Design of Laboratory Stand for Displacement Measurement of IPMC Actuators

Abstract

:1. Introduction

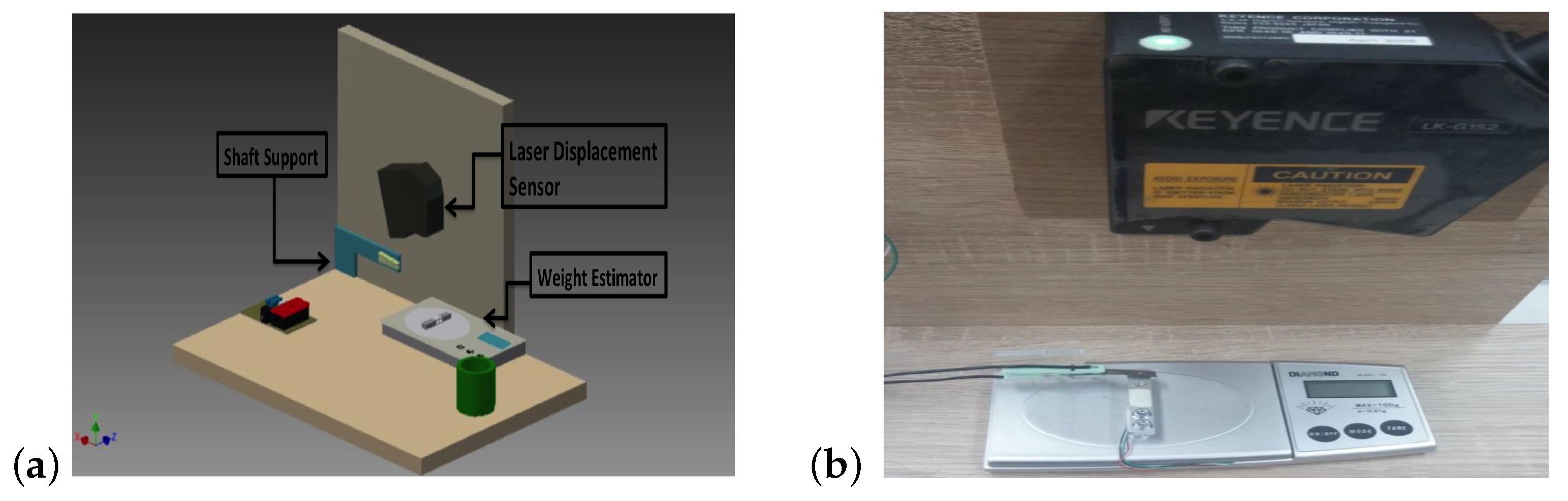

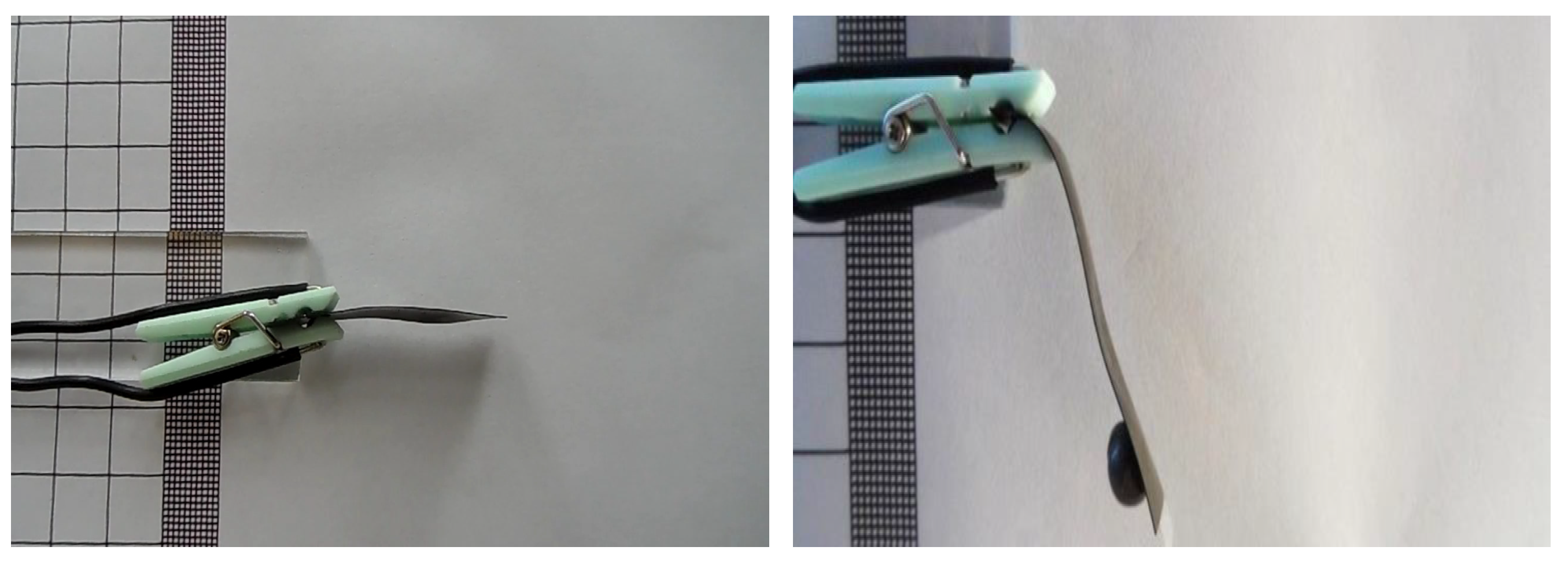

2. Materials

2.1. Electroactive IPMC

2.2. Fabrication of IPMCs

3. Experimental Tests and Setup

4. Results

4.1. Displacement Measurement of the Tested Polymers Using the Laser Method

4.2. Displacement Measurement of Tested Polymers by Image Analysis

4.3. Displacement Measurement of the Tested Polymers under Load

Temperature Dependence of Ionic Electroactive Polymers

5. Conclusions

- For materials powered by a higher voltage value, an increased deflection value was noted for a power supply with a lower value of the output voltage in the system.

- The geometric dimension also has a significant influence on the behavior of the sample.

- In case of displacement, the longer the sample is, the higher the displacement value is.

- On the other hand, by analyzing a sample under load, the length of the sample affects adversely its performance, resulting in an increase in the load on the sample.

- The movement is less stable and smaller for the lowest weight sample value.

- The thickness of the sample is also of great importance. For samples of thick sized, a more stable movement with and without load can be noticed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Neuhaus, R.; Zahiri, N.; Petrs, J.; Tahouni, Y.; Siegert, J.; Kolaric, I.; Dahy, H.; Bauernhansl, T. Integrating ionic electroactive polymer actuators and sensors into adaptive building skins–potentials and limitations. Front. Built Environ. 2020, 6, 95. [Google Scholar] [CrossRef]

- Maksimkin, A.V.; Dayyoub, T.; Telyshev, D.V.; Gerasimenko, A.Y. Electroactive Polymer-Based Composites for Artificial Muscle-like Actuators: A Review. Nanomaterials 2022, 12, 2272. [Google Scholar] [CrossRef] [PubMed]

- Mierzwa-Hersztek, M.; Gondek, K.; Kopeć, M. Degradation of polyethylene and biocomponent-derived polymer materials: An overview. J. Polym. Environ. 2019, 27, 600–611. [Google Scholar] [CrossRef] [Green Version]

- Tabata, Y.; Ikada, Y. Phagocytosis of polymer microspheres by macrophages. In New Polymer Materials; Advances in Polymer Science" book series; Springer: Berlin/Heidelberg, Germany, 1990; pp. 107–141, Conference paper, part of the “Advances in Polymer Science” book series (POLYMER, volume 94). [Google Scholar]

- Tian, X.; Liu, Y.; Wang, K.; Wang, J. Response Mechanism of Soil Carbon and Nitrogen Transformation to Polymer Materials Under Drip Irrigation. J. Soil Sci. Plant Nutr. 2022, 22, 1351–1361. [Google Scholar] [CrossRef]

- Park, S.W.; Kim, S.J.; Park, S.H.; Lee, J.; Kim, H.; Kim, M.K. Recent Progress in Development and Applications of Ionic Polymer–Metal Composite. Micromachines 2022, 13, 1290. [Google Scholar] [CrossRef]

- Chang, L.; Liu, Y.; Yang, Q.; Yu, L.; Liu, J.; Zhu, Z.; Lu, P.; Wu, Y.; Hu, Y. Ionic electroactive polymers used in bionic robots: A review. J. Bionic Eng. 2018, 15, 765–782. [Google Scholar] [CrossRef]

- Soares, G.; Vázquez-Fernández, N.; Hokka, M. Thermomechanical Behavior of Steels in Tension Studied with Synchronized Full-Field Deformation and Temperature Measurements. Exp. Tech. 2021, 45, 627–643. [Google Scholar] [CrossRef]

- Yesaswi, C.S.; Sreekanth, P. Characterisation of Silver-coated Teflon fabric-reinforced Nafion ionic polymer metal composite with carbon nanotubes and graphene nanoparticles. Iran. Polym. J. 2022, 31, 485–502. [Google Scholar] [CrossRef]

- Al Abeach, L.; Nefti-Meziani, S.; Theodoridis, T.; Davis, S. A variable stiffness soft gripper using granular jamming and biologically inspired pneumatic muscles. J. Bionic Eng. 2018, 15, 236–246. [Google Scholar] [CrossRef]

- Kamely, N. Interaction of Light with Different Electroactive Materials: A Review. J. Electron. Mater. 2022, 51, 953–965. [Google Scholar] [CrossRef]

- Reedlunn, B.; Daly, S.; Hector, L.; Zavattieri, P.; Shaw, J. Tips and tricks for characterizing shape memory wire part 5: Full-field strain measurement by digital image correlation. Exp. Tech. 2013, 37, 62–78. [Google Scholar] [CrossRef] [Green Version]

- De, A.; Pal, A.; Ash, D.; Das, K.; Mondal, K.; Dhar, P.; Chakraborty, R.; Rakshit, P.; Bhattacharya, S.; Bepari, B.; et al. Taste Sensor Using Ionic Polymer Metal Composite. IEEE Sensors Lett. 2021, 5, 1–4. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, M.; Zhang, Z.; Xu, Y.; Xiao, Y.; Li, T. Review of soft linear actuator and the design of a dielectric elastomer linear actuator. Acta Mech. Solida Sin. 2019, 32, 566–579. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.H.; Kim, H.J.; Ahn, S.H.; Hong, S.H.; Chai, M.J.; Kwon, O.E.; Kim, S.C.; Kim, Y.J.; Choi, C.H.; Kim, H.S. Modeling and simulation for a tractor equipped with hydro-mechanical transmission. J. Biosyst. Eng. 2013, 38, 171–179. [Google Scholar] [CrossRef] [Green Version]

- Lim, S.J.; Kwon, H.J.; Kang, Y.S.; Lee, P.U.; Kim, T.J.; Kim, Y.J.; Kim, Y.S. Power analysis of a 3-kW class motor-driven multipurpose walking-type transplanter. J. Biosyst. Eng. 2019, 44, 135–145. [Google Scholar] [CrossRef]

- Bai, X.; Shang, J.; Luo, Z.; Jiang, T.; Yin, Q. Development of amphibious biomimetic robots. J. Zhejiang Univ.-Sci. A 2022, 23, 157–187. [Google Scholar] [CrossRef]

- Vora, J.; Jain, A.; Sheth, M.; Gajjar, K.; Abhishek, K.; Chaudhari, R. A Review on Machining Aspects of Shape Memory Alloys. In Recent Advances in Mechanical Infrastructure; Springer: Berlin/Heidelberg, Germany, 2022; pp. 449–458. [Google Scholar]

- Rodrigues, B.; Saron, C. Electrostatic separation of polymer waste by tribocharging system based on friction with PVC. Int. J. Environ. Sci. Technol. 2021, 19, 1–8. [Google Scholar] [CrossRef]

- Annabestani, M.; Sayad, M.H.; Esmaeili-Dokht, P.; Fardmanesh, M. Toward a High Performance IPMC Soft Actuator using A disturbance-aided method. arXiv 2021, arXiv:2106.13040. [Google Scholar]

- Zhao, D.; Ru, J.; Wang, T.; Wang, Y.; Chang, L. Performance Enhancement of Ionic Polymer-Metal Composite Actuators with Polyethylene Oxide. Polymers 2022, 14, 80. [Google Scholar] [CrossRef]

- Saccardo, M.C.; Zuquello, A.G.; Gonçalves, R.; Tozzi, K.A.; Barbosa, R.; Hirano, L.A.; Scuracchio, C.H. Electromechanical Evaluation of Ionomeric Polymer-Metal Composites Using Video Analysis. Mater. Res. 2021, 24. [Google Scholar] [CrossRef]

- Yu, M.; Li, Y.; He, Q.; Song, L.; Dai, Z. A bionic eye actuated by ionic polymer-metal composite (IPMC) artificial muscle. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) 2011, International Society for Optics and Photonics, San Diego, CA, USA, 7–10 March 2011; Volume 7976, p. 797623. [Google Scholar]

- Park, M.; Kim, J.; Song, H.; Kim, S.; Jeon, M. Fast and Stable Ionic Electroactive Polymer Actuators with PEDOT:PSS/(Graphene–Ag-Nanowires) Nanocomposite Electrodes. Sensors 2018, 18, 3126. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.; Lee, Y.S.; Kabir, M.S.N.; Kang, T.K.; Lee, S.H.; Chung, S.O. Kinematic analysis for design of the transportation part of a tractor-mounted Chinese cabbage collector. J. Biosyst. Eng. 2019, 44, 226–235. [Google Scholar] [CrossRef]

- Ye, Z.; Hou, P.; Chen, Z. 2D maneuverable robotic fish propelled by multiple ionic polymer–metal composite artificial fins. Int. J. Intell. Robot. Appl. 2017, 1, 195–208. [Google Scholar] [CrossRef]

- Zhao, Y.; Sheng, J.; Xu, D.; Gao, M.; Meng, Q.; Wu, D.; Wang, L.; Lv, W.; Chen, Q.; Xiao, J.; et al. Improve the Performance of Mechanoelectrical Transduction of Ionic Polymer-Metal Composites Based on Ordered Nafion Nanofibres by Electrospinning. Polymers 2018, 10, 803. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hwang, T.; Palmre, V.; Nam, J.; Lee, D.C.; Kim, K.J. A new ionic polymer–metal composite based on Nafion/poly (vinyl alcohol-co-ethylene) blends. Smart Mater. Struct. 2015, 24, 105011. [Google Scholar] [CrossRef]

- Jo, C.; Pugal, D.; Oh, I.K.; Kim, K.J.; Asaka, K. Recent advances in ionic polymer–metal composite actuators and their modeling and applications. Prog. Polym. Sci. 2013, 38, 1037–1066. [Google Scholar] [CrossRef]

- MohdIsa, W.; Hunt, A.; HosseinNia, S. Sensing and Self-Sensing Actuation Methods for Ionic Polymer–Metal Composite (IPMC): A Review. Sensors 2019, 19, 3967. [Google Scholar] [CrossRef] [Green Version]

- Luqman, M.; Shaikh, H.; Anis, A.; Al-Zahrani, S.; Alam, M. A Convenient and Simple Ionic Polymer-Metal Composite (IPMC) Actuator Based on a Platinum-Coated Sulfonated Poly(ether ether ketone)–Polyaniline Composite Membrane. Polymers 2022, 14, 668. [Google Scholar] [CrossRef]

- He, C.; Gu, Y.; Zhang, J.; Ma, L.; Yan, M.; Mou, J.; Ren, Y. Preparation and Modification Technology Analysis of Ionic Polymer-Metal Composites (IPMCs). Int. J. Mol. Sci. 2022, 23, 3522. [Google Scholar] [CrossRef]

- Alique, D.; Martinez-Diaz, D.; Sanz, R.; Calles, J.A. Review of supported pd-based membranes preparation by electroless plating for ultra-pure hydrogen production. Membranes 2018, 8, 5. [Google Scholar] [CrossRef] [Green Version]

- Siddikali, P.; Sreekanth, P.R. Performance Evaluation of CNT Reinforcement on Electroless Plating on Solid Free-Form-Fabricated PETG Specimens for Prosthetic Limb Application. Polymers 2022, 14, 3366. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Yip, J. Characterization and actuation of ionic polymer metal composites with various thicknesses and lengths. Polymers 2019, 11, 91. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- elemental-analyzer/keyence. Available online: https://www.keyence.com/products/microscope/elemental-analyzer/ (accessed on 30 December 2022).

- Manaf, E.; Fitzgerald, K.; Higginbotham, C.L.; Lyons, J.G. Computer Vision System: Measuring Displacement and Bending Angle of Ionic Polymer-Metal Composites. Appl. Sci. 2022, 12, 6744. [Google Scholar] [CrossRef]

| Nr Sample | Geometric Dimensions [mm] | Weight [g] | Surface Area [mm] |

|---|---|---|---|

| 1 | 30.5 × 4.4 × 0.3 | 0.1 | 134.2 |

| 2 | 44 × 8 × 0.3 | 0.22 | 320 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koślik, K.; Kowol, P.; Brociek, R.; Wajda, A.; Lo Sciuto, G. Design of Laboratory Stand for Displacement Measurement of IPMC Actuators. Sensors 2023, 23, 1271. https://doi.org/10.3390/s23031271

Koślik K, Kowol P, Brociek R, Wajda A, Lo Sciuto G. Design of Laboratory Stand for Displacement Measurement of IPMC Actuators. Sensors. 2023; 23(3):1271. https://doi.org/10.3390/s23031271

Chicago/Turabian StyleKoślik, Karina, Paweł Kowol, Rafał Brociek, Agata Wajda, and Grazia Lo Sciuto. 2023. "Design of Laboratory Stand for Displacement Measurement of IPMC Actuators" Sensors 23, no. 3: 1271. https://doi.org/10.3390/s23031271