Contribution of Ribbon-Structured SiO2 Films to AlN-Based and AlN/Diamond-Based Lamb Wave Resonators

Abstract

:1. Introduction

2. Design and Methods

3. Results and Discussion

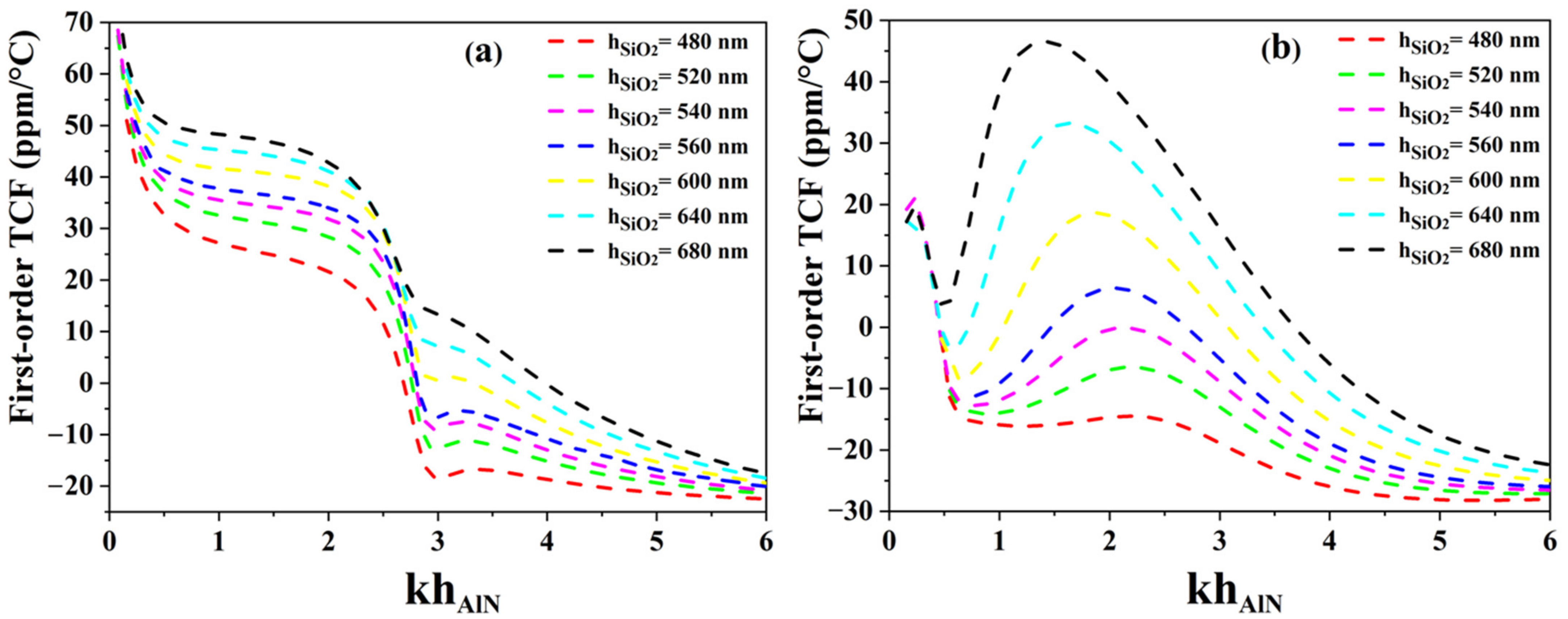

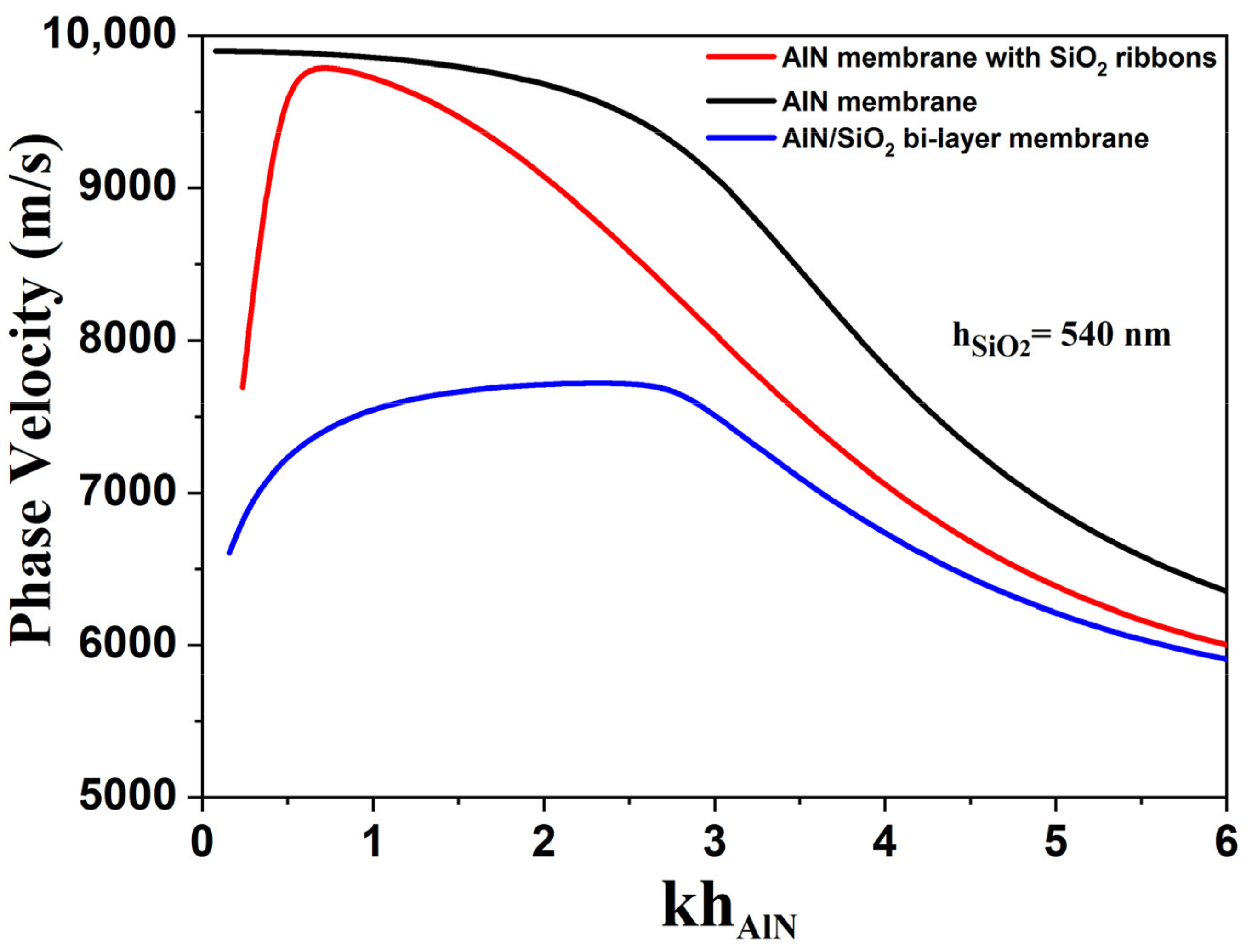

3.1. TCF and Phase Velocity in SiO2/AlN Structures

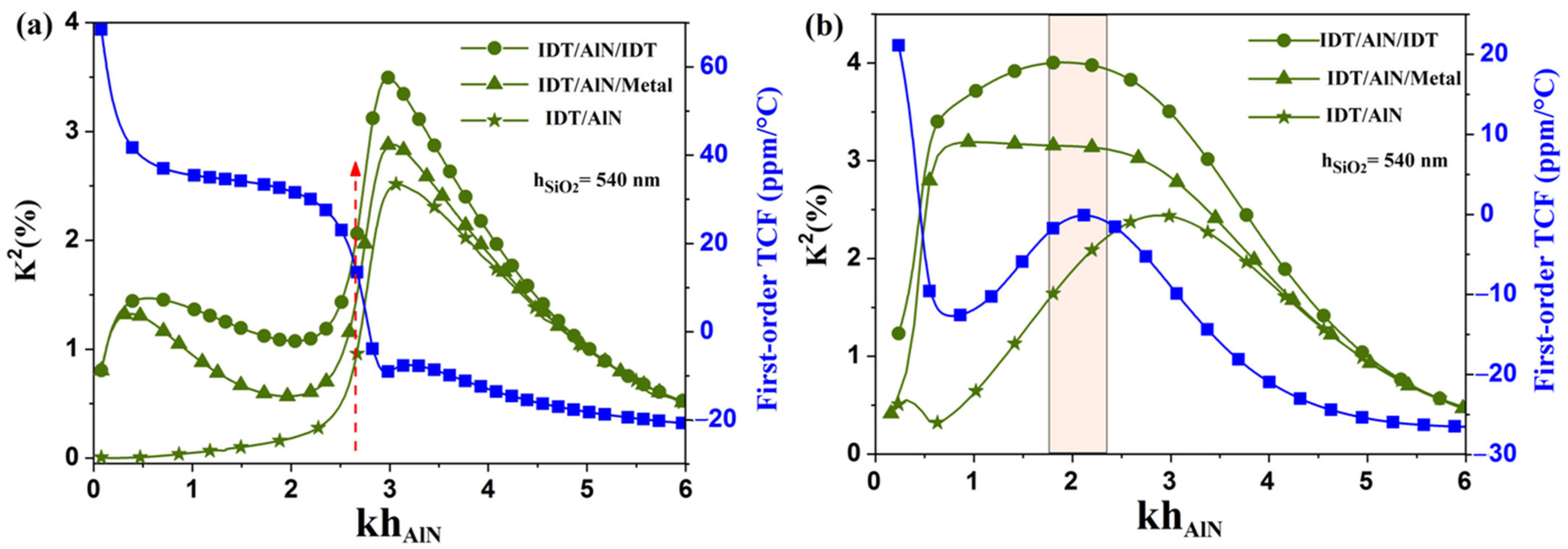

3.2. Electromechanical Coupling Coefficients in SiO2/AlN Structures

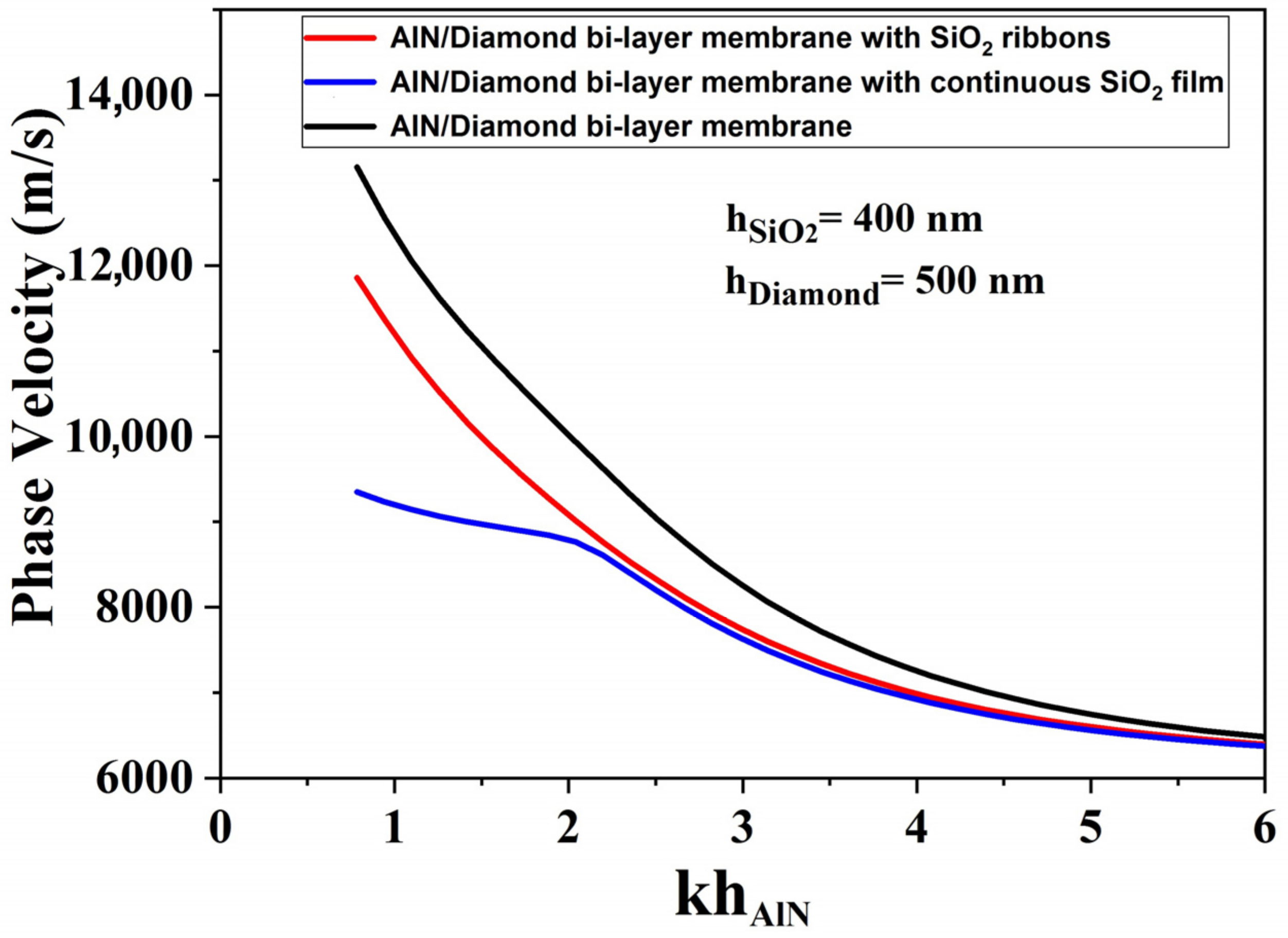

3.3. Phase Velocity in SiO2/AlN/Diamond Structures

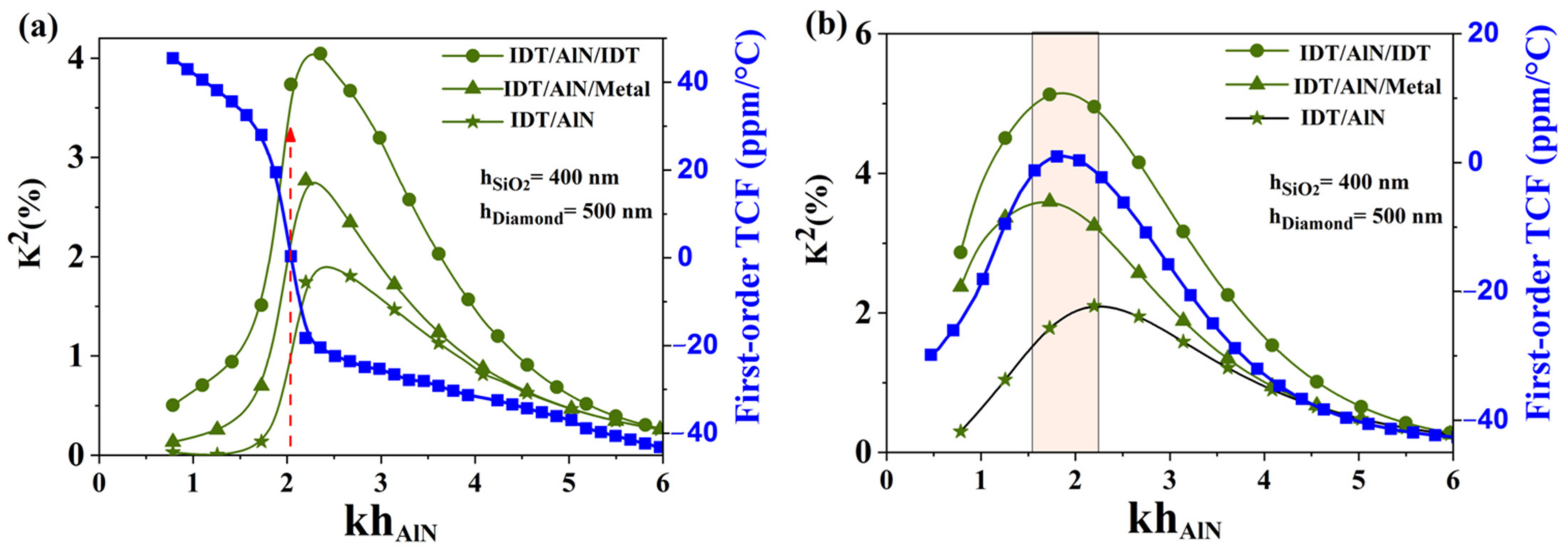

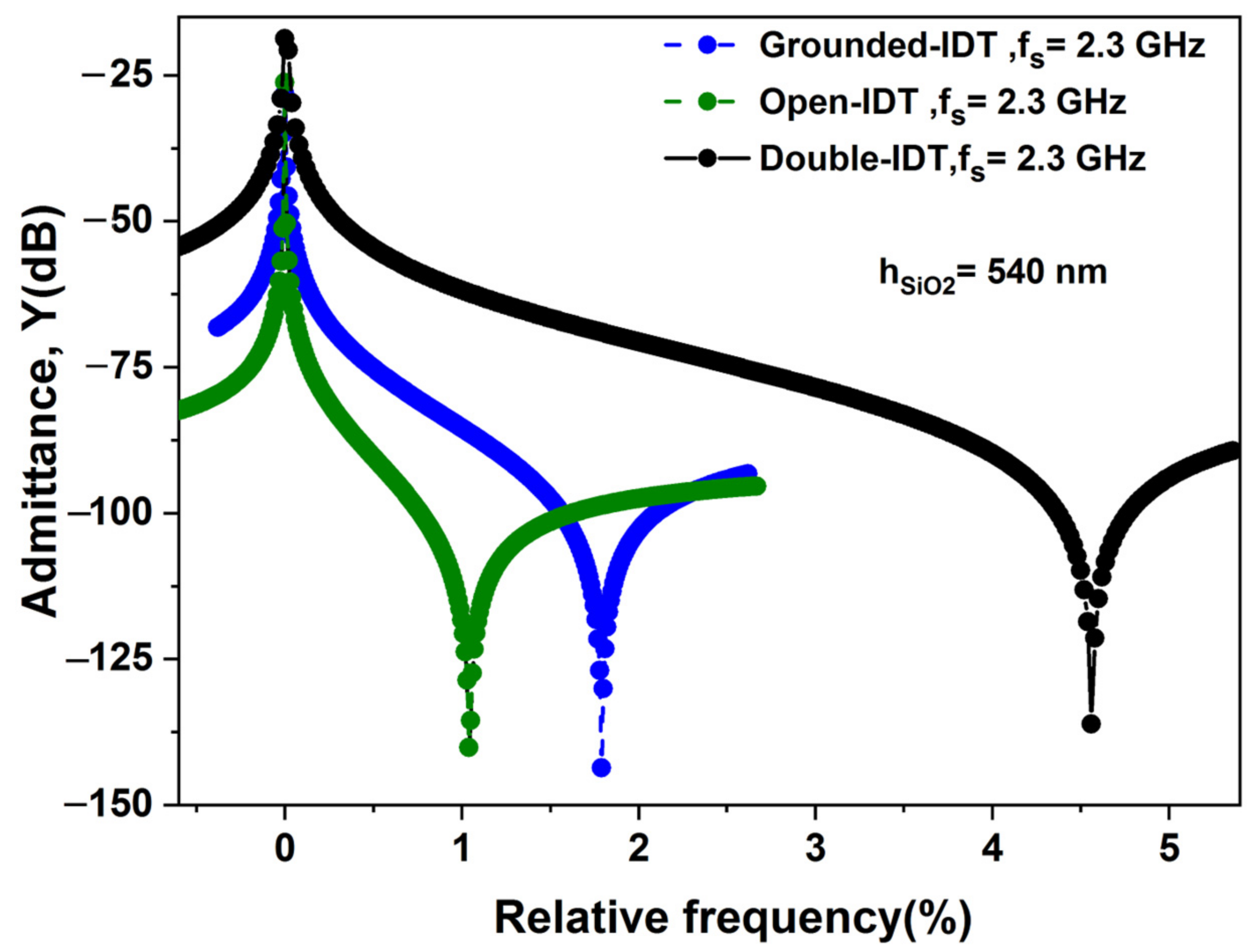

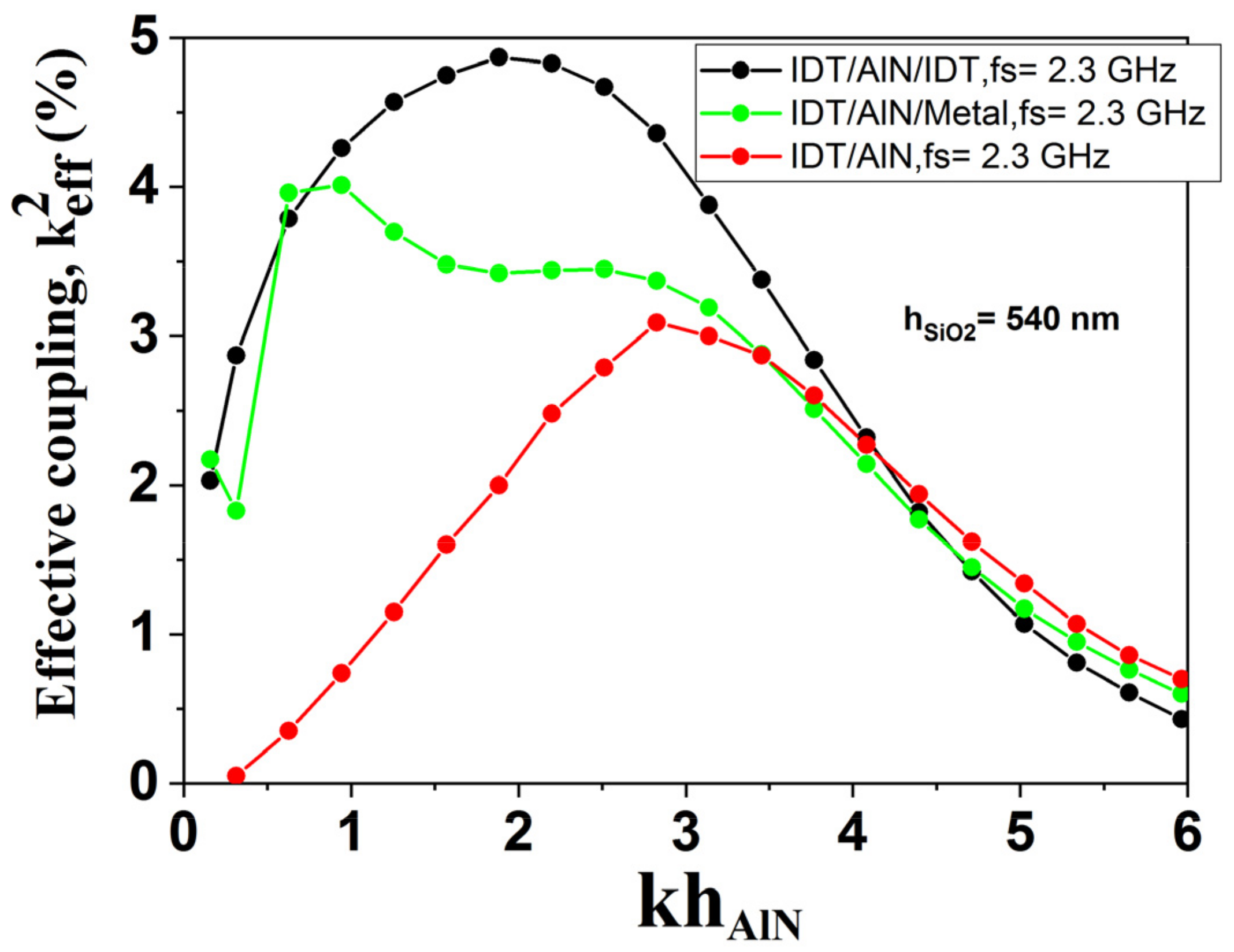

3.4. Electromechanical Coupling Coefficient of SiO2/AlN/Diamond Structures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hickernell, F.S. Surface acoustic wave devices: A rewarding past, a significant present and a promising future. In Proceedings of the 12th Conference on Microwaves and Radar, Krakow, Poland, 20–22 May 1998; p. 159. [Google Scholar] [CrossRef]

- Yamamoto, Y. SAW filters and resonators for public communication systems. In Proceedings of the IEEE Ultrasonics Symposium, Baltimore, MD, USA, 31 October–3 November 1993; p. 95. [Google Scholar] [CrossRef]

- Tominaga, T.; Takayanagi, S.; Yanagitani, T. c-Axis-tilted ScAlN films grown on silicon substrates for surface acoustic wave devices. Jpn. J. Appl. Phys. 2022, 61, SG1054. [Google Scholar] [CrossRef]

- Tsubouchi, K.; Sugai, K.; Mikoshina, N. AlN Material Constants Evaluation and SAW Properties on AlN/Al2O3 and AlN/Si. In Proceedings of the Ultrasonics Symposiums, Chicago, IL, USA, 14–16 October 1981; p. 375. [Google Scholar] [CrossRef]

- Nakahata, H.; Higaki, K.; Fujii, S.; Hachigo, A.; Kitabayashi, H.; Tanabe, K.; Seki, Y.; Shikata, S. SAW devices on diamond. In Proceedings of the IEEE Ultrasonics Symposium, Seattle, WA, USA, 7–10 November 1995; p. 361. [Google Scholar] [CrossRef]

- Lei, L.; Dong, B.; Hu, Y.; Lei, Y.; Wang, Z.; Ruan, S. High-Frequency Surface Acoustic Wave Resonator with Diamond/AlN/IDT/AlN/Diamond Multilayer Structure. Sensors 2022, 22, 6479. [Google Scholar] [CrossRef]

- Mortet, V.; Elmazria, O.; Nesladek, M.; Assouar, M.B.; Vanhoyland, G.; D’Haen, J.; D’Olieslaeger, M.; Alnot, P. Surface acoustic wave propagation in aluminum nitride-unpolished freestanding diamond structures. Appl. Phys. Lett. 2002, 81, 1720–1722. [Google Scholar] [CrossRef]

- Kirsch, P.; Assouar, M.B.; Elmazria, O.; Mortet, V.; Alnot, P. 5GHz SAW devices based on AlN/diamond layered structure realized using e-beam lithography. Appl. Phys. Lett. 2006, 88, 223504-1–223504-3. [Google Scholar] [CrossRef]

- Elmazria, O.; Zhgoon, S.; Le Brizoual, L.; Sarry, F.; Tsimbal, D.; Djouadi, M.A. AlN/ZnO/diamond structure combining isolated and surface acoustic waves. Appl. Phys. Lett. 2009, 95, 233503. [Google Scholar] [CrossRef]

- Rinaldi, M.; Zuniga, C.; Zuo, C.; Piazza, G. AlN contour-mode resonators for narrow-band filters above 3 GHz. In Proceedings of the IEEE International Frequency Control Symposium Joint with the 22nd European Frequency and Time Forum, Besancon, France, 20–24 April 2009; pp. 70–74. [Google Scholar] [CrossRef]

- Yantchev, V.; Katardjiev, I. Thin film Lamb wave resonators in frequency control and sensing applications: A review. J. Micromech. Microeng. 2013, 23, 043001. [Google Scholar] [CrossRef]

- Wingqvist, G.; Arapan, L.; Yantchev, V.; Katardjiev, I. A micromachined thermally compensated thin film Lamb wave resonator for frequency control and sensing applications. J. Micromech. Microeng. 2009, 19, 035018. [Google Scholar] [CrossRef]

- Li, C.; Liu, X.Z.; Peng, B.; Shu, L.; Li, Y.R. AlN-based surface acoustic wave resonators on platinum bottom electrodes for high-temperature sensing applications. Rare Met. 2016, 35, 408. [Google Scholar] [CrossRef]

- Dou, S.; Qi, M.; Chen, C.; Zhou, H.; Wang, Y.; Shang, Z.; Yang, J.; Wang, D.; Mu, X. High-temperature high-sensitivity AlN-on-SOI lamb wave resonant strain sensor. AIP Adv. 2018, 8, 065315. [Google Scholar] [CrossRef] [Green Version]

- Fan, S.; Wang, W.; Li, X.; Jia, Y.; Sun, Y.; Liu, M. Optimization of AIN Composite Structure Based Surface Acoustic Wave Device for Potential Sensing at Extremely High Temperature. Sensors 2020, 20, 4160. [Google Scholar] [CrossRef]

- Schmid, P.; Triendl, F.; Zarfl, C.; Schwarz, S.; Artner, W.; Schneider, M.; Schmid, U. Influence of the AlN/Pt-ratio on the electro-mechanical properties of multilayered AlN/Pt thin film strain gauges at high temperatures. Sens. Actuator A Phys. 2020, 302, 111805. [Google Scholar] [CrossRef]

- Arab, F.; Kanouni, F.; Serhane, R.; Pennec, Y.; Özer, Z.; Bouamama, K. Electro-Acoustic Properties of Scandium-Doped Aluminum Nitride (ScxAl1-xN) Material and its Application to Phononic Crystal-Coupled SAW Devices. Crystals 2022, 12, 1431. [Google Scholar] [CrossRef]

- Kimura, T.; Daimon, K.; Ogami, T.; Kadota, M. S0 Mode Lamb Wave Resonators Using LiNbO3 Thin Plate on Acoustic Multilayer Reflector. Jpn. J. Appl. Phys. 2013, 52, 07HD03. [Google Scholar] [CrossRef]

- Kadota, M.; Tanaka, S. Simulation of solidly mounted plate wave resonator with wide bandwidth using 0-th shear horizontal mode in LiNbO3 plate. Jpn. J. Appl. Phys. 2015, 54, 07HD09. [Google Scholar] [CrossRef]

- Qiu, L.; Li, X.; Matsuoka, N.; Omori, T.; Hashimoto, K.Y. Impact of Transverse Mode Resonances on Second Harmonic Generation in Radio-frequency Bulk Acoustic Wave Resonators. Jpn. J. Appl. Phys. 2019, 58, SGGC02. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.-M.; Chen, Y.-Y.; Felmetsger, V.V.; Lien, W.-C.; Riekkinen, T.; Senesky, D.G.; Pisano, A.P. Surface acoustic wave on AlN/3C–SiC/Si multilayer structures. J. Micromech. Microeng. 2013, 23, 025019. [Google Scholar] [CrossRef]

- Wu, T.T.; Lin, C.M. Analysis of SFIT SAW filter using coupling of modes model. J. Chin. Inst. Eng. 2004, 27, 973. [Google Scholar] [CrossRef]

- Zhou, W. Thermal and dielectric properties of the AlN particles reinforced linear low-density polyethylene composites. Thermochim. Acta 2011, 512, 183–188. [Google Scholar] [CrossRef]

- Shelton, S.; Chan, M.L.; Park, H.; Horsle, D.; Boser, B.; Izyumin, I.; Przybyla, R.; Frey, T.; Judy, M.; Nunan, K.; et al. CMOS-compatible AlN piezoelectric micromachined ultrasonic transducers. In Proceedings of the 2009 IEEE International Ultrasonics Symposium, Rome, Italy, 20–23 September 2009. [Google Scholar] [CrossRef]

- Muhea, W.E.; Fida, M.; Sharma, A.; Avrutin, V.; Morkoc, H. Analytical model for schottky barrier height and threshold voltage of AlGaN/GaN HEMTs with piezoelectric effect. IEEE Trans. Electron Devices 2018, 65, 901–907. [Google Scholar] [CrossRef]

- Bhadwal, N.; Ben Mrad, R.; Behdinan, K. Review of Zinc Oxide Piezoelectric Nanogenerators: Piezoelectric Properties, Composite Structures and Power Output. Sensors 2023, 23, 3859. [Google Scholar] [CrossRef]

- Butt, Z.; Pasha, R.A.; Qayyum, F.; Anjum, Z.; Ahmad, N.; Elahi, H. Generation of electrical energy using lead zirconate titanate (PZT-5A) piezoelectric material: Analytical, numerical and experimental verifications. J. Mech. Sci. Technol. 2016, 30, 3553–3558. [Google Scholar] [CrossRef] [Green Version]

- Caliendo, C. Gigahertz-band electroacoustic devices based on AlN thick films sputtered on Al2O3 at low temperature. Appl. Phys. Lett. 2003, 83, 4851. [Google Scholar] [CrossRef]

- Aubert, T.; Bardong, J.; Legrani, O.; Elmazria, O.; Assouar, B.; Bruckner, G.; Talbi, A. In situ high-temperature characterization of AlN-based surface acoustic wave devices. J. Appl. Phys. 2013, 114, 014505. [Google Scholar] [CrossRef]

- Yen, T.-T.; Lin, C.-M.; Zhao, X.; Felmetsger, V.V.; Senesky, D.G.; Hopcroft, M.A.; Pisano, A.P. Characterization of aluminum nitride lamb wave resonators operating at 600 °C for harsh environment RF applications. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems, MEMS, Hong Kong, China, 24–28 January 2010; p. 731. [Google Scholar] [CrossRef]

- Lin, C.; Chen, Y.; Pisano, A.P. Theoretical investigation of Lamb wave characteristics in AlN/3C–SiC composite membranes. Appl. Phys. Lett. 2010, 97, 193506. [Google Scholar] [CrossRef] [Green Version]

- Hoang, T.; Rey, P.; Vaudaine, M.-H.; Danel, J.-S.; Robert, P.; Benech, P.; Lemaitre-Auger, P. Temperature-compensated structure for SAW pressure sensor in very high temperature. In Proceedings of the 2007 IEEE International Frequency Control Symposium Joint with the 21st European Frequency and Time Forum, Geneva, Switzerland, 29 May–1 June 2007; p. 40. [Google Scholar] [CrossRef]

- Lin, C.-M.; Yen, T.-T.; Felmetsger, V.V.; Hopcroft, M.A.; Kuypers, J.H.; Pisano, A.P. Surface acoustic wave propagation properties in AlN/3C-SiC/Si composite structure. In Proceedings of the IEEE Ultrasonics Symposium, San Diego, CA, USA, 11–14 October 2010; p. 1696. [Google Scholar] [CrossRef]

- Lin, C.-M.; Yen, T.-T.; Felmetsger, V.V.; Hopcroft, M.A.; Kuypers, J.H.; Pisano, A.P. Thermally compensated aluminum nitride Lamb wave resonators for high temperature applications. Appl. Phys. Lett. 2010, 97, 083501. [Google Scholar] [CrossRef] [Green Version]

- Doppalapudi, D.; Mlcak, R.; LeClair, J.; Gwynne, P.; Bridgham, J.; Purchase, S.; Skelton, M.; Schultz, G.; Tuller, H. MEMS microresonators for high temperature sensor applications. MRS Online Proc. Libr. (OPL) 2010, 1222, 1222-DD01-02. [Google Scholar] [CrossRef]

- Bartoli, F.; Aubert, T.; Moutaouekkil, M.; Streque, J.; Pigeat, P.; Zhgoon, S.; Talbi, A.; Hage-Ali, S.; M’Jahed, H.; Elmazria, O. AlN/GaN/Sapphire heterostructure for high-temperature packageless acoustic wave devices. Sens. Actuator A Phys. 2018, 283, 9. [Google Scholar] [CrossRef]

- Qi, M.; Li, M.; Chen, Y.; Cheng, Y.; Zhang, S.; Cao, L.; Shang, Z.; Mu, X. AlScN-Based Dual-Mode Devices with Temperature Compensated Strategy and Process Optimization. IEEE Sens. J. 2022, 22, 24027. [Google Scholar] [CrossRef]

- Kuypers, J.H.; Lin, C.-M.; Vigevani, G.; Pisano, A.P. Intrinsic temperature compensation of aluminum nitride Lamb wave resonators for multiple-frequency references. In Proceedings of the IEEE International Frequency Control Symposium, Honolulu, HI, USA, 19–21 May 2008; p. 240. [Google Scholar] [CrossRef]

- Lin, C.-M.; Yen, T.-T.; Lai, Y.-J.; Felmetsger, V.V.; Hopcroft, M.A.; Kuypers, J.H.; Pisano, A.P. Temperature-compensated aluminum nitride Lamb wave resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 524. [Google Scholar] [CrossRef]

- Zou, J.; Lin, C.-M.; Chen, Y.-Y.; Pisano, A.P. Theoretical study of thermally stable SiO2/AlN/SiO2 Lamb wave resonators at high temperatures. J. Appl. Phys. 2014, 115, 094510. [Google Scholar] [CrossRef]

- Moutaouekkil, M.; Elmazria, O.; Talbi, A.; Pernod, P.; Matar, O.B.; El Boudouti, E.H. Theoretical Study of Lamb wave mode S0 of AlN membrane bridges SiO2. In Proceedings of the IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; p. 1. [Google Scholar] [CrossRef]

- Bjurstrom, J.; Wingqvist, G.; Yantchev, V.; Katardjiev, I. Temperature compensation of liquid FBAR sensors. J. Micromech. Microeng. 2007, 17, 651. [Google Scholar] [CrossRef]

- Nakahata, H. Theoretical study on SAW characteristics of layered structures including a diamond layer. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1995, 42, 2. [Google Scholar] [CrossRef]

- Talbi, A.; Soltani, A.; Mortet, V.; Gerbedoen, J.-C.; De Jaeger, J.-C.; Pernod, P. Theoretical study of Lamb acoustic waves characteristics in a AlN/diamond composite membranes for super high frequency range operating devices. Diam. Relat. Mater. 2012, 22, 66. [Google Scholar] [CrossRef]

- Aigner, R. Bringing BAW technology into volume production: The ten commandments and the seven deadly sins. In Proceedings of the IEEE Symposium on Acoustic Wave, Devices for Future Mobile Communication Systems (IEEE, 2007), Chiba, Japan, 6–8 March 2007; pp. 85–91. [Google Scholar]

| Constants | Symbol | AlN [42] | SiO2 [42] | Diamond [43] |

|---|---|---|---|---|

| Stiffness constant (GPa) | C11 | 345 | 78.5 | 78.5 |

| C12 | 125 | 16.1 | 16.1 | |

| C13 | 120 | 16.1 | 16.1 | |

| C33 | 395 | 78.5 | 78.5 | |

| C44 | 118 | 31.2 | 31.2 | |

| C66 | 110 | 31.2 | 31.2 | |

| Temperature coefficient of elastic | TC11 | −0.37 | 2.39 | −0.14 |

| Constant (10−4/°C) | TC13 | −0.018 | 5.84 | −0.57 |

| TC33 | −0.65 | 2.39 | −0.14 | |

| TC44 | −0.5 | 1.51 | −0.125 | |

| Density (Kg/m3) | ρ | 3260 | 2210 | 3510 |

| Piezoelectric constant(C/m2) | e15 | −0.48 | - | - |

| e31 | −0.58 | - | - | |

| e33 | 1.55 | - | - | |

| Temperature coefficient of mass density | Tρ | −14.69 | −1.65 | −3.6 |

| (10−6/°C) | ||||

| Dielectric constant (10−11F/m) | ε11 | 8 | 3.32 | 5.7 |

| ε33 | 9 | 3.32 | 5.7 |

| Device Structure | Transducer Configurations | Advantages | Disadvantages |

|---|---|---|---|

| SiO2/AlN bi-layer membrane | electrode topologies (A) | The fabrication process of continuous SiO2 film is a little simpler, the fabrication process of a single electrode is a little simpler | low phase velocity, bad temperature stability |

| electrode topologies (B) | The fabrication process of continuous SiO2 film is a little simpler | low phase velocity, bad temperature stability, the fabrication process of the electrode is less difficult | |

| electrode topologies (C) | The fabrication process of continuous SiO2 film is a little simpler | low phase velocity, bad temperature stability, the fabrication process of an IDT electrode is a little complicated | |

| AlN membrane with SiO2 ribbons | electrode topologies (A) | high phase velocity, excellent temperature stability, the fabrication process of a single electrode is a little simpler | ― |

| electrode topologies (B) | high phase velocity, excellent temperature stability, K2 = 3% | The fabrication process of a metal electrode is less difficult | |

| electrode topologies (C) | high phase velocity, excellent temperature stability, K2 = 4% | The fabrication process of IDT electrode is a little complicated | |

| SiO2/AlN/Diamond multilayer membrane | electrode topologies (A) | The fabrication process of continuous SiO2 film is a little simpler, the fabrication process of a single electrode is a little simpler | low phase velocity, bad temperature stability |

| electrode topologies (B) | The fabrication process of continuous SiO2 film is a little simpler | low phase velocity, bad temperature stability, the fabrication process of the electrode is less difficult | |

| electrode topologies (C) | The fabrication process of continuous SiO2 film is a little simpler | low phase velocity, bad temperature stability, the fabrication process of an IDT electrode is a little complicated | |

| SiO2/AlN/Diamond with SiO2 ribbons | electrode topologies (A) | high phase velocity, excellent temperature stability, the fabrication process of a single electrode is a little simpler | ― |

| electrode topologies (B) | high phase velocity, excellent temperature stability, K2 = 3.8% | The fabrication process of a metal electrode is less difficult | |

| electrode topologies (C) | high phase velocity, excellent temperature stability, K2 = 5.2% | The fabrication process of an IDT electrode is a little complicated |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moutaouekkil, M.; Streque, J.; Marbouh, O.; El Boudouti, E.H.; Elmazria, O.; Pernod, P.; Bou Matar, O.; Talbi, A. Contribution of Ribbon-Structured SiO2 Films to AlN-Based and AlN/Diamond-Based Lamb Wave Resonators. Sensors 2023, 23, 6284. https://doi.org/10.3390/s23146284

Moutaouekkil M, Streque J, Marbouh O, El Boudouti EH, Elmazria O, Pernod P, Bou Matar O, Talbi A. Contribution of Ribbon-Structured SiO2 Films to AlN-Based and AlN/Diamond-Based Lamb Wave Resonators. Sensors. 2023; 23(14):6284. https://doi.org/10.3390/s23146284

Chicago/Turabian StyleMoutaouekkil, Mohammed, Jérémy Streque, Othmane Marbouh, El Houssaine El Boudouti, Omar Elmazria, Philippe Pernod, Olivier Bou Matar, and Abdelkrim Talbi. 2023. "Contribution of Ribbon-Structured SiO2 Films to AlN-Based and AlN/Diamond-Based Lamb Wave Resonators" Sensors 23, no. 14: 6284. https://doi.org/10.3390/s23146284