Artificial Intelligence Methods for the Construction and Management of Buildings

Abstract

:1. Introduction

2. Methodology

3. History of Creation and Management of Smart Objects Using Artificial Intelligence

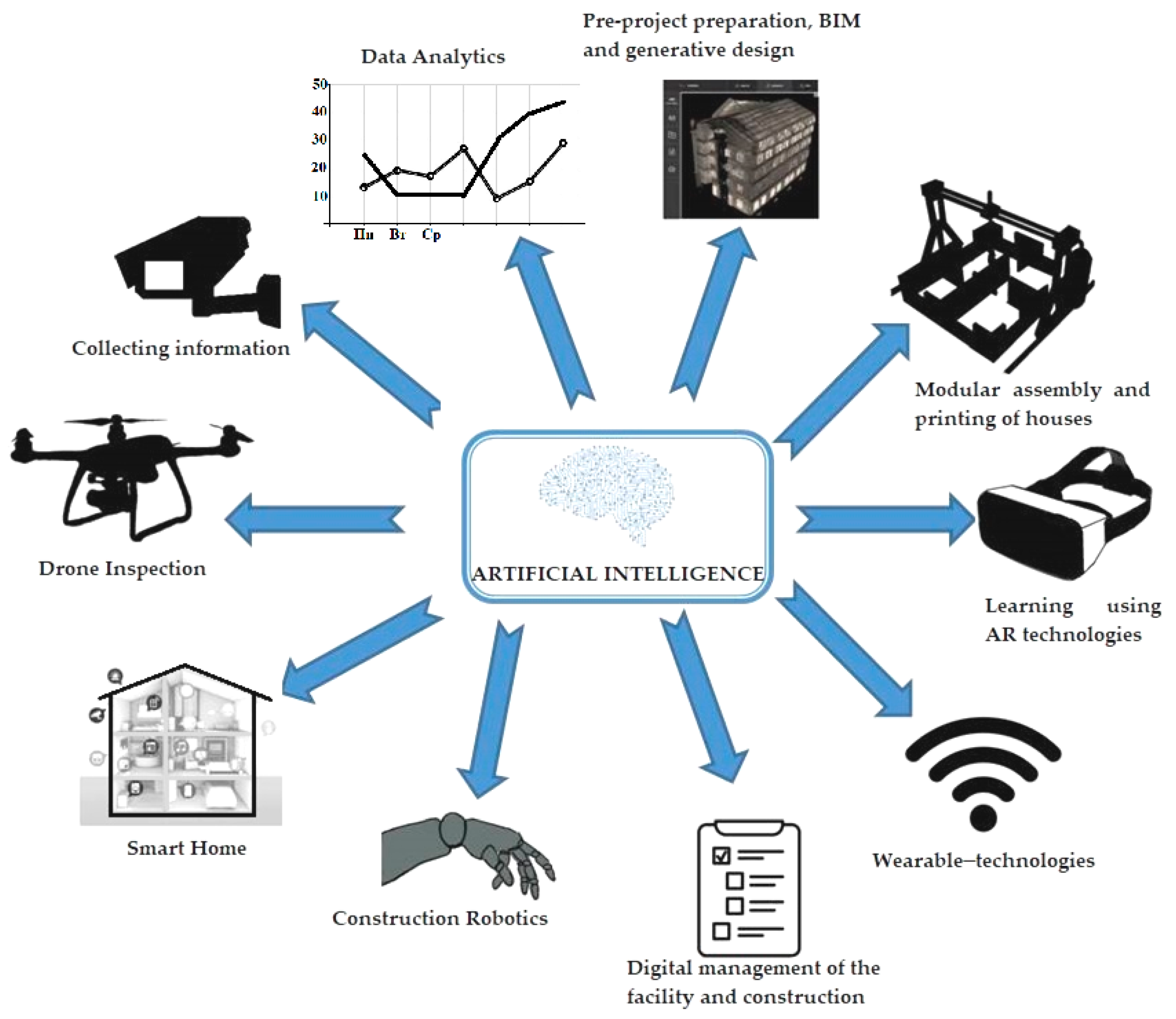

4. The Role of AI in the Building and Management of Smart Objects

5. The Relevance of the Use of AI in the Building Sector

- Software tools that manage design and construction;

- Software and hardware complexes for delivering information from project to object (BIM-to-field); this group includes tools that through users’ mobile devices deliver information about products and processes directly to workplaces in the field;

- Robotic applications for performing construction work on the site;

- Software and hardware complexes for collecting information from an object and providing it to control functions (field-to-BIM).

6. AI to Ensure the Safety of Construction

7. Application of AI for Cost Estimation Contracts and Management of Applications, Tenders and Conflicts

8. AI at the Design Stage

9. AI in Construction Logistics

10. AI in the Process of Building Construction

11. Advantages and Disadvantages of AI in Construction

- -

- The analysis and identification of the necessary stock of material values and the turnover of inventory [214] determine the profitability of the construction business;

- -

- The automation and aggregation of document flow, improvement of logistics management by reducing the number of dealers and direct access to resource suppliers [219];

- -

- Forecasting the demand for material resources and the formation of a supply schedule [220].

12. Prospects and Limitations of AI Use in Construction

- -

- Algorithms require sufficiently large amounts of data for accurate training (training the system to detect a worker without a helmet required machine learning based on millions of different images of a worker in a helmet), and insufficient data volume excludes the possibility of conducting such training [221];

- -

- The need to integrate all possible sources of information and provide conditions (a single platform) for storing, accessing and processing the collected data [221];

- -

- Most construction organizations do not have enough data to train their algorithms [222];

- -

- The high level of requirements of data processing specialists can be met only by large players in the construction business [223];

- -

- For the proper functioning of AI technologies, human service is necessary (each event or decision depends on several external factors leading to various consequences) [221].

13. Consequences of the Use of Artificial Intelligence in Politics

14. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choi, S.D.; Guo, L.; Kim, J.; Xiong, S. Comparison of fatal occupational injuries in construction industry in the United States, South Korea, and China. Int. J. Ind. Ergon. 2019, 71, 64–74. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2021, 122, 103517. [Google Scholar] [CrossRef]

- Zeng, L.; Li, R.Y.M. Construction safety and health hazard awareness in Web of Science and Weibo between 1991 and 2021. Saf. Sci. 2022, 152, 105790. [Google Scholar] [CrossRef]

- Abioye, S.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.D.; Bilal, M.; Olugbenga, O.A.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Chien, C.F.; Dauzère-Pérès, S.; Huh, W.T.; Jang, Y.J.; Morrison, J.R. Artificial intelligence in manufacturing and logistics systems: Algorithms, applications, and case studies. Int. J. Prod. Res. 2020, 58, 2730–2731. [Google Scholar] [CrossRef]

- Chui, M.; McKinsey, S.F. Global Institute Study, Artificial Intelligence, The Next Digital Frontier; McKinsey and Company: New York, NY, USA, 2017; p. 80. [Google Scholar]

- Young, D.; Panthi, K.; Noor, O. Challenges involved in adopting BIM on the construction jobsite. EPiC Ser. Built Environ. 2021, 2, 302–310. [Google Scholar]

- Delgado, J.M.D.; Oyedele, L. Digital Twins for the built environment: Learning from conceptual and process models in manufacturing. Adv. Eng. Inf. 2021, 49, 101332. [Google Scholar] [CrossRef]

- Bello, S.A.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Delgado, J.M.D.; Akanbi, L.A.; Ajayi, A.O.; Owolabi, H.A. Cloud computing in construction industry: Use cases, benefits and challenges. Autom. Construct. 2021, 122, 103441. [Google Scholar] [CrossRef]

- Delgado, J.M.D.; Oyedele, L. Deep learning with small datasets: Using autoencoders to address limited datasets in construction management. Appl. Soft Comput. 2021, 112, 107836. [Google Scholar] [CrossRef]

- Gbadamosi, A.; Mahamadu, A.; Manu, P.; Akinade, O.; Sierra, F.; Lam, T.T.; Alzaatreh, A. A BIM based approach for optimization of construction and assembly through material selection. In Proceedings of the Creative Construction, Ljubljana, Slovenia, 30 June–3 July 2018; pp. 955–962. [Google Scholar] [CrossRef]

- Gbadamosi, A.-Q.; Mahamadu, A.-M.; Oyedele, L.O.; Akinade, O.O.; Manu, P.; Mahdjoubi, L.; Aigbavboa, C. Offsite construction: Developing a BIM-Based optimizer for assembly. J. Clean. Prod. 2019, 215, 1180–1190. [Google Scholar] [CrossRef]

- Zaher, M.; Greenwood, D.; Marzouk, M. Mobile augmented reality applications for construction projects. Construct. Innov. 2018, 18, 152–166. [Google Scholar] [CrossRef]

- Mrosla, L.; Koch, V.; Both, P.V. Quo vadis AI in Architecture? Survey of the current possibilities of AI in the architectural practice. Des. Artif. Intell. 2019, 2, 45–54. [Google Scholar] [CrossRef]

- Steenson, M.W. Architectural Intelligence: How Designers, and Architects Created the Digital Landscape; The MIT Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Poh, C.; Ubeynarayana, C.U.; Goh, Y.M. Safety leading indicators for construction sites: A machine learning approach. Autom. Constr. 2018, 93, 375–386. [Google Scholar] [CrossRef]

- Palacios, A.T.; Cordero, J.M.E.B.; Bello, M.R.; Palacios, E.T.; Martínez González, J.L. New applications of 3D SLAM on risk management using unmanned aerial vehicles in the construction industry. In Drones-Applications; Dekoulis, G., Ed.; IntechOpen: London, UK, 2018; Available online: https://www.intechopen.com/chapters/58901 (accessed on 25 July 2023).

- Wei, C.; Li, Y. Design of energy consumption monitoring and energy-saving management system of intelligent building based on the Internet of things. In Proceedings of the International Conference on Electronics, Communications and Control (ICECC), Ningbo, China, 9–11 September 2011; pp. 3650–3652. [Google Scholar] [CrossRef]

- Lanko, A.; Vatin, N.; Kaklauskas, A. Application of RFID combined with blockchain technology in logistics of construction materials. In Proceedings of the Business Technologies for Sustainable Urban Development (MATEC), Saint Petersburg, Russia, 20–22 December 2017. [Google Scholar] [CrossRef]

- Chen, H.-P.; Ying, K.-C. Artificial Intelligence in the Construction Industry: Main Development Trajectories and Future Outlook. Appl. Sci. 2022, 12, 5832. [Google Scholar] [CrossRef]

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and Adoption Challenges of AI in the Construction Industry: A PRISMA Review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- Shukla, A.K.; Janmaijaya, M.; Abraham, A.; Muhuri, P.K. Engineering applications of artificial intelligence: A bibliometric analysis of 30 years (1988–2018). Eng. Appl. Artif. Intell. 2019, 85, 517–532. [Google Scholar] [CrossRef]

- Gorodnova, N.V. Application of Artificial Intelligence and Nanotechnology in the Investment and Construction Sector in Russia. Vestnik NSUEM 2021, 3, 81–95. [Google Scholar] [CrossRef]

- Xin, X.; Tu, Y.; Stojanovic, V.; Wang, H.; Shi, K.; He, S.; Pan, T. Online reinforcement learning multiplayer non-zero sum games of continuous-time Markov jump linear systems. Appl. Math. Comput. 2022, 412, 126537. [Google Scholar] [CrossRef]

- The Future of AI: Construction-Grade Artificial Intelligence. Available online: https://onekeyresources.milwaukeetool.com/en/ai-in-construction (accessed on 27 June 2023).

- Horst, D.J.; de Andrade Júnior, P.P. Sustainability of the Steel Industry: A Systematic Review. Biointerface Res. Appl. Chem. 2023, 13, 525. [Google Scholar] [CrossRef]

- Erdélyi, D.; Kern, Z.; Nyitrai, T.; Hatvani, I.G. Predicting the spatial distribution of stable isotopes in precipitation using a machine learning approach: A comparative assessment of random forest variants. GEM 2023, 14, 14. [Google Scholar] [CrossRef]

- Frehywot, S.; Vovides, Y. An equitable and sustainable community of practice framework to address the use of artificial intelligence for global health workforce training. Hum. Resour. Health 2023, 21, 45. [Google Scholar] [CrossRef]

- Baghdadi, A.; Lama, S.; Singh, R.; Sutherland, G.R. Tool-tissue force segmentation and pattern recognition for evaluating neurosurgical performance. Sci. Rep. 2023, 13, 9591. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Han, C.; Yu, Z. An environment safety monitoring system for agricultural production based on artificial intelligence, cloud computing and big data networks. J. Cloud Comput. 2023, 12, 83. [Google Scholar] [CrossRef]

- Cheng, Q.; Chunhong, Z.; Qianglin, L. Development and application of random forest regression soft sensor model for treating domestic wastewater in a sequencing batch reacto. Sci. Rep. 2023, 13, 9149. [Google Scholar] [CrossRef]

- Marwaha, J.S.; Raza, M.M.; Kvedar, J.C. The digital transformation of surgery. Digit. Med. 2023, 6, 103. [Google Scholar] [CrossRef]

- Burgueño, A.M.; Aldana-Martín, J.F.; Vázquez-Pendón, M.; Barba-González, C.; Jiménez Gómez, Y.; García Millán, V.; Navas-Delgado, I. Scalable approach for high-resolution land cover: A case study in the Mediterranean Basin. J. Big Data 2023, 10, 91. [Google Scholar] [CrossRef]

- Babović, Z.; Bajat, B.; Barac, D.; Bengin, V.; Đokić, V.; Đorđević, F.; Drašković, D.; Filipović, N.; French, S.; Furht, B.; et al. Teaching computing for complex problems in civil engineering and geosciences using big data and machine learning: Synergizing four different computing paradigms and four different management domains. J. Big Data 2023, 10, 89. [Google Scholar] [CrossRef]

- Guinot, L.; Ando, K.; Takahashi, S.; Iwata, H. Analysis of implicit robot control methods for joint task execution. ROBOMECH J. 2023, 10, 12. [Google Scholar] [CrossRef]

- Lew, A.J.; Jin, K.; Buehler, M.J. Designing architected materials for mechanical compression via simulation, deep learning, and experimentation. Comput. Mater. 2023, 9, 80. [Google Scholar] [CrossRef]

- Sidlauskiene, J.; Joye, Y.; Auruskeviciene, V. AI-based chatbots in conversational commerce and their effects on product and price perceptions. Electron. Mark. 2023, 33, 24. [Google Scholar] [CrossRef] [PubMed]

- Prosekov, A.; Rada, A.; Kuznetsov, A.; Osintseva, M.; Petrik, N. Features of using unmanned aircraft as an element of digitalization of industry in the Siberian federal district of Russia. AIP Conf. Proc. 2022, 2632, 020037. [Google Scholar] [CrossRef]

- Hsu, H.-C. A study on computer vision for facial emotion recognition. Sci. Rep. 2023, 13, 8425. [Google Scholar] [CrossRef]

- Zayed, S.M.; Attiya, G.; El-Sayed, A.; Sayed, A.; Hemdan, E.E.-D. An Efficient Fault Diagnosis Framework for Digital Twins Using Optimized Machine Learning Models in Smart Industrial Control Systems. Int. J. Comput. Intell. Syst. 2023, 16, 69. [Google Scholar] [CrossRef]

- Rada, A.O.; Kuznetsov, A.D. Digital inventory of agricultural land plots in the Kemerovo Region. Foods Raw Mater. 2022, 10, 206–215. [Google Scholar] [CrossRef]

- Obianyo, J.I.; Udeala, R.C.; Alaneme, G.U. Application of neural networks and neuro-fuzzy models in construction scheduling. Sci. Rep. 2023, 13, 8199. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Liu, X.; Zhao, C.; Chen, G.-Q. Applications of synthetic biology in medical and pharmaceutical fields. Signal Transduct. Target. Ther. 2023, 8, 199. [Google Scholar] [CrossRef] [PubMed]

- Bačiulienė, V.; Bilan, Y.; Navickas, V.; Lubomír, C. The Aspects of Artificial Intelligence in Different Phases of the Food Value and Supply Chain. Foods 2023, 12, 1654. [Google Scholar] [CrossRef]

- Sicard, J.; Barbe, S.; Boutrou, R.; Bouvier, L.; Delaplace, G.; Lashermes, G.; Théron, L.; Vitrac, O.; Tonda, A. A primer on predictive techniques for food and bioresources transformation processes. J. Food Process Eng. 2023, 46, e14325. [Google Scholar] [CrossRef]

- Kryukov, K.M.; Metlev, A.M. Possibilities of using artificial intelligence in construction Engineering. Bull. Don. 2022, 10, 1–10. (In Russian) [Google Scholar]

- Warszawski, A.; Sangrey, D.A. Robotics in building construction. J. Constr. Eng. Manag. 1985, 111, 260–280. [Google Scholar] [CrossRef]

- Warszawski, A. Robots in the construction industry. Robotica 1986, 4, 181–188. [Google Scholar] [CrossRef]

- Adachi, R.; Mogi, S.; Tsuji, H.; Nakano, T.; Shiozaki, H.; Ohtani, H.; Ohba, K.; Shinohara, H.; Matsui, H.; Jitsukawa, T.; et al. Application of intelligent robot arc-welding system to large-sized steel construction. Hitachi Zosen Tech. Rev. 1985, 46, 32–39. [Google Scholar]

- Hirokazu, K.S.; Nakada, T.; Akagi, F. Method of optimal work assignment for robot’s hand used in construction. Nippon. Kikai Gakkai Ronbunshu C Hen/Trans. Jpn. Soc. Mech. Eng. Part. C 1983, 49, 243–249. [Google Scholar] [CrossRef]

- Paulson, B.C. Automation and robotics for construction. J. Constr. Eng. Manag. 1985, 111, 190–207. [Google Scholar] [CrossRef]

- Levitt, R.E.; Kartam, N.A.; Kunz, J.C. Artificial intelligence techniques for generating construction project plans. J. Constr. Eng. Manag. 1988, 114, 329–343. [Google Scholar] [CrossRef]

- McGartland, M.R.; Hendrickson, C.T. Expert systems for construction project monitoring. J. Constr. Eng. Manag. 1985, 111, 293–307. [Google Scholar] [CrossRef]

- Furuta, H.; Tu, K.-S.; Yao, J.T.P. Structural engineering applications of expert systems. Comput. Aided Des. 1985, 17, 410–419. [Google Scholar] [CrossRef]

- Ashley, D.B.; Levitt, R.E. Expert systems in construction: Work in progress. J. Comput. Civ. Eng. 1987, 1, 303–311. [Google Scholar] [CrossRef]

- Williams, T.P.; Kangari, R. Knowledge-based system for planning a construction operation. Microcomput. Civ. Eng. 1988, 3, 345–353. [Google Scholar] [CrossRef]

- Saleh, M.A.E. Automation of quantity surveying in construction projects. J. Archit. Eng. 1999, 5, 141–148. [Google Scholar] [CrossRef]

- Scdano, B.G.; Cerrolaza, M.; Alarcon, E. QL-CONST1: An expert system for quality level prediction in concrete structures. Civ. Eng. Syst. 1988, 5, 206–212. [Google Scholar] [CrossRef]

- Hirayama, Y. Automatic design system for custom-made houses. Fujitsu Sci. Tech. J. 1981, 17, 27–45. [Google Scholar]

- Althoff, K.-D.; Kratz, N.; Richter, M.M.; Spieker, P. Planning systems and artificial intelligence. Ann. Oper. Res. 1988, 16, 1–12. [Google Scholar] [CrossRef]

- Bowen, P.A.; Edwards, P.J. Uncertainty and incomplete information in the evaluation of building projects. Invest. Anal. J. 1985, 14, 11–21. [Google Scholar] [CrossRef]

- Hendrickson, C.; Zozaya-Gorostiza, C.; Rehak, D.; Baracco-Miller, E.; Lim, P. Expert system for construction planning. J. Comput. Civ. Eng. 1987, 1, 253–269. [Google Scholar] [CrossRef]

- Vladimirova, I.L.; Bareshenkova, K.A. Digital engineering in the field procurement in the implementation of investment and construction projects. Econ. Entrep. Law 2020, 10, 377–394. (In Russian) [Google Scholar] [CrossRef]

- Mamadjanov, A.M.; Yusupov, S.M.; Sadirov, S. Advantages and the Future of CNC Machines. Sci. Prog. 2021, 2, 1638–1647. [Google Scholar]

- How Does Artificial Intelligence Impact the Construction Industry? Available online: https://requestum.com/blog/artificial-intelligence-in-construction-industry (accessed on 2 July 2023).

- Artificial Intelligence in the Construction Industry. Available online: https://thinkml.ai/artificial-intelligence-in-the-construction-industry (accessed on 10 July 2023).

- Ghosh, T.; Martinsen, K. Generalized approach for multi-response machining process optimization using machine learning and evolutionary algorithms. Eng. Sci. Technol. 2020, 23, 650–663. [Google Scholar] [CrossRef]

- Reinventing Construction through a Productivity Revolution. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/reinventing-construction-through-a-productivity-revolution (accessed on 10 July 2023).

- Wan, S.; Li, D.; Gao, J.; Roy, R.; He, F. A collaborative machine tool maintenance planning system based on content management technologies. Int. J. Adv. Manuf. Technol. 2018, 94, 1639–1653. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Kumar, A.; Kumar, V.; Garza-Reyes, J.A.A. Machine learning applications for sustainable manufacturing: A bibliometric-based review for future research. J. Enterp. Inf. Manag. 2022, 35, 566–596. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Y.; Kumar, M.; Qin, J.; Ren, Y. Energy consumption modelling using deep learning embedded semi-supervised learning. Comput. Ind. Eng. 2019, 135, 757–765. [Google Scholar] [CrossRef]

- Nasir, V.; Sassani, F. A review on deep learning in machining and tool monitoring: Methods, opportunities, and challenges. Int. J. Adv. Manuf. Technol. 2021, 115, 2683–2709. [Google Scholar] [CrossRef]

- Moore, J.; Stammers, J.; Dominguez-Caballero, J. The application of machine learning to sensor signals for machine tool and process health assessment. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2021, 235, 1543–1557. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Xu, N. Digital Twin for Sustainability Evaluation of Railway Station Buildings. Front. Built Environ. 2018, 4, 77. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Huang, J.; Zhu, Y.; Ngamkhanong, C.; Remennikov, A.M. Machine Learning Based Design of Railway Prestressed Concrete Sleepers. Appl. Sci. 2022, 12, 10311. [Google Scholar] [CrossRef]

- Sresakoolchai, J.; Kaewunruen, S. Integration of building information modeling (BIM) and artificial intelligence (AI) to detect combined defects of infrastructure in the railway system. In Resilient Infrastructure. Lecture Notes in Civil Engineering; Kolathayar, S., Ghosh, C., Adhikari, B.R., Pal, I., Mondal, A., Eds.; Springer Nature: Singapore, 2021; Volume 202, pp. 377–386. [Google Scholar] [CrossRef]

- Alkaissy, M.; Arashpour, M.; Golafshani, E.M.; Hosseini, M.R.; Khanmohammadi, S.; Bai, Y.; Feng, H. Enhancing construction safety: Machine learning-based classification of injury types. Saf. Sci. 2023, 162, 106102. [Google Scholar] [CrossRef]

- Anwer, S.; Li, H.; Umer, W.; Antwi-Afari, M.F.; Mehmood, I.; Yu, Y.; Haas, C.; Wong, A. Yu Lok Identification and Classification of Physical Fatigue in Construction Workers Using Linear and Nonlinear Heart Rate Variability Measurements. J. Constr. Eng. Manag. 2023, 149, 04023057. [Google Scholar] [CrossRef]

- Luo, X.; Li, X.; Goh, Y.M.; Song, X.; Liu, Q. Application of machine learning technology for occupational accident severity prediction in the case of construction collapse accidents. Saf. Sci. 2023, 163, 106138. [Google Scholar] [CrossRef]

- Chern, W.-C.; Hyeon, J.; Nguyen, T.V.; Asari, V.K.; Kim, H. Context-aware safety assessment system for far-field monitoring. Autom. Constr. 2023, 149, 104779. [Google Scholar] [CrossRef]

- Chen, W.; Li, C.; Guo, H. A lightweight face-assisted object detection model for welding helmet use. Expert. Syst. Appl. 2023, 2211, 119764. [Google Scholar] [CrossRef]

- Dadashi Haji, M.; Behnam, B.; Sebt, M.H.; Ardeshir, A.; Katooziani, A. BIM-Based Safety Leading Indicators Measurement Tool for Construction Sites. Int. J. Civ. Eng. 2023, 21, 265–282. [Google Scholar] [CrossRef]

- Ramadan, A.S.; Elgendi, E.O. A review of optimization techniques and algorithms used for FRP applications in civil engineering. J. Eng. Appl. Sci. 2023, 70, 61. [Google Scholar] [CrossRef]

- Wang, Y.; Dai, F.; Jia, R.; Wang, R.; Sharifi, H.; Wang, Z. A novel combined intelligent algorithm prediction model for the tunnel surface settlement. Sci. Rep. 2023, 13, 9845. [Google Scholar] [CrossRef]

- Sánchez-Garrido, A.J.; Navarro, I.J.; García, J.; Yepes, V. A systematic literature review on modern methods of construction in building: An integrated approach using machine learning. J. Build. Eng. 2023, 7315, 106725. [Google Scholar] [CrossRef]

- Wu, X.; Lu, G.; Wu, Z. Remote sensing technology in the construction of digital twin basins: Applications and prospects. Water 2023, 15, 2040. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Q.; Liang, H. System simulation of land use spatial planning method and environment management strategy analysis by using machine vision. Soft Comput. 2023, 27, 5985–5994. [Google Scholar] [CrossRef]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Autom. Constr. 2022, 2022, 104440. [Google Scholar] [CrossRef]

- Sayed, Y.A.K.; Ibrahim, A.A.; Tamrazyan, A.G.; Fahmy, M.F.M. Machine-learning-based models versus design-oriented models for predicting the axial compressive load of FRP-confined rectangular RC columns. Eng. Struct. 2023, 28515, 116030. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, J.; Shou, W.; Hosseini, M.R.; Bai, Y. Graph neural networks for construction. Autom. Constr. 2023, 154, 104984. [Google Scholar] [CrossRef]

- Wang, D.; Chang, F. Application of machine learning-based BIM in green public building design. Soft Comput. 2023, 13, 9031–9040. [Google Scholar] [CrossRef]

- Mowafy, N.; El Zayat, M.; Marzouk, M. Parametric BIM-based life cycle assessment framework for optimal sustainable design. J. Build. Eng. 2023, 7515, 106898. [Google Scholar] [CrossRef]

- Al-Musawi, R.; Naimi, S. Evaluation of Construction Project’s Cost Using BIM Technology. Math. Model. Eng. Probl. 2023, 10, 469–476. [Google Scholar] [CrossRef]

- Vakaj, E.; Cheung, F.; Cao, J.; Tawil, A.-R.H.; Patlakas, P. An ontology-based cost estimation for offsite construction. J. Inf. Technol. Constr. 2023, 28, 220–245. [Google Scholar] [CrossRef]

- Simić, N.; Ivanišević, N.; Nedeljković, Ð.; Senić, A.; Stojadinović, Z.; Ivanović, M. Early Highway Construction Cost Estimation: Selection of Key Cost Drivers. Sustainability 2023, 15, 5584. [Google Scholar] [CrossRef]

- Maaouane, M.; Chennaif, M.; Zouggar, S.; Krajačić, G.; Amrani, S.; Zahboune, H. Cost-effective design of energy efficiency measures in the building sector in North Africa using Building Information Modeling. EnergyBuild 2023, 2941, 113283. [Google Scholar] [CrossRef]

- Ranjbar, N.; Balali, A.; Valipour, A.; Pignatta, G.; Wei, S. Identification and prioritization of energy consumption optimization strategies in the building industry using the hybrid swara-bim model. J. Green Build. 2023, 18, 37–69. [Google Scholar] [CrossRef]

- Zhang, L.; Yao, H.; Fu, Y.; Chen, Y. Comparing subjective and objective measurements of contract complexity in influencing construction project performance: Survey versus machine learning. J. Manag. Eng. 2023, 39, 04023017. [Google Scholar] [CrossRef]

- Ottoni, A.L.; Novo, M.S.; Costa, D.B. Deep Learning for vision systems in Construction 4.0: A systematic review. Signal Image Video Process 2023, 17, 1821–1829. [Google Scholar] [CrossRef]

- Alsugair, A.M.; Alsanabani, N.M.; Al-Gahtani, K.S. Forecasting the Final Contract Cost on the Basis of the Owner’s Cost Estimation Using an Artificial Neural Network. Buildings 2023, 13, 786. [Google Scholar] [CrossRef]

- Qiu, Y.; Chen, H. A systematic review of the knowledge domain of institutional theory in construction project management. Eng. Constr. Archit. Manag. 2023, 30, 2523–2544. [Google Scholar] [CrossRef]

- Salahaldain, Z.; Naimi, S.; Alsultani, R. Estimation and Analysis of Building Costs Using Artificial Intelligence Support Vector Machine. Math. Model. Eng. Probl. 2023, 10, 405–411. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, Y.; Sekula, P.; Ding, L. Machine learning in construction: From shallow to deep learning. Dev. Built Environ. 2021, 6, 100045. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.; Zhang, Y. Exploring the risk propagation mechanisms of supply chain for prefabricated building projects. J. Build. Eng. 2023, 741, 106771. [Google Scholar] [CrossRef]

- Koc, K.; Ekmekcioğlu, Ö.; Işık, Z. Developing a probabilistic decision-making model for reinforced sustainable supplier selection. Int. J. Prod. Econ. 2023, 259, 108820. [Google Scholar] [CrossRef]

- Sadatnya, A.; Sadeghi, N.; Sabzekar, S.; Khanjani, M.; Tak, A.N.; Taghaddos, H. Machine learning for construction crew productivity prediction using daily work reports. Autom. Constr. 2023, 152, 104891. [Google Scholar] [CrossRef]

- Geng, S.; Luo, Q.; Liu, K.; Li, Y.; Hou, Y.; Long, W. Research status and prospect of machine learning in construction 3D printing. Case Stud. Constr. Mater. 2023, 18, e01952. [Google Scholar] [CrossRef]

- Ahila, P.R.; Arivazhagan, S.; Arun, M. Crack recognition on concrete structures based on machine crafted and hand crafted features. Expert. Syst. Appl. 2023, 228, 120447. [Google Scholar] [CrossRef]

- Alsakka, F.; El-Chami, I.; Yu, H.; Al-Hussein, M. Computer vision-based process time data acquisition for offsite construction. Autom. Constr. 2023, 149, 104803. [Google Scholar] [CrossRef]

- Zou, M.; Yu, J.; Lv, Y.; Lu, B.; Chi, W.; Sun, L. A Novel Day-to-Night Obstacle Detection Method for Excavators Based on Image Enhancement and Multisensor Fusion. IEEE Sens. J. 2023, 10, 10825–10835. [Google Scholar] [CrossRef]

- Abu Kharmeh, S.; Natsheh, E.; Sulaiman, B.; Abuabiah, M.; Tarapiah, S. Indoor WiFi-Beacon Dataset Construction Using Autonomous Low-Cost Robot for 3D Location Estimation. Appl. Sci. 2023, 13, 6768. [Google Scholar] [CrossRef]

- Oke, A.E.; Aliu, J.; Oluwasefunmi Fadamiro, P.; Akanni, P.O.; Stephen, S.S. Attaining digital transformation in construction: An appraisal of the awareness and usage of automation techniques. J. Build. Eng. 2023, 6715, 105968. [Google Scholar] [CrossRef]

- Wu, C.; Li, X.; Jiang, R.; Guo, Y.; Wang, J.; Yang, Z. Graph-based deep learning model for knowledge base completion in constraint management of construction projects. Comput. Aided Civ. Infrastruct. Eng. 2023, 38, 702–719. [Google Scholar] [CrossRef]

- Wen, H.; Liu, L.; Zhang, J.; Hu, J.; Huang, X. A hybrid machine learning model for landslide-oriented risk assessment of long-distance pipelines. J. Environ. Manag. 2023, 342, 118177. [Google Scholar] [CrossRef]

- Lin, P.; Wu, M.; Zhang, L. Probabilistic safety risk assessment in large-diameter tunnel construction using an interactive and explainable tree-based pipeline optimization method. Appl. Soft Comput. 2023, 143, 110376. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Antwi-Afari, M.F. Exploring the design risk factors for modular integrated construction projects. Constr. Innov. 2023, 23, 213–228. [Google Scholar] [CrossRef]

- Osorio-Sandoval, C.A.; Crick, G.; Collinge, W.H.; Farghaly, K.; Mosleh, M.H.; Manu, P.; Cheung, C.M. Dataset of characterized construction safety risks and related treatments. Data Brief 2023, 48, 109293. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Y.; Lin, J. BIM–based time-varying system reliability analysis for buildings and infrastructures. J. Build. Eng. 2023, 761, 106958. [Google Scholar] [CrossRef]

- Eastman, C. The use of computers instead of drawings in building design. Art 1975, 63, 46–50. [Google Scholar]

- Sacks, R.; Girolami, M.; Brilakis, I. Building information modelling, artificial intelligence and construction tech. Dev. Built Environ. 2020, 4, 100011. [Google Scholar] [CrossRef]

- Zhang, Y. Safety management of civil engineering construction based on artificial intelligence and machine vision technology. Adv. Civ. Eng. 2021, 2021, 3769634. [Google Scholar] [CrossRef]

- Construction Safety Statistics for 2022. Available online: https://www.bigrentz.com/blog/construction-safety-statistics (accessed on 30 May 2023).

- Safety+Health. Available online: www.safetyandhealthmagazine.com (accessed on 30 May 2023).

- Health and Safety Statistics. Available online: www.hse.gov.uk (accessed on 30 May 2023).

- Bigham, G.F.; Adamtey, S.; Onsarigo, L.; Jha, N. Artificial intelligence for construction safety: Mitigation of the risk of fall. In Intelligent Systems and Applications (IntelliSys 2018); Arai, K., Kapoor, S., Bhatia, R., Eds.; Springer International Publishing: Cham, Switzerland, 2019; Volume 2, pp. 1024–1037. [Google Scholar]

- Razi, P.Z.; Sulaiman, S.K.; Ali, M.I.; Ramli, N.I.; Saad, M.S.H.; Jamaludin, O.; Doh, S.I. How Artificial Intelligence Changed the Construction Industry in Safety Issues. IOP Conf. Ser. Earth Environ. Sci. 2023, 1140, 012004. [Google Scholar] [CrossRef]

- Ayhan, B.U.; Tokdemir, O.B. Safety assessment in megaprojects using artificial intelligence. Saf. Sci. 2019, 118, 273–287. [Google Scholar] [CrossRef]

- Gheraibia, Y.; Kabir, S.; Aslansefat, K.; Sorokos, I.; Papadopoulos, Y. Safety+ AI: A novel approach to update safety models using artificial intelligence. IEEE Access 2019, 7, 135855–135869. [Google Scholar] [CrossRef]

- Yeon-Chul, K.; Wi Seong, Y.; Yoonseok, S. Application of artificial neural networks to prediction of construction safety accidents. J. Korean Soc. Hazard. Mitig. 2017, 17, 7–14. [Google Scholar]

- Li, R.Y.M.; Leung, T.H. Computer vision and hybrid reality for construction safety risks: A pilot study. In Fourth International Congress on Information and Communication Technology (ICICT 2019); Springer Nature: Singapore, 2020; Volume 2, pp. 17–22. [Google Scholar]

- Choi, J.; Gu, B.; Chin, S.; Lee, J.S. Machine learning predictive model based on national data for fatal accidents of construction workers. Autom. Constr. 2020, 110, 102974. [Google Scholar] [CrossRef]

- Wu, J.; Cai, N.; Chen, W.; Wang, H.; Wang, G. Automatic detection of hardhats worn by construction personnel: A deep learning approach and benchmark dataset. Autom. Constr. 2019, 106, 102894. [Google Scholar] [CrossRef]

- Fang, W.; Zhong, B.; Zhao, N.; Love, P.E.; Luo, H.; Xue, J.; Xu, S. A deep learning-based approach for mitigating falls from height with computer vision: Convolutional neural network. Adv. Eng. Inform. 2019, 39, 170–177. [Google Scholar]

- Fang, W.; Ding, L.; Luo, H.; Love, P.E. Falls from heights: A computer vision-based approach for safety harness detection. Autom. Constr. 2018, 91, 53–61. [Google Scholar]

- Huang, X.; Wu, X.; Usmani, A. Perspectives of using artificial intelligence in building fire safety. In Handbook of Cognitive and Autonomous Systems for Fire Resilient Infrastructures; Springer International Publishing: Cham, Switzerland, 2022; pp. 139–159. [Google Scholar]

- Zhang, J.; Zi, L.; Hou, Y.; Wang, M.; Jiang, W.; Deng, D. A deep learning-based approach to enable action recognition for construction equipment. Adv. Civ. Eng. 2020, 2020, 8812928. [Google Scholar] [CrossRef]

- Zhu, C.; Zhu, J.; Bu, T.; Gao, X. Monitoring and Identification of Road Construction Safety Factors via UAV. Sensors 2022, 22, 8797. [Google Scholar] [CrossRef]

- 140Mohan, M.; Varghese, S. Artificial intelligence enabled safety for construction sites. Int. Res. J. Eng. Technol. 2019, 6, 1–6. [Google Scholar]

- Fang, W.; Love, P.E.; Luo, H.; Ding, L. Computer vision for behaviour-based safety in construction: A review and future directions. Adv. Eng. Inform. 2020, 43, 100980. [Google Scholar] [CrossRef]

- Guo, B.H.; Zou, Y.; Fang, Y.; Goh, Y.M.; Zou, P.X. Computer vision technologies for safety science and management in construction: A critical review and future research directions. Saf. Sci. 2021, 135, 105130. [Google Scholar] [CrossRef]

- Tay, J.; Shi, P.; He, Y.; Nath, T. Application of computer vision in the construction industry. In Proceedings of the 10th World Construction Symposium, Colombo, Sri Lanka, 24–26 June 2022; Sandanayake, Y.G., Gunatilake, S., Waidyasekara, K.G.A.S., Eds.; pp. 125–137. Available online: http://dl.lib.uom.lk/handle/123/19960 (accessed on 30 May 2023). [CrossRef]

- Anysz, H.; Foremny, A.; Kulejewski, J. Comparison of ANN classifier to the neuro-fuzzy system for collusion detection in the tender procedures of road construction sector. IOP Conf. Ser. Mater. Sci. Eng. 2020, 471, 112064. [Google Scholar] [CrossRef]

- Sarkar, D.; Dhaneshwar, D.; Raval, P. Automation in Monitoring of Construction Projects through BIM-IoT-Blockchain Model. J. Inst. Eng. (India) Ser. A 2023, 104, 317–333. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arc. Comput. Methods Eng. 2023, 30, 1081–1110. [Google Scholar] [CrossRef]

- Cocco, L.; Tonelli, R.; Marchesi, M. A System Proposal for Information Management in Building Sector Based on BIM, SSI, IoT and Blockchain. Future Internet 2022, 14, 140. [Google Scholar] [CrossRef]

- Ke, W. The construction of enterprise’s financial supply chain management under blockchain technology. Expert Syst. 2023; in press. [Google Scholar] [CrossRef]

- Liu, H.; Han, S.H.; Zhu, Z. Blockchain Technology toward Smart Construction: Review and Future Directions. J. Constr. Eng. Manag. 2023, 149, 03123002. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, T.; Rahman, A.; Zhou, L. Blockchain Applications for Construction Contract Management: A Systematic Literature Review. J. Constr. Eng. Manag. 2023, 149, 03122011. [Google Scholar] [CrossRef]

- Fu, Y.; Xu, C.; Zhang, L.; Chen, Y. Control, coordination, and adaptation functions in construction contracts: A machine-coding model. Autom. Constr. 2023, 152, 104890. [Google Scholar] [CrossRef]

- Shuai, B. A rationale-augmented NLP framework to identify unilateral contractual change risk for construction projects. Comput. Ind. 2023, 149, 103940. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Liu, H.; Gan, V.J.L.; Das, M.; Tao, X.; Zhou, S. Construction cost management using blockchain and encryption. Autom. Constr. 2023, 152, 104841. [Google Scholar] [CrossRef]

- Zimon, G.; Nakonieczny, J.; Chudy-Laskowska, K.; Wójcik-Jurkiewicz, M.; Kochański, K. An Analysis of the Financial Liquidity Management Strategy in Construction Companies Operating in the Podkarpackie Province. Risks 2022, 10, 5. [Google Scholar] [CrossRef]

- Dimitriou, L.; Marinelli, M.; Fragkakis, N. Early bill-of-quantities estimation of concrete road bridges: An artificial intelligence-based application. Public Work. Manag. Policy 2018, 23, 127–149. [Google Scholar] [CrossRef]

- Juszczyk, M. The challenges of nonparametric cost estimation of construction works with the use of artificial intelligence tools. Procedia Eng. 2017, 196, 415–422. [Google Scholar] [CrossRef]

- Peng, H.; Wu, H.; Wang, J.; Dede, T. Research on the prediction of the water demand of construction engineering based on the BP neural network. Adv. Civ. Eng. 2020, 2020, 8868817. [Google Scholar] [CrossRef]

- Lin, X.; Lu, Y. Research on mathematical model of cost budget in the early stage of assembly construction project based on improved neural network algorithm. Math. Probl. Eng. 2020, 2020, 3674929. [Google Scholar] [CrossRef]

- Beljkaš, Ž.; Knežević, M.; Rutešić, S.; Ivanišević, N. Application of artificial intelligence for the estimation of concrete and reinforcement consumption in the construction of integral bridges. Adv. Civ. Eng. 2020, 2020, 8645031. [Google Scholar] [CrossRef]

- Gondia, A.; Siam, A.; El-Dakhakhni, W.; Nassar, A.H. Machine learning algorithms for construction projects delay risk prediction. J. Constr. Eng. Manag. 2020, 146, 04019085. [Google Scholar] [CrossRef]

- Minli, Z.; Shanshan, Q. Research on the application of artificial neural networks in tender offer for construction projects. Phys. Procedia 2012, 24, 1781–1788. [Google Scholar] [CrossRef]

- Kim, J.M.; Bae, J.; Son, S.; Son, K.; Yum, S.G. Development of model to predict natural disaster-induced financial losses for construction projects using deep learning techniques. Sustainability 2021, 13, 5304. [Google Scholar] [CrossRef]

- Sharma, S.; Ahmed, S.; Naseem, M.; Alnumay, W.S.; Singh, S.; Cho, G.H. A survey on applications of artificial intelligence for pre-parametric project cost and soil shear-strength estimation in construction and geotechnical engineering. Sensors 2021, 21, 463. [Google Scholar] [CrossRef]

- Mojtahedi, S.F.; Ahmadihosseini, A.; Sadeghi, H. An Artificial Intelligence Based Data-Driven Method for Forecasting Unconfined Compressive Strength of Cement Stabilized Soil by Deep Mixing Technique. Geotech. Geol. Eng. 2023, 41, 491–514. [Google Scholar] [CrossRef]

- Jiang, Y.; Bai, Y.; Han, S. Determining ground elevations covered by vegetation on construction sites using drone-based orthoimage and convolutional neural network. J. Comput. Civ. Eng. 2020, 34, 04020049. [Google Scholar] [CrossRef]

- Wang, X.Q.; Chen, P.; Chow, C.L.; Lau, D. Artificial-intelligence-led revolution of construction materials: From molecules to Industry 4.0. Matter 2023, 6, 1831–1859. [Google Scholar] [CrossRef]

- Zhong, B.; Wu, H.; Ding, L.; Love, P.E.; Li, H.; Luo, H.; Jiao, L. Mapping computer vision research in construction: Developments, knowledge gaps and implications for research. Autom. Constr. 2019, 107, 102919. [Google Scholar] [CrossRef]

- Practical Application of BIM Technologies on the Example of a Moscow Developer. Available online: https://vc.ru/life/321724-prakticheskoe-primenenie-bim-tehnologiy-na-primere-moskovskogo-developera (accessed on 10 July 2023).

- Cao, Y.; Zandi, Y.; Agdas, A.S.; Wang, Q.; Qian, X.; Fu, L.; Wakil, K.; Selmi, A.; Issakhov, A.; Roco Videla, Á. A review study of application of artificial intelligence in construction management and composite beams. Steel Compos. Struct. 2021, 39, 685–700. [Google Scholar]

- Elhegazy, H.; Chakraborty, D.; Elzarka, H.; Ebid, A.M.; Mahdi, I.M.; Aboul Haggag, S.Y.; Abdel Rashid, I. Artificial intelligence for developing accurate preliminary cost estimates for composite flooring systems of multi-storey buildings. J. Asian Archit. Build. Eng. 2022, 21, 120–132. [Google Scholar] [CrossRef]

- Rahimian, F.P.; Seyedzadeh, S.; Oliver, S.; Rodriguez, S.; Dawood, N. On-demand monitoring of construction projects through a game-like hybrid application of BIM and machine learning. Autom. Constr. 2020, 110, 103012. [Google Scholar] [CrossRef]

- Braun, A.; Borrmann, A. Combining inverse photogrammetry and BIM for automated labeling of construction site images for machine learning. Autom. Constr. 2019, 106, 102879. [Google Scholar] [CrossRef]

- Jiang, Y.; Bai, Y. Estimation of construction site elevations using drone-based orthoimagery and deep learning. J. Constr. Eng. Manag. 2020, 146, 04020086. [Google Scholar] [CrossRef]

- Li, D.; Cong, A.; Guo, S. Sewer damage detection from imbalanced CCTV inspection data using deep convolutional neural networks with hierarchical classification. Autom. Constr. 2019, 101, 199–208. [Google Scholar] [CrossRef]

- Pandian, A.P. Artificial intelligence application in smart warehousing environment for automated logistics. J. Artif. Intell. 2019, 1, 63–72. [Google Scholar]

- Klumpp, M. Automation and artificial intelligence in business logistics systems: Human reactions and collaboration requirements. Int. J. Logist. Res. Appl. 2018, 21, 224–242. [Google Scholar] [CrossRef]

- Oleśków-Szłapka, J.; Wojciechowski, H.; Domański, R.; Pawłowski, G. Logistics 4.0 maturity levels assessed based on GDM (grey decision model) and artificial intelligence in logistics 4.0-trends and future perspective. Procedia Manuf. 2019, 39, 1734–1742. [Google Scholar] [CrossRef]

- Strandhagen, J.O.; Vallandingham, L.R.; Fragapane, G.; Strandhagen, J.W.; Stangeland, A.B.H.; Sharma, N. Logistics 4.0 and emerging sustainable business models. Adv. Manuf. 2017, 5, 359–369. [Google Scholar] [CrossRef]

- Zhang, Y. The application of artificial intelligence in logistics and express delivery. J. Phys. Conf. Ser. 2019, 1325, 012085. [Google Scholar] [CrossRef]

- Woschank, M.; Rauch, E.; Zsifkovits, H. A review of further directions for artificial intelligence, machine learning, and deep learning in smart logistics. Sustainability 2020, 12, 3760. [Google Scholar] [CrossRef]

- Arabi, S.; Haghighat, A.; Sharma, A. A deep-learning-based computer vision solution for construction vehicle detection. Comput.-Aided Civ. Infrastruct. Eng. 2020, 35, 753–767. [Google Scholar] [CrossRef]

- Rashid, K.M.; Louis, J. Times-series data augmentation and deep learning for construction equipment activity recognition. Adv. Eng. Inform. 2019, 42, 100944. [Google Scholar] [CrossRef]

- Qian, X.; Papadonikolaki, E. Shifting trust in construction supply chains through blockchain technology. Eng. Constr. Archit. Manag. 2021, 28, 584–602. [Google Scholar] [CrossRef]

- Xu, S.; Wang, J.; Shou, W.; Ngo, T.; Sadick, A.M.; Wang, X. Computer vision techniques in construction: A critical review. Arch. Comput. Methods Eng. 2021, 28, 3383–3397. [Google Scholar] [CrossRef]

- Ercan, M.F.; Wang, R.B. Computer Vision-Based Inspection System for Worker Training in Build and Construction Industry. Computers 2022, 11, 100. [Google Scholar] [CrossRef]

- Kwiatek, C.; Sharif, M.; Li, S.; Haas, C.; Walbridge, S. Impact of augmented reality and spatial cognition on assembly in construction. Autom. Constr. 2019, 108, 102935. [Google Scholar] [CrossRef]

- Rada, A.O.; Kuznetsov, A.D.; Zverev, R.E.; Timofeev, A.E. Automation of monitoring construction works based on laser scanning from unmanned aerial vehicles. Nanotechnol. Constr. 2023, 15, 373–382. [Google Scholar] [CrossRef]

- Digital Transformation in the Construction and Engineering Industry—Part Two. Available online: https://pwc.blogs.com/industry_perspectives/2017/05/digital-transformation-in-the-construction-and-engineering-industry-part-two.html (accessed on 30 May 2023).

- Digital Twins and Digital Doubles: Populating our Virtual Worlds. Available online: https://www.futuregrasp.com/digital-twins-and-digital-doubles (accessed on 30 May 2023).

- China Is Using AI and 3D Printing to Build a 590-Foot-Tall Dam without the Need for Human Workers, Scientists Say. Available online: https://www.businessinsider.com/china-robots-ai-3d-print-dam-no-human-labor-2022-5 (accessed on 10 July 2023).

- China: Artificial Intelligence Used to Monitor Workers’ Safety on Construction Sites. Available online: https://www.business-humanrights.org/en/latest-news/china-artificial-intelligence-used-to-monitor-workers-safety-on-construction-sites (accessed on 10 July 2023).

- How Construction Control Is Carried Out with the Help of IAS “Monitoring”: The Experience of RosKapStroy. Available online: https://digital-build.ru/kak-proishodit-czifrovoj-kontrol-stroitelstva-pri-pomoshhi-ias-monitoring-opyt-roskapstroj (accessed on 10 July 2023).

- SITE SAFETY AT SIEMENS →→→SIEMENS Contracted DEKRA to Develop and Implement a Comprehensive Safety Concept in Accordance with International Standards for the Construction of a New Digital Factory in Nanjing, China. Available online: https://gb2021.dekra-online.de/en/kickstart/service-divisions/consulting (accessed on 9 July 2023).

- Construction Site Security. Video Monitoring and Security Solutions Built for the Construction Industry. Available online: https://calibercommunications.ca/construction-security (accessed on 10 July 2023).

- Newly Developed Safety Monitoring System for Construction Sites. Available online: https://indiaeducationdiary.in/newly-developed-safety-monitoring-system-for-construction-sites (accessed on 10 July 2023).

- Enhancing Workers’ Safety-Towards Automated Industrial Safety Monitoring Systems. Available online: https://social-innovation.hitachi/en-in/knowledge-hub/viewpoint/industrial-safety-monitoring-systems (accessed on 10 July 2023).

- Artificial Intelligence the Way to The fully Automated Construction Site. Available online: https://openexperience.de/en/themen/Kuenstliche-Intelligenz-im-Bau (accessed on 10 July 2023).

- The Rise of Artificial Intelligence in Construction Industry. Available online: https://gharpedia.com/blog/artificial-intelligence-in-construction (accessed on 10 July 2023).

- Artificial Intelligence in Construction. Examples of AI for the Construction Industry. Available online: https://elport.ru/articles/iskusstvennyiy_intellekt_v_stroitelstve_primeryi_ii_dlya_stroitelnoy_otrasli (accessed on 10 July 2023).

- Digital Technologies in Construction. Available online: https://tadviser.com/index.php/Article:Digital_Technologies_in_Construction (accessed on 10 July 2023).

- Inspiring BIM Projects You Need to See. Available online: https://constructionblog.autodesk.com/successful-bim-projects/ (accessed on 10 July 2023).

- Building Routes to Economic Growth and Prosperity. Available online: https://www.bechtel.com/services/infrastructure/civil-infrastructure (accessed on 10 July 2023).

- Application of BIM in Steel Structures Design. Available online: https://steelexplained.com/application-of-bim-in-steel-structures-design/ (accessed on 10 July 2023).

- DUBAI METRO 2020. Available online: https://www.acciona.com/projects/dubai-metro-2020/?_adin=0924833216 (accessed on 10 July 2023).

- Siebert, S.; Teizer, J. Mobile 3D mapping for surveying earthwork projects using an Unmanned Aerial Vehicle (UAV) system. Autom. Constr. 2014, 41, 1–14. [Google Scholar] [CrossRef]

- Digital Tools in Road Construction. Available online: https://innovation.strabag.com/en/project/digital-tools-in-road-construction (accessed on 10 July 2023).

- Driving Digitalisation in Road Construction. Available online: https://www.dwtc.com/en/industry-insights/driving-digitalisation-in-road-construction (accessed on 10 July 2023).

- Road and Bridge Digital Twins in Action: Four Case Studies. Available online: https://www.cadalyst.com/collaboration/digital-twin/road-and-bridge-digital-twins-action-four-case-studies-75827 (accessed on 10 July 2023).

- China’s AI Implementation is Edging Ahead of the US. Available online: https://www.forbes.com/sites/craigsmith/2023/01/14/chinas-ai-implementation-is-edging-ahead-of-the-us/?sh=7dc2e92c2dfb (accessed on 10 July 2023).

- Roberts, H.; Cowls, J.; Morley, J.; Taddeo, M.; Wang, V.; Floridi, L. The Chinese approach to artificial intelligence: An analysis of policy, ethics, and regulation. AI Soc. 2021, 36, 59–77. [Google Scholar] [CrossRef]

- Artificial Intelligence (AI) in China’s Construction Industry (2016–2025)-Analysis on AI Spending with 15+ KPIs, Market Size & Forecast Across 6+ Application Segments, AI Domains, and Technology. Available online: https://www.businesswire.com/news/home/20190329005250/en/Artificial-Intelligence-AI-in-Chinas-Construction-Industry-2016-2025---Analysis-on-AI-Spending-with-15-KPIs-Market-Size-Forecast-Across-6-Application-Segments-AI-Domains-and-Technology---ResearchAndMarkets.com (accessed on 10 July 2023).

- Yan, J.-K.; Zheng, Z.; Zhou, Y.-C.; Lin, J.-R.; Deng, Y.-C.; Lu, X.-Z. Recent Research Progress in Intelligent Construction: A Comparison between China and Developed Countries. Buildings 2023, 13, 1329. [Google Scholar] [CrossRef]

- Martinez, P.; Al-Hussein, M.; Ahmad, R. A scientometric analysis and critical review of computer vision applications for construction. Autom. Constr. 2019, 107, 102947. [Google Scholar] [CrossRef]

- Oprach, S.; Bolduan, T.; Steuer, D.; Vössing, M.; Haghsheno, S. Building the future of the construction industry through artificial intelligence and platform thinking. Digit. Welt 2018, 3, 40–44. [Google Scholar] [CrossRef]

- McAleenan, P. Moral responsibility and action in the use of artificial intelligence in construction. Proc. Inst. Civ. Eng. Manag. Procure. Law 2020, 173, 166–174. [Google Scholar] [CrossRef]

- Alekseeva, T.R. BIM technologies and artificial intelligence in infrastructural construction. BST Bull. Constr. Equip. 2022, 1, 52–54. (In Russian) [Google Scholar]

- Khanzode, K.C.A.; Sarode, R.D. Advantages and disadvantages of artificial intelligence and machine learning: A literature review. Int. J. Libr. Inform. Sci. 2020, 9, 30–36. [Google Scholar]

- Soori, M.; Arezoo, B.; Habibi, M. Dimensional and geometrical errors of three-axis CNC milling machines in a virtual machining system. Comput. Aided Des. 2013, 45, 1306–1313. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Habibi, M. Tool deflection error of three-axis computer numerical control milling machines, monitoring and minimizing by a virtual machining system. J. Manuf. Sci. Eng. 2016, 138, 081005. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, T.; Ye, Y.; Gao, W.; Zhang, C. A knowledge generation mechanism of machining process planning using cloud technology. J. Ambient. Intell. Hum. Comput. 2019, 10, 1081–1092. [Google Scholar] [CrossRef]

- Shishkunova, D.V.; Ishhenko, A.V. Construction Production Logistics: Problems and Solutions. Inzhenernyj Vestn. Dona 2020, 1. Available online: http://Ivdon.ru/ru/magazine/archive/N1y2020/6292 (accessed on 2 September 2023).

- Chui, M.; Manyika, J.; Miremadi, M.; Henke, N.; Chung, R.; Nel, P.; Malhotra, S. Notes from the AI Frontier: Applications and Value of Deep Learning. Available online: https://www.mckinsey.com/featured-insights/artificial-intelligence/notes-from-the-ai-frontier-applications-and-value-of-deep-learning (accessed on 10 July 2023).

- Pandey, K.; Datta, S. Hot machining of difficult-tocut materials: A review. Mater. Today Proc. 2021, 44, 2710–2715. [Google Scholar] [CrossRef]

- Shokrani, A.; Betts, J. A new hybrid minimum quantity lubrication system for machining difficult-tocut materials. CIRP Ann. 2020, 69, 73–76. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Wang, B.; Hu, J. PVD AlTiN coating effects on tool-chip heat partition coefficient and cutting temperature rise in orthogonal cutting Inconel 718. Int. J. Heat. Mass. Transf. 2020, 163, 120449. [Google Scholar] [CrossRef]

- Pradhananga, P.; Elzomor, M.; Santi Kasabdji, G. Identifying the challenges to adopting robotics in the us construction industry. J. Constr. Eng. Manag. 2021, 147, 05021003. [Google Scholar] [CrossRef]

- Marzouk, M.; Azab, S.; Metawie, M. BIM-based approach for optimizing life cycle costs of sustainable building. J. Clean. Prod. 2018, 188, 217–226. [Google Scholar] [CrossRef]

- Bagherzadeh, A.; Budak, E. Investigation of machinability in turning of difficult-to-cut materials using a new cryogenic cooling approach. Tribol. Int. 2018, 119, 510–520. [Google Scholar] [CrossRef]

- De Galarreta, S.R.; Jeffers, J.R.; Ghouse, S. A validated finite element analysis procedure for porous structures. Mater. Des. 2020, 189, 108546. [Google Scholar] [CrossRef]

- Bykov, I.A. Artificial intelligence as a source of political judgments. J. Political Stud. 2020, 4, 23–33. [Google Scholar]

- Zhilin, V.V.; Safaryan, O.A. Artificial intelligence in data storage systems. Bull. Don. State Tech. Univ. 2020, 20, 196–200. [Google Scholar] [CrossRef]

- Arroyo, P.; Schöttle, A.; Christensen, R. The Ethical and Social. Dilemma of AI Uses in The Construction Industry. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction (IGLC), Lima, Peru, 12–18 July 2021. [Google Scholar] [CrossRef]

- Ilvitskaya, S.V.; Lobkova, T.V. Green housing architecture and Green BIM technologies. Archit. Constr. Russ. 2018, 1, 108–113. [Google Scholar]

- Karaguzel, U.; Olgun, U.; Uysal, E.; Budak, E.; Bakkal, M. Increasing tool life in machining of difficultto-cut materials using nonconventional turning processes. Int. J. Adv. Manuf. Technol. 2015, 77, 1993–2004. [Google Scholar] [CrossRef]

- Parida, A.K.; Maity, K. Study of machinability in heat-assisted machining of nickel-base alloy. Measurement 2021, 170, 108682. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Soliman, M.; Kishawy, H.A. Effects of nano-cutting fluids on tool performance and chip morphology during machining Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 3449–3458. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B. A Review in Machining-Induced Residual Stress. J. New Technol. Mater. 2022, 12, 64–83. [Google Scholar]

- Marinelli, M. From Industry 4.0 to Construction 5.0: Exploring the Path towards Human–Robot Collaboration in Construction. Systems 2023, 11, 152. [Google Scholar] [CrossRef]

- Soori, M.; Asmael, M.; Solyalı, D. Recent Development in Friction Stir Welding Process: A Review. SAE Int. J. Mater. Manuf. 2021, 14, 63–80. [Google Scholar] [CrossRef]

- Păvăloaia, V.-D.; Necula, S.-C. Artificial Intelligence as a Disruptive Technology—A Systematic Literature Review. Electronics 2023, 12, 1102. [Google Scholar] [CrossRef]

- Syed, A.S.; Sierra-Sosa, D.; Kumar, A.; Elmaghraby, A. IoT in smart cities: A survey of technologies, practices and challenges. Smart Cities 2021, 4, 429–475. [Google Scholar] [CrossRef]

- Alahi, M.E.E.; Sukkuea, A.; Tina, F.W.; Nag, A.; Kurdthongmee, W.; Suwannarat, K.; Mukhopadhyay, S.C. Integration of IoT-Enabled Technologies and Artificial Intelligence (AI) for Smart City Scenario: Recent Advancements and Future Trends. Sensors 2023, 23, 5206. [Google Scholar] [CrossRef]

- Nikitas, A.; Michalakopoulou, K.; Njoya, E.T.; Karampatzakis, D. Artificial Intelligence, Transport and the Smart City: Definitions and Dimensions of a New Mobility Era. Sustainability 2020, 12, 2789. [Google Scholar] [CrossRef]

- Summary of AI Provisions from the National Defense Authorization Act 2023. Available online: https://hai.stanford.edu/summary-ai-provisions-national-defense-authorization-act-2023 (accessed on 25 September 2023).

- European Parliamentary Research Service. Available online: https://www.europarl.europa.eu/RegData/etudes/STUD/2020/634452/EPRS_STU(2020)634452_EN.pdf (accessed on 25 September 2023).

- Gaumond, E.; Régis, C. Assessing Impacts of AI on Human Rights: It’s Not Solely About Privacy and Nondiscrimination. Available online: https://www.lawfaremedia.org/article/assessing-impacts-of-ai-on-human-rights-it-s-not-solely-about-privacy-and-nondiscrimination (accessed on 25 September 2023).

| Application Areas | AI Technologies | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| Health/Safety | [77,78,79] | [80,81] | - | - | [82,83] | - |

| Project planning and design | [83,84,85] | [86,87] | [88,89] | [4] | [90,91] | [84,92] |

| Cost estimation | - | - | [4,93] | - | [94,95] | [96,97] |

| Contracts, conflict management and tenders | [98] | [99,100] | - | - | [101] | [102] |

| Supply management, equipment and logistics | [2,4,103] | - | [104] | - | [13,105] | [45] |

| Site monitoring and performance evaluation | [106,107] | [108,109,110] | - | [111,112] | [113] | - |

| Risk management | [114,115] | - | - | [4,99] | [116,117] | - |

| Stability | - | - | - | - | [4,86] | [118] |

| The Proposed Safety Solution | AI Method | Prediction Accuracy, % | Sources |

|---|---|---|---|

| Early detection and accident prevention platform | Computer vision and AI | 97.40 | [121] |

| Predicting accidents at a construction site | Artificial neural network and case-based reasoning | 86.00 | [127] |

| Detection of abnormal situations and transfer of information to the operator | Machine learning and decision tree | - | [128] |

| Road construction safety monitoring platform | AI and UAVs with deep learning algorithms, including YOLOv4 and DeepSORT | - | [128] |

| Practical guide to the preliminary prevention of accidents on construction sites | Artificial neural networks | 80.00 | [129] |

| Detection of hazards at construction sites | Convolutional neural networks based on regions | - | [130] |

| Assessment of safe and unsafe conditions on construction sites | Building information modeling and computer vision | - | [128] |

| Model for determining potential risks on construction sites (fatal accidents) | Machine learning methods: (AdaBoost analysis, decision tree and logistic regression, random forest) | 91.98 | [131] |

| Helmet wearing recognition of construction workers | Convolutional neural network | 83.89 | [132] |

| Proximity warning alert system | Automatic computer vision, which uses a convolutional neural network model based on regions | 90.00 | [133] |

| Safety belt detection system for workers to reduce the risk of falling from elevations | Computer sight and convolutional neural networks | 99.0 | [134] |

| A system that ensures the safety of builders by creating advance warnings and alarms at underground construction sites | Internet of Things | - | [4] |

| The Proposed Safety Solution | AI Method | Sources |

|---|---|---|

| Estimation and planning | BIM-IoT-blockchain technology; BIM for estimation of the time and cost; Deep learning for estimation of the time and cost. | [143,144,145] |

| Supply chain management | Blockchain technologies; Risk monitoring system; Mobile supply chain. | [2,146,147,148] |

| Construction contract management | Machine learning algorithms; Blockchain technologies. | [103,149,150] |

| Cost management | Blockchain technologies and encryption. | [4,151] |

| Audit systems of financial statements of building company | Statistical and cluster analysis; Blockchain technologies for audit of the BIM modification. | [4,88,151,152] |

| Object | Technologies Used | Country | Sources |

|---|---|---|---|

| Dam construction | AI technologies and 3D printer | China | [188] |

| Safety monitoring at construction sites | Internet of Things and remote sensing | China, USA, Russia, Canada, etc. | [136,189,190,191,192,193,194] |

| Effective construction management | ESKIMO system | Germany | [195] |

| Construction of a two-storey building | 3D printer | India (Larsen & Toubro Company) | [196] |

| Construction management | Digital twins created from images of robots with cameras and neural networks | USA (Droxel company) | [197] |

| Design of buildings | BIM technologies | Great Britain, Russia, France, etc. | [136,198,199,200] |

| Helsinki Airport and Tampere Deck and Arena | BIM technologies | Finland | [136] |

| Reinforced concrete bridge | BIM technologies | Peru and France | [136] |

| Pidekso Dam | BIM technologies | Indonesia | [136] |

| Motorway with tunnels | BIM technologies | Norway | [136] |

| Auckland International Airport | BIM technologies | New Zealand | [199] |

| Shanghai Tower, Disneyland and Shanghai World Financial Center | BIM technologies | China | [199,201] |

| City of New Alamein | BIM technologies | Egypt | [201] |

| Metro | Autocad civil 3D and Autodesk Revit software, Synchro Pro and BIM technologies | Dubai (Acciona Company) | [202] |

| Road construction | Digital twins and shooting from a UAV | Germany, China, Czech Republic, Italy, USA, Malaysia, etc. | [203,204,205,206] |

| Advantages | Disadvantages |

|---|---|

| Task completion speed | High costs at the investment stage |

| Safe, efficient and timely execution of projects | Technology costs |

| Ability to solve complex and stressful tasks | Expensive and complex equipment repairs |

| Possibility of simultaneous execution of several processes | Risks of unemployment of specialists |

| Reduction in administrative processes | The need for training and retraining of the workforce |

| Reducing the cost of project implementation | Efforts and funds for the maintenance of AI technologies |

| Forecasting of safety and quality risks at work sites | Risks of hacker attacks and data leaks |

| Minimum number of errors | Computational constraints |

| The possibility of long-term forecasting of events | Presence of errors |

| Ability to process qualitative and quantitative factors | The operation and efficiency of the system depends on an AI specialist |

| Reduction in operating costs | Increasing technological dependence |

| Reduction in paperwork | Dependence on electricity and internet connection |

| No need for control (operation without an operator) | Limitations of the scope of application |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivanova, S.; Kuznetsov, A.; Zverev, R.; Rada, A. Artificial Intelligence Methods for the Construction and Management of Buildings. Sensors 2023, 23, 8740. https://doi.org/10.3390/s23218740

Ivanova S, Kuznetsov A, Zverev R, Rada A. Artificial Intelligence Methods for the Construction and Management of Buildings. Sensors. 2023; 23(21):8740. https://doi.org/10.3390/s23218740

Chicago/Turabian StyleIvanova, Svetlana, Aleksandr Kuznetsov, Roman Zverev, and Artem Rada. 2023. "Artificial Intelligence Methods for the Construction and Management of Buildings" Sensors 23, no. 21: 8740. https://doi.org/10.3390/s23218740