Highly Sensitive Detection of NO2 by Au and TiO2 Nanoparticles Decorated SWCNTs Sensors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Preparation and Characterization

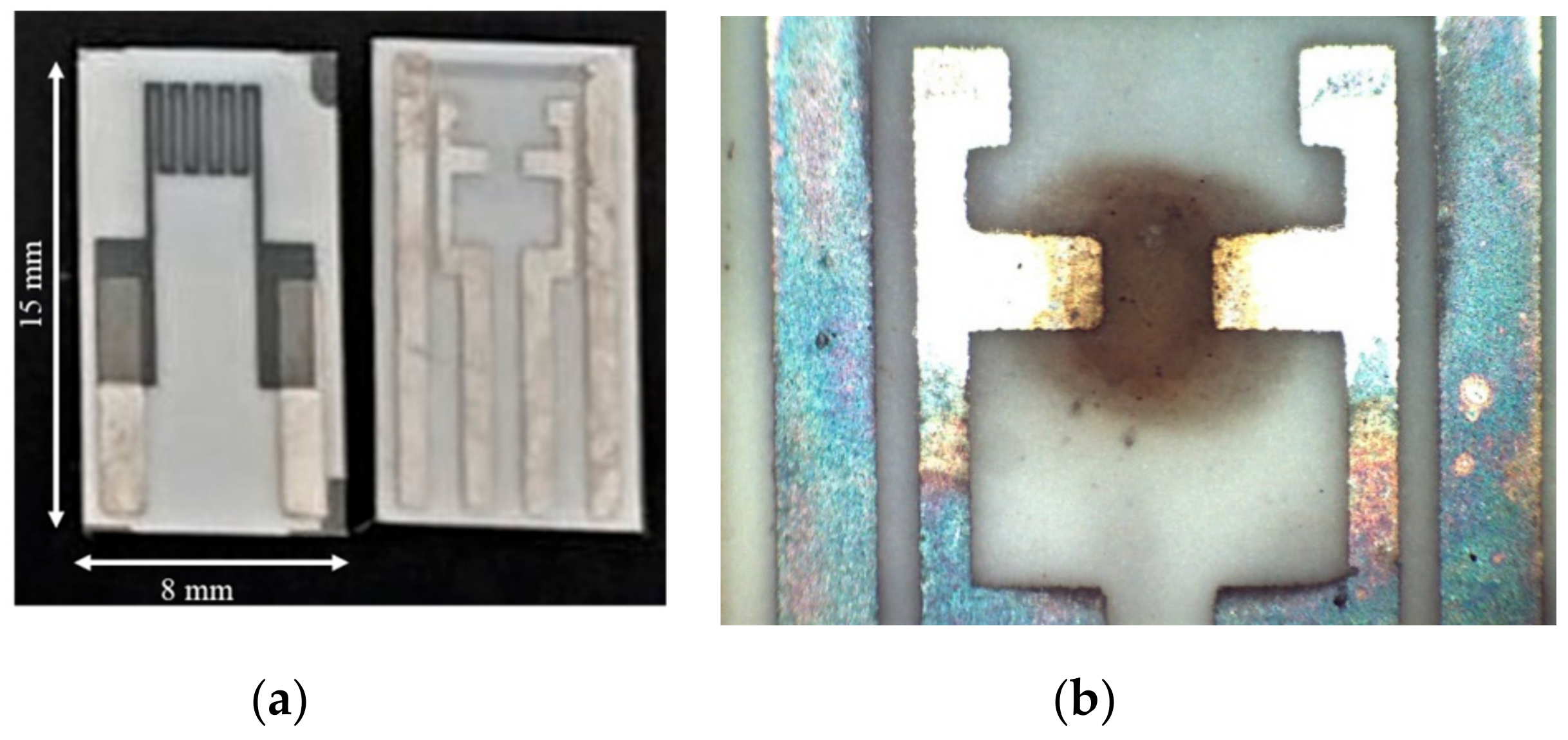

2.2. Sensor Realization and Gas Sensing Characterization System

3. Results and Discussion

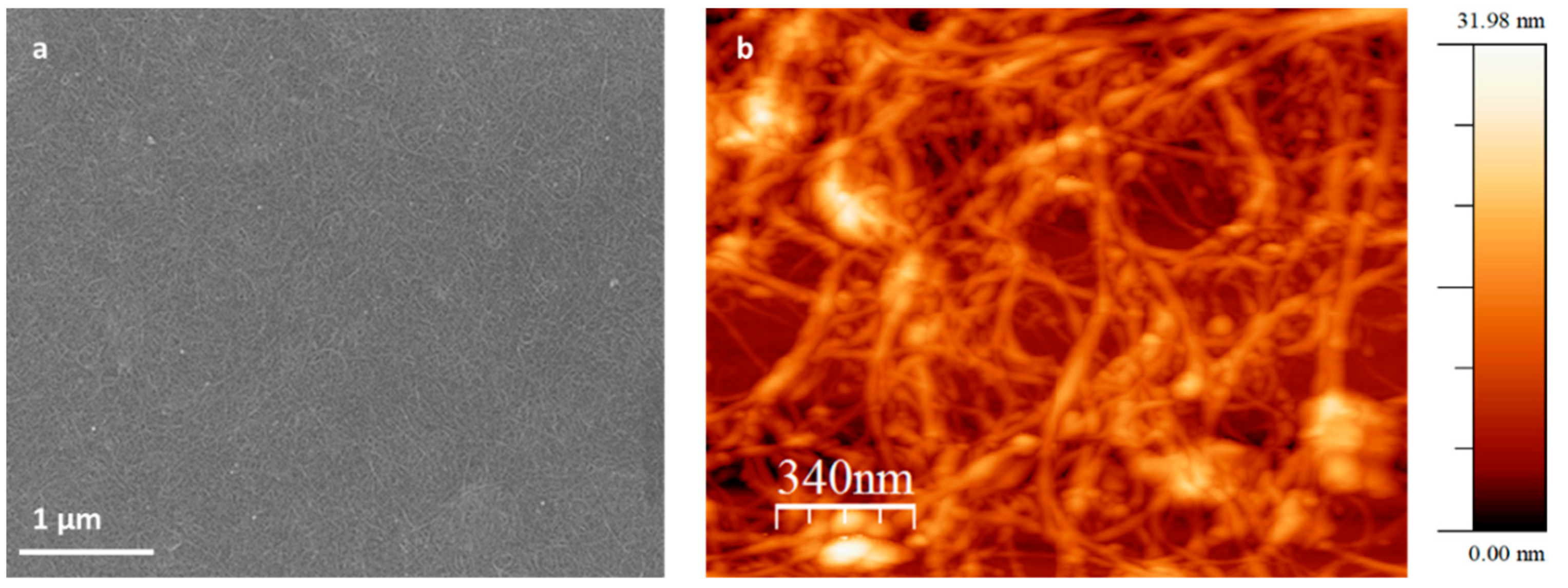

3.1. Physical Characterization

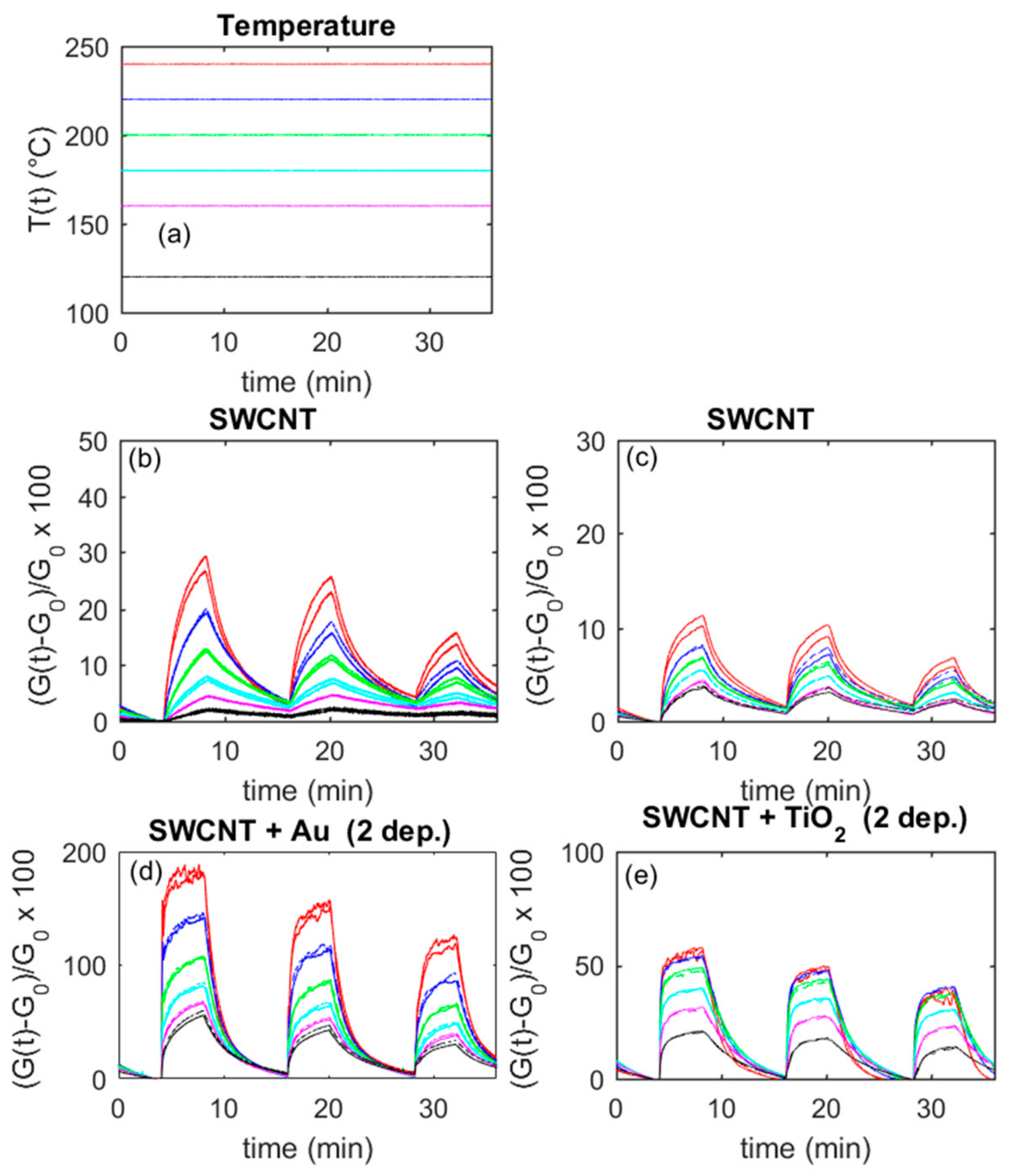

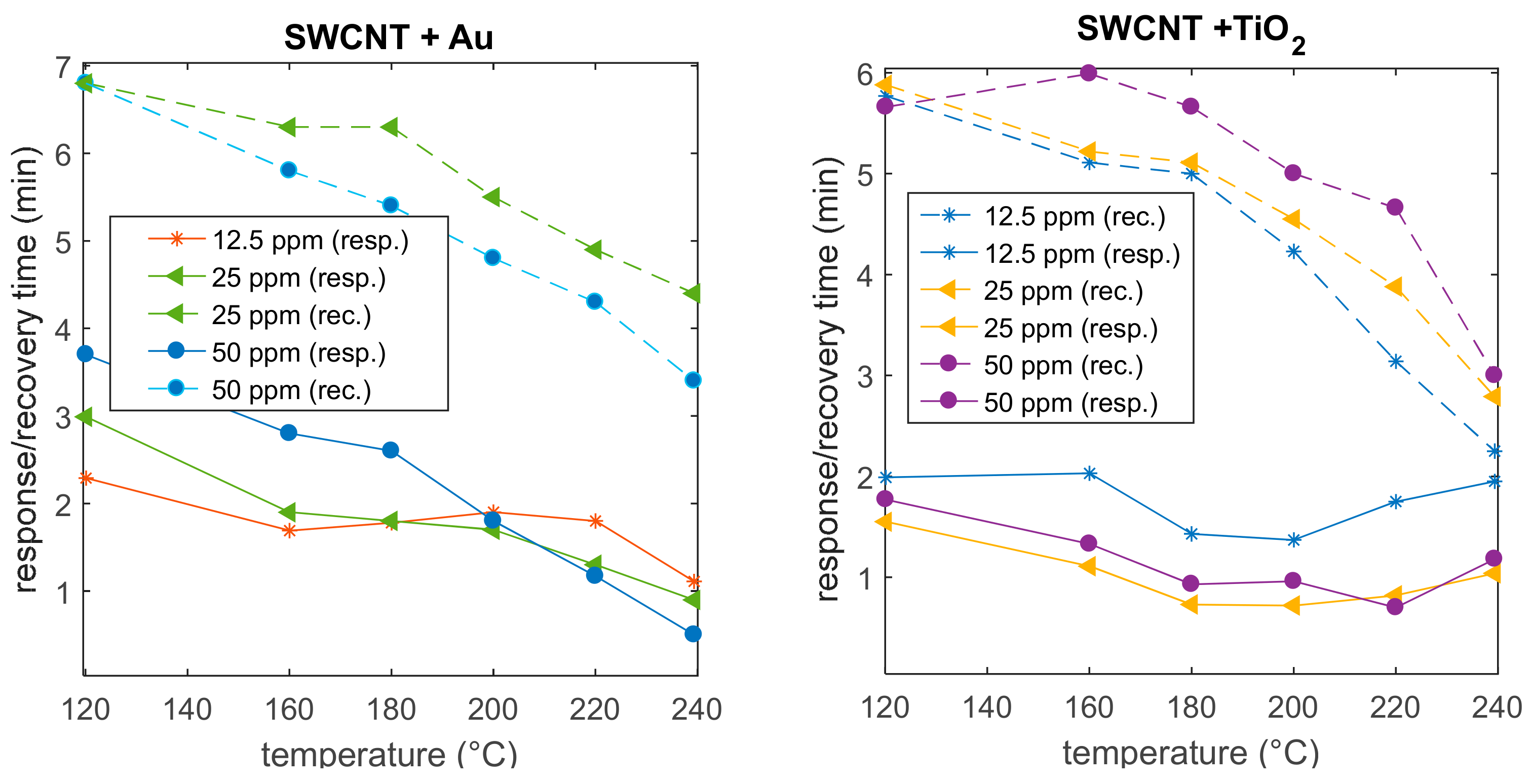

3.2. Gas Measurement Results

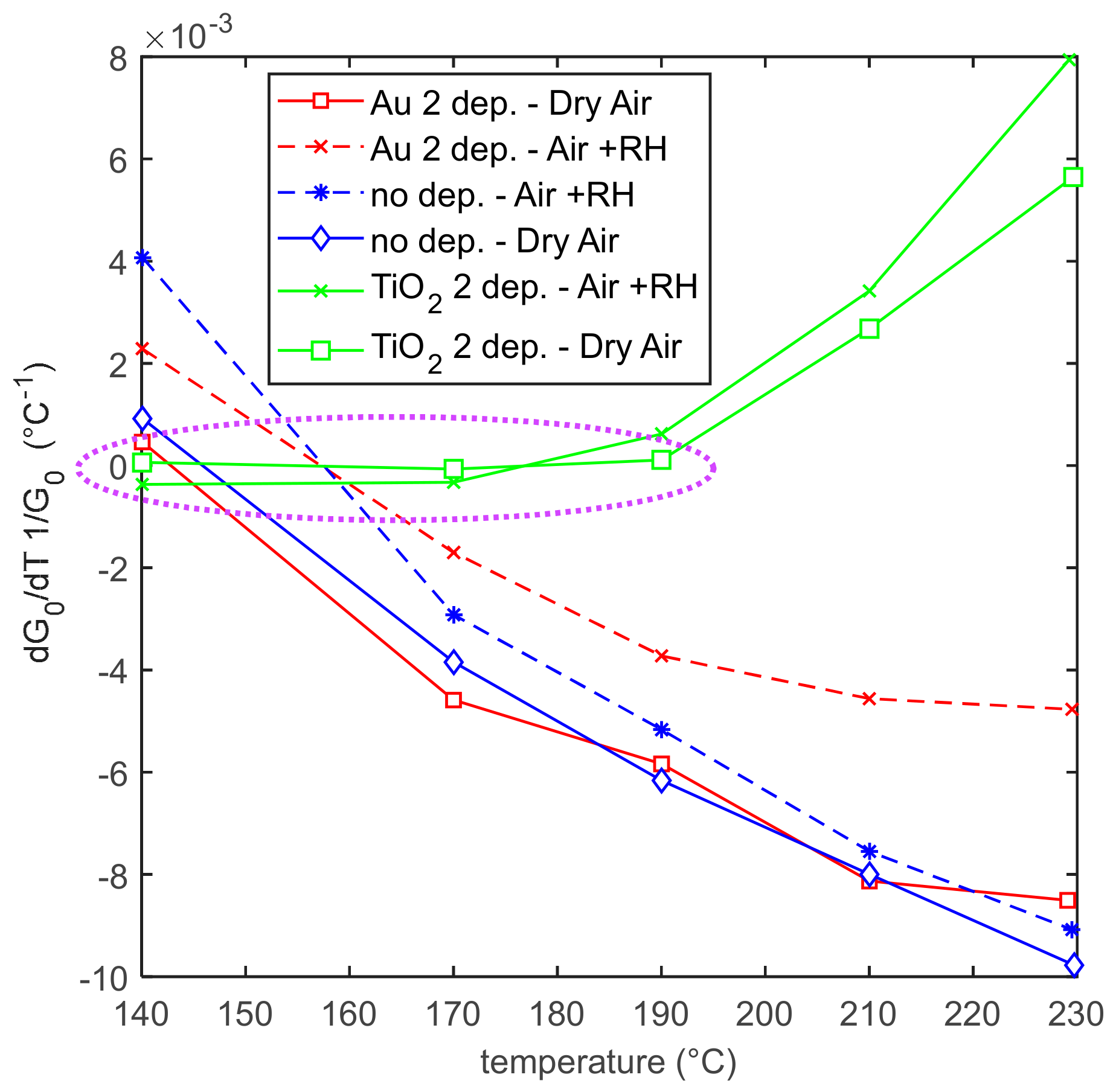

3.3. Study of the Baseline Conductance

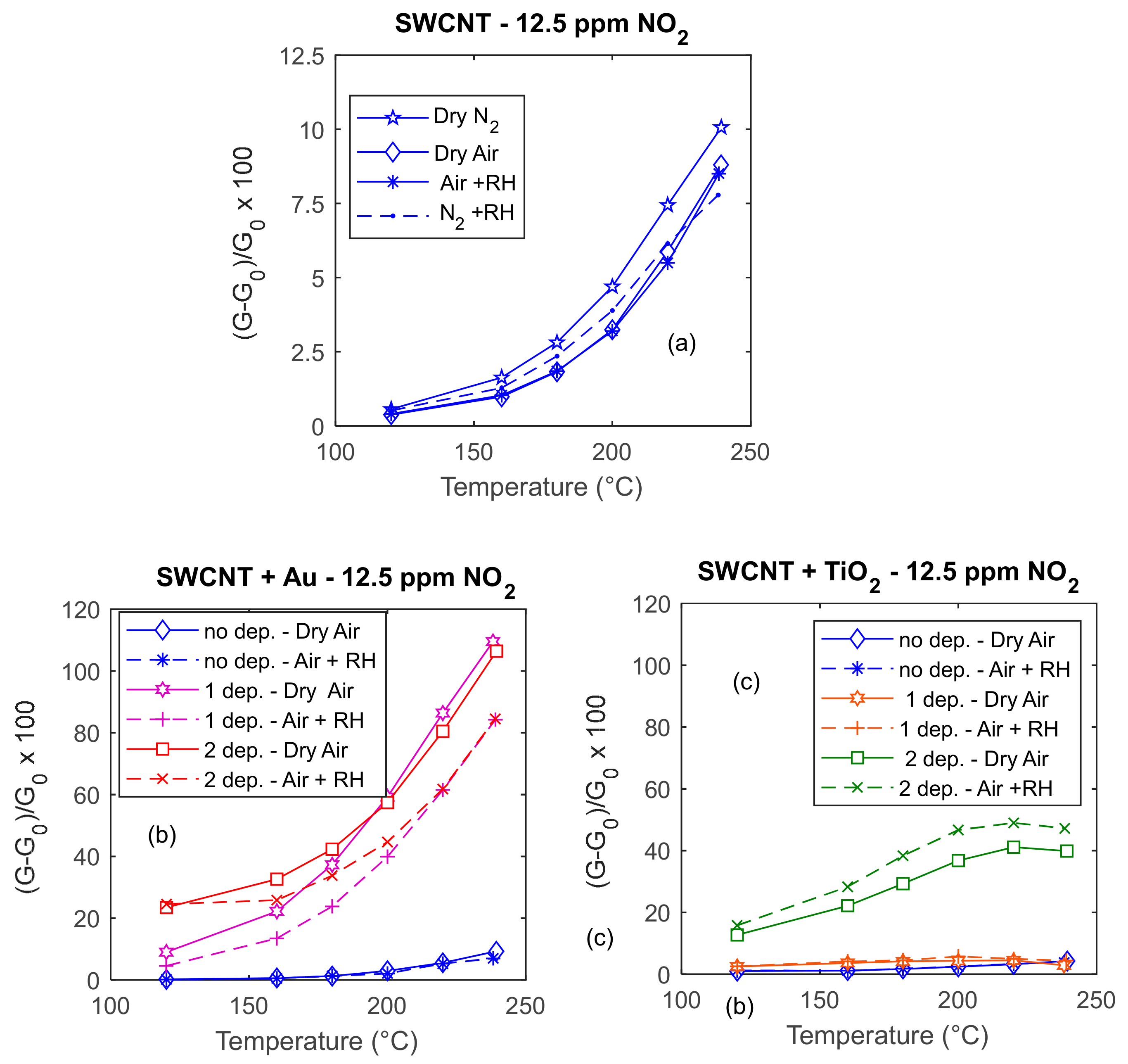

3.4. Study of the Response to NO2

3.5. Low Temperature Operations

3.6. Cross-Sensitivity toward CO

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Venkataraman, A.; Amadi, E.V.; Chen, Y.; Papadopoulos, C. Carbon Nanotube Assembly and Integration for Applications Nanoscale. Res. Lett. 2019, 14, 220. [Google Scholar]

- Chen, Y.; Meng, F.; Li, M.; Liu, J. Novel capacitive sensor: Fabrication from carbon nanotube arrays and sensing property characterization. Sens. Actuators B Chem. 2009, 140, 396–401. [Google Scholar] [CrossRef]

- Zandi, A.; Gilani, A.; Ghafoori fard, H.; Koohsorkhi, J. An optimized resistive CNT-based gas sensor with a novel configuration by top electrical contact. Diam. Relat. Mater. 2019, 93, 224–232. [Google Scholar] [CrossRef]

- Chopra, S.; McGuire, K.; Gothard, N.; Rao, A.M.; Pham, A. Selective gas detection using a carbon nanotube sensor. Appl. Phys. Lett. 2003, 83, 2280–2282. [Google Scholar] [CrossRef]

- Kroto, H.W.; Fischer, D.C.J.E. The Fullerenes: New Horizons for the Chemistry, Physics and Astrophysics of Carbon; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Saito, R.; Fujita, M.; Dresselhaus, G.; Dresselhaus, M.S. Electronic structure of chiral graphene tubules. Appl. Phys. Lett. 1992, 60, 2204–2206. [Google Scholar] [CrossRef]

- Wang, Y.; Yeow, J.T.W. A Review of Carbon Nanotubes-Based Gas Sensors. J. Sens. 2009, 2009, 493904. [Google Scholar] [CrossRef]

- Rana, M.; Ibrahim, D.; Mohd Asyraf, M.; Jarin, S.; Tomal, A. A review on recent advances of CNTs as gas sensors. Sens. Rev. 2017, 37, 127–136. [Google Scholar] [CrossRef]

- Camilli, L.; Passacantando, M. Advances on Sensors Based on Carbon Nanotubes. Chemosensors 2018, 6, 62. [Google Scholar] [CrossRef] [Green Version]

- Aroutiounian, V.M. Gas sensors based on functionalized carbon nanotubes. J. Contemp. Phys. 2015, 50, 333–354. [Google Scholar] [CrossRef]

- Ziegler, D.; Bekyarova, E.; Marchisio, A.; Tulliani, J.; Naishadham, K. Highly Selective Ozone Sensors Based on Functionalized Carbon Nanotubes. In Proceedings of the 2018 IEEE SENSORS, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar]

- Zhang, X.; Cui, H.; Gui, Y.; Tang, J. Mechanism and Application of Carbon Nanotube Sensors in SF6 Decomposed Production Detection: A Review. Nanoscale Res. Lett. 2017, 12, 177. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Buldum, A.; Han, J.; Lu, J.P. Gas molecule adsorption in carbon nanotubes and nanotube bundles. Nanotechnology 2002, 13, 195–200. [Google Scholar] [CrossRef]

- Sharma, S.; Hussain, S.; Singh, S.; Islam, S.S. MWCNT-conducting polymer composite based ammonia gas sensors: A new approach for complete recovery process. Sens. Actuators B Chem. 2014, 194, 213–219. [Google Scholar] [CrossRef]

- George, J.; Abdelghani, A.; Bahoumina, P.; Tantot, O.; Baillargeat, D.; Frigui, K.; Bila, S.; Hallil, H.; Dejous, C. CNT-Based Inkjet-Printed RF Gas Sensor: Modification of Substrate Properties during the Fabrication Process. Sensors 2019, 19, 1768. [Google Scholar] [CrossRef] [Green Version]

- Agarwal, P.B.; Alam, B.; Sharma, D.S.; Sharma, S.; Mandal, S.; Agarwal, A. Flexible NO2 gas sensor based on single-walled carbon nanotubes on polytetrafluoroethylene substrates. Flex. Print. Electron. 2018, 3, 035001. [Google Scholar] [CrossRef]

- Asad, M.; Sheikhi, M.H.; Pourfath, M.; Moradi, M. Highly sensitive and selective flexible H2S gas sensors based on Cu nanoparticle decorated SWCNTs. Sens. Actuators B Chem. 2015, 210, 1–8. [Google Scholar] [CrossRef]

- Someya, T.; Small, J.; Kim, P.; Nuckolls, C.; Yardley, J.T. Alcohol Vapor Sensors Based on Single-Walled Carbon Nanotube Field Effect Transistors. Nano Lett. 2003, 3, 877–881. [Google Scholar] [CrossRef]

- Zhang, J.; Boyd, A.; Tselev, A.; Paranjape, M.; Barbara, P. Mechanism of NO2 detection in carbon nanotube field effect transistor chemical sensors. Appl. Phys. Lett. 2006, 88, 123112. [Google Scholar] [CrossRef]

- Hu, P.; Zhang, J.; Li, L.; Wang, Z.; O’Neill, W.; Estrela, P. Carbon Nanostructure-Based Field-Effect Transistors for Label-Free Chemical/Biological Sensors. Sensors 2010, 10, 5133–5159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zaporotskova, I.V.; Boroznina, N.P.; Parkhomenko, Y.N.; Kozhitov, L.V. Carbon nanotubes: Sensor properties. A review. Mod. Electron. Mater. 2016, 2, 95–105. [Google Scholar] [CrossRef]

- Hannon, A.; Lu, Y.; Li, J.; Meyyappan, M. Room temperature carbon nanotube based sensor for carbon monoxide detection. J. Sens. Sens. Syst. 2014, 3, 349–354. [Google Scholar] [CrossRef]

- Zhang, G.D.; Tai, H.L.; Xie, G.Z.; Jiang, Y.D.; Zhou, Y. A carbon monoxide sensor based on single-walled carbon nanotubes doped with copper chloride. Sci. China Technol. Sci. 2013, 56, 2576. [Google Scholar] [CrossRef]

- Espinosa, E.H.; Ionescu, R.; Chambon, B.; Bedis, G.; Sotter, E.; Bittencourt, C.; Felten, A.; Pireaux, J.-J.; Correig, X.; Llobet, E. Hybrid metal oxide and multiwall carbon nanotube films for low temperature gas sensing. Sens. Actuators B Chem. 2007, 127, 137–142. [Google Scholar] [CrossRef]

- Kerdcharoen, T.; Wongchoosuk, C. Carbon nanotube and metal oxide hybrid materials for gas sensing. In Woodhead Publishing Series in Electronic and Optical Materials. Semiconductor Gas Sensors; Jaaniso, R., Tan, O.K., Eds.; Woodhead Publishing: Cambridge, UK, 2013; pp. 386–407. [Google Scholar]

- Wang, J.; Liu, L.; Cong, S.; Qi, J.; Xu, B. An enrichment method to detect low concentration formaldehyde. Sens. Actuators B Chem. 2008, 134, 1010–1015. [Google Scholar] [CrossRef]

- Bittencourt, C.; Felten, A.; Espinosa, E.H.; Ionescu, R.; Llobet, E.; Correig, X.; Pireaux, J.-J. WO3 films modified with functionalized multi-wall carbon nanotubes: Morphological, compositional and gas response studies. Sens. Actuators B Chem. 2006, 115, 33–41. [Google Scholar] [CrossRef]

- Penza, M.; Rossi, R.; Alvisi, M.; Serra, E. Metal-modified and vertically aligned carbon nanotube sensors array for landfill gas monitoring applications. Nanotechnology 2010, 21, 105501. [Google Scholar] [CrossRef] [Green Version]

- Leghrib, R.; Felten, A.; Demoisson, F.; Reniers, F.; Pireaux, J.J.; Llobet, E. Room-temperature, selective detection of benzene at trace levels using plasma-treated metal-decorated multiwalled carbon nanotubes. Carbon 2010, 48, 3477–3484. [Google Scholar] [CrossRef]

- Savu, R.; Silveira, J.; Alaferdov, A.; Joanni, E.; Gobbi, A.; Canesqui, M.; De Lara, D.; Souza Filho, A.; Moshkalev, S. Gas sensors based on locally heated multiwall carbon nanotubes decorated with metal nanoparticles. J. Sens. 2015, 2015, 260382. [Google Scholar] [CrossRef]

- Okafor, E.C.; Somarathne, K.D.K.A.; Hayakawa, A.; Kudo, T.; Kurata, O.; Iki, N.; Kobayashi, H. Towards the development of an efficient low-NOx ammonia combustor for a micro gas turbine. Proc. Combust. Inst. 2019, 37, 4597–4606. [Google Scholar] [CrossRef]

- Addabbo, T.; Fort, A.; Mugnaini, M.; Vignoli, V. Low temperature NO2 sensor based on YCoO3 and TiO2 nanoparticle composites. Lect. Notes Electr. Eng. 2019, 539, 3–10. [Google Scholar]

- Kumar, S.; Pavelyev, V.; Mishra, P.; Tripathi, N. Sensitive detection of nitrogen dioxide using gold nanoparticles decorated single walled carbon nanotubes. In Proceedings of the International Conference ITNT 2017- “Information Technology and Nanotechnology 2017”, Samara, Russia, 25–27 April 2017; pp. 74–77. [Google Scholar]

- Addabbo, T.; Bertocci, F.; Fort, A.; Mugnaini, M.; Vignoli, V.; Shahin, L. Versatile measurement system for characterization of gas sensing materials. In Proceedings of the 2013 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Minneapolis, MN, USA, 6–9 May 2013. [Google Scholar]

- Pradhan, B.; Kohlmeyer, R.R.; Setyowati, K.; Owen, H.A.; Chen, J. Advanced carbon nanotube/polymer composite infrared sensors. Carbon 2009, 47, 1686–1692. [Google Scholar] [CrossRef]

- Sharma, R.; Al-Hamry, A.; Vijayragavan, S.; Benchirouf, A.; Sanli, A.; Müller, C.; Kanoun, O. Single-wall carbon nanotubes based near-infrared sensors on flexible substrate. In Proceedings of the 2014 IEEE 11th International Multi-Conference on Systems, Signals & Devices (SSD14), Barcelona, Spain, 11–14 February 2014; pp. 1–5. [Google Scholar]

- Kumar, D.; Chaturvedi, P.; Saho, P.; Jha, P.; Chouksey, A.; Lal, M.; Rawat, J.S.B.S.; Tandon, R.P.; Chaudhury, P.K. Effect of single wall carbon nanotube networks on gas sensor response and detection limit. Sens. Actuators B Chem. 2017, 240, 1134–1140. [Google Scholar] [CrossRef]

- Müller, C.; Al-Hamry, A.; Kanoun, O.; Rahaman, M.; Zahn, D.; Matsubara, E.; Rosolen, J. Humidity Sensing Behavior of Endohedral Li-Doped and Undoped SWCNT/SDBS Composite Films. Sensors 2019, 19, 171. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, R.; Al-Dossary, O.; Kumar, G.; Umar, A. Zinc oxide nanostructures for NO2 gas–sensor applications: A review. Nano-Micro Lett. 2015, 7, 97–120. [Google Scholar] [CrossRef] [Green Version]

- Xu, K.; Fu, C.; Gao, Z.; Wei, F.; Ying, Y.; Xu, C.; Fu, G. Nanomaterial-based gas sensors: A review. Instrum. Sci. Technol. 2018, 46, 115–145. [Google Scholar] [CrossRef]

- Peng, S.; Cho, K. Chemical control of nanotube electronics. Nanotechnology 2000, 11, 57–60. [Google Scholar] [CrossRef]

- Addabbo, T.; Fort, A.; Mugnaini, M.; Vignoli, V.; Baldi, A.; Bruzzi, M. Quartz-Crystal Microbalance Gas Sensors Based on TiO2 Nanoparticles. IEEE Trans. Instrum. Meas. 2018, 67, 722–730. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fort, A.; Panzardi, E.; Al-Hamry, A.; Vignoli, V.; Mugnaini, M.; Addabbo, T.; Kanoun, O. Highly Sensitive Detection of NO2 by Au and TiO2 Nanoparticles Decorated SWCNTs Sensors. Sensors 2020, 20, 12. https://doi.org/10.3390/s20010012

Fort A, Panzardi E, Al-Hamry A, Vignoli V, Mugnaini M, Addabbo T, Kanoun O. Highly Sensitive Detection of NO2 by Au and TiO2 Nanoparticles Decorated SWCNTs Sensors. Sensors. 2020; 20(1):12. https://doi.org/10.3390/s20010012

Chicago/Turabian StyleFort, Ada, Enza Panzardi, Ammar Al-Hamry, Valerio Vignoli, Marco Mugnaini, Tommaso Addabbo, and Olfa Kanoun. 2020. "Highly Sensitive Detection of NO2 by Au and TiO2 Nanoparticles Decorated SWCNTs Sensors" Sensors 20, no. 1: 12. https://doi.org/10.3390/s20010012