Nondestructive Determination of Strength of Concrete Incorporating Industrial Wastes as Partial Replacement for Fine Aggregate

Abstract

:1. Introduction

Novelty/Contribution to Knowledge

2. Materials and Methods

2.1. Materials

2.2. Physical Properties of Materials

2.3. Chemical Properties of Materials

2.4. Mix Design

2.5. Rebound Hammer Test on Concrete

3. Results and Discussion

3.1. Compressive Strength of Concrete

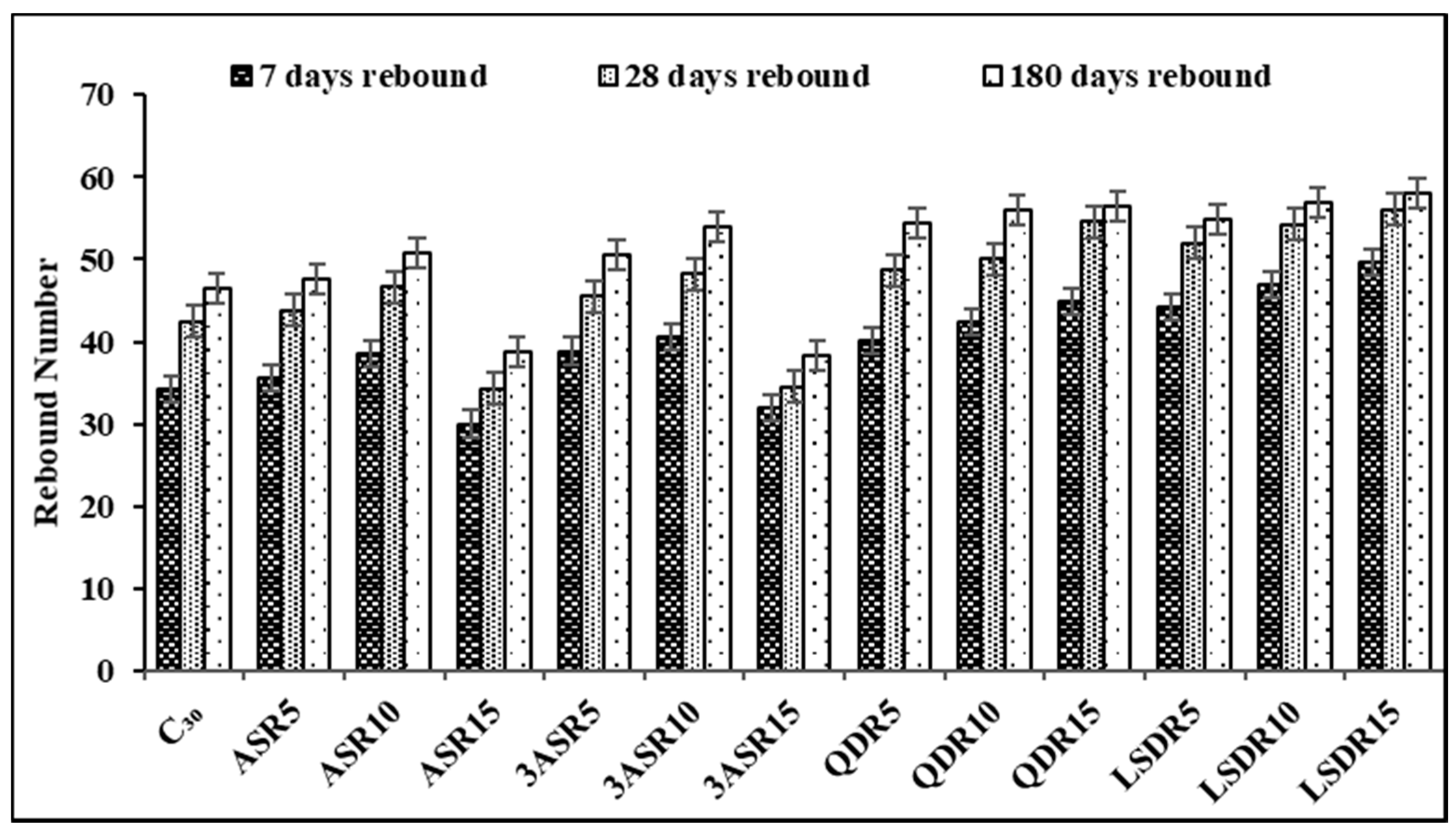

3.2. Effect of Industrial Waste Materials on Rebound Hammer Numbers

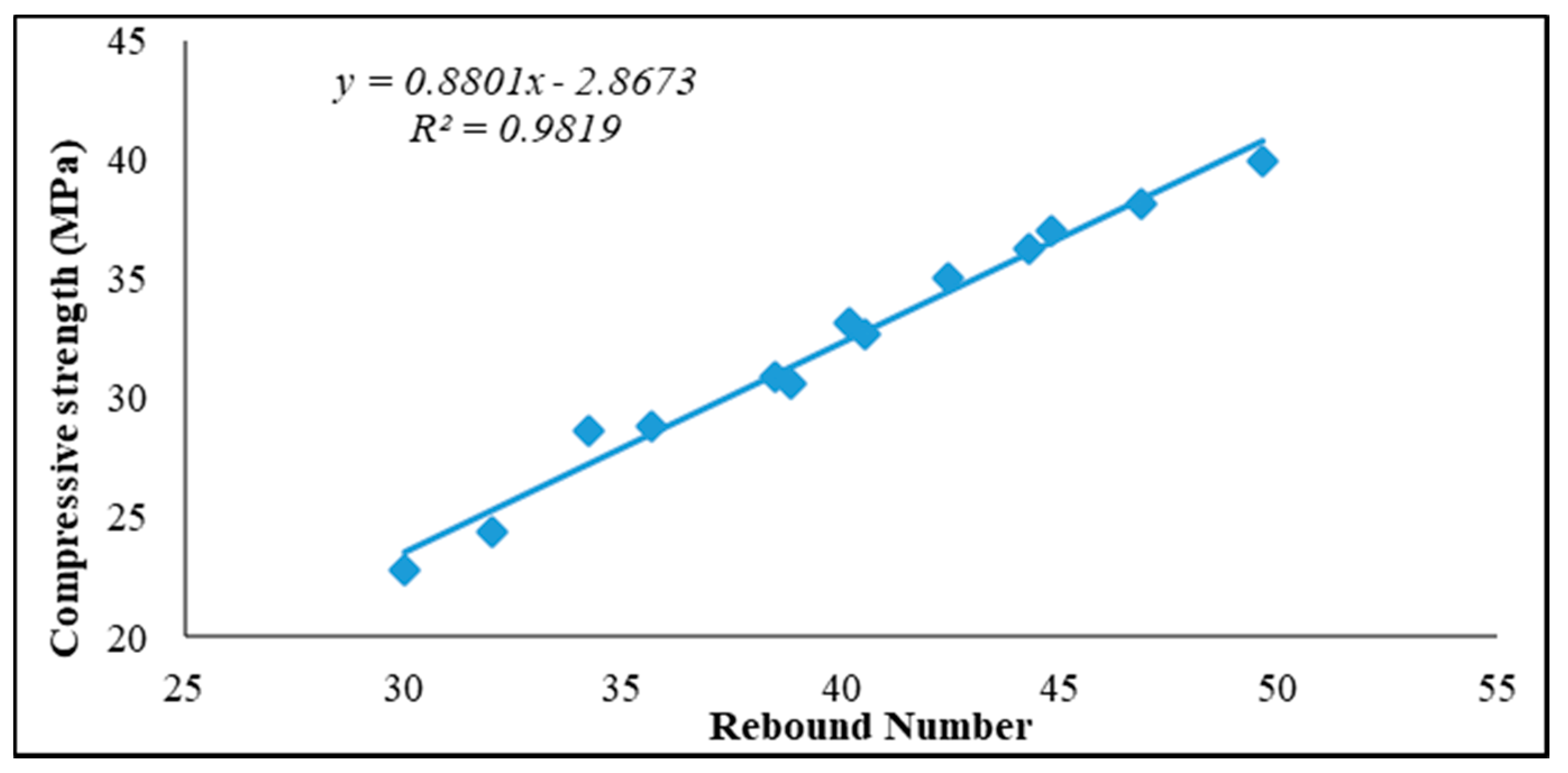

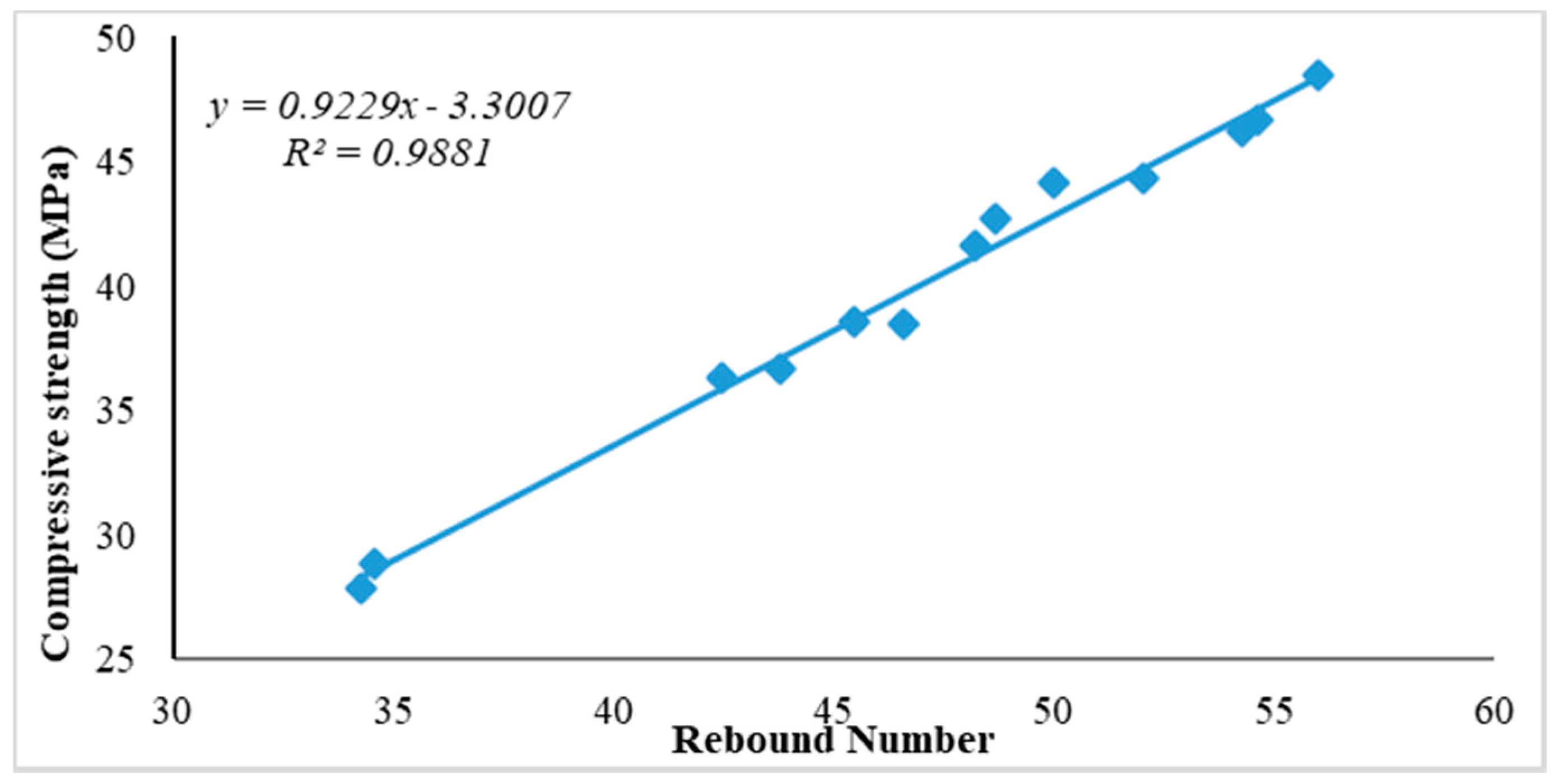

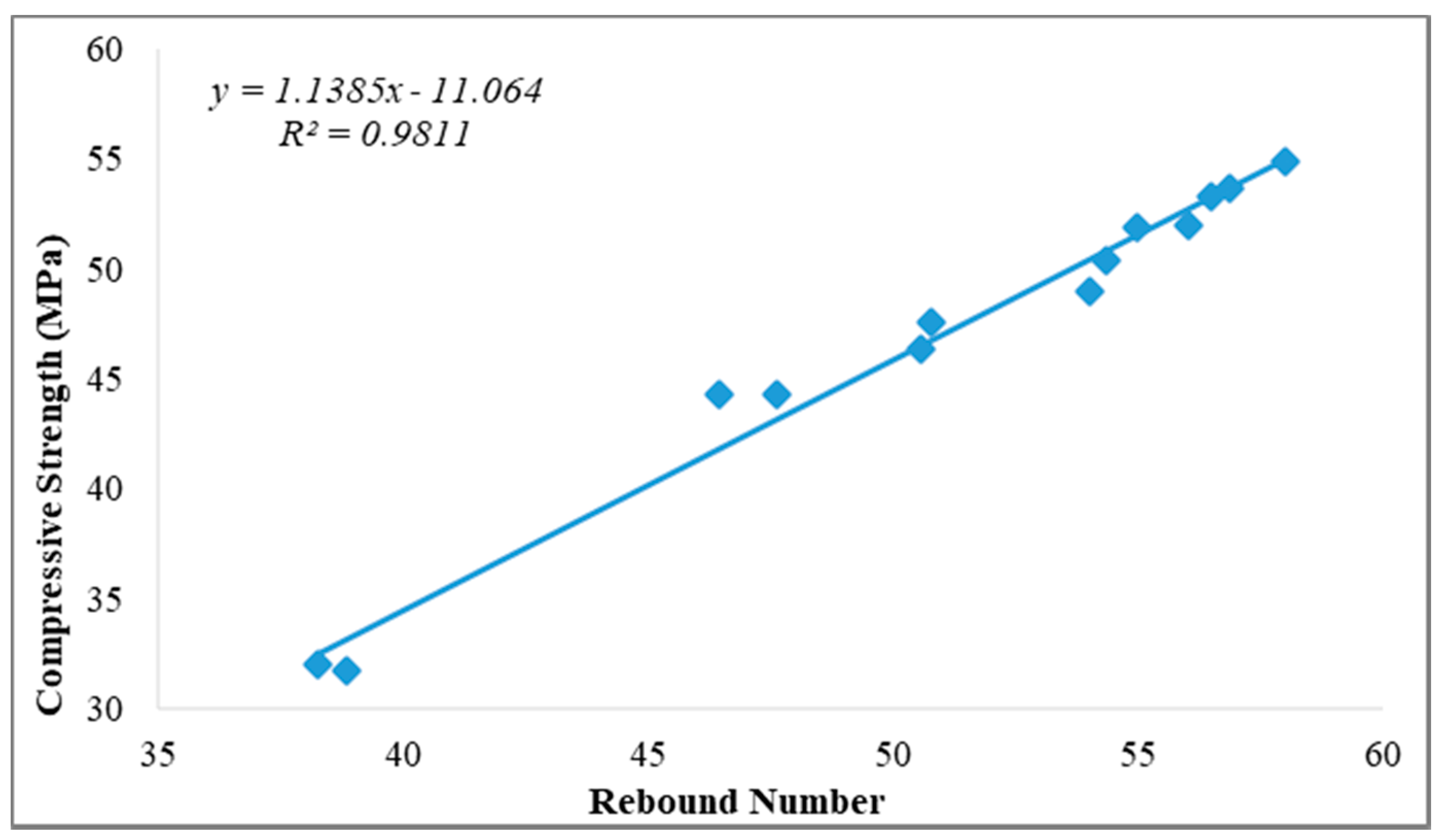

Relationship between Compressive Strength and Rebound Number

4. Conclusions

- All industrial waste materials employed in this study have proved to be good materials for the replacement of fine aggregate in concrete production up to long-term curing age (180 days). Among all the replacement materials, concrete produced with alum sludge waste from a drinking water treatment plant demonstrated impressive results in both destructive and nondestructive test methods.

- The Schmidt rebound number increases with an increase in industrial waste material and as percentage replacement content of concrete increases. The study also showed that the rebound number value progressively increases with an increase in curing age.

- The use of Schmidt rebound number for prediction and estimation of compressive strength yields values that are similar to the conventional concrete compressive strength values in this study. Hence, the Schmidt rebound number of the nondestructive test method is a reliable test method for the prediction of compressive strength of concrete.

- The proposed correlation showed an excellent relationship between rebound number and compressive strength of concrete produced in this study at all curing ages, with correlation coefficients of R2 = 0.98, R2 = 0.99 and R2 = 0.98. Thus, it can be used for the prediction of the compressive strength of concrete.

Limitations and Future Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schmidt, E. A non-destructive concrete tester. Concrete 1951, 59, 34–35. [Google Scholar]

- Snell, L.M. Using the rebound hammer. In Proceedings of the 11th Annual Mongolian Concrete Conference, Ulaanbaatar, Mongolia, 15 June 2012. [Google Scholar]

- Roknuzzaman, M.; Hossain, M.B.; Mostazid, M.I.; Haque, R.M. Application of rebound hammer method for estimating compressive strength of bricks. J. Civ. Eng. Res. 2017, 7, 99–104. [Google Scholar] [CrossRef]

- Jobli, A.F.; Hampden, A.; Tawie, R. The role of ultrasonic velocity and schmidt hammer hardness—The simple and economical non-destructive test for the evaluation of mechanical properties of weathered granite. In Proceedings of the International Conference on Applied Physics and Engineering (ICAPE2016), Penang, Malaysia, 2–3 November 2016. [Google Scholar]

- Mohammed, B.S.; Azmi, N.J.; Abdullahi, M. Evaluation of rubbercrete based on ultrasonic pulse velocity and rebound hammer tests. Constr. Build. Mater. 2011, 25, 1388–1397. [Google Scholar] [CrossRef]

- Aguwamba, J.C.; Adagba, T. A comparative analysis of the rebound hammer and ultrasonic pulse velocity in testing concrete. Niger. J. Technol. 2012, 31, 31–39. [Google Scholar]

- Mandal, T.; Tinjumb, J.M.; Tuncer, B.; Edil, T.B. Non-destructive testing of cementitiously stabilized materials using ultrasonic pulse velocity test. Transp. Geotech. 2016, 6, 97–107. [Google Scholar] [CrossRef]

- John, T.; Petro, J.; Kim, J. Detection of delamination in concrete using ultrasonic pulse velocity test. Constr. Build. Mater. 2012, 26, 574–582. [Google Scholar]

- Hassan, M.; Burdet, O.; Favre, R. Ultrasonic measurements and static load tests in bridge evaluation. NDTE Int. 2005, 28, 331–337. [Google Scholar] [CrossRef]

- Kaish, A.B.M.A.; Temple, C.O.; Ideris, Z.; Manal, M.A.; Lutfun, N. Properties of concrete incorporating alum sludge in different conditions as partial replacement of fine aggregate. Constr. Build. Mater. 2021, 284, 122669. [Google Scholar] [CrossRef]

- Selçuk, L.; Nar, A. Prediction of uniaxial compressive strength of intact rocks using ultrasonic pulse velocity and rebound-hammer number. Q. J. Eng. Geol. Hydrogeol. 2015, 49, 67–75. [Google Scholar] [CrossRef]

- Karpuz, C.; Pasamehmetoglu, A.G. Field characterization of weathered Ankara andezites. Eng. Geol. 1977, 46, 1–17. [Google Scholar] [CrossRef]

- Karaman, K.; Ercikdi, B.; Cihangir, F.; Kesimal, A. Examining the Schmidt hammer methods in Estimating of the uniaxial compressive strength. In Proceedings of the 22nd International Mining Congress of Turkey, Ankara, Turkey, 11–13 May 2011; pp. 87–94. [Google Scholar]

- Karaman, K.; Ayhan, K. A comparative study of Schmidt hammer test methods for estimating the uniaxial compressive strength of rocks. Bull. Eng. Geol. Environ. 2015, 74, 507–520. [Google Scholar] [CrossRef]

- Arslan, M.; Khan, M.S.; Yaqub, M. Prediction of durability and strength from Schmidt rebound hammer number for limestone rocks from Salt Range, Pakistan. J. Himal. Earth Sci. 2015, 48, 9–13. [Google Scholar]

- Yılmaz, I.; Sendir, H. Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng. Geol. 2002, 66, 211–219. [Google Scholar] [CrossRef]

- Shariati, M.; Ramli-Sulong, N.H.; Arabnejad, M.M.; Shafigh, P.; Sinaei, H. Assessing the strength of reinforced concrete structures through Ultrasonic Pulse Velocity and Schmidt Rebound Hammer tests. Sci. Res. Essays 2011, 6, 213–220. [Google Scholar]

- Sanchez, K.; Tarranza, N.I. Reliability of rebound hammer test in concrete compressive strength estimation. Int. J. Adv. Agric. Environ. Eng. 2014, 1, 198–202. [Google Scholar]

- Sadevicius, R.; Sankauskiene, T.; Milius, P. Comparison of concrete compressive strength values obtained using rebound hammer and drilled core specimens. In Proceedings of the 7th International Scientific Conference, Kaunas, Lithuania, 19–20 November 2015. [Google Scholar]

- Kurtulus, C.; Sertçelik, F.; Sertçel, I. Estimation of unconfined uniaxial compressive strength using Schmidt hardness and ultrasonic pulse velocity. Tech. Gaz. 2018, 25, 1569–1574. [Google Scholar] [CrossRef] [Green Version]

- Samson, D.; Moses, O.T. Correlation between non-destructive testing (NDT) and destructive testing (DT) of compressive strength of concrete. Int. J. Eng. Sci. Invent. 2014, 3, 12–17. [Google Scholar]

- Rahmouni, A.; Boulanouar, A.; Boukalouch, M.; Géraud, Y.; Samaouali, A.; Harnafi, M.; Sebbani, J. Prediction of porosity and density of calcarenite rocks from P-wave velocity measurements. Int. J. Geosci. 2013, 4, 1292–1299. [Google Scholar] [CrossRef] [Green Version]

- Aydın, F.; Sarıbıyık, M. Compressive strength of various ages concretes by non-destructive test methods. Sci. Res. Essays 2010, 5, 1644–1648. [Google Scholar]

- Khan, M.N.; Jamil, M.; Karim, M.; Zain, M.; Kaish, A. Filler effect of pozzolanic materials on the strength and microstructure development of mortar. KSCE J. Civ. Eng. 2017, 21, 274–284. [Google Scholar] [CrossRef]

- Liu, J.C.; Sue, M.L.; Kou, C.H. Estimating the strength of concrete using surface rebound value and design parameters of concrete material. Tamkang J. Sci. Eng. 2009, 12, 1–7. [Google Scholar]

- Aliabdo, E.A.; Elmoaty, A.E. Reliability of using nondestructive tests to estimate compressive strength of building stones and bricks. Alex. Eng. J. 2012, 51, 193–203. [Google Scholar] [CrossRef] [Green Version]

- Owaid, H.M.; Roszilah, H.; Taha, M.R. Durability properties of multiple-blended binder concretes incorporating thermally activated alum sludge ash. Constr. Build. Mater. 2019, 200, 591–603. [Google Scholar] [CrossRef]

- Nur Quraatu’Aini, M.R.; Hamid, R. Mechanical properties of lightweight alum sludge aggregate concrete. Appl. Mech. Mater. 2015, 754–755, 413–416. [Google Scholar]

- Hamid, N.A.; Kadir, A.A.; Kamil, N.F.; Hassan, M.H. Overview on the utilization of quarry dust as a replacement material in construction industry. Int. J. Integr. Eng. 2018, 10, 112–117. [Google Scholar]

- Breesem, K.M.; Abood, M.M.; Rahman, N.A. Influence of magnesium sulfate on self-compacting alum sludge concrete incorporating with pozzolanic materials. Mod. Appl. Sci. 2016, 10, 187–197. [Google Scholar] [CrossRef] [Green Version]

- Kaish, A.M.; Temple, C.O.; Ideris, Z.; Manal, M.A. Effects of different industrial waste materials as partial replacement of fine aggregate on strength and microstructure properties of concrete. J. Build. Eng. 2021, 35, 102092. [Google Scholar] [CrossRef]

- Meisuh, B.K.; Kankam, C.K.; Buabin, T.K. Effect of quarry rock dust on the flexural strength of concrete. Case Stud. Constr. Mater. 2018, 8, 16–22. [Google Scholar] [CrossRef]

- Lohani, T.K.; Padhi, M.; Dash, K.P.; Jena, S. Optimum utilization of quarry dust as partial replacement of sand in concrete. Int. J. Appl. Sci. Eng. 2012, 1, 2391–2404. [Google Scholar]

- Prakash, K.S.; Rao, C.H. Study on compressive strength of quarry dust as fine aggregate in concrete. Adv. Civ. Eng. 2016, 5, 1742769. [Google Scholar] [CrossRef] [Green Version]

- Sravani, T.; Anitha, A.; Kumar, D.S. Experimental studies on concrete replacing fine aggregate with quarry dust wastes. Int. J. Prog. Civ. Eng. 2014, 1, 1–4. [Google Scholar]

- Subramanian, K.; Kannan, A. An experimental study on usage of quarry dust as partial replacement for sand in concrete and mortar. Aust. J. Basic Appl. Sci. 2013, 7, 955–967. [Google Scholar]

- Omar, M.O.; AbdElhameed, G.D.; Sherif, M.A.; Mohamadien, H.A. Influence of limestone waste as partial replacement material for sand and marble powder in concrete properties. Hous. Build. Natl. Res. Cent. J. 2012, 8, 193–203. [Google Scholar] [CrossRef] [Green Version]

- ASTM. Standard Specification for Portland Cement; ASTM International: West Conshocken, PA, USA, 2020. [Google Scholar]

- BS. Specification for Aggregates from Natural Sources for Concrete; British Standards Institution: London, UK, 1992. [Google Scholar]

- ASTM C33/C33M-18. Standard Specification for Concrete Aggregate; ASTM International: West Conshocken, PA, USA, 2018. [Google Scholar]

- BS. Methods of Test for Water for Making Concrete; British Standards Institution: London, UK, 1980. [Google Scholar]

- Kaish, A.B.M.A.; Breesem, K.M.; Abood, M.M. Influence of pre-treated alum sludge on properties of high-strength self-compacting concrete. J. Clean. Prod. 2018, 202, 1085–1096. [Google Scholar] [CrossRef]

- BS. Concrete—Complementary British Standard to BS EN 206; British Standards Institution: London, UK, 2006. [Google Scholar]

- BS. Testing Concrete, Recommendations for Surface Hardness Testing by Rebound Hammer; British Standards Institution: London, UK, 1986. [Google Scholar]

- Liu, S.; Yan, P. Effect of limestone powder on microstructure of concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2009, 25. [Google Scholar] [CrossRef]

| Test | CA | FA | AA | TA | LS | QD |

|---|---|---|---|---|---|---|

| Specific gravity | 2.75 | 2.62 | 2.38 | 2.35 | 2.57 | 2.58 |

| Water absorption (%) | 0.54 | 0.76 | 12.52 | 12.5 | 1 | 1.10 |

| Samples | SiO2% | Al2O3% | CaO% | Fe2O3% | Na2O% | K2O% | MgO% | MnO% | TiO2% |

|---|---|---|---|---|---|---|---|---|---|

| FA | 80.96 | 11.62 | 3.58 | 1.78 | 1.43 | 1.21 | 0.77 | 0.05 | - |

| AA | 41.98 | 33.09 | 0.43 | 5.05 | 0.06 | 1.83 | 0.31 | 0.03 | 0.58 |

| TA | 42.74 | 33.28 | 0.43 | 4.91 | - | 1.88 | 0.32 | 0.02 | 0.6 |

| LS | 13.7 | 4.8 | 77.8 | 3.5 | 0.9 | 0.13 | 1.2 | - | - |

| QD | 66.8 | 17.82 | 0.84 | 12.62 | - | 2.12 | 4.27 | - | - |

| S/N | OPC | Coarse Agg. | Fine Agg | Air-Dried Alum Sludge | Treated Alum Sludge | Lime Stone | Quarry Dust | W/C |

|---|---|---|---|---|---|---|---|---|

| C30 | 410 | 1022 | 679 | 0 | 0 | 0 | 0 | 0.52 |

| AASR5 | 410 | 1022 | 648 | 34 | 0 | 0 | 0 | 0.52 |

| AASR10 | 410 | 1022 | 614 | 68 | 0 | 0 | 0 | 0.52 |

| AASR15 | 410 | 1022 | 580 | 102 | 0 | 0 | 0 | 0.52 |

| TASR5 | 410 | 1022 | 648 | 0 | 34 | 0 | 0 | 0.52 |

| TASR10 | 410 | 1022 | 614 | 0 | 68 | 0 | 0 | 0.52 |

| TASR15 | 410 | 1022 | 580 | 0 | 102 | 0 | 0 | 0.52 |

| LSDR5 | 410 | 1022 | 648 | 0 | 0 | 34 | 0 | 0.52 |

| LSDR10 | 410 | 1022 | 614 | 0 | 0 | 68 | 0 | 0.52 |

| LSDR15 | 410 | 1022 | 580 | 0 | 0 | 102 | 0 | 0.52 |

| QDR5 | 410 | 1022 | 648 | 0 | 0 | 0 | 34 | 0.52 |

| QDR10 | 410 | 1022 | 614 | 0 | 0 | 0 | 68 | 0.52 |

| QDR15 | 410 | 1022 | 580 | 0 | 0 | 0 | 102 | 0.52 |

| Average Rebound Number | Quality of Concrete |

|---|---|

| More than 40 | Very Good Hard Layer |

| 30 to 40 | Good layer |

| 20 to 30 | Fair |

| Less than 20 | Poor Concrete |

| 0 | Delamination |

| Experimental (MPa) | Theoretical Results Obtained from Proposed Formulas by (Rnt) | Theoretical/Experimental (Rnt/fc) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S/N | Rn | fc | Equation (1) | Equation (2) | Equation (3) | Equation (4) | Equation (5) | Equation (1) | Equation (2) | Equation (3) | Equation (4) | Equation (5) |

| C30 | 42.45 | 36.36 | 28.94 | 30.43 | 28.22 | 32.69 | 35.88 | 0.79 | 0.83 | 0.78 | 0.9 | 0.98 |

| AASR5 | 43.8 | 36.64 | 30.02 | 33.04 | 29.28 | 33.80 | 37.13 | 0.82 | 0.90 | 0.80 | 0.92 | 1.01 |

| AASR10 | 46.6 | 38.46 | 31.78 | 38.46 | 31.47 | 36.11 | 39.71 | 0.83 | 1.0 | 0.82 | 0.93 | 1.03 |

| AASR15 | 34.25 | 27.84 | 22.38 | 14.58 | 21.79 | 25.93 | 28.30 | 0.80 | 0.52 | 0.78 | 0.93 | 1.01 |

| TASR5 | 45.45 | 38.53 | 31.34 | 36.23 | 30.57 | 35.17 | 38.65 | 0.81 | 0.94 | 0.79 | 0.91 | 1.00 |

| TASR10 | 48.2 | 41.61 | 33.54 | 41.55 | 32.72 | 37.43 | 41.19 | 0.81 | 0.99 | 0.78 | 0.90 | 0.99 |

| TASR15 | 34.55 | 28.88 | 22.62 | 15.16 | 22.03 | 26.17 | 28.60 | 0.78 | 0.52 | 0.76 | 0.91 | 0.99 |

| QDR5 | 48.65 | 42.7 | 33.90 | 42.42 | 33.08 | 37.81 | 41.60 | 0.79 | 0.99 | 0.77 | 0.88 | 0.97 |

| QDR10 | 50 | 44.11 | 34.98 | 45.03 | 34.14 | 38.92 | 42.85 | 0.79 | 1.02 | 0.77 | 0.88 | 0.97 |

| QDR15 | 54.6 | 46.67 | 38.66 | 53.92 | 37.75 | 42.71 | 47.09 | 0.83 | 1.15 | 0.81 | 0.91 | 1.00 |

| LSDR5 | 52 | 44.31 | 36.58 | 48.90 | 35.71 | 40.57 | 44.69 | 0.82 | 1.10 | 0.80 | 0.91 | 1.00 |

| LSDR10 | 54.25 | 46.24 | 38.38 | 53.24 | 37.47 | 42.43 | 46.77 | 0.83 | 1.15 | 0.81 | 0.92 | 1.01 |

| LSDR15 | 56 | 48.43 | 39.78 | 56.63 | 38.84 | 43.87 | 48.39 | 0.82 | 1.17 | 0.80 | 0.91 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Odimegwu, T.C.; Kaish, A.B.M.A.; Zakaria, I.; Abood, M.M.; Jamil, M.; Ngozi, K.-O. Nondestructive Determination of Strength of Concrete Incorporating Industrial Wastes as Partial Replacement for Fine Aggregate. Sensors 2021, 21, 8256. https://doi.org/10.3390/s21248256

Odimegwu TC, Kaish ABMA, Zakaria I, Abood MM, Jamil M, Ngozi K-O. Nondestructive Determination of Strength of Concrete Incorporating Industrial Wastes as Partial Replacement for Fine Aggregate. Sensors. 2021; 21(24):8256. https://doi.org/10.3390/s21248256

Chicago/Turabian StyleOdimegwu, Temple Chimuanya, A. B. M. Amrul Kaish, Ideris Zakaria, Manal Mohsen Abood, Maslina Jamil, and Kayode-Ojo Ngozi. 2021. "Nondestructive Determination of Strength of Concrete Incorporating Industrial Wastes as Partial Replacement for Fine Aggregate" Sensors 21, no. 24: 8256. https://doi.org/10.3390/s21248256