Temperature Stability and Spectral Tuning of Long Period Fiber Gratings Fabricated by Femtosecond Laser Direct Writing

Abstract

:1. Introduction

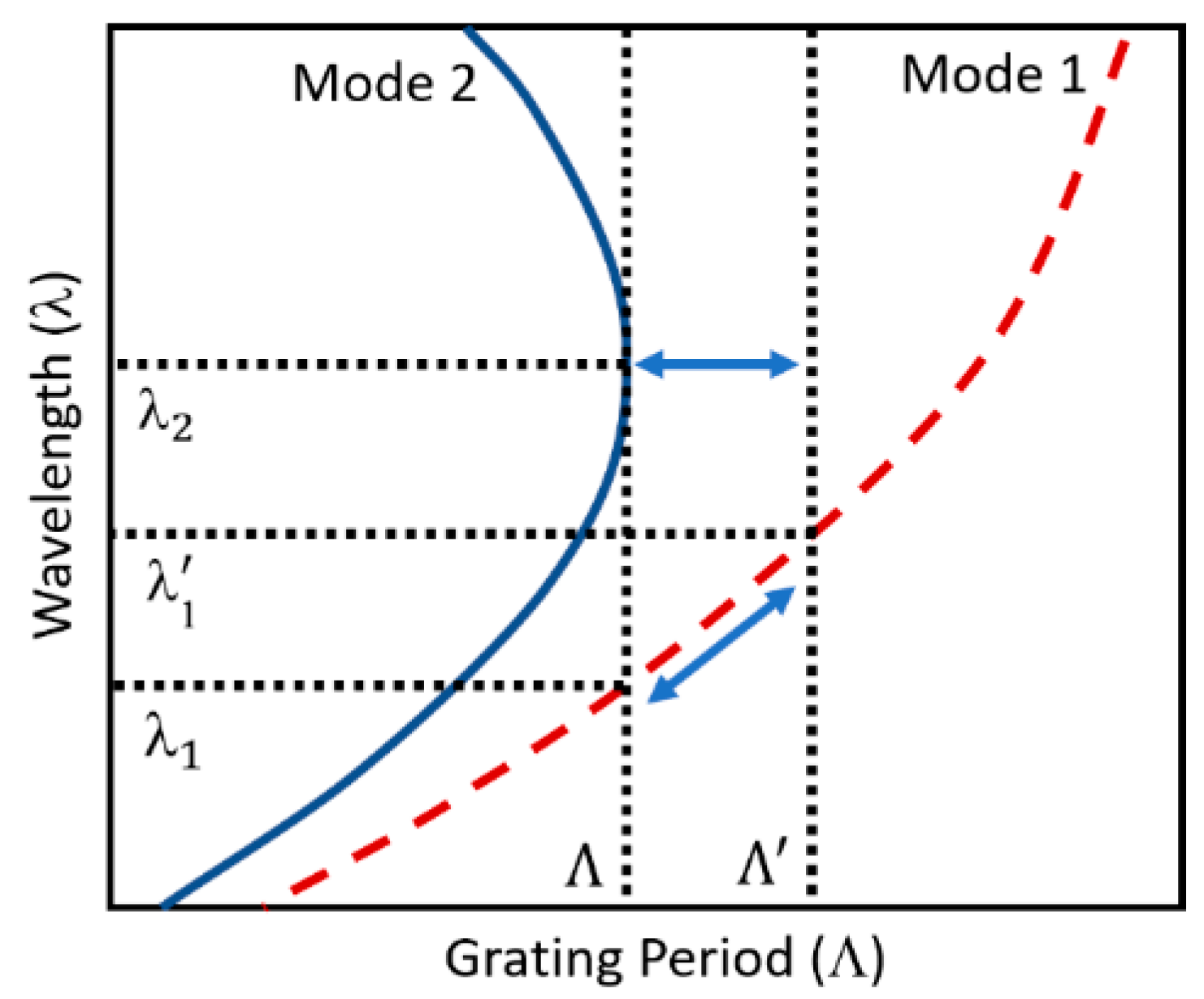

2. LPFGs Theory

Temperature Sensitivity

3. Materials and Methods

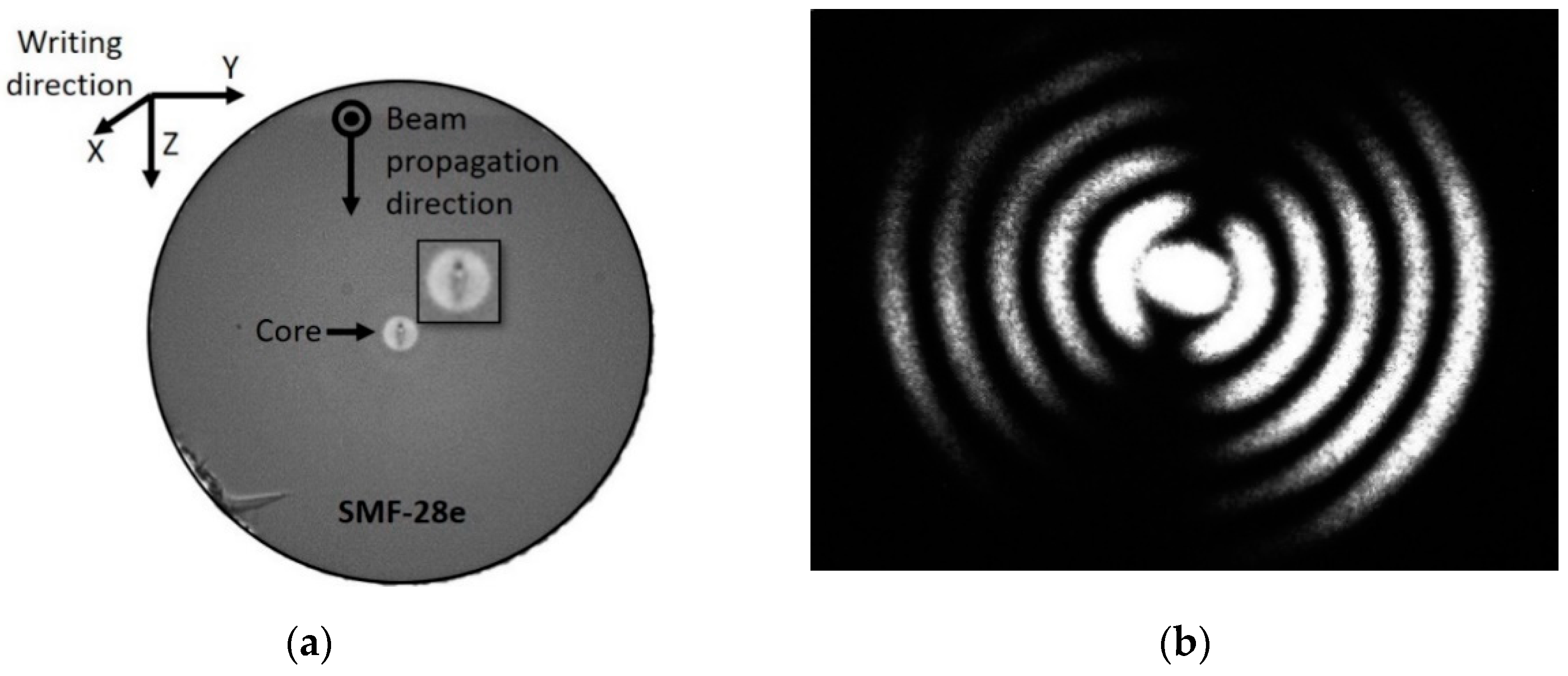

3.1. Fabrication Procedures

3.2. Characterization Procedures

4. Results

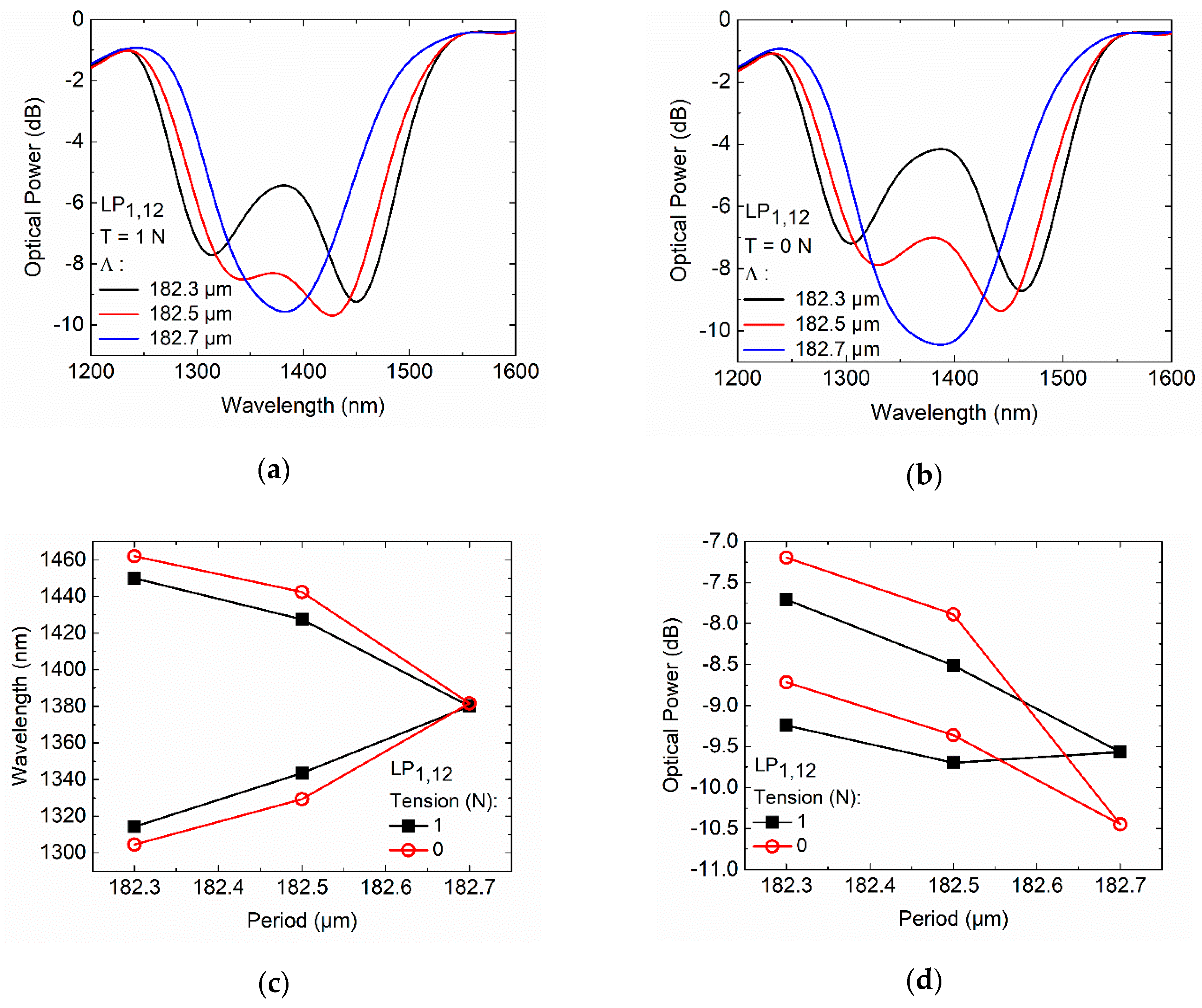

4.1. Characterization of the LPFGs Writing

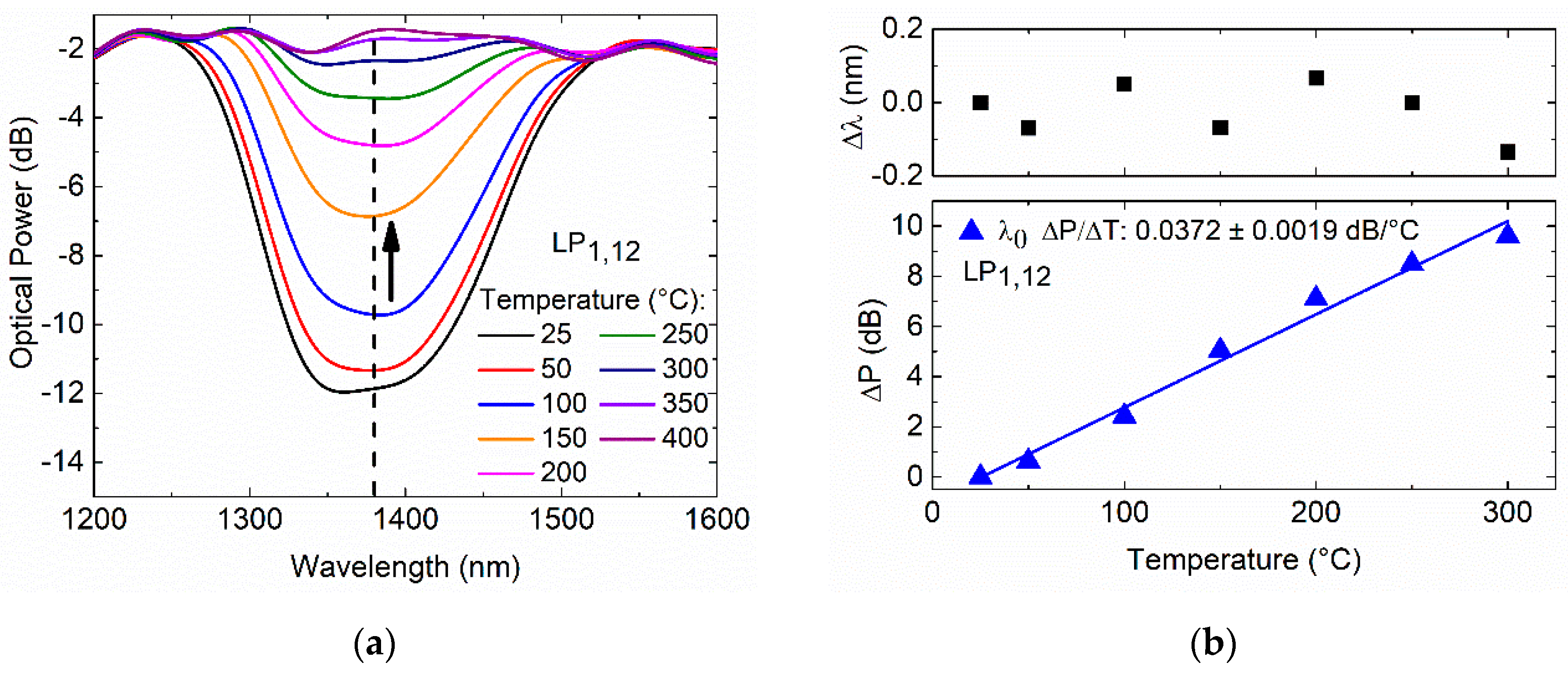

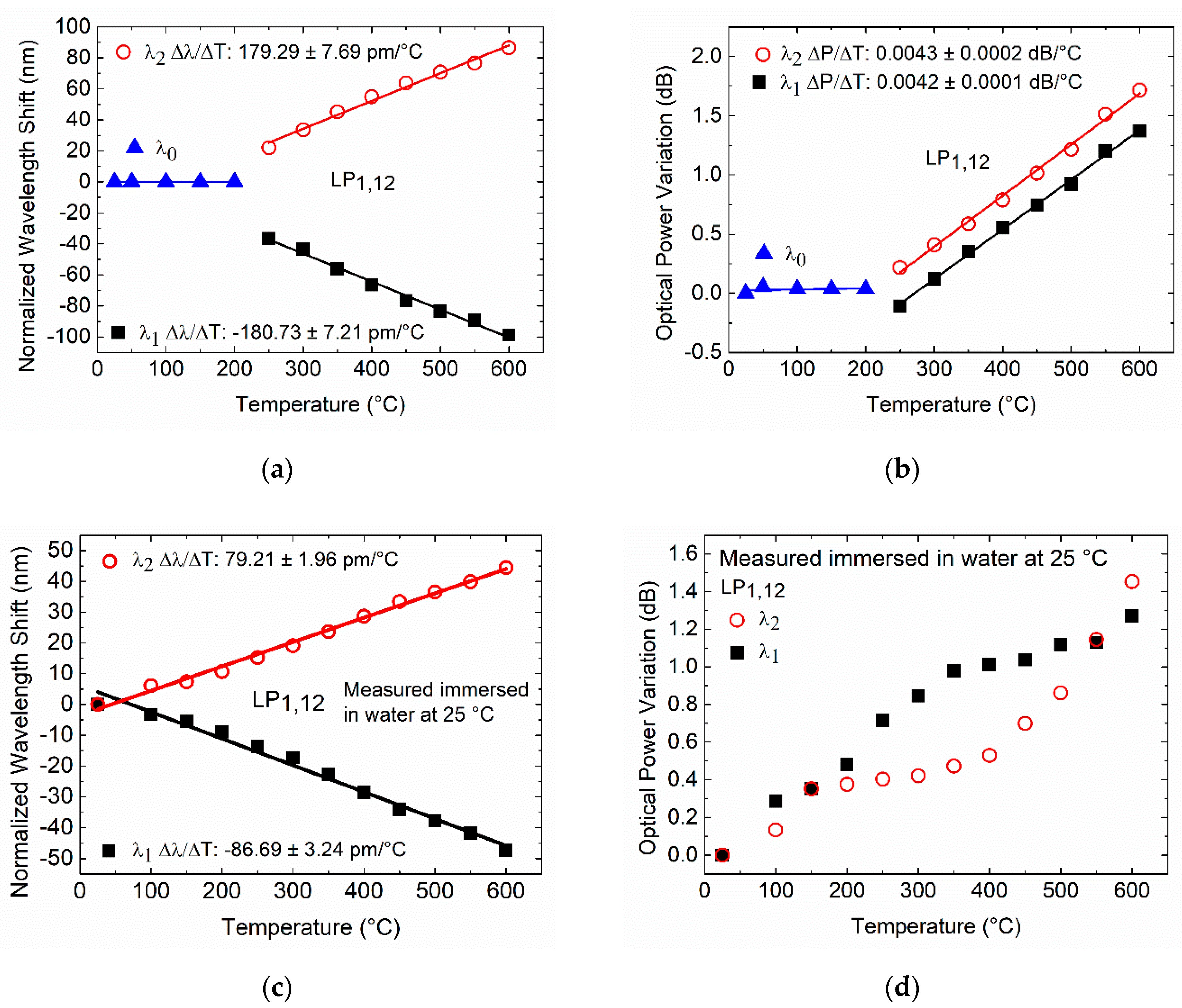

4.2. Temperature Characterization

4.2.1. Long Period Fiber Gratings

4.2.2. Turn Around Point Long-Period Fiber Gratings

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- James, S.W.; Tatam, R.P. Optical fibre long–period grating sensors: Characteristics and application. Meas. Sci. Technol. 2003, 14, R49. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Luo, M.; Ji, Q. Sensing characteristics of femtosecond laser–induced long period gratings by filling cladding holes in photonic crystal fiber. J. Light Technol. 2014, 32, 2287–2292. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, P.; Qiao, D.; Xi, Y.; Zhu, Y.; Xu, Q.; Wang, C. Sensing characteristics of long period grating by writing directly in SMF–28 based on 800 nm femtosecond laser pulses. Opt. Laser Technol. 2020, 121. [Google Scholar] [CrossRef]

- Wolf, A.A.; Dostovalov, A.V.; Lobach, I.A.; Babin, S.A. Femtosecond Laser Inscription of Long–Period Fiber Gratings in a Polarization–Maintaining Fiber. J. Light. Technol. 2015, 33, 5178–5183. [Google Scholar] [CrossRef]

- Schlangen, S.; Bremer, K.; Zheng, Y.; Böhm, S.; Steinke, M.; Wellmann, F.; Neumann, J.; Roth, B.; Overmeyer, L. Long-period gratings in highly germanium–doped, single–mode optical fibers for sensing applications. Sensors 2018, 18, 1363. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kalachev, A.I.; Nikogosyan, D.N.; Brambilla, G. Long–period fiber grating fabrication by high–intensity femtosecond pulses at 211 nm. J. Light. Technol. 2005, 23, 2568–2578. [Google Scholar] [CrossRef]

- Viveiros, D.; de Almeida, J.M.M.M.; Coelho, L.; Vasconcelos, H.; Amorim, V.A.; Maia, J.M.; Jorge, P.A.S.; Marques, P.V.S. Femtosecond laser-written long period fibre gratings coated with titanium dioxide for improved sensitivity. In Proceedings of the Optical Sensing and Detection VI., International Society for Optics and Photonics, Online forum, 6–10 April 2020; Volume 11354, p. 113540C. [Google Scholar]

- Shen, F.; Zhou, K.; Zhang, L.; Shu, X. Long period fiber grating around the dispersion turning point fabricated with a femtosecond laser. In Proceedings of the Asia Communications and Photonics Conference (ACP), Guangzhou, China, 10–13 November 2017. [Google Scholar]

- Biswas, P.; Basumallick, N.; Bandyopadhyay, S.; Dasgupta, K.; Ghosh, A.; Bandyopadhyay, S. Sensitivity enhancement of turn-around–point long period gratings by tuning initial coupling condition. IEEE Sens. J. 2015, 15, 1240–1245. [Google Scholar] [CrossRef]

- Gambhir, M.; Gupta, S. Review of Turn around Point Long Period Fiber Gratings. J. Sens. Technol. 2015, 5, 81–89. [Google Scholar] [CrossRef] [Green Version]

- Del Villar, I.; Fuentes, O.; Chiavaioli, F.; Corres, J.M.; Matias, I.R. Optimized strain long–period fiber grating (LPFG) sensors operating at the dispersion turning point. J. Light. Technol. 2018, 36, 2240–2247. [Google Scholar] [CrossRef]

- Gambhir, M.; Gupta, S. Sensitivity analysis of phase matched turning point long period fiber gratings. Lect. Notes Inst. Comput. Sci. Soc. Telecommun. Eng. 2018, 220, 247–253. [Google Scholar]

- Shu, X.; Zhang, L.; Bennion, I. Sensitivity characteristics of long–period fiber gratings. J. Light. Technol. 2002, 20, 255–266. [Google Scholar]

- Lan, X.; Han, Q.; Wei, T.; Huang, J.; Xiao, H. Turn–Around-Point Long–Period Fiber Gratings Fabricated by CO Laser Point-by-Point Irradiations. IEEE Photonics Technol. Lett. 2011, 23, 1664–1666. [Google Scholar] [CrossRef]

- Lan, X.; Han, Q.; Huang, J.; Wang, H.; Gao, Z.; Kaur, A.; Xiao, H. Turn–around point long-period fiber grating fabricated by CO2 laser for refractive index sensing. Sens. Actuators B Chem. 2013, 177, 1149–1155. [Google Scholar] [CrossRef]

- Wong, R.Y.N.; Chehura, E.; Staines, S.E.; James, S.W.; Tatam, R.P. Fabrication of fiber optic long period gratings operating at the phase matching turning point using an ultraviolet laser. Appl. Opt. 2014, 53, 4669–4674. [Google Scholar] [CrossRef]

- Nespereira, M.; Coelho, J.M.P.; Abreu, M.; Rebordão, J.M. Ultrashort Long-Period Fiber Grating Sensors Inscribed on a Single Mode Fiber Using CO2 Laser Radiation. J. Sens. 2017, 2017, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Rego, G.; Ivanov, O.V.; Marques, P.V.S. Demonstration of coupling to symmetric and antisymmetric cladding modes in arc-induced long-period fiber gratings. Opt. Express 2006, 14, 9594–9599. [Google Scholar] [CrossRef] [PubMed]

- Colaço, C.; Caldas, P.; Del Villar, I.; Chibante, R.; Rego, G. Arc-induced long-period fiber gratings in the dispersion turning points. J. Light. Technol. 2016, 34, 4584–4590. [Google Scholar] [CrossRef]

- Del Villar, I.; Partridge, M.; Rodriguez, W.E.; Fuentes, O.; Socorro, A.B.; Diaz, S.; Corres, J.M.; James, S.W.; Tatam, R.P. Sensitivity enhancement in low cutoff wavelength long–period fiber gratings by cladding diameter reduction. Sensors 2017, 17, 2094. [Google Scholar] [CrossRef] [Green Version]

- Viveiros, D.; de Almeida, J.M.M.M.; Coelho, L.; Vasconcelos, H.; Amorim, V.A.; Maia, J.M.; Jorge, P.A.S.; De Almeida, J.M.M.M.; Coelho, L.; Vasconcelos, H. Spectral Tuning of Long Period Fiber Gratings Fabricated by Femtosecond Laser Micromachining through Thermal Annealing. In Proceedings of the Multidisciplinary Digital Publishing Institute, Napoli, Italy, 9–11 May 2019; Volume 15, p. 4. [Google Scholar]

- Zhang, C.; Cheng, L.; Fu, S.; Tang, M.; Liu, D. Long Period Fiber Grating Fabrication by Two–Step Infrared Femtosecond Fiber Laser Exposure. IEEE Photonics J. 2017, 9, 1–7. [Google Scholar] [CrossRef]

- Liu, Y.; Qu, S. Femtosecond laser pulses induced ultra–long–period fiber gratings for simultaneous measurement of high temperature and refractive index. Optik 2013, 124, 1303–1306. [Google Scholar] [CrossRef]

- Tang, J.; Fu, C.; Bai, Z.; Liao, C.; Wang, Y. Sensing characteristics of tilted long period fiber gratings inscribed by infrared femtosecond laser. Sensors 2018, 18, 3003. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- MacDougall, T.W.; Pilevar, S.; Haggans, C.W.; Jackson, M.A. Generalized expression for the growth of long period gratings. IEEE Photonics Technol. Lett. 1998, 10, 1449–1451. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings, 2nd ed.; Academic Press: Cambridge, MA, USA, 2010. [Google Scholar]

- Grubsky, V.; Feinberg, J. Long–period fiber gratings with variable coupling for real-time sensing applications. Opt. Lett. 2000, 25, 203–205. [Google Scholar] [CrossRef] [PubMed]

- Kryukov, P.G.; Larionov, Y.V.; Rybaltovskii, A.A.; Zagorul’ko, K.A.; Dragomir, A.; Nikogosyan, D.N.; Ruth, A.A. Long–period fibre grating fabrication with femtosecond pulse radiation at different wavelengths. Microelectron. Eng. 2003, 69, 248–255. [Google Scholar] [CrossRef]

- Vainos, N.A. Laser Growth and Processing of Photonic Devices, 1st ed.; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- Mihailov, S.J. Femtosecond Laser-Inscribed Fiber Bragg Gratings for Sensing Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2018. [Google Scholar]

| LPFGs Number | Mode | (µm) | λres (nm) | Intensity (dB) | FWHM (nm) |

|---|---|---|---|---|---|

| 1 | LP1,6 | 372.5 | 1494.97 | −11.86 | 11.97 |

| 2 | 1495.04 | −11.71 | 12.63 | ||

| 3 | LP1,12 | 182.7 | 1385.45 | −9.76 | 64.54 |

| 4 | 1385.43 | −11.17 | 65.55 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viveiros, D.; de Almeida, J.M.M.M.; Coelho, L.; Vasconcelos, H.; Maia, J.M.; Amorim, V.A.; Jorge, P.A.S.; Marques, P.V.S. Temperature Stability and Spectral Tuning of Long Period Fiber Gratings Fabricated by Femtosecond Laser Direct Writing. Sensors 2020, 20, 3898. https://doi.org/10.3390/s20143898

Viveiros D, de Almeida JMMM, Coelho L, Vasconcelos H, Maia JM, Amorim VA, Jorge PAS, Marques PVS. Temperature Stability and Spectral Tuning of Long Period Fiber Gratings Fabricated by Femtosecond Laser Direct Writing. Sensors. 2020; 20(14):3898. https://doi.org/10.3390/s20143898

Chicago/Turabian StyleViveiros, Duarte, José M. M. M. de Almeida, Luís Coelho, Helena Vasconcelos, João M. Maia, Vítor A. Amorim, Pedro A. S. Jorge, and Paulo V. S. Marques. 2020. "Temperature Stability and Spectral Tuning of Long Period Fiber Gratings Fabricated by Femtosecond Laser Direct Writing" Sensors 20, no. 14: 3898. https://doi.org/10.3390/s20143898