Characterization of Damage Progress in the Defective Grouted Sleeve Connection Using Combined Acoustic Emission and Ultrasonics

Abstract

:1. Introduction

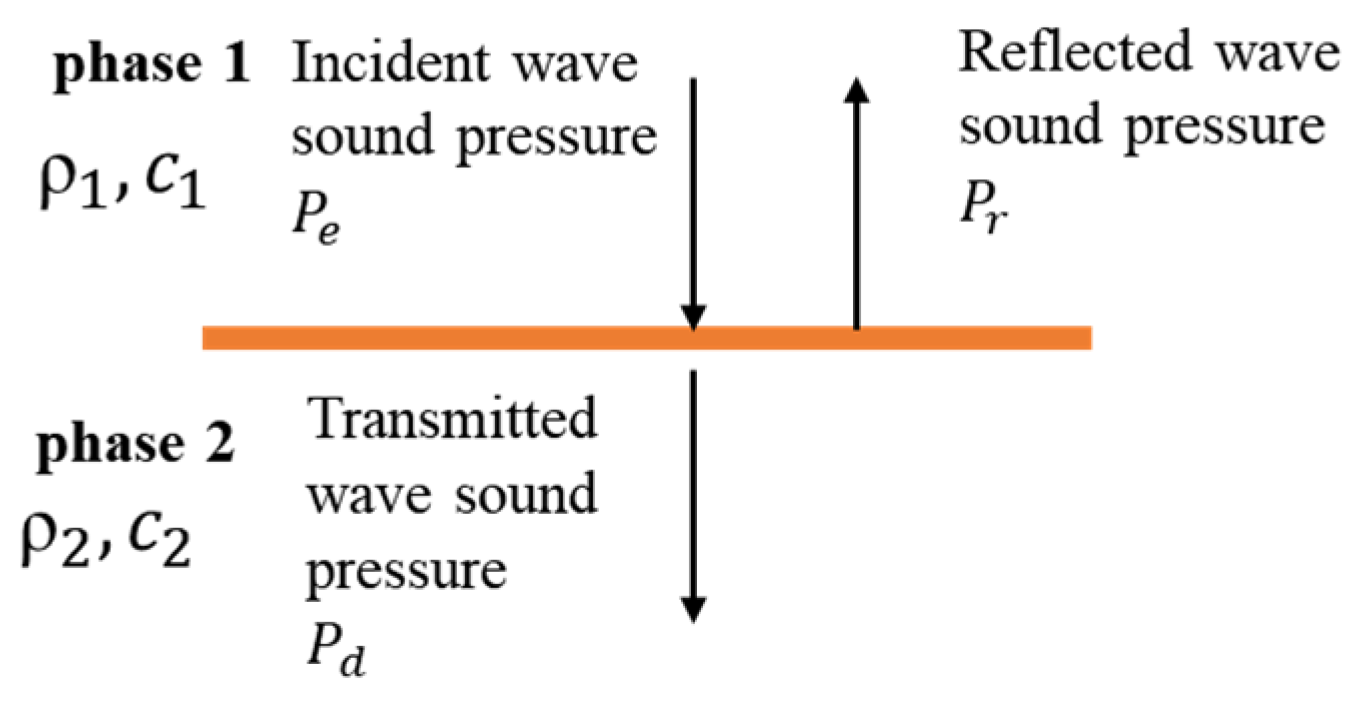

2. The Mechanism of Ultrasonic-Based Detection on the Internal Flaws

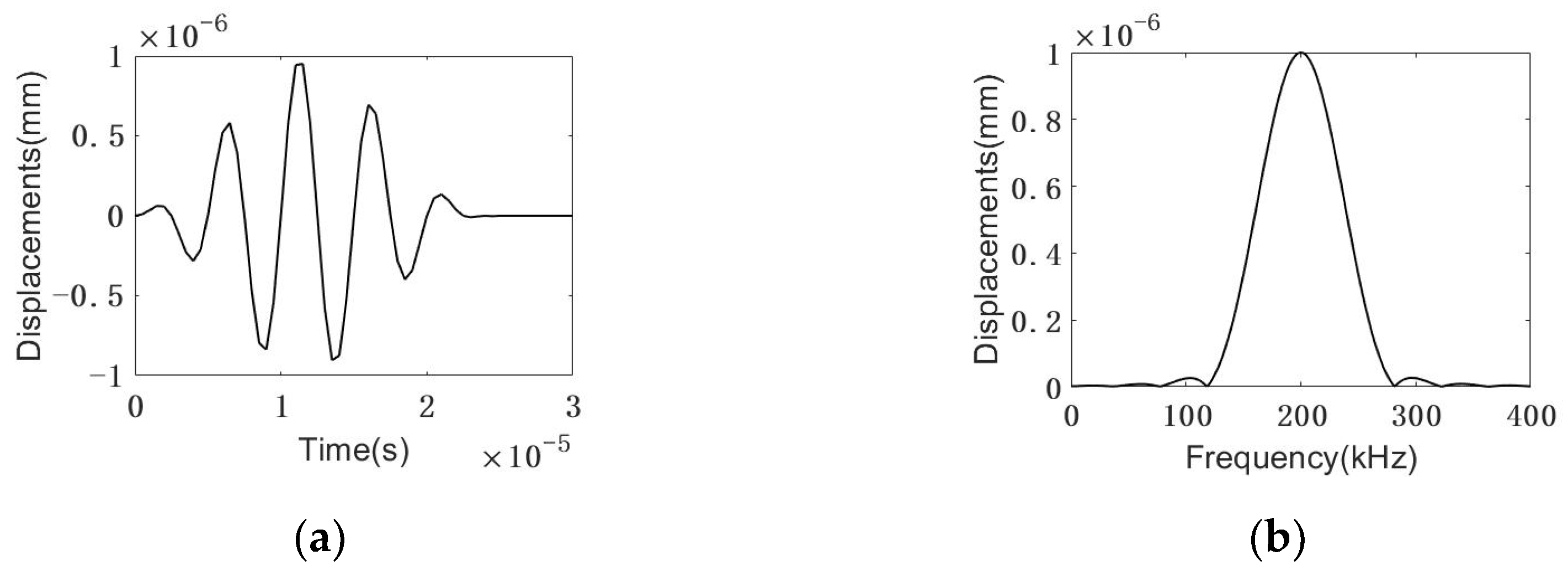

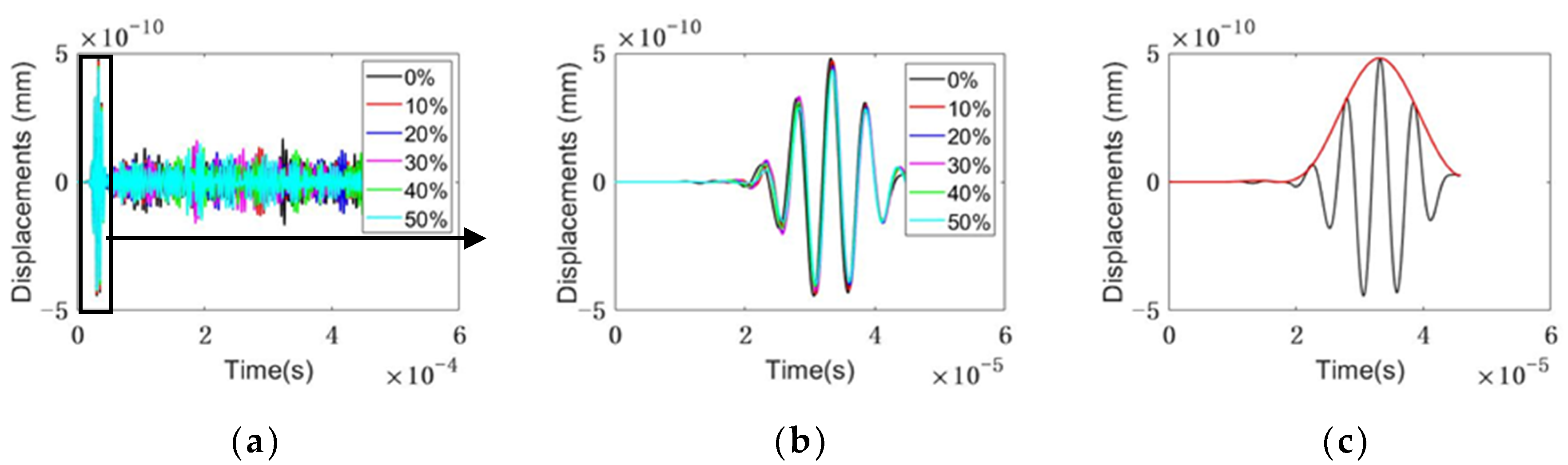

3. Numerical Validation

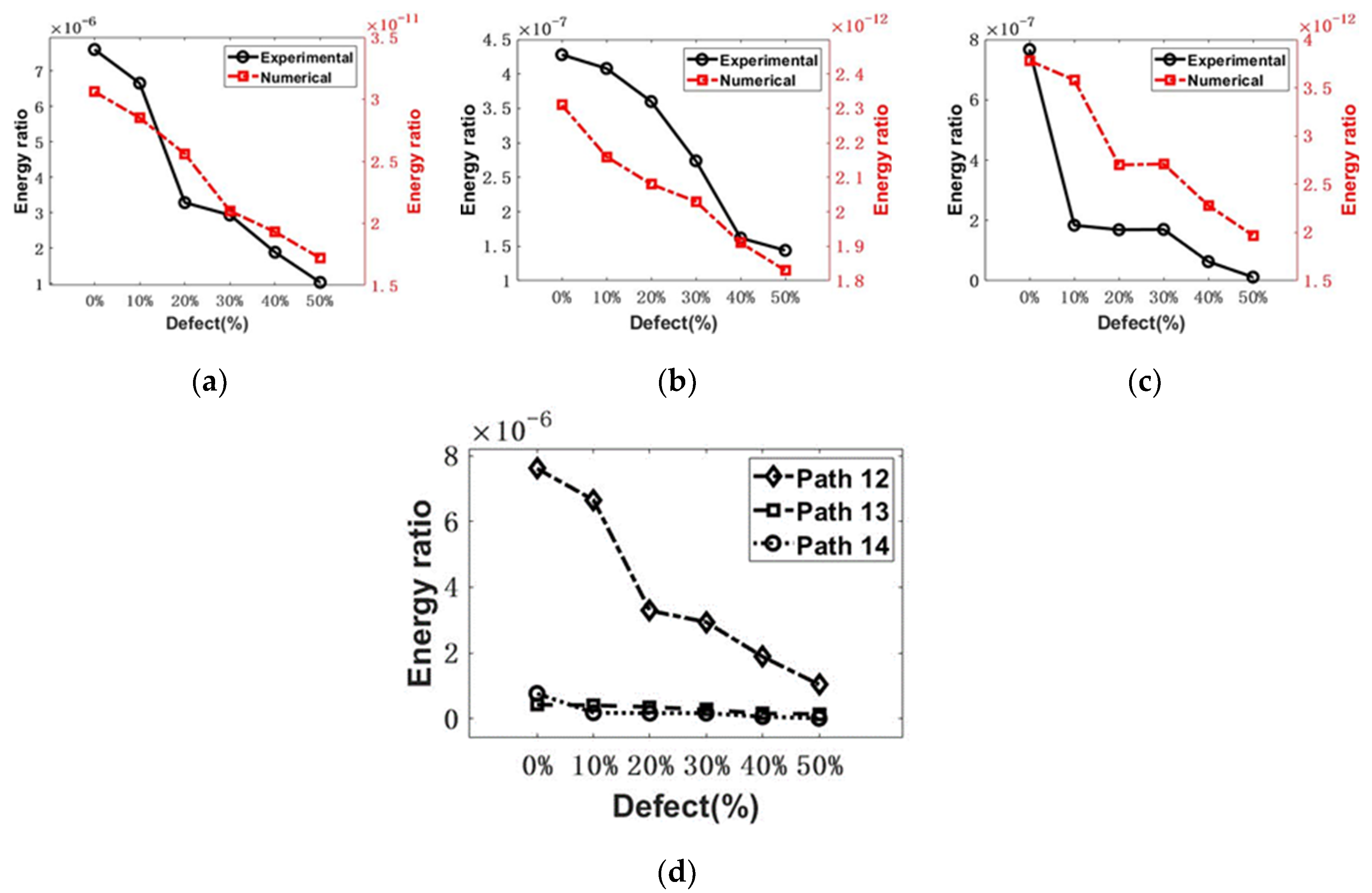

4. Numerical Results

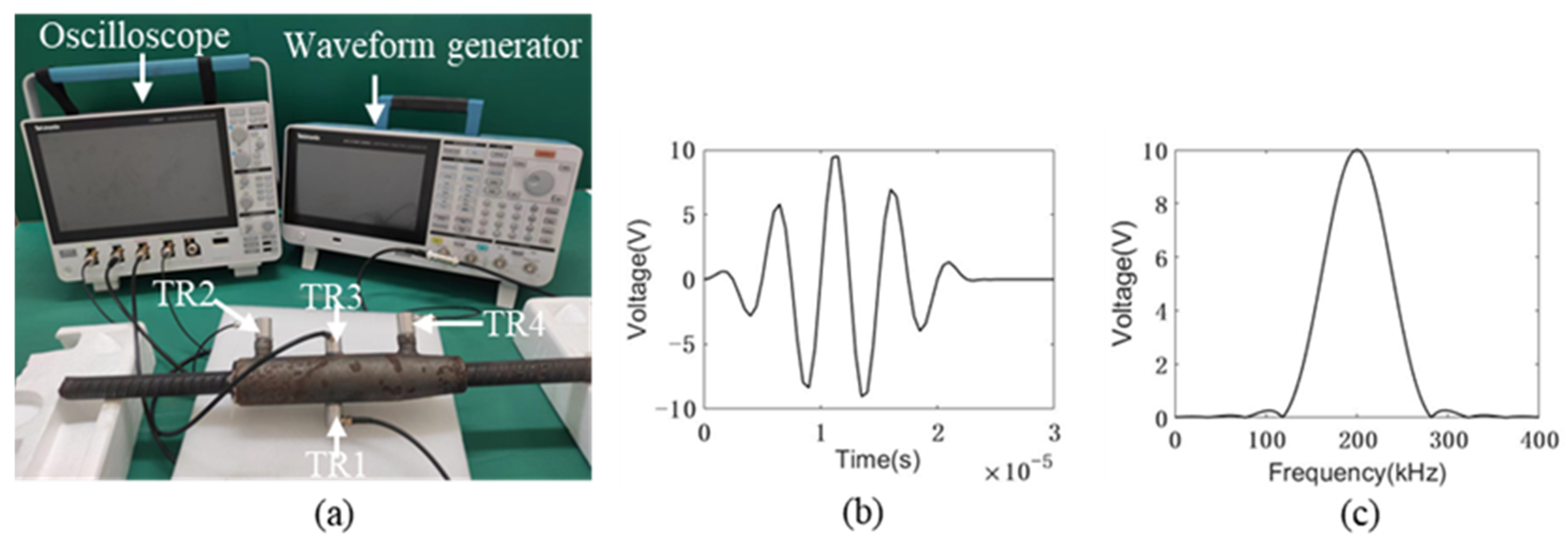

5. Experimental Verification

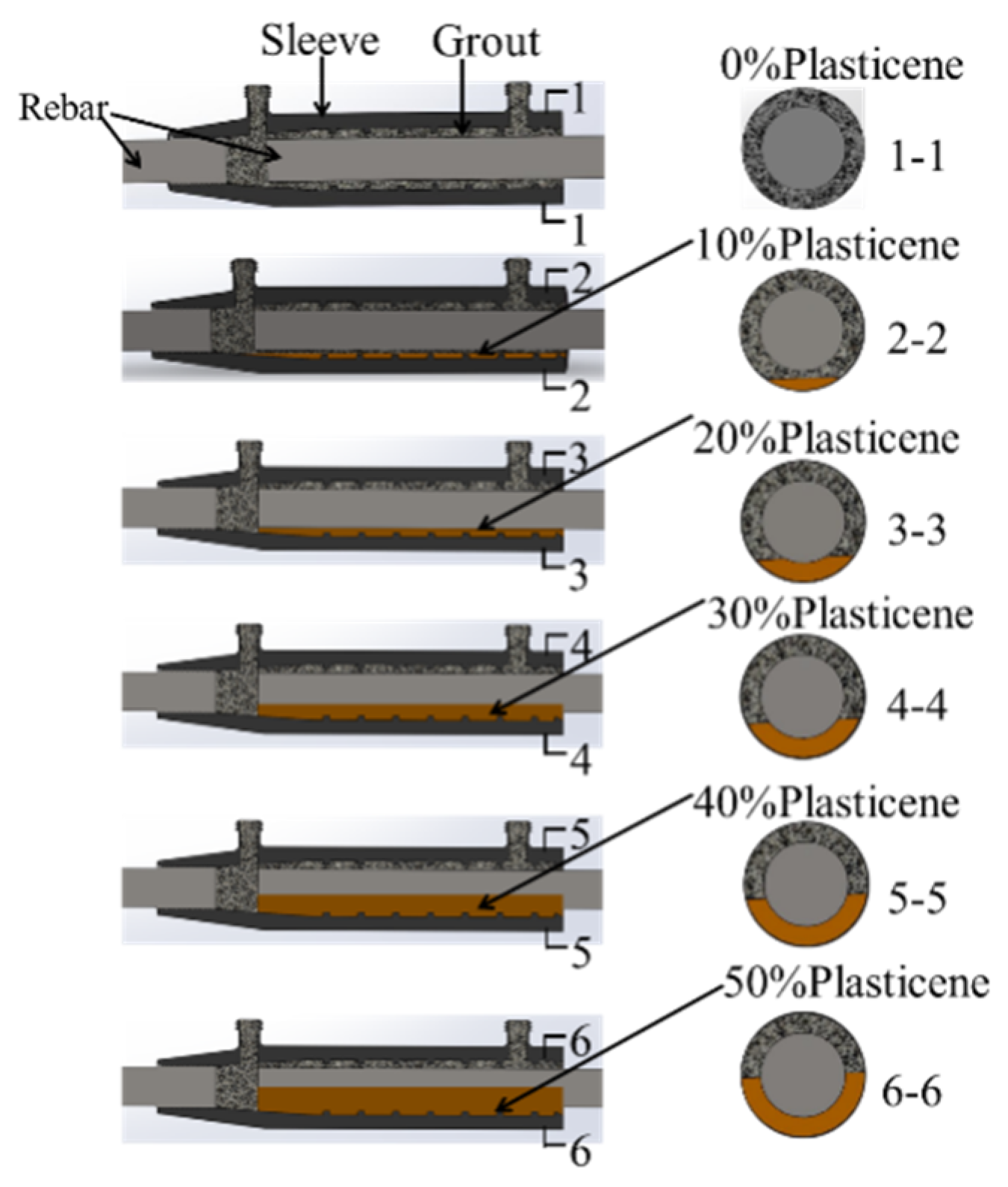

5.1. The Preparation of Specimens

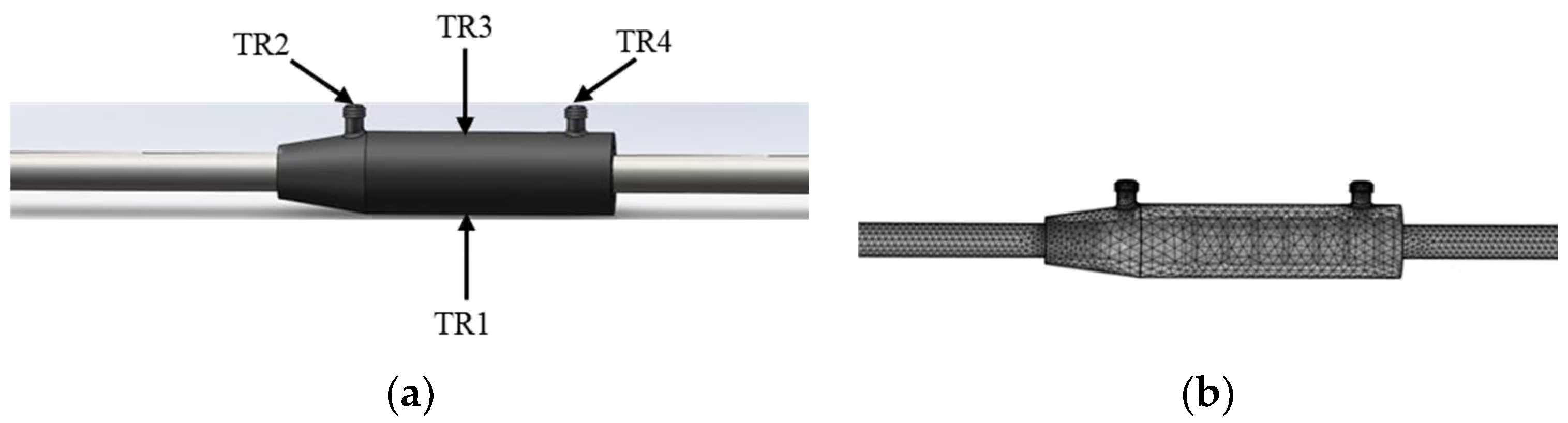

5.2. Experimental Setup

5.3. Experimental Result

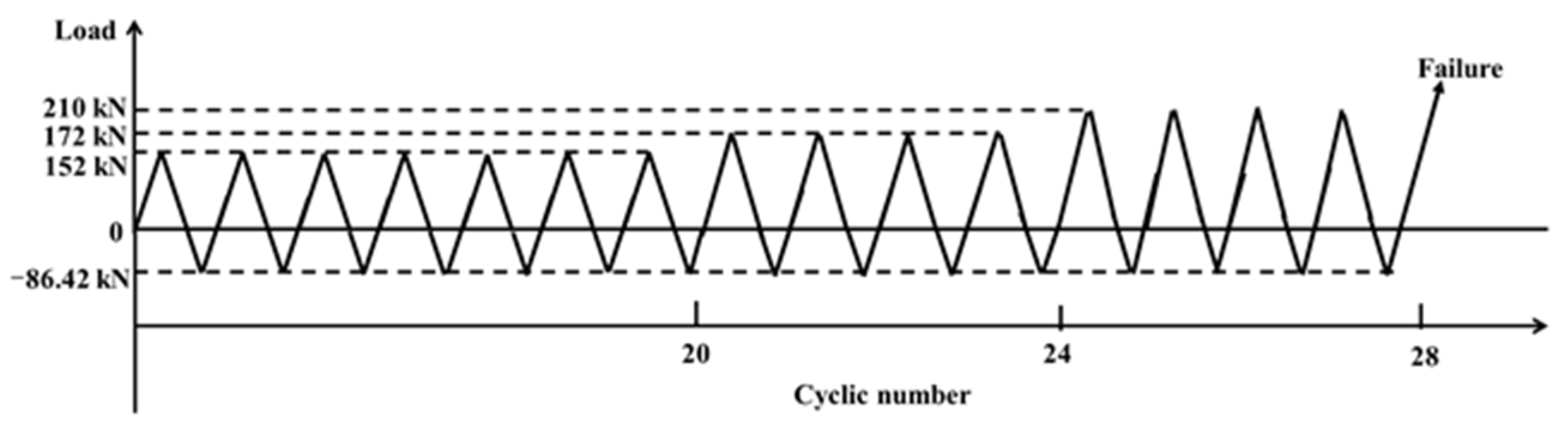

6. AE Characterization of Damage Progress in Grouted Sleeve Connector

6.1. Experimental Setup

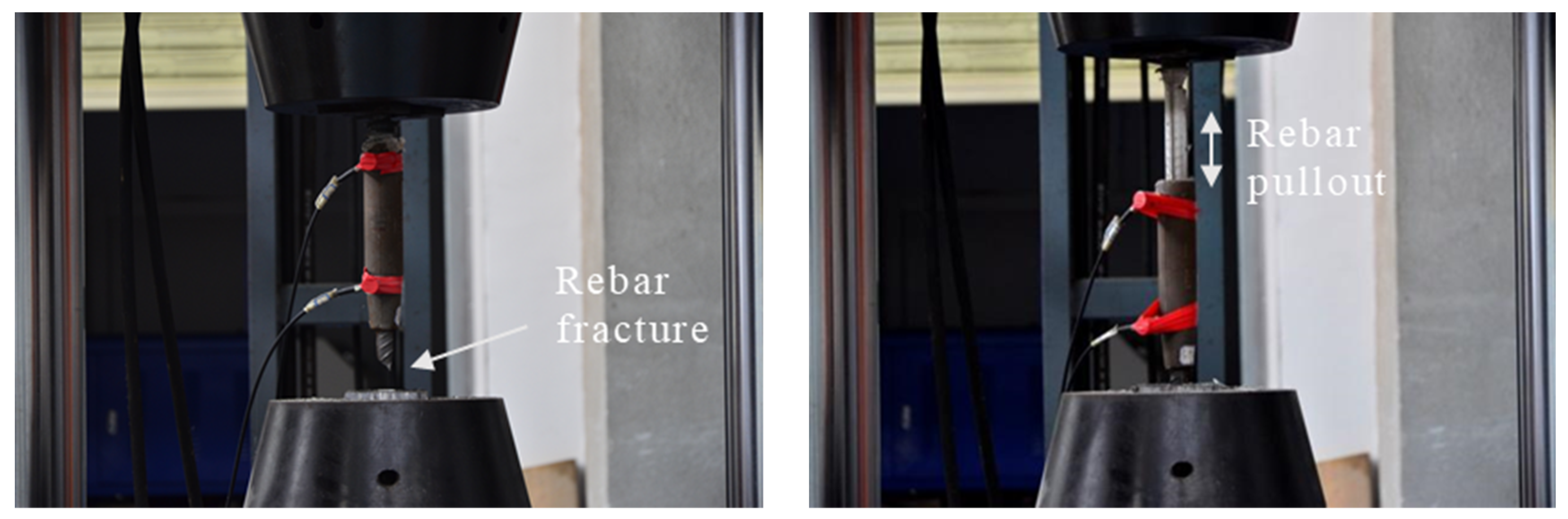

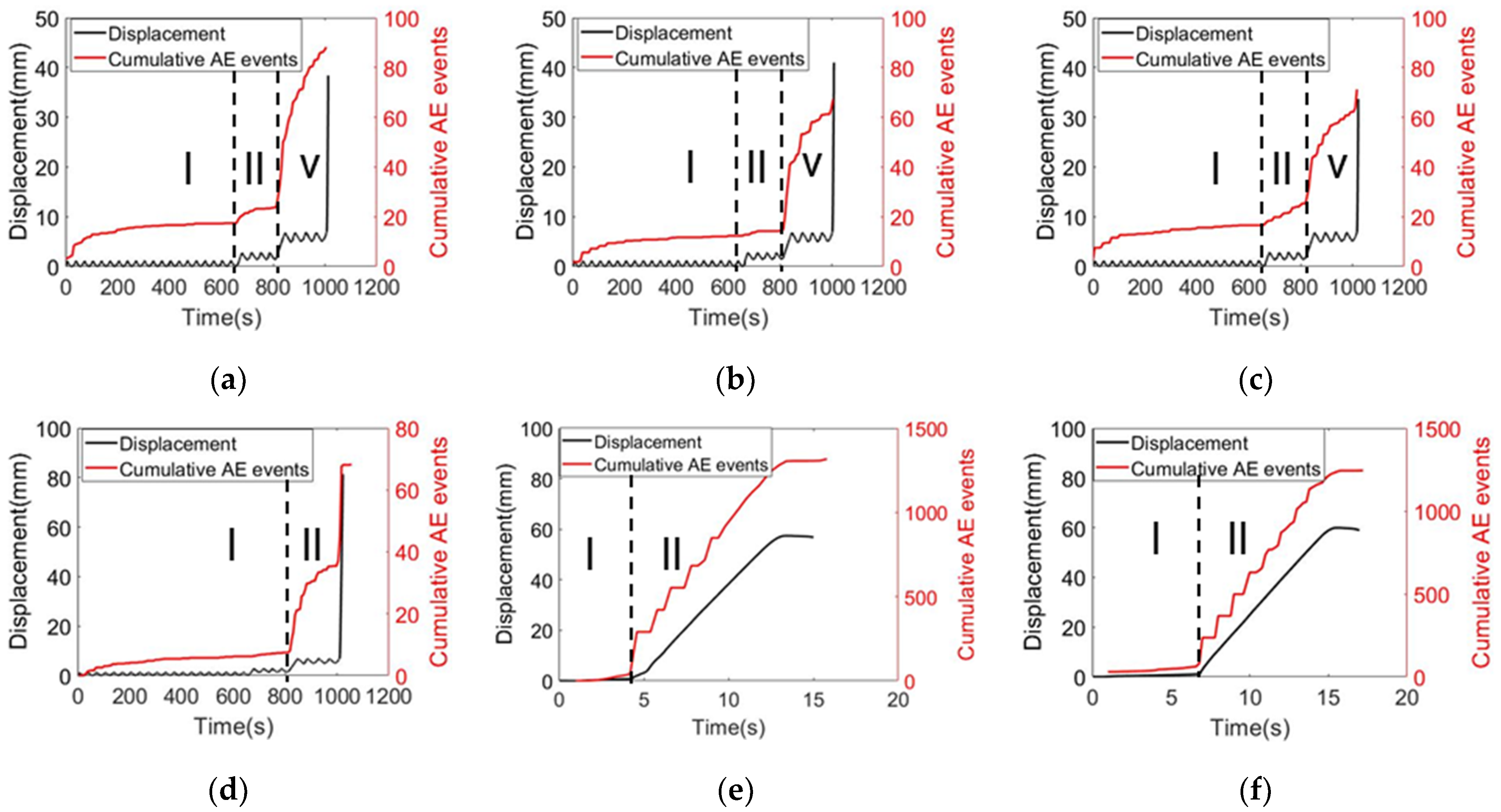

6.2. Grouted Sleeve Connector Cyclic Loading Test Results and AE Monitoring

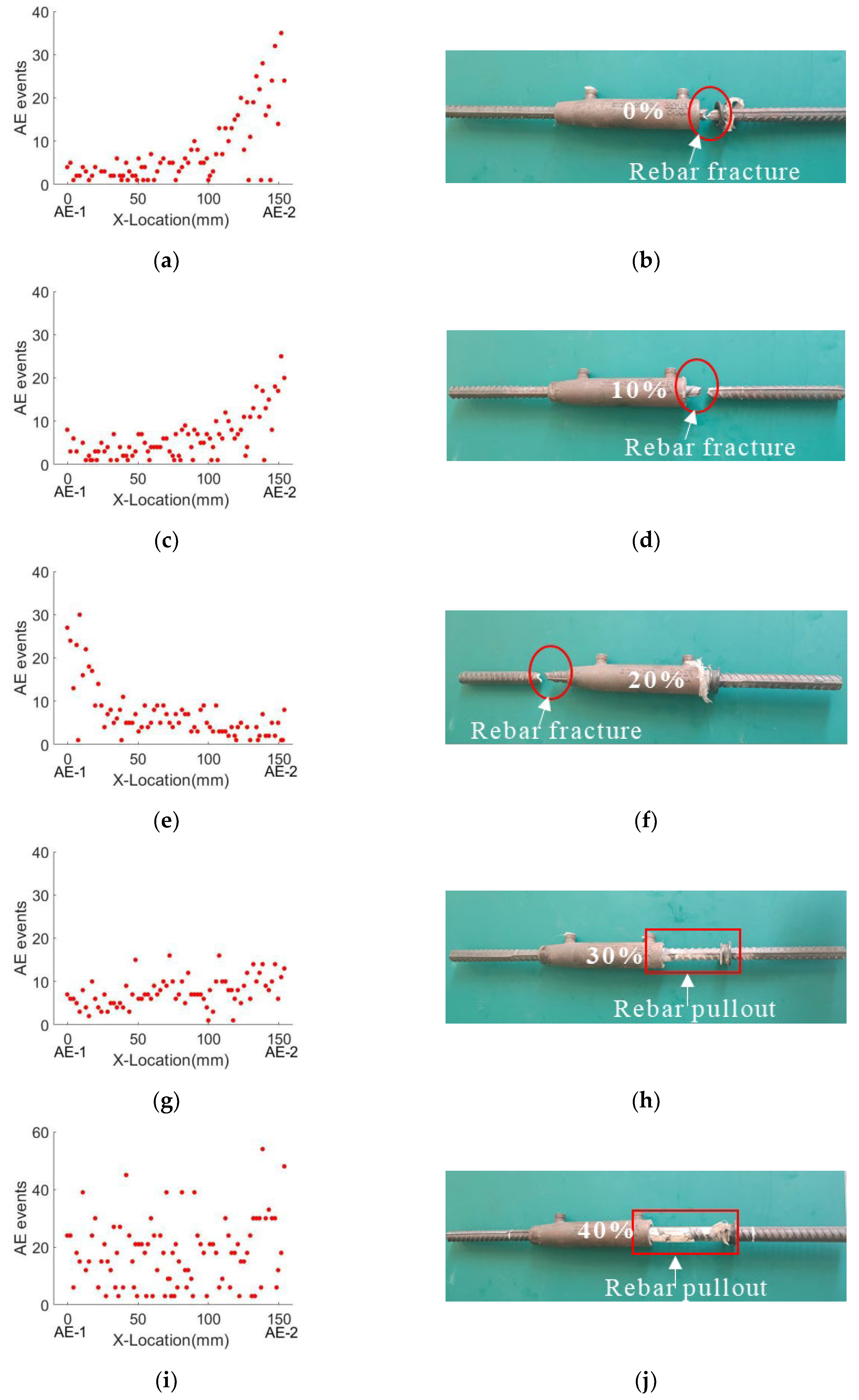

6.3. AE Localization of Damage

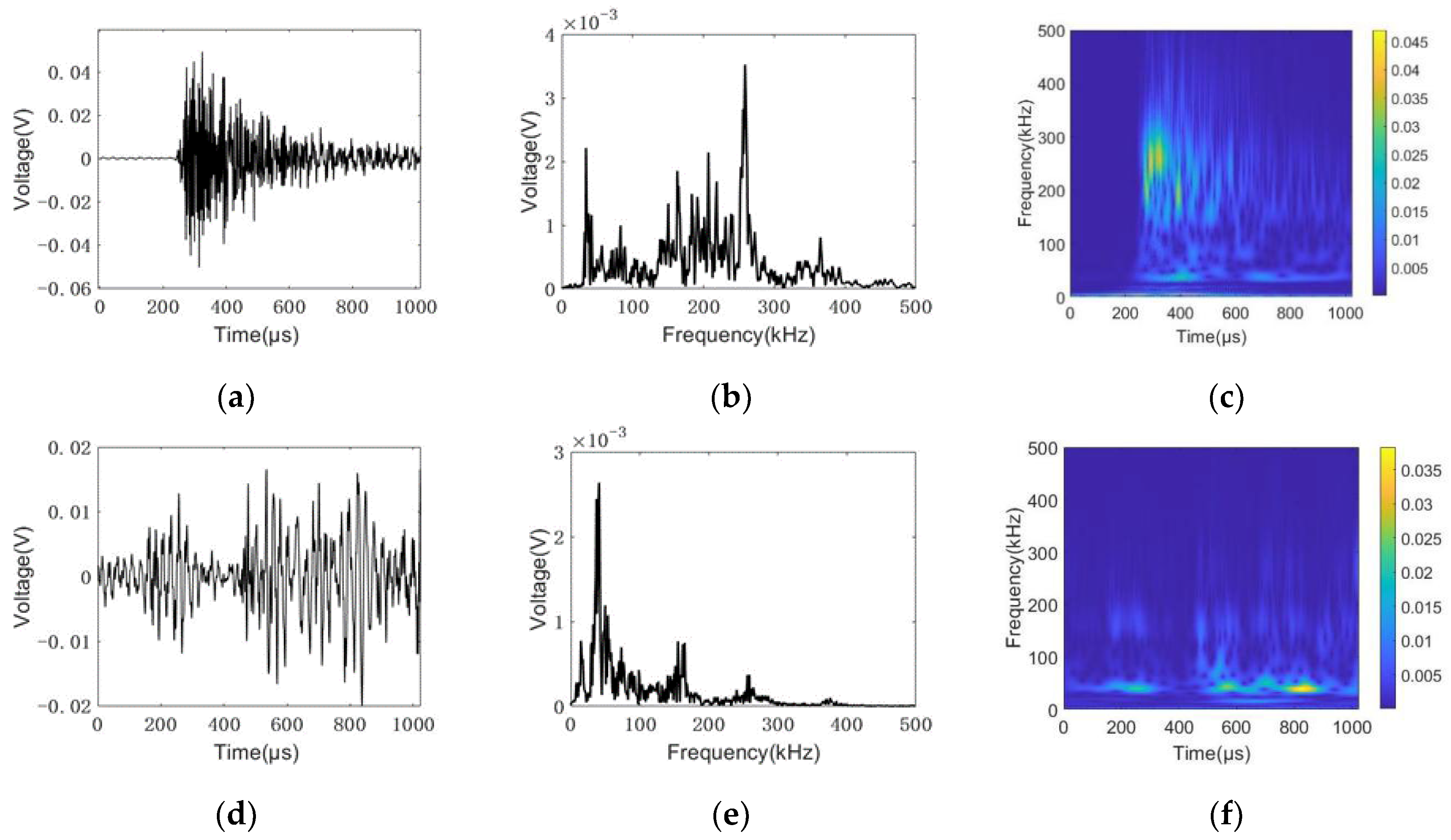

6.4. AE Signatures of Damage Progress

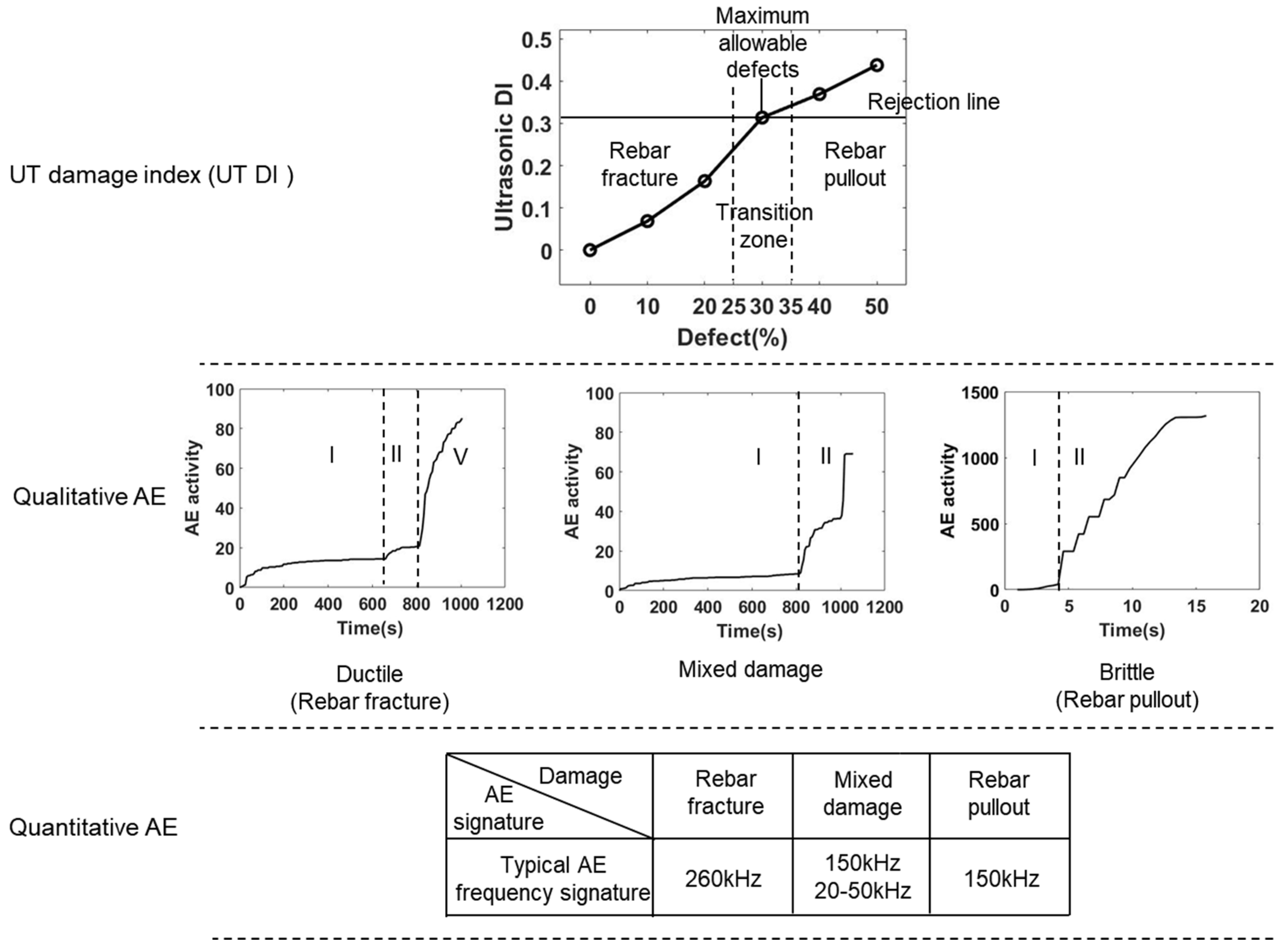

6.5. Comprehensive AE and UT Characterization of Damage Status and Processing

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Luo, L. SWOT analysis and Internet of Things-enabled platform for prefabrication housing production in Hong Kong. Habitat Int. 2016, 57, 74–87. [Google Scholar] [CrossRef]

- Yao, F.; Ji, Y.; Li, H.X.; Liu, G.; Tong, W.; Liu, Y.; Wang, X. Evaluation of informatization performance of construction industrialization EPC enterprises in China. Adv. Civ. Eng. 2020, 2020, 1314586. [Google Scholar] [CrossRef] [Green Version]

- Cao, Z.; Li, Q.W. Seismic fragility analysis of precast RC shear wall-frame structures with connection defects. In Proceedings of the 13th International Conference on Applications of Statistics and Probability in Civil Engineering (ICASP13), Seoul, Korea, 26–30 May 2019. [Google Scholar]

- Xu, L.; Pan, J.; Cai, J. Seismic performance of precast RC and RC/ECC composite columns with grouted sleeve connections. Eng. Struct. 2019, 188, 104–110. [Google Scholar] [CrossRef]

- Amedi, M.J.; Brown, D.N.; Parks, J.E.; Pantelides, C.P. Seismic column-to-footing connections using grouted splice sleeves. ACI Struct. J. 2016, 113, 1021–1030. [Google Scholar]

- Yan, Q.; Chen, T.; Xie, Z. Seismic experimental study on a precast concrete beam-column connection with grout sleeves. Eng. Struct. 2018, 155, 330–344. [Google Scholar] [CrossRef]

- Xu, F.; Wang, K.; Wang, S.; Li, W.; Liu, W.; Du, D. Experimental bond behavior of deformed rebars in half-grouted sleeve connections with insufficient grouting defect. Constr. Build. Mater 2018, 185, 264–274. [Google Scholar] [CrossRef]

- Tullini, N.; Minghini, F. Grouted sleeve connections used in precast reinforced concrete construction–Experimental investigation of a column-to-column joint. Eng. Struct. 2016, 127, 784–803. [Google Scholar] [CrossRef]

- Qi, B.; Wang, D.; Bai, S.; Jin, L. Common Quality Problems and Preventive Measures. Constr. Econ. 2016, 37, 3–8. (In Chinese) [Google Scholar]

- Gao, R.; Li, X.; Wang, Z.; Zhang, F.; Xu, Q. Research on testing technology of grouting plumpness of sleeve based on embedded steel wire drawing method. Constr. Technol. 2017, 46, 1–5. (In Chinese) [Google Scholar]

- Li, X.; Gao, R.; Wang, Z.; Zhang, F.; Leng, Y. Research on the Applied Technology of Testing Grouting Compaction of Sleeves Based on Damped Vibration Method. ICCTE 2017, 135, 317–323. [Google Scholar]

- Li, X.; Gao, R.; Xu, Q.; Wang, Z.; Zhang, F.; Liu, H. Experimental study on testing grouting plumpness of sleeve by drilling method combined with endoscopy. Constr. Technol. 2019, 48, 6–9. (In Chinese) [Google Scholar]

- Gao, R.D.; Li, X.M.; Zhang, F.W.; Xu, Q.F.; Wang, Z.L.; Liu, H. Experiment on detection of coupler grouting compactness based on industrial X-CT. Nondestruct. Test. 2017, 4, 12–17. [Google Scholar]

- Zhang, F.; Li, X.; Gao, R.; Xu, Q. Study on Detection of Grouting Compactness of Grout Sleeve by Portable X-ray Technology. Constr. Technol. 2017, 46, 6–9. (In Chinese) [Google Scholar]

- He, X.; Liu, J.; Guo, Y. Research on the Technology of Defects Detection in Prestressed Pipe Grouting. Adv. Mater. Res. Vols. 2012, 446–449, 1312–1318. [Google Scholar] [CrossRef]

- Tang, Y.-C.; Li, L.-J.; Feng, W.-X.; Liu, F.; Zou, X.-J.; Chen, M.-Y. Binocular vision measurement and its application in full-field convex deformation of concrete-filled steel tubular columns. Measurement 2018, 130, 372–383. [Google Scholar] [CrossRef]

- Tang, Y.; Zhu, M.; Chen, Z.; Wu, C.; Chen, B.; Li, C.; Li, L. Seismic performance evaluation of recycled aggregate concrete-filled steel tubular columns with field strain detected via a novel mark-free vision method. Structures 2022, 37, 426–441. [Google Scholar] [CrossRef]

- Hamid Reza, A. A harmonic vibration, output only and time-frequency representation based method for damage detection in Concrete piers of complex bridges. Int. J. Civ. Struct. Eng. 2012, 2, 987–1002. [Google Scholar] [CrossRef] [Green Version]

- Hamid Reza, A.; Mahdavi, N.; Bayat, M. A new index based on short time fourier transform for damage detection in bridge piers. Comput. Concr. 2021, 27, 447–455. [Google Scholar]

- Hamid Reza, A.; Diana, A. Health monitoring of pedestrian truss bridges using cone-shaped kernel distribution. Smart Struct. Syst. 2018, 22, 699–709. [Google Scholar]

- Liu, H.; Li, X.; Xu, Q. Test on Detection of Grouting Compactness of Grout Sleeve by Impact-echo Method. Nondestruct. Test. 2017, 39, 12–16. [Google Scholar]

- Luo, J.; Wang, X.; Zhao, J. Study on Infrared Thermal Imaging Method for Detecting Fullness of Reinforcement Sleeve Grouting. Build. Constr. 2021, 43, 1947–1951. [Google Scholar]

- Wu, H.; Shu, Z.; Liu, C. Experimental Research on the Detection of Inner Defects of Bellows Based on Ground Penetrating Radar. Russ. J. Nondestruct. Test. 2020, 56, 516–526. [Google Scholar]

- Li, Z.; Zheng, L.; Chen, C.; Long, Z.; Wang, Y. Ultrasonic Detection Method for Grouted Defects in Grouted Splice Sleeve Connector Based on Wavelet Pack Energy. Sensors 2019, 19, 1642. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, H.; Song, B.; Wang, M. Ultrasonic Testing Signal of Grouting Defect in Prefabricated Building Sleeve. EKOLOJI 2019, 28, 945–953. [Google Scholar]

- Liu, H.; Qi, Y.; Chen, Z.; Tong, H.; Liu, C.; Zhuang, M. Ultrasonic inspection of grouted splice sleeves in precast concrete structures using elastic reverse time migration method. Mech. Syst. Signal Process. 2021, 148, 107152. [Google Scholar] [CrossRef]

- Huijer, A.; Kassapoglou, C.; Pahlavan, L. Acoustic Emission Monitoring of Carbon Fibre Reinforced Composites with Embedded Sensors for In-Situ Damage Identification. Sensors 2021, 21, 6926. [Google Scholar] [CrossRef]

- Šofer, M.; Cienciala, J.; Fusek, M.; Pavlíček, P.; Moravec, R. Damage Analysis of Composite CFRP Tubes Using Acoustic Emission Monitoring and Pattern Recognition Approach. Materials 2021, 14, 786. [Google Scholar] [CrossRef]

- Jeong, S.-M.; Hong, S.; Oh, J.-S. A New Fracture Detection Algorithm of Low Amplitude Acoustic Emission Signal Based on Kalman Filter-Ripple Voltage. Sensors 2021, 21, 4247. [Google Scholar] [CrossRef]

- Nazaripoor, H.; Ashrafizadeh, H.; Schultz, R.; Runka, J.; Mertiny, P. Acoustic Emission Damage Detection during Three-Point Bend Testing of Short Glass Fiber Reinforced Composite Panels: Integrity Assessment. J. Compos. Sci. 2022, 6, 48. [Google Scholar] [CrossRef]

- Wang, J.; Huo, L.; Liu, C.; Song, G. A new acoustic emission damage localization method using synchrosqueezed wavelet transforms picker and time-order method. Struct. Health Monit. 2021, 20, 2917–2935. [Google Scholar] [CrossRef]

- Li, S.; Wu, Y.; Shi, H. A novel acoustic emission monitoring method of cross-section precise localization of defects and wire breaking of parallel wire bundle Struct. Control HLTH 2019, 26, e2334. [Google Scholar] [CrossRef]

- Hu, P.Y.; Li, S.L.; Jiang, N. Investigation of the impressed current cathodic protection method for the cable parallel wires in the rainwater electrolyte based on acoustic emission method. Constr. Build. Mater. 2019, 229, 116918. [Google Scholar] [CrossRef]

- Wu, Y.; Li, S.; Wang, D. Characteristic analysis of acoustic emission signals of masonry specimens under uniaxial compression test. Constr. Build. Mater. 2019, 196, 637–648. [Google Scholar] [CrossRef]

- Li, S.L.; Wu, G.M.; Wu, H. Study on acoustic emission characteristics of a semirigid base of dense skeleton type during complete uniaxial compression tests. Adv. Mater. Sci. Eng. 2016, 2016, 9238698. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Wu, G.; Shi, H. Acoustic emission characteristics of semi-rigid bases with three moisture conditions during bending tests. Road Mate. Pavement Des. 2019, 20, 187–198. [Google Scholar] [CrossRef]

- Antoine, B.; Jacqueline, S.; Zoubir, M.S. Evaluation of the acoustic emission 3D localisation accuracy for the mechanical damage monitoring in concrete. Eng. Fract. Mech. 2020, 223, 106742. [Google Scholar]

- Wu, Y.; Li, S.; Wang, D.; Zhao, G. Damage monitoring of masonry structure under in-situ uniaxial compression test using acoustic emission parameters. Constr. Build. Mater. 2019, 215, 812–822. [Google Scholar] [CrossRef]

- Shahidan, S.; Pulin, R.; Muhamad Bunnori, N.; Holford, K.M. Damage classification in reinforced concrete beam by acoustic emission signal analysis. Constr. Build. Mater. 2013, 45, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Parks, J.E.; Papulak, T.; Pantelides, C.P. Acoustic emission monitoring of grouted splice sleeve connectors and reinforced precast concrete bridge assemblies. Constr. Build. Mater. 2016, 122, 537–547. [Google Scholar] [CrossRef]

- Han, R.; Li, S.; Sun, W. Effect of grouting material strength on bond strength of sleeve and acoustic emission characterization of bond failure damage process. Constr. Build. Mater. 2022, 324, 126503. [Google Scholar] [CrossRef]

- Zheng, Q.; Wang, N.; Tao, L.; Xu, W. Experimental study on effects of grout defects on the connection behaviors of grout sleeve splicing for reinforcing bars. Build. Sci. 2017, 33, 5036505. [Google Scholar]

- Guo, T.; Yang, J.; Wang, W.; Li, C. Experimental investigation on connection performance of fully-grouted sleeve connectors with various grouting defects. Constr. Build. Mater. 2022, 327, 126981. [Google Scholar] [CrossRef]

- Hui, J.; Eric, R.; Tanguy, R. Compressive creep and indentation behavior of plasticine between 103 and 353 K. Mech. Mater. 2009, 41, 199–209. [Google Scholar]

- Zhang, L.; Mostavi, A.; Basantes Defaz, A.D.C.; Ozevin, D. The measurement of weld morphology and inclusions using ultrasonics. Measurement 2019, 144, 33–43. [Google Scholar] [CrossRef]

- ISO 15835–2:2018; Steels for the Reinforcement of Concrete–Reinforcement Couplers for Mechanical Splices of Bars. International Organization for Standardization: Geneva, Switzerland, 2018.

| Boundary | Reflection Coefficient (R) | Transmission Coefficient (T) |

|---|---|---|

| Sleeve/Flaws | 0.85 | 0.15 |

| Flaws/Mortar | 0.49 | 0.51 |

| Mortar/Rebar | 0.63 | 0.37 |

| Rebar/Mortar | 0.63 | 0.37 |

| Mortar/Sleeve | 0.60 | 0.40 |

| Materials | Density (kg/m3) | Young’s Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| HRB400 (Rebar) | 7850 | 210 | 0.30 |

| Ductile Iron (Sleeve) | 7300 | 162 | 0.29 |

| Concrete Mortar (Grout) | 2300 | 20 | 0.20 |

| Plasticene [45] (Artificial flaw) | 1384 | 0.0031 | 0.40 |

| Grouted Sleeve Defect Rate | Failure Mode |

|---|---|

| 0% | Rebar fracture |

| 10% | Rebar fracture |

| 20% | Rebar fracture |

| 30% | Rebar pullout |

| 40% | Rebar pullout |

| 50% | Rebar pullout |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Fang, Z.; Tang, Y.; Li, H.; Liu, Q. Characterization of Damage Progress in the Defective Grouted Sleeve Connection Using Combined Acoustic Emission and Ultrasonics. Sensors 2022, 22, 8579. https://doi.org/10.3390/s22218579

Zhang L, Fang Z, Tang Y, Li H, Liu Q. Characterization of Damage Progress in the Defective Grouted Sleeve Connection Using Combined Acoustic Emission and Ultrasonics. Sensors. 2022; 22(21):8579. https://doi.org/10.3390/s22218579

Chicago/Turabian StyleZhang, Lu, Zhenmin Fang, Yongze Tang, Hongyu Li, and Qizhou Liu. 2022. "Characterization of Damage Progress in the Defective Grouted Sleeve Connection Using Combined Acoustic Emission and Ultrasonics" Sensors 22, no. 21: 8579. https://doi.org/10.3390/s22218579