Diagnosing Time-Varying Harmonics in Low-k Oxide Thin Film (SiOF) Deposition by Using HDP CVD

Abstract

:1. Introduction

2. Materials and Methods

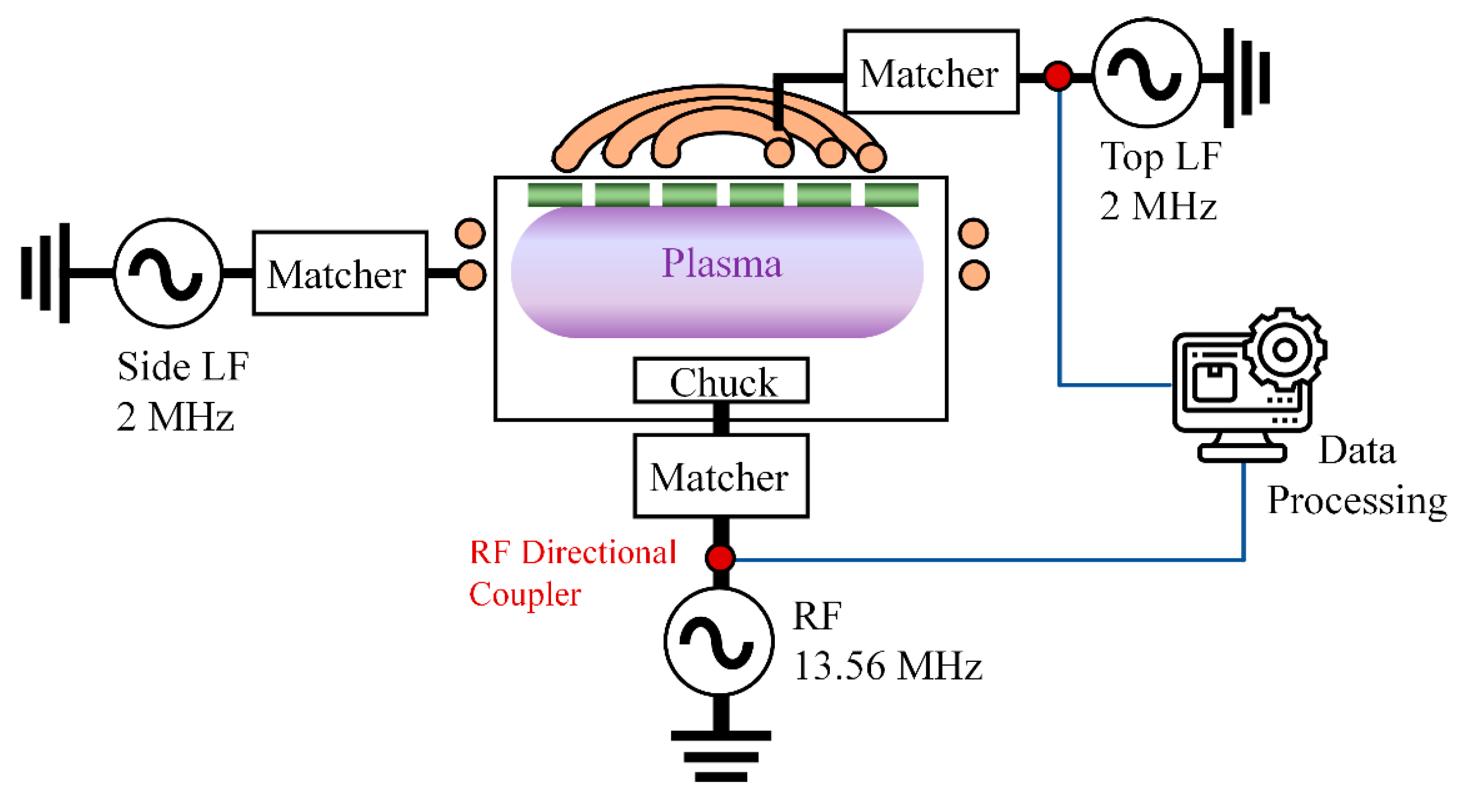

2.1. Experimental Setup

2.2. Experimental Condition

3. Results and Discussion

3.1. The Time-Varying Behavior of LF Power Harmonics

3.2. The Time-Varying Characteristics of RF-Driven Electrode Plasma Harmonics

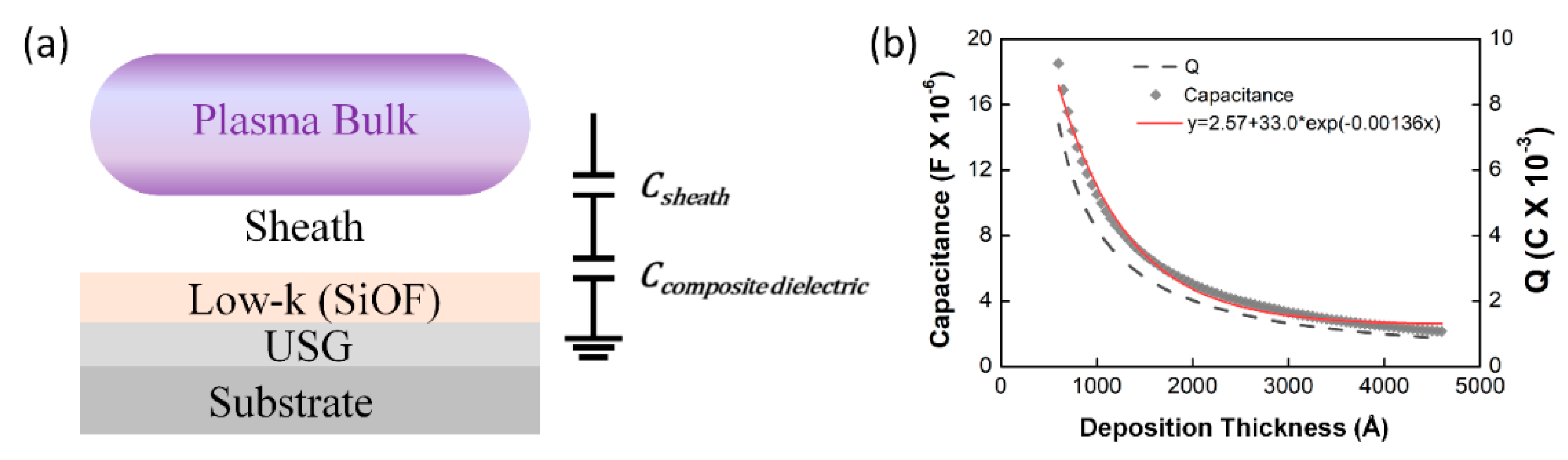

3.2.1. The Relation between Series Resonance Frequency and Harmonics

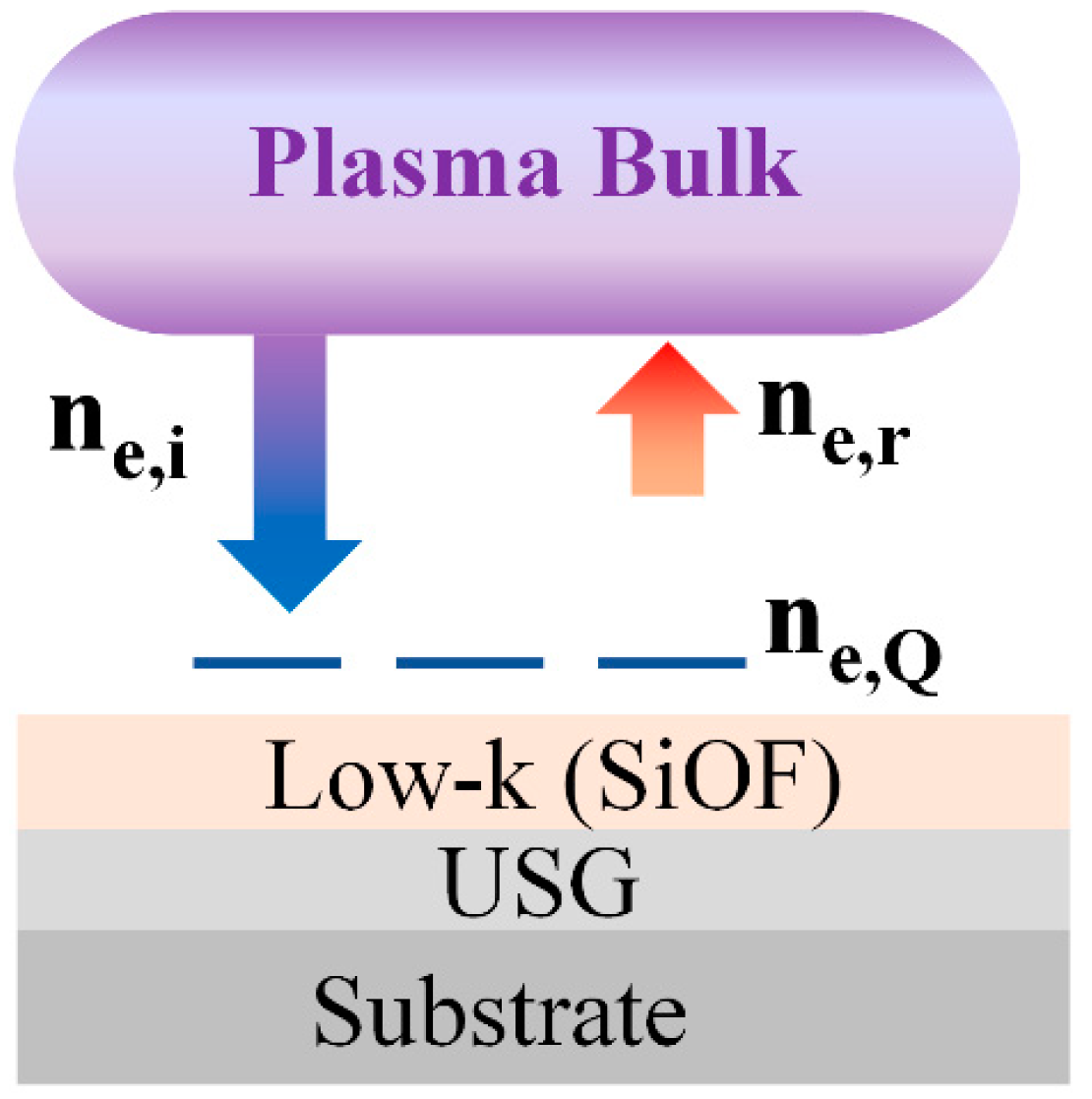

3.2.2. The Time-Varying Behavior of Harmonics at the RF Driven Electrode

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clark, R.; Tapily, K.; Yu, K.-H.; Hakamata, T.; Consiglio, S.; O’Meara, D.; Wajda, C.; Smith, J.; Leusink, G. Perspective: New process technologies required for future devices and scaling. APL Mater. 2018, 6, 058203. [Google Scholar] [CrossRef]

- Tilke, A.; Culmsee, M.; Jaiswal, R.; Hampp, R.; Conti, R.; Galiano, M.; Stapelmann, C.; Wille, W.; Jain, A. STI Gap-fill technology with High Aspect ratio process for 45nm CMOS and beyond. In Proceedings of the 17th Annual SEMI/IEEE ASMC Conference 2006, Boston, MA, USA, 22–24 May 2006; pp. 71–76. [Google Scholar]

- Lieberman, M.A.; Lichtenberg, A.J. Principles of plasma discharges and materials processing. MRS Bull. 1994, 30, 899–901. [Google Scholar]

- Matsuura, M.; Tottori, I.; Goto, K.; Maekawa, K.; Mashiko, Y.; Hirayama, M. A highly reliable self-planarizing low-k intermetal dielectric for sub-quarter micron interconnects. In Proceedings of the International Electron Devices Meeting. IEDM Technical Digest, Washington, DC, USA, 10 December 1997; pp. 785–788. [Google Scholar]

- Nguyen, S. High-density plasma chemical vapor deposition of silicon-based dielectric films for integrated circuits. IBM J. Res. Dev. 1999, 43, 109–126. [Google Scholar] [CrossRef] [Green Version]

- Nandakumar, M.; Chatterjee, A.; Sridhar, S.; Joyner, K.; Rodder, M.; Chen, I.-C. Shallow trench isolation for advanced ULSI CMOS technologies. In Proceedings of the IEEE IEDM Technical Digest (Cat. No. 98CH36217), San Francisco, CA, USA, 6–9 December 1997; pp. 133–136. [Google Scholar]

- Bhan, M.K.; Huang, J.; Cheung, D. Deposition of stable, low κ and high deposition rate SiF4-doped TEOS fluorinated silicon dioxide (SiOF) films. Thin Solid Films 1997, 308, 507–511. [Google Scholar] [CrossRef]

- Carrere, J.; Oberlin, J.-C.; Haond, M. Topographical dependence of charging and new phenomenon during inductively coupled plasma (ICP) CVD process. In Proceedings of the IEEE PPID Symposium (IEEE Cat. No. 00TH8479), Santa Clara, CA, USA, 22–24 May 2000; pp. 164–167. [Google Scholar]

- Cheung, K.P.; Pai, C.-S. Charging damage from plasma enhanced TEOS deposition. IEEE Electron Device Lett. 1995, 16, 220–222. [Google Scholar] [CrossRef]

- Howling, A.; Belinger, A.; Bulkin, B.; Delaunay, L.; Elyaakoubi, M.; Hollenstein, C.; Perrin, J.; Sansonnens, L.; Schmitt, J.; Turlot, E. Mechanism of substrate charging after plasma processing. In Proceedings of the 15th International Symposium on Plasma Chemistry, Orleans, France, 9–13 July 2001; pp. 33–39. [Google Scholar]

- Cheung, K.P. Mechanism of charging damage during plasma-enhanced silicon nitride/oxide thin-film deposition. IEEE Trans. Device Mater. Reliab. 2006, 6, 448–454. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Lee, W.-S.; Seo, Y.-J. Prevention of plasma-induced damage during HDP–CVD deposition. J. Mater. Process. 2004, 147, 211–216. [Google Scholar] [CrossRef]

- Yu, C.-S.; Chen, Y.-T.; Shih, Y.-H.; Lu, C.-Y. A promising solution to reduce plasma induced damage (PID) of high density plasma (HDP) oxide without sacrificing the gap-fill and throughput performance—Chin-Tsan Yeh. In Proceedings of the 2017 Joint International Symposium on e-Manufacturing and Design Collaboration (eMDC) & Semiconductor Manufacturing (ISSM), Hsinchu, Taiwan, 15 September 2017; pp. 1–4. [Google Scholar]

- Shin, H.-C.; Hu, C. Thin gate oxide damage due to plasma processing. Semicond. Sci. Technol. 1996, 11, 463. [Google Scholar] [CrossRef]

- Byun, K.-M.; Kim, D.-H.; Cha, Y.-W.; Lee, S.-H.; Kim, M.; Lee, J.-B.; Park, I.-S.; Lee, H.-D.; Song, C.-L. Reduction of plasma-induced damage during intermetal dielectric deposition in high-density plasma. In Proceedings of the 2005 International Conference on Integrated Circuit Design and Technology, ICICDT, Austin, TX, USA, 9–11 May 2005; pp. 99–102. [Google Scholar]

- Hwang, G.S.; Giapis, K.P. Mechanism of charging damage during interlevel oxide deposition in high-density plasma tools. In Proceedings of the 1998 3rd International Symposium on Plasma Process-Induced Damage (Cat. No. 98EX100), Honolulu, HI, USA, 4–5 June 1998; pp. 164–167. [Google Scholar]

- Braithwaite, N.S.J.; LauroTaroni, L.; Haas, F.; Turner, M. Displacement of charge and conduction current in collisionless planar sheaths during voltage transients. Contrib. Plasma Phys. 2008, 48, 412–417. [Google Scholar] [CrossRef]

- Oates, T.W.; Pigott, J.; McKenzie, D.R.; Bilek, M.M. Electric probe measurements of high-voltage sheath collapse in cathodic arc plasmas due to surface charging of insulators. IEEE Trans. Plasma Sci. 2003, 31, 438–443. [Google Scholar] [CrossRef]

- Tian, X.; Tang, B.; Chu, P.K. Accurate determination of pulsed current waveform in plasma immersion ion implantation processes. J. Appl. Phys. 1999, 86, 3567–3570. [Google Scholar] [CrossRef]

- Godyak, V. Nonlinear effects in inductive discharges. Bulg. J. Phys. 2000, 27, 13–19. [Google Scholar]

- Helmer, J.C.; Feinstein, J. Ponderomotive transport of charge in the induction plasma. J. Vac. Sci. Technol. B 1994, 12, 507–511. [Google Scholar] [CrossRef]

- Smolyakov, A.; Godyak, V.; Duffy, A. On nonlinear effects in inductively coupled plasmas. Phys. Plasmas 2000, 7, 4755–4762. [Google Scholar] [CrossRef] [Green Version]

- Wilczek, S.; Schulze, J.; Brinkmann, R.P.; Donkó, Z.; Trieschmann, J.; Mussenbrock, T. Electron dynamics in low pressure capacitively coupled radio frequency discharges. J. Appl. Phys. 2020, 127, 181101. [Google Scholar] [CrossRef]

- Krenz, J.; Kino, G. Harmonic generation and parametric oscillations in a plasma. J. Appl. Phys. 1965, 36, 2387–2395. [Google Scholar] [CrossRef]

- Wilczek, S.; Trieschmann, J.; Eremin, D.; Brinkmann, R.P.; Schulze, J.; Schuengel, E.; Derzsi, A.; Korolov, I.; Hartmann, P.; Donkó, Z. Kinetic interpretation of resonance phenomena in low pressure capacitively coupled radio frequency plasmas. Phys. Plasmas 2016, 23, 063514. [Google Scholar] [CrossRef] [Green Version]

- Ku, V.P.; Annaratone, B.M.; Allen, J.E. Plasma-sheath resonances and energy absorption phenomena in capacitively coupled radio frequency plasmas. Part I. J. Appl. Phys. 1998, 84, 6536–6545. [Google Scholar] [CrossRef]

- Boeuf, J.; Belenguer, P. Fundamental properties of RF glow discharges: An approach based on self—Consistent numerical models. In Nonequilibrium Processes in Partially Ionized Gases; Springer: New York, NY, USA, 1990; pp. 155–186. [Google Scholar]

- Lieberman, M.A. Analytical solution for capacitive RF sheath. IEEE Trans. Plasma Sci. 1988, 16, 638–644. [Google Scholar] [CrossRef]

- Mutsukura, N.; Kobayashi, K.; Machi, Y. Plasma sheath thickness in radio-frequency discharges. J. Appl. Phys. 1990, 68, 2657–2660. [Google Scholar] [CrossRef]

- Klick, M. Nonlinearity of the radio-frequency sheath. J. Appl. Phys. 1996, 79, 3445–3452. [Google Scholar] [CrossRef]

- Holcomb, F.H.; Briggs, S.J. Understanding and Managing Power System Harmonics; Defence Technical Information Center: Fort Belvoir, VA, USA, 1994.

- Gahan, D.; Hopkins, M. Collisionless electron power absorption in capacitive radio-frequency plasma sheaths. J. Appl. Phys. 2006, 100, 043304. [Google Scholar] [CrossRef]

- Law, V.; Kenyon, A.; Thornhill, N.; Srigengan, V.; Batty, I. Remote-coupled sensing of plasma harmonics and process end-point detection. Vacuum 2000, 57, 351–364. [Google Scholar] [CrossRef]

- Lisovskiy, V.; Booth, J.-P.; Landry, K.; Douai, D.; Cassagne, V.; Yegorenkov, V. Applying RF current harmonics for end-point detection during etching multi-layered substrates and cleaning discharge chambers with NF3 discharge. Vacuum 2007, 82, 321–327. [Google Scholar] [CrossRef] [Green Version]

- Vijayaraghavan, R.K.; Kelly, S.; Coates, D.; Gaman, C.; MacGearailt, N.; McNally, P. Uses of radio emission spectroscopy for non-contact and in situ diagnostics of low pressure radio frequency plasma processing. Res. Sq. 2021. [Google Scholar] [CrossRef]

- Turkot Jr, R.; Ruzic, D. Time-and space-resolved radio-frequency plasma electron energy distributions from a displacement-current-based electric probe diagnostic. J. Appl. Phys. 1993, 73, 2173–2179. [Google Scholar] [CrossRef] [Green Version]

- Stenzel, R. High-frequency instability of the sheath–plasma resonance. Phys. Fluids B 1989, 1, 2273–2282. [Google Scholar] [CrossRef] [Green Version]

- Buckley, R. A theory of resonance rectification. The response of a spherical plasma probe to alternating potentials. Proc. R. Soc. A 1966, 290, 186–219. [Google Scholar]

- Law, V.; Kenyon, A.; Thornhill, N.; Seeds, A.; Batty, I. Rf probe technology for the next generation of technological plasmas. J. Phys. D 2001, 34, 2726. [Google Scholar] [CrossRef]

- Rawat, A.; Ganguli, A.; Narayanan, R.; Tarey, R. A novel ex situ diagnostic technique for characterizing harmonics in radio frequency discharges. Rev. Sci. Instrum. 2020, 91, 094705. [Google Scholar] [CrossRef]

- Batty, I.; Cooke, M.; Law, V. Harmonic characterisation of a plasma-tool using a diplexer. Vacuum 1999, 52, 509–514. [Google Scholar] [CrossRef]

- Van Nguyen, S.; Albaugh, K. The characterization of electron cyclotron resonance plasma deposited silicon nitride and silicon oxide films. J. Electrochem. Soc. 1989, 136, 2835. [Google Scholar] [CrossRef]

- Si, X.-J.; Zhao, S.-X.; Xu, X.; Bogaerts, A.; Wang, Y.-N. Fluid simulations of frequency effects on nonlinear harmonics in inductively coupled plasma. Phys. Plasmas 2011, 18, 033504. [Google Scholar] [CrossRef] [Green Version]

- Godyak, V.; Piejak, R.; Alexandrovich, B. Observation of second harmonic currents in inductively coupled plasmas. Phys. Rev. Lett. 1999, 83, 1610. [Google Scholar] [CrossRef]

- Ostrikov, K.; Tsakadze, E.; Xu, S.; Vladimirov, S.V.; Storer, R. Nonlinear electromagnetic fields in 0.5 MHz inductively coupled plasmas. Phys. Plasmas 2003, 10, 1146–1151. [Google Scholar] [CrossRef] [Green Version]

- Godyak, V.A.; Piejak, R.B.; Alexandrovich, B.M.; Kolobov, V.I. Hot plasma and nonlinear effects in inductive discharges. Phys. Plasmas 1999, 6, 1804–1812. [Google Scholar] [CrossRef]

- Myra, J.R. A tutorial on radio frequency sheath physics for magnetically confined fusion devices. J. Plasma Phys. 2021, 87, 905870504. [Google Scholar] [CrossRef]

- Myra, J.R.; D’Ippolito, D.A.; Rice, J.A.; Hazelton, C.S. Radio-frequency sheath mitigation by insulating antenna limiters. J. Nucl. Mater. 1997, 249, 190–198. [Google Scholar] [CrossRef]

- Jaeger, E.; Berry, L.; Tolliver, J.; Batchelor, D. Power deposition in high-density inductively coupled plasma tools for semiconductor processing. Phys. Plasmas 1995, 2, 2597–2604. [Google Scholar] [CrossRef]

- Cheng, Y.-L.; Lee, C.-Y.; Haung, C.-W. Plasma Damage on Low-k Dielectric Materials; IntechOpen: Vienna, Austria, 2018. [Google Scholar]

- Robertson, J. High dielectric constant oxides. EPJ Appl. Phys. 2004, 28, 265–291. [Google Scholar] [CrossRef] [Green Version]

- Warwick, A.; King-Hele, D.G. Frequency, theorem and formula: Remembering Joseph Larmor in electromagnetic theory. Notes Rec. R. Soc. Lond. 1993, 47, 49–60. [Google Scholar]

- Rohrlich, F. The dynamics of a charged sphere and the electron. Am. J. Phys. 1997, 65, 1051–1056. [Google Scholar] [CrossRef] [Green Version]

| No. | Step | Gas | Power |

|---|---|---|---|

| 1 | Chamber cleaning | SF6 | Microwave (GHz) |

| 2 | Chamber seasoning | SiH4, O2, Ar | Top and side LF |

| 3 | Wafer loading | --- | --- |

| 4 | Pressure stabilization | Ar, O2 | --- |

| 5 | Plasma on | Ar, O2 | Top and side LF |

| 6 | Throttle valve on | Ar, O2 | Top LF ramp-up |

| 7 | Preheating for heat-up | Ar, O2 | Top and side LF |

| 8 | SRO and USG deposition | SiH4, Ar, O2 | Top and side LF |

| 9 | SiOF deposition | SiH4, SiF4, Ar, O2 | Top and side LF, RF |

| 10 | Transition | --- | Reduced top and side LF, RF |

| 11 | Power and gas off | --- | --- |

| Step | Time (s) | Thickness (Å) | Power | Condition (kW) |

|---|---|---|---|---|

| Heat-up | 40.9 | -- | Top, side, bias (RF) | 1.3, 3.1, 0 |

| SRO deposition | 2 | 600 | Top, side, bias (RF) | 1.5, 2.5, 0 |

| USG deposition | 5.1 | Top, side, bias (RF) | 1.5, 2.5, 0 | |

| SiOF deposition | 77.5 | 4000 | Top, side, bias (RF) | 1.5, 3, 2.84 |

| No. | Step | Ar | Ar (Top) | O2 | SiH4 (Side) | SiH4 (Top) | SiF4 |

|---|---|---|---|---|---|---|---|

| 1 | Gas turn on | 110 | 16 | -- | -- | -- | -- |

| 2 | Side RF power on | 110 | 16 | -- | -- | -- | -- |

| 3 | Open throttle VV | 110 | 16 | -- | -- | -- | -- |

| 4 | Heat up (preheat) | 110 | 16 | 110 | -- | -- | -- |

| 5 | SRO deposition | 110 | 16 | 110 | -- | 20 | -- |

| 6 | USG deposition | 60 | 5 | 120 | 42 | 4 | -- |

| 7 | SiOF deposition | 60 | 5 | 120 | 34 | 3.5 | 40 |

| 8 | SiH4 gas off | 60 | 5 | 120 | -- | -- | -- |

| 9 | Transition | 60 | 5 | 120 | -- | -- | -- |

| 10 | De-chuck | 110 | 16 | 120 | -- | -- | -- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, Y.; Liu, P.; Lee, S.; Cho, J.; Joo, E.; Kim, H.-U.; Kim, T. Diagnosing Time-Varying Harmonics in Low-k Oxide Thin Film (SiOF) Deposition by Using HDP CVD. Sensors 2023, 23, 5563. https://doi.org/10.3390/s23125563

Park Y, Liu P, Lee S, Cho J, Joo E, Kim H-U, Kim T. Diagnosing Time-Varying Harmonics in Low-k Oxide Thin Film (SiOF) Deposition by Using HDP CVD. Sensors. 2023; 23(12):5563. https://doi.org/10.3390/s23125563

Chicago/Turabian StylePark, Yonggyun, Pengzhan Liu, Seunghwan Lee, Jinill Cho, Eric Joo, Hyeong-U Kim, and Taesung Kim. 2023. "Diagnosing Time-Varying Harmonics in Low-k Oxide Thin Film (SiOF) Deposition by Using HDP CVD" Sensors 23, no. 12: 5563. https://doi.org/10.3390/s23125563