Introduction

Magnetoelastic sensors have attracted considerable interest within the sensor community as they form an excellent sensor platform that can be used to measure a wide range of environmental parameters including pressure [

1,

2,

3], humidity [

3,

4,

5], temperature [

5,

6], liquid viscosity and density [

7,

8,

9,

10], thin-film elasticity [

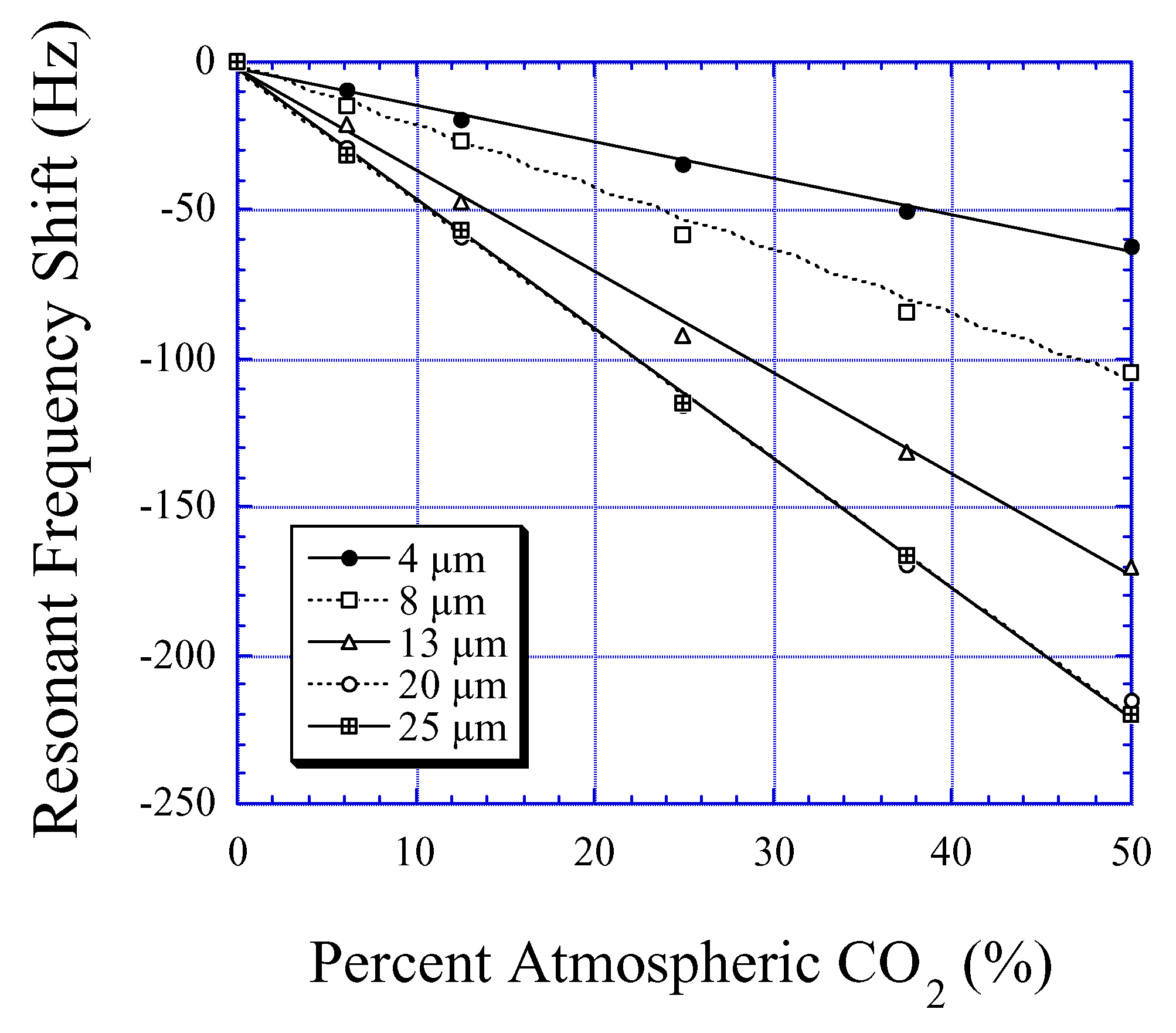

11], and chemicals such as carbon dioxide [

12,

13], ammonia [

14], and pH [

15]. Magnetoelastic sensors are typically made of amorphous ferromagnetic ribbons or wires, mostly iron-rich alloys such as Fe

40Ni

38Mo

4B

18 (Metglas brand 2826MB) and Fe

81B

13.5Si

3.5C

2 (Metglas 2605SC) ribbons [

15] that have a high mechanical tensile strength (~1000-1700 MPa), and a low material cost allowing them to be used on a disposable basis. In addition, these Metglas ribbons have a high magnetoelastic coupling coefficient, as high as 0.98, and magnetostriction on the order of 10-5 [

17,

18,

19]. The high magnetoelastic coupling allows efficient conversion between magnetic and elastic energies and vice versa. When excited by a time varying magnetic field, the large magnetostriction allows these materials to exhibit a pronounced magnetoelastic resonance the resonance frequency of which can be remotely detected either by magnetic, acoustic, or optical means. The environmental parameter of interest is measured by tracking the resonant frequency of the sensor.

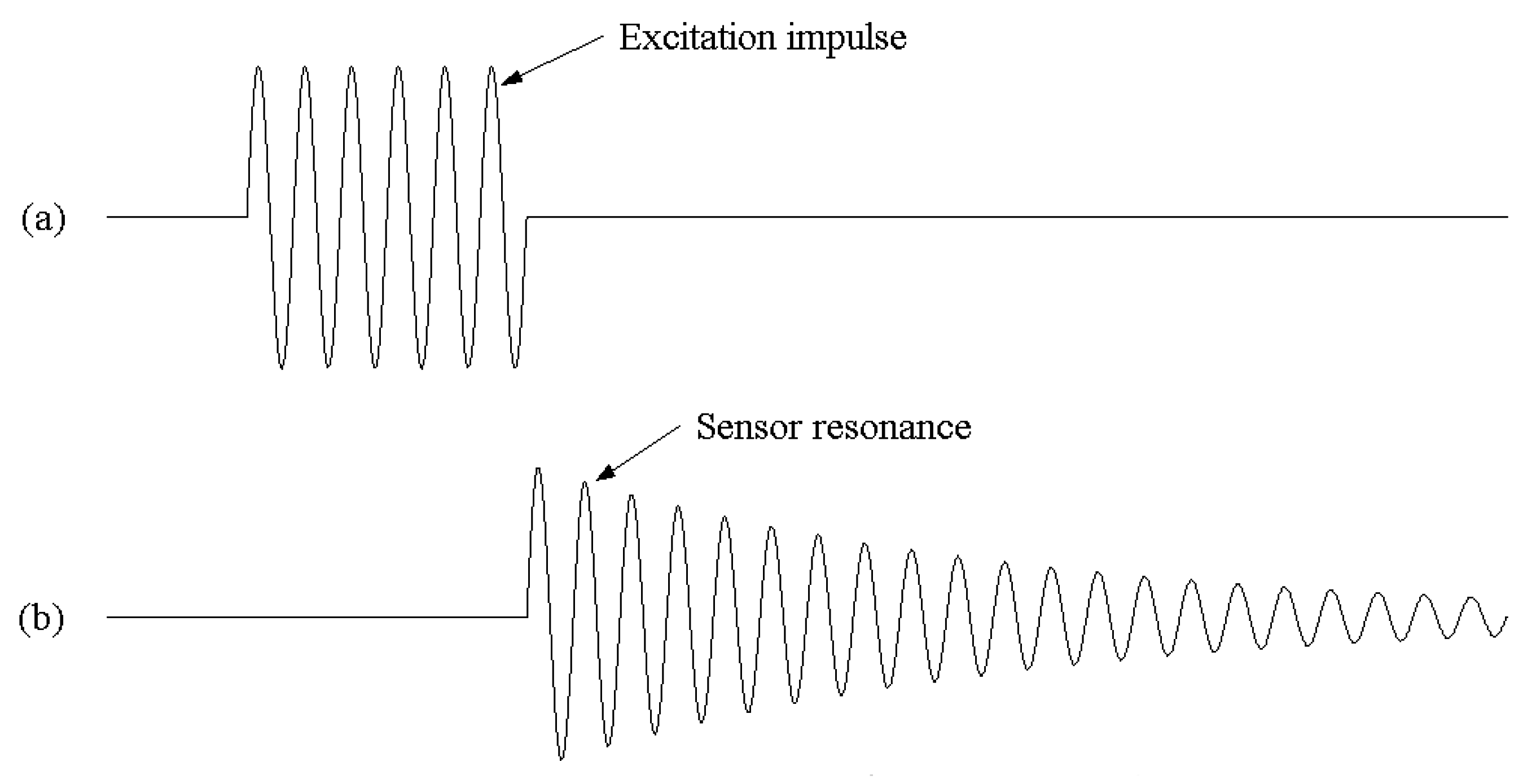

The magnetic state of the sensor, and hence its stress and temperature dependencies, are controllable by transverse-field annealing the sensor [

20,

21], or changing the bias field and/or sensor aspect ratio which in turn determines the magnetic demagnetizing field of the sensor. The mechanical vibration of the magnetoelastic sensor is generated through the magnetoelastic effect by sending a time-varying magnetic signal. Through the inverse magnetoelastic effect, the vibration of the sensor in turn generates a time varying magnetic flux, which can be measured with a set of pick-up coils. The time-domain signal is then converted into the frequency domain by performing a Fast Fourier Transform (FFT), and the resonant frequency is determined [

9]. The resonant frequency of the transiently excited sensor can also be determined by counting the zero crossings of the sensor response for a given time period. Alternatively, the magnetoelastic sensors can be interrogated in the frequency domain by sweeping the frequency and recording the measured amplitude each incremental frequency [

22].

In addition to generating magnetic flux, the mechanical vibrations of the sensor also generate an acoustic wave that can be detected with a microphone in air or hydrophone in liquid [

10]. Furthermore a laser beam can reflected from the surface of the sensor, and the response of the sensor characterized by recording the changes in the returned beam intensity.

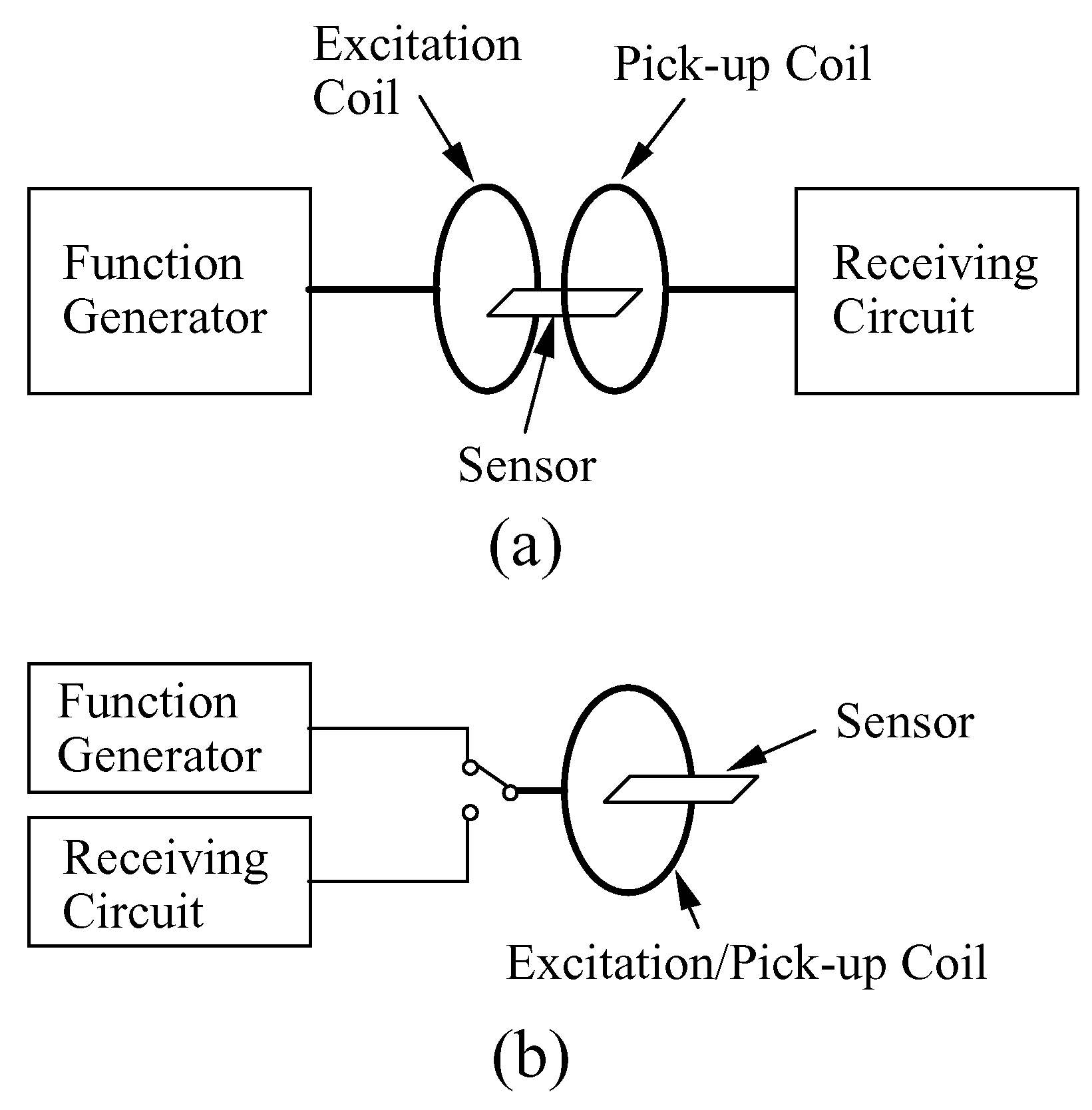

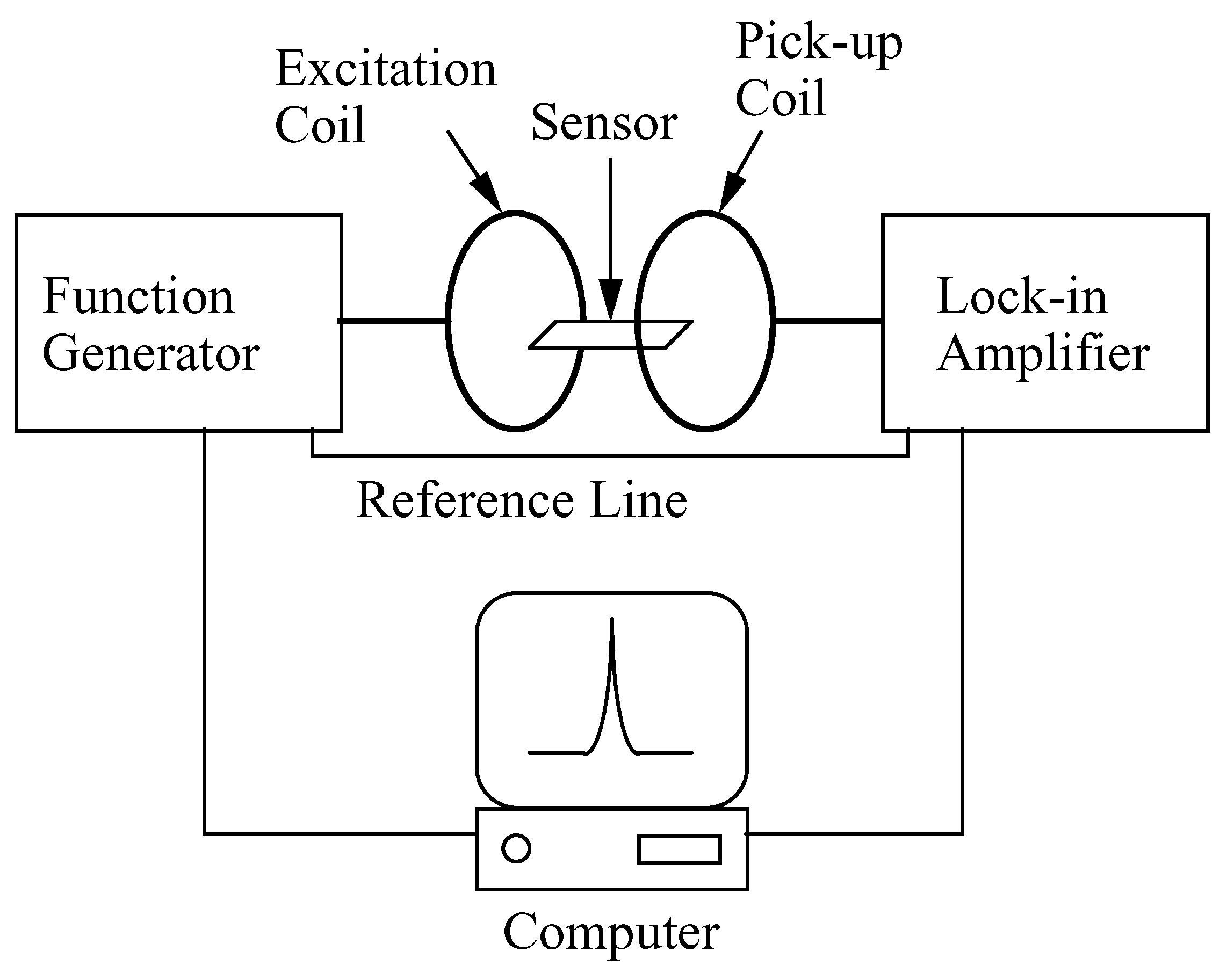

Fig. 1 illustrates the three different ways to monitor a magnetoelastic sensor: magnetically, acoustically, and optically. The magnetic detection method has the highest precision, but for a 1.0 cm long sensor has a detection range limit of approximately 30 cm. The same sensor can be detected acoustically up to approximately 2.0 m, while optical detection has been used over a 6 m range.

Figure 1.

The magnetoelastic sensor is interrogated with an excitation coil producing a magnetic field impulse, and can be detected magnetically with a pickup coil, acoustically with a microphone, or optically with a laser emitter and a phototransistor.

Figure 1.

The magnetoelastic sensor is interrogated with an excitation coil producing a magnetic field impulse, and can be detected magnetically with a pickup coil, acoustically with a microphone, or optically with a laser emitter and a phototransistor.

Another method of detecting the magnetoelastic sensors is to insert the sensor inside an inductor (solenoid) and measure the impedance variation in the inductor. Since the permeability of the sensor increases at the sensor resonance, the resonant frequency of the sensor can be determined by finding the frequency at which the maximum variation in the impedance of the inductor occurs. Although this method cannot detect the sensor from a distance, it requires only a single electronic instrument that measures the impedance spectrum of an inductor, i.e., an impedance analyzer.

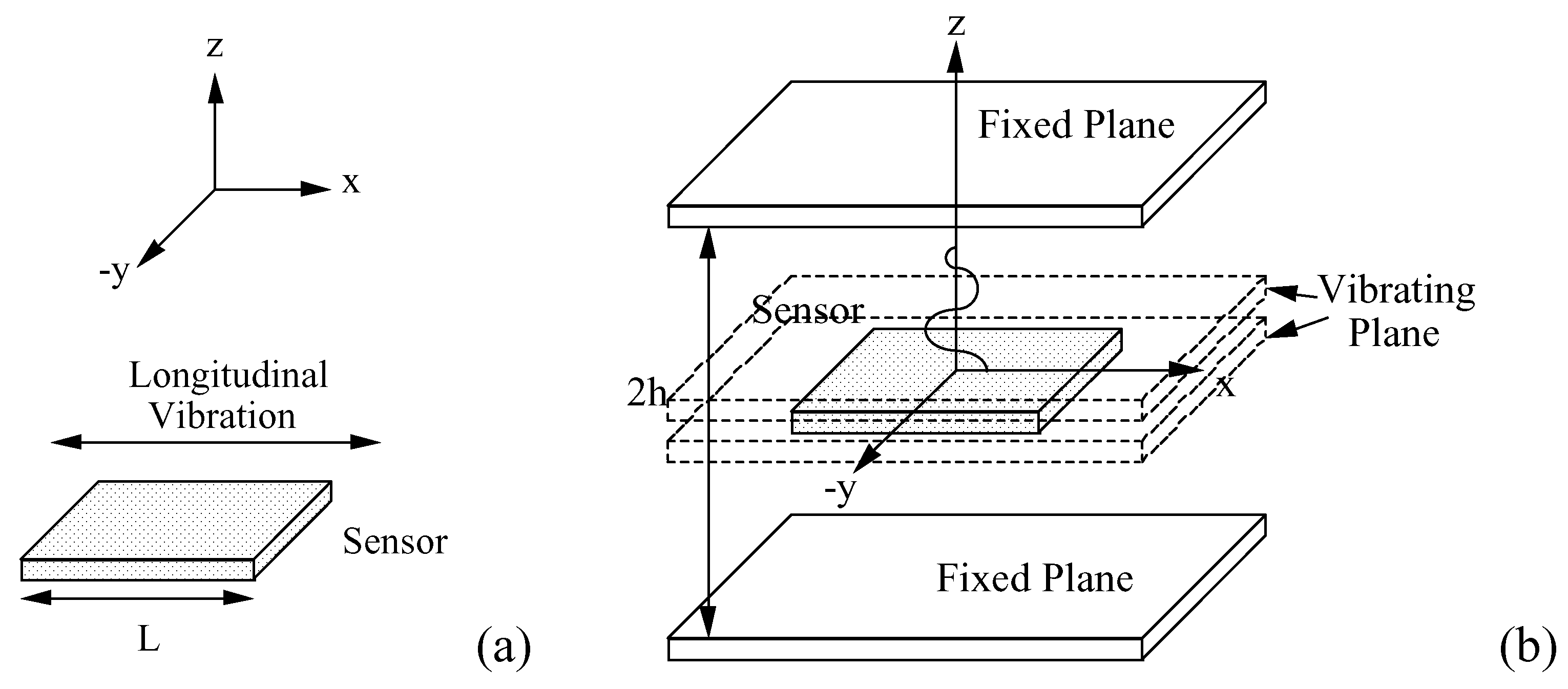

Figure 2.

(a) A sensor free of external forces is modeled as a thin plate exhibiting vibration in the x-direction. (b) When immersing in a liquid, the sensor is modeled as a vibrating plate bounded by two infinite planes from a distance h and two infinite planes touching the sensor surface.

Figure 2.

(a) A sensor free of external forces is modeled as a thin plate exhibiting vibration in the x-direction. (b) When immersing in a liquid, the sensor is modeled as a vibrating plate bounded by two infinite planes from a distance h and two infinite planes touching the sensor surface.

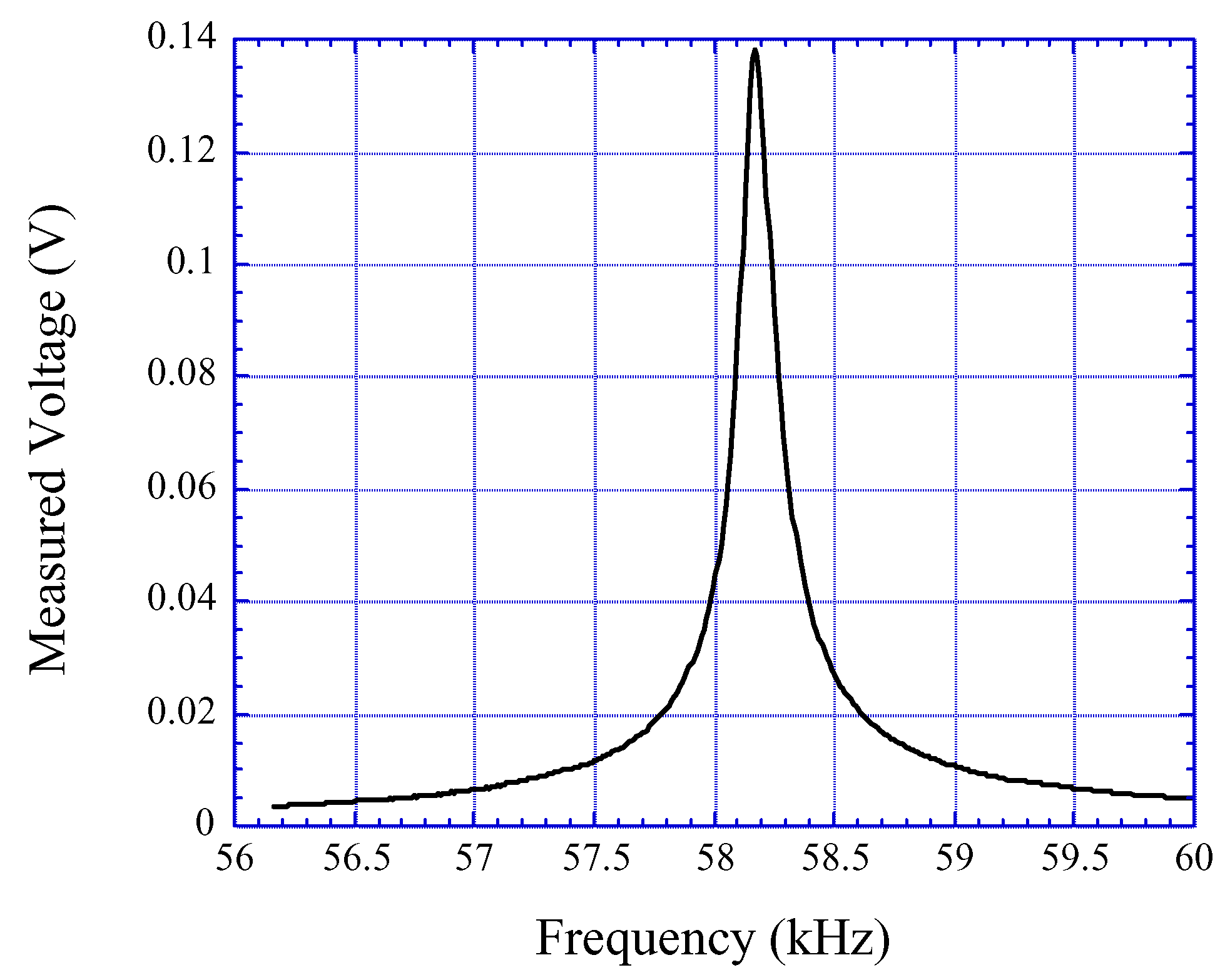

Figure 3.

The frequency response of a 4 cm × 1.3 cm × 28 µm as-cast Metglas 2826MB ribbon. The resonant frequency is the maximal of the frequency spectrum.

Figure 3.

The frequency response of a 4 cm × 1.3 cm × 28 µm as-cast Metglas 2826MB ribbon. The resonant frequency is the maximal of the frequency spectrum.

Theoretical Model

The vibrating magnetoelastic sensor is modeled as a rectangular plate with its length parallel to the

x-axis and excited by an

x-directed ac magnetic field (see

Fig. 2a), which can be described with the equation of motion as [

23]:

where

ρS is the density of the sensor,

σ is the Poison’s ratio, and

Es is Young’s modulus. The resonant frequency of the sensor is determined by solving Eq. (1) as:

where

L is the length of the ribbon. In most applications only the fundamental resonant frequency

f0 (

n = 1) is considered because of the higher signal amplitude and lower frequency. The fundamental resonance for a 4 cm × 1.3 cm × 28 µm Metglas 2826MB sensor ribbon, measured in air at room temperature, is shown in

Fig. 3, where the resonant frequency is at the peak of the curve at 58.18 kHz.

Effect of Mass Loading the Sensor

If a coating with mass

Δm is uniformly applied on the sensor surface, the density

ρs in Eq. (1) can be replaced by (

mS + Δ

m)

Ad where

ms is the mass of the sensor,

A is the surface area, and

d is the thickness of the sensor. Solving the equation of motion using the modified

ρs yields a new fundamental resonant frequency

fload [

23]:

For mass loads small relative to the mass of the sensor the resonant frequency shift of the sensor is approximately:

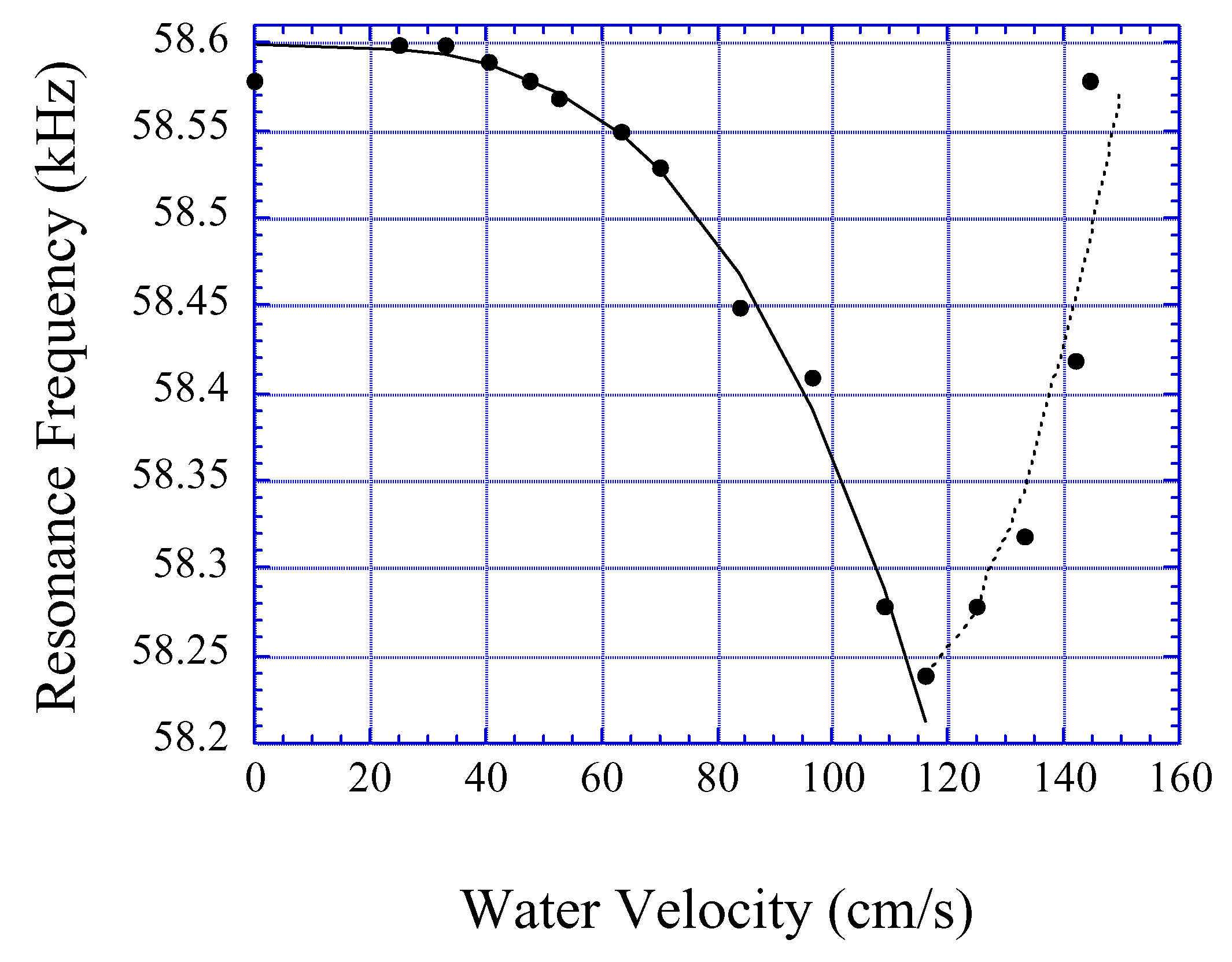

Effect of Liquid Viscosity and Density

When immersed in a viscous liquid, the resonant frequency of a vibrating sensor decreases due to the dissipative shear force created by the viscous liquid. The theoretical model for a sensor exhibiting an

x-directed vibration in a viscous liquid with viscosity

η and density

ρl is shown in

Fig. 2b, where the liquid is represented by an incompressible fluid bounded by two infinite planes on each side, one touching the sensor surface and one shifted

h in the

z-direction. The plane shifted

h from the sensor is fixed, while the plane touching the sensor surface is vibrating in the

x-direction and creating a damping force against the sensor vibration so the equation of motion in Eq. (1) becomes [

8]:

where

κ = (1+

j)/

δ with

j the complex number and

δ the penetration depth of the wave into the liquid given by

δ = (

η/

πρlf)

1/2. Solving Eq. (5) the fundamental resonant frequency of the sensor immersed in a viscous liquid

fliquid is:

where the first term of the right hand side corresponds to the square of the resonant frequency of the sensor in an inviscid medium (identical to Eq. (2)), and the second term is the contribution of the damping force due to the liquid. In the case of highly viscous liquid, where 2

h/

δ << 1, the resonant frequency shift of the sensor

Δf becomes:

Compared to Eq. (4), the resonant frequency shift in the viscous fluid is almost identical to that of a solid mass load except the smaller constant. This result is expected because at high viscosity the penetration depth δ is large compared to h, so the liquid layer bounded by h oscillates synchronously with the sensor just like a solid mass load. However Eq. (4) is more appropriate to describe a solid mass load because the numerical constant in Eq. (7) originates from the second term of the RHS of Eq. (6) that is only present in the liquid phase.

For a low viscosity liquid, where 2

h/

δ >> 1 , the resonant frequency shift becomes:

The resonant frequency of the sensor is proportional to the product of liquid viscosity and density. In practice, two sensors with different degrees of surface roughness are needed to separate them (see

Section 4: Applications).

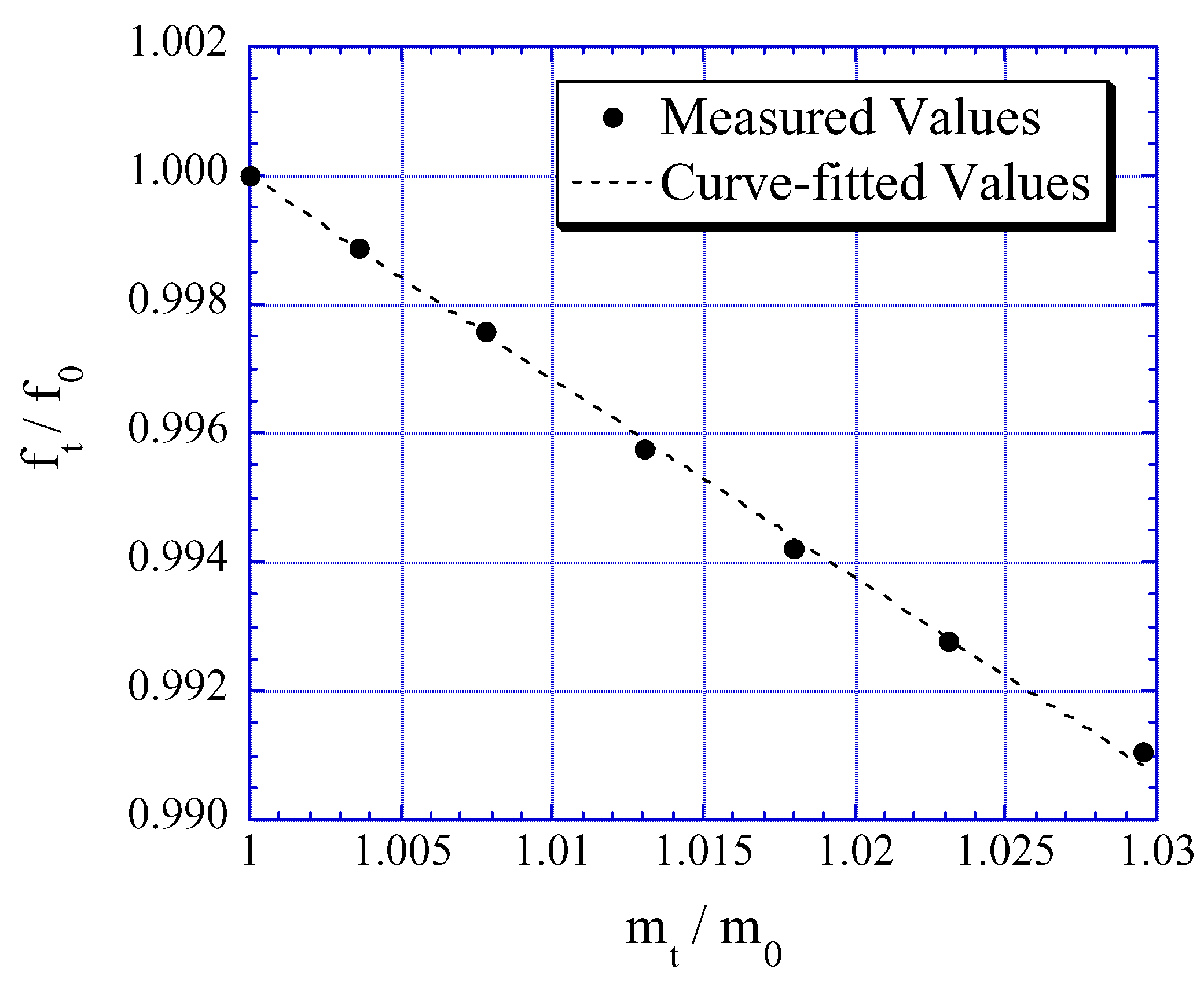

Effect of Coating Elasticity

Eq. (4) describes the relationship between the resonant frequency and a uniformly applied mass load. However, it does not consider the elastic stress in the mass load, applying only to a mass load of translational oscillation, not one of contraction and expansion. To consider the effect of coating elasticity on the sensor resonant frequency, the effective Young’s modulus

Eeff and density

ρeff of a uniformly coated sensor are expressed as [

24]:

where

Ec and

Es are the Young’s modulus of the coating and the sensor, respectively, and

ρc and

ρs are the density of the coating and sensor, respectively, and

αc and

αs are the fractional thicknesses of the coating and the sensor, respectively. Substituting Eqs. (9) and (10) into Eq. (2), and assuming the Poisson ratio

σ is close to zero, the fundamental resonant frequency of the coated sensor

fcoat is:

The ratio of the resonant frequency of the coated sensor to a bare sensor is:

Eq. (12) can be simplified by relating

αc to the total mass

mt and the sensor mass

ms as [

24]:

and becomes:

where

β is:

Eq. (14) can be used to determine the elasticity of a coating provided that the density and mass of the coating, and the elasticity, density and mass of the sensor are known.

Effect of Temperature and Applied Field

Eq. (2) describes the resonant frequency as a function of mechanical properties. To extend the model to include the change in elasticity with applied field, i.e. the

ΔE effect, we first note

ΔE is expressed as [

25]:

where

T is the temperature,

λs is the magnetostriction,

H is the applied field,

Ms is the saturation magnetization,

Hkσ is the anisotropy field when the sensor is under a longitudinal stress

σ,

EM is the modulus of elasticity at constant magnetization, and

Es is the modulus of elasticity at field

H. Substituting Eq. (16) into Eq. (2) and including the temperature dependence of the different variables, the resonant frequency

f0 is expressed as [

26]:

The consequence of Eq. (17) is that an applied dc biasing field of appropriate magnitude can be used to cancel the temperature dependence of the sensor.

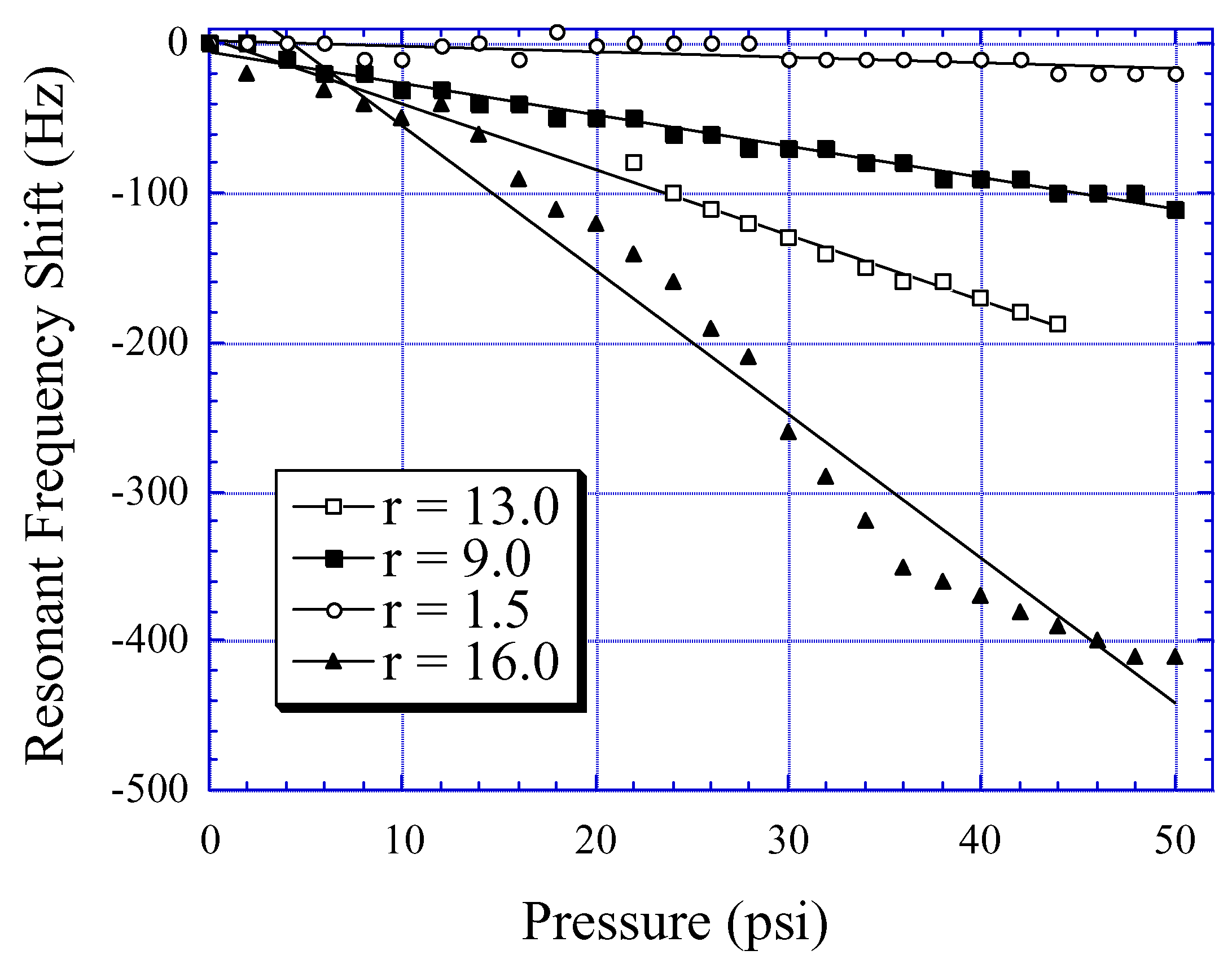

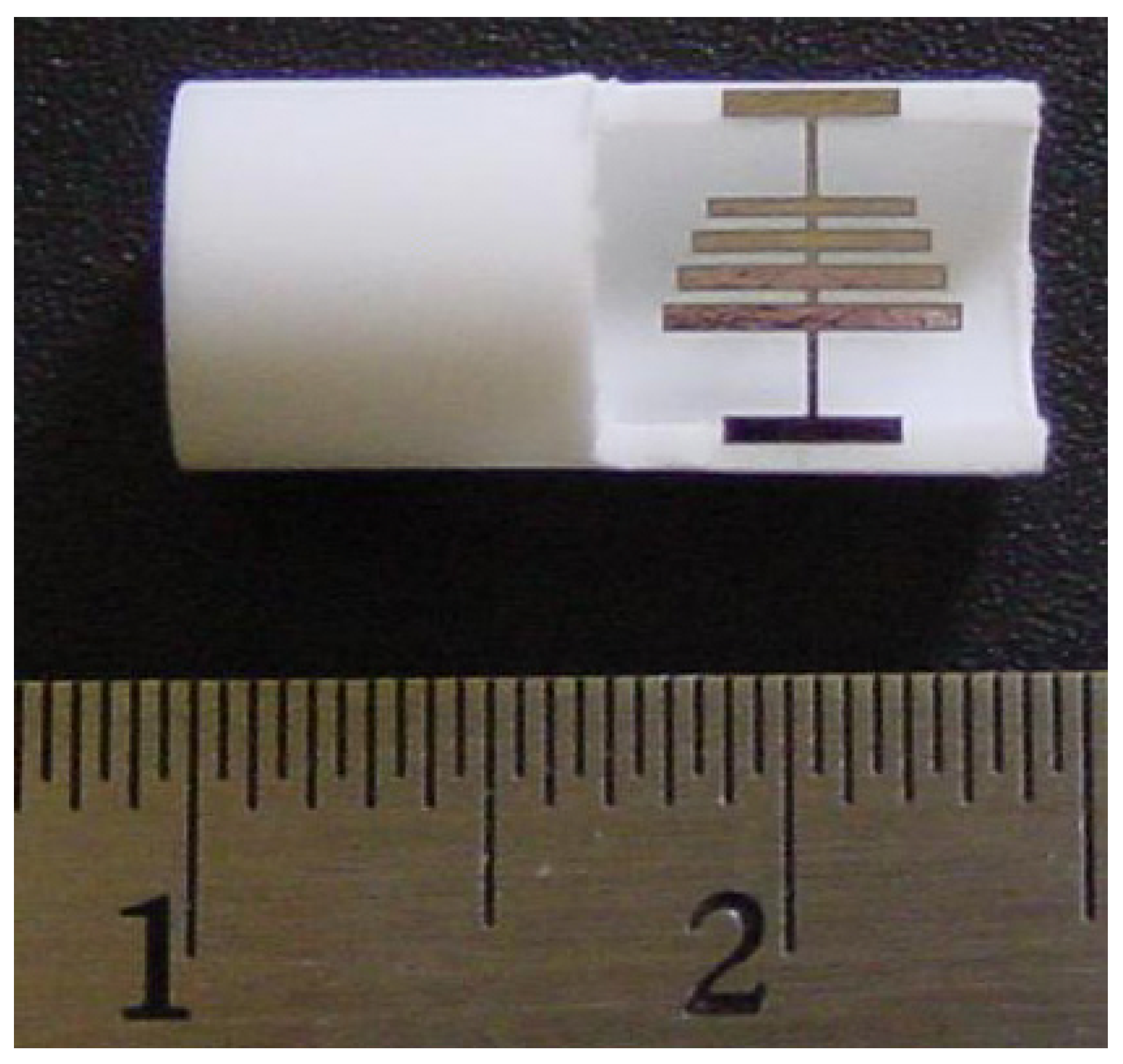

Magnetoelastic Sensor Arrays

A magnetoelastic sensor array can be constructed by placing sensors of different length (with different resonant frequencies) in parallel as shown in

Fig. 15. Since the magnetoelastic sensors operate via mechanical vibrations, they can be monitored simultaneously with minimum interference. As shown in

Fig. 16, the resonance of the four sensor elements can be distinctively measured. The array elements can be designed, or biased, to enable simultaneous multi-parameter sensing. For example, adjacent placement of a magnetically hard biasing strip of sufficient field strength will cancel the effect of temperature, enabling pressure measurement in a changing temperature environment. Alternatively, a perfectly flat sensor will not respond to changes in pressure, enabling temperature to be measured in a changing pressure environment. The effect of fluid flow velocity can be countered by placing the sensors within a porous protective shell, etc.

Figure 15.

A magnetoelastic sensor array consisting of four sensor elements (the four horizontal strips at the center) mounted on a tube at its support tabs (the top and bottom strips). The major scale is in cm.

Figure 15.

A magnetoelastic sensor array consisting of four sensor elements (the four horizontal strips at the center) mounted on a tube at its support tabs (the top and bottom strips). The major scale is in cm.

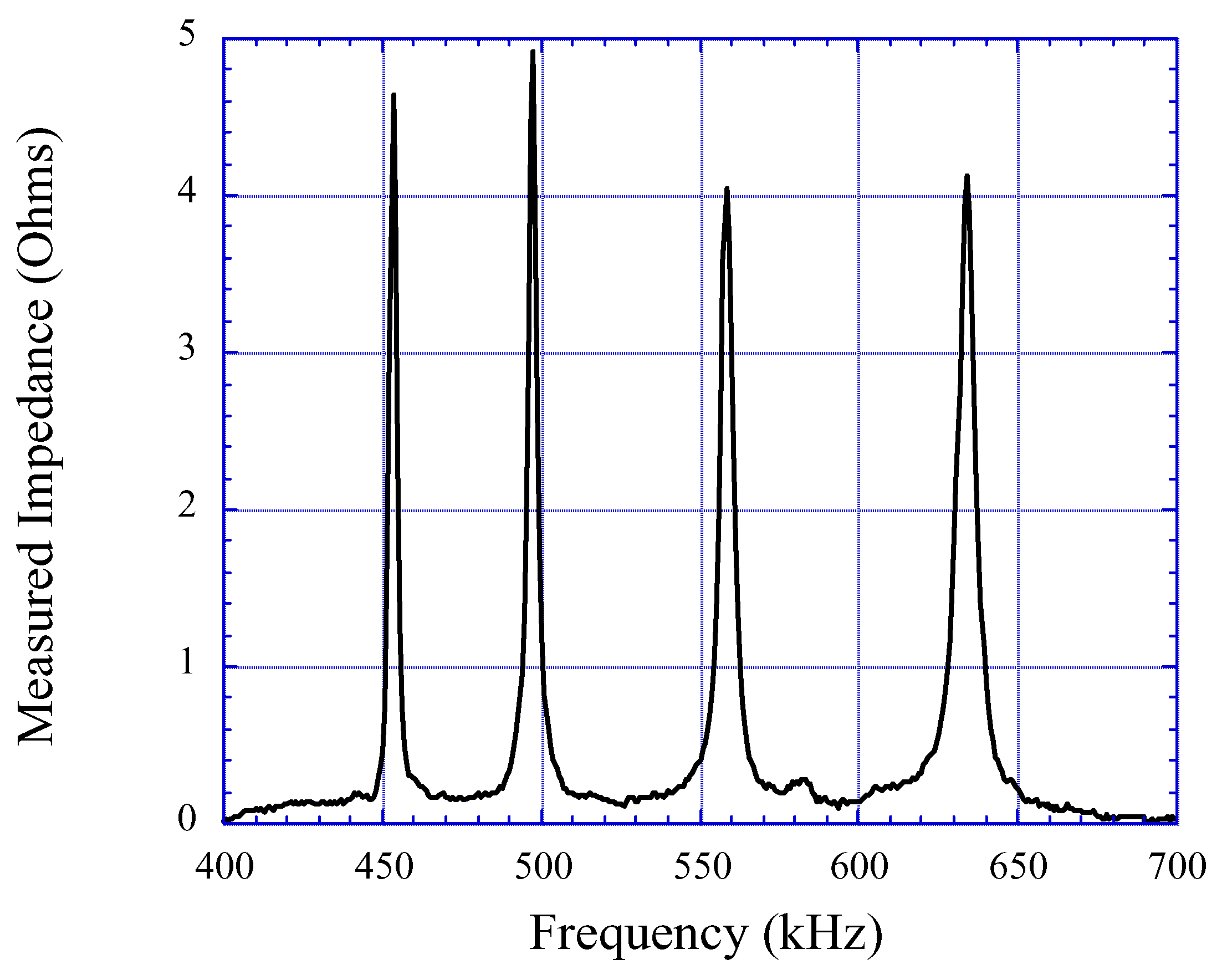

Figure 16.

The frequency response of the four-element sensor array measured by inserting the sensor array into a solenoid. The impedance of the solenoid is eliminated with a background subtraction.

Figure 16.

The frequency response of the four-element sensor array measured by inserting the sensor array into a solenoid. The impedance of the solenoid is eliminated with a background subtraction.

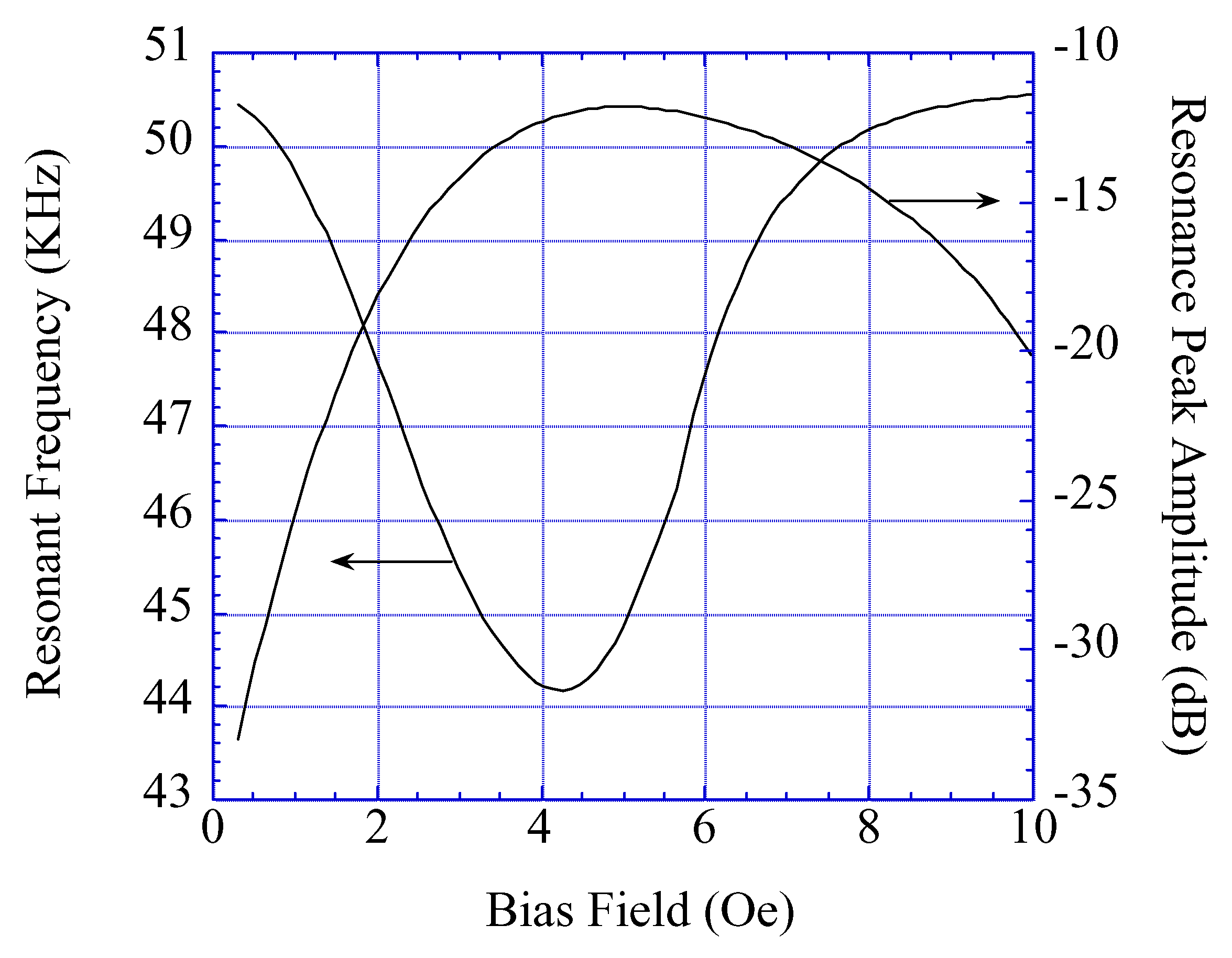

Optimizing Sensor Performance

Fig. 17 shows the resonant frequency shift of a magnetoelastic sensor as a function of bias field amplitude. The shift in the resonant frequency and change in measured amplitude is due to the change of elasticity

Es, the so-called

ΔE effect, due to the changing bias field.

Fig. 17 shows there is an optimal bias field where sensor amplitude is maximum, which corresponds to the anisotropy field of the sensor

Hk [

25].

Figure 17.

The resonant frequency and amplitude of a magnetoelastic sensor varies with applied field amplitude H due to changing elasticity (ΔE effect).

Figure 17.

The resonant frequency and amplitude of a magnetoelastic sensor varies with applied field amplitude H due to changing elasticity (ΔE effect).

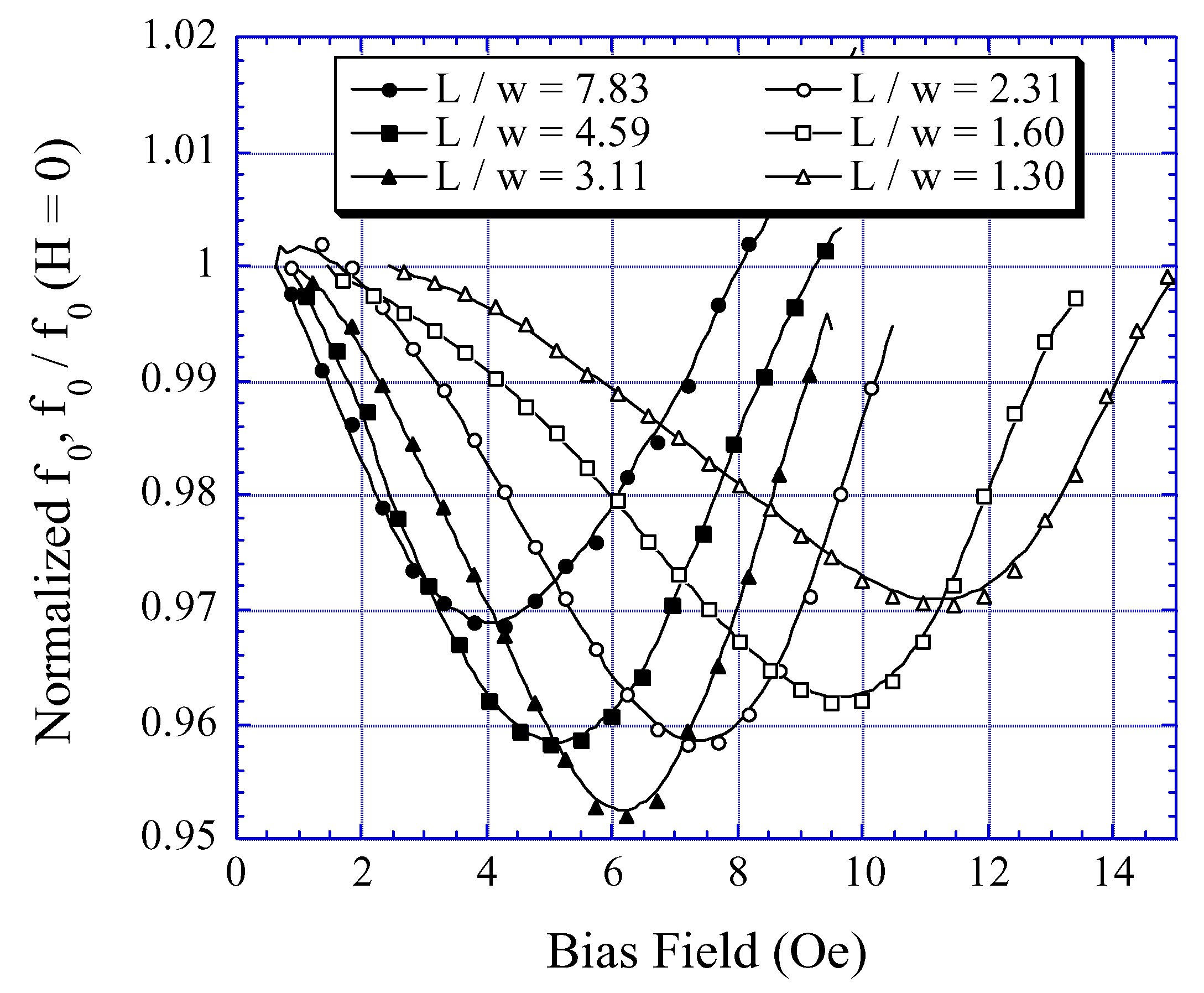

Figure 18.

The applied bias field required for the sensor to exhibit maximum ΔE effect increases with decreasing sensor length to width ratio.

Figure 18.

The applied bias field required for the sensor to exhibit maximum ΔE effect increases with decreasing sensor length to width ratio.

Although the anisotropy field

Hk does not change with sensor length, the applied

H field has to be increased when the length of the sensor is reduced to compensate for the demagnetizing field and to maintain the internal field,

Hi, at

Hk. The internal field

Hi is given as:

where

M is the magnetization and

D is the demagnetizing factor.

Fig. 18 plots the resonant frequency as a function of the sensor length to width ratio and

H. As can be seen from

Fig. 18, a higher bias field is required for the sensor to exhibit maximum Δ

E effect as the aspect ratio of the sensor decreases. The applied field for maximum

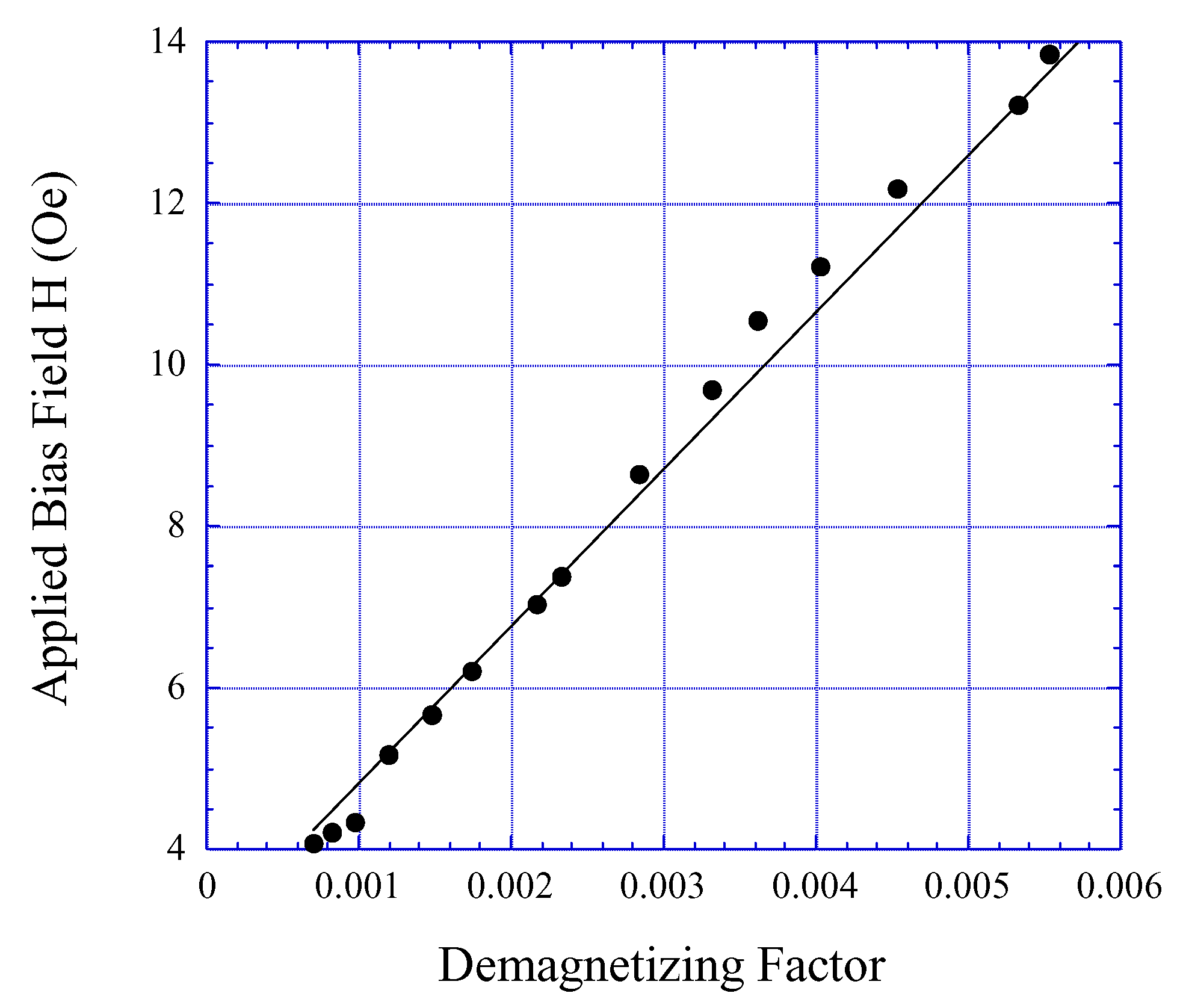

ΔE effect linearly increases with demagnetizing factor

D as illustrated in

Fig. 19.

Figure 19.

The optimal bias field increases linearly with the demagnetizing factor of the sensor.

Figure 19.

The optimal bias field increases linearly with the demagnetizing factor of the sensor.

Figure 20.

Transverse-field annealing of the magnetoelastic sensor increases the ΔE effect and decreases the anisotropy field Hk.

Figure 20.

Transverse-field annealing of the magnetoelastic sensor increases the ΔE effect and decreases the anisotropy field Hk.

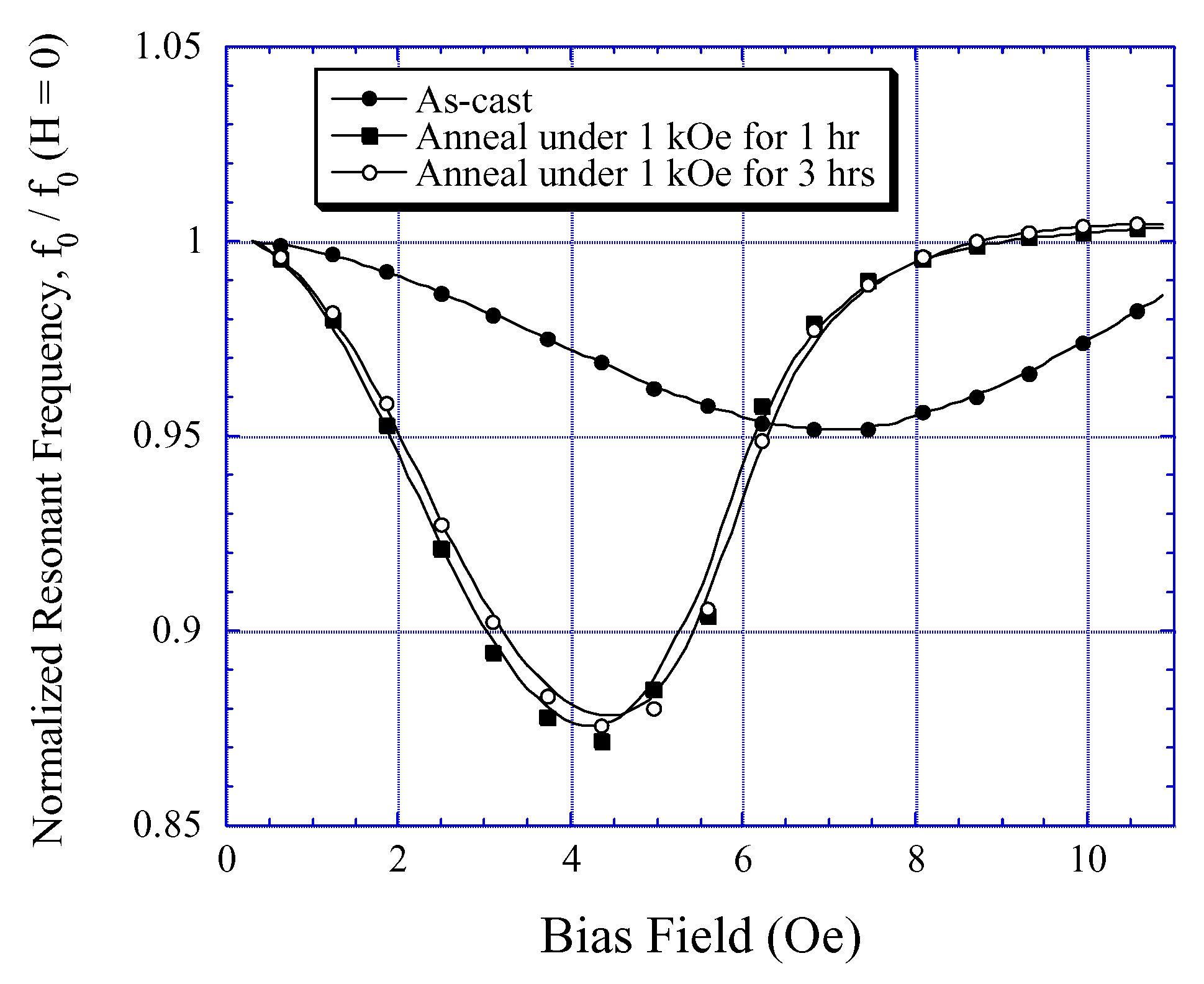

Another way to increase the sensor performance and the magnitude of the

ΔE effect is by annealing the sensor while exposed to a transverse magnetic field [

21,

22,

29,

30].

Fig. 20 shows the bias-field dependent resonant frequency of an as-cast 4 × 1.3 cm × 28 µm 2826MB ribbon, and the same ribbon after a 1 kOe transverse field anneal at 350°C for 1 hr and 3 hr. As can be seen, the magnitude of the

ΔE effect of the transverse-field annealed sensors is improved by more than 150%, while

Hk is reduced by 30%.

Conclusions

The operational principles and applications of magnetoelastic sensors are presented. Magnetoelastic sensors are amorphous ferromagnetic ribbons that exhibit a magneto-mechanical resonance when excited by a time varying magnetic field. Magnetoelastic sensors have successfully been used for stress, pressure, liquid viscosity and density, fluid flow velocity, elasticity, and temperature monitoring. Chemical sensors based on the magnetoelastic sensor platform have been fabricated by combining the magnetoelastic sensors with mass changing, chemically responsive layers (both polymeric and metal oxides).

Theoretical models have been developed to understand the behavior of the sensor under different operating conditions. For small mass loads the resonant frequency of the sensor is found to linearly decrease. For uniformly applied coatings the shift in resonant frequency is proportional to the difference in the speed of sound between the coating and sensor; a coating with a speed of sound identical to that in the sensor material will not induce a shift in resonant frequency. The resonant frequency of a sensor immersed in liquid is dependent upon the product of the liquid viscosity and density; two sensors with different surface roughnesses can be used to separate the two effects. To measure atmospheric pressure, the sensor is bent so it exhibits out-of-plane vibrations, increasing by several orders of magnitude the surface area able to interact with the ambient atmosphere.

For optimal performance, the magnetoelastic sensor is set to operate at the point where it exhibits highest ΔE effect. The optimal operating point for the sensor is set by changing the bias field or the dimension of the sensor. Generally, a higher bias field is needed to set the sensor at the optimal operating point when the length of the sensor decreases. This is due to the demagnetizing field of the sensor, which increases with decreasing sensor aspect ratio. Annealing the sensor under transverse fields also increases the performance of the sensor by increasing the ΔE effect, which will increase the magnetoelastic coupling, and reducing the anisotropy field. The bias field can be used to counteract mechanical properties, enabling a temperature independent response with proper biasing field amplitude. By proper selection of differently designed magnetoelastic elements a sensor array can be made able to simultaneously measurement multiple environmental parameters.