Robot Localisation Using UHF-RFID Tags: A Kalman Smoother Approach † †

Abstract

1. Introduction

2. Related Work

3. Materials and Methods

3.1. Signal Model

3.2. Filter Design

EKF Smoother

3.3. Experimental Setup

4. Results

4.1. Simulation Results

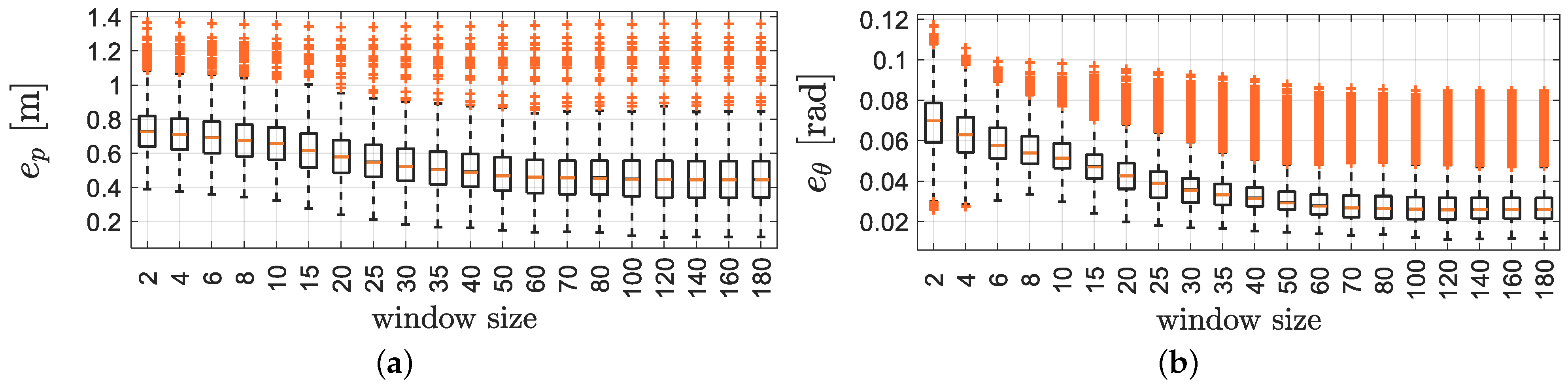

4.1.1. Optimal Window Length

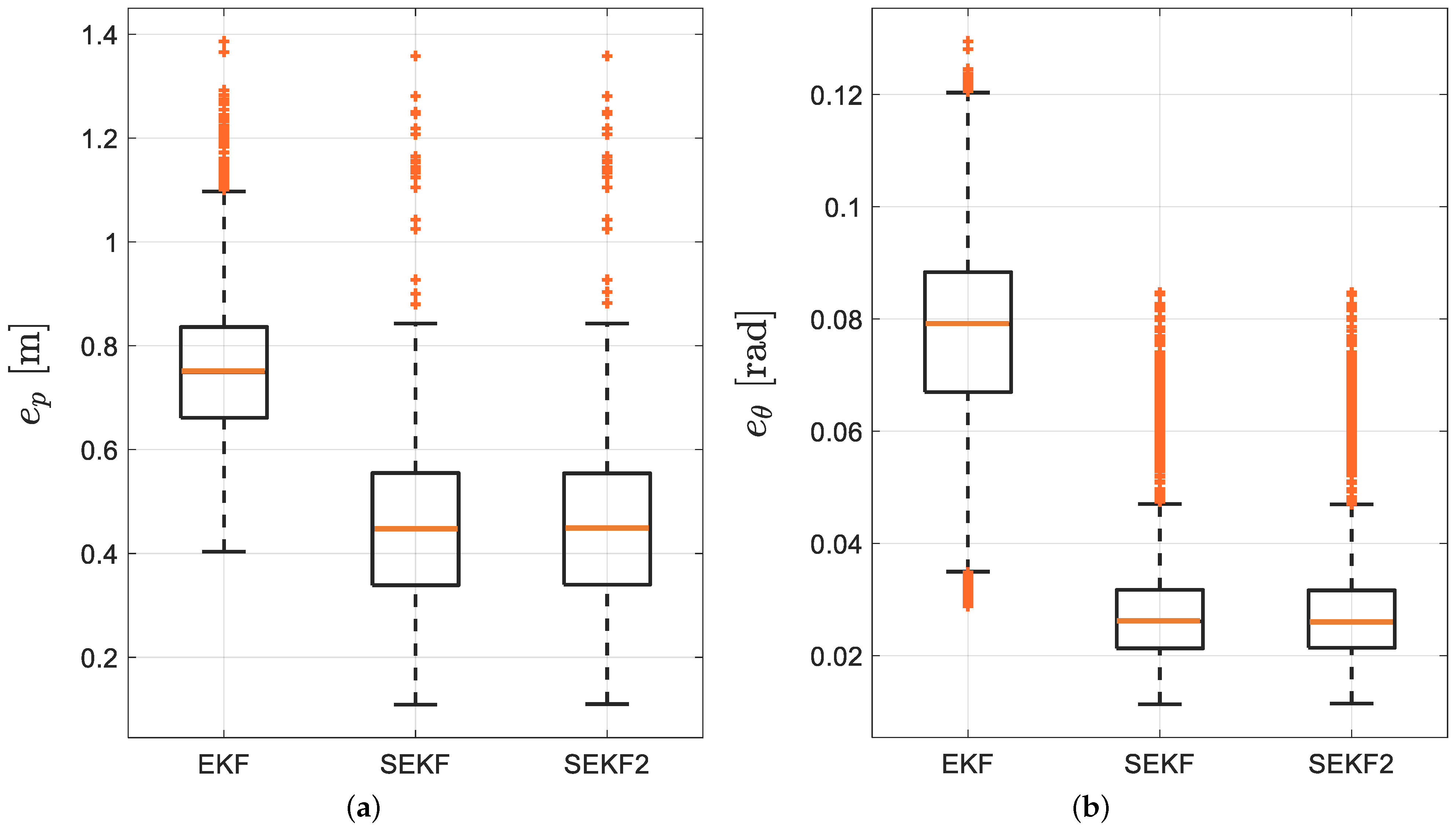

4.1.2. Comparative Analysis

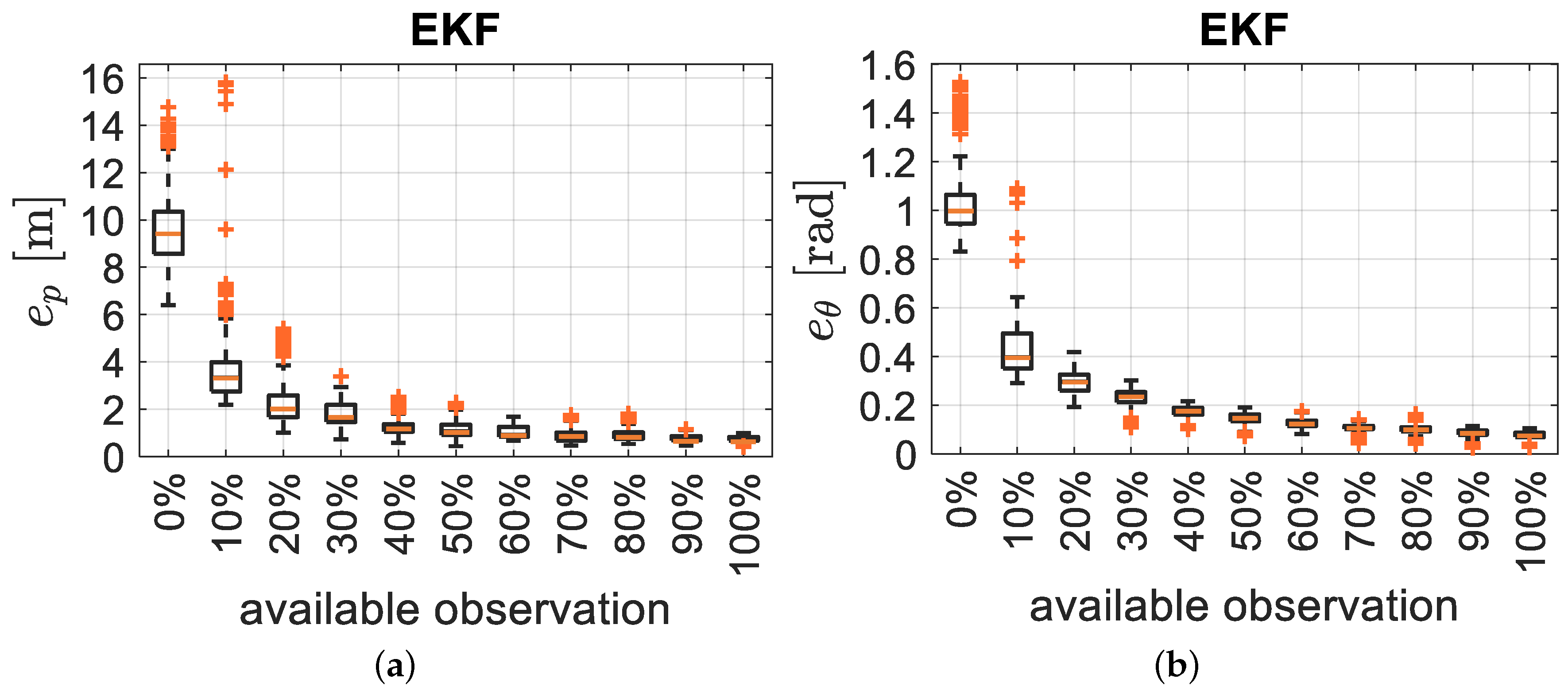

4.1.3. Filter Robustness

4.1.4. Vehicle Dynamic

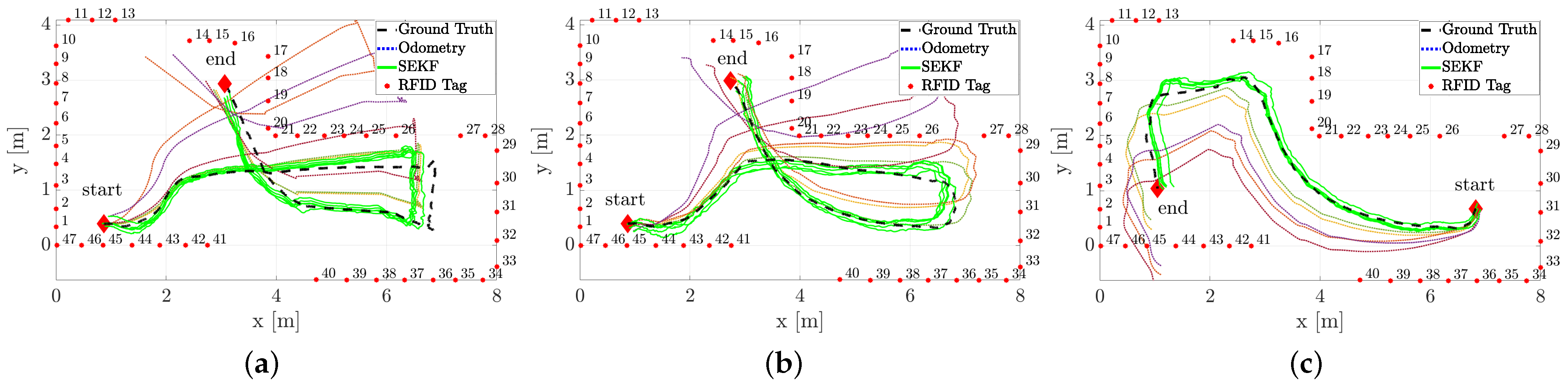

4.2. Experimental Results

5. Discussion

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| EKF | Extended Kalman Filter |

| EKF-RTS | Extended Kalman Filter Rauch-Tung-Striebel smoother |

| LiDAR | Laser Imaging Detection and Ranging |

| RF | Radio Frequency |

| RFID | Radio Frequency IDentification |

| SEKF | Fixed-lag Extended Kalman Filter Rauch-Tung-Striebel smoother |

| SEKF | Full-length Extended Kalman Filter Rauch-Tung-Striebel smoother |

| UHF | Ultra-High-Frequency |

| UKF | Unscented Kalman Filter |

| UWB | Ultra Wide Band |

References

- Drath, R.; Horch, A. Industrie 4.0: Hit or Hype? [Industry Forum]. IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Batalla, J.M.; Mavromoustakis, C.X.; Mastorakis, G.; Xiong, N.N.; Wozniak, J. Adaptive Positioning Systems Based on Multiple Wireless Interfaces for Industrial IoT in Harsh Manufacturing Environments. IEEE J. Sel. Areas Commun. 2020, 38, 899–914. [Google Scholar] [CrossRef]

- Kulyukin, V.; Kutiyanawala, A.; LoPresti, E.; Matthews, J.; Simpson, R. iWalker: Toward a Rollator-Mounted Wayfinding System for the Elderly. In Proceedings of the IEEE International Conference on RFID, Las Vegas, NV, USA, 16–17 April 2008; pp. 303–311. [Google Scholar]

- Nazemzadeh, P.; Moro, F.; Fontanelli, D.; Macii, D.; Palopoli, L. Indoor Positioning of a Robotic Walking Assistant for Large Public Environments. IEEE Trans. Instrum. Meas. 2015, 64, 2965–2976. [Google Scholar] [CrossRef]

- Gallant, M.J.; Marshall, J.A. Two-Dimensional Axis Mapping Using LiDAR. IEEE Trans. Robot. 2016, 32, 150–160. [Google Scholar] [CrossRef]

- Mautz, R.; Tilch, S. Survey of optical indoor positioning systems. In Proceedings of the International Conference on Indoor Positioning and Indoor Navigation (IPIN), Guimaraes, Portugal, 21–23 September 2011; pp. 1–7. [Google Scholar]

- Nazemzadeh, P.; Fontanelli, D.; Macii, D.; Palopoli, L. Indoor Localization of Mobile Robots through QR Code Detection and Dead Reckoning Data Fusion. IEEE/ASME Trans. Mechatron. 2017, 22, 2588–2599. [Google Scholar] [CrossRef]

- Ijaz, F.; Yang, H.K.; Ahmad, A.; Lee, C. Indoor positioning: A review of indoor ultrasonic positioning systems. In Proceedings of the 15th International Conference on Advanced Communication Technology (ICACT), PyeongChang, Korea, 27–30 January 2013; pp. 1146–1150. [Google Scholar]

- Li, C.; Mo, L.; Zhang, D. Review on UHF RFID Localization methods. IEEE J. Radio Freq. Identif. 2019, 3, 205–215. [Google Scholar] [CrossRef]

- Chen, P.; Xu, Y.B.; Chen, L.; Deng, Z.A. Survey of WLAN Fingerprinting Positioning System. Appl. Mech. Mater. 2013, 380, 2499–2505. [Google Scholar] [CrossRef]

- Giovanelli, D.; Farella, E.; Fontanelli, D.; Macii, D. Bluetooth-based Indoor Positioning through ToF and RSSI Data Fusion. In Proceedings of the International Conference on Indoor Positioning and Indoor Navigation (IPIN), Nantes, France, 24–27 September 2018; pp. 1–8. [Google Scholar]

- Jiménez Ruiz, A.R.; Seco Granja, F. Comparing Ubisense, BeSpoon, and DecaWave UWB Location Systems: Indoor Performance Analysis. IEEE Trans. Instrum. Meas. 2017, 66, 2106–2117. [Google Scholar] [CrossRef]

- Magnago, V.; Corbalán, P.; Picco, G.; Palopoli, L.; Fontanelli, D. Robot Localization via Odometry-assisted Ultra-wideband Ranging with Stochastic Guarantees. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and System (IROS), Macau, China, 3–8 November 2019. [Google Scholar]

- Motroni, A.; Nepa, P.; Magnago, V.; Buffi, A.; Tellini, B.; Fontanelli, D.; Macii, D. SAR-based Indoor Localization of UHF-RFID Tags via Mobile Robot. In Proceedings of the International Conference on Indoor Positioning and Indoor Navigation (IPIN), Nantes, France, 24–27 September 2018; pp. 1–8. [Google Scholar]

- Buffi, A.; Fontanelli, D.; Macii, D.; Magnago, V.; Motroni, A.; Nepa, P.; Tellini, B. UHF-RFID Localization: The Problem of Antenna Phase Center in Phase-based Methods. In Proceedings of the 2019 13th European Conference on Antennas and Propagation (EuCAP), Krakow, Poland, 31 March–5 April 2019; pp. 1–5. [Google Scholar]

- Sarkka, S.; Viikari, V.V.; Huusko, M.; Jaakkola, K. Phase-Based UHF RFID Tracking With Nonlinear Kalman Filtering and Smoothing. IEEE Sens. J. 2012, 12, 904–910. [Google Scholar] [CrossRef]

- Yang, L.; Cao, J.; Zhu, W.; Tang, S. Accurate and Efficient Object Tracking Based on Passive RFID. IEEE Trans. Mob. Comput. 2015, 14, 2188–2200. [Google Scholar] [CrossRef]

- Martinelli, F. Simultaneous Localization and Mapping Using the Phase of Passive UHF-RFID Signals. J. Intell. Robot. Syst. 2019, 94, 711–725. [Google Scholar] [CrossRef]

- Park, S.; Lee, H. Self-Recognition of Vehicle Position Using UHF Passive RFID Tags. IEEE Trans. Ind. Electron. 2013, 60, 226–234. [Google Scholar] [CrossRef]

- Motroni, A.; Buffi, A.; Nepa, P.; Tellini, B. Sensor-Fusion and Tracking Method for Indoor Vehicles with Low-Density UHF-RFID Tags. IEEE Trans. Instrum. Meas. 2020. [Google Scholar] [CrossRef]

- Bernardini, F.; Buffi, A.; Motroni, A.; Nepa, P.; Tellini, B.; Tripicchio, P.; Unetti, M. Particle Swarm Optimization in SAR-based Method enabling Real-Time 3D Positioning of UHF-RFID Tags. IEEE J. Radio Freq. Identif. 2020. [Google Scholar] [CrossRef]

- Motroni, A.; Buffi, A.; Nepa, P. A survey on Indoor Vehicle Localization through RFID Technology. IEEE Access 2020. [Google Scholar] [CrossRef]

- Duan, C.; Rao, X.; Yang, L.; Liu, Y. Fusing RFID and computer vision for fine-grained object tracking. In Proceedings of the IEEE INFOCOM 2017—IEEE Conference on Computer Communications, Atlanta, GA, USA, 1–4 May 2017; pp. 1–9. [Google Scholar] [CrossRef]

- Shamsfakhr, F.; Palopoli, L.; Fontanelli, D.; Motroni, A.; Buffi, A. Robot Localisation using UHF-RFID Tags for Industrial IoT Applications. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 IoT, Roma, Italy, 3–5 June 2020; pp. 659–664. [Google Scholar] [CrossRef]

- Motroni, A.; Nepa, P.; Buffi, A.; Tellini, B. A Phase-Based Method for Mobile Node Localization through UHF-RFID Passive Tags. In Proceedings of the 2019 IEEE International Conference on RFID Technology and Applications (RFID-TA), Pisa, Italy, 25–27 September 2019; pp. 470–475. [Google Scholar]

- Pomárico-Franquiz, J.J.; Shmaliy, Y.S. Accurate Self-Localization in RFID Tag Information Grids Using FIR Filtering. IEEE Trans. Ind. Inform. 2014, 10, 1317–1326. [Google Scholar] [CrossRef]

- Gueaieb, W.; Miah, M.S. Mobile robot navigation using particle swarm optimization and noisy RFID communication. In Proceedings of the 2008 IEEE International Conference on Computational Intelligence for Measurement Systems and Applications, Istanbul, Turkey, 14–16 July 2008; pp. 111–116. [Google Scholar] [CrossRef]

- Nikitin, P.V.; Martinez, R.; Ramamurthy, S.; Leland, H.; Spiess, G.; Rao, K.V.S. Phase based spatial identification of UHF RFID tags. In Proceedings of the 2010 IEEE International Conference on RFID (IEEE RFID 2010), Orlando, FL, USA, 14–16 April 2010; pp. 102–109. [Google Scholar]

- Buffi, A.; Nepa, P.; Lombardini, F. A Phase-Based Technique for Localization of UHF-RFID Tags Moving on a Conveyor Belt: Performance Analysis and Test-Case Measurements. IEEE Sens. J. 2015, 15, 387–396. [Google Scholar] [CrossRef]

- Tzitzis, A.; Megalou, S.; Siachalou, S.; Tsardoulias, E.; Filotheou, A.; Yioultsis, T.; Dimitriou, A.G. Trajectory Planning of a Moving Robot Empowers 3D Localization of RFID Tags with a Single Antenna. IEEE J. Radio Freq. Identif. 2020. [Google Scholar] [CrossRef]

- Buffi, A.; Motroni, A.; Nepa, P.; Tellini, B.; Cioni, R. A SAR-Based Measurement Method for Passive-Tag Positioning With a Flying UHF-RFID Reader. IEEE Trans. Instrum. Meas. 2019, 68, 845–853. [Google Scholar] [CrossRef]

- DiGiampaolo, E.; Martinelli, F. Mobile Robot Localization Using the Phase of Passive UHF RFID Signals. IEEE Trans. Ind. Electron. 2014, 61, 365–376. [Google Scholar] [CrossRef]

- Martinelli, F. A Robot Localization System Combining RSSI and Phase Shift in UHF-RFID Signals. IEEE Trans. Control Syst. Technol. 2015, 23, 1782–1796. [Google Scholar] [CrossRef]

- Buffi, A.; Nepa, P.; Motroni, A.; Tellini, B. Mobile Device Self-Location Method Using at Least One Passive Radio-Frequency Device. EP 20197281.7, 21 September 2020. [Google Scholar]

- Tao, B.; Wu, H.; Gong, Z.; Yin, Z.; Ding, H. An RFID-Based Mobile Robot Localization Method Combining Phase Difference and Readability. IEEE Trans. Autom. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Magnago, V.; Palopoli, L.; Fontanelli, D.; Macii, D.; Motroni, A.; Nepa, P.; Buffi, A.; Tellini, B. Robot Localisation based on Phase Measures of backscattered UHF-RFID Signals. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019; pp. 1–6. [Google Scholar]

- Magnago, V.; Palopoli, L.; Buffi, A.; Tellini, B.; Motroni, A.; Nepa, P.; Macii, D.; Fontanelli, D. Ranging-free UHF-RFID Robot Positioning through Phase Measurements of Passive Tags. IEEE Trans. Instrum. Meas. 2020. [Google Scholar] [CrossRef]

- Nepa, P.; Motroni, A.; Congi, A.; Ferro, E.M.; Pesi, M.; Giorgi, G.; Buffi, A.; Lazzarotti, M.; Bellucci, J.; Galigani, S.; et al. I-READ 4.0: Internet-of-READers for an efficient asset management in large warehouses with high stock rotation index. In Proceedings of the 2019 IEEE 5th International Forum on Research and Technology for Society and Industry (RTSI), Florence, Italy, 9–12 September 2019; pp. 67–72. [Google Scholar] [CrossRef]

- Magnago, V.; Palopoli, L.; Passerone, R.; Fontanelli, D.; Macii, D. Effective Landmark Placement for Robot Indoor Localization with Position Uncertainty Constraints. IEEE Trans. Instrum. Meas. 2019, 68, 4443–4455. [Google Scholar] [CrossRef]

- Palopoli, L.; Macii, D.; Fontanelli, D. A Positioning Filter based on Uncertainty and Observability Analyses for Nonholonomic Robots. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020. [Google Scholar]

- Simon, D. Optimal State Estimation: Kalman, H Infinity, and Nonlinear Approaches; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Nassar, S.; Niu, X.; El-Sheimy, N. Land-vehicle INS/GPS accurate positioning during GPS signal blockage periods. J. Surv. Eng. 2007, 133, 134–143. [Google Scholar] [CrossRef]

- Magnago, V.; Andreetto, M.; Divan, S.; Fontanelli, D.; Palopoli, L. Ruling the Control Authority of a Service Robot based on Information Precision. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 7204–7210. [Google Scholar] [CrossRef]

- Andreetto, M.; Divan, S.; Ferrari, F.; Fontanelli, D.; Palopoli, L.; Zenatti, F. Simulating passivity for Robotic Walkers via Authority-Sharing. IEEE Robot. Autom. Lett. 2018, 3, 1306–1313. [Google Scholar] [CrossRef]

- Guide to the Expression of Uncertainty in Measurement; BIPM: Sèvres, France, 1993.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shamsfakhr, F.; Motroni, A.; Palopoli, L.; Buffi, A.; Nepa, P.; Fontanelli, D. Robot Localisation Using UHF-RFID Tags: A Kalman Smoother Approach †. Sensors 2021, 21, 717. https://doi.org/10.3390/s21030717

Shamsfakhr F, Motroni A, Palopoli L, Buffi A, Nepa P, Fontanelli D. Robot Localisation Using UHF-RFID Tags: A Kalman Smoother Approach †. Sensors. 2021; 21(3):717. https://doi.org/10.3390/s21030717

Chicago/Turabian StyleShamsfakhr, Farhad, Andrea Motroni, Luigi Palopoli, Alice Buffi, Paolo Nepa, and Daniele Fontanelli. 2021. "Robot Localisation Using UHF-RFID Tags: A Kalman Smoother Approach †" Sensors 21, no. 3: 717. https://doi.org/10.3390/s21030717

APA StyleShamsfakhr, F., Motroni, A., Palopoli, L., Buffi, A., Nepa, P., & Fontanelli, D. (2021). Robot Localisation Using UHF-RFID Tags: A Kalman Smoother Approach †. Sensors, 21(3), 717. https://doi.org/10.3390/s21030717