Towards a Functional Performance Validation Standard for Industrial Low-Back Exoskeletons: State of the Art Review

Abstract

:1. Introduction

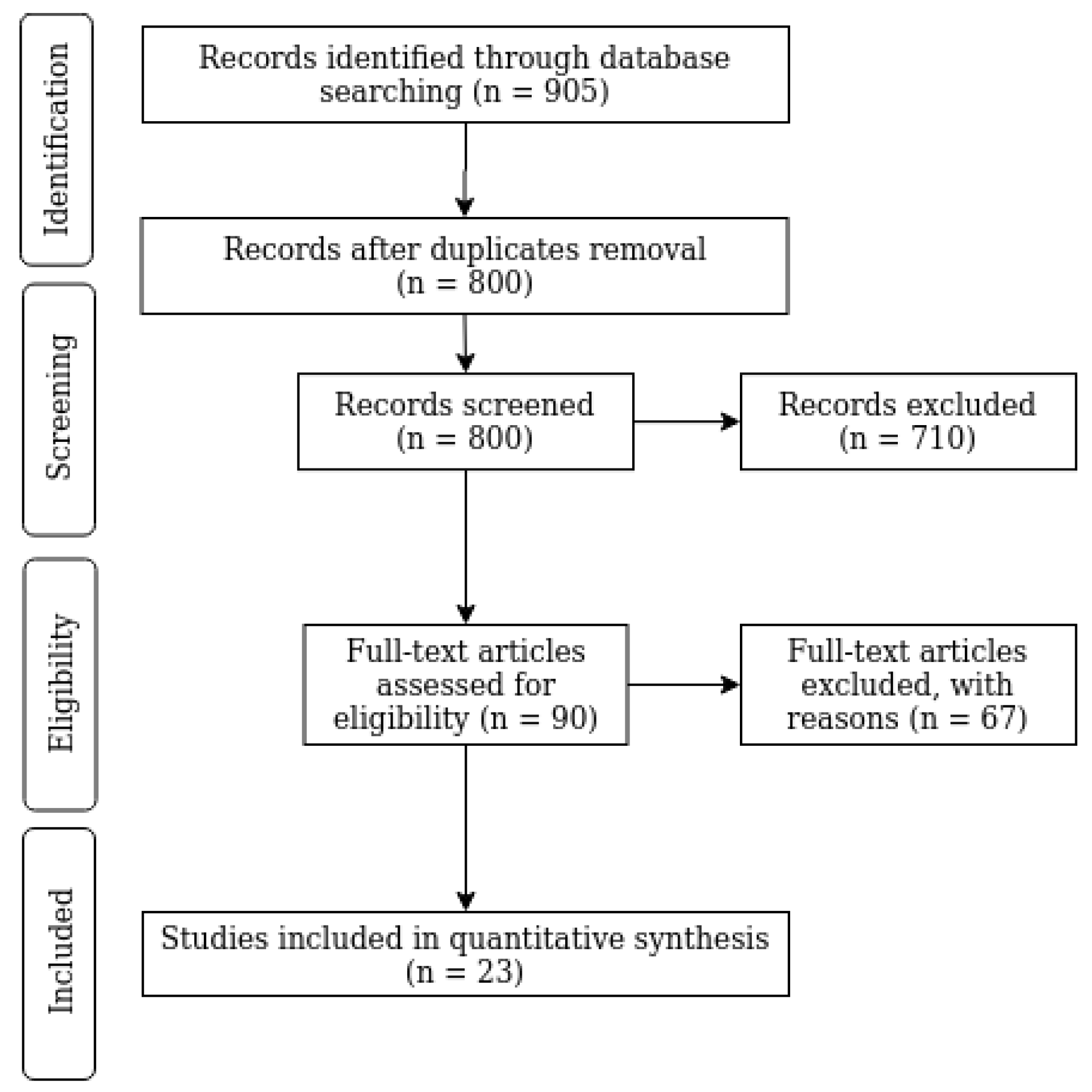

2. Materials and Methods

2.1. Search Methods for Data Collection

2.2. Query Results and Exclusion Criteria

- PubMed (www.ncbi.nlm.nih.gov/pubmed);

- Web of Science (www.webofknowledge.com).

2.3. Data Analysis

- (i)

- Technical features of each assistive device. We report their most important characteristics, such as actuation type, number and type of their degrees of freedom (DoF), and assisted tasks.

- (ii)

- Characteristics of the validation strategy. We analyzed study type and contribution and the evaluation criteria and metrics used for functional validation. With the term functional validation, here we intend the evaluation of the effectiveness of the device in assisting the end user, thus reducing their physical workload. Again, we do not foresee nor search for any carryover effect induced by the device (i.e., rehabilitation effect) or any raw physical power increase (i.e., human augmentation effect).

3. Low-Back Exoskeletons

3.1. Actuation and Mechanical Design

3.2. Sensors and Control

4. Assistance Evaluation

4.1. Study Type and Contribution

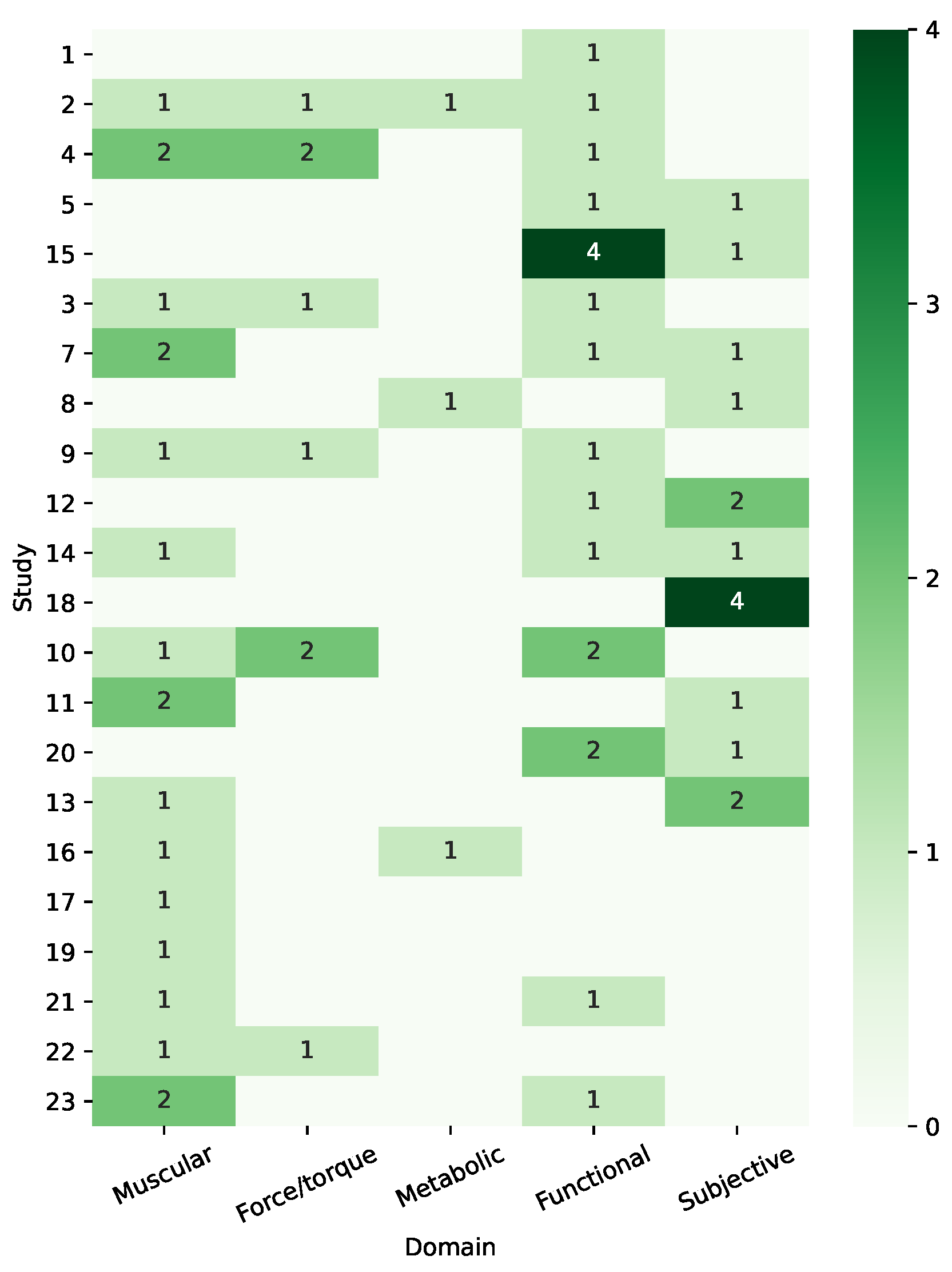

4.2. Evaluation Criteria and Metrics

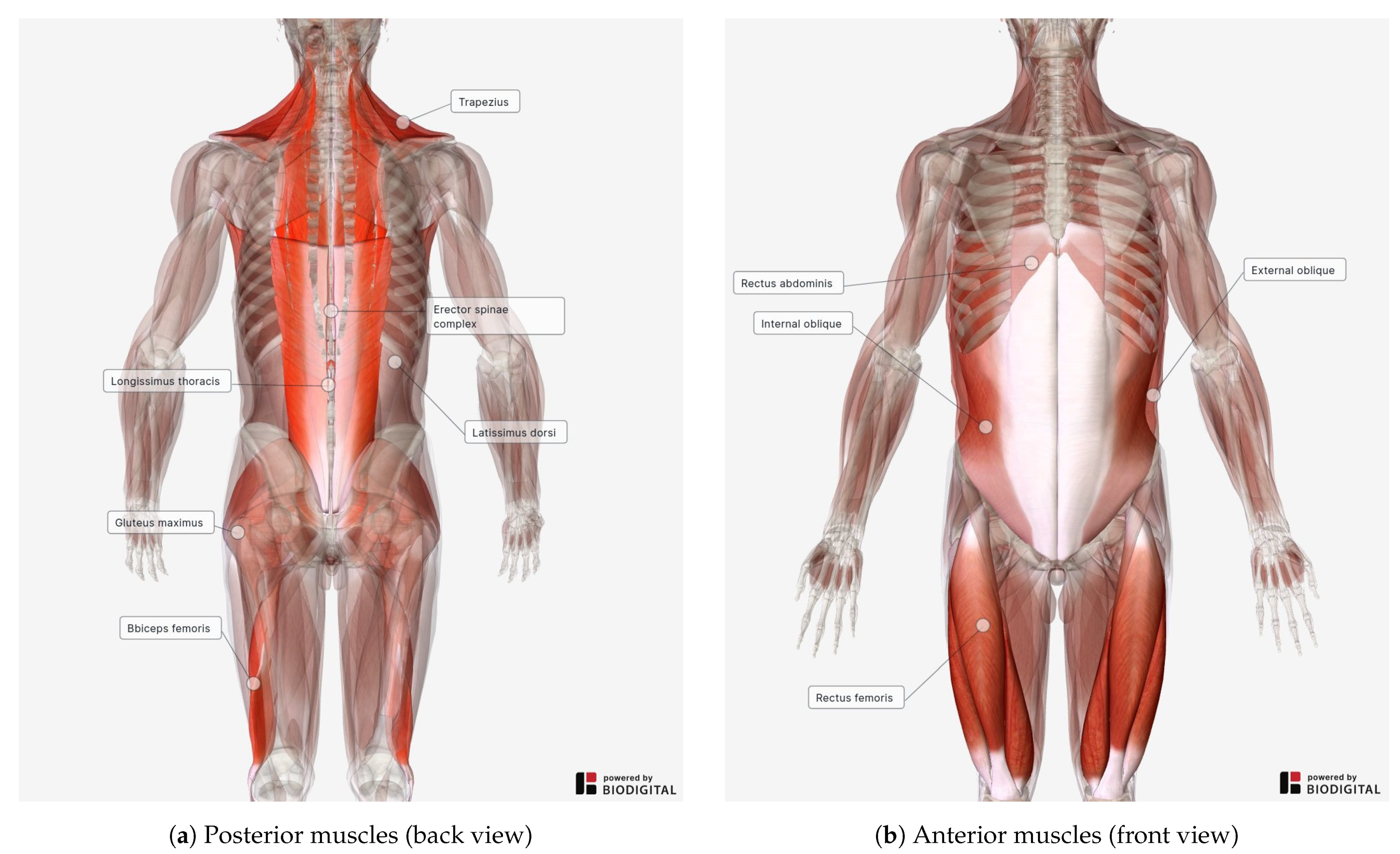

- Muscular: EMG-based metrics measured to evaluate a change of muscular activity due to the use of the exoskeleton.

- Force/torque: Computation of the compression force acting on the L5-S1 joint or the flexion-extension moment about that joint; joint net torque; mechanical joint work; and ground reaction force (GRF).

- Metabolic: Measurement of the metabolic cost or metabolic rate and derived quantities.

- Functional: Task-related metrics, such as measurements of kinematics, performance time, posture holding time, repetition count, walking distance (carrying a payload or not), and so on.

- Subjective: Perceived task difficulty (PTD), measures of system usability and acceptability, perceived effort, and pain measures.

4.3. Muscular Domain

4.4. Functional Domain

4.5. Metabolic Domain

4.6. Force/Torque Domain

4.7. Subjective Domain

4.8. Performance Analysis and Comparison

Performance Comparison

5. Discussion

5.1. Proposed Validation Framework

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mosher, R.S. Handyman to hardiman. Sae Trans. 1968, 76, 588–597. [Google Scholar]

- Liepert, J.; Hamzei, F.; Weiller, C. Lesion-induced and training-induced brain reorganization. Restor. Neurol. Neurosci. 2004, 22, 269–277. [Google Scholar] [PubMed]

- Posteraro, F.; Mazzoleni, S.; Aliboni, S.; Cesqui, B.; Battaglia, A.; Dario, P.; Micera, S. Robot-mediated therapy for paretic upper limb of chronic patients following neurological injury. J. Rehabil. Med. 2009, 41, 976–980. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Micera, S.; Caleo, M.; Chisari, C.; Hummel, F.C.; Pedrocchi, A. Advanced Neurotechnologies for the Restoration of Motor Function. Neuron 2020, 105, 604–620. [Google Scholar] [CrossRef] [PubMed]

- Jezernik, S.; Colombo, G.; Keller, T.; Frueh, H.; Morari, M. Robotic orthosis lokomat: A rehabilitation and research tool. Neuromodul. Technol. Neural Interface 2003, 6, 108–115. [Google Scholar] [CrossRef] [PubMed]

- Zeilig, G.; Weingarden, H.; Zwecker, M.; Dudkiewicz, I.; Bloch, A.; Esquenazi, A. Safety and tolerance of the ReWalk™ exoskeleton suit for ambulation by people with complete spinal cord injury: A pilot study. J. Spinal Cord Med. 2012, 35, 96–101. [Google Scholar] [CrossRef] [Green Version]

- Bogue, R. Exoskeletons and robotic prosthetics: A review of recent developments. Ind. Robot. Int. J. 2009, 36. [Google Scholar] [CrossRef]

- Young, A.J.; Ferris, D.P. State of the art and future directions for lower limb robotic exoskeletons. IEEE Trans. Neural Syst. Rehabil. Eng. 2016, 25, 171–182. [Google Scholar] [CrossRef]

- Parent-Thirion, A.; Biletta, I.; Cabrita, J.; Vargas, O.; Vermeylen, G.; Wilczynska, A.; Wilkens, M. Eurofound (2017), Sixth European Working Conditions Survey—Overview Report (2017 Update); Publications Office of the European Union: Luxembourg; Available online: https://www.eurofound.europa.eu/publications/report/2016/working-conditions/sixth-european-working-conditions-survey-overview-report (accessed on 10 June 2020).

- Fox, S.; Aranko, O.; Heilala, J.; Vahala, P. Exoskeletons: Comprehensive, comparative and critical analyses of their potential to improve manufacturing performance. J. Manuf. Technol. Manag. 2019, 31. [Google Scholar] [CrossRef] [Green Version]

- Bogue, R. Exoskeletons—A review of industrial applications. Ind. Robot. Int. J. 2018, 45. [Google Scholar] [CrossRef]

- De Looze, M.P.; Bosch, T.; Krause, F.; Stadler, K.S.; O’Sullivan, L.W. Exoskeletons for industrial application and their potential effects on physical work load. Ergonomics 2016, 59, 671–681. [Google Scholar] [CrossRef] [Green Version]

- Kneller, R.; Mongeon, M.; Cope, J.; Garner, C.; Ternouth, P. Industry-university collaborations in Canada, Japan, the UK and USA–With emphasis on publication freedom and managing the intellectual property lock-up problem. PLoS ONE 2014, 9, e90302. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pratt, G.A.; Williamson, M.M. Series elastic actuators. In Proceedings of the 1995 IEEE/RSJ International Conference on Intelligent Robots and Systems, Human Robot Interaction and Cooperative Robots, Pittsburgh, PA, USA, 5–9 August 1995; Volume 1, pp. 399–406. [Google Scholar]

- Näf, M.B.; Koopman, A.S.; Baltrusch, S.; Rodriguez-Guerrero, C.; Vanderborght, B.; Lefeber, D. Passive back support exoskeleton improves range of motion using flexible beams. Front. Robot. AI 2018, 5, 72. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.W.; Kim, G. Design and Control of a Lifting Assist Device for Preventing Lower Back Injuries in Industrial Athletes. Int. J. Precis. Eng. Manuf. 2019, 20, 1825–1838. [Google Scholar] [CrossRef]

- Sado, F.; Yap, H.J.; Ghazilla, R.A.R.; Ahmad, N. Design and control of a wearable lower-body exoskeleton for squatting and walking assistance in manual handling works. Mechatronics 2019, 63, 102272. [Google Scholar] [CrossRef]

- Bosch, T.; van Eck, J.; Knitel, K.; de Looze, M. The effects of a passive exoskeleton on muscle activity, discomfort and endurance time in forward bending work. Appl. Ergon. 2016, 54, 212–217. [Google Scholar] [CrossRef]

- CYBERDYNE. HAL Lumbar Type for Labor Support. 2015. Available online: https://www.cyberdyne.jp/english/products/Lumbar_LaborSupport.html (accessed on 15 July 2020).

- SuitX. BackX. 2016. Available online: https://www.suitx.com/backx (accessed on 15 July 2020).

- Stadler, K.S.; Altenburger, R.; Schmidhauser, E.; Scherly, D.; Ortiz, J.; Toxiri, S.; Mateos, L.; Masood, J. Robo-mate an exoskeleton for industrial use—Concept and mechanical design. In Advances in Cooperative Robotics; World Scientific: Singapore, 2017; pp. 806–813. [Google Scholar]

- Giovacchini, F.; Vannetti, F.; Fantozzi, M.; Cempini, M.; Cortese, M.; Parri, A.; Yan, T.; Lefeber, D.; Vitiello, N. A light-weight active orthosis for hip movement assistance. Robot. Auton. Syst. 2015, 73, 123–134. [Google Scholar] [CrossRef]

- Huysamen, K.; de Looze, M.; Bosch, T.; Ortiz, J.; Toxiri, S.; O’Sullivan, L.W. Assessment of an active industrial exoskeleton to aid dynamic lifting and lowering manual handling tasks. Appl. Ergon. 2018, 68, 125–131. [Google Scholar] [CrossRef]

- Wei, W.; Zha, S.; Xia, Y.; Gu, J.; Lin, X. A Hip Active Assisted Exoskeleton That Assists the Semi-Squat Lifting. Appl. Sci. 2020, 10, 2424. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Kadrolkar, A.; Sup, F.C. Design and preliminary evaluation of a passive spine exoskeleton. J. Med Devices 2016, 10, 011002. [Google Scholar] [CrossRef]

- Wehner, M.; Rempel, D.; Kazerooni, H. Lower extremity exoskeleton reduces back forces in lifting. In Proceedings of the Dynamic Systems and Control Conference, Hollywood, CA, USA, 12–14 October 2009; Volume 48937, pp. 49–56. [Google Scholar]

- Baltrusch, S.; Houdijk, H.; van Dieën, J.; Kruif, J. Passive Trunk Exoskeleton Acceptability and Effects on Self-efficacy in Employees with Low-Back Pain: A Mixed Method Approach. J. Occup. Rehabil. 2020. [Google Scholar] [CrossRef] [PubMed]

- Baltrusch, S.; van Dieën, J.; Koopman, A.; Näf, M.; Rodriguez-Guerrero, C.; Babič, J.; Houdijk, H. SPEXOR passive spinal exoskeleton decreases metabolic cost during symmetric repetitive lifting. Eur. J. Appl. Physiol. 2020, 120, 401–412. [Google Scholar] [CrossRef] [Green Version]

- Koopman, A.S.; Kingma, I.; de Looze, M.P.; van Dieën, J.H. Effects of a passive back exoskeleton on the mechanical loading of the low-back during symmetric lifting. J. Biomech. 2020, 102, 109486. [Google Scholar] [CrossRef] [Green Version]

- Koopman, A.S.; Näf, M.; Baltrusch, S.J.; Kingma, I.; Rodriguez-Guerrero, C.; Babič, J.; de Looze, M.P.; van Dieën, J.H. Biomechanical evaluation of a new passive back support exoskeleton. J. Biomech. 2020, 105, 109795. [Google Scholar] [CrossRef]

- Kozinc, Ž.; Baltrusch, S.; Houdijk, H.; Šarabon, N. Short-Term Effects of a Passive Spinal Exoskeleton on Functional Performance, Discomfort and User Satisfaction in Patients with Low Back Pain. J. Occup. Rehabil. 2020, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Kozinc, Ž.; Baltrusch, S.; Houdijk, H.; Šarabon, N. Reliability of a battery of tests for functional evaluation of trunk exoskeletons. Appl. Ergon. 2020, 86, 103117. [Google Scholar] [CrossRef]

- Madinei, S.; Alemi, M.M.; Kim, S.; Srinivasan, D.; Nussbaum, M.A. Biomechanical evaluation of passive back-support exoskeletons in a precision manual assembly task: “Expected” effects on trunk muscle activity, perceived exertion, and task performance. Hum. Factors 2020, 62, 441–457. [Google Scholar] [CrossRef] [PubMed]

- Baltrusch, S.; van Dieën, J.; Bruijn, S.; Koopman, A.; van Bennekom, C.; Houdijk, H. The effect of a passive trunk exoskeleton on metabolic costs during lifting and walking. Ergonomics 2019, 62, 903–916. [Google Scholar] [CrossRef] [Green Version]

- Koopman, A.S.; Kingma, I.; Faber, G.S.; de Looze, M.P.; van Dieën, J.H. Effects of a passive exoskeleton on the mechanical loading of the low back in static holding tasks. J. Biomech. 2019, 83, 97–103. [Google Scholar] [CrossRef] [Green Version]

- Koopman, A.S.; Toxiri, S.; Power, V.; Kingma, I.; van Dieën, J.H.; Ortiz, J.; de Looze, M.P. The effect of control strategies for an active back-support exoskeleton on spine loading and kinematics during lifting. J. Biomech. 2019, 91, 14–22. [Google Scholar] [CrossRef] [Green Version]

- Von Glinski, A.; Yilmaz, E.; Mrotzek, S.; Marek, E.; Jettkant, B.; Brinkemper, A.; Fisahn, C.; Schildhauer, T.A.; Geßmann, J. Effectiveness of an on-body lifting aid (HAL® for care support) to reduce lower back muscle activity during repetitive lifting tasks. J. Clin. Neurosci. 2019, 63, 249–255. [Google Scholar] [CrossRef] [PubMed]

- Baltrusch, S.; Van Dieën, J.; Van Bennekom, C.; Houdijk, H. The effect of a passive trunk exoskeleton on functional performance in healthy individuals. Appl. Ergon. 2018, 72, 94–106. [Google Scholar] [CrossRef] [Green Version]

- Baltrusch, S.J.; Van Dieen, J.H.; Van Bennekom, C.A.; Houdijk, H. Testing an Exoskeleton that Helps Workers with Low-Back Pain: Less Discomfort with the Passive SPEXOR Trunk Device. IEEE Robot. Autom. Mag. 2019, 27, 66–76. [Google Scholar] [CrossRef]

- Hensel, R.; Keil, M. Subjective evaluation of a passive industrial exoskeleton for lower-back support: A field study in the automotive sector. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 213–221. [Google Scholar] [CrossRef]

- Miura, K.; Kadone, H.; Koda, M.; Abe, T.; Kumagai, H.; Nagashima, K.; Mataki, K.; Fujii, K.; Noguchi, H.; Funayama, T.; et al. The hybrid assistive limb (HAL) for Care Support successfully reduced lumbar load in repetitive lifting movements. J. Clin. Neurosci. 2018, 53, 276–279. [Google Scholar] [CrossRef]

- Lanotte, F.; Grazi, L.; Chen, B.; Vitiello, N.; Crea, S. A low-back exoskeleton can reduce the erector spinae muscles activity during freestyle symmetrical load lifting tasks. In Proceedings of the 2018 7th IEEE International Conference on Biomedical Robotics and Biomechatronics (Biorob), Enschede, The Netherlands, 26–29 August 2018; pp. 701–706. [Google Scholar]

- Thorstensson, A.; Karlsson, J.; Viitasalo, J.; Luhtanen, P.; Komi, P. Effect of strength training on EMG of human skeletal muscle. Acta Physiol. Scand. 1976, 98, 232–236. [Google Scholar] [CrossRef] [PubMed]

- Hermens, H.; Freriks, B. The State of the Art on Sensors and Sensor Placement Procedures for sUrface Electromyography: A Proposal for Sensor Placement Procedures; Deliverable of the SENIAM Project; Roessingh Research and Development: Enschede, The Netherlands, 1997. [Google Scholar]

- Kingma, I.; de Looze, M.P.; Toussaint, H.M.; Klijnsma, H.G.; Bruijnen, T.B. Validation of a full body 3-D dynamic linked segment model. Hum. Mov. Sci. 1996, 15, 833–860. [Google Scholar] [CrossRef]

- Fleiss, J.L. Design and Analysis of Clinical Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 73. [Google Scholar]

- Torricelli, D.; Pons, J.L. EUROBENCH: Preparing robots for the real world. In International Symposium on Wearable Robotics; Springer: Berlin/Heidelberg, Germany, 2018; pp. 375–378. [Google Scholar]

- Maugliani, N.; Caimmi, M.; Malosio, M.; Airoldi, F.; Borro, D.; Rosquete, D.; Sergio, A.; Giusino, D.; Fraboni, F.; Ranieri, G.; et al. Lower-Limbs Exoskeletons Benchmark Exploiting a Stairs-Based Testbed: The STEPbySTEP Project. Available online: https://www.researchgate.net/profile/Loris_Roveda/publication/344403172_Lower-Limbs_Exoskeletons_Benchmark_Exploiting_a_Stairs-Based_Testbed_the_STEPbySTEP_Project/links/5f71c84692851c14bc9ade0c/Lower-Limbs-Exoskeletons-Benchmark-Exploiting-a-Stairs-Based-Testbed-the-STEPbySTEP-Project.pdf (accessed on 28 September 2020).

| Actuation | Device Type | Body Part |

|---|---|---|

| Active | Exoskeleton | Low-Back |

| Passive | Assistive device | Trunk |

| Hybrid | Exo-suit | Lower Limb |

| Wearable device | Hip | |

| Wearable robot |

| 1. | Duplicates articles | 5. | Review articles |

| 2. | False Positive | 6. | Literature not in English |

| 3. | Exoskeletons not for low-back/trunk | 7. | Exoskeletons for disabled people |

| 4. | Studies only with simulated results |

| Device Name | f | Assisted Task(s) | Actuation | Power | A-DoF | (#) | N-DoF | Sensors | Control |

|---|---|---|---|---|---|---|---|---|---|

| SPEXOR * [15] | 6 | Static forward bending Load lifting Repetitive lifting | Passive | 25 Nm | -Hip -L5-S1 | (2) | |||

| Laevo * [18] | 6 | Static forward bending Load lifting Load carrying Precision manual assembly | Passive | -Hip | (1) | ||||

| HAL * [19] | 2 | Stoop load lifting Load lifting | Active | 30 Nm | -Hip | (1) | EMG Angle sensors | Hybrid EMG + Inclination (CVC + CAC) | |

| BackX AC * [20] | 1 | Precision manual assembly | Passive | -Hip | (1) | ||||

| Robo-Mate [21] | 1 | Load lifting | Active | 40 Nm | -Hip | (1) | EMG IMU | EMG threshold; Inclination angle Hybrid EMG + IMU | |

| APO [22] | 1 | Load lifting | Hybrid | 35 Nm | -Hip | (1) | -Hip | Joint encoders | -Hip-dependent torque profile |

| ‘Active industrial exo’ [23] | 1 | Load lifting Dynamic load handling | Active | 40 Nm | -Hip | (1) | Inclination sensor | Torque | |

| MeBot-EXO [24] | 1 | Static forward bending Semi-squat lifting | Active | 160 Nm | -Hip | (1) | KinematicsInteraction force | -Hip torque control w/interaction force minim. | |

| ‘Lower-limbexoskeleton’ [17] | 1 | Squat load lifting Load carrying | Active | 76 Nm | -Hip -Knee | (2) | -Ankle

-Ankle | Torque sensors Joint encoders GRF sensors | (Human torque amplification (estimated by Kalman Filter) |

| ‘Lifting Assist Device (LAD)’ [16] | 1 | Load lifting | Hybrid | -Hip

-L5-S1 | (2) | -Hip

-L5-S1 | IMU Potentiometers | Pre-defined force profiles (State machine) | |

| ‘Passive spine exoskeleton’ [25] | 1 | Dynamic bending Static forward bending | Passive | 30 Nm | -Hip | (1) | |||

| ‘Lower extremity exoskeleton’ [26] | 1 | Load lifting | Passive | -Hip | (1) |

| Study | Exoskeleton | Experimental Setup | Study Type | Contribution | ||

|---|---|---|---|---|---|---|

| Scenario | Subjects | |||||

| 1 | [27] | SPEXOR | LAB | W-LBP | Pilot | Effectiveness analysis |

| 2 | [28] | SPEXOR | LL | W-MIX | Pilot | Effectiveness analysis |

| 3 | [29] | Laevo | LAB | Healthy | Pilot | Effectiveness analysis |

| 4 | [30] | SPEXOR | LAB | Workers | Pilot | Effectiveness analysis |

| 5 | [31] | SPEXOR | LAB | W-LBP | Pilot | Effectiveness analysis |

| 6 | [32] | SPEXOR | LAB | Healthy | Pilot (test–retest) | Feasibility analysis |

| 7 | [33] | BackX AC Laevo | LAB | Healthy | Pilot | Feasibility analysis |

| 8 | [34] | Laevo | LAB | Healthy | Pilot | Effectiveness analysis |

| 9 | [35] | Laevo | LAB | Healthy | Pilot | Effectiveness analysis |

| 10 | [36] | Robo-Mate | LAB | Healthy | Pilot | Effectiveness analysis |

| 11 | [37] | HAL | LL | Healthy | Pilot | Feasibility analysis |

| 12 | [38] | Laevo | LAB | Healthy | Pilot | Effectiveness analysis |

| 13 | [23] | ‘Active industrial exo’ | LAB | Healthy | Pilot | Effectiveness analysis |

| 14 | [18] | Laevo | LAB | Healthy | Pilot | Effectiveness analysis |

| 15 | [39] | SPEXOR | LAB | W-MIX | Pilot | Effectiveness analysis |

| 16 | [24] | MeBot-EXO | LAB | Healthy | Proof of Concept | Feasibility analysis |

| 17 | [17] | ‘Lower-limb exoskeleton’ | LAB | Healthy | Proof of Concept | Feasibility analysis |

| 18 | [40] | Laevo | RW | Workers | Pilot | User-acceptance analysis |

| 19 | [16] | ‘Lift Assist Device’ | LAB | Workers | Proof of Concept | Feasibility analysis |

| 20 | [41] | HAL | LAB | Healthy | Pilot | Feasibility analysis |

| 21 | [25] | ‘Passive spine exoskeleton’ | LAB | Healthy | Proof of Concept | Feasibility analysis |

| 22 | [26] | ‘Lower extremity exoskeleton’ | LAB | Healthy | Proof of Concept | Feasibility analysis |

| 23 | [42] | APO | LAB | Healthy | Proof of Concept | Effectiveness analysis |

| Type of Study | f | % |

|---|---|---|

| Pilot | 17 | 73.91 |

| Proof of Concept | 6 | 26.09 |

| RCT | 0 | 0 |

| Contribution | f | % |

| Effectiveness analysis | 14 | 60.87 |

| Feasibility analysis | 8 | 34.78 |

| User-acceptance analysis | 1 | 4.35 |

| Scenario | f | % |

| LAB | 20 | 86.96 |

| Living lab (LL) | 2 | 8.70 |

| Real world (RW) | 1 | 4.35 |

| Test Subjects | f | % |

| Healthy subjects (Healthy) | 16 | 69.57 |

| Healthy workers (Workers) | 3 | 13.04 |

| Workers with LBP (W-LBP) | 2 | 8.70 |

| Mixed workers (W-MIX) | 2 | 8.70 |

| Muscular domain | f |

|---|---|

| Muscle activity | 15 |

| Integral of muscle activity (iEMG) | 2 |

| Average muscle activity | 1 |

| Force/torque domain | f |

| L5-S1 flex-ext moment | 5 |

| L5-S1 peak compression force | 4 |

| Mechanical joint work | 1 |

| Muscular force | 1 |

| Metabolic domain | f |

| Metabolic cost | 3 |

| Functional domain | f |

| Kinematics | 11 |

| Performance time | 6 |

| Posture holding time | 4 |

| Load carrying distance | 3 |

| Repetition count | 3 |

| Task performance | 1 |

| Time to extend the trunk | 1 |

| Metabolic domain | f |

| Metabolic cost | 3 |

| Erector Spinae | 27 | Longissimus Iliocostalis | 9 8 | Longissimus thoracis (LT) Longissimus lumborum (LL) Iliocostalis lumborum (IL) | 2 1 6 |

| Trapezius | 1 | Tr. Pars ascendens (TA) | 1 | ||

| Gluteus | 1 | Gluteus maximus (GM) | 1 | ||

| Biceps femori (BF) | 3 | ||||

| Gastrocnemius | 1 | ||||

| External oblique (EO) | 7 | ||||

| Internal oblique (IO) | 3 | ||||

| Rectus abdominis (RA) | 9 | ||||

| Quadriceps femoris (QF) | 3 | Rectus femoris (RF) | 1 | ||

| Vastus intermedialis (VI) | 1 |

| # | Device | Subj. | Tasks | (Domain) Evaluation Metrics and Criteria |

|---|---|---|---|---|

| 1 | SPEXOR | 19 ♂ | Lifting; Repetitive bending Standing and walking Static forward bending | (Subjective) M-SFS ▼ |

| 2 | SPEXOR | 11 ♂ | Static forward bending; Lifting Repetitive lifting; Kneeling Load carrying; Sit to stand (StS) | (Muscular) LT ▼ , IL ▼ , LL ▼ , EO ∼, RA ∼ (Functional) Kinematics ∼ (Metabolic) Met. cost ▼ 18% (Force/torque) Joint work ▼ |

| 4 | SPEXOR | 10 ♂ | Static forward bending Load lifting | (Muscular) IL-LL ∼, RA-EO ∼. (Force/torque) L5-S1 Fc ▼ , L5-S1 Mfe ▼ (Functional) -Hip ▼ (Muscular) ▼ (avg.), (Force/torque) L5-S1 Fc ▼ (Functional) -Hip ∼ |

| 5 | SPEXOR | 🟉7 ♂ 🟉7 ♀ | Static forward bending; Lifting Load carrying; Kneeling; Walking Sit to stand; Stair climbing | (Functional) Posture holding time: ▲ for SFB; ▲ for StS; ▲ for climbing (Subjective) Discomfort: ▼ for SFB and sit to stand |

| 15 | SPEXOR | 🟉13 ♂ 11 ♂ | Static forward bending; Lifting Load carrying; Kneeling; Walking Sit to stand; Stair climbing | (Functional) Lifts/2-min ▲ ; Posture holding time ▲ for SFB; Walk dist. ▼ Perf. time ▲ for stair climbing. (Subjective) PTD ▼ for SFB, lifting, kneeling |

| 3 | Laevo | 11 | Lifting | (Muscular) ▼ (avg.) (Force/torque) L5-S1 Fc ▼ (Functional) Peak -Hip ▼ |

| 7 | BackX AC Laevo | 9 ♂ 9 ♀ | Static forward bending | (Musc.) TES-IL ▼ , ▼ (avg.) (Func.) Perf. time ▲ (Subjective) BORG ▲ (Musc.) TES-IL ▼ , ▼ (avg.) (Func.) Perf. time ▲ (Subjective) |

| 8 | Laevo | 18 ♂ | Static forward bending Walking; Sitting; Squatting | (Metabolic) For lifting: Met. cost ▼ . (Subjective) PTD ▼ for SFB. For load carrying: Met. cost ▲ 14.5% PTD ▲ for walking, sitting, squatting |

| 9 | Laevo | 11 ♂ | Static forward bending | (Muscular) IL ▼, EO ▲ +, IO ▲ +, RA ∼, LL ∼ (Force/torque) L5-S1 Mfe ▼ (Functional) -Hip ▼ |

| 12 | Laevo | 18 ♂ | Static forward bending; Lifting Load carrying; Sit to stand | (Functional) Perf. time ▲ for SFB (Subjective) PTD ▼ for SFB PTD ▲ for StS and walking. LD ▼ for SFB (low back). LD ▲ for SFB (chest) |

| 14 | Laevo | 9 ♂ 9 ♀ | Static forward bending Static holding task (SHT) | (Muscular) For SFB: BF ▼ , TA ▼ , (Functional) -Hip ▲ ESL▼, ESI▼ (Subjective) LD ▼ (low back) For SHT: BF ▼ , TA ▼ LD ▲ (chest) ESL▼, ESI▼ |

| 18 | Laevo | 30 ♂ | Static forward bending Load lifting | (Subjective) LPD (over time): ▼ (low back), ▼ (wrist), ▲ (chest) UMUX (over time): ∼ Donning/doffing, ▼ Task perf. Intention to use(over time) ▼ 25% |

| 10 | Robo-Mate | 10 ♂ | Load lifting | (Muscular) IL-LL ▼ (Force/torque) L5-S1 Fc ▼, L5-S1 Mfe ▼ (Functional) -Hip ▼ , -Hip ▼ |

| 11 | HAL | 14 ♂ | Lifting | (Muscular) Muscle activity: TES ▼, LES▼, QF▲ (Subjective) BORG ∼ iEMG: TES ▼, LES▼ |

| 20 | HAL | 11 ♂ 7 ♀ | Stoop load lifting | (Functional) Number of lifts ▲; Lifting time ▲ (Subjective) ▼ Perceived lumbar fatigue |

| 13 | ‘Active indus-trial exo’ | 12 ♂ | lifting; Lowering | (Muscular) RA ∼, BF▼, LES▼ (w/7.5 kg) (Subjective) BORG ▼ (w/7.5 kg) LES ▼ (w/15 kg) BORG ▼ (w/15 kg) SUS > 60 |

| 16 | MeBot-EXO | 7 ♂ | Semi-squat load lifting | (Muscular) TES ▼, LES▼ (Metabolic) Met. cost ▼ |

| 17 | Lower-limb exo | 5 ♂ | Lifting; Load carrying | (Muscular) For lifting: VI ▼, GA▼. For carrying: VI▼, GA▼ |

| 19 | LAD | 1 ♂ | Lifting | (Muscular) RA ▼, ES▼ |

| 21 | ‘Passive spine exoskeleton’ | 3 ♂ | Dynamic bending Static forward bending | Muscular) TES ▼, LES▼ (Functional) Kinematics ∼ |

| 22 | ‘Lower extremity exoskeleton’ | 5 ♂ 1 ♀ | Lifting | (Muscular) ES ▼ (Force/torque) [l]L5-S1 Fc ▼ (w/4.5 kg payload) L5-S1 Fc ▼ (w/13.6 kg payload |

| 23 | APO | 5 ♂ | Lifting; Lowering | (Muscular) iEMG (average iEMG): TES ▼ (▼); LES▼ (▼); BF▼ (▲) ESI ▼ (▼) RF▲ (▲) (Functional) Time for trunk extension ▼ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pesenti, M.; Antonietti, A.; Gandolla, M.; Pedrocchi, A. Towards a Functional Performance Validation Standard for Industrial Low-Back Exoskeletons: State of the Art Review. Sensors 2021, 21, 808. https://doi.org/10.3390/s21030808

Pesenti M, Antonietti A, Gandolla M, Pedrocchi A. Towards a Functional Performance Validation Standard for Industrial Low-Back Exoskeletons: State of the Art Review. Sensors. 2021; 21(3):808. https://doi.org/10.3390/s21030808

Chicago/Turabian StylePesenti, Mattia, Alberto Antonietti, Marta Gandolla, and Alessandra Pedrocchi. 2021. "Towards a Functional Performance Validation Standard for Industrial Low-Back Exoskeletons: State of the Art Review" Sensors 21, no. 3: 808. https://doi.org/10.3390/s21030808