A Permanent Magnet Ferromagnetic Wear Debris Sensor Based on Axisymmetric High-Gradient Magnetic Field

Abstract

:1. Introduction

- The chamfered structure of the sensor can enhance the strength and axial gradient of the magnetic field in the flow channel, which improves the sensing performance of the wear debris sensor;

- A mathematical model and a simulation model of the sensor is established. The influence of related design parameters on sensor performance was analyzed and the simulation was verified by single wear debris experiments;

- Lube oil cycle experiments were carried out, it was found that the sensor can effectively detect iron particles of 50 μm in size in lube oil at a flow rate of 500 mL/min.

2. Structure, Principle and Model

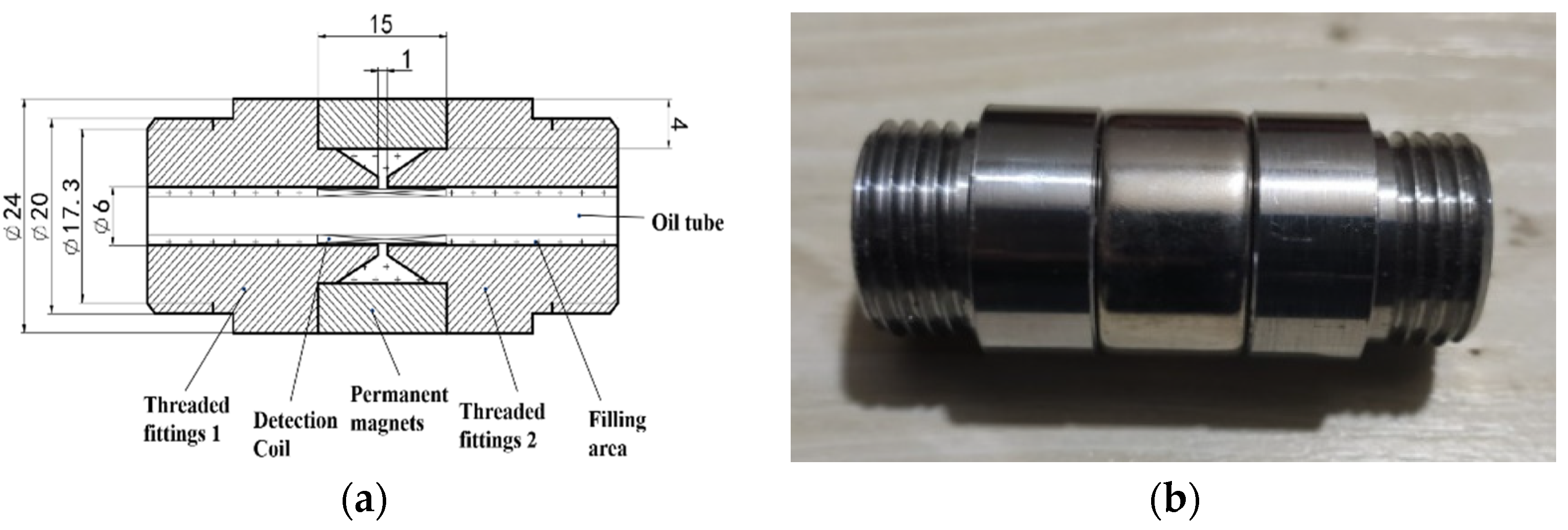

2.1. Sensor Structure

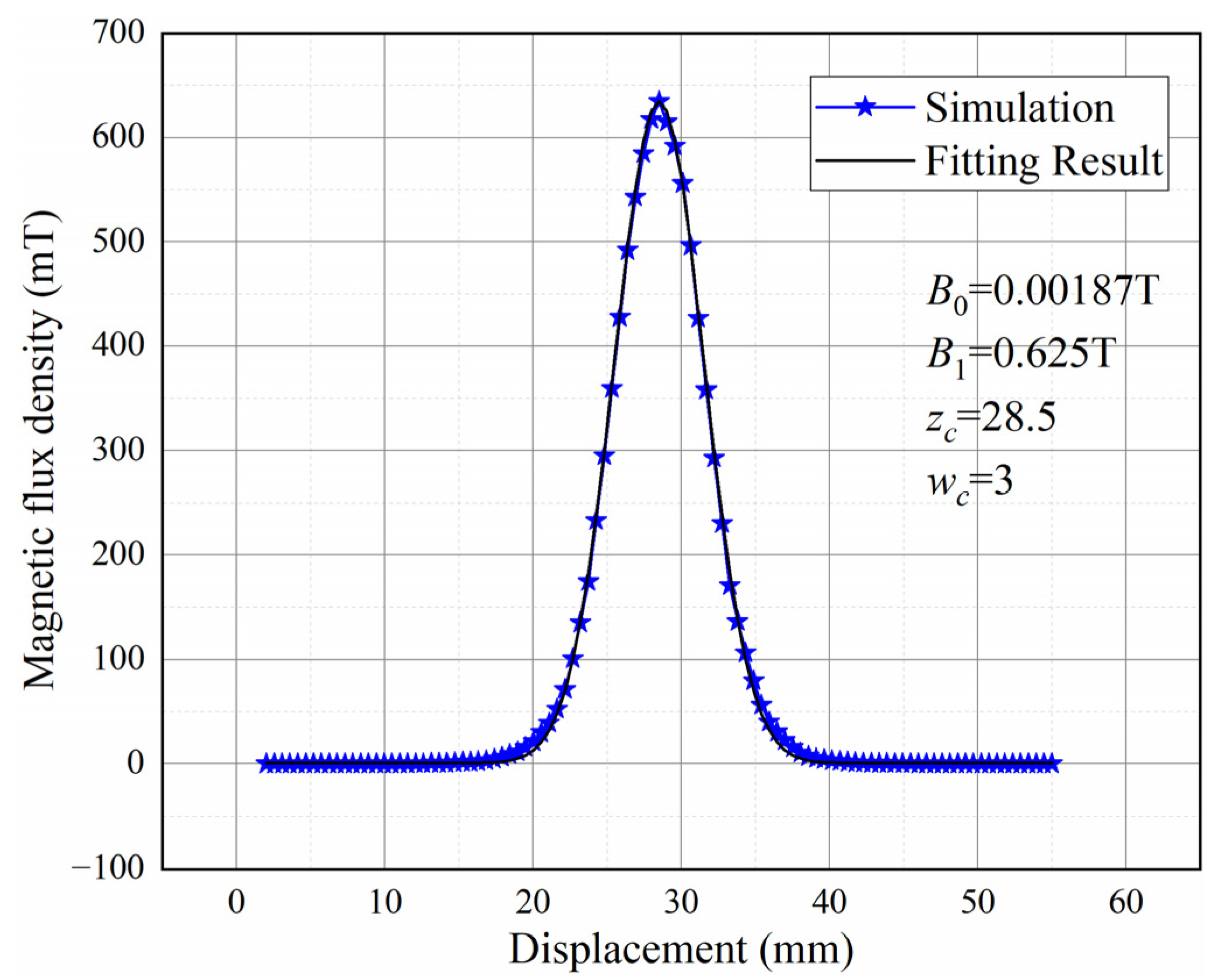

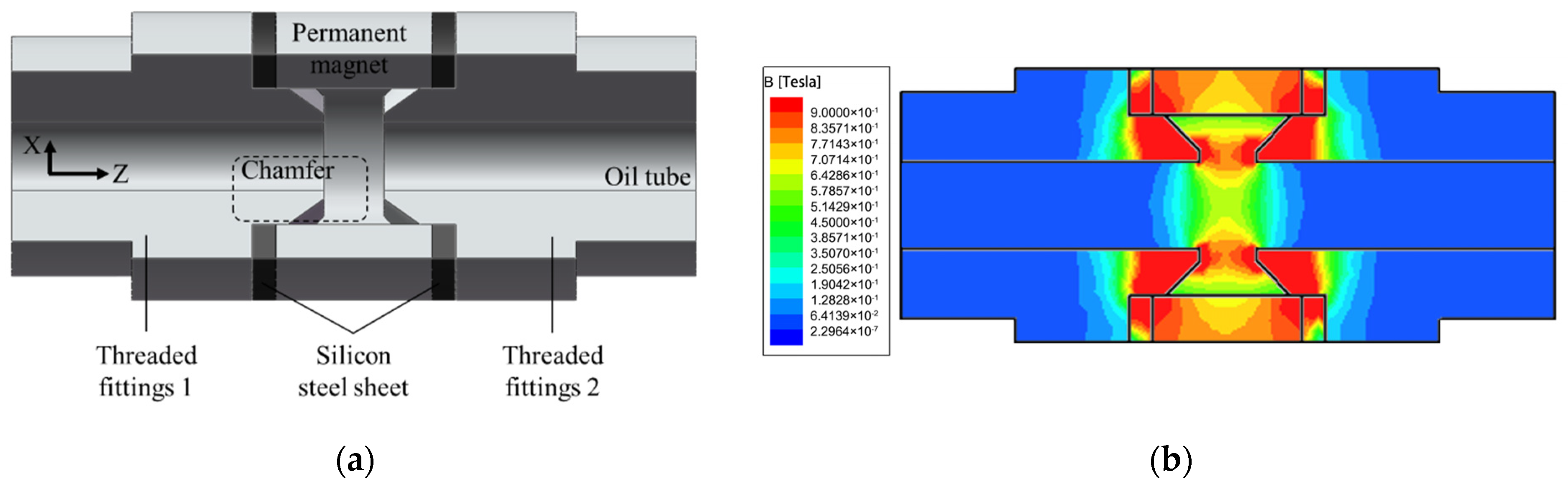

2.2. Magnetic Field Analysis

2.3. Detetion Principle and Inductive Voltage Model

3. Simulation and Analysis of Factors Affecting Sensing Performance

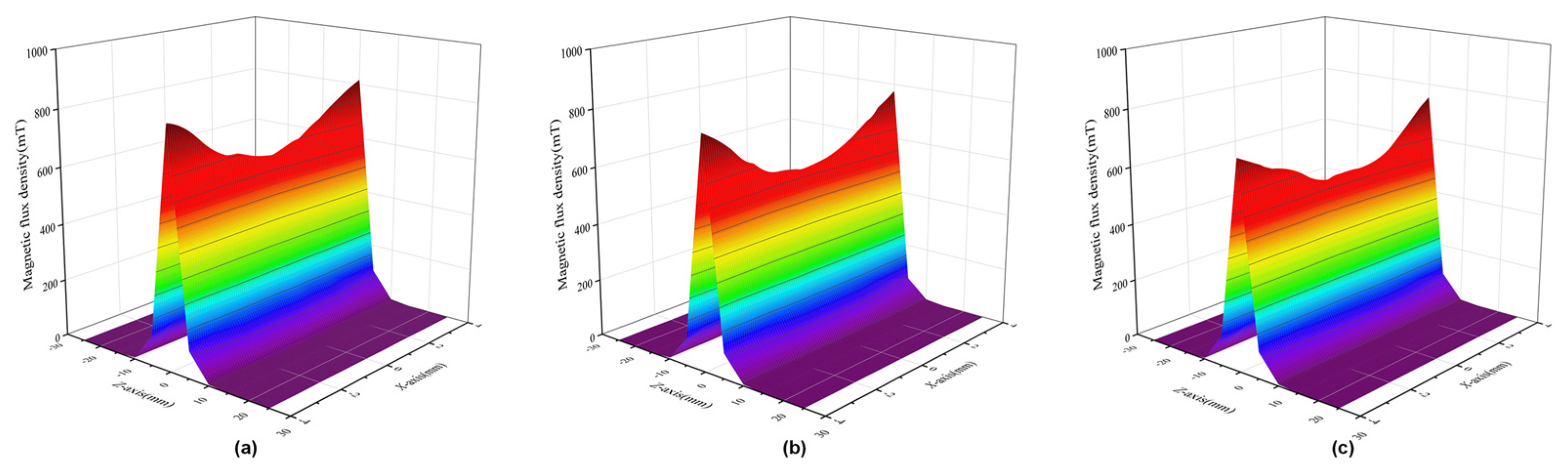

3.1. Effect of Air Gap Distance

3.2. Effect of the Chamfer Angle

3.3. Effect of Relative Magnetic Permeability

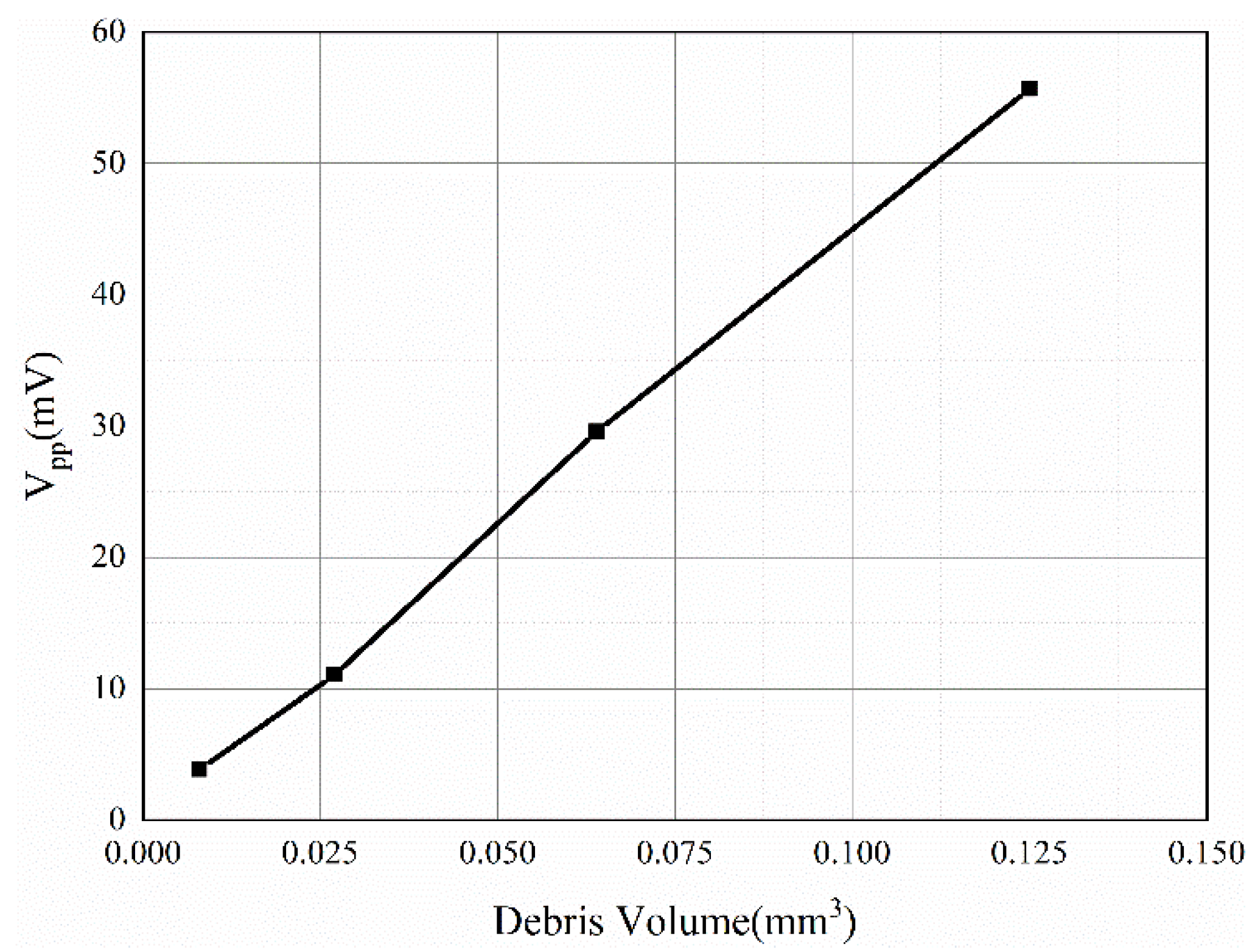

3.4. Effect of Wear Debris Volume

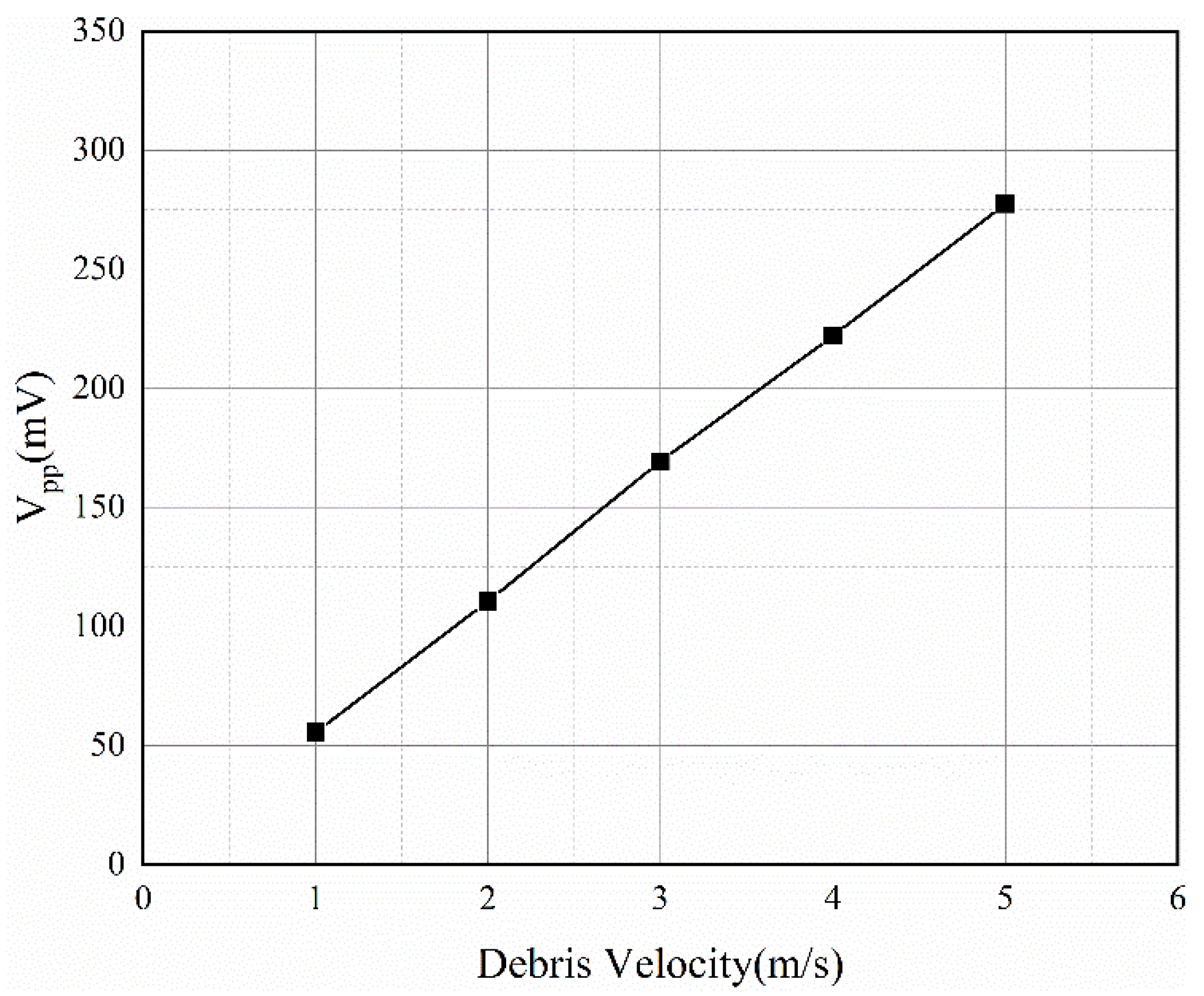

3.5. Effect of Wear Debris Velocity

4. Experiment, Verification, and Discussion

4.1. Experimental Verification of Different Air Gap Distances

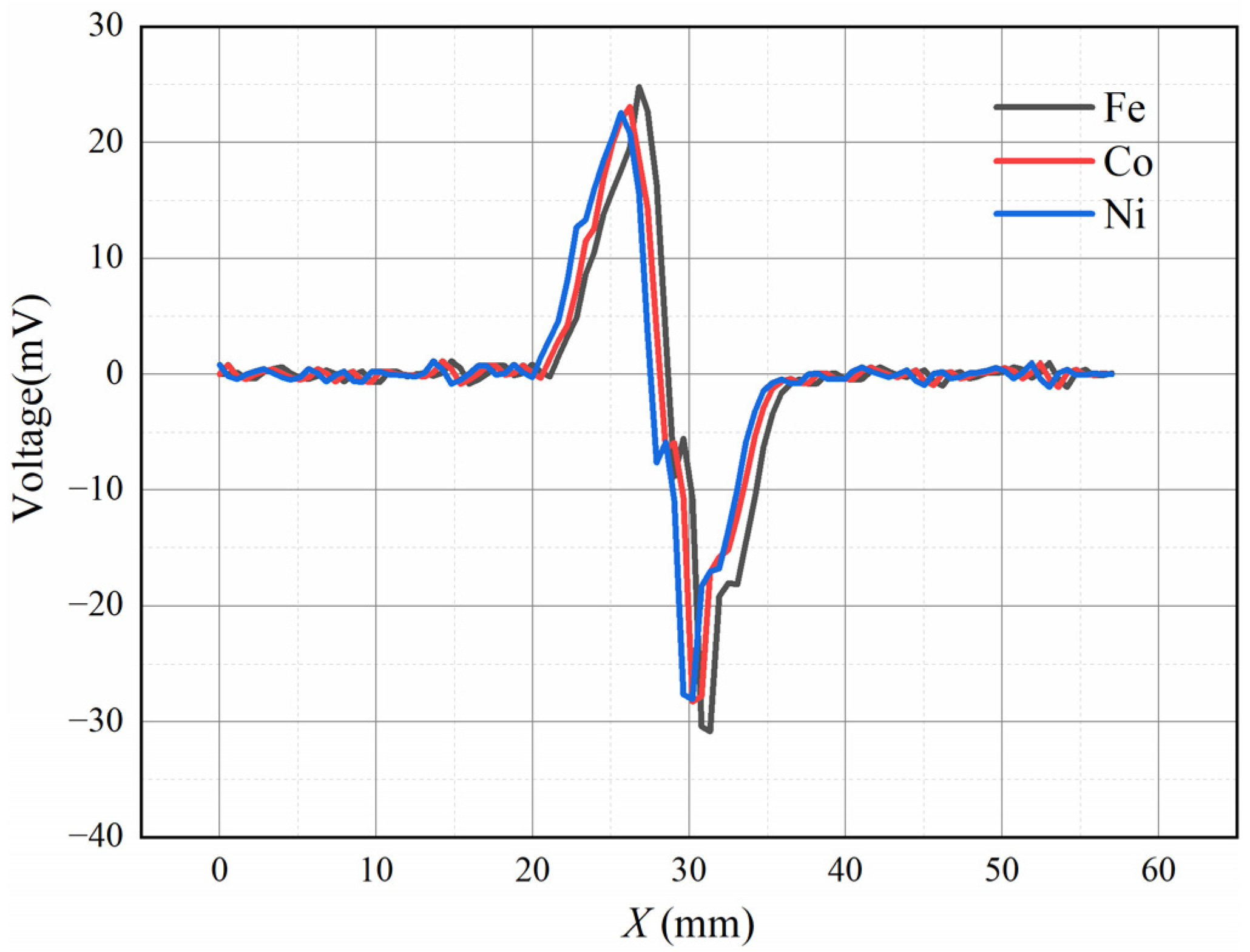

4.2. Experimental Verification for Different Relative Magnetic Permeabilities

4.3. Experimental Verification for Different Wear Debris Volumes

4.4. Experimental Verification for Wear Debris with Different Velocties

4.5. Comparation with Other Electromagnetic Sensors

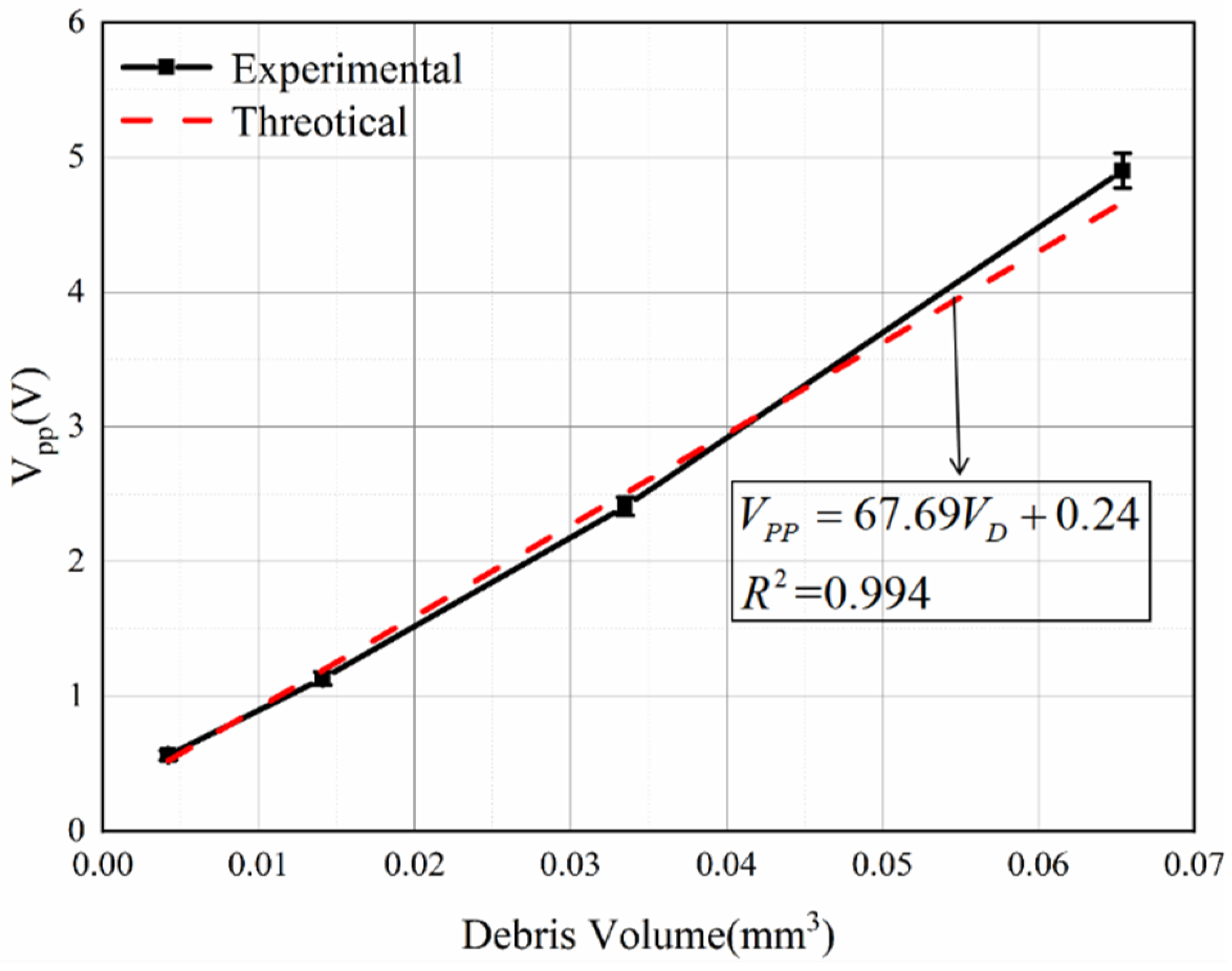

5. Sensor Calibration

6. Detection Accuracy of Ferromagnetic Particle

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, R.; Gao, R.X. Complexity as a Measure for Machine Health Evaluation. IEEE Trans. Instrum. Meas. 2004, 53, 1327–1334. [Google Scholar] [CrossRef]

- Bartelmus, W.; Zimroz, R. Vibration condition monitoring of planetary gearbox under varying external load. Mech. Syst. Signal Process. 2008, 23, 246–257. [Google Scholar] [CrossRef]

- Cao, W.; Dong, G.; Xie, Y.B.; Peng, Z. Prediction of wear trend of engines via on-line wear debris monitoring. Tribol. Int. 2018, 120, 510–519. [Google Scholar] [CrossRef]

- Kumar, M.; Mukherjee, P.S.; Misra, N.M. Advancement and current status of wear debris analysis for machine condition monitoring: A review. Ind. Lubr. Tribol. 2013, 65, 3–11. [Google Scholar] [CrossRef]

- Lim, T.C.; Singh, R. Vibration transmission through rolling element bearings, part II: System studies. J. Sound Vib. 1990, 139, 201–225. [Google Scholar] [CrossRef]

- Zhu, J.; Yoon, J.M.; He, D.; Bechhoefer, E. Online particle-contaminated lubrication oil condition monitoring and remaining useful life prediction for wind turbines. Wind. Energy 2014, 18, 1131–1149. [Google Scholar] [CrossRef]

- Wakiru, J.M.; Pintelon, L.; Muchiri, P.N.; Chemweno, P.K. A review on lubricant condition monitoring information analysis for maintenance decision support. Mech. Syst. Signal Process. 2019, 118, 108–132. [Google Scholar] [CrossRef]

- Loutas, T.H.; Roulias, D.; Pauly, E.; Kostopoulos, V. The combined use of vibration, acoustic emission and oil debris on-line monitoring towards a more effective condition monitoring of rotating machinery. Mech. Syst. Signal Process. 2011, 25, 1339–1352. [Google Scholar] [CrossRef]

- Muthuvel, P.; George, B.; Ramadass, G.A. Magnetic-Capacitive Wear Debris Sensor Plug for Condition Monitoring of Hydraulic Systems. IEEE Sens. J. 2018, 18, 9120–9127. [Google Scholar] [CrossRef]

- Li, B.; Wu, W.; Zhou, M.; Xi, Y.; Wei, H.; Mao, J. A Full Field-of-View Online Visual Ferrograph Debris Detector Based on Reflected Light Microscopic Imaging. IEEE Sens. J. 2021, 21, 16584–16597. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, P.; Wang, H.; Li, Y.; Lv, C. Ultrasonic echo waveshape features extraction based on QPSO-matching pursuit for online wear debris discrimination. Mech. Syst. Signal Process. 2015, 60, 301–315. [Google Scholar] [CrossRef]

- Xiao, H.; Wang, X.; Li, H.; Luo, J.; Feng, S. An inductive debris sensor for a large-diameter lubricating oil circuit based on a high-gradient magnetic field. Appl. Sci. 2019, 9, 1546. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Wu, J.; Guo, Q. Electromagnetic Sensor for Detecting Wear Debris in Lubricating Oil. IEEE Trans. Instrum. Meas. 2020, 69, 2533–2541. [Google Scholar] [CrossRef]

- Muthuvel, P.; George, B.; Ramadass, G.A. A Planar Inductive Based Oil Debris Sensor Plug. In Proceedings of the 13th International Conference on Sensing Technology (ICST), Macquarie Univ, Sydney, Australia, 2–4 December 2019. [Google Scholar] [CrossRef]

- Yimeng, L.; Jing, W.; Qiang, G. Design on Electromagnetic Detection Sensor on Wear Debris in Lubricating Oil. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019; p. 5. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.; Li, J.; Li, F.; Li, J.; Lu, H. Online oil debris monitoring of rotating machinery: A detailed review of more than three decades. Mech. Syst. Signal Process. 2021, 149, 107341. [Google Scholar] [CrossRef]

- Muir, D.; Howe, B. In-Line Oil Debris Monitor (ODM) for the Advanced Tactical Fighter Engine; GASTOPS LTD: Gloucester, ON, Canada, 1996. [Google Scholar]

- Zeng, L.; Yu, Z.; Zhang, H.; Zhang, X.; Chen, H. A high sensitive multi-parameter micro sensor for the detection of multi-contamination in hydraulic oil. Sens. Actuators A Phys. 2018, 282, 197–205. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J.; Carletta, J.; Veillette, R.; Choy, F. Real-time monitoring of wear debris in lubrication oil using a microfluidic inductive Coulter counting device. Microfluid. Nanofluidics 2010, 9, 1241–1245. [Google Scholar] [CrossRef]

- Du, L.; Zhu, X.; Han, Y.; Zhao, L.; Zhe, J. Improving sensitivity of an inductive pulse sensor for detection of metallic wear debris in lubricants using parallel LC resonance method. Meas. Technol. 2013, 24, 660–664. [Google Scholar] [CrossRef]

- Zhu, X.; Du, L.; Zhe, J. A 3×3 wear debris sensor array for real time lubricant oil conditioning monitoring using synchronized sampling. Mech. Syst. Signal Process. 2017, 83, 296–304. [Google Scholar] [CrossRef]

- Ren, Y.J.; Li, W.; Zhao, G.F.; Feng, Z.H. Inductive debris sensor using one energizing coil with multiple sensing coils for sensitivity improvement and high throughput. Tribol. Int. 2018, 128, 96–103. [Google Scholar] [CrossRef]

- Lei, H.; Wei, H.; Shaoping, W. The key points of inductive wear debris sensor. In Proceedings of the 2011 International Conference on Fluid Power and Mechatronics, Beijing, China, 17–20 August 2011; pp. 809–815. [Google Scholar] [CrossRef]

- Qian, M.; Ren, Y.; Zhao, G.; Feng, Z. Ultrasensitive Inductive Debris Sensor With a Two-Stage Autoasymmetrical Compensation Circuit. IEEE Trans. Ind. Electron. 2021, 68, 8885–8893. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. A high throughput inductive pulse sensor for online oil debris monitoring. Tribol. Int. 2021, 44, 175–179. [Google Scholar] [CrossRef]

- Feng, S.; Yang, L.; Qiu, G.; Luo, J.; Li, R.; Mao, J. An Inductive Debris Sensor Based on a High-Gradient Magnetic Field. IEEE Sens. J. 2019, 19, 2879–2886. [Google Scholar] [CrossRef]

- Feng, S.; Yang, L.; Fan, B.; Li, R.; Luo, J.; Mao, J. A Ferromagnetic Wear Debris Sensor Based on a Rotational Symmetry High-Gradient Magnetostatic Field. IEEE Trans. Instrum. Meas. 2020, 70, 9504709. [Google Scholar]

- Hong, W.; Wang, S.; Tomovic, M.; Han, L.; Shi, J. Radial inductive debris detection sensor and performance analysis. Meas. Ence Technol. 2013, 24, 125103. [Google Scholar] [CrossRef] [Green Version]

- Hong, W.; Wang, S.; Tomovic, M.M.; Liu, H.; Wang, X. A new debris sensor based on dual excitation sources for online debris monitoring. Meas. Sci. Technol. 2015, 26, 095101. [Google Scholar] [CrossRef]

- Yuan, Z.; Feng, S.; Tan, J.; Liu, H. A Passive Ferro-particle Sensor of Lube-oil Based on Single Permanent Magnetic Ring. IEEE Sens. J. 2021, 22, 8565–8573. [Google Scholar] [CrossRef]

- Zhang, X.; Zeng, L.; Zhang, H.; Huang, S. Magnetization Model and Detection Mechanism of a Microparticle in a Harmonic Magnetic Field. IEEE/ASME Trans. Mechatron. 2019, 24, 1882–1892. [Google Scholar] [CrossRef]

- GasTops, Ltd. “On-line Oil Debris Monitor MS4000,” Documentation. Available online: https://www.gastops.com/wp-content/uploads/MS4000-Product-Overview.pdf (accessed on 24 October 2022).

- Shi, H.; Zhang, H.; Ma, L.; Rogers, F.; Zhao, X.; Zeng, L. An Impedance Debris Sensor Based on a High-Gradient Magnetic Field for High Sensitivity and High Throughput. IEEE Trans. Ind. Electron. 2021, 68, 5376–5384. [Google Scholar] [CrossRef]

| Parameter | Explanation | Value |

|---|---|---|

| Material of permanent magnet | NdFeB | |

| Air gap distance | 1, 2, 3, 4, 5, 6, 7, 8, 9 mm | |

| Chamfer angle | 45°, 60°, 75° | |

| Relative Magnetic Permeability | Fe (7000), Co (174), Ni (1120) | |

| Square iron wear debris of different sizes | length of 0.2–0.5 mm | |

| Wear debris velocity | 1, 2, 3, 4, 5 m/s |

| Metal Material | Density (g/cm3) | Relative Magnetic Permeability |

|---|---|---|

| Fe | 7.86 | 7000 |

| Co | 8.9 | 174 |

| Ni | 8.9 | 1120 |

| Ref | Minimum Detectable Ferro-Particle Size (μm) | Diameter of Oil Tube (mm) | Easy to Fabricate | Easy to Extract Signal |

|---|---|---|---|---|

| [32] | 100 | 7.6 | NO | NO |

| [33] | 16 | 0.5 | NO | NO |

| [30] | 30 | 2 | YES | YES |

| This paper | 50 | 6 | YES | YES |

| VD (mm3) | v (m/s) | Vpp (V) |

|---|---|---|

| 1.1102 | 0.4476 ± 0.0324 | |

| 0.0042 | 1.4761 | 0.5630 ± 0.0358 |

| 1.8427 | 0.6840 ± 0.0294 | |

| 1.1102 | 0.8945 ± 0.0341 | |

| 0.0141 | 1.4761 | 1.1334 ± 0.0492 |

| 1.8427 | 1.3848 ± 0.0479 | |

| 1.1102 | 1.8247 ± 0.0217 | |

| 0.0335 | 1.4761 | 2.4099 ± 0.0680 |

| 1.8427 | 2.9636 ± 0.1031 | |

| 1.1102 | 3.5967 ± 0.0575 | |

| 0.0654 | 1.4761 | 4.8997 ± 0.1299 |

| 1.8427 | 6.1112 ± 0.3113 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, B.; Liu, Y.; Zhang, P.; Wang, L.; Zhang, C.; Wang, J. A Permanent Magnet Ferromagnetic Wear Debris Sensor Based on Axisymmetric High-Gradient Magnetic Field. Sensors 2022, 22, 8282. https://doi.org/10.3390/s22218282

Fan B, Liu Y, Zhang P, Wang L, Zhang C, Wang J. A Permanent Magnet Ferromagnetic Wear Debris Sensor Based on Axisymmetric High-Gradient Magnetic Field. Sensors. 2022; 22(21):8282. https://doi.org/10.3390/s22218282

Chicago/Turabian StyleFan, Bin, Yong Liu, Peng Zhang, Lianfu Wang, Chao Zhang, and Jianguo Wang. 2022. "A Permanent Magnet Ferromagnetic Wear Debris Sensor Based on Axisymmetric High-Gradient Magnetic Field" Sensors 22, no. 21: 8282. https://doi.org/10.3390/s22218282