. 2009, 115, 296–302. [Google Scholar] [CrossRef]

- Ju, S.; Watekar, P.R.; Kim, C.; Han, W.-T. Particle size control of PbTe quantum dots incorporated in the germano-silicate glass optical fiber by heat treatment. J. Non-Cryst. Solids 2010, 356, 2273–2276. [Google Scholar] [CrossRef]

- Ju, S.; Jeong, S.; Kim, Y.; Lee, S.-H.; Linganna, K.; Kim, C.J.; Han, W.-T. Effect of heat treatment of optical fiber incorporated with Au nano-particles on surface plasmon resonance. Opt. Mater. Express 2015, 5, 1440–1449. [Google Scholar] [CrossRef]

- Mishra, Y.K.; Singh, F.; Pivin, J.C.; Malinovska, D.; Pippel, E.; Avasthi, D.K. Synthesis of elongated Au nanoparticles in silica matrix by ion irradiation. Appl. Phys. Lett. 2007, 91, 063103. [Google Scholar] [CrossRef]

- D’Orléans, C.; Stoquert, J.P.; Estournès, C.; Cerruti, C.; Grob, J.J.; Guille, J.L.; Haas, F.; Muller, D.; Richard-Plouet, M. Anisotropy of Co nanoparticles induced by swift heavy ions. Phys. Rev. B 2003, 67, 220101. [Google Scholar] [CrossRef]

- Daniel, M.-C.; Astruc, D. Gold nanoparticles: Assembly, supramolecular chemistry, quantum-size-related properties, and applications toward biology, catalysis, and nanotechnology. Chem. Rev. 2004, 104, 93–346. [Google Scholar] [CrossRef]

- Bringa, E.M.; Johnson, R.E. Coulomb explosion and thermal spikes. Phys. Rev. Lett. 2002, 88, 165501. [Google Scholar] [CrossRef]

- Joseph, B.; Ghatak, J.; Lenka, H.P.; Kuiri, P.K.; Sahu, G.; Mishra, N.C.; Mahapatra, D.P. Effect of 100 MeV Au irradiation on embedded Au nanoclusters in silica glass. Nucl. Instr. Meth. Phys. Res. B 2007, 256, 659–664. [Google Scholar] [CrossRef]

- Slavík, R.; Homola, J.; Čtyroký, J.; Brynda, E. Novel spectral fiber optic sensor based on surface plasmon resonance. Sens. Actuators B Chem. 2001, 74, 106–111. [Google Scholar] [CrossRef]

- Sharma, A.K.; Jha, R.; Gupta, B.D. Fiber-optic sensors based on surface plasmon resonance: A comprehensive review. IEEE Sens. J. 2007, 7, 1118–1129. [Google Scholar] [CrossRef]

- Gupta, B.D.; Verma, R.K. Surface plasmon resonance-based fiber optic sensors: Principle, probe designs, and some applications. J. Sens. 2009, 2009, 1–12. [Google Scholar] [CrossRef]

- Mitsushio, M.; Higashi, S.; Higo, M. Construction and evaluation of a gold-deposited optical fiber sensor system for measurements of refractive indices of alcohols. Sens. Actuators A Phys. 2004, 111, 252–259. [Google Scholar] [CrossRef]

- Ju, S.; Jeong, S.; Kim, Y.; Jeon, P.; Park, M.-S.; Jeong, H.; Boo, S.; Jang, J.-H.; Han, W.-T. Experimental demonstration of surface plasmon resonance enhancement of the tapered optical fiber coated with Au/Ti thin film. J. Non-Cryst. Solids 2013, 383, 146–152. [Google Scholar] [CrossRef]

- Singh, S.; Verma, R.K.; Gupta, B.D. Surface plasmon resonance based fiber optic sensor with symmetric and asymmetric metallic coatings: A comparative study. Sens. Transducers J. 2009, 100, 116–124. [Google Scholar]

- Jeong, H.-H.; Erdene, N.; Park, J.-H.; Jeong, D.-H.; Lee, S.-K. Analysis of fiber-optic localized surface plasmon resonance sensor by controlling formation of gold nanoparticles and its bio-application. J. Nanosci. Nanotechnol. 2012, 12, 7815–7821. [Google Scholar] [CrossRef]

- Lee, B.; Roh, S.; Park, J. Current status of micro- and nano-structured optical fiber sensors. Opt. Fiber Technol. 2009, 15, 209–221. [Google Scholar] [CrossRef]

- Shevchenko, Y.Y.; Albert, J. Plasmon resonances in gold-coated tilted fiber Bragg grating. Opt. Lett. 2007, 32, 211–213. [Google Scholar] [CrossRef]

- Sanders, M.; Lin, Y.; Wei, J.; Bono, T.; Lindquist, R.G. An enhanced LSPR fiber-optic nanoprobe for ultrasensitive detection of protein biomarkers. Biosens. Bioelectron. 2014, 61, 95–101. [Google Scholar] [CrossRef]

- Caucheteur, C.; Guo, T.; Albert, J. Review of plasmonic fiber optic biochemical sensors: Improving the limit of detection. Anal. Bioanal. Chem. 2015, 407, 3883–3897. [Google Scholar] [CrossRef]

- Cao, J.; Tu, M.H.; Sun, T.; Grattan, K.T.V. Wavelength-based localized surface plasmon resonance optical fiber biosensor. Sensor. Actuat. B Chem. 2013, 181, 611–619. [Google Scholar] [CrossRef]

- Ju, S.; Jeong, S.; Kim, Y.; Lee, S.-H.; Han, W.-T. Surface plasmon resonance characteristics of optical fiber incorporated with Au nano-particles in cladding region. J. Nanosci. Nanotechnol. 2016, 16, 6308–6312. [Google Scholar] [CrossRef]

- Ju, S.; Jeong, S.; Kim, Y.; Jeon, P.; Boo, S.; Han, W.-T. Development of specialty optical fiber incorporated with Au nano-particles in cladding for surface plasmon resonance sensors. Sens. Transducers J. 2013, 18, 76–83. [Google Scholar]

- Roman, J.E.; Wincik, K.A. Photowritten gratings in ion-exchanged glass waveguides. Opt. Lett. 1993, 18, 808–810. [Google Scholar] [CrossRef]

- Girard, S.; Kuhnhenn, J.; Gusarov, A.; Brichard, B.; Van Uffelen, M.; Ouerdane, Y.; Boukenter, A.; Marcandella, C. Radiation effects on silica-based optical fibers: Recent advances and future challenges. IEEE Trans. Nucl. Sci. 2013, 60, 2015–2036. [Google Scholar] [CrossRef]

- Chu, P.L.; Whitbread, T. Measurement of stresses in optical fiber and preform. Appl. Opt. 1982, 21, 4241–4245. [Google Scholar] [CrossRef]

- Kim, B.H.; Park, Y.; Ahn, T.-J.; Kim, D.Y.; Lee, B.H.; Chung, Y.; Paek, U.-C.; Han, W.-T. Residual stress relaxation in the core of optical fiber by CO2 laser irradiation. Opt. Lett. 2001, 26, 1657–1659. [Google Scholar] [CrossRef]

- Kim, B.H.; Ahn, T.-J.; Kim, D.Y.; Lee, B.H.; Chung, Y.; Paek, U.-C.; Han, W.-T. Effect of CO2 laser irradiation on the refractive-index change in optical fibers. Appl. Opt. 2002, 41, 3809–3815. [Google Scholar] [CrossRef]

- Chen, H.; Kou, X.; Yang, Z.; Ni, W.; Wang, J. Shape- and size-dependent refractive index sensitivity of gold nanoparticles. Langmuir 2008, 24, 5233–5237. [Google Scholar] [CrossRef]

- Dou, X.; Phillips, B.M.; Chung, P.-Y.; Jiang, P. High surface plasmon resonance sensitivity enabled by optical disks. Opt. Lett. 2012, 37, 3681–3683. [Google Scholar] [CrossRef]

- Lee, M.; Chae, L.; Lee, K.C. Microstructure and surface plasmon absorption of sol-gel-prepared Au nanoclusters in TiO2 thin films. NanoStruct. Mater. 1999, 11, 195–201. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Pal, T. Interparticle coupling effect on the surface plasmon resonance of Gold nanoparticles: From theory to applications. Chem. Rev. 2007, 107, 4794–4862. [Google Scholar] [CrossRef]

- El-Brolossy, T.A.; Abdallah, T.; Mohamed, M.B.; Abdallah, S.; Easawi, K.; Negm, S.; Talaat, H. Shape and size dependence of the surface plasmon resonance of gold nanoparticles studied by photoacoustic technique. Eur. Phys. J. Spec. Top. 2008, 153, 361–364. [Google Scholar] [CrossRef]

- Kim, Y.; Ju, S.; Jeong, S.; Lee, S.H.; Han, W.-T. Gamma-ray radiation response at 1550 nm of fluorine-doped radiation hard single-mode optical fiber. Opt. Express 2016, 24, 3910–3920. [Google Scholar] [CrossRef]

- Regnier, E.; Flammer, I.; Girard, S.; Gooijer, F.; Achten, F.; Kuyt, G. Low-dose radiation-induced attenuation at infrared wavelengths for P-doped, Ge-doped and pure silica-core optical fibres. IEEE Trans. Nucl. Sci. 2007, 54, 1115–1119. [Google Scholar] [CrossRef]

- Origlio, G.; Boukenter, A.; Girard, S.; Richard, N.; Cannas, M.; Boscaino, R.; Ouerdane, Y. Irradiation induced defects in fluorine doped silica. Nucl. Instrum. Methods Phys. Res. Sect. B 2008, 266, 2918–2922. [Google Scholar] [CrossRef]

- Kajihara, K.; Hirano, M.; Skuja, L.; Hosono, H. 60Co γ-ray-induced intrinsic defect processes in fluorine-doped synthetic SiO2 glasses of different fluorine concentrations. Mater. Sci. Eng. B 2009, 161, 96–99. [Google Scholar] [CrossRef]

- Giacomazzi, L.; Martin-Samos, L.; Boukenter, A.; Ouerdane, Y.; Girard, S.; Richard, N. Ge(2), Ge(1) and Ge-E′ centers in irradiated Ge-doped silica: A first-principles EPR study. Opt. Mater. Express 2015, 5, 1054–1064. [Google Scholar] [CrossRef]

- Kyoto, M.; Chigusa, Y.; OOE, M.; Watanabe, M.; Matubara, T.; Yamamoto, T.; Okamoto, S. Gamma-ray irradiation effect on loss increase of single mode optical fibers, (I). J. Nucl. Sci. Technol. 1989, 26, 507–515. [Google Scholar] [CrossRef]

- Yeri, A.S.; Gao, L.; Gao, D. Mutation screening based on the mechanical properties of DNA molecules tethered to a solid surface. J. Phys. Chem. B 2010, 114, 1064–1068. [Google Scholar] [CrossRef]

- Kazuma, E.; Tatsuma, T. Localized surface plasmon resonance sensors based on wavelength-tunable spectral dips. Nanoscale 2014, 6, 2397–2405. [Google Scholar] [CrossRef]

| γ-ray Irradiation | Total γ-ray Irradiation Dose [Gy] | Sensitivity [nm/RIU] | Average Intensity [dB] | Average FWHM [nm] |

|---|---|---|---|---|

| Before (SPR at 380 nm) | 0 | 407 | 2.087 | 60.554 |

| After (SPR at 750 nm) | 1190 | 3553 | 0.204 | 284.207 |

| 2380 | 1483 | 0.170 | 274.592 | |

| 3570 | 2335 | 0.084 | 272.026 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, S.; Han, W.-T. Effect of Gamma-Ray Irradiation on the Growth of Au Nano-Particles Embedded in the Germano-Silicate Glass Cladding of the Silica Glass Fiber and its Surface Plasmon Resonance Response. Sensors 2019, 19, 1666. https://doi.org/10.3390/s19071666

Ju S, Han W-T. Effect of Gamma-Ray Irradiation on the Growth of Au Nano-Particles Embedded in the Germano-Silicate Glass Cladding of the Silica Glass Fiber and its Surface Plasmon Resonance Response. Sensors. 2019; 19(7):1666. https://doi.org/10.3390/s19071666

Chicago/Turabian StyleJu, Seongmin, and Won-Taek Han. 2019. "Effect of Gamma-Ray Irradiation on the Growth of Au Nano-Particles Embedded in the Germano-Silicate Glass Cladding of the Silica Glass Fiber and its Surface Plasmon Resonance Response" Sensors 19, no. 7: 1666. https://doi.org/10.3390/s19071666

APA StyleJu, S., & Han, W.-T. (2019). Effect of Gamma-Ray Irradiation on the Growth of Au Nano-Particles Embedded in the Germano-Silicate Glass Cladding of the Silica Glass Fiber and its Surface Plasmon Resonance Response. Sensors, 19(7), 1666. https://doi.org/10.3390/s19071666