Weak Magnetic Internal Signal Characteristics of Pipe Welds under Internal Pressure

Abstract

:1. Introduction

2. Mechanism of Weak Magnetic Internal Detection in Long-Distance Oil and Gas Pipelines

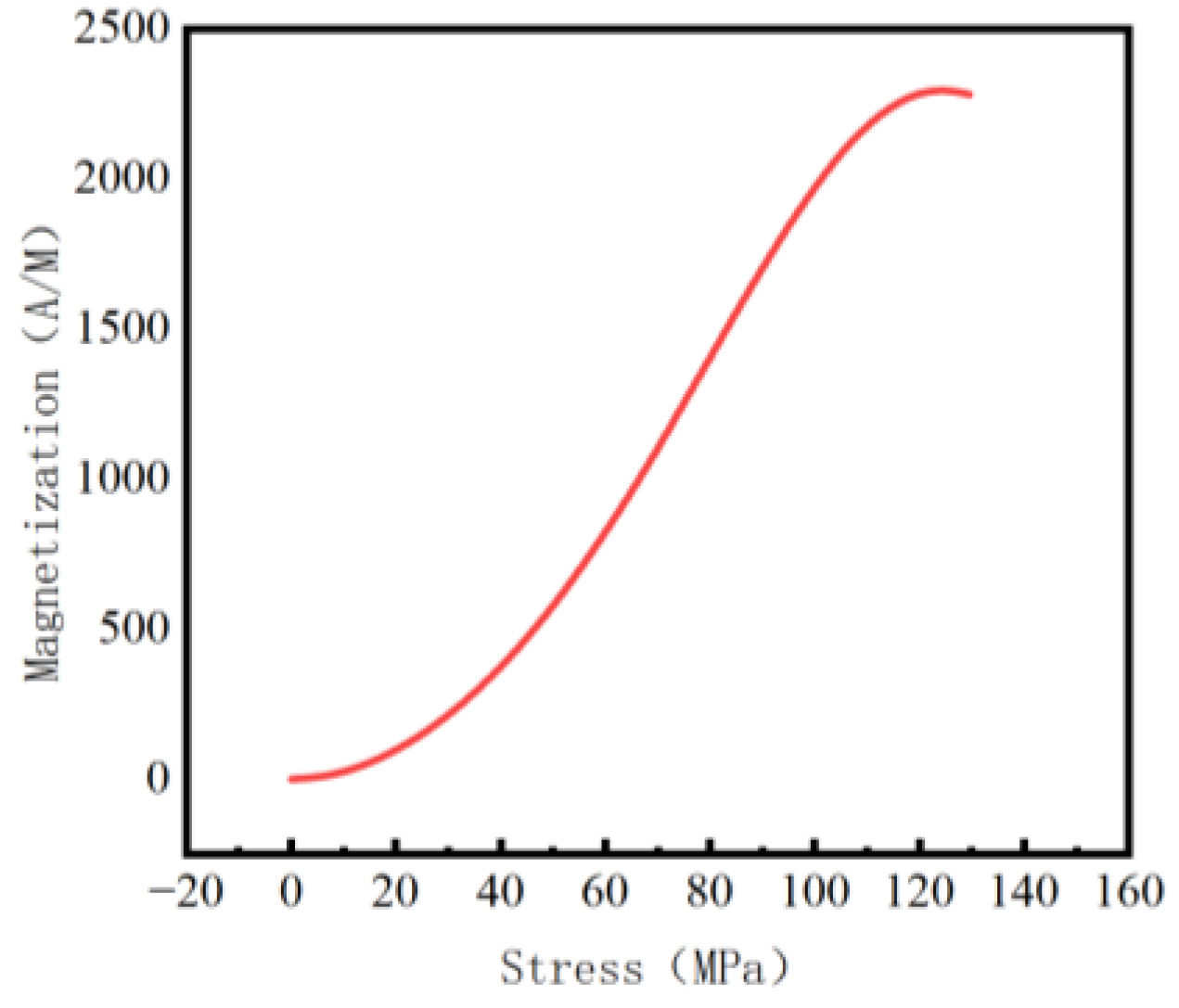

2.1. Magnetic Detection Mechanism

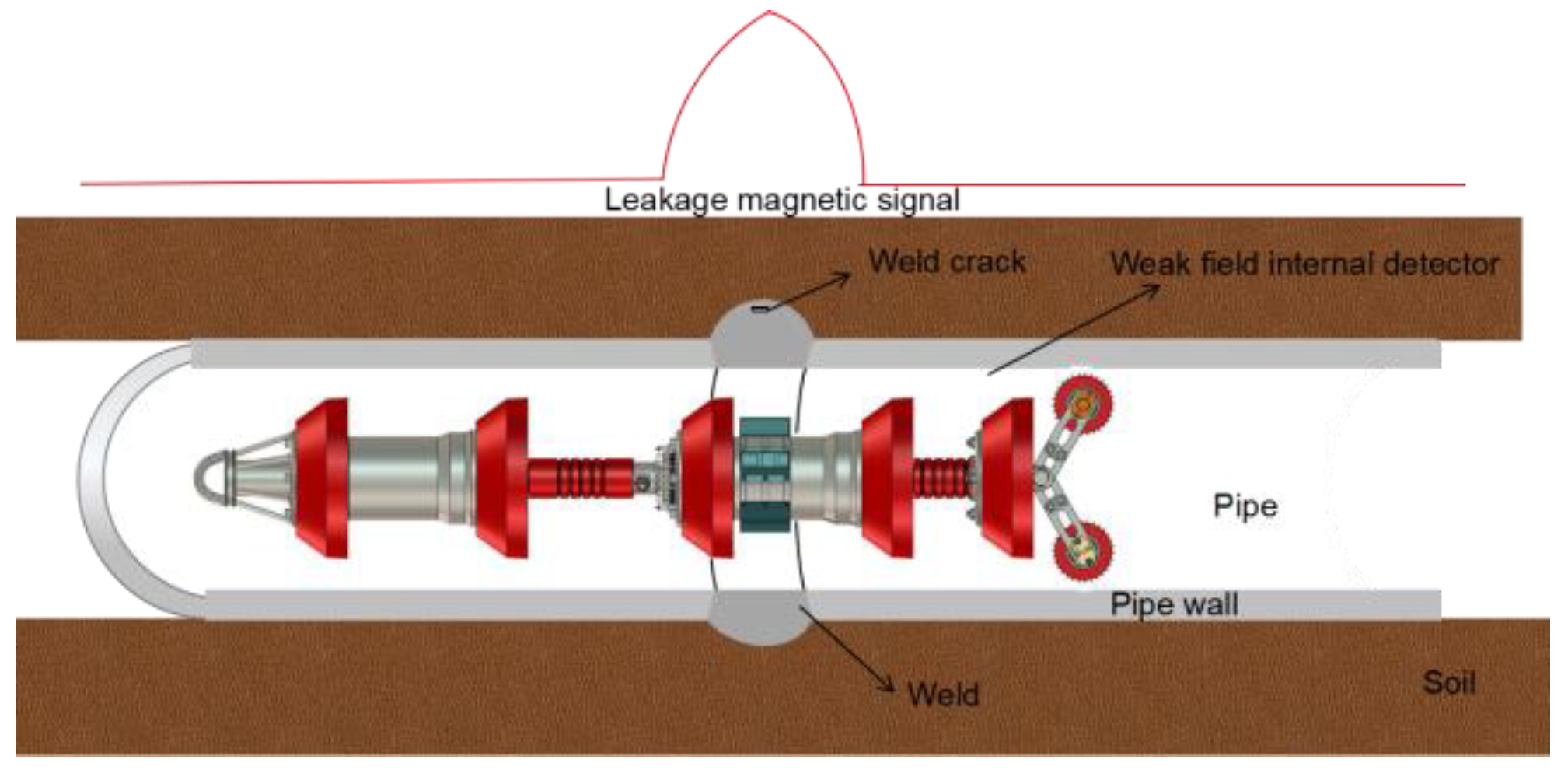

2.2. Research on the Weak Magnetic Internal Detection Mechanism of the Pipeline

2.3. Characteristic Analysis of the Weak Magnetic Signal

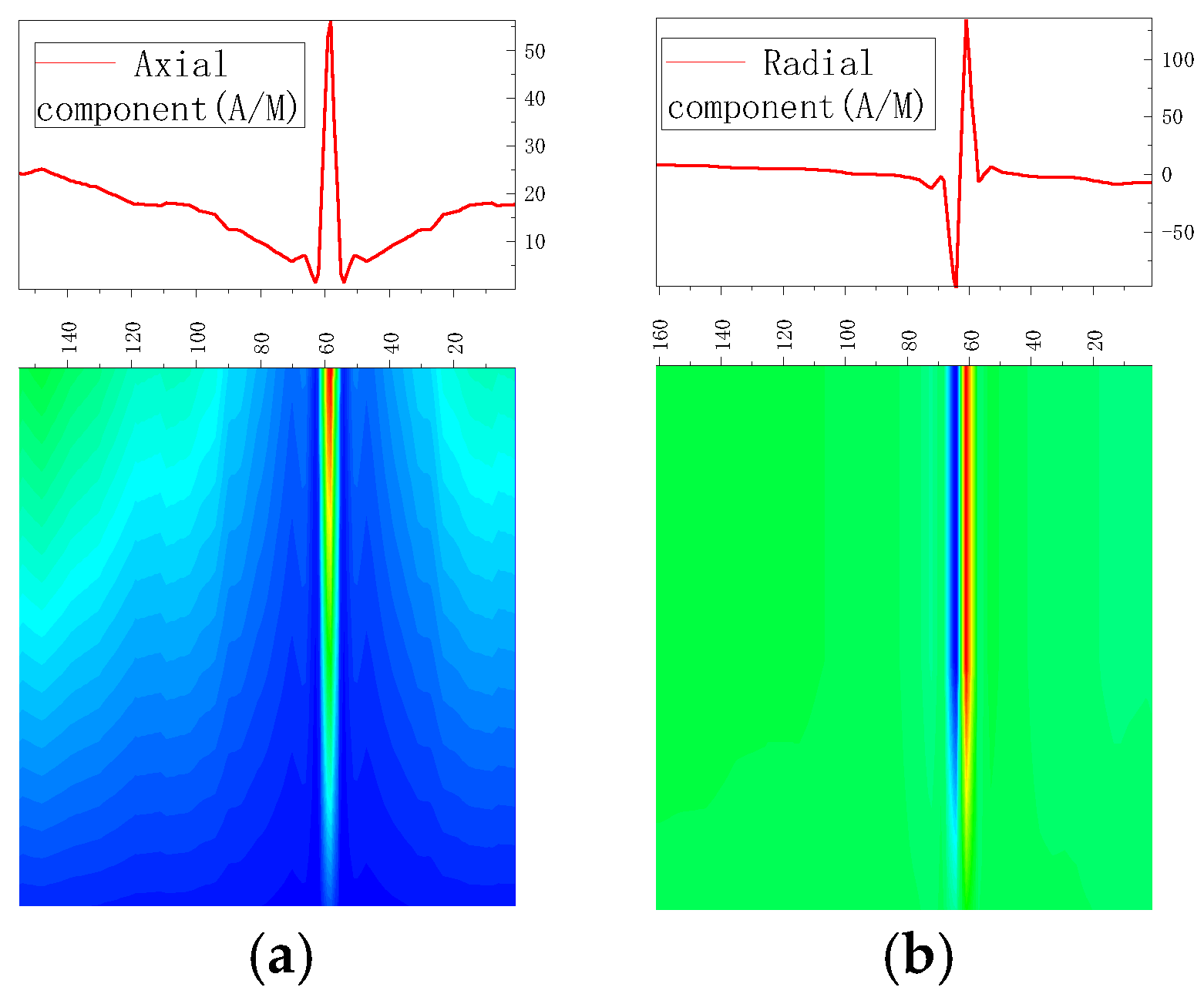

2.3.1. Weak Magnetic Signals in the Weld Pipe

2.3.2. Weak Magnetic Signals in Weld Cracks

2.3.3. Weak Magnetic Signal of Base Material Crack

3. Analysis of Influences of Internal Pressure on Weak Magnetic Signal Characteristics

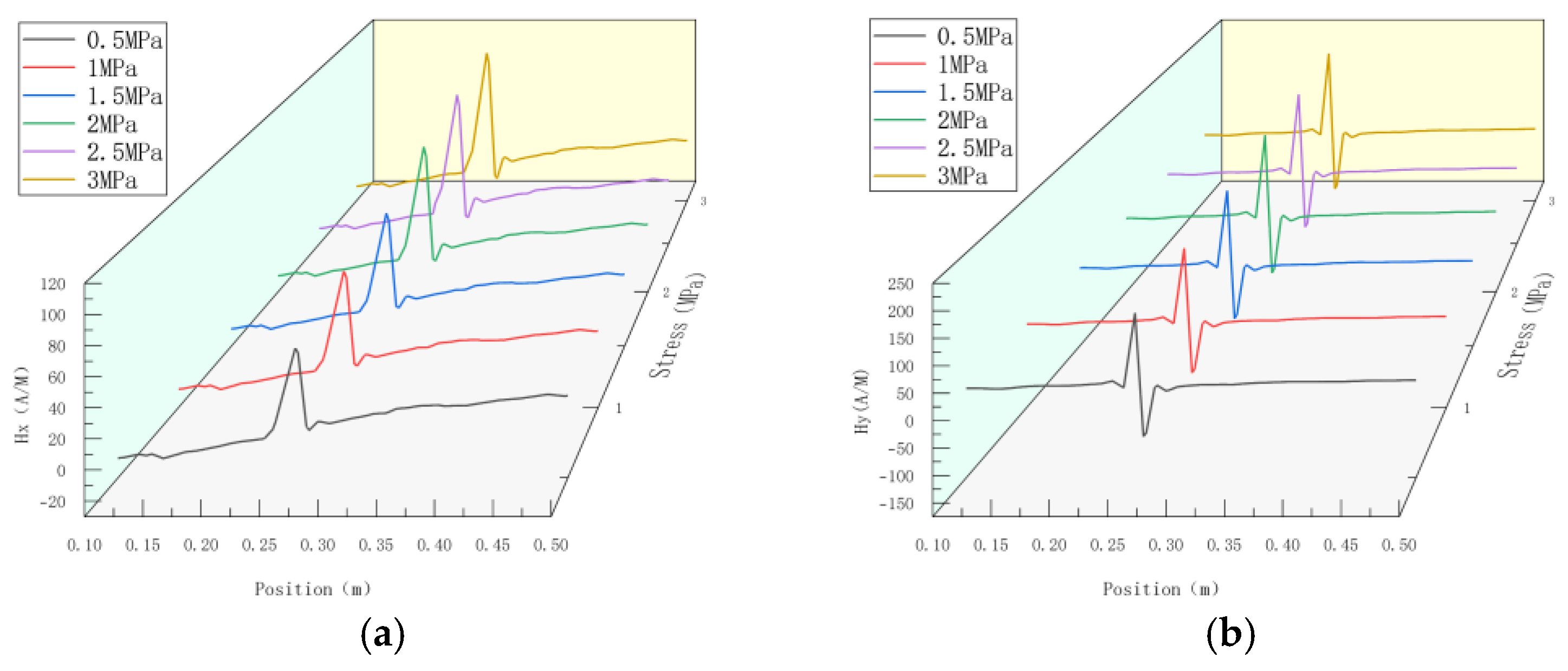

3.1. Influences of Internal Pressure on Weak Magnetic Signal Characteristics of Weld

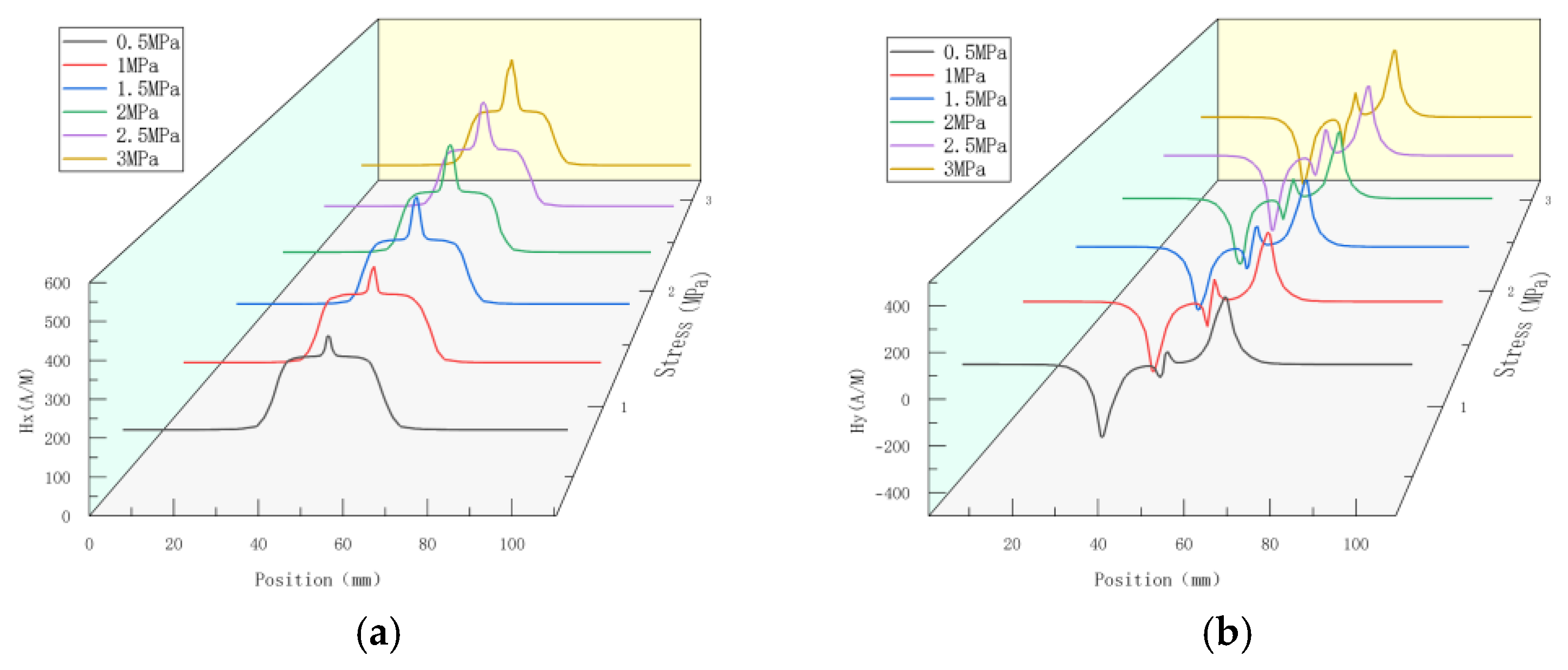

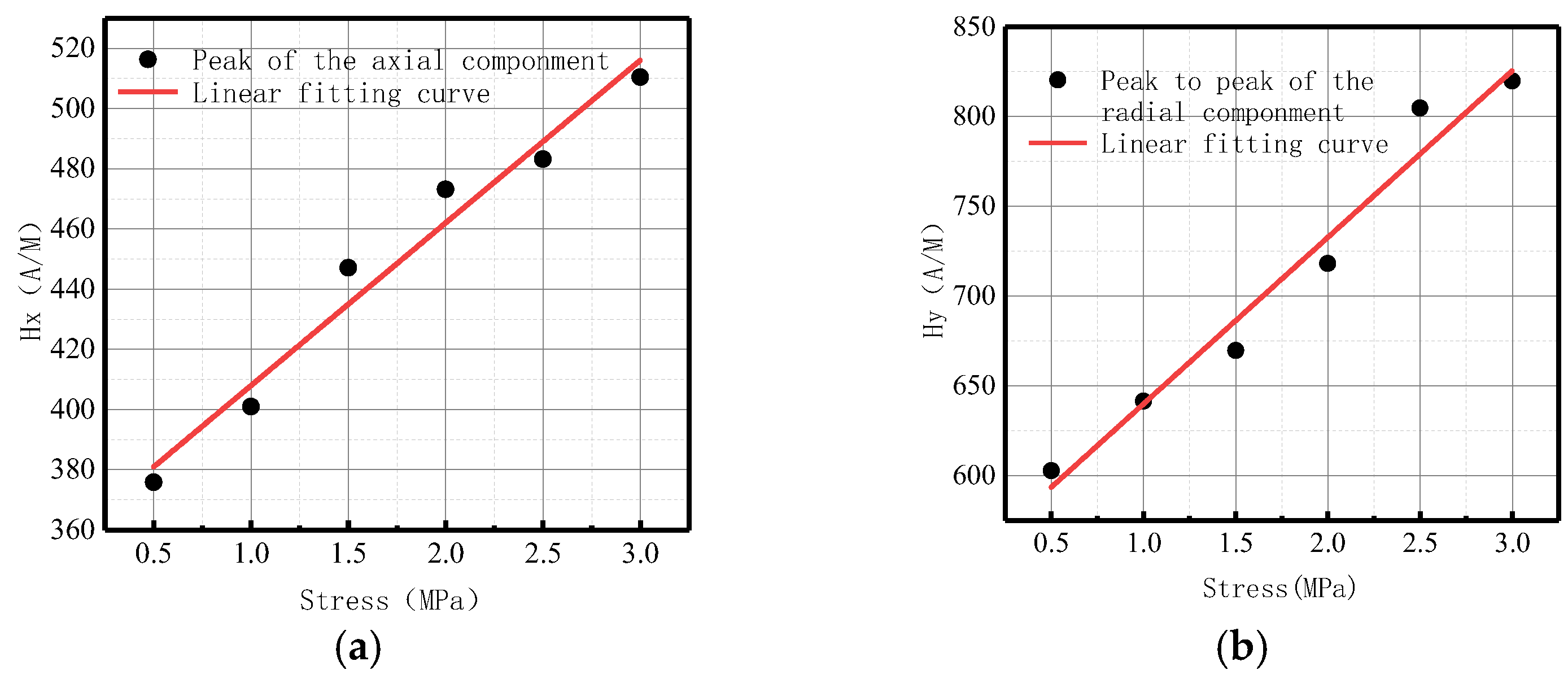

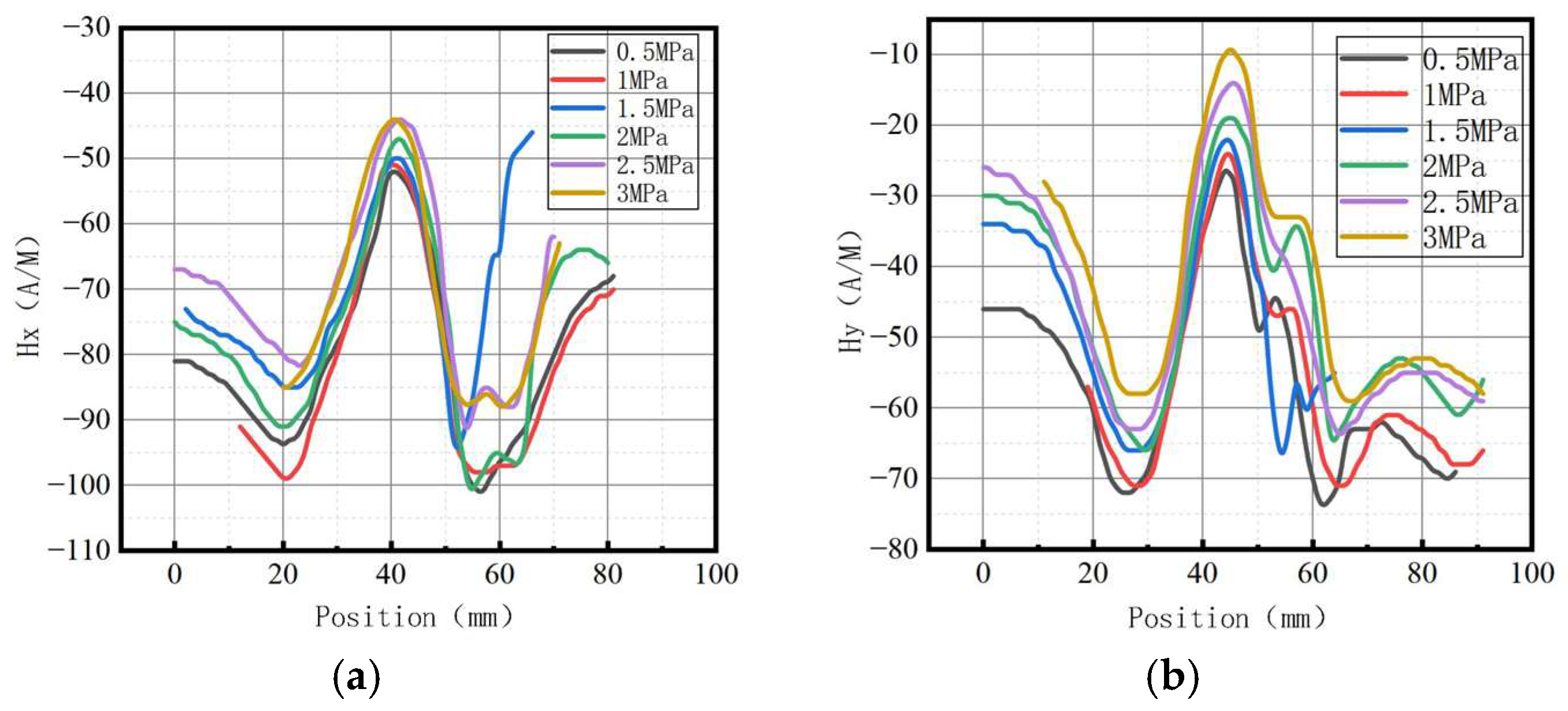

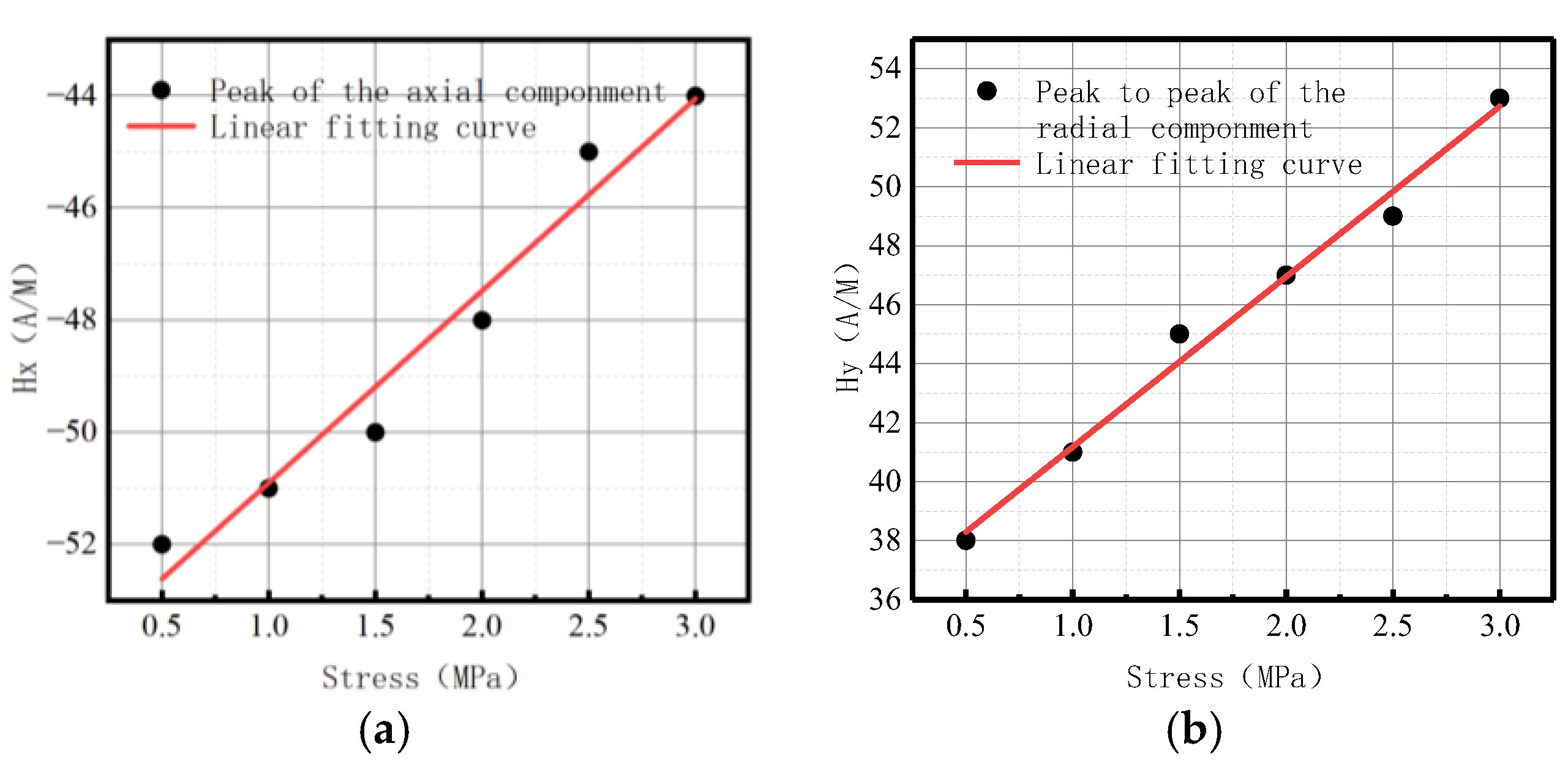

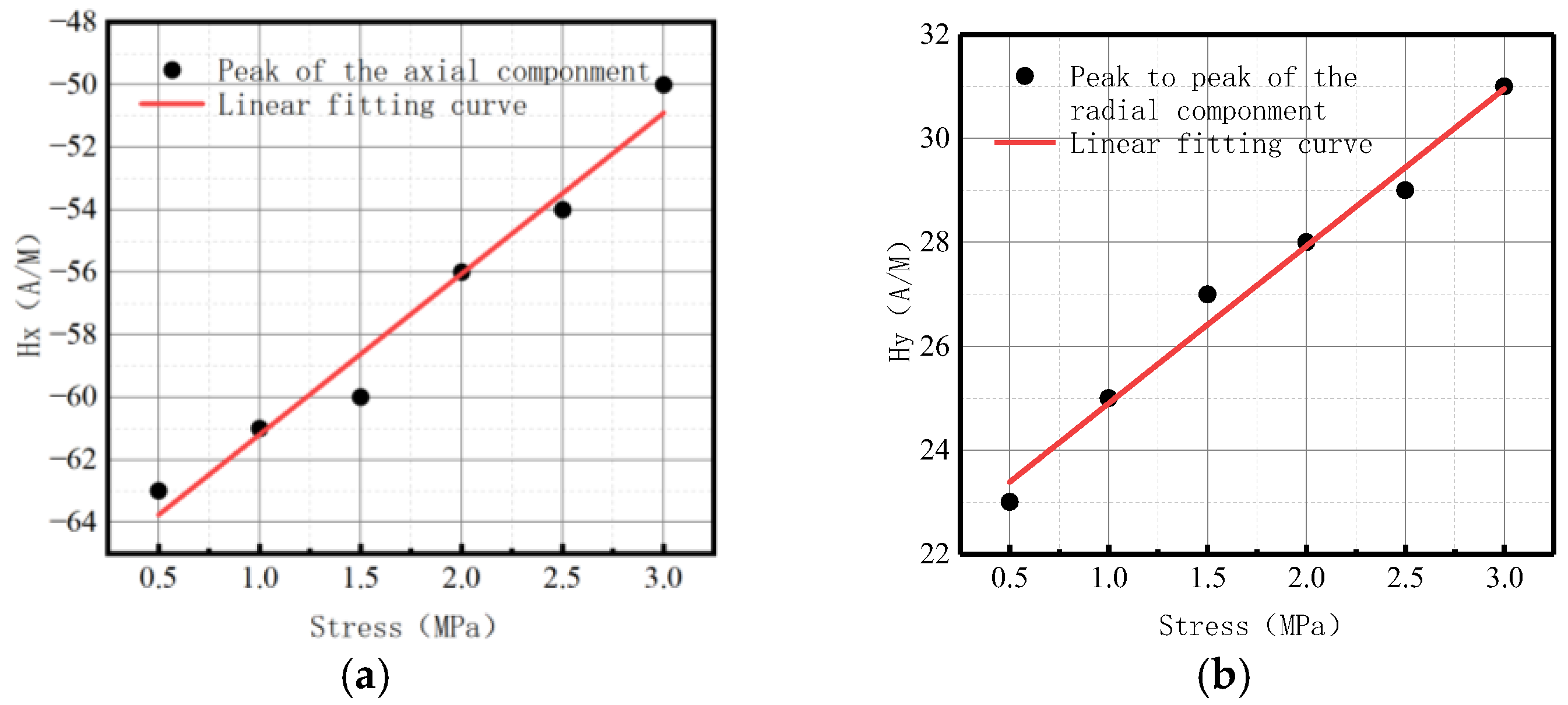

3.1.1. Peak Values in Axial and Radial Components at Weld Varies

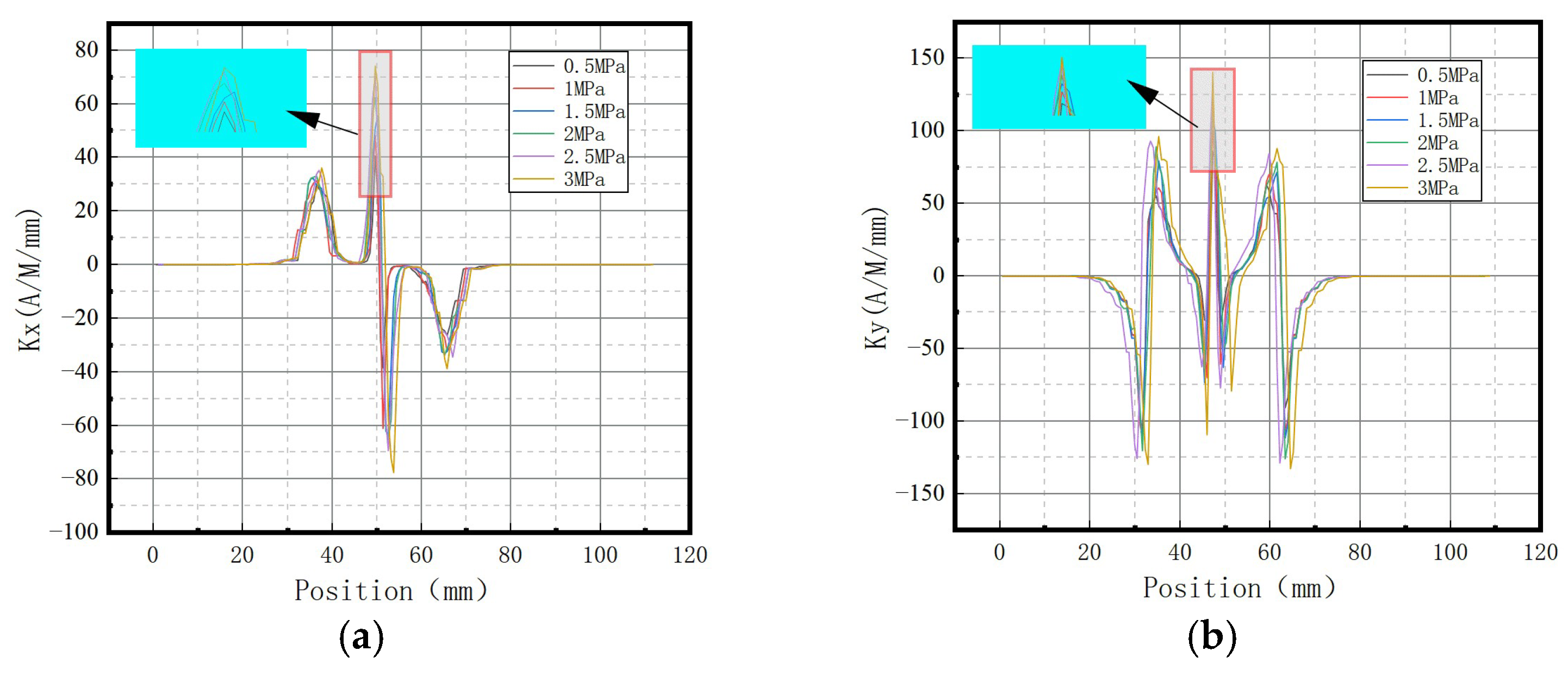

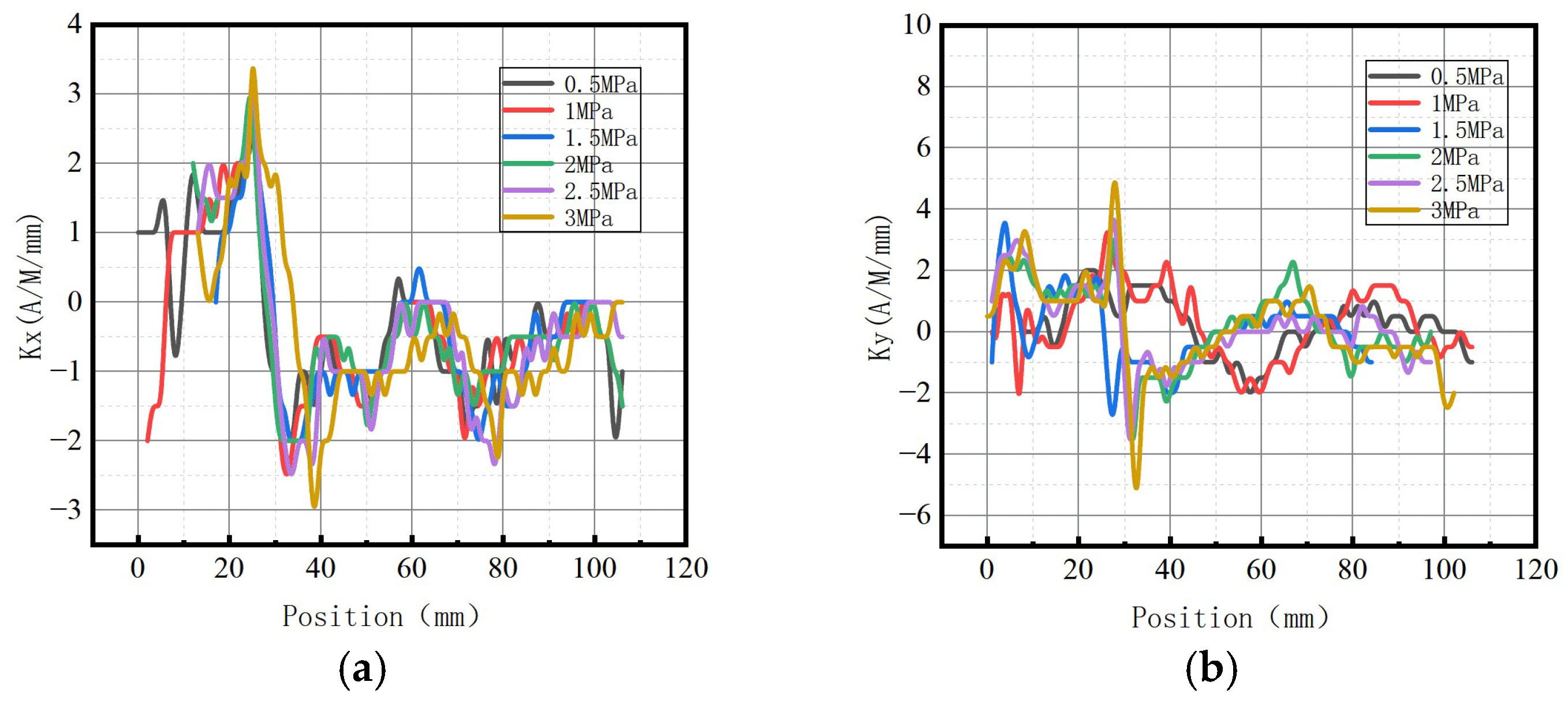

3.1.2. Magnetic Field Strength Gradient K at Weld Varies

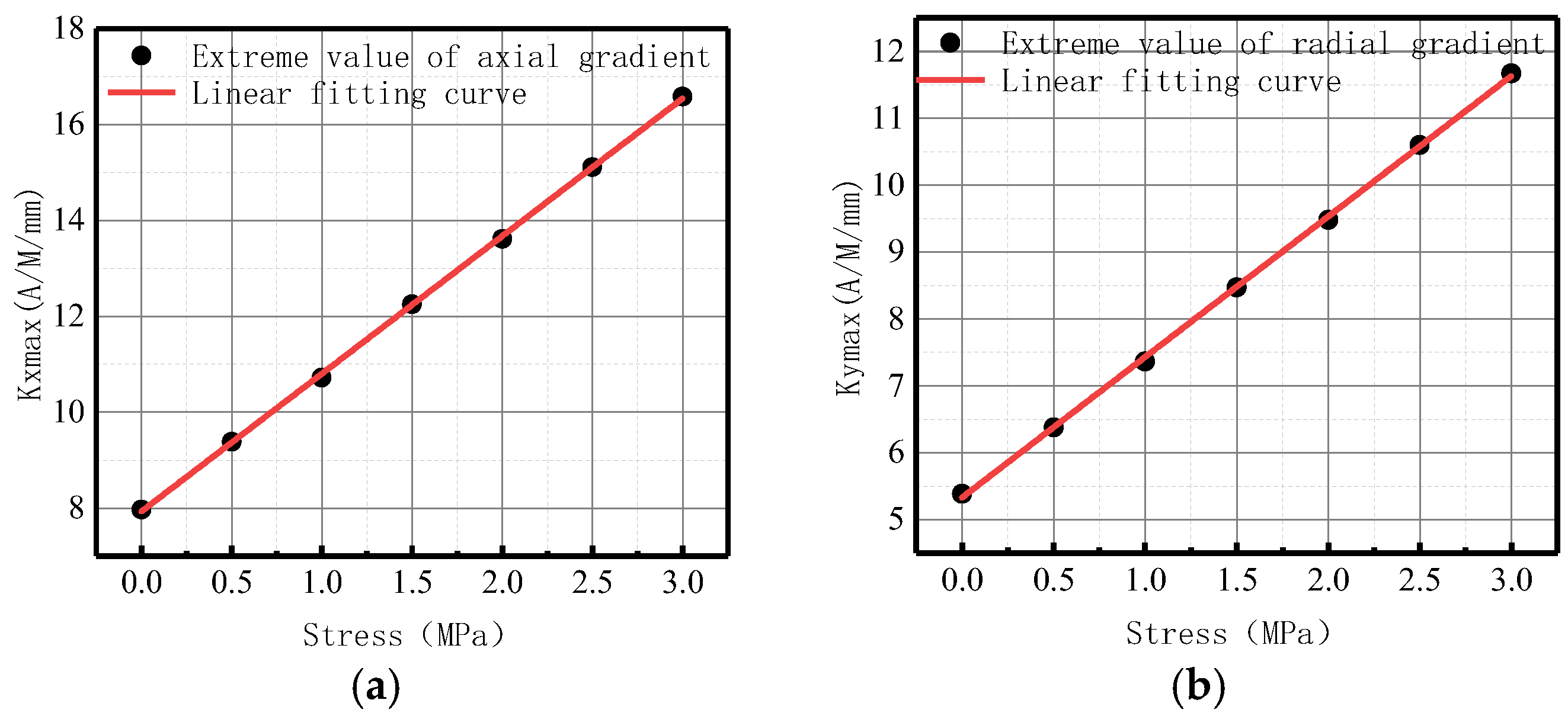

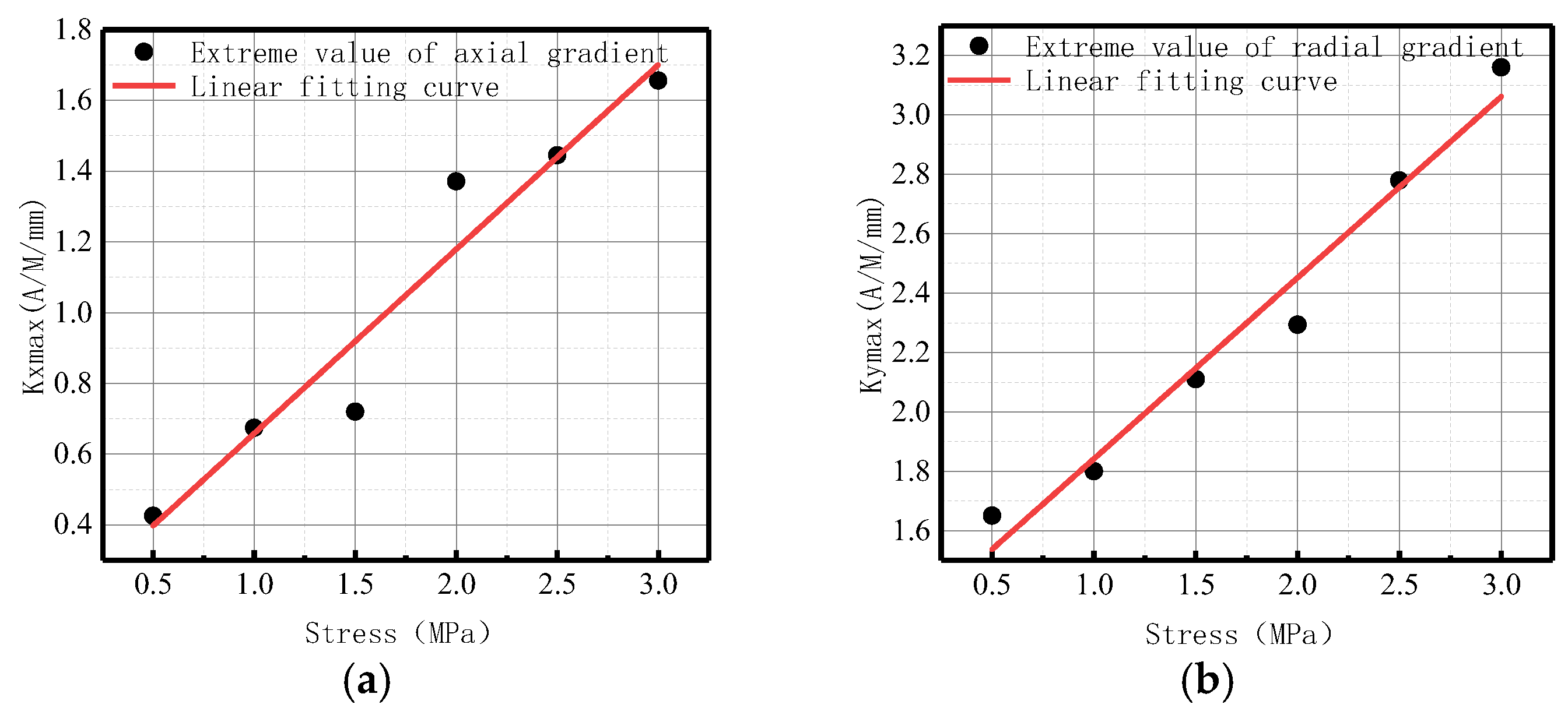

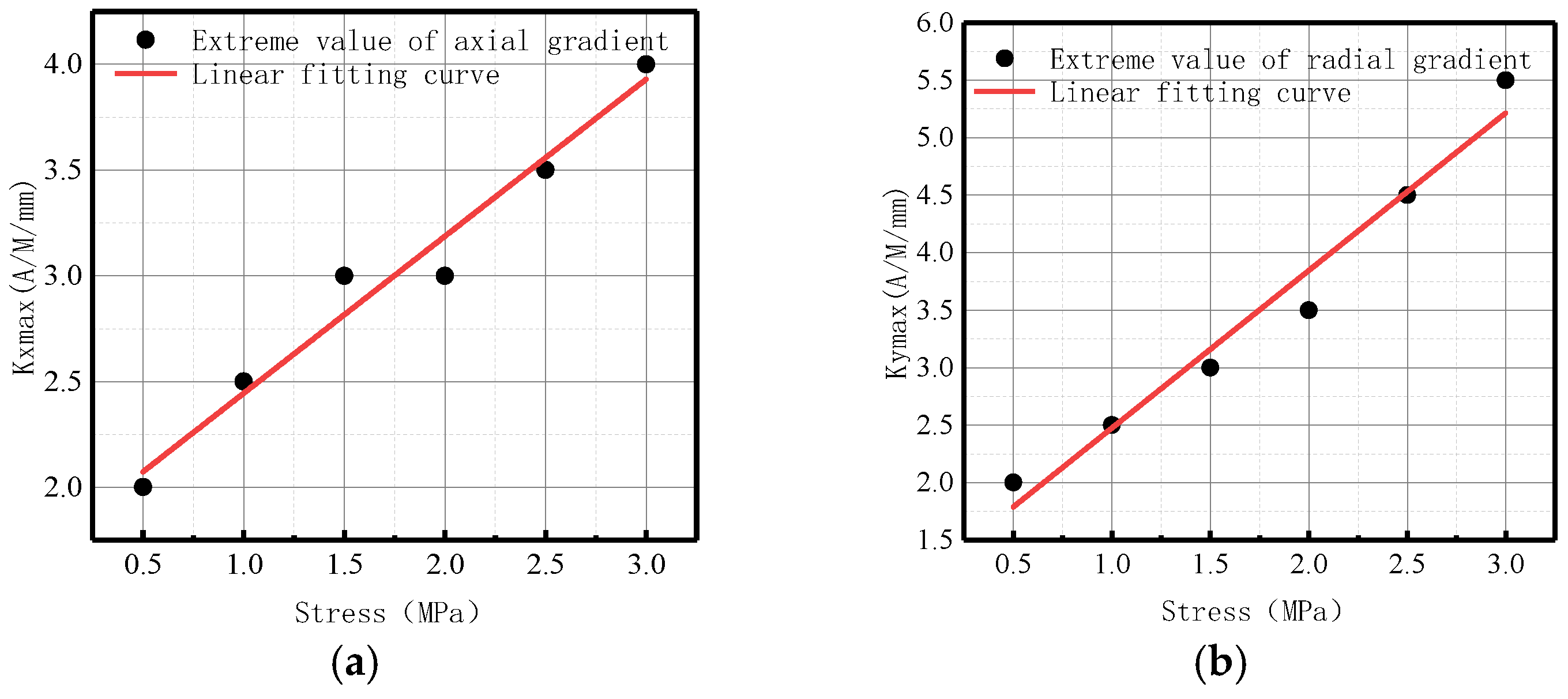

3.1.3. Maximum Magnetic Field Strength Gradient Kmax at Weld Varies

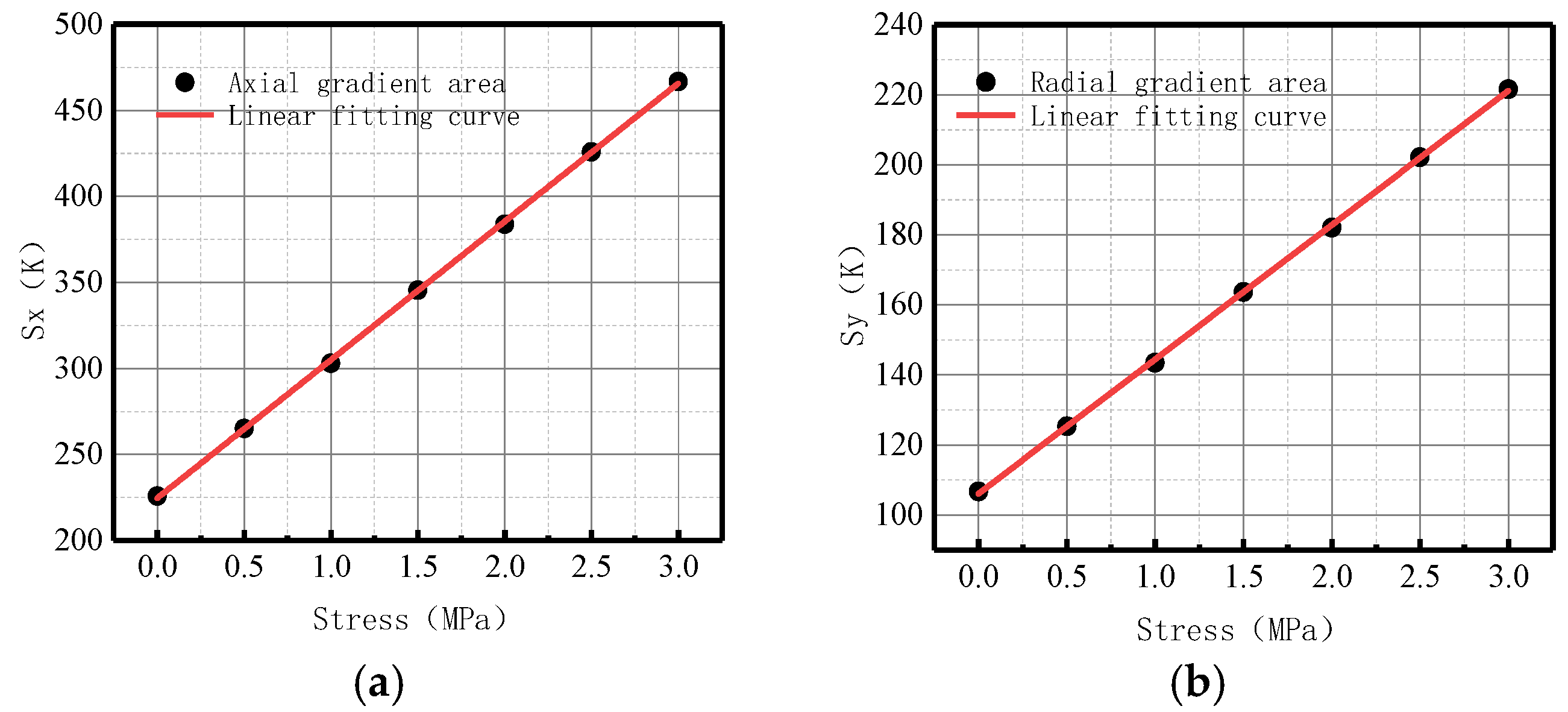

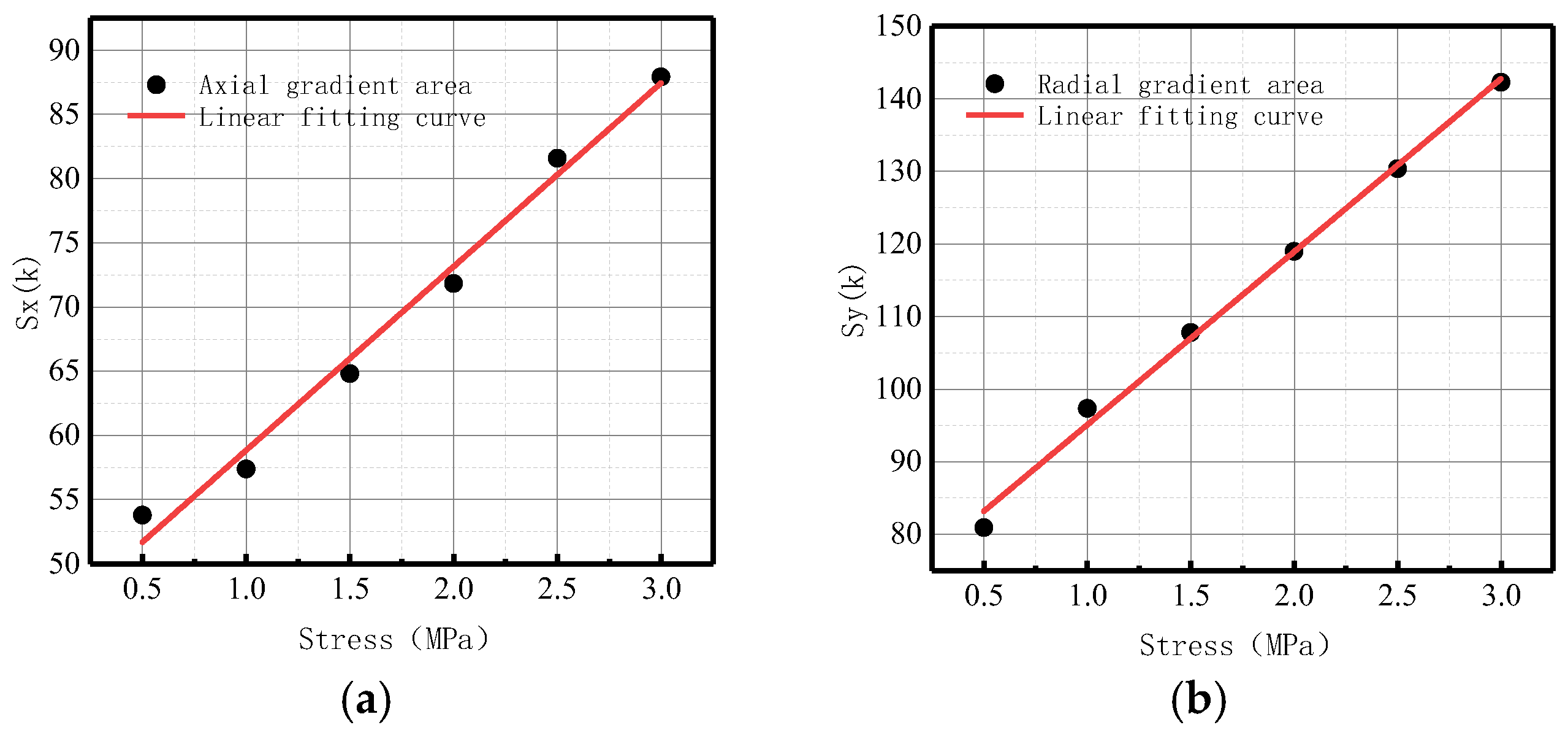

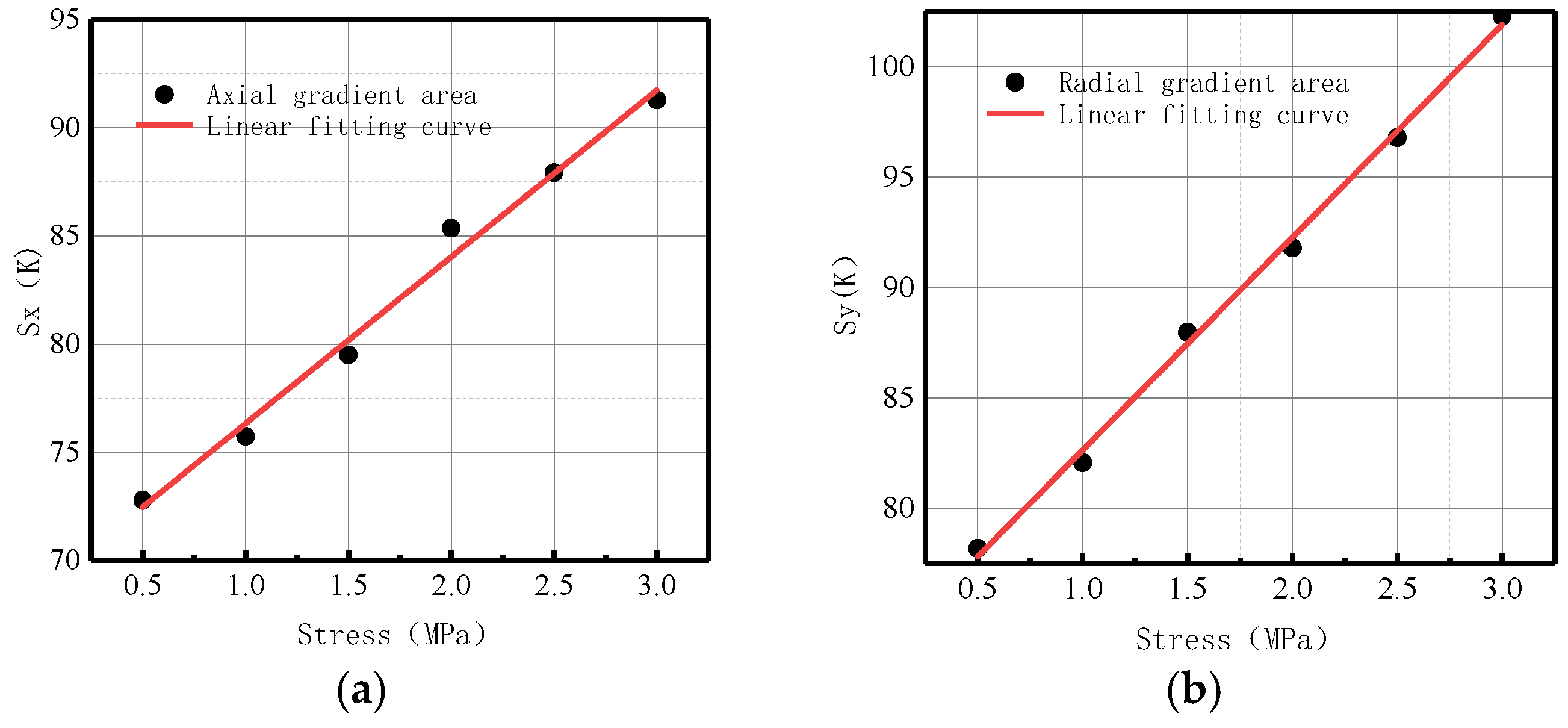

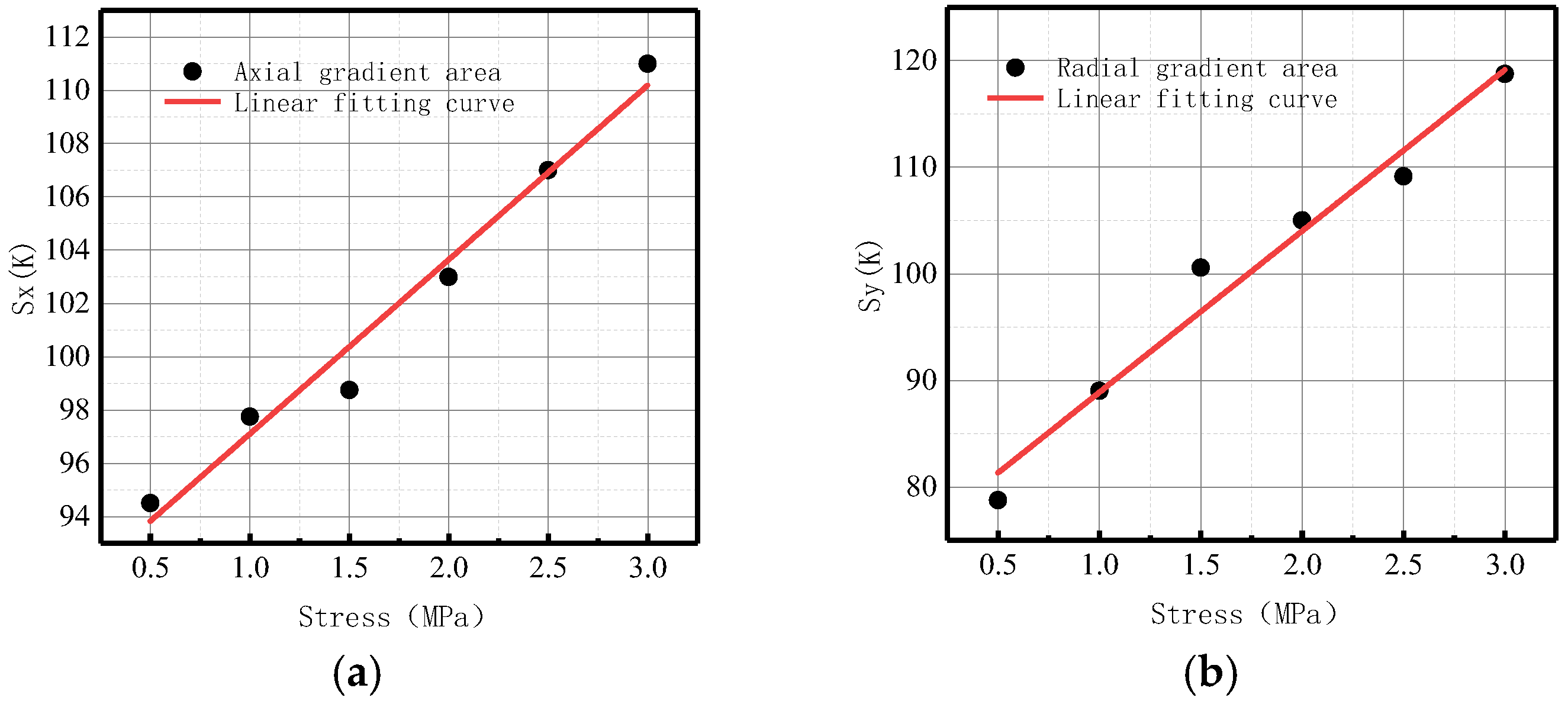

3.1.4. Gradient Energy Factor S(K) at Weld Varies

3.2. Influences of Internal Pressure on the Weak Magnetic Signal of Weld Crack

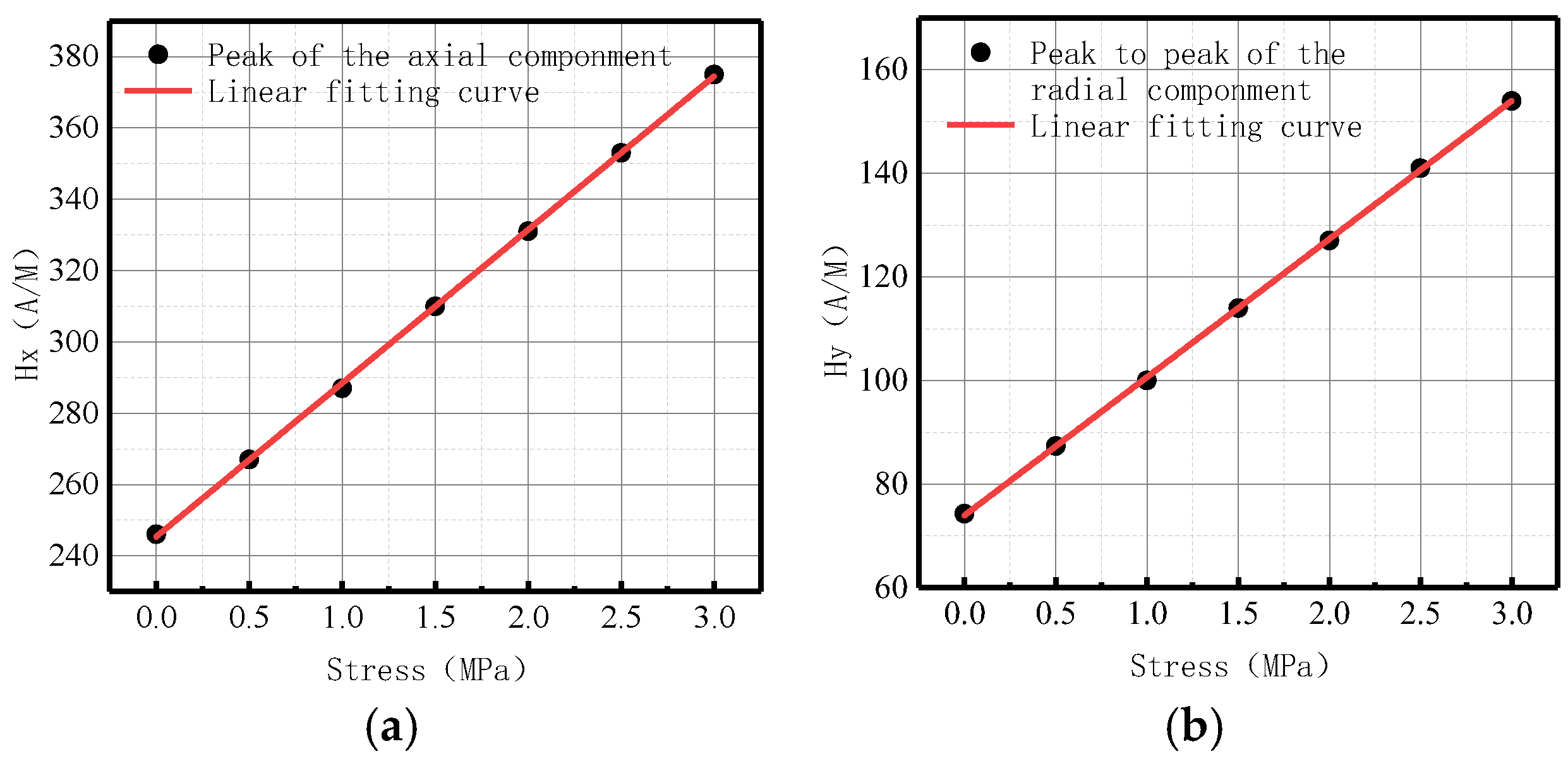

3.2.1. Peak Values in Axial and Radial Components at Weld Crack

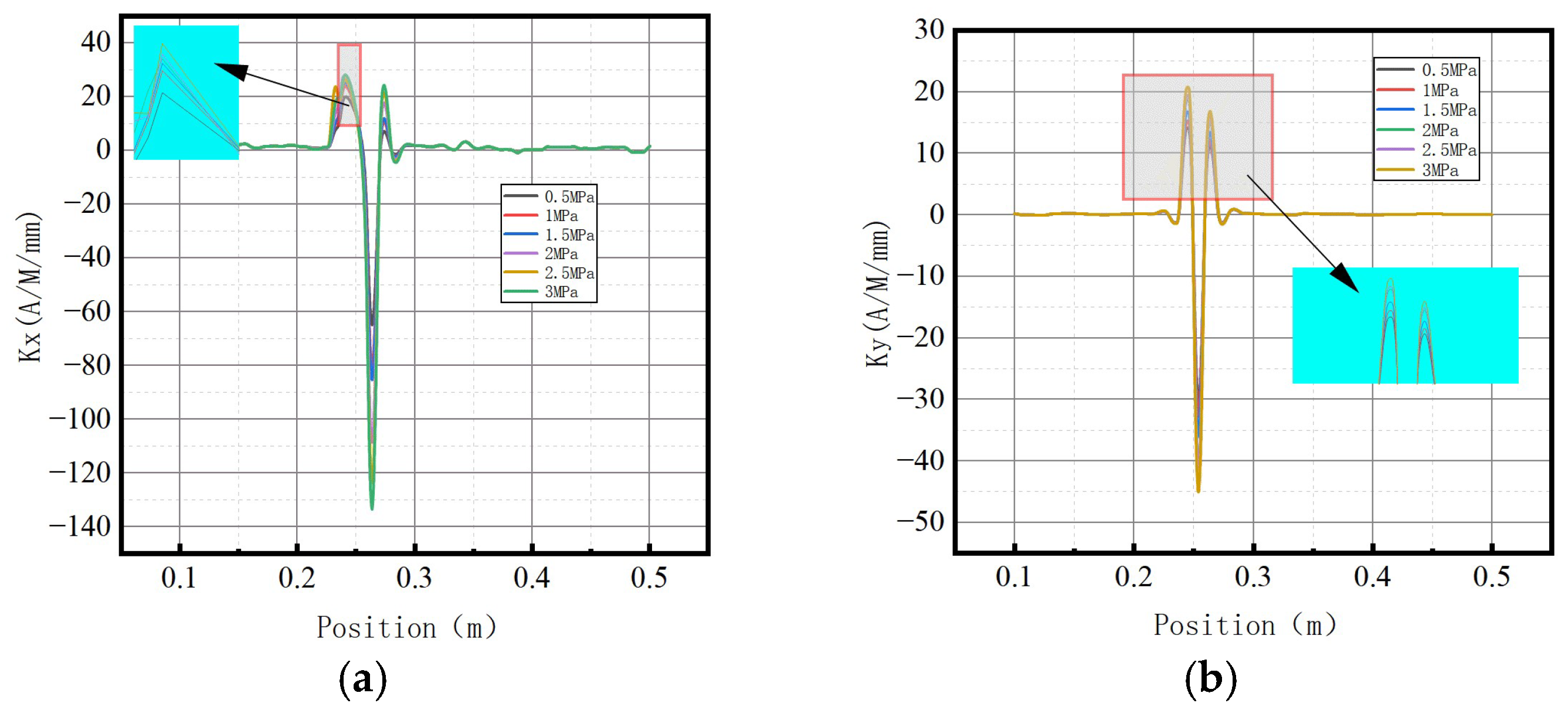

3.2.2. Magnetic Field Strength Gradient K at Weld Crack

3.2.3. Maximum Magnetic Field Strength Gradient Kmax at Weld Crack

3.2.4. Gradient Energy Factor S(K) at Weld Crack

3.3. Effects of Internal Pressure on Weak Magnetic Signal of Pipeline Base Metal Crack

3.3.1. Peak Values in Axial and Radial Components at the Crack of Base Metal

3.3.2. Magnetic Field Strength Gradient K at the Crack of Base Metal

3.3.3. Maximum Magnetic Field Strength Gradient Kmax at the Crack of Base Metal

3.3.4. Gradient Energy Factor S(K) at the Crack of Base Metal

3.4. Comprehensive Analysis of Characteristic Parameters of Weak Magnetic Signals

4. Experiment and Analysis

4.1. Experimental Materials

4.2. Experimental Equipment

4.3. Experimental Methods

4.4. Analysis of the Experimental Results

4.4.1. Weak Magnetic Signal of Weld

- Peak values in axial and radial components

- 2.

- Magnetic field strength gradient K

- 3.

- Maximum magnetic field intensity gradient Kmax

- 4.

- Gradient energy factor S(K)

4.4.2. Weld Crack

- Peak values in axial and radial components

- 2.

- Magnetic field strength gradient K

- 3.

- Maximum magnetic field intensity gradient Kmax

- 4.

- Gradient energy factor S(K)

4.4.3. Crack of Pipe Base Metal

- Peak values in axial and radial components

- 2.

- Magnetic field strength gradient K

- 3.

- Maximum magnetic field intensity gradient Kmax

- 4.

- Gradient energy factor S(K)

4.5. Comprehensive Analysis of Characteristic Parameters

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Li, S.; Chen, S.; Luo, Y.; Zhang, X.; Zhou, S. Discussion on Fracture of Circumferential Weld of High Grade Natural Gas Pipeline. Pet. Tubul. Goods Instrum. 2020, 6, 49–52. [Google Scholar]

- Feng, G. Study on the Characteristics of Weld Crack Signal Based on Magnetic Memory Testing Technology. Master’s Thesis, Shenyang University of Technology, Shenyang, China, 2021. [Google Scholar]

- He, L. Based on the Stress Internal Detection Mechanism of Magnetic Memory Oil and Gas Pipeline. Ph.D. Thesis, Shenyang University of Technology, Shenyang, China, 2020. [Google Scholar]

- Li, G.; Shen, G.; Li, H. Nondestructive testing technologys for industrial pipelines. J. Papers 2006, 28, 89–93. [Google Scholar]

- Li, Q.; Zhao, M.; Ren, X.; Wang, L.; Feng, X.; Niu, Y. Construction status and development trend of Chinese oil & gas pipeline. Oil-Gas Field Surf. Eng. 2019, 38, 14–17. [Google Scholar]

- Bo, Z.; Xiao-Jia, X.U.; Hua-Dong, S. Review of in-pipe inspection technology and systemdevelopment in pipeline. Pipeline Technol. Equip. 2018, 3, 22–25. [Google Scholar]

- Yang, L.; Geng, H.; Gao, S. Internal magnetic leakage detection technology of long oil and gas pipeline. Instrument 2016, 37, 1736–1746. [Google Scholar]

- Xie, S.; Chen, Z.; Takagi, T. Development of A Very Fast Simulator for Pulsed Eddy Current Testing Signals of Local Wall Thinning. NDT E Int. 2012, 51, 45–50. [Google Scholar] [CrossRef]

- Xie, S.; Chen, Z.; Takagi, T. Quantitative Non-destructive Evaluation of Wall Thinning Defect in Double-layer Pipe of Nuclear Power Plants Using Pulsed ECT Method. NDT E Int. 2016, 75, 87–95. [Google Scholar] [CrossRef]

- Liu, B.; He, L.Y.; Zhang, H.; Cao, Y.; Fernandes, H. The Axial Crack Testing Model for Long Distance Oil-gas Pipeline Based on Magnetic Flux Leakage Internal Inspection Method. Measurement 2017, 103, 275–282. [Google Scholar] [CrossRef] [Green Version]

- Xu, K.; Qiu, X.; Tian, X. Investigation of Metal Magnetic Memory Signals of Welding Cracks. J. Nondestruct. Eval. 2017, 36, 20. [Google Scholar] [CrossRef]

- Chen, H.; Wang, C.; Zuo, X. Research on methods of defect classification based on metal magneticmemory. NDT E Int. 2017, 92, 82–87. [Google Scholar] [CrossRef]

- Ni, C.; Hua, L.; Wang, X. Crack propagation analysis and fatigue life prediction for structural alloy steel based on metal magnetic memory testing. J. Magn. Magn. Mater. 2018, 462, 144–152. [Google Scholar] [CrossRef]

- Huang, H.; Qian, Z.; Yang, C.; Han, G.; Liu, Z. Magnetic memory signals of ferromagnetic weldment induced by dynamic bending load. Nondestruct. Test. Eval. 2016, 32, 166–184. [Google Scholar] [CrossRef]

- Liu, B.; Fu, Y.; Ren, J. Modelling and analysis of magnetic memory testing method based on thedensity functional theory. Nondestr. Test. Eval. 2015, 30, 13–25. [Google Scholar] [CrossRef]

- Yao, K.; Wang, Z.D.; Deng, B.; Shen, K. Experimental Research on Metal Magnetic Memory Method. Exp. Mech. 2012, 52, 305–314. [Google Scholar] [CrossRef]

- Zeng, W.G.; Dang, X.F.; Li, S.H.; Wang, H.M.; Wang, H.; Wang, B. Application of non-contact magnetic corresponding on the detection for natural gas pipeline. E3S Web Conf. 2020, 185, 1090. [Google Scholar] [CrossRef]

- He, G.; He, T.; Liao, K.; Zhu, H.; Zhao, S. A Novel Three-Dimensional Non-Contact Magnetic Stress Inspection Technology and Its Application on LNG Pipeline. 2020 13th International Pipeline Conference. 2020. Available online: https://xueshu.baidu.com/usercenter/paper/show?paperid=100c0tx0bx2106b0y9160ad089783964&site=xueshu_se (accessed on 24 December 2022).

- Konnov, V.V. Processing of magnetometric data during remote diagnostics of underground steel pipelines. Oil Gas Bus. 2012, 6, 147–162. [Google Scholar]

- Narkhov, E.D.; Sapunov, V.; Denisov, A.U.; Savelyev, D.V. Novel quantum NMR magnetometer non-contact defectoscopy and monitoring technique for the safe exploitation of gas pipelines. WIT Trans. Ecolog. Environ. 2015, 186, 649–658. [Google Scholar]

- Bhadran, V.; Shukla, A.; Karki, H. Non-contact flaw detection and condition monitoring of subsurface metallic pipelines using magnetometric method. Mater. Today 2020, 28, 860–864. [Google Scholar] [CrossRef]

- Su, S.; Zhao, X.; Wang, W.; Zhang, X. Metal magnetic memory inspection of Q345 steel specimens with butt weld in tensile and bending test. J. Nondestruct. Eval. 2019, 38, 64. [Google Scholar] [CrossRef]

- Lu, W.; Li, J.; Huang, Z.; Chen, Q.; Chen, T. Studies on the magnetic memory testing for the welding cold crack of low alloy high strength steel. Value Eng. 2019, 38, 123–125. [Google Scholar]

- Birss, R.R.; Faunce, C.A.; Isaac, E.D. Magnetomechanical effects in iron and iron-carbon alloys. J. Phys. D Appl. Phys. 1971, 4, 1040–1048. [Google Scholar] [CrossRef]

- Liu, B.; Zheng, S.; He, L.; Zhang, H.; Ren, J. Study on internal detection in oil–gas pipelines based on complex stress magnetomechanical modeling. IEEE Trans. Instrum. Meas. 2019, 69, 5027–5036. [Google Scholar] [CrossRef]

- Liu, Q.Y.; Luo, X.; Zhu, H.Y.; Han, Y.W.; Liu, J.X. Modeling plastic deformation effect on the hysteresis loops of ferromagnetic materials based on modified Jiles-Atherton model. Acta Phys. Sinica. 2017, 66, 107501. [Google Scholar]

- Peng, K. Research on the Mechanism and Performance Evolution of Martensite Phase Transition during the Cold Drawing of 304H Stainless Steel Wire. Master’s Thesis, Wuhan University of Science and Technology, Wuhan, China, 2021. [Google Scholar]

- Li, Y.; Yu, D.; Li, B.; Chen, X. Martensitic transformation of anaustenitic stainless steel under non-proportional cyclic loading. Int. J. Fatigue 2019, 124, 338–347. [Google Scholar] [CrossRef]

- Hu, B.; Liu, Y.; Yu, R. Numerical simulation on magnetic–mechanical behaviors of 304 austenite stainless steel. Measurement 2020, 151, 107185. [Google Scholar] [CrossRef]

- Paul, S.K.; Stanford, N.; Hilditch, T. IJF-2017-austenite plasticitymechanisms and their behavior during cyclic loading. Int. J. Fatigue 2017, 106, 185–195. [Google Scholar] [CrossRef]

- Yang, X. Residual Stress Analysis of Pipe Welding and Its Fatigue Life Assessment. Master’s Thesis, Harbin Engineering University, Harbin, China, 2019. [Google Scholar]

- Wang, C. Numerical Simulation of the Welding Temperature Field and the Stress Field. Master’s Thesis, Shenyang University of Technology, Shenyang, China, 2005. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Fu, Y.; He, L.; Geng, H.; Yang, L. Weak Magnetic Internal Signal Characteristics of Pipe Welds under Internal Pressure. Sensors 2023, 23, 1147. https://doi.org/10.3390/s23031147

Liu B, Fu Y, He L, Geng H, Yang L. Weak Magnetic Internal Signal Characteristics of Pipe Welds under Internal Pressure. Sensors. 2023; 23(3):1147. https://doi.org/10.3390/s23031147

Chicago/Turabian StyleLiu, Bin, Yanduo Fu, Luyao He, Hao Geng, and Lijian Yang. 2023. "Weak Magnetic Internal Signal Characteristics of Pipe Welds under Internal Pressure" Sensors 23, no. 3: 1147. https://doi.org/10.3390/s23031147