A CMOS Image Sensor Based Refractometer without Spectrometry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Finite-Difference Time-Domain Simulation

2.2. Fabrication of Ag-Thin-Film-Coated Glass

2.3. Analyte for Refractive Index Measurements

2.4. Experimental Setup

3. Results and Discussion

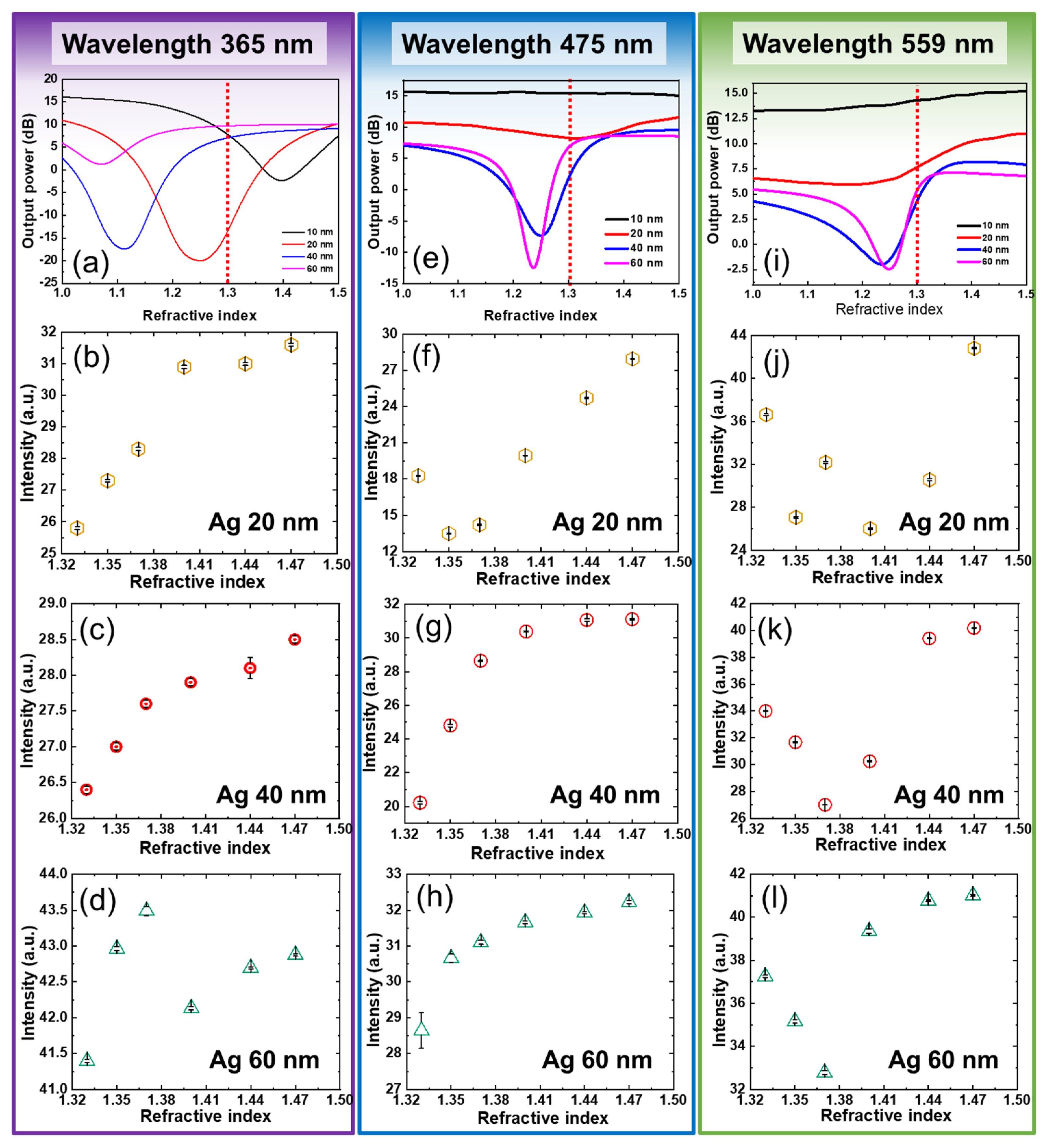

3.1. FDTD Simulation Results

3.2. Experimental Results of the Refractive Index of the Liquid

3.3. Measurements of the Refractive Index of Ethanol–Water and Acetone–Water Solutions

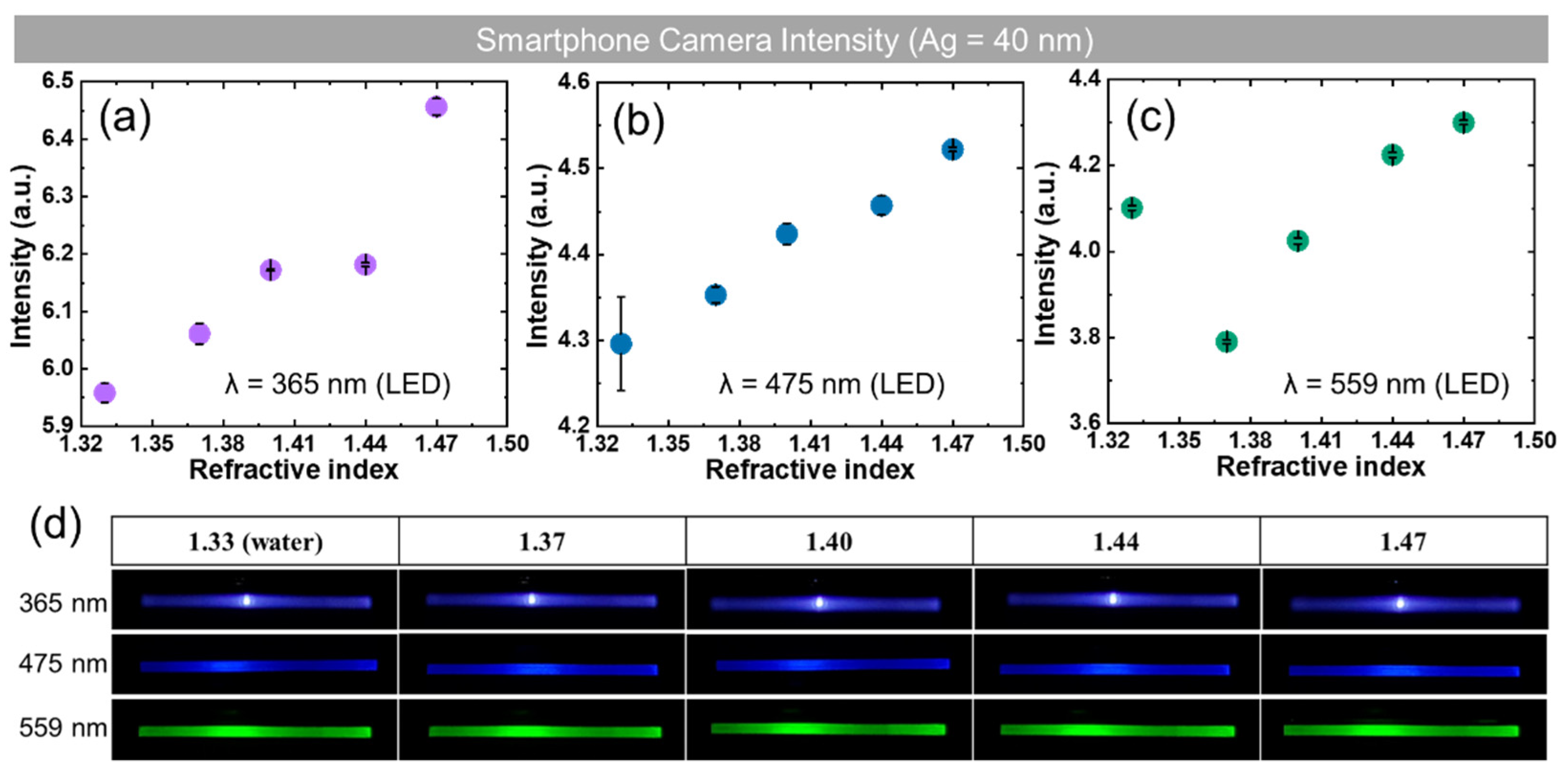

3.4. Smartphone Camera-Based Refractive Index Detection

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hecht, E. Optics: Pearson New International Edition; Pearson custom library; Pearson Education: London, UK, 2014; ISBN 9781292021577. [Google Scholar]

- Ulaby, F.T. Electromagnetics for Engineers; Pearson: London, UK, 2005. [Google Scholar]

- Macleod, H.A. Structure-related Optical Properties of Thin Films. J. Vac. Sci. Technol. A 1986, 4, 418–422. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Plasmonic Sensors Based on Metal-Insulator-Metal Waveguides for Refractive Index Sensing Applications: A Brief Review. Physica E Low Dimens. Syst. Nanostruct. 2020, 117, 113798. [Google Scholar] [CrossRef]

- Velázquez-González, J.S.; Monzón-Hernández, D.; Moreno-Hernández, D.; Martínez-Piñón, F.; Hernández-Romano, I. Simultaneous Measurement of Refractive Index and Temperature Using a SPR-Based Fiber Optic Sensor. Sens. Actuators B Chem. 2017, 242, 912–920. [Google Scholar] [CrossRef]

- Bassey, C.E.; Siguenza, C.A. Detection of Drinks Contamination Using Optical Refractometry Technique (ORT). Biophys. J. 2009, 96, 633a. [Google Scholar] [CrossRef] [Green Version]

- Paselk, R.A. The Evolution of the Abbe Refractometer. Bull.-Sci. Instrum. Soc. 1999, 62, 19–22. [Google Scholar]

- Rheims, J.; Köser, J.; Wriedt, T. Refractive-Index Measurements in the near-IR Using an Abbe Refractometer. Meas. Sci. Technol. 1997, 8, 601–605. [Google Scholar] [CrossRef]

- Singh, S. Refractive Index Measurement and Its Applications. Phys. Scr. 2002, 65, 167–180. [Google Scholar] [CrossRef]

- Urrutia, A.; Del Villar, I.; Zubiate, P.; Zamarreño, C.R. A Comprehensive Review of Optical Fiber Refractometers: Toward a Standard Comparative Criterion. Laser Photon. Rev. 2019, 13, 1900094. [Google Scholar] [CrossRef]

- Qiu, X.; Chen, X.; Liu, F.; Guan, B.-O.; Guo, T. Plasmonic Fiber-Optic Refractometers Based on a High Q-Factor Amplitude Interrogation. IEEE Sens. J. 2016, 16, 5974–5978. [Google Scholar] [CrossRef]

- Raether, H. Surface Plasmons on Smooth and Rough Surfaces and on Gratings; Springer: New York, NY, USA, 2014; ISBN 9783662151235. [Google Scholar]

- Albers, W.M.; Vikholm-Lundin, I. Surface Plasmon Resonance on Nanoscale Organic Films. In Nano-Bio-Sensing; Carrara, S., Ed.; Springer: New York, NY, USA, 2011; pp. 83–125. ISBN 9781441961693. [Google Scholar]

- Eggins, B.R. Biosensors: An Introduction; Teubner Studienbücher Chemie; Springer Vieweg Verlag: Berlin, Germany, 2012; ISBN 9783663056652. [Google Scholar]

- Tang, Y.; Zeng, X.; Liang, J. Surface Plasmon Resonance: An Introduction to a Surface Spectroscopy Technique. J. Chem. Educ. 2010, 87, 742–746. [Google Scholar] [CrossRef] [Green Version]

- Homola, J.; Piliarik, M. Surface Plasmon Resonance (SPR) Sensors. In Surface Plasmon Resonance Based Sensors; Homola, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 45–67. ISBN 9783540339199. [Google Scholar]

- Kumar, S.; Tokunaga, K.; Namura, K.; Fukuoka, T.; Suzuki, M. Experimental Evidence of a Twofold Electromagnetic Enhancement Mechanism of Surface-Enhanced Raman Scattering. J. Phys. Chem. C Nanomater. Interfaces 2020, 124, 21215–21222. [Google Scholar] [CrossRef]

- Zeng, Y.; Hu, R.; Wang, L.; Gu, D.; He, J.; Wu, S.-Y.; Ho, H.-P.; Li, X.; Qu, J.; Gao, B.Z.; et al. Recent Advances in Surface Plasmon Resonance Imaging: Detection Speed, Sensitivity, and Portability. Nanophotonics 2017, 6, 1017–1030. [Google Scholar] [CrossRef]

- Shao, Y.; Xu, S.; Zheng, X.; Wang, Y.; Xu, W. Optical Fiber LSPR Biosensor Prepared by Gold Nanoparticle Assembly on Polyelectrolyte Multilayer. Sensors 2010, 10, 3585–3596. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, H.; Sugimoto, M.; Matsui, Y.; Kondoh, J. Effects of Gold Film Thickness on Spectrum Profile and Sensitivity of a Multimode-Optical-Fiber SPR Sensor. Sens. Actuators B Chem. 2008, 132, 26–33. [Google Scholar] [CrossRef]

- Lertvachirapaiboon, C.; Baba, A.; Shinbo, K.; Kato, K. A Smartphone-Based Surface Plasmon Resonance Platform. Anal. Methods 2018, 10, 4732–4740. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Q.; Chen, S.; Cheng, F.; Wang, H.; Peng, W. Surface Plasmon Resonance Biosensor Based on Smart Phone Platforms. Sci. Rep. 2015, 5, 12864. [Google Scholar] [CrossRef] [Green Version]

- Villatoro, J.; Monzón-Hernández, D.; Talavera, D. High Resolution Refractive Index Sensing with Cladded Multimode Tapered Optical Fibre. Electron. Lett. 2004, 40, 106. [Google Scholar] [CrossRef]

- Banerjee, A.; Mukherjee, S.; Verma, R.K.; Jana, B.; Khan, T.K.; Chakroborty, M.; Das, R.; Biswas, S.; Saxena, A.; Singh, V. Fiber Optic Sensing of Liquid Refractive Index. Sens. Actuators B Chem. 2007, 123, 594–605. [Google Scholar] [CrossRef]

- Yüksel, K. Optical Fiber Sensor System for Remote and Multi-Point Refractive Index Measurement. Sens. Actuators A Phys. 2016, 250, 29–34. [Google Scholar] [CrossRef] [Green Version]

- Debackere, P.; Scheerlinck, S.; Bienstman, P.; Baets, R. Surface Plasmon Interferometer in Silicon-on-Insulator: Novel Concept for an Integrated Biosensor. Opt. Express 2006, 14, 7063–7072. [Google Scholar] [CrossRef]

- Foley, J.J., IV; Harutyunyan, H.; Rosenmann, D.; Divan, R.; Wiederrecht, G.P.; Gray, S.K. When Are Surface Plasmon Polaritons Excited in the Kretschmann-Raether Configuration? Sci. Rep. 2015, 5, 9929. [Google Scholar] [CrossRef]

- Kumar, S.; Doi, Y.; Namura, K.; Suzuki, M. Plasmonic Nanoslit Arrays Fabricated by Serial Bideposition: Optical and Surface-Enhanced Raman Scattering Study. ACS Applied Bio Materials 2020, 3, 3226–3235. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Synopsys. Available online: https://www.synopsys.com/ (accessed on 16 December 2021).

- Johnson, P.B.; Christy, R.W. Optical Constants of the Noble Metals. Phys. Rev. B Condens. Matter Mater. Phys. 1972, 6, 4370–4379. [Google Scholar] [CrossRef]

- Lapeira, E.; Bou-Ali, M.M.; Madariaga, J.A.; Santamaría, C. Thermodiffusion Coefficients of Water/Ethanol Mixtures for Low Water Mass Fractions. Microgravity Sci. Technol. 2016, 28, 553–557. [Google Scholar] [CrossRef]

- Kurtz, S.S., Jr.; Wikingsson, A.E.; Camin, D.L.; Thompson, A.R. Refractive Index and Density of Acetone-Water Solutions. J. Chem. Eng. Data 1965, 10, 330–334. [Google Scholar] [CrossRef]

- Uddin, S.M.A.; Chowdhury, S.S.; Kabir, E. A theoretical model for determination of optimum metal thickness in kretschmann configuration based surface plasmon resonance biosensors. In Proceedings of the 2017 International Conference on Electrical, Computer and Communication Engineering (ECCE), Cox’s Bazar, Bangladesh, 16–18 February 2017. [Google Scholar]

- Gong, J.; Dai, R.; Wang, Z.; Zhang, Z. Thickness Dispersion of Surface Plasmon of Ag Nano-Thin Films: Determination by Ellipsometry Iterated with Transmittance Method. Sci. Rep. 2015, 5, 9279. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mitsushio, M.; Higo, M. Properties of a Gold-Deposited Surface Plasmon Resonance-Based Glass Rod Sensor with Various Light-Emitting Diodes and Its Application to a Refractometer. Opt. Commun. 2012, 285, 3714–3720. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Shin, S.; Kumar, S.; Seo, D.; Oh, S.; Lee, M.; Seo, S. A CMOS Image Sensor Based Refractometer without Spectrometry. Sensors 2022, 22, 1209. https://doi.org/10.3390/s22031209

Yang H, Shin S, Kumar S, Seo D, Oh S, Lee M, Seo S. A CMOS Image Sensor Based Refractometer without Spectrometry. Sensors. 2022; 22(3):1209. https://doi.org/10.3390/s22031209

Chicago/Turabian StyleYang, Haechang, Sanghoon Shin, Samir Kumar, Dongmin Seo, Sangwoo Oh, Moonjin Lee, and Sungkyu Seo. 2022. "A CMOS Image Sensor Based Refractometer without Spectrometry" Sensors 22, no. 3: 1209. https://doi.org/10.3390/s22031209