A Novel IoT-Enabled Wireless Sensor Grid for Spatial and Temporal Evaluation of Tracer Gas Dispersion

Abstract

:1. Introduction

2. Materials and Methods

2.1. IoT Applications in Indoor Air

2.2. Background of Different Tracer Gases

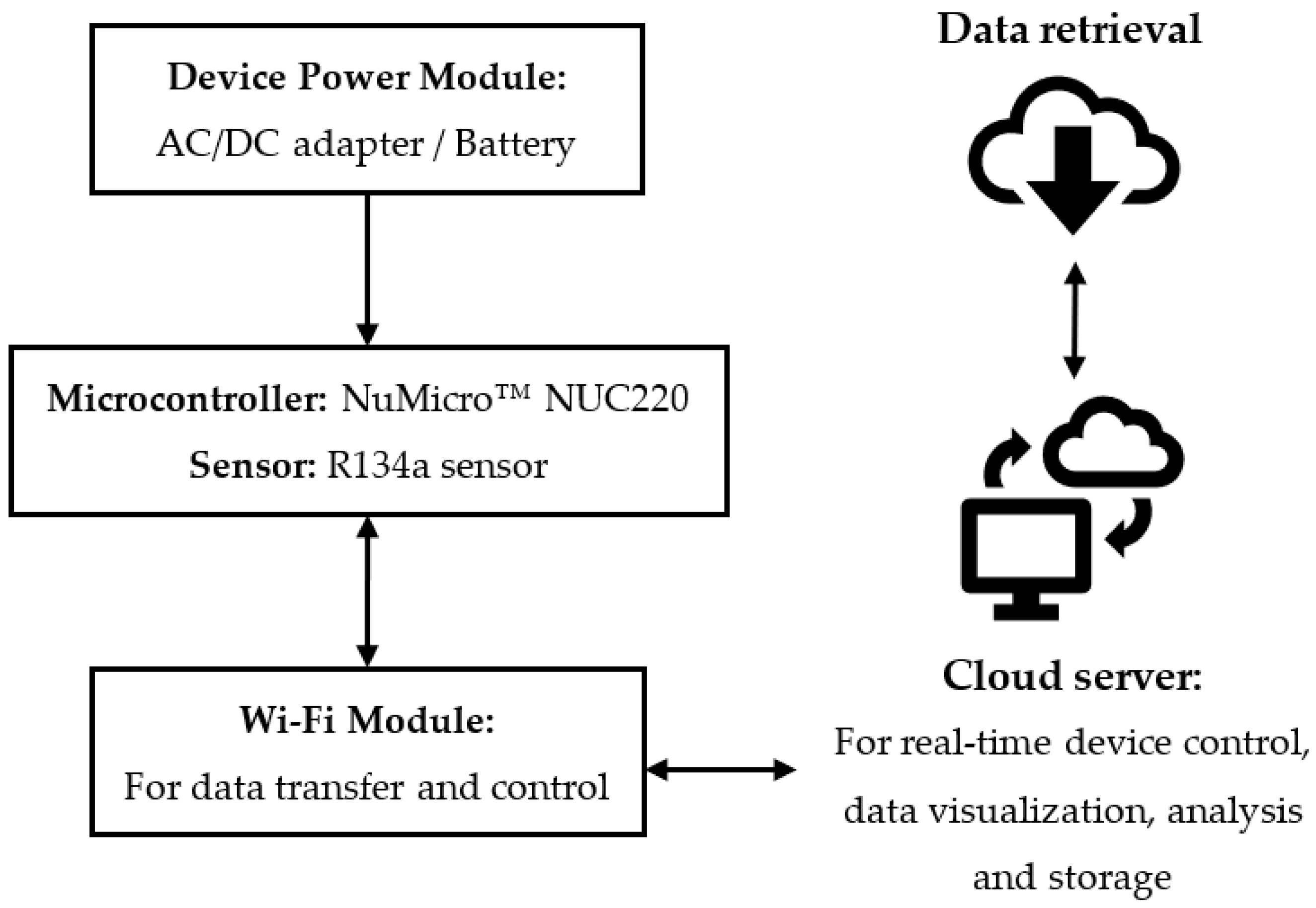

2.3. Development of the R134a Tracer-Gas-Sensing Network

2.3.1. Tracer-Gas-Sensing Network with Calibrated R134a Sensor

2.3.2. Sampling, Data Transfer, Storage, and Real-Time Data Analysis

2.4. Experiment Setup for Systems Comparison

2.4.1. Spatial and Temporal Variation

2.4.2. System Response Time and Ventilation Performance Evaluation

3. Results and Discussion

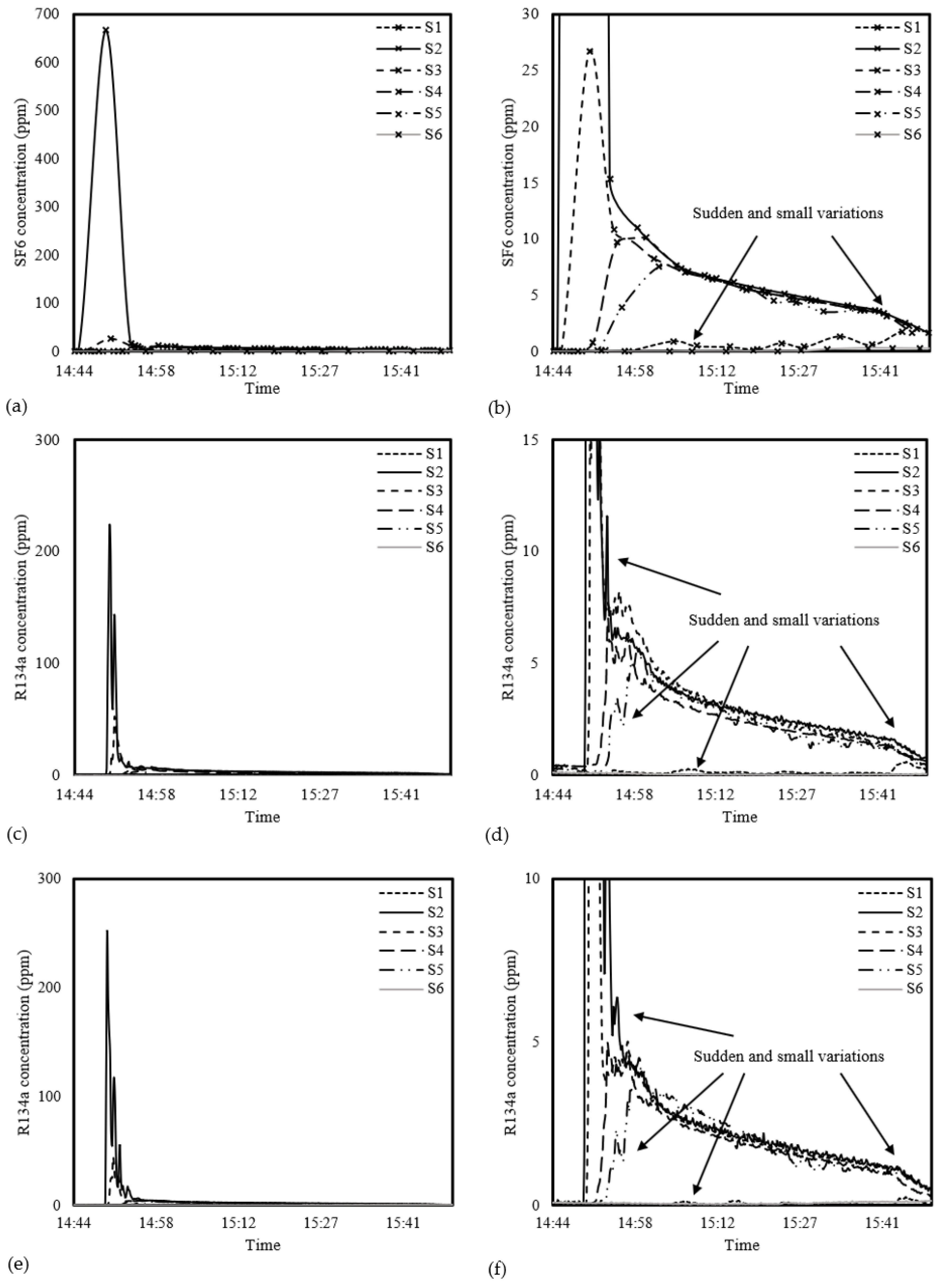

3.1. Identification of Spatial and Temporal Variation

3.2. System Response

3.3. Potential Application and Limitations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Health Organization. Modes of Transmission of Virus Causing COVID-19: Implications for IPC Precaution Recommendations: Scientific Brief, 29 March 2020. Available online: https://www.who.int/news-room/commentaries/detail/modes-of-transmission-of-virus-causing-covid-19-implications-for-ipc-precaution-recommendations (accessed on 26 January 2023).

- Lu, J.; Gu, J.; Li, K.; Xu, C.; Su, W.; Lai, Z.; Zhou, D.; Yu, C.; Xu, B.; Yang, Z. COVID-19 Outbreak Associated with Air Conditioning in Restaurant, Guangzhou, China, 2020. Emerg. Infect. Dis. 2020, 26, 1628–1631. [Google Scholar] [CrossRef] [PubMed]

- Kwon, K.S.; Park, J.I.; Park, Y.J.; Jung, D.M.; Ryu, K.W.; Lee, J.H. Evidence of long-distance droplet transmission of SARS-CoV-2 by direct air flow in a restaurant in Korea. J. Korean Med. Sci. 2020, 35, e415. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Qian, H.; Hang, J.; Chen, X.; Cheng, P.; Ling, H.; Wang, S.; Liang, P.; Li, J.; Xiao, S.; et al. Probable airborne transmission of SARS-CoV-2 in a poorly ventilated restaurant. Build. Environ. 2021, 196, 107788. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Li, C.; Dong, H.; Wang, Z.; Martinez, L.; Sun, Z.; Handel, A.; Chen, Z.; Chen, E.; Ebell, M.; et al. Airborne transmission of COVID-19: Epidemiologic evidence from two outbreak investigations. SSRN 2020. preprint. [Google Scholar] [CrossRef]

- Nissen, K.; Krambrich, J.; Akaberi, D.; Hoffman, T.; Ling, J.; Lundkvist, Å.; Salaneck, E. Long-distance airborne dispersal of SARS-CoV-2 in COVID-19 wards. Sci. Rep. 2020, 10, 1–9. [Google Scholar]

- Hwang, S.E.; Chang, J.H.; Oh, B.; Heo, J. Possible aerosol transmission of COVID-19 associated with an outbreak in an apartment in Seoul, South Korea, 2020. Int. J. Infect. Dis. 2021, 104, 73–76. [Google Scholar] [CrossRef]

- XieXie, X.; Li, Y.; Sun, H.; Liu, L. Exhaled droplets due to talking and coughing. J. R. Soc. Interface 2009, 6, S703–S714. [Google Scholar]

- Morawska, L.J.G.R.; Johnson, G.R.; Ristovski, Z.D.; Hargreaves, M.; Mengersen, K.; Corbett, S.; Chao, C.Y.H.; Li, Y.; Katoshevski, D. Size distribution and sites of origin of droplets expelled from the human respiratory tract during expiratory activities. J. Aerosol Sci. 2009, 40, 256–269. [Google Scholar] [CrossRef] [Green Version]

- Van Doremalen, N.; Bushmaker, T.; Morris, D.H.; Holbrook, M.G.; Gamble, A.; Williamson, B.N.; Tamin, A.; Smith, J.O.L.; de Wit, E.; Munster, V.J. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N. Engl. J. Med. 2020, 382, 1564–1567. [Google Scholar] [CrossRef]

- Tang, J.; Li, Y.; Eames, I.; Chan, P.; Ridgway, G. Factors involved in the aerosol transmission of infection and control of ventilation in healthcare premises. J. Hosp. Infect. 2006, 64, 100–114. [Google Scholar] [CrossRef]

- Li, Y.; Leung, G.M.; Tang, J.W.; Yang, X.; Chao, C.Y.H.; Lin, J.Z.; Lu, J.W.; Nielsen, P.V.; Niu, J.; Qian, H.; et al. Role of ventilation in airborne transmission of infectious agents in the built environment? A multidisciplinary systematic review. Indoor Air 2007, 17, 2–18. [Google Scholar] [CrossRef] [PubMed]

- Tsang, T.-W.; Mui, K.-W.; Wong, L.-T. Computational Fluid Dynamics (CFD) studies on airborne transmission in hospitals: A review on the research approaches and the challenges. J. Build. Eng. 2023, 63, 105533. [Google Scholar] [CrossRef]

- Wu, Y.; Tung, T.C.; Niu, J.-L. On-site measurement of tracer gas transmission between horizontal adjacent flats in residential building and cross-infection risk assessment. Build. Environ. 2016, 99, 13–21. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Lin, Z.; Niu, J.; Choi, G.K.Y.; Fung, J.C.; Lau, A.K.; Louie, P.; Leung, K.K.M.; Huang, J.; Cheng, P.; et al. Spread of SARS-CoV-2 aerosols via two connected drainage stacks in a high-rise housing outbreak of COVID-19. J. Hazard. Mater. 2022, 430, 128475. [Google Scholar] [CrossRef]

- Bivolarova, M.; Ondráček, J.; Melikov, A.; Ždímal, V. A comparison between tracer gas and aerosol particles distribution indoors: The impact of ventilation rate, interaction of airflows, and presence of objects. Indoor Air 2017, 27, 1201–1212. [Google Scholar] [CrossRef] [Green Version]

- Gao, N.; Niu, J.; Perino, M.; Heiselberg, P. The airborne transmission of infection between flats in high-rise residential buildings: Particle simulation. Build. Environ. 2009, 44, 402–410. [Google Scholar] [CrossRef]

- Ai, Z.; Mak, C.M.; Gao, N.; Niu, J. Tracer gas is a suitable surrogate of exhaled droplet nuclei for studying airborne transmission in the built environment. Build. Simul. 2020, 13, 489–496. [Google Scholar] [CrossRef] [Green Version]

- LumaSense Technologies. User Manual for 1303 Multipoint Sampler and Doser; LumaSense Technologies: Santa Clara, CA, USA, 2008. [Google Scholar]

- Bolashikov, Z.D.; Barova, M.; Melikov, A.K. Wearable personal exhaust ventilation: Improved indoor air quality and reduced exposure to air exhaled from a sick doctor. Sci. Technol. Built Environ. 2015, 21, 1117–1125. [Google Scholar] [CrossRef] [Green Version]

- Saini, J.; Dutta, M.; Marques, G. Sensors for indoor air quality monitoring and assessment through Internet of Things: A systematic review. Environ. Monit. Assess. 2021, 193, 66. [Google Scholar] [CrossRef]

- Chojer, H.; Branco, P.; Martins, F.; Alvim-Ferraz, M.; Sousa, S. Development of low-cost indoor air quality monitoring devices: Recent advancements. Sci. Total. Environ. 2020, 727, 138385. [Google Scholar] [CrossRef]

- Peladarinos, N.; Cheimaras, V.; Piromalis, D.; Arvanitis, K.G.; Papageorgas, P.; Monios, N.; Dogas, I.; Stojmenovic, M.; Tsaramirsis, G. Early Warning Systems for COVID-19 Infections Based on Low-Cost Indoor Air-Quality Sensors and LPWANs. Sensors 2021, 21, 6183. [Google Scholar] [CrossRef] [PubMed]

- Sherman, M. Tracer-gas techniques for measuring ventilation in a single zone. Build. Environ. 1990, 25, 365–374. [Google Scholar] [CrossRef]

- Fu, L.; Yang, M.; Niu, J.; Ren, W.; You, R. Transient tracer gas measurements: Development and evaluation of a fast-response SF 6 measuring system based on quartz-enhanced photoacoustic spectroscopy. Indoor Air 2022, 32, e12952. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Pan, Z.; Li, C. Tempo-spatial infection risk assessment of airborne virus via CO2 concentration field monitoring in built environment. Build. Environ. 2022, 217, 109067. [Google Scholar] [CrossRef] [PubMed]

- Weimann, J. Toxicity of nitrous oxide. Best Pr. Res. Clin. Anaesthesiol. 2003, 17, 47–61. [Google Scholar] [CrossRef]

- Olmedo, I.; Berlanga, F.; Villafruela, J.; de Adana, M.R. Experimental variation of the personal exposure in a hospital room influenced by wall heat gains. Build. Environ. 2019, 154, 252–262. [Google Scholar] [CrossRef]

- Berlanga, F.A.; de Adana, M.R.; Olmedo, I.; Villafruela, J.M.; San José, J.F.; Castro, F. Experimental evaluation of thermal comfort, ventilation performance indices and exposure to airborne contaminant in an airborne infection isolation room equipped with a displacement air distribution system. Energy Build. 2018, 158, 209–221. [Google Scholar] [CrossRef] [Green Version]

- Berlanga, F.A.; Olmedo, I.; de Adana, M.R.; Villafruela, J.M.; San José, J.F.; Castro, F. Experimental assessment of different mixing air ventilation systems on ventilation performance and exposure to exhaled contaminants in hospital rooms. Energy Build. 2018, 177, 207–219. [Google Scholar] [CrossRef] [Green Version]

- Tomasi, R.; Krajčík, M.; Simone, A.; Olesen, B. Experimental evaluation of air distribution in mechanically ventilated residential rooms: Thermal comfort and ventilation effectiveness. Energy Build. 2013, 60, 28–37. [Google Scholar] [CrossRef]

- Krajčík, M.; Simone, A.; Olesen, B.W. Air distribution and ventilation effectiveness in an occupied room heated by warm air. Energy Build. 2012, 55, 94–101. [Google Scholar] [CrossRef]

- Bolashikov, Z.; Melikov, A.K.; Spilak, M.; Nastase, I.; Meslem, A. Improved inhaled air quality at reduced ventilation rate by control of airflow interaction at the breathing zone with lobed jets. HVAC&R Res. 2014, 20, 238–250. [Google Scholar]

- Ko, M.K.W.; Sze, N.-D.; Rodríguez, J.M.; Weistenstein, D.K.; Heisey, C.W.; Wayne, R.P.; Biggs, P.; Canosa-Mas, C.E.; Sidebottom, H.W.; Treacy, J. CF3chemistry: Potential implications for stratospheric ozone. Geophys. Res. Lett. 1994, 21, 101–104. [Google Scholar] [CrossRef]

- Barker, P.; Cary, R.; Dobson, S. World Health Organization & International Programme on Chemical Safety. 1,1,1,2-Tetrafluoroethane; World Health Organization: Geneva, Switzerland, 1999. [Google Scholar]

- Ehhalt, D.; Prather, M.; Dentener, F.; Derwent, R.; Dlugokencky, E.; Holland, E.; Isaksen, I.; Katima, J.; Kirchhoff, V.; Matson, P.; et al. Atmospheric Chemistry and Greenhouse Gases. In Climate Change 2001: The Scientific Basis. Contribution of Working Group I to the Third Assessment Report of the Intergovernmental Panel on Climate Change; Houghton, J.T., Ding, Y., Griggs, D.J., Noguer, M., van der Linden, P.J., Dai, X., Maskell, K., Johnson, C.A., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2001; pp. 241–280. [Google Scholar]

- Cui, S.; Cohen, M.; Stabat, P.; Marchio, D. CO2 tracer gas concentration decay method for measuring air change rate. Build. Environ. 2015, 84, 162–169. [Google Scholar] [CrossRef]

- Figaro. TGS 3830—For the Detection Chlorofluorocarbons (CFCs)—Product Information; Figaro: Rolling Meadows, IL, USA, 2016. [Google Scholar]

- Espressif Systems. ESP-WROOM-02D/02U Datasheet; Espressif Systems: Shanghai, China, 2023. [Google Scholar]

- Giorgino, T. Computing and visualizing dynamic time warping alignments in R: The dtw package. J. Stat. Softw. 2009, 31, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Senin, P. Dynamic Time Warping Algorithm Review; Information and Computer Science Department University of Hawaii: Manoa Honolulu, HI, USA, 2008; pp. 1–23. Available online: https://csdl.ics.hawaii.edu/techreports/2008/08-04/08-04.pdf (accessed on 26 January 2023).

- Laussmann, D.; Helm, D. Air change measurements using tracer gases: Methods and results. Significance of air change for indoor air quality. In Chemistry, Emission Control, Radioactive Pollution and Indoor Air Quality; IntechOpen: London, UK, 2011. [Google Scholar]

- Martín-Garín, A.; Millán-García, J.; Baïri, A.; Millán-Medel, J.; Sala-Lizarraga, J. Environmental monitoring system based on an Open Source Platform and the Internet of Things for a building energy retrofit. Autom. Constr. 2018, 87, 201–214. [Google Scholar] [CrossRef]

- Ali, A.S.; Zanzinger, Z.; Debose, D.; Stephens, B. Open Source Building Science Sensors (OSBSS): A low-cost Arduino-based platform for long-term indoor environmental data collection. Build. Environ. 2016, 100, 114–126. [Google Scholar] [CrossRef] [Green Version]

- Carre, A.; Williamson, T. Design and validation of a low cost indoor environment quality data logger. Energy Build. 2018, 158, 1751–1761. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.U.; Khan, M.E.; Hasan, M.; Zakri, W.; Alhazmi, W.; Islam, T. An Efficient Wireless Sensor Network Based on the ESP-MESH Protocol for Indoor and Outdoor Air Quality Monitoring. Sustainability 2022, 14, 16630. [Google Scholar] [CrossRef]

| Receiver C | Receiver B | |||||

|---|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | S5 | S6 | |

| S1 | 22.2 | 1074.5 | 1395.2 | 1526.8 | 1038.8 | 361.7 |

| S2 | 2982.0 | 1123.6 | 1568.9 | 1961.7 | 2051.8 | 2746.9 |

| S3 | 1329.6 | 537.0 | 140.6 | 136.5 | 222.6 | 926.1 |

| S4 | 2610.2 | 738.7 | 338.3 | 322.8 | 796.9 | 2206.7 |

| S5 | 632.4 | 606.8 | 533.8 | 667.3 | 225.9 | 160.3 |

| S6 | 342.1 | 733.0 | 876.1 | 1128.0 | 543.7 | 47.5 |

| S1-A | S1-B | S1-C | S2-A | S2-B | S2-C | S3-A | S3-B | S3-C | S4-A | S4-B | S4-C | S5-A | S5-B | S5-C | S6-A | S6-B | S6-C | |

| S1-A | 1.000 | 0.652 | 0.725 | −0.258 | −0.258 | −0.263 | −0.196 | −0.278 | −0.250 | 0.155 | 0.003 | 0.048 | 0.282 | 0.166 | 0.202 | 0.698 | −0.616 | 0.112 |

| S1-B | 0.652 | 1.000 | 0.854 | −0.217 | −0.217 | −0.218 | −0.172 | −0.209 | −0.209 | 0.120 | 0.051 | 0.073 | 0.187 | 0.129 | 0.160 | 0.446 | −0.378 | 0.138 |

| S1-C | 0.725 | 0.854 | 1.000 | −0.224 | −0.228 | −0.228 | −0.206 | −0.256 | −0.229 | 0.066 | −0.050 | −0.016 | 0.228 | 0.150 | 0.195 | 0.444 | −0.434 | 0.005 |

| S2-A | −0.258 | −0.217 | −0.224 | 1.000 | 0.998 | 1.000 | 0.889 | 0.918 | 0.979 | −0.318 | −0.292 | −0.320 | −0.367 | −0.331 | −0.340 | −0.155 | 0.508 | −0.002 |

| S2-B | −0.258 | −0.217 | −0.228 | 0.998 | 1.000 | 0.999 | 0.912 | 0.938 | 0.989 | −0.268 | −0.240 | −0.269 | −0.328 | −0.286 | −0.298 | −0.175 | 0.490 | −0.025 |

| S2-C | −0.263 | −0.218 | −0.228 | 1.000 | 0.999 | 1.000 | 0.893 | 0.922 | 0.981 | −0.311 | −0.281 | −0.311 | −0.367 | −0.328 | −0.339 | −0.159 | 0.512 | 0.000 |

| S3-A | −0.196 | −0.172 | −0.206 | 0.889 | 0.912 | 0.893 | 1.000 | 0.991 | 0.963 | 0.147 | 0.163 | 0.139 | −0.012 | 0.047 | 0.027 | −0.242 | 0.297 | −0.155 |

| S3-B | −0.278 | −0.209 | −0.256 | 0.918 | 0.938 | 0.922 | 0.991 | 1.000 | 0.978 | 0.064 | 0.109 | 0.076 | −0.120 | −0.041 | −0.068 | −0.281 | 0.416 | −0.103 |

| S3-C | −0.250 | −0.209 | −0.229 | 0.979 | 0.989 | 0.981 | 0.963 | 0.978 | 1.000 | −0.123 | −0.095 | −0.124 | −0.250 | −0.202 | −0.215 | −0.194 | 0.457 | −0.038 |

| S4-A | 0.155 | 0.120 | 0.066 | −0.318 | −0.268 | −0.311 | 0.147 | 0.064 | −0.123 | 1.000 | 0.963 | 0.982 | 0.858 | 0.896 | 0.875 | −0.215 | −0.578 | −0.458 |

| S4-B | 0.003 | 0.051 | −0.050 | −0.292 | −0.240 | −0.281 | 0.163 | 0.109 | −0.095 | 0.963 | 1.000 | 0.996 | 0.706 | 0.797 | 0.754 | −0.291 | −0.378 | −0.335 |

| S4-C | 0.048 | 0.073 | −0.016 | −0.320 | −0.269 | −0.311 | 0.139 | 0.076 | −0.124 | 0.982 | 0.996 | 1.000 | 0.761 | 0.834 | 0.798 | −0.277 | −0.452 | −0.386 |

| S5-A | 0.282 | 0.187 | 0.228 | −0.367 | −0.328 | −0.367 | −0.012 | −0.120 | −0.250 | 0.858 | 0.706 | 0.761 | 1.000 | 0.967 | 0.984 | −0.215 | −0.781 | −0.649 |

| S5-B | 0.166 | 0.129 | 0.150 | −0.331 | −0.286 | −0.328 | 0.047 | −0.041 | −0.202 | 0.896 | 0.797 | 0.834 | 0.967 | 1.000 | 0.993 | −0.366 | −0.626 | −0.663 |

| S5-C | 0.202 | 0.160 | 0.195 | −0.340 | −0.298 | −0.339 | 0.027 | −0.068 | −0.215 | 0.875 | 0.754 | 0.798 | 0.984 | 0.993 | 1.000 | −0.304 | −0.679 | −0.660 |

| S6-A | 0.698 | 0.446 | 0.444 | −0.155 | −0.175 | −0.159 | −0.242 | −0.281 | −0.194 | −0.215 | −0.291 | −0.277 | −0.215 | −0.366 | −0.304 | 1.000 | −0.197 | 0.743 |

| S6-B | −0.616 | −0.378 | −0.434 | 0.508 | 0.490 | 0.512 | 0.297 | 0.416 | 0.457 | −0.578 | −0.378 | −0.452 | −0.781 | −0.626 | −0.679 | −0.197 | 1.000 | 0.426 |

| S6-C | 0.112 | 0.138 | 0.005 | −0.002 | −0.025 | 0.000 | −0.155 | −0.103 | −0.038 | −0.458 | −0.335 | −0.386 | −0.649 | −0.663 | −0.660 | 0.743 | 0.426 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsang, T.-W.; Mui, K.-W.; Wong, L.-T.; Law, K.-Y.; Shek, K.-W. A Novel IoT-Enabled Wireless Sensor Grid for Spatial and Temporal Evaluation of Tracer Gas Dispersion. Sensors 2023, 23, 3920. https://doi.org/10.3390/s23083920

Tsang T-W, Mui K-W, Wong L-T, Law K-Y, Shek K-W. A Novel IoT-Enabled Wireless Sensor Grid for Spatial and Temporal Evaluation of Tracer Gas Dispersion. Sensors. 2023; 23(8):3920. https://doi.org/10.3390/s23083920

Chicago/Turabian StyleTsang, Tsz-Wun, Kwok-Wai Mui, Ling-Tim Wong, Kwok-Yung Law, and Ka-Wing Shek. 2023. "A Novel IoT-Enabled Wireless Sensor Grid for Spatial and Temporal Evaluation of Tracer Gas Dispersion" Sensors 23, no. 8: 3920. https://doi.org/10.3390/s23083920