Electromagnetic Force on an Aluminum Honeycomb Sandwich Panel Moving in a Magnetic Field

Abstract

:1. Introduction

| Spacecraft | Orbit | Rotation Angular Rate (Time) | Reference |

|---|---|---|---|

| GOES 8 | GEO | 22.4/s (12 December 2013) 21.84/s (27 February 2014) 4.76/s (25 July 2014) | [11] |

| GOES 10 | GEO | 15.6/s (28 February 2014) 11.1/s (19 March 2014) 13.7/s (28 August 2014) | [11] |

| BSAT 1A | GEO | 114.87/s (15 April 2014) 115.42/s (28 March 2015) 115.5/s (11 September 2015) | [12] |

| Brazilsat B1 | GEO | 94.22/s (28 March 2015) | [12] |

| KOREASAT 1 | GEO | 4.9/s (23 June 2013) | [13] |

| BREEZE-M body | HEO | 400.9/s (6 January 2004) | [14] |

| INTELSAT 4-F7 | GEO | 139/s (6 January 2004) | [14] |

| GLONAS satellite | GEO | 1.1/s–42.2/s | [14] |

| ASTRO-H | LEO | 69/s (28 March 2016) | [13] |

| Cosmos 2082 body | LEO | 8.8/s (6 January 2004) | [15] |

| ENVISAT | LEO | 1.96/s (28 April 2016) | [14] |

| ADEOS-2 | LEO | 4.3/s (30 March 2016) | [14] |

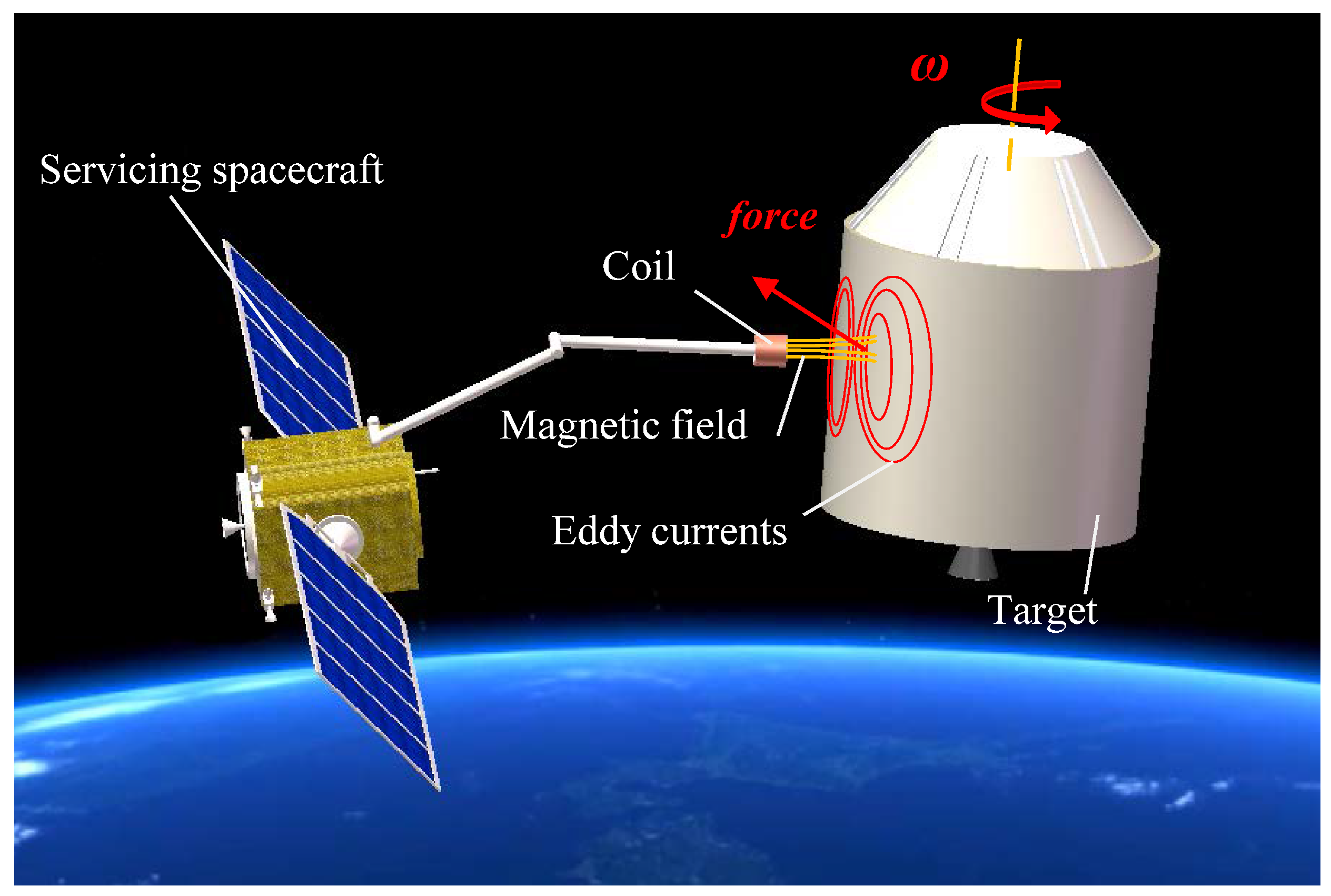

2. Basic Principles of Electromagnetic Detumbling

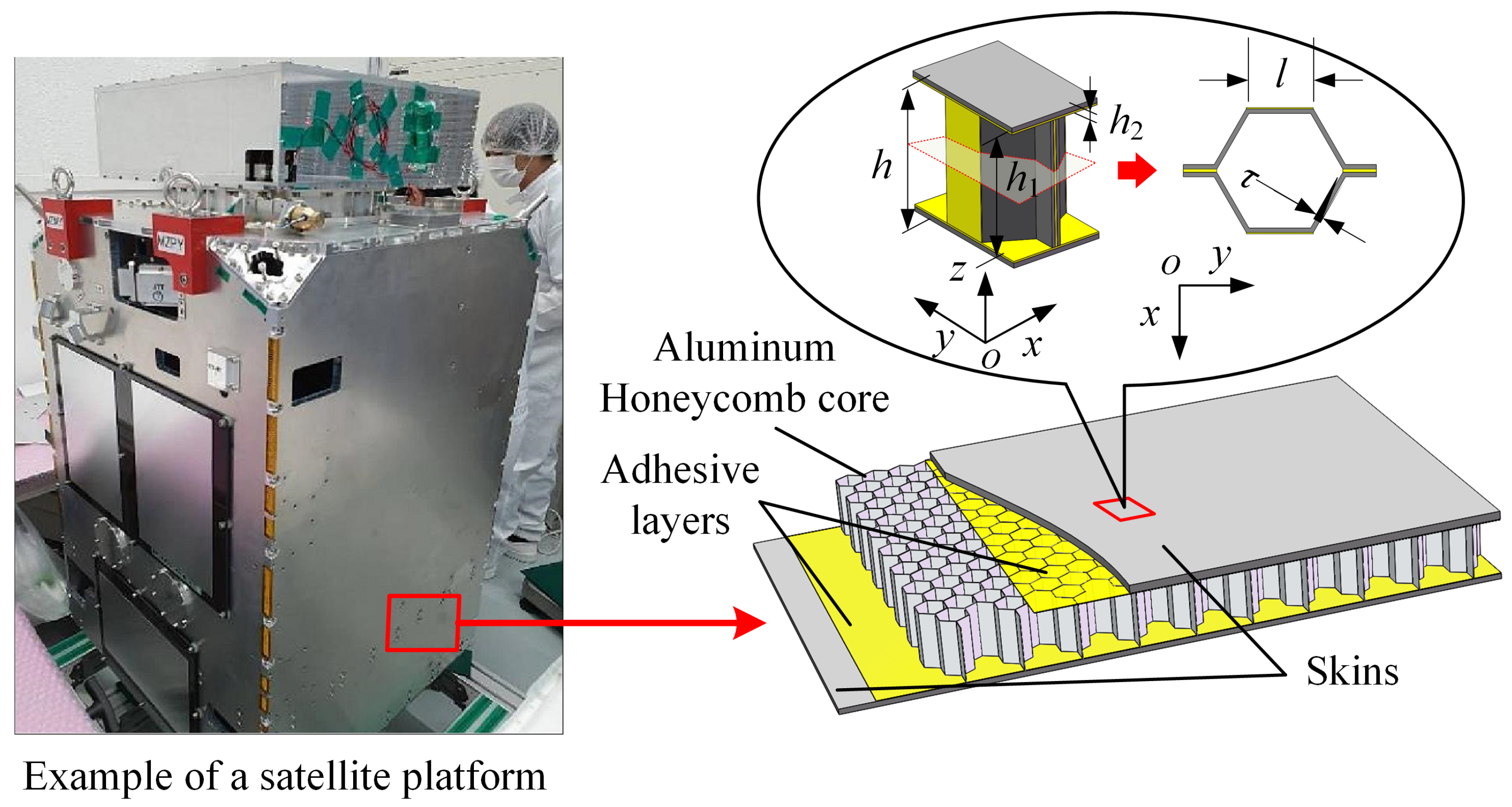

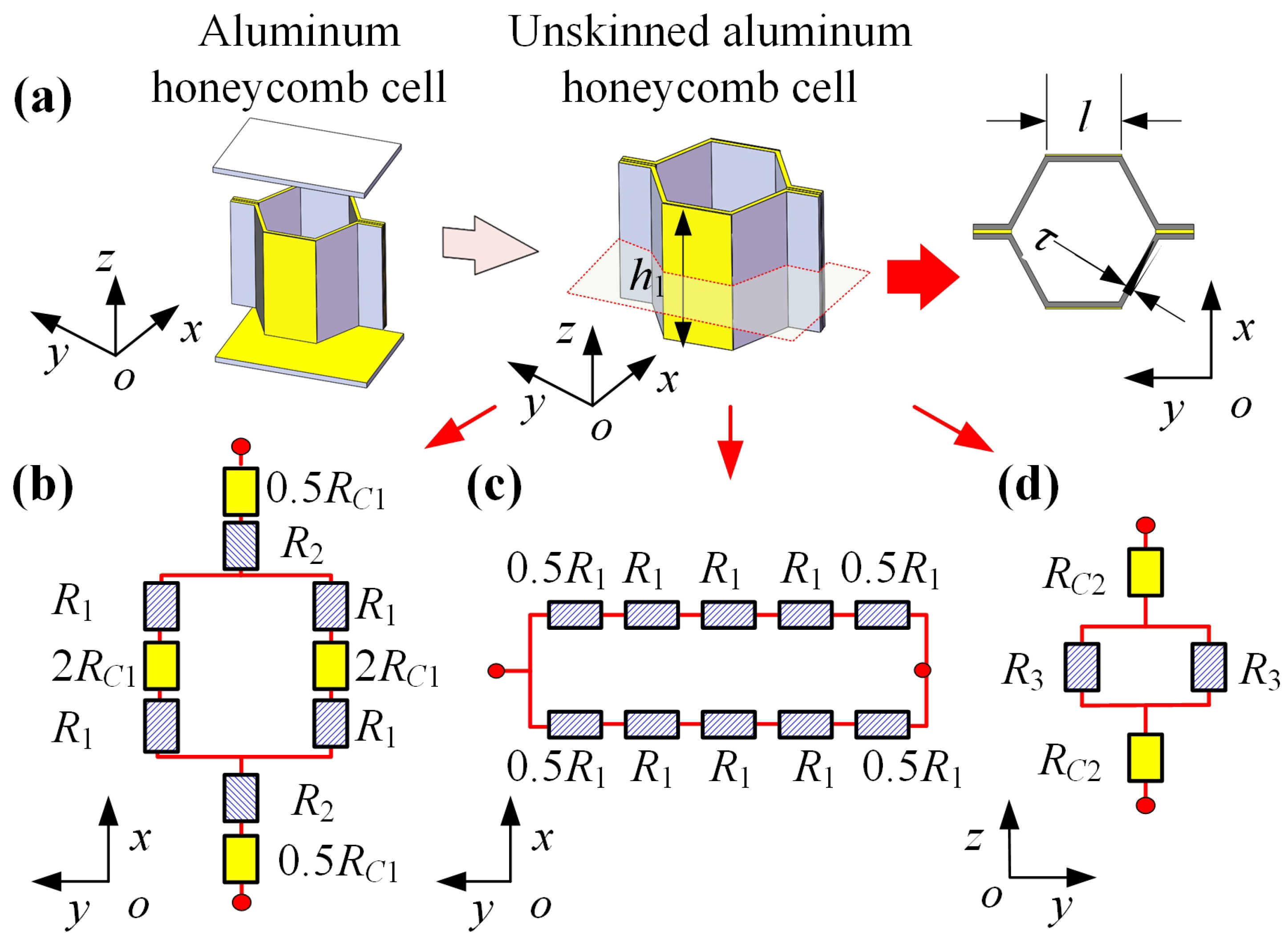

3. Equivalent Conductivity Tensor

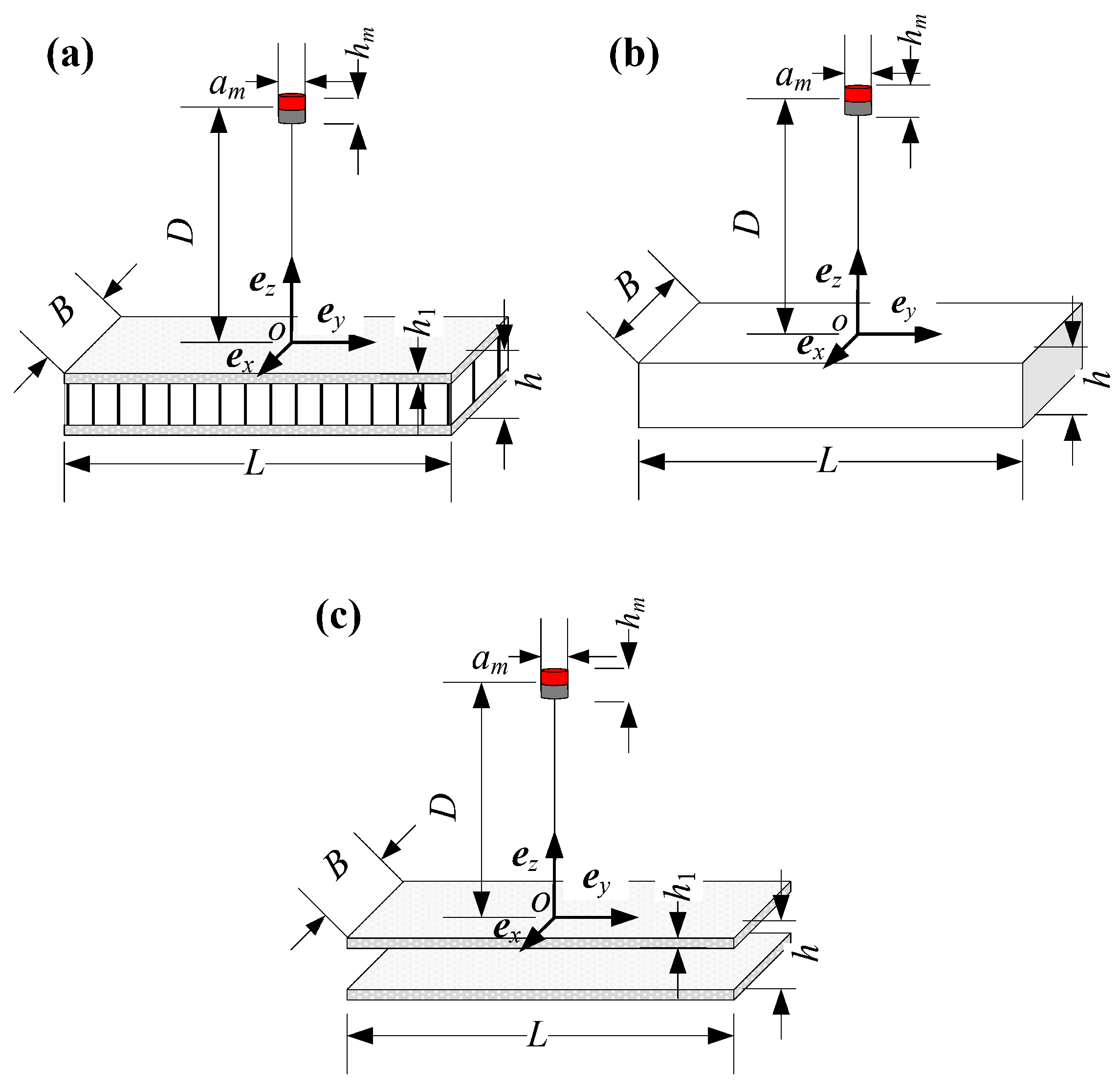

4. Finite Element Models and Numerical Calculation Results

4.1. Case One: Aluminum Skins

4.2. Case Two: CFRP Skins

5. Experiment

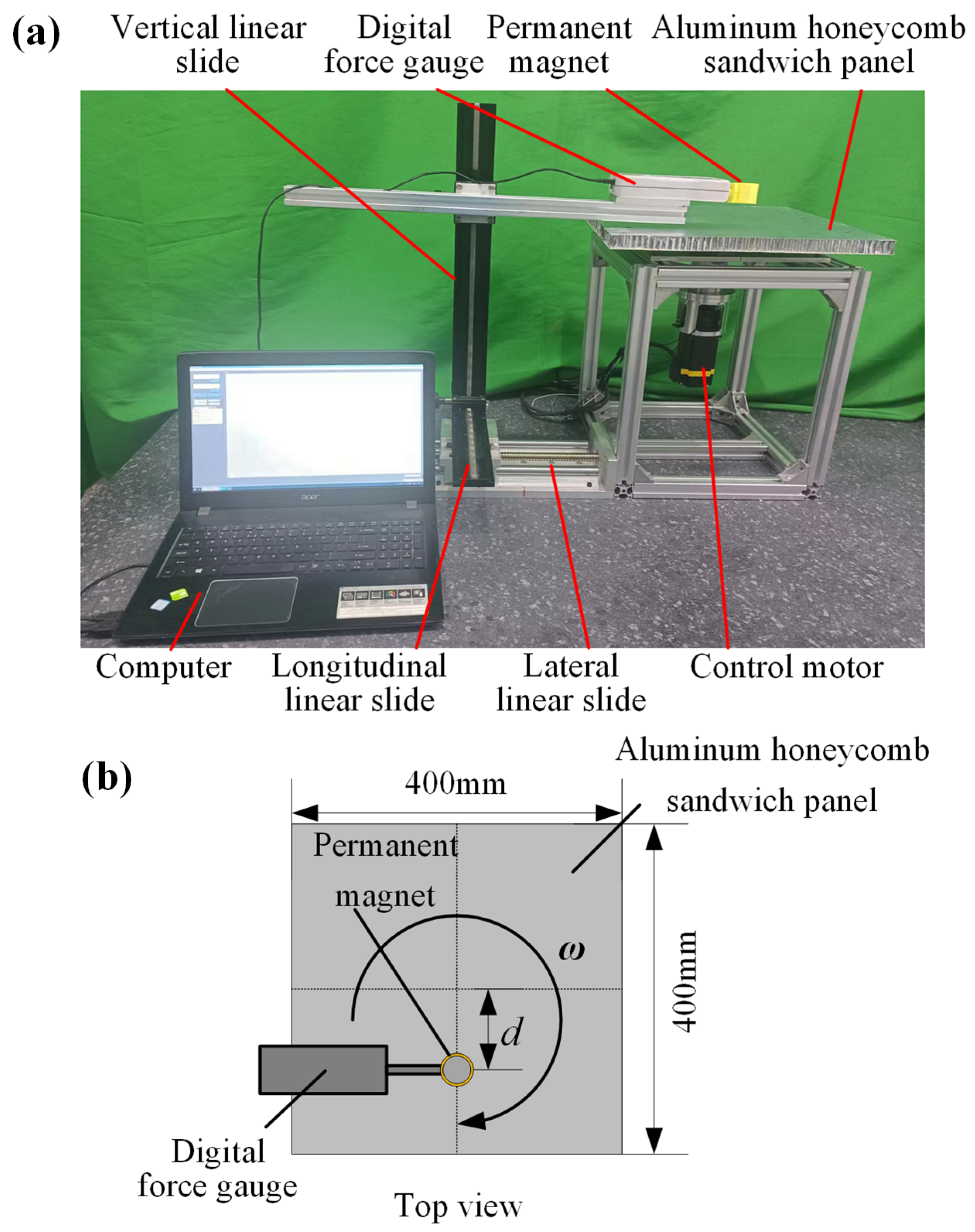

5.1. Experiment Up

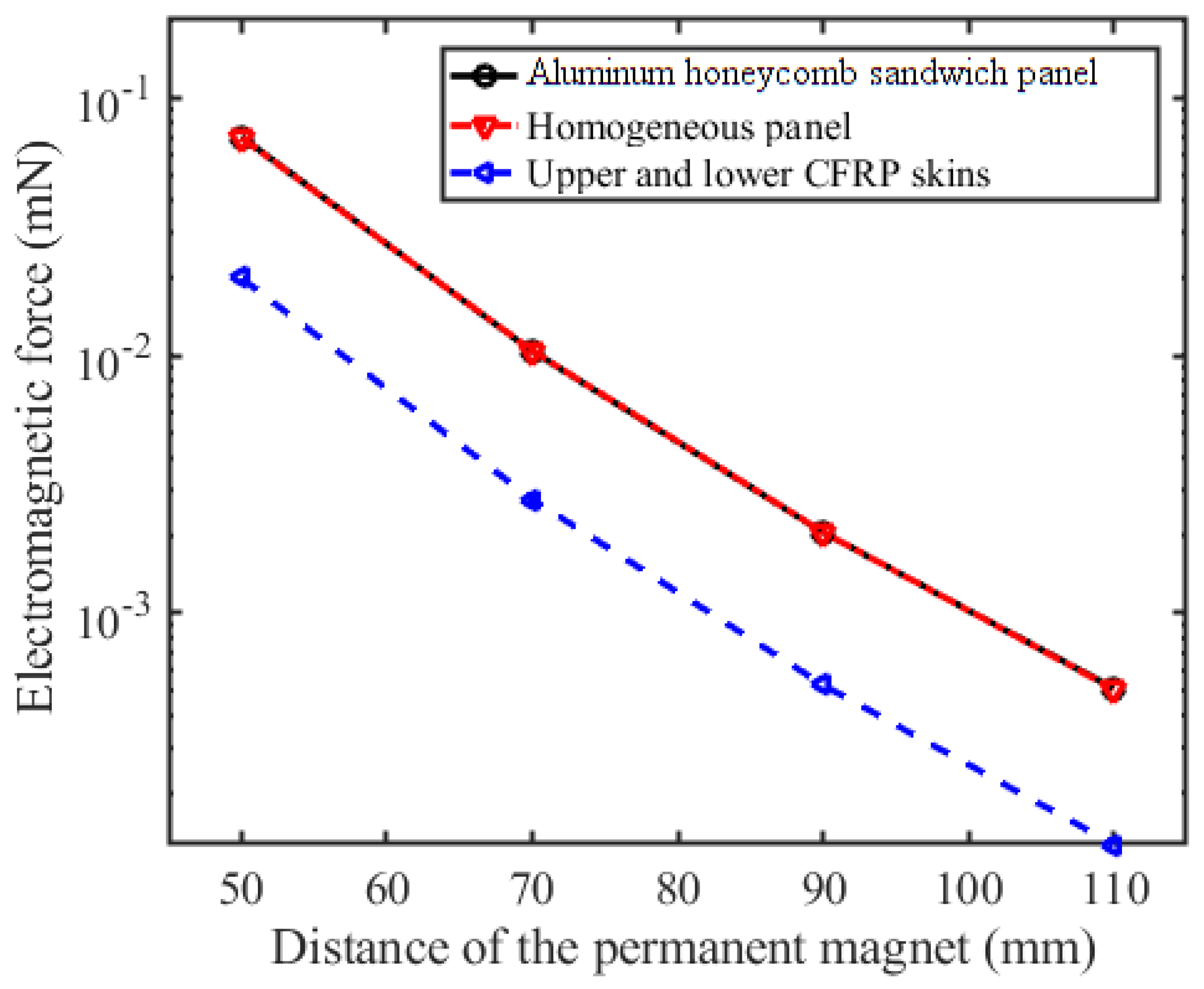

5.2. Experiment Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Mark, P.C.; Kamath, S. Review of active space debris removal methods. Space Policy 2019, 47, 194–206. [Google Scholar] [CrossRef]

- Ledkov, A.; Aslanov, V. Review of contact and contactless active space debris removal approaches. Prog. Aerosp. Sci. 2022, 134, 100858. [Google Scholar] [CrossRef]

- Du, L.; Chen, Z.; Hu, H.; Zhao, J.; Liu, X.; Zhang, Q.; Zhang, K. Contactless de-tumbling of the uncooperative targets using arc-linear electromagnetic device. Adv. Space Res. 2023, 71, 3290–3300. [Google Scholar] [CrossRef]

- Augai, F.; Abiko, S.; Tsujita, T.; Jiang, X.; Uchiyama, M. Detumbling an uncontrolled satellite with contactless force by using an eddy current brake. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 783–788. [Google Scholar]

- Li, M.; Zhang, Y.; Zhang, J.; Lin, H.; Yang, F. Detumbling Method for Uncontrolled Satellite Based on Eddy Currents. J. Guid. Control Dyn. 2020, 43, 142–149. [Google Scholar] [CrossRef]

- Gómez, N.O.; Walker, S.J. Earth’s gravity gradient and eddy currents effects on the rotational dynamics of space debris objects: Envisat case study. Adv. Space Res. 2015, 56, 494–508. [Google Scholar] [CrossRef]

- Yu, Y.F.; Yue, H.H.; Yang, F.; Zhao, H.H.; Lu, Y.F. Electromagnetic interaction between a slowly rotating conducting shell and magnetic dipoles: A theoretical and numerical study. IEEE Trans. Magn. 2021, 57, 1–11. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, Q.; Hou, L.Q.; Wu, S.F. Non-propellant eddy current brake and traction in space using magnetic pulses. Aerospace 2021, 8, 24. [Google Scholar] [CrossRef]

- Liu, X.G.; Lu, Y.; Zhou, Y.; Yin, Y.H. Prospects of using a permanent magnetic end effector to despin and detumble an uncooperative target. Adv. Space Res. 2018, 61, 2147–2158. [Google Scholar] [CrossRef]

- Pham, L.N.; Tabor, G.F.; Pourkand, A.; Aman, J.L.; Hermans, T. Dexterous magnetic manipulation of conductive non-magnetic objects. Nature 2021, 598, 439–443. [Google Scholar] [CrossRef] [PubMed]

- Cognion, R. Rotation rates of inactive satellites near geosynchronous earth orbit. In Proceedings of the Advanced Maui Optical and Space Surveillance Technologies Conference, Maui, HI, USA, 9–12 September 2014. [Google Scholar]

- Ryan, W.H.; Ryan, E.V. Photometric studies of rapidly spinning decommissioned geo satellites. In Proceedings of the Advanced Maui Optical and Space Surveillance Technologies Conference, Maui, HI, USA, 15–18 September 2014. [Google Scholar]

- Choi, J.; Jo, J.H.; Kim, M.J.; Roh, D.G.; Park, S.Y. Determining the rotation periods of an inactive leo satellite and the first korean space debris on geo, koreasat 1. J. Astron. Space Sci. 2016, 33, 127–135. [Google Scholar] [CrossRef]

- Šilha, J.; Pittet, J.N.; Hamara, M.; Schildknecht, T. Apparent rotation properties of space debris extracted from photometric measurements. Adv. Space Res. 2018, 61, 844–861. [Google Scholar] [CrossRef]

- Yanagisawa, T.; Kurosaki, H. Shape and motion estimate of leo debris using light curves. Adv. Space Res. 2012, 50, 136–145. [Google Scholar] [CrossRef]

- Smith, G.L. Effects of Magnetically Induced Eddy Current Torques on Spin Motions of an Earth Satellite; Tech. Rep. NASA TN D-2198; NASA Langley Research Center: Hampton, VA, USA, 1965. [Google Scholar]

- Ormsby, J.F. Eddy Current Torques and Motion Decay on Rotating Shells; Tech. Rep. ESD-TR-67-94; MITRE CORP: Bedford, MA, USA, 1967. [Google Scholar]

- Nurge, M.A.; Youngquist, R.C.; Caracciolo, R.A.; Peck, M.; Leve, F.A. A slowly rotating hollow sphere in a magnetic field: First steps to de-spin a space object. Am. J. Phys. 2016, 84, 181–191. [Google Scholar]

- Youngquist, R.C.; Nurge, M.A.; Starr, S.O.; Leve, F.A.; Peck, M. A thick-walled sphere rotating in a uniform magnetic field: The next step to de-spin a space object. Am. J. Phys. 2017, 85, 596–610. [Google Scholar]

- Praly, N.; Hillion, M.; Bonnal, C.; Laurent-Varin, J.; Petit, N. Study on the eddy current damping of the spin dynamics of space debris from the Ariane launcher upper stages. Acta Astronaut. 2012, 74, 145–153. [Google Scholar] [CrossRef]

- Liu, X.G.; Lu, Y.; Zhang, Q.; Zhang, K.M. An application of eddy current effect on the active detumble of uncontrolled satellite with tilt air gap. IEEE Trans. Magn. 2019, 55, 1–11. [Google Scholar] [CrossRef]

- Murayama, Y. Mesoscopic Systems: Fundamentals and Applications; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar]

- Della, R.; Devin, J. A graphical interpretation of the electrical conductivity tensor. J. Atmos. Sol.-Terr. 2005, 67, 337–343. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Length of aluminum honeycomb sandwich panel, L | 100 mm |

| Width of aluminum honeycomb sandwich panel, B | 100 mm |

| Height of aluminum honeycomb sandwich panel, H | 20 mm |

| Skin thickness, | 0.6 mm |

| Foil thickness, | 0.06 mm |

| Cell length, l | 3 mm |

| Diameter of permanent magnet, | 20 mm |

| Height of permanent magnet, | 20 mm |

| Remanence of magnet, | 1.45 T |

| Relative moving speed, v | 1 m/s |

| Relative permeability of aluminum and air | 1 |

| Parameter | Value |

|---|---|

| Length of aluminum honeycomb sandwich panel, L | 400 mm |

| Width of aluminum honeycomb sandwich panel, B | 400 mm |

| Height of aluminum honeycomb sandwich panel, H | 21 mm |

| Skin thickness, | 0.3 mm |

| Foil thickness, | 0.03 mm |

| Cell length, l | 5 mm |

| Conductivity of the skins (LY12) | 1.9 × 10 S/m |

| Conductivity of the foil (LF2Y) | 2.06 × 10 S/m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Yue, H.; Wen, F.; Zhao, H.; Zhou, A. Electromagnetic Force on an Aluminum Honeycomb Sandwich Panel Moving in a Magnetic Field. Sensors 2023, 23, 8577. https://doi.org/10.3390/s23208577

Yu Y, Yue H, Wen F, Zhao H, Zhou A. Electromagnetic Force on an Aluminum Honeycomb Sandwich Panel Moving in a Magnetic Field. Sensors. 2023; 23(20):8577. https://doi.org/10.3390/s23208577

Chicago/Turabian StyleYu, Yunfeng, Honghao Yue, Feiyang Wen, Haihong Zhao, and Aiyu Zhou. 2023. "Electromagnetic Force on an Aluminum Honeycomb Sandwich Panel Moving in a Magnetic Field" Sensors 23, no. 20: 8577. https://doi.org/10.3390/s23208577