Study on Contact Stress Distribution Characteristics and Damage of Plug Seedlings Based on Flexible Pressure Sensor

Abstract

:1. Introduction

2. Materials and Methods

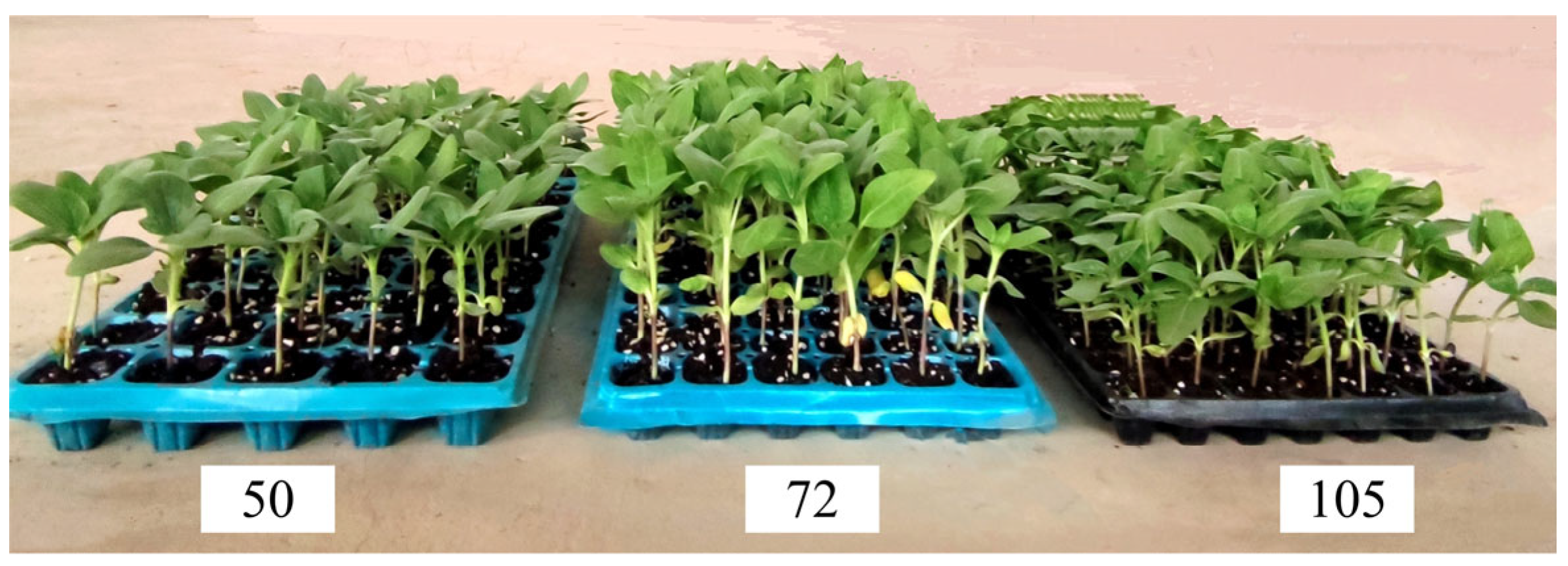

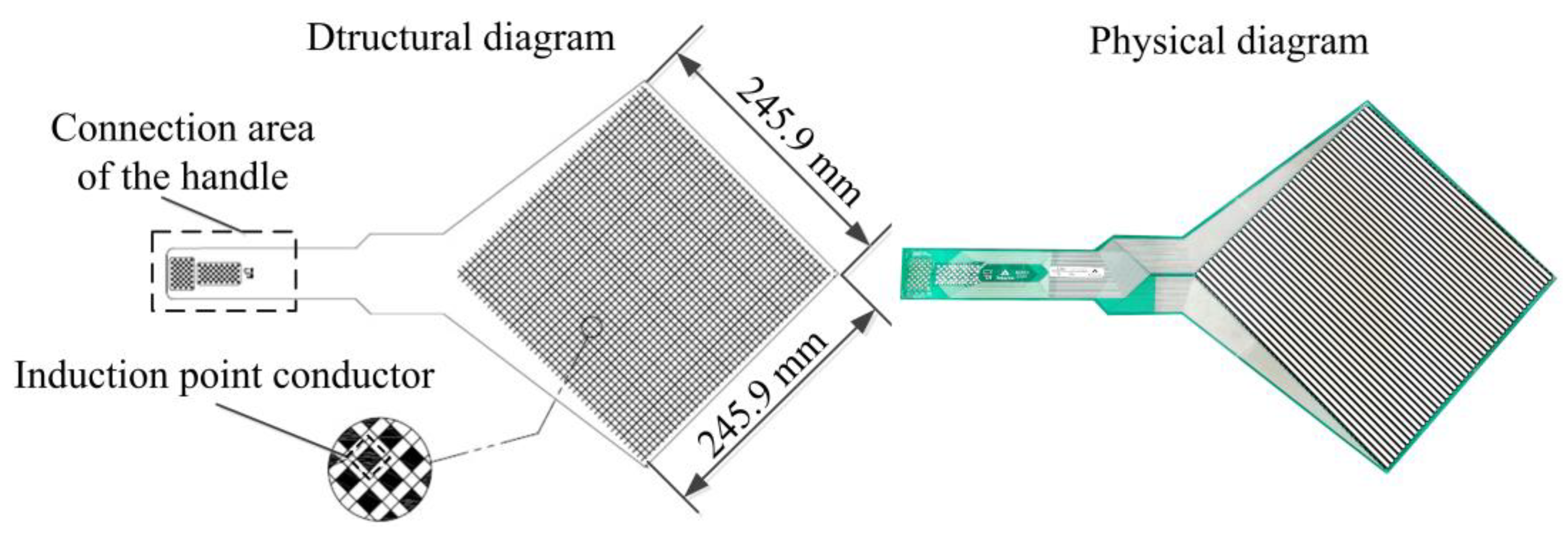

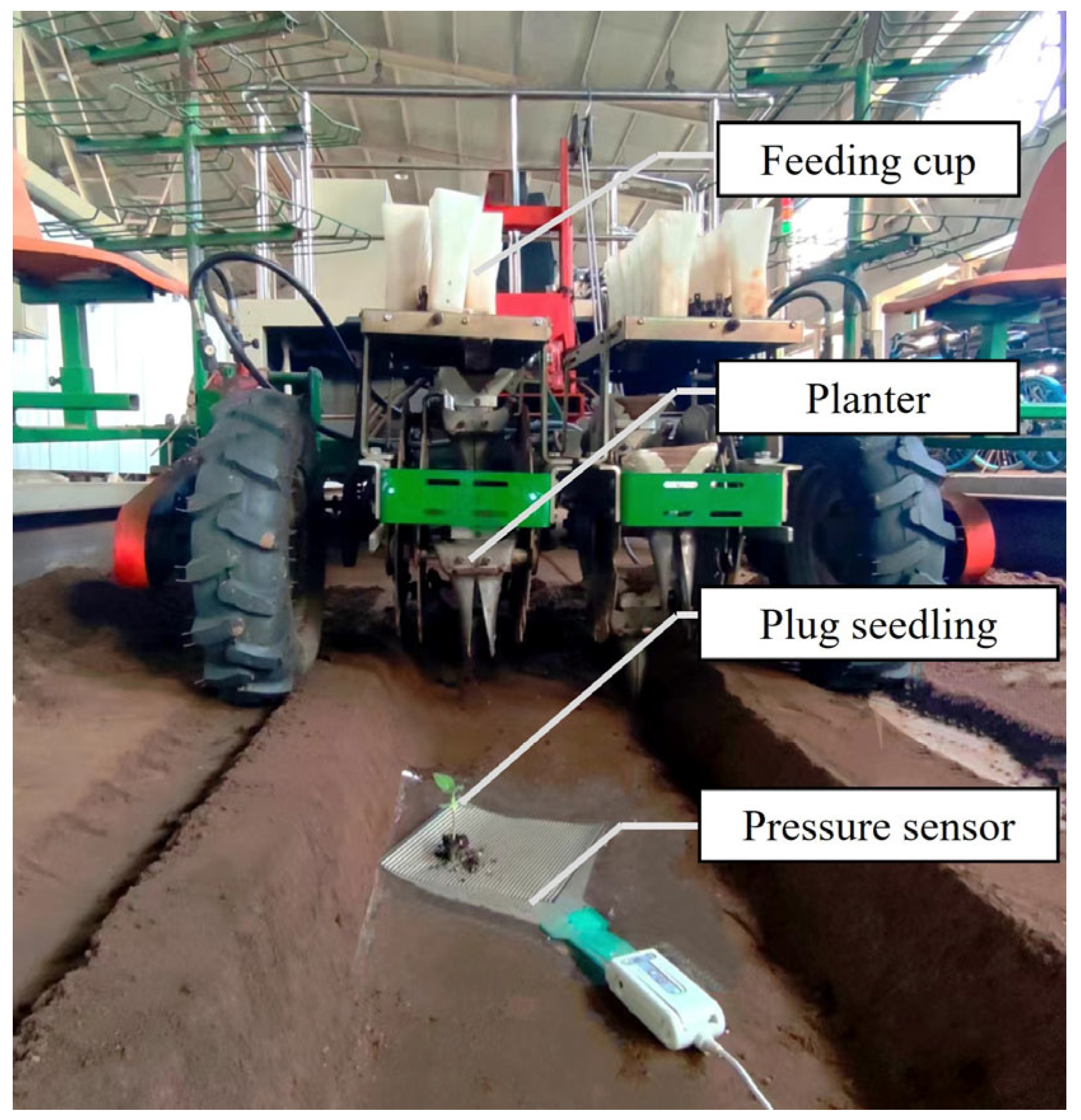

2.1. Test Materials and Equipment

2.2. Single-Factor Experimental Method

2.3. Box–Behnken Experimental Design

2.4. Data Processing

3. Results

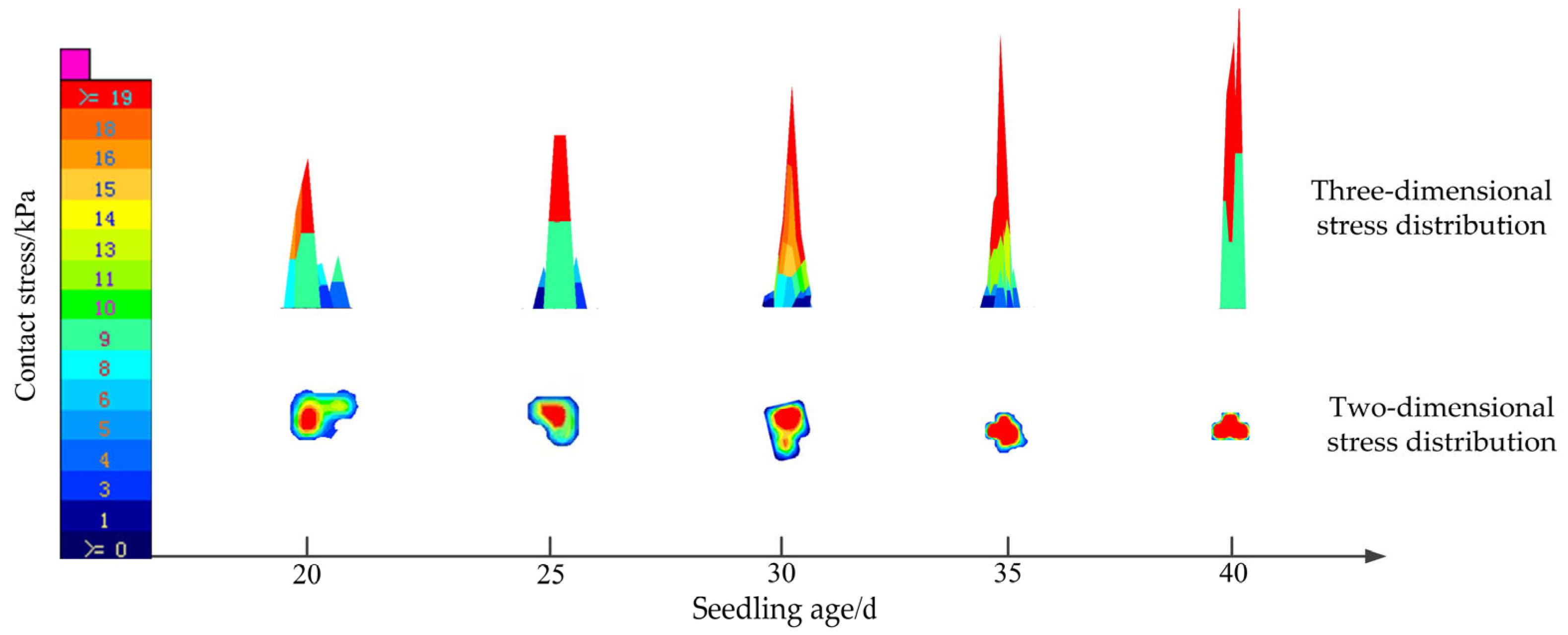

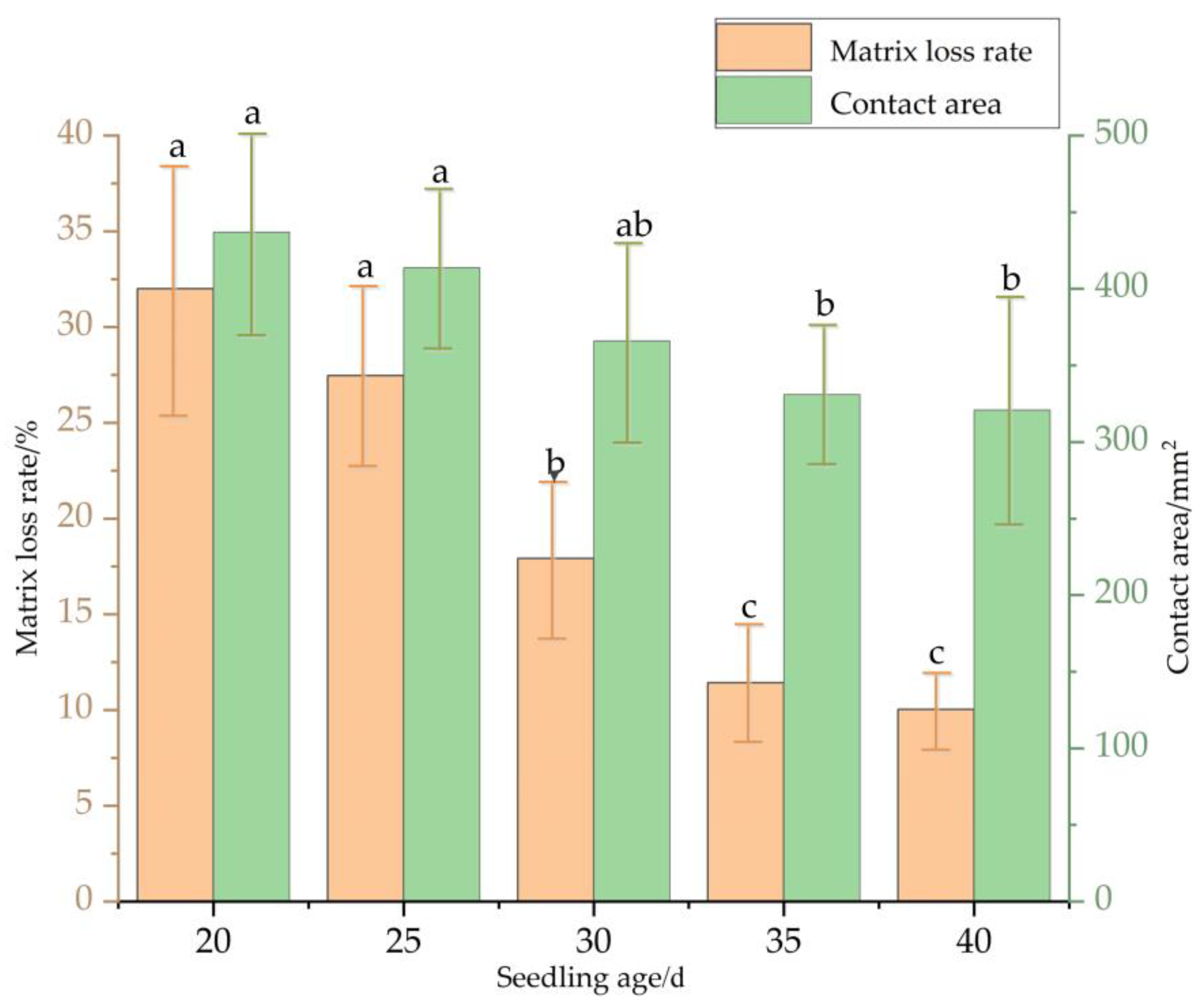

3.1. Rules of Pot Damage at Different Seedling Ages

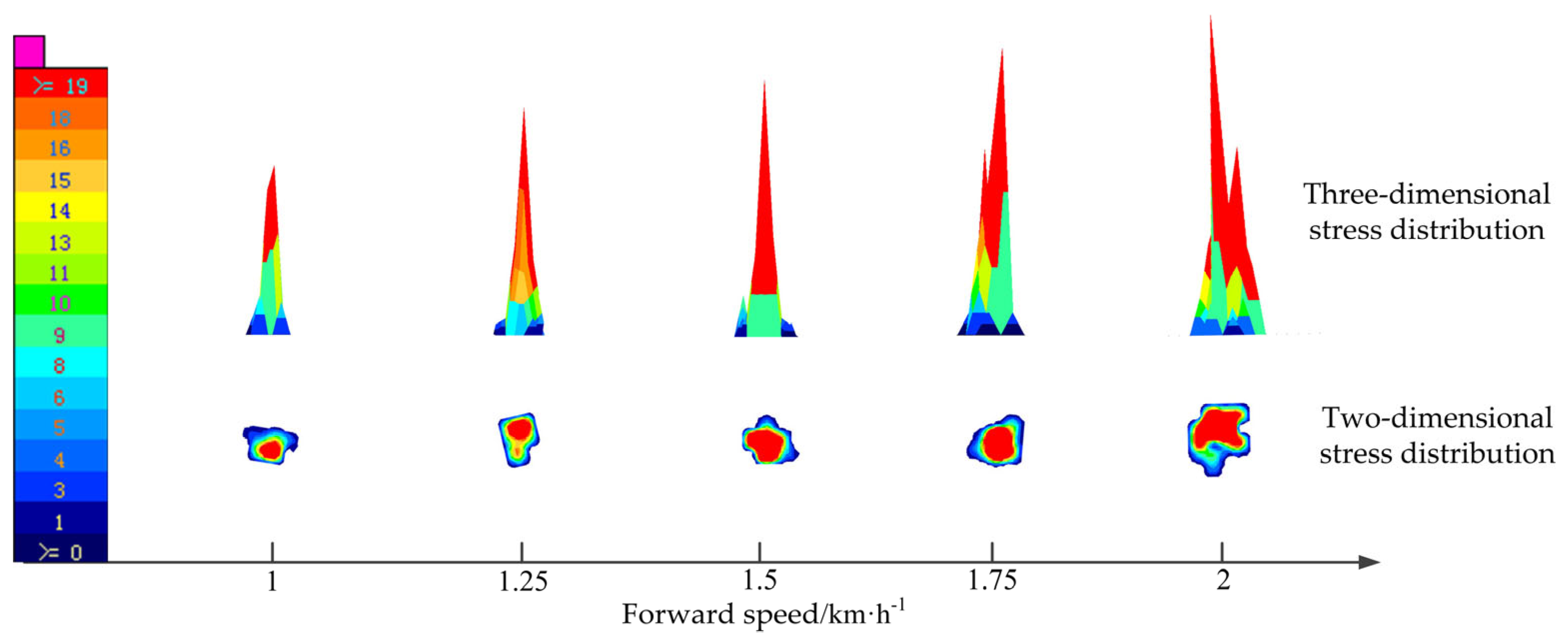

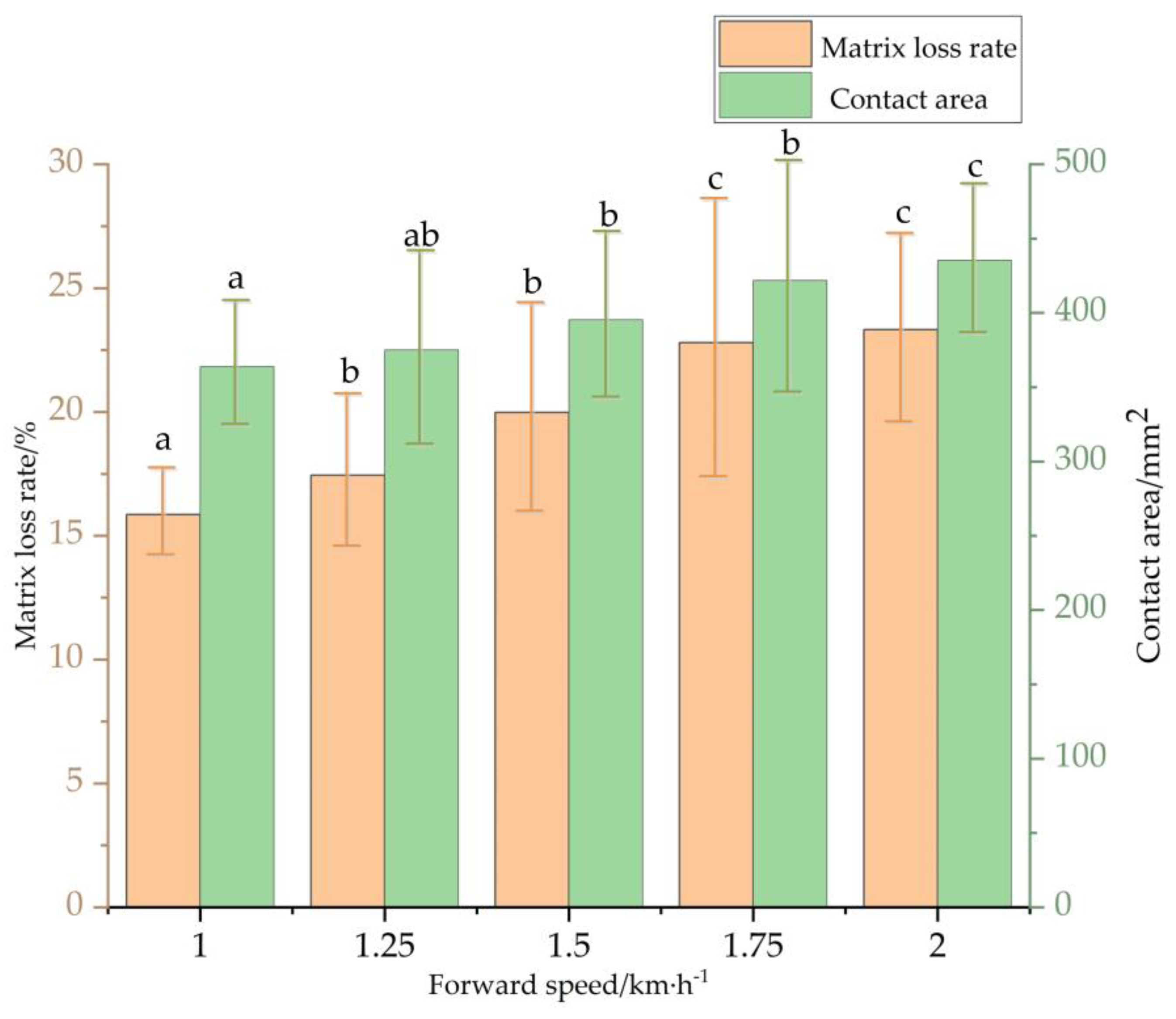

3.2. Rules of Pot Damage at Different Forward Speeds

3.3. Box–Behnken Experimental Optimization Design

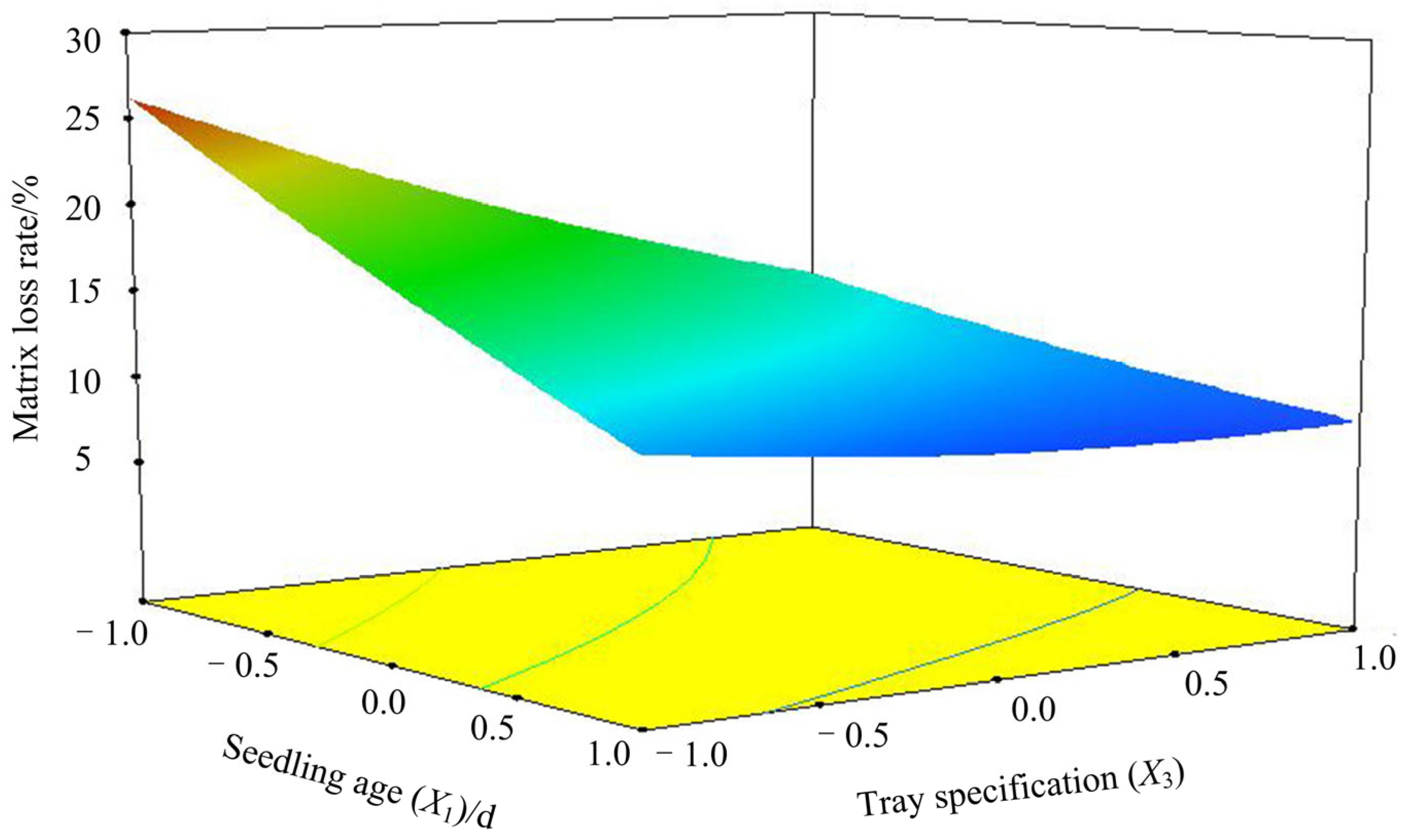

3.4. Analysis of Interaction

3.5. Determination of the Optimal Parameter Combination

4. Discussion

5. Conclusions

- When the forward speed and plug specifications were constant, the contact stress increased gradually with the increase of seedling age, but the contact area and matrix loss rate decreased gradually. When the seedling age and soil plug specifications are constant, the contact stress, contact area, and matrix loss rate gradually increase with the forward speed.

- This study established the regression model of the three factors on the matrix loss rate by the orthogonal test of seedling age, tray specification, and forward speed. The results showed that the tray specification, seedling age, and forward speed had highly significant effects on the matrix loss rate, and there was an interaction between seedling age and tray specification.

- Through the Design Expert software, the optimal parameter combination is the following: the tray specification is 72, the seedling age is 30 d, and the forward speed of the transplanter is 1.25 km·h−1. The repeated experiments show that the parameter combination is reliable and can be used in plug seedling transplanting production operations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, Z.; Wang, L.; Wang, Y.; Chu, Y.; Lin, D.; Yang, Y. Morphological and Physiological Properties of Greenhouse-Grown Cucumber Seedlings as Influenced by Supplementary Light-Emitting Diodes with Same Daily Light Integral. Horticulturae 2021, 7, 361. [Google Scholar] [CrossRef]

- Wei, H.; Ye, X.; Du, Z.; Fan, S.; Robilian; Liu, S.; Huang, C. Accelerate the construction of a new development pattern and focus on promoting the high-quality development of agriculture and rural areas—Authoritative experts deeply interpret the spirit of the 20th National Congress of the Communist Party of China. Chin. Rural. Econ. 2022, 12, 2–34. [Google Scholar]

- Zhao, K. Research on the impact of agricultural mechanization development on the transformation of China’s agricultural economic development mode. Ph.D. Thesis, Heilongjiang Bayi Agricultural Reclamation University, Daqing, China, 2014. [Google Scholar]

- Zhiwei, T.; Wei, M.; Qichang, Y.; Sen, Y.; Mei, Z.; Famin, D.; Haidong, X. Research status and problem analysis of greenhouse cave tray seedling transplanting machinery. J. China Agric. Univ. 2022, 27, 22–38. [Google Scholar]

- Dihingia, P.C.; Kumar, G.P.; Sarma, P.K.; Neog, P. Production of soil block seedlings in plug trays for mechanical transplanting. Int. J. Veg. Sci. 2017, 23, 471–485. [Google Scholar] [CrossRef]

- Han, L.; Kumi, F.; Mao, H.; Hu, J. Design and tests of a multi-pin flexible seedling pick-up gripper for automatic transplanting. Appl. Eng. Agric. 2019, 35, 949–957. [Google Scholar] [CrossRef]

- Jorg, O.J.; Sportelli, M.; Fontanelli, M.; Frasconi, C.; Raffaelli, M.; Fantoni, G. Design, development and testing of feeding grippers for vegetable plug transplanters. AgriEngineering 2021, 3, 669–680. [Google Scholar] [CrossRef]

- Mohamed, S.; Liu, J. Effect of Soil Moisture Content and End-Effector Speed on Pick-up Force and Lump Damage for Seedling Transplanting. AgriEngineering 2019, 1, 343–356. [Google Scholar] [CrossRef]

- Peng, W.; Xiuhua, Z.; Fukun, H.; Shuo, H.; Maokai, J. Design and simulation of taking-putting seedling manipulator of plug seedling transplanter. In Proceedings of the 2021 ASABE Annual International Virtual Meeting, 2021; ASABE: St. Joseph, MI, USA, 2021; p. 1. [Google Scholar]

- Wang, M.; Song, J.; Liu, C.; Wang, Y.; Sun, Y. Design and test of crank pendulum type seedling clamping mechanism of vegetable transplanting machine. Trans. Chin. Soc. Agric. Eng. 2015, 31, 9. [Google Scholar]

- Wen, Y.; Zhang, J.; Zhang, Y.; Tian, J.; Yuan, T.; Tan, Y.; Li, W. Development of vegetable burrow tray seedling insertion ejection type seedling retrieval device. Trans. Chin. Soc. Agric. Eng. 2020, 36, 96–104. [Google Scholar]

- Han, C. Design and Experimental Study of Automatic Feeding System of Cave Tray Seedling Transplanting Machine. Ph.D. Thesis, Nanjing Agricultural University, Nanjing, China, 2014. [Google Scholar]

- Wang, Y.; Chen, J.; Wu, J.; Zhao, Y. Mechanical properties test of broccoli bowl seedlings for mechanized cultivation. Trans. Chin. Soc. Agric. Eng. 2014, 30, 1080. [Google Scholar]

- Liu, Y.; Mao, H.; Wang, T.; Li, B.; Li, Y. Optimization and experiment of movement analysis and experiment of tomato cave tray seedlings in hanging cup transplanting mechanism. Trans. Chin. Soc. Agric. Mach. 2018, 49, 9. [Google Scholar]

- Holthusen, D.; Brandt, A.A.; Reichert, J.M.; Horn, R.; Fleige, H.; Zink, A. Soil functions and in situ stress distribution in subtropical soils as affected by land use, vehicle type, tire inflation pressure and plant residue removal. Soil Tillage Res. 2018, 184, 78–92. [Google Scholar] [CrossRef]

- Sun, N.; Fan, B.; Ding, Y.; Liu, Y.; Bi, Y.; Seglah, P.A.; Gao, C.J.S. Analysis of the Development Status and Prospect of China’s Agricultural Sensor Market under Smart Agriculture. Sensors 2023, 23, 3307. [Google Scholar] [CrossRef]

- Wang, X.; Hu, H.; Wang, Q.; Li, H.; He, J.; Chen, W. Discrete-based soil model parameter calibration method. Trans. Chin. Soc. Agric. Mach. 2017, 48, 78–85. [Google Scholar]

- Wu, J.; Guo, K.; Gu, R.; Zhang, J.; Qi, C. Dynamic viscoelastic characteristics of Korla pears at different expansion levels. Trans. Chin. Soc. Agric. Mach. 2010, 041, 113–117. [Google Scholar]

- Komarnicki, P.; Stopa, R.; Kuta, Ł.; Szyjewicz, D. Determination of apple bruise resistance based on the surface pressure and contact area measurements under impact loads. Comput. Electron. Agric. 2017, 142, 155–164. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, H.; Cai, X.; Wang, J.; Xu, T.; Yu, g.; Yao, F.; Yan, F. Contact stress distribution characteristics of potato drop collisions. J. South China Agric. Univ. 2020, 41, 10. [Google Scholar]

- Wang, Y.; Yu, H. Experiment and analysis of influencing factors of substrate integrity rate of seedling retrieval by manipulator of acupuncture tray seedlings. Trans. Chin. Soc. Agric. Eng. 2015, 31, 7. [Google Scholar]

- Bai, H.; Li, X.; Zeng, F.; Cui, J.; Zhang, Y. Study on the Impact Damage Characteristics of Transplanting Seedlings Based on Pressure Distribution Measurement System. Horticulturae 2022, 8, 1080. [Google Scholar] [CrossRef]

- Cui, J.; Li, X.; Zeng, F.; Bai, H.; Zhang, Y.J.A.S. Parameter Calibration and Optimization of a Discrete Element Model of Plug Seedling Pots Based on a Collision Impact Force. Appl. Sci. 2023, 13, 6278. [Google Scholar] [CrossRef]

- He, C.; Guo, Y.; Guo, X.; Sang, H. A mathematical model for predicting the draft force of shank-type tillage tine in a compacted sandy loam. Soil Tillage Res. 2023, 228, 105642. [Google Scholar] [CrossRef]

- Yan, D. Simulation analysis and experimental study of soybean seed particle modeling, seeding and soil covering suppression process. Ph.D. Thesis, Jilin University, Changchun, China, 2021. [Google Scholar]

- Liu, Y. Optimization and Experiment of Vegetable Hole Tray Seedling Transplanting Seedling Bowl Breakage Mechanism and Planter Hole Forming Movement. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2019. [Google Scholar]

- Fandi, Z.; Xuying, L.; Hongbin, B.; Ji, C.; Xuening, L.; Yongzhi, Z. Experimental Research and Analysis of Soil Disturbance Behavior during the Hole Drilling Process of a Hanging-Cup Transplanter by DEM. Processes 2023, 11, 600. [Google Scholar]

- Tang, H. Parameter Optimization and Performance Experimental Study of Vegetable Bowl Seedling Hanging Cup Planter. Master’s Thesis, Zhejiang University, Hangzhou, China, 2016. [Google Scholar]

- He, Y. Design and Research of Automatic Seedling Retrieval System for High-Speed Planting of Vegetable Burrow Seedlings. Ph.D. Thesis, Chinese Academy of Agricultural Mechanization, Beijing, China, 2018. [Google Scholar]

- Zhang, J.; Long, X.; Han, C.; Yuan, P.; Gao, J. Design and test of mechanical driven pepper burrow tray seedling automatic seedling taking and feeding system. Trans. Chin. Soc. Agric. Eng. 2021, 37, 11. [Google Scholar]

- Han, B.; Shen, D.; Guo, C.; Liu, Q.; Wang, X.; Song, C. Design and test of adjustable end effector for seedling extraction of cabbage bowls. Trans. Chin. Soc. Agric. Mach. 2019, 50, 10. [Google Scholar]

- Zeng, F.; Li, X.; Bai, H.; Cui, J.; Liu, X.; Zhang, Y. Experimental Study on Pot Damage and Contact Stress Distribution Characteristics of Oil Sunflower Plug Seedlings. Appl. Sci. 2022, 12, 10889. [Google Scholar] [CrossRef]

| Items | Specifications |

|---|---|

| Number of Sensels | 1936 |

| Pitch | 5.588 mm |

| Thickness | 0.102 mm |

| Max Pressure | 1724 kPa |

| Factors | Level | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Seedling age/d | 20 | 25 | 30 | 35 | 40 |

| Forward speed (v)/km·h−1 | 1 | 1.25 | 1.5 | 1.75 | 2 |

| Level | Factors | ||

|---|---|---|---|

| Seedling Age (X1)/d | Forward Speed (X2)/km·h−1 | Tray Specification (X3) | |

| −1 | 25 | 1 | 50 |

| 0 | 30 | 1.25 | 72 |

| 1 | 35 | 1.5 | 105 |

| Test Number | Seedling Age (X1)/d | Forward Speed (X2)/km·h−1 | Tray Specification (X3) | Matrix Loss Rate/% |

|---|---|---|---|---|

| 1 | −1 | 0 | −1 | 27.49 |

| 2 | −1 | 0 | 1 | 13.05 |

| 3 | 0 | 0 | 0 | 13.56 |

| 4 | 1 | −1 | 0 | 8.33 |

| 5 | 0 | 1 | −1 | 19.98 |

| 6 | 0 | 0 | 0 | 13.86 |

| 7 | 1 | 0 | −1 | 11.13 |

| 8 | 0 | 1 | 1 | 12.01 |

| 9 | 1 | 1 | 0 | 10.36 |

| 10 | 0 | 0 | 0 | 13.86 |

| 11 | 0 | −1 | −1 | 15.00 |

| 12 | 0 | 0 | 0 | 13.86 |

| 13 | 1 | 0 | 1 | 7.51 |

| 14 | −1 | −1 | 0 | 16.27 |

| 15 | 0 | −1 | 1 | 10.88 |

| 16 | −1 | 1 | 0 | 21.00 |

| 17 | 0 | 0 | 0 | 13.86 |

| Source of Variation | Mean Square | Degree of Freedom | Sum of Square | p-Value |

|---|---|---|---|---|

| Model | 378.24 | 9 | 42.03 | <0.0001 ** |

| X1 | 204.83 | 1 | 204.83 | <0.0001 ** |

| X2 | 20.70 | 1 | 20.70 | 0.0044 ** |

| X3 | 113.63 | 1 | 113.63 | <0.0001 ** |

| X1X2 | 1.82 | 1 | 1.82 | 0.2596 |

| X1X3 | 29.27 | 1 | 29.27 | 0.0017 ** |

| X2X3 | 3.71 | 1 | 3.71 | 0.1237 |

| X12 | 0.70 | 1 | 0.70 | 0.4709 |

| X22 | 0.03 | 1 | 0.03 | 0.8839 |

| X32 | 3.31 | 1 | 3.31 | 0.1424 |

| Residual | 8.48 | 7 | 1.21 | |

| Lack of fit | 5.89 | 3 | 1.96 | 0.1562 |

| Pure error | 2.59 | 4 | 0.65 | |

| Sum | 386.72 | 16 | 42.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, J.; Li, X.; Zeng, F.; Bai, H. Study on Contact Stress Distribution Characteristics and Damage of Plug Seedlings Based on Flexible Pressure Sensor. Sensors 2023, 23, 8175. https://doi.org/10.3390/s23198175

Cui J, Li X, Zeng F, Bai H. Study on Contact Stress Distribution Characteristics and Damage of Plug Seedlings Based on Flexible Pressure Sensor. Sensors. 2023; 23(19):8175. https://doi.org/10.3390/s23198175

Chicago/Turabian StyleCui, Ji, Xuying Li, Fandi Zeng, and Hongbin Bai. 2023. "Study on Contact Stress Distribution Characteristics and Damage of Plug Seedlings Based on Flexible Pressure Sensor" Sensors 23, no. 19: 8175. https://doi.org/10.3390/s23198175