Cloud Data-Driven Intelligent Monitoring System for Interactive Smart Farming

Abstract

:1. Introduction

- Lack of standards that complicates data processing. It is difficult for one system to be compatible with different IoT devices.

- Data and information management. IoT devices generate fragmented, inconsistent, noisy, and heterogeneous data that must be transformed.

- Organizational inability to manage the complexities of IoT. Data need to be organized and visualized in an understandable format, regardless of the lack of standard analysis approaches and proper visualization of overall results

- Privacy and security. There are four classes of cyber-attacks—data attacks, networking and equipment attacks, supply chain, and other relevant attacks in a smart farming ecosystem. Therefore, all entry and exit points of the system must be doubly protected.

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Data-Driven System Architecture

- -

- Sensors—collect data from the environment and transmit it to the system core for identification and analytics.

- -

- Identification—intelligent systems must automatically recognize specific information and transmit it to subscribed services or channels.

- -

- Data analytics—an essential function of an intelligent system is its ability to process collected data.

- -

- Self-learning—the intelligent system needs to include artificial intelligence or machine learning functionalities.

- -

- Real-time communication—an intelligent system needs to have the ability to simulate or emulate in real-time or near real-time.

- -

- User Experience (UX)–to interact with users, intelligent systems must have interfaces such as web pages, reports, dashboards, or other types of visualization.

- -

- Remote system management—an intelligent system allows users to interact with it from any location.

- -

- Interoperability and connectivity—an intelligent system must combine its elements into a holistic communication process.

- -

- Protection—an intelligent system’s ecosystem, networks, and communications must be secure to be available and reliable to function properly.

- -

- IoT Hub—enables a reliable and secure bi-directional communication process between IoT devices and the Cloud. It is a working IoT service which is hosted in the Cloud. In addition, the IoT hub provides scalable device-to-cloud and cloud-to-device messaging and secure communications. The IoT Hub is the only external entry point for the system. Part of the IoT Hub is the Defender for IoT service, which provides device registration and identification along with comprehensive monitoring and alerts in case of threat detection against IoT environments. It is a standalone service designed to add an additional layer of threat protection for the IoT Hub and registered IoT devices. In addition, IoT Defender uses masked IP addresses and processes and stores the data in a different geographical location from the IoT Hub. The IoT Hub is also responsible for synchronizing the received data from the IoT devices and propagating them forward to the subscribed services.

- -

- Stream Analytics—Stream Analytics is a stream processing engine that processes large volumes of fast streaming data with minimal latencies from multiple sources simultaneously. It can work with data from a variety of input sources including IoT devices, driverless vehicles, and different applications. The output can deliver data to another service for alerts and actions, dynamic dashboarding, data warehousing, and storage. Stream Analytics is the logical part of the architecture. All data that pass through it are filtered based on predefined queries, sorted, and then transmitted to the subscribed services.

- -

- Blob (binary large object) Storage is object data storage. It is part of Azure DataLake. In addition, it is optimized for storing massive amounts of unstructured data, such as text, images, IoT data, video, and audio. There are two types of blob storage—hot storage and cold storage. The hot tier of storage is for storing frequently accessed data—data that require high durability, availability, and quick time to access. The cold storage tier is for storing data that are long-lived and infrequently accessed. Blob storages are used for persisting raw and filtered data and system operational logs.

- -

- The machine learning service is completely cloud-based and self-contained. It features a complete development, testing, and production environment for quickly creating predictive analytic solutions. It is the data analytics and machine learning part of the system. In it, the data are transformed and modelled to build a machine learning model to predict future values.

- -

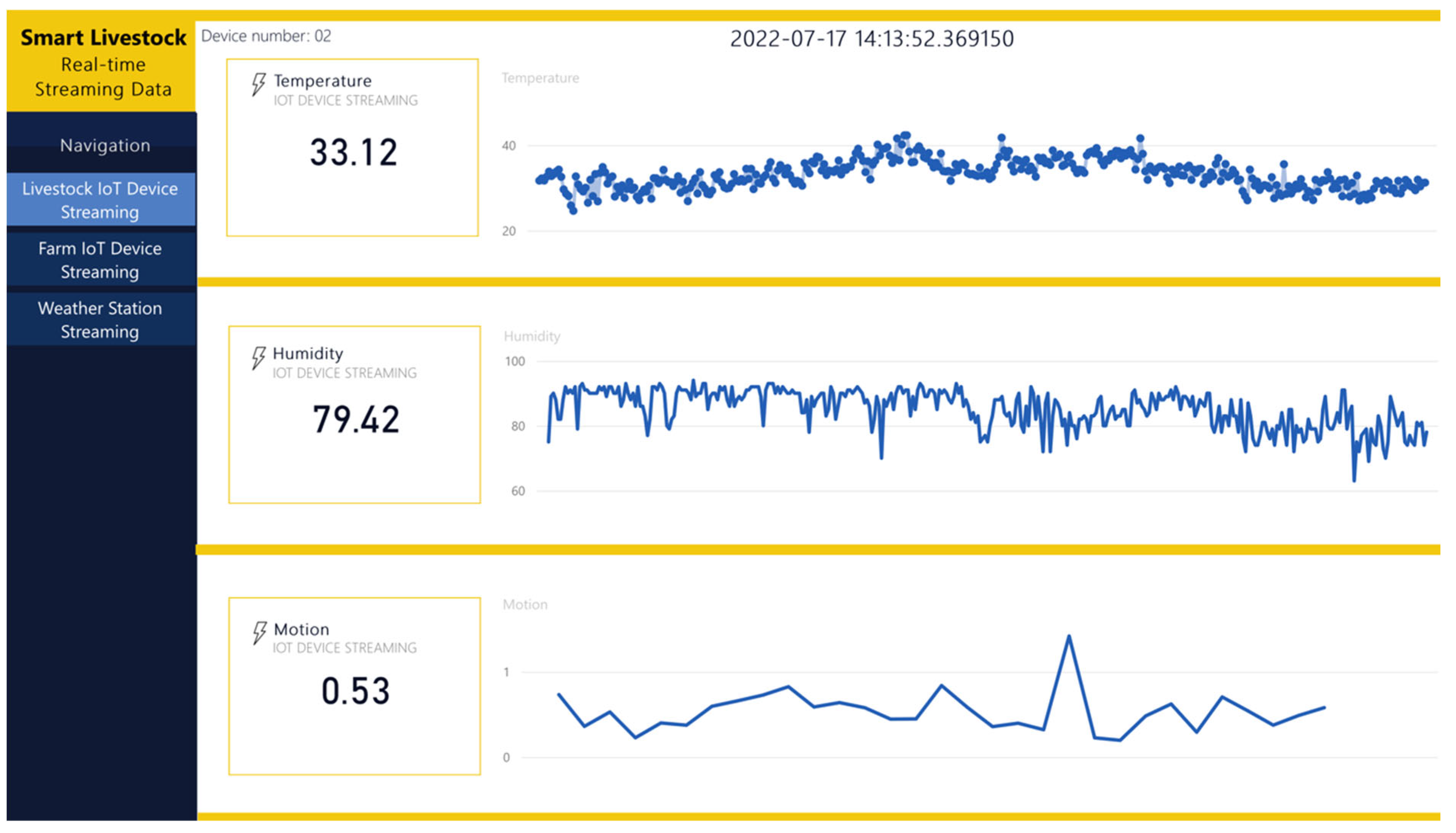

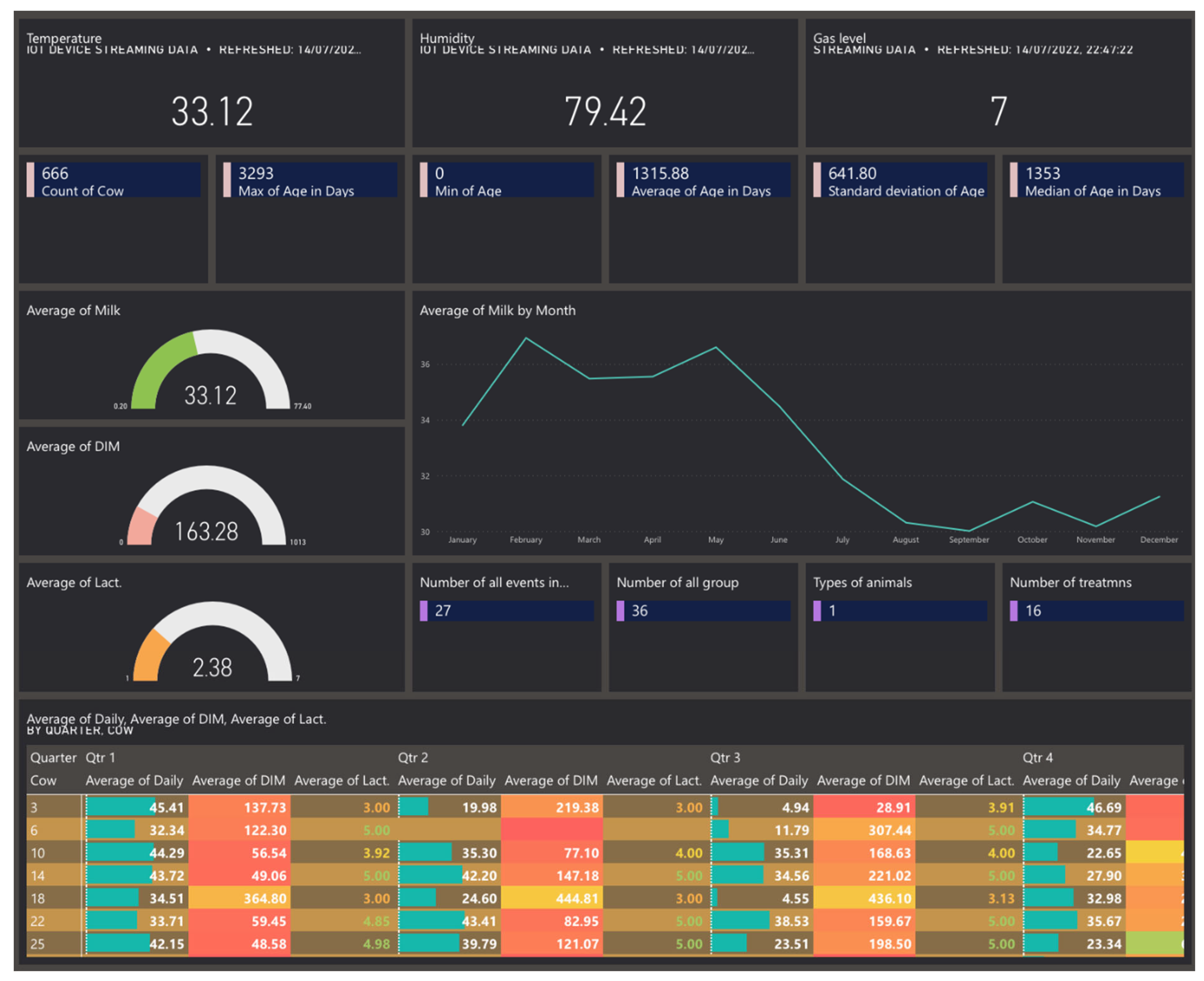

- Power BI is an interactive data visualization and business intelligence tool that converts data from different data sources to interactive dashboards and dynamic reports. Data can be entered by reading directly from a database, streamed by IoT devices, webpage, or structured files such as excel spreadsheets, CSV (comma-separated values), XML (Extensible Markup Language), and JSON (JavaScript Object Notation). Power BI is the representation part of the architecture. Interactive reports and dashboards are designed and built. They visualize machine learning predictions, real-time data, and statistical information based on raw historical data using charts, tables, and other visual tools.

3. Results

- Building data-driven pipelines in Azure Cloud:

- ○

- Setting up Azure IoT Hub to accept the registration of IoT Devices.

- ○

- Setting up Azure Storage Account with Blob Storages to persist IoT historical and real-time data.

- ○

- Setting up Azure Stream Analytic to process IoT data.

- ○

- Monitoring and testing the data-driven pipelines.

- Design and implement the Azure Machine Learning Workflow.

- Design and build interactive Power Bi reports and dashboards.

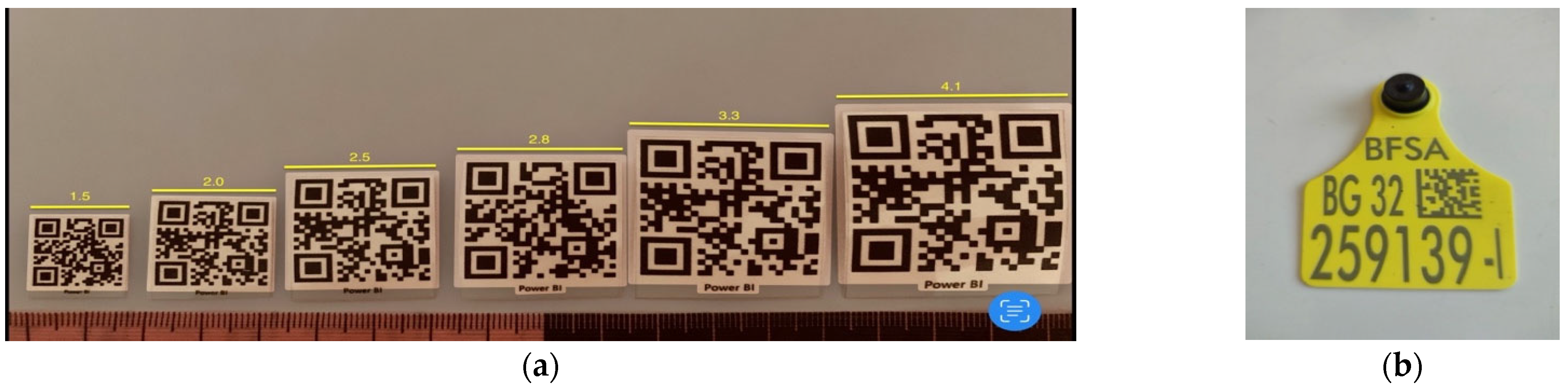

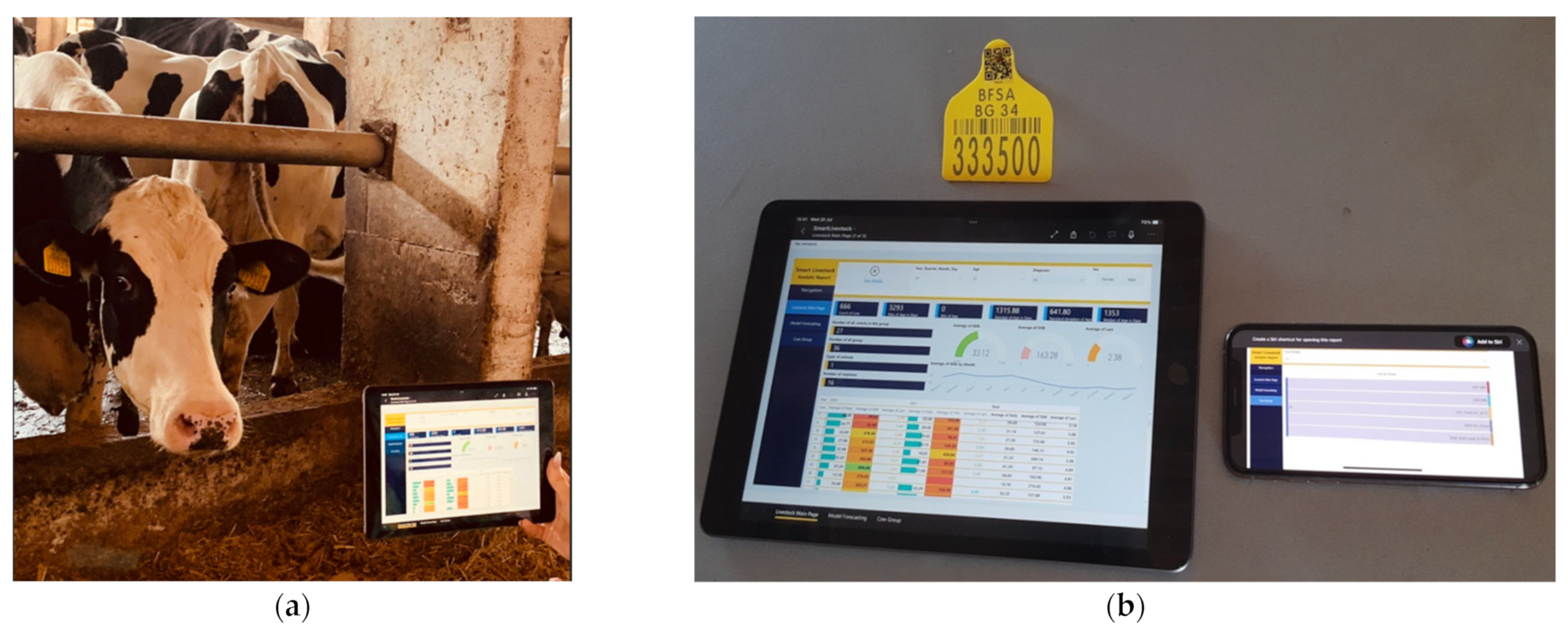

- Integrate QR codes with Power Bi interactive reports.

- Define system limitations.

3.1. Data-Driven Pipelines

3.1.1. IoT Hub for IoT Devices Registration and Communication

- -

- IoT device metadata and state information for all connected devices are stored, synchronized, and queried.

- -

- IoT device state is set either per device or in a group depending on the farm structure.

- -

- State change in IoT devices can be automatically responded to by using message routing integration.

3.1.2. Azure Storage Account with Blob Storages

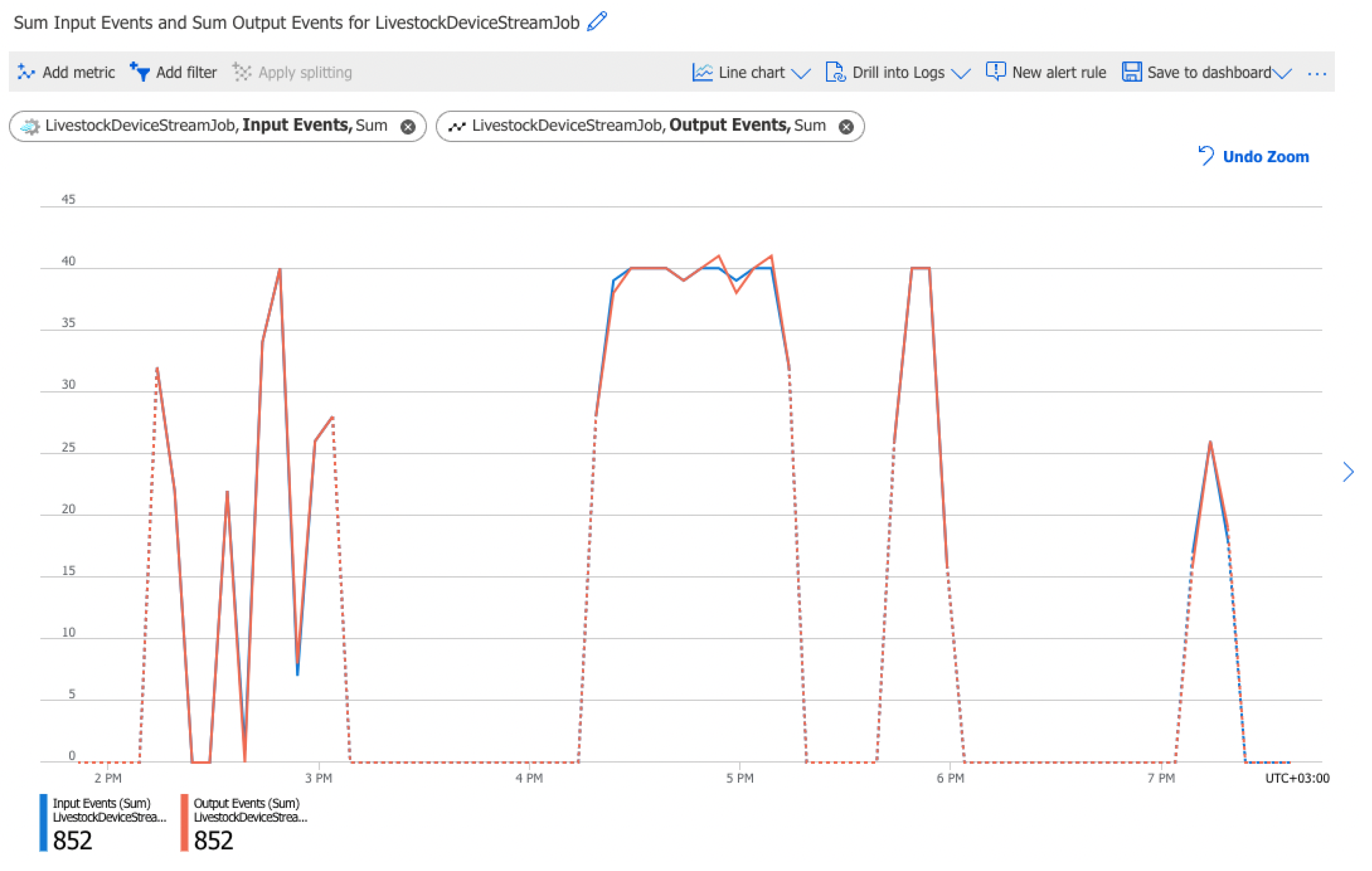

3.1.3. Stream Analytics

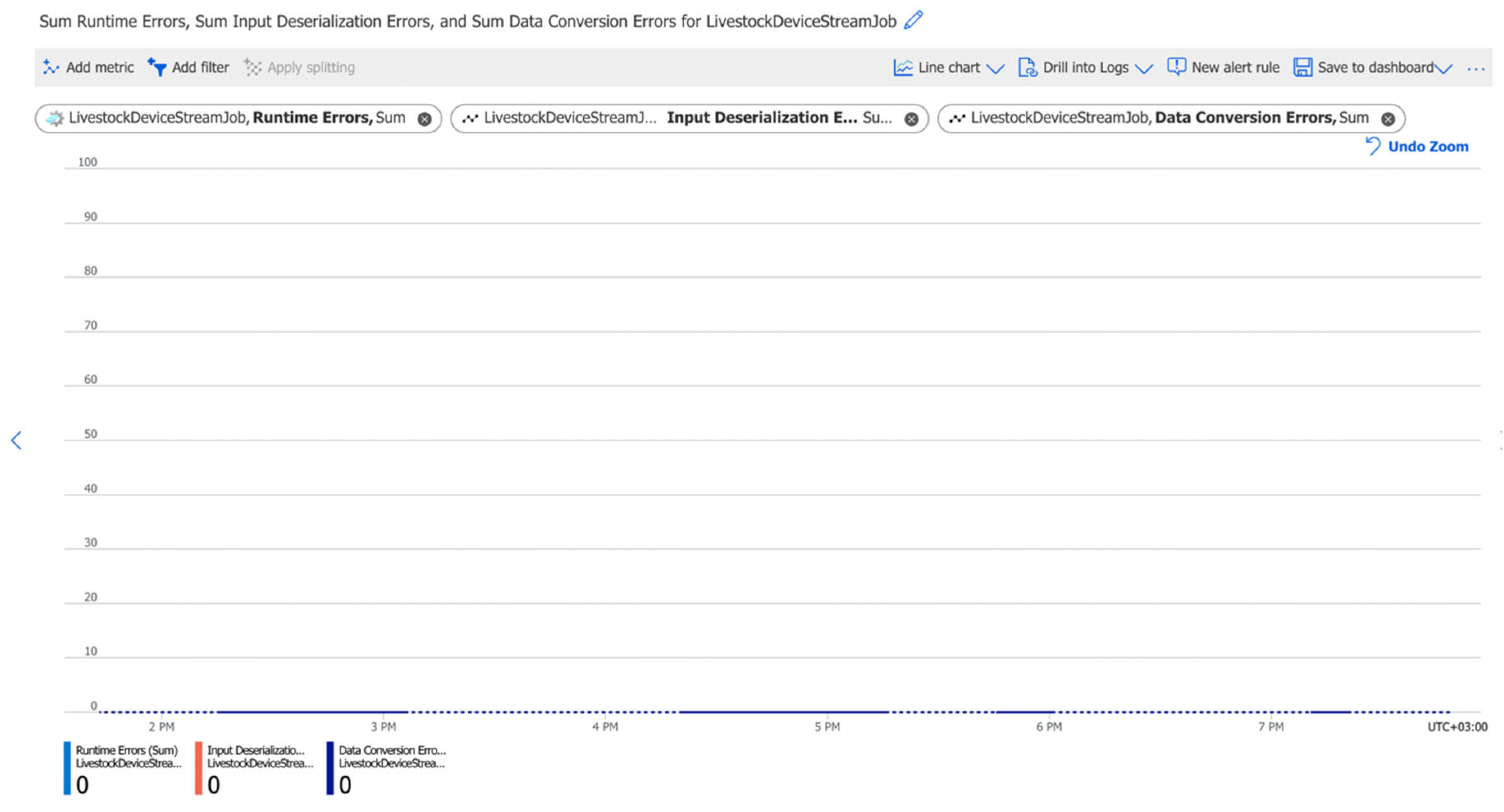

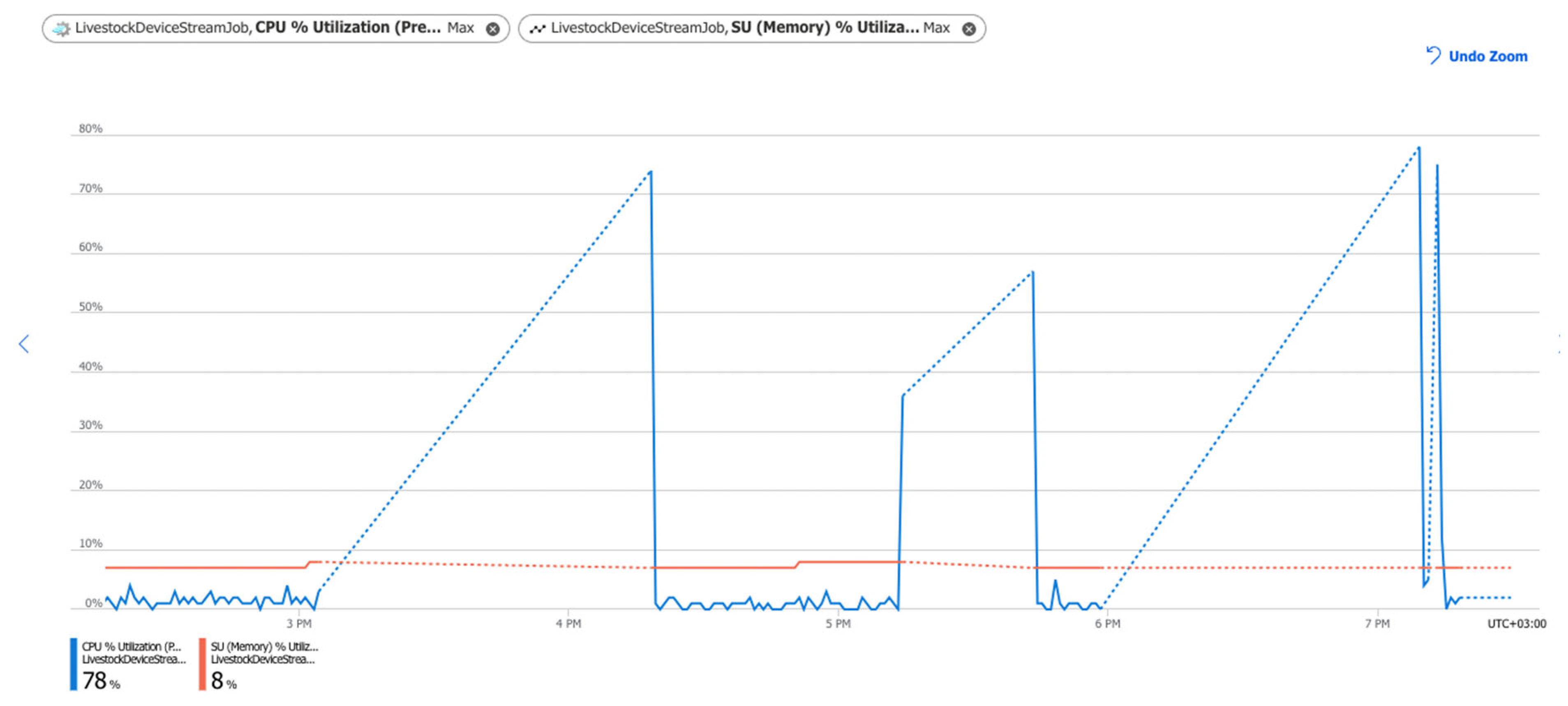

3.1.4. Monitoring and Testing of Data-Driven System Pipelines

- -

- The sum of input and output events that are deserialized and sent to the target,

- -

- The delay measurement between input and output events in the stream job,

- -

- The number and type of errors that occur in the stream job,

- -

- The percentage of processor utilization and memory utilization during job executions.

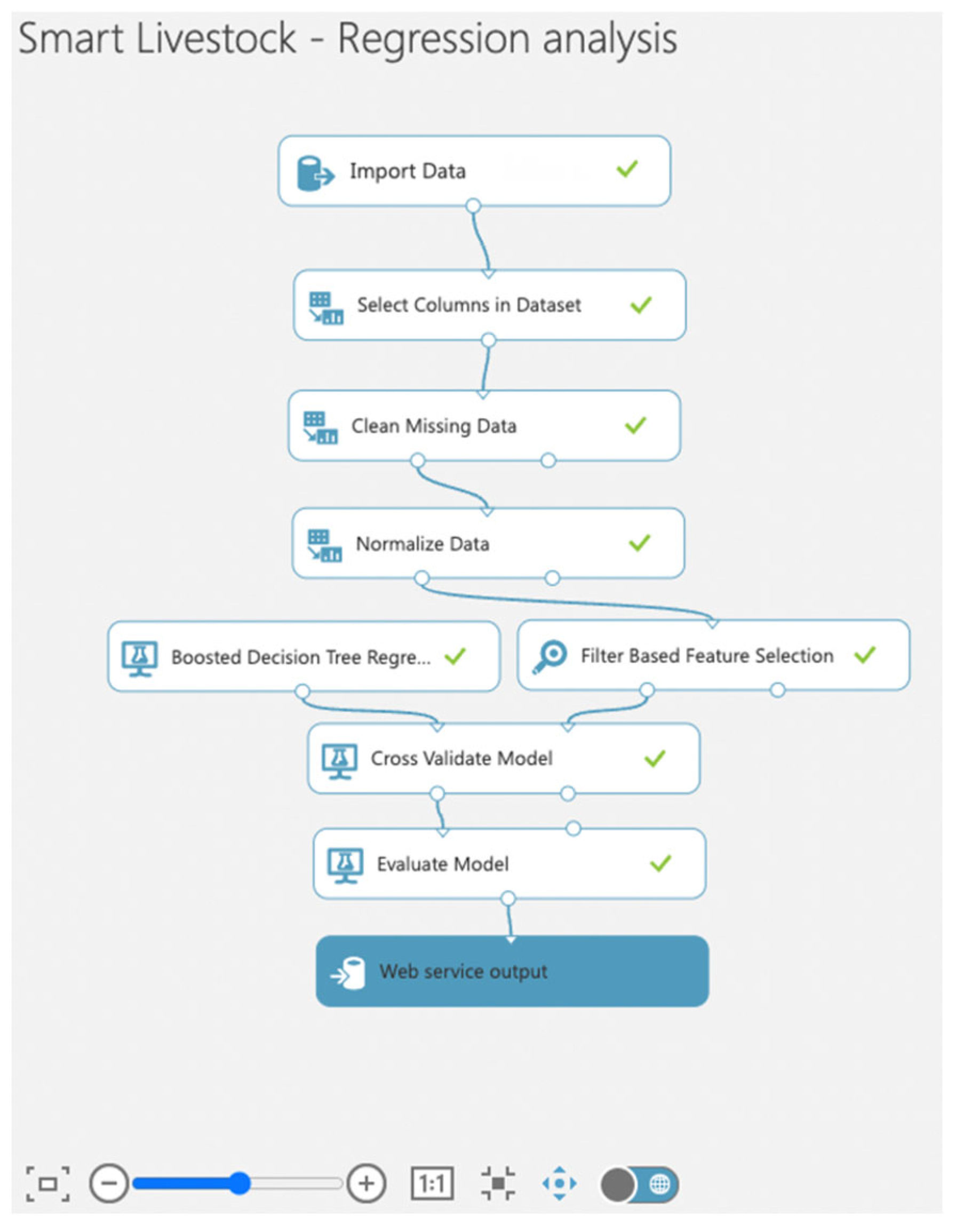

3.2. Azure Machine Learning

- ○

- The output of the tree ht(x) is given a weight w relative to its accuracy,

- ○

- The output of the ensemble is the weighted sum:

- ○

- After each iteration, each data sample is given a weight based on its classification. The goal is to minimize the function:

3.3. Power BI Data Visualisation (Reporting and Dashboards)

3.4. QR Code

3.5. System Limitations

4. Discussion

4.1. Materials and Methods

4.2. Results

4.2.1. Azure IoT Hubs

4.2.2. Stream Analytics

4.2.3. Azure Machine Learning

4.2.4. Power BI

4.2.5. Pipelines Tests and Monitoring

4.3. System Limitations and Costs

4.4. Research on the Broader Integration of IoT Systems in Smart Agriculture

4.5. Privacy and Security

4.6. Future Work

- -

- Research and design of new features for ML models.

- -

- Research and development of approaches, techniques, and tools to automatically calculate BCS (Body Condition Score), to better track the health status and fat levels of an animal along with the general condition of the herd.

- -

- Research on automatic analysis of daily animal activity to improve early detection of animal diseases.

- -

- Designing and building additional reports and dashboards for monitoring and improving their interactivity.

- -

- Automatic generation and export of daily, weekly, monthly, and annual reports with statistical information, both for the entire farm and for each individual animal. Automatic comparative analysis against generated results.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M. Big Data in Smart Farming—A review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Oliveira, A.S.; dos Santos Silva, B.C.; Ferreira, C.V.; Sampaio, R.R.; Machado, B.A.S.; Coelho, R.S. Adding Technology Sustainability Evaluation to Product Development: A Proposed Methodology and an Assessment Model. Sustainability 2021, 13, 2097. [Google Scholar] [CrossRef]

- How Smart Agriculture Is Evolving the Farming Industry. Available online: https://www.iot-now.com/2022/07/18/122382-how-smart-agricult2ure-is-evolving-the-farming-industry/?source=seoarticle (accessed on 20 July 2022).

- Amiri-Zarandi, M.; Hazrati Fard, M.; Yousefinaghani, S.; Kaviani, M.; Dara, R. A Platform Approach to Smart Farm Information Processing. Agriculture 2022, 12, 838. [Google Scholar] [CrossRef]

- Sarri, D.; Lombardo, S.; Pagliai, A.; Perna, C.; Lisci, R.; De Pascale, V.; Rimediotti, M.; Cencini, G.; Vieri, M. Smart Farming Introduction in Wine Farms: A Systematic Review and a New Proposal. Sustainability 2020, 12, 7191. [Google Scholar] [CrossRef]

- Schönfeld, M.V.; Heil, R.; Bittner, L. Big Data on a Farm—Smart Farming. In Big Data in Context; Springer Briefs in Law; Hoeren, T., Kolany-Raiser, B., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Barnes, H. Pushing beyond Enterprise Tech Buyer Regret. Address Buying Challenges to Accelerate Tech Sales Growth. Gartner, e-Book. 2022. Available online: https://www.gartner.com/en/industries/high-tech/trends/pushing-beyond-enterprise-tech-buyer-regret?source=BLD-200123&utm_medium=social&utm_source=bambu&utm_campaign=SM_GB_YOY_GTR_SOC_BU1_SM-BA-RM-MISC-HT-OC-JB (accessed on 23 July 2022).

- New B2B Buying Journey & Its Implication for Sales. Available online: https://www.gartner.co.uk/en/sales/insights/b2b-buying-journey (accessed on 28 July 2022).

- Bernier, C. The AgTech Revolution: How Technology Is Boosting the Agriculture Industry. 9 June 2022. Available online: https://www.automate.org/industry-insights/agtech-automation-of-agriculture (accessed on 15 August 2022).

- Hine, E.; Leeson, M.; Martínez-Ramón, M.; Pardo, M.; Llobet, E.; Iliescu, D.; Yang, J. Intelligent Systems: Techniques and Applications. Shaker. 2008. Available online: https://www.academia.edu/62853162/Intelligent_systems_techniques_and_applications (accessed on 14 August 2022).

- De-Pablos-Heredero, C. Future Intelligent Systems and Networks 2019. In Future Internet; MDPI: Basel, Switzerland, 2019. [Google Scholar] [CrossRef]

- García, L.; Parra, L.; Jimenez, J.M.; Lloret, J.; Lorenz, P. IoT-Based Smart Irrigation Systems: An Overview on the Recent Trends on Sensors and IoT Systems for Irrigation in Precision Agriculture. Sensors 2020, 20, 1042. [Google Scholar] [CrossRef]

- Subeesh, A.; Mehta, C.R. Automation and digitization of agriculture using artificial intelligence and internet of things. Artif. Intell. Agric. 2021, 5, 278–291. [Google Scholar] [CrossRef]

- Li, F.; Wang, H.; Sun, L.; Wang, Z.; Ran, Y.; Xia, Y. Data Collection of Digital Monitoring System for Agricultural Facilities Environment, IPEC 2021. J. Phys. Conf. Ser. 2021, 1952, 042138. [Google Scholar] [CrossRef]

- Guojia, S.; Shuhua, L.; Haolun, L.; Zelin, F.; Baojun, Y.; Ju, L.; Jian, T.; Qing, Y.; Jiajun, X. Intelligent Monitoring System of Migratory Pests Based on Searchlight Trap and Machine Vision. Front. Plant Sci. 2022, 13, 897739. [Google Scholar] [CrossRef]

- Antanaitis, R.; Juozaitienė, V.; Televičius, M.; Malašauskienė, D.; Urbutis, M.; Baumgartner, W. Influence of Subclinical Ketosis in Dairy Cows on Ingestive-Related Behaviours Registered with a Real-Time System. Animals 2020, 10, 2288. [Google Scholar] [CrossRef]

- Jayaraman, P.P.; Yavari, A.; Georgakopoulos, D.; Morshed, A.; Zaslavsky, A. Internet of Things Platform for Smart Farming: Experiences and Lessons Learnt. Sensors 2016, 16, 1884. [Google Scholar] [CrossRef]

- Ouafiq, E.M.; Abdessamad, E.R.; Mehdary, A.; Chehri, A.; Rachid, S.; Wahbi, M. IoT in Smart Farming Analytics, Big Data Based Architecture. In Human Centred Intelligent Systems; Springer: Singapore, 2021; pp. 269–279. [Google Scholar] [CrossRef]

- Salau, J.; Krieter, J. Instance Segmentation with Mask R-CNN Applied to Loose-Housed Dairy Cows in a Multi-Camera Setting. Animals 2020, 10, 2402. [Google Scholar] [CrossRef] [PubMed]

- Hao, S.; Cai, S.; Sun, R.; Li, J.; Cheng, C. Design and implementation of IoT-based beef cattle breeding system. Int. Agric. Eng. J. 2017, 26, 302–309. [Google Scholar]

- Chen, P.J.; Du, Y.C.; Cheng, K.A.; Po, C.Y. Development of a management system with RFID and QR code for matching and breeding in Taiwan pig farm. In Proceedings of the 13th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, ECTI-CON 2016, Chiang Mai, Thailand, 28 June–1 July 2016. [Google Scholar] [CrossRef]

- Dineva, K.; Atanasova, T.; Petrov, P.; Parvanov, D.; Mateeva, G.; Kostadinov, G. Towards CPS/IoT System for Livestock Smart Farm Monitoring. In Proceedings of the 2021 International Conference Automatics and Informatics (ICAI), IEEE, Varna, Bulgaria, 30 September–1 October 2021; pp. 252–255. [Google Scholar] [CrossRef]

- Saravanan, K.; Saraniya, S. Cloud IoT based novel livestock monitoring and identification system using UID. Sens. Rev. 2018, 38, 21–33. [Google Scholar] [CrossRef]

- Caria, M.; Sara, G.; Todde, G.; Polese, M.; Pazzona, A. Exploring Smart Glasses for Augmented Reality: A Valuable and Integrative Tool in Precision Livestock Farming. Animals 2019, 9, 903. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zhao, B.; Yang, Q.; Zhou, L.; Jiang, H.; Niu, K.; Ding, J. Design and test of intelligent inspection and monitoring system for cotton bale storage based on RFID. Sci. Rep. 2022, 12, 4491. [Google Scholar] [CrossRef]

- Wark, J.D. Power Up: Combining Behavior Monitoring Software with Business Intelligence Tools to Enhance Proactive Animal Welfare Reporting. Animals 2022, 12, 1606. [Google Scholar] [CrossRef]

- Shao, C.; Yang, Y.; Juneja, S.; GSeetharam, T. IoT data visualization for business intelligence in corporate finance. Inf. Process. Manag. 2022, 59, 102736. [Google Scholar] [CrossRef]

- Kummar, L.; Al-Aani, F.S.; Kahtan, H.; Darr, M.; Al-Bashirl, H. Data Visualization for Smart Farming Using Mobile Application. Int. J. Comput. Sci. Netw. Sec. 2019, 19, 1–7. [Google Scholar]

- Sungheetha, A. Assimilation of IoT sensors for Data Visualization in a Smart Campus Environment. J. Ubiquitous Comput. Commun. Technol. 2021, 3, 241. [Google Scholar] [CrossRef]

- Poonam, G.; Mittal, A. Eminent Data Visualization Tools for Integration of Big Data with IoT. Int. J. Adv. Res. Sci. Commun. Technol. 2021, 5, 131–134. [Google Scholar] [CrossRef]

- Protopsaltis, A.; Sarigiannidis, P.; Margounakis, D.; Lytos, A. Data visualization in internet of things: Tools, methodologies, and challenges. In Proceedings of the 15th International Conference on Availability, Reliability and Security, ARES’20, Virtual Event, 25 August 2020; pp. 1–11. [Google Scholar] [CrossRef]

- Debauche, O.; Mahmoudi, S.; Manneback, P.; Lebeau, F. Cloud and distributed architectures for data management in agriculture 4.0: Review and future trends. J. King Saud Univ.-Comput. Inf. Sci. 2021, in press. [Google Scholar] [CrossRef]

- Tawalbeh, L.; Muheidat, F.; Tawalbeh, M.; Quwaider, M. IoT Privacy and Security: Challenges and Solutions. Appl. Sci. 2020, 10, 4102. [Google Scholar] [CrossRef]

- Gupta, M.; Abdelsalam, M.; Khorsandroo, S.; Mittal, S. Security and Privacy in Smart Farming: Challenges and Opportunities. IEEE Access 2020, 8, 34564–34584. [Google Scholar] [CrossRef]

- Dineva, K.; Atanasova, T. Cloud Services Providers Evaluation Model for Designing High Performance, Real-Time IoT Big Data Solutions, 2022. In Proceedings of the 8th SWS International Scientific Conference on Social Sciences—ISCSS 2021, Vienna, Austria, 7–8 December 2021. [Google Scholar] [CrossRef]

- Velosa, A.; Friedman, T.; Thielemann, K.; Berthelsen, E.; Havart-Simkin, P.; Goodness, E.; Flatley, M.; Jones, L.; Quinn, K. Magic Quadrant for Industrial IoT Platforms. Gartner. 2021. Available online: https://www.gartner.com/doc/reprints?id=1-27IESWUW&ct=210922&st=sb (accessed on 8 August 2022).

- Dineva, K.; Atanasova, T. Expandable IoT Architecture for Livestock in Agriculture 5.0. In Proceedings of the 21st International Multidisciplinary Scientific Geoconference—SGEM 2021, 6.1, Albena, Bulgaria, 16–22 August 2021; pp. 147–154. [Google Scholar] [CrossRef]

- Tiwari, S. An Introduction to QR Code Technology. In Proceedings of the International Conference on Information Technology (ICIT), Bhubaneswar, India, 22–24 December 2016; pp. 39–44. [Google Scholar]

- Lendel, V.; Špaleková, D.; Lendelová, L.; Šotek, M. The Innovative Intelligence System—A Tool for Discovering Innovative Opportunities and for Ensuring the Sustainability and Business Prosperity. Sustainability 2021, 13, 12305. [Google Scholar] [CrossRef]

- Mankad, K. Intelligent Systems Design Approaches: A Review. Int. J. Eng. Manag. Res. 2015, 5, 208–213. [Google Scholar]

- Rovira Más, F.; Zhang, Q.; Hansen, A. Design of Intelligent Systems. In Mechatronics and Intelligent Systems for Off-Road Vehicles; Springer: London, UK, 2010. [Google Scholar] [CrossRef]

- Karthikeyan, S. Azure Well-Architected Framework: What and why? In Demystifying the Azure Well-Architected Framework; Apress: Berkeley, CA, USA, 2021. [Google Scholar] [CrossRef]

- Daher, Z.; Hajjdiab, H. Cloud Storage Comparative Analysis Amazon Simple Storage vs. Microsoft Azure Blob Storage. Int. J. Mach. Learn. Comput. 2018, 8, 85–89. [Google Scholar] [CrossRef]

- Barnes, J. Microsoft Azure Essentials Azure Machine Learning; Microsoft Press: Unterschleissheim, Germany, 2015. [Google Scholar]

- Dmitrieva, N.Y. Power BI as an auxiliary tool for biostatistics. Real-World Data Evid. 2022, 2, 36–39. [Google Scholar] [CrossRef]

- Sharma, S. A Comparative Study on Machine Learning Algorithms for Customer Churn Analytics with Power BI Dashboard. University School of Management and Entrepreneurship. Delhi Technological University. 2020. Available online: http://dspace.dtu.ac.in:8080/jspui/handle/repository/17995 (accessed on 12 July 2022).

- Tsochev, G.; Trifonov, R. Cloud computing security requirements: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1216, 012001. [Google Scholar] [CrossRef]

- Azure Blob Storage Documentation. 2021. Available online: https://docs.microsoft.com/en-us/azure/storage/blobs/storage-blobs-overview (accessed on 21 July 2022).

- Azure Stream Analytics Documentation. 2022. Available online: https://docs.microsoft.com/en-us/azure/stream-analytics/stream-analytics-introduction (accessed on 21 July 2022).

- Buuren, S. Flexible Imputation of Missing Data, 2nd ed.; Chapman & Hall/CRC: Boca Raton, FL, USA, 2018. [Google Scholar]

- Mund, S. Microsoft Azure Machine Learning. Professional Expertise Distilled; Packt Publishing: Birmingham, UK, 2015. [Google Scholar]

- Friedman, J.H. Greedy function approximation: A gradient boosting machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Ketipov, R.; Kostadinov, G.; Petrov, P.; Zankinski, I.; Balabanov, T. Genetic Algorithm Based Formula Generation for Curve Fitting in Time Series Forecasting Implemented as Mobile Distributed Computing. Adv. High Perform. Comput. 2020, 902, 40–47. [Google Scholar] [CrossRef]

- Yuan, T.; Ou, D.; Wang, J.; Jiang, C.; Cérin, C.; Yan, L. PPCTS: Performance Prediction-Based Co-Located Task Scheduling in Clouds. In Algorithms and Architectures for Parallel Processing; ICA3PP 2021, Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2021; Volume 13157. [Google Scholar] [CrossRef]

- Martins, N.; Martins, S.; Brandão, D. Design Principles in the Development of Dashboards for Business Management. In Perspectives on Design II; Springer Series in Design and Innovation; Raposo, D., Neves, J., Silva, J., Eds.; Springer: Cham, Switzerland, 2022; Volume 16. [Google Scholar] [CrossRef]

- Dineva, K.; Atanasova, T. Security in IoT Systems. In Proceedings of the 19th International Multidisciplinary Scientific Geoconference SGEM 2019, Albena, Bulgaria, 30 June–6 July 2019; Volume 19, Book number 2.1. pp. 569–578. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dineva, K.; Atanasova, T. Cloud Data-Driven Intelligent Monitoring System for Interactive Smart Farming. Sensors 2022, 22, 6566. https://doi.org/10.3390/s22176566

Dineva K, Atanasova T. Cloud Data-Driven Intelligent Monitoring System for Interactive Smart Farming. Sensors. 2022; 22(17):6566. https://doi.org/10.3390/s22176566

Chicago/Turabian StyleDineva, Kristina, and Tatiana Atanasova. 2022. "Cloud Data-Driven Intelligent Monitoring System for Interactive Smart Farming" Sensors 22, no. 17: 6566. https://doi.org/10.3390/s22176566

APA StyleDineva, K., & Atanasova, T. (2022). Cloud Data-Driven Intelligent Monitoring System for Interactive Smart Farming. Sensors, 22(17), 6566. https://doi.org/10.3390/s22176566