Correction of Error of Airborne Anemometers Caused by Self-Excited Air Turbulence

Abstract

:1. Introduction

2. Methods

2.1. Basic Control Equation

2.2. Calculation Method

2.3. Turbulence Model

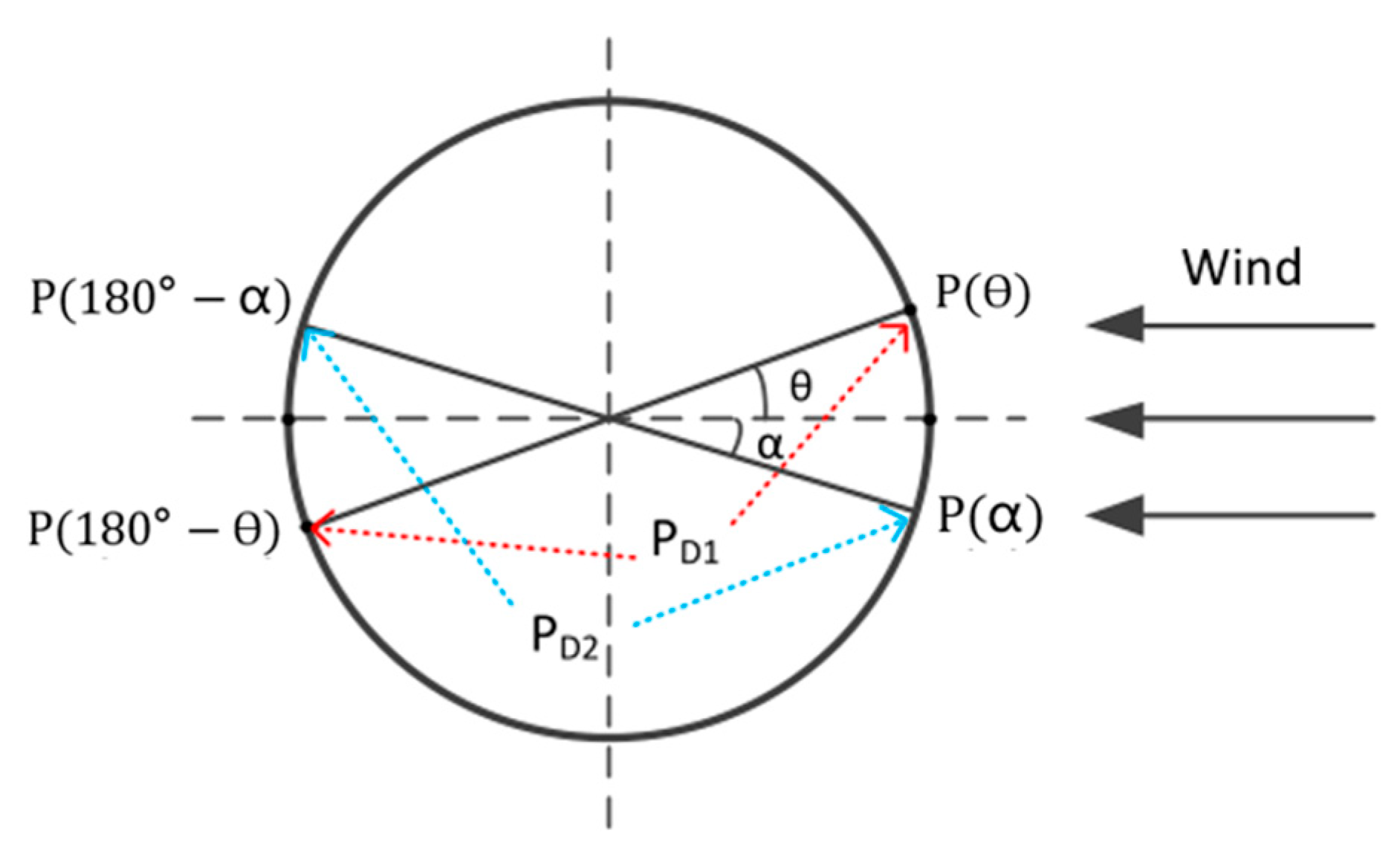

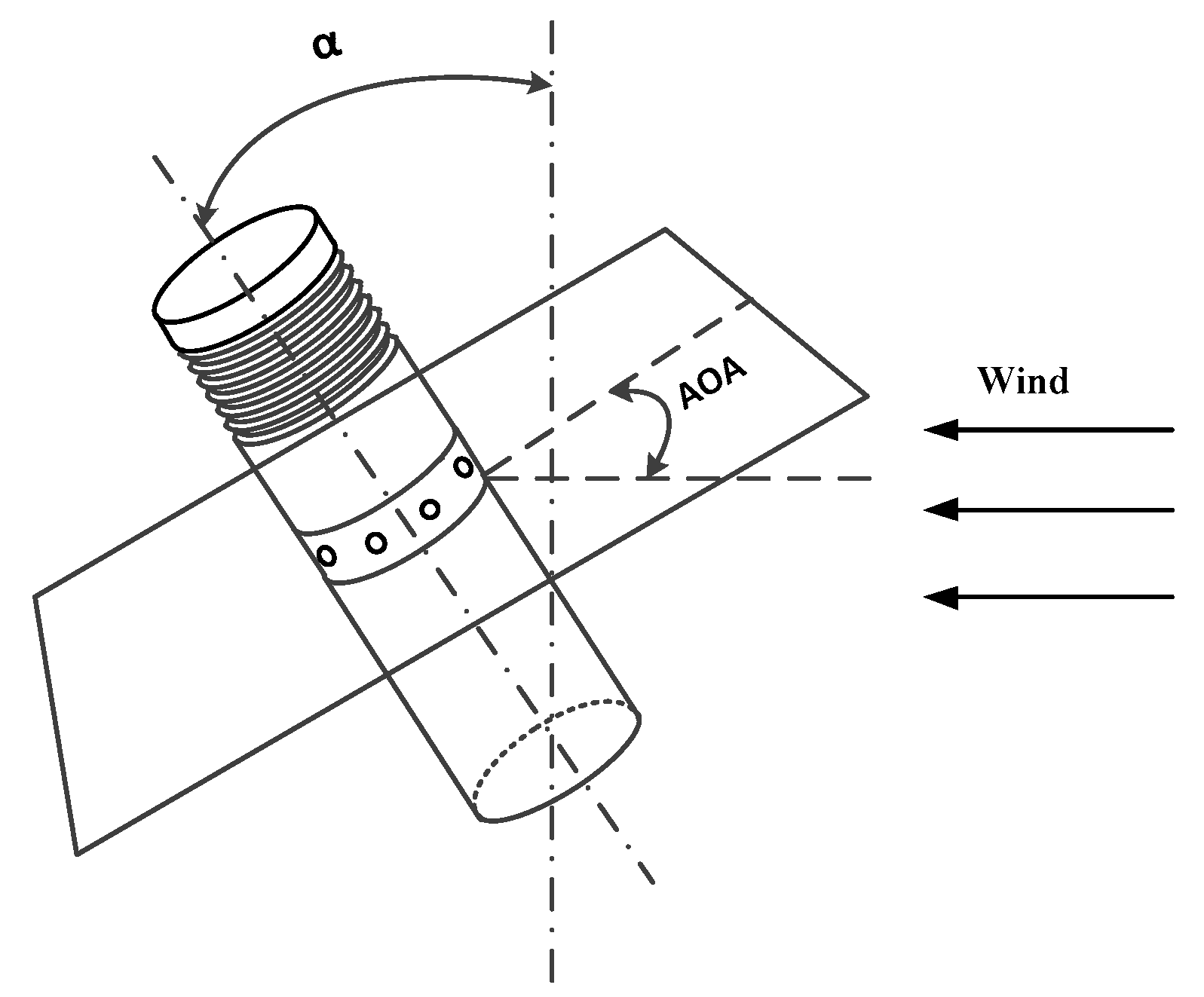

2.4. Correction Model of the Angle of Attack

3. Simulation and Modeling

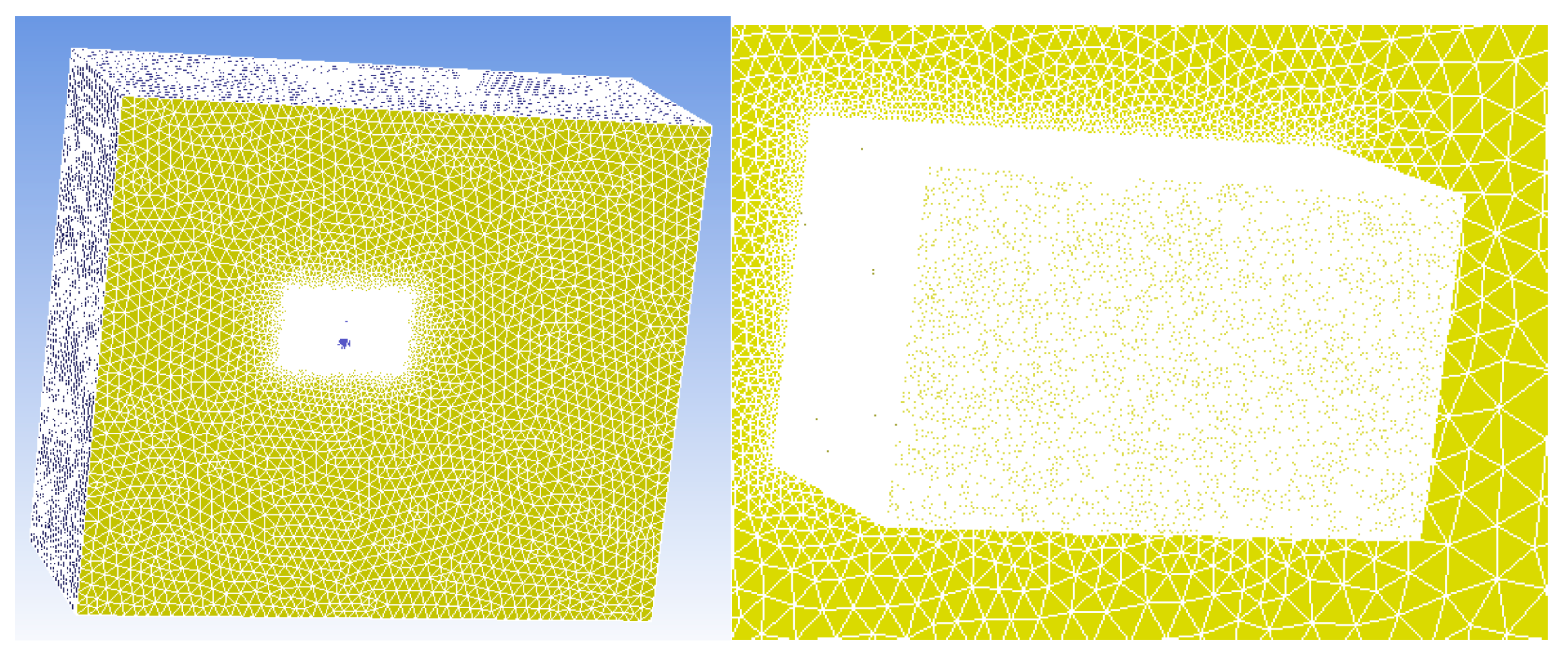

3.1. Mesh and Boundary Conditions

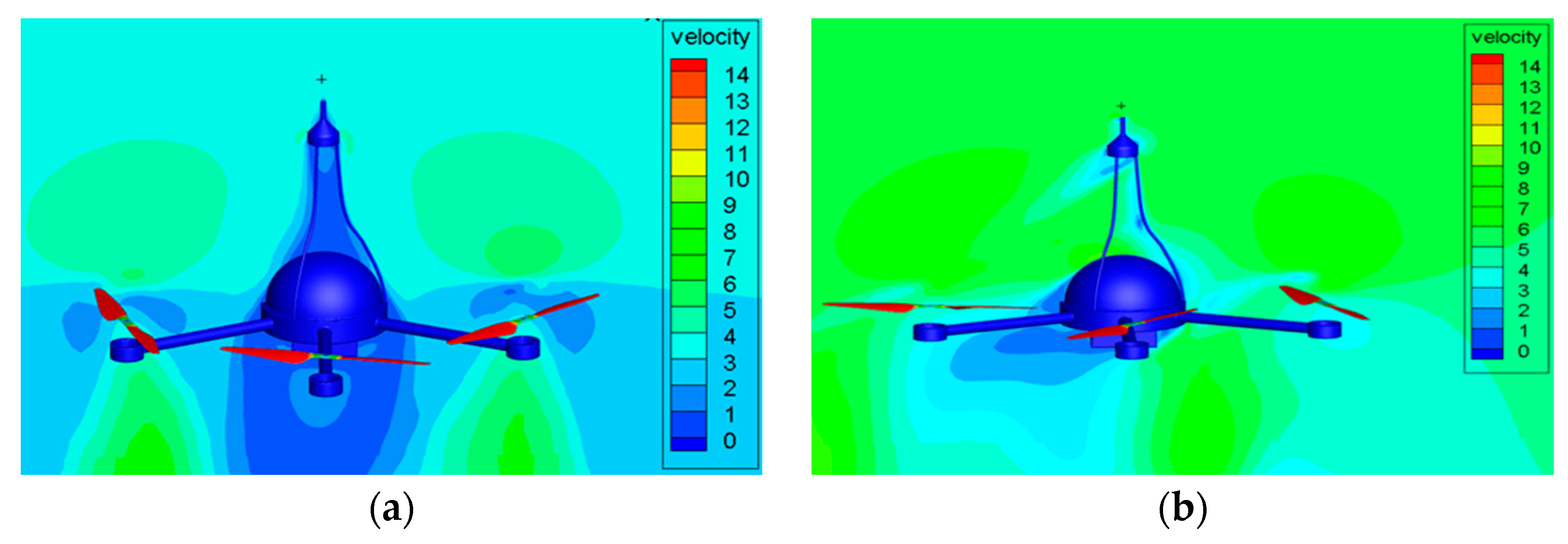

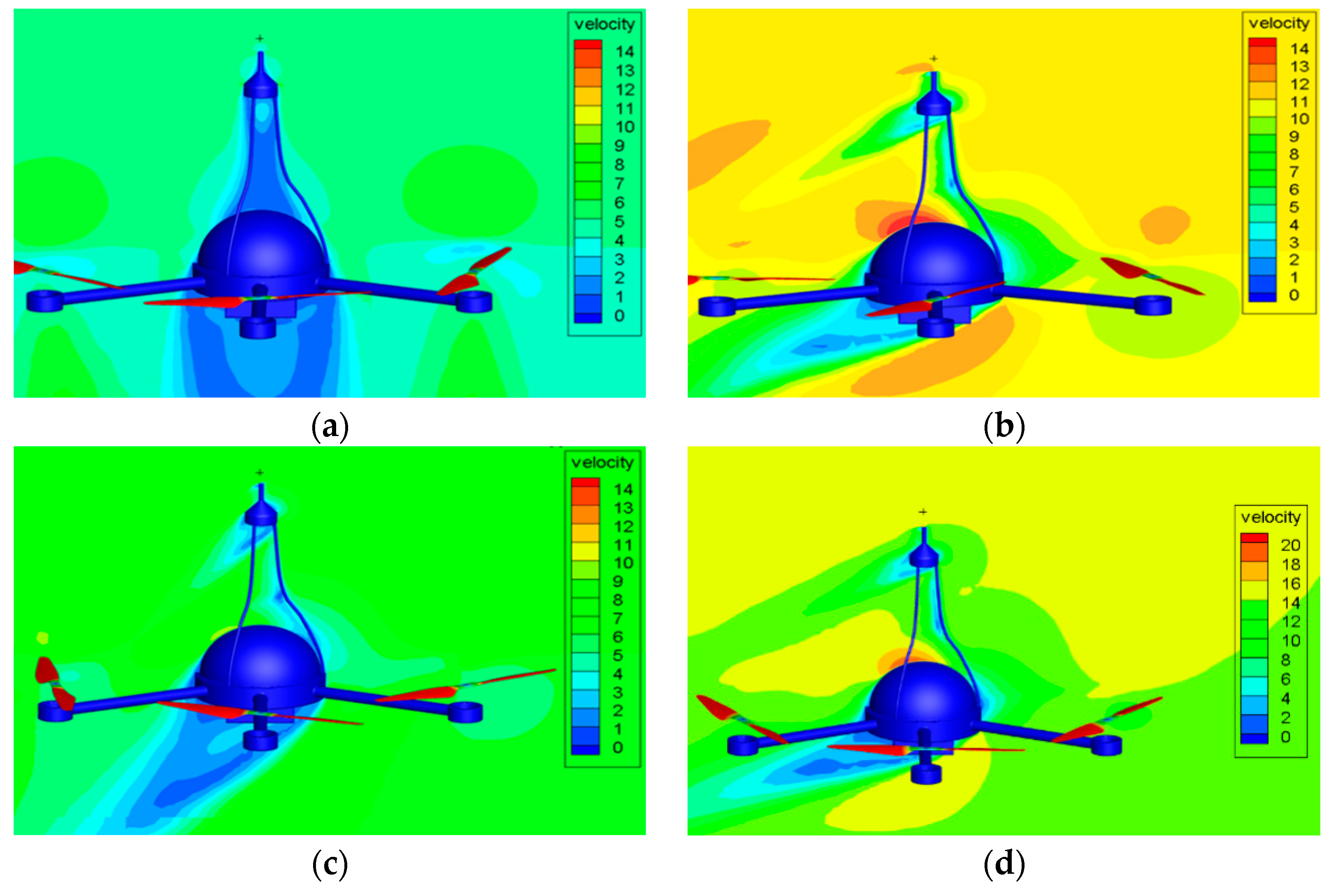

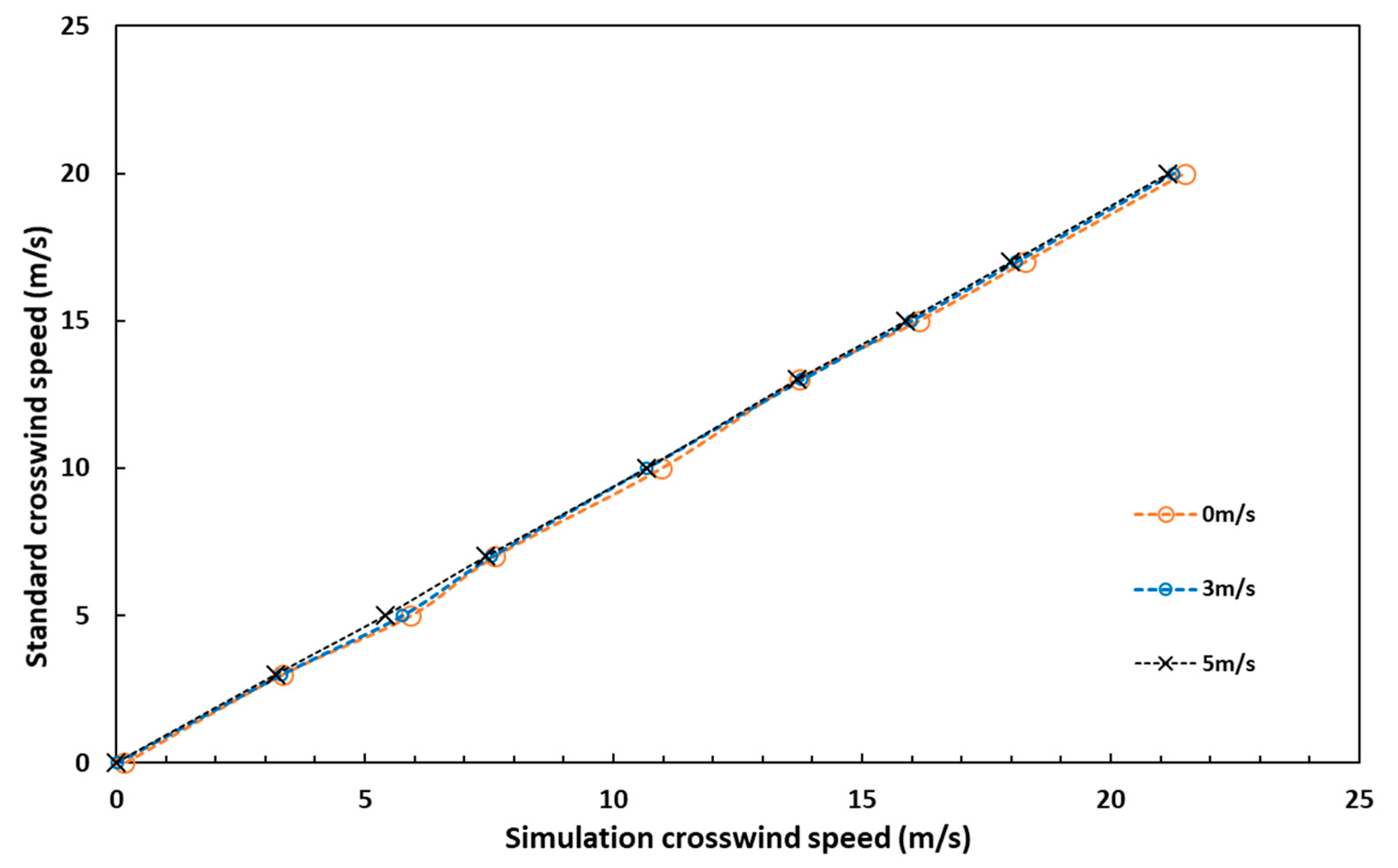

3.2. Simulation and Results

3.3. Modeling

4. Test and Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Javier, B.; Marco, S. Environmental chemical sensing using small drones: A review. Sci. Total Environ. 2020, 748, 141172. [Google Scholar] [CrossRef]

- Ahirwar, S.; Swarnkar, R.; Bhukya, S.; Namwade, G. Application of drone in agriculture. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 2500–2505. [Google Scholar] [CrossRef]

- Mogili, U.M.R.; Deepak, B. Review on application of drone systems in precision agriculture. Procedia Comput. Sci. 2018, 133, 502–509. [Google Scholar] [CrossRef]

- Li, C.; Sun, X. A novel meteorological sensor data acquisition approach based on unmanned aerial vehicle. Int. J. Sens. Netw. 2018, 28, 80–88. [Google Scholar] [CrossRef]

- Malaver Rojas, J.; Gonzalez, F.; Motta, N.; Depari, A.; Corke, P. Towards the development of a gas sensor system for monitoring pollutant gases in the low troposphere using small unmanned aerial vehicles. In Proceedings of the Workshop on Robotics for Environmental Monitoring, 11 July 2012; pp. 1–3. Available online: http://eprints.qut.edu.au/52042/ (accessed on 5 December 2022).

- Zhang, J.; Tang, J.; Wang, T.; Chen, F. Energy-efficient data-gathering rendezvous algorithms with mobile sinks for wireless sensor networks. Int. J. Sens. Netw. 2017, 23, 248–257. [Google Scholar] [CrossRef]

- Potter, B.; Valentino, G.; Yates, L.; Benzing, T.; Salman, A. Environmental Monitoring Using a Drone-Enabled Wireless Sensor Network. In Proceedings of the Systems and Information Engineering Design Symposium (SIEDS), Charlottesville, VA, USA, 26 April 2019. [Google Scholar] [CrossRef]

- Xing, Z.; Zhang, Y.; Su, C.Y.; Qu, Y.; Yu, Z. Kalman filter-based wind estimation for forest fire monitoring with a quadrotor UAV. In Proceedings of the 2019 IEEE Conference on Control Technology and Applications (CCTA), Hong Kong, China, 19–21 August 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 783–788. [Google Scholar] [CrossRef]

- Ma, R.; Li, X.; Sun, M.; Kuang, Z. Experiment of Meteorological Disaster Monitoring on Unmanned Aerial Vehicle. In Proceedings of the 2018 7th International Conference on Agro-Geoinformatics (Agro-Geoinformatics), Hangzhou, China, 6–9 August 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Leuenberger, D.; Haefele, A.; Omanovic, N.; Fengler, M.; Martucci, G.; Calpini, B.; Fuhrer, O.; Rossa, A. Improving high-impact numerical weather prediction with lidar and drone observations. Bull. Am. Meteorol. Soc. 2020, 101, E1036–E1051. [Google Scholar] [CrossRef]

- Yoon, S.; Lee, H.C.; Pulliam, T.H. Computational analysis of multi-rotor flows. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 0812. [Google Scholar] [CrossRef]

- Chaderjian, N.M. Advances in rotor performance and turbulent wake simulation using DES and adaptive mesh refinement. In Proceedings of the 7th International Conference on Computational Fluid Dynamics, Big Island, HI, USA, 9–13 July 2012. [Google Scholar]

- Thibault, S.; Holman, D.; Garcia, S.; Trapani, G. CFD Simulation of a quad-rotor UAV with rotors in motion explicitly modeled using an LBM approach with adaptive refinement. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017; p. 0583. [Google Scholar] [CrossRef]

- Guo, Q.; Zhu, Y.; Tang, Y.; Hou, C.; He, Y.; Zhuang, J.; Zheng, Y.; Luo, S. CFD simulation and experimental verification of the spatial and temporal distributions of the downwash airflow of a quad-rotor agricultural UAV in hover. Comput. Electron. Agric. 2020, 172, 105343. [Google Scholar] [CrossRef]

- Zhang, H.; Qi, L.; Wu, Y.; Musiu, E.M.; Cheng, Z.; Wang, P. Numerical simulation of airflow field from a six–rotor plant protection drone using lattice Boltzmann method. Biosyst. Eng. 2020, 197, 336–351. [Google Scholar] [CrossRef]

- Nakai, T.; Van Der Molen, M.K.; Gash, J.H.C.; Kodama, Y. Correction of sonic anemometer angle of attack errors. Agric. For. Meteorol. 2006, 136, 19–30. [Google Scholar] [CrossRef]

- Nakai, T.; Shimoyama, K. Ultrasonic anemometer angle of attack errors under turbulent conditions. Agric. For. Meteorol. 2012, 162, 14–26. [Google Scholar] [CrossRef]

- Liu, C.; Du, L.; Zhao, Z. A directional cylindrical anemometer with four sets of differential pressure sensors. Rev. Sci. Instrum. 2016, 87, 035105. [Google Scholar] [CrossRef] [PubMed]

- Yichen, P.; Zhenyu, L.; Zhen, F.; Lidong, D.; Zhan, Z. An angle-of-attack correction method for a 2-D miniature differential pressure solid-state anemometer. Measurement 2021, 171, 108833. [Google Scholar] [CrossRef]

- Horlock, J.H. Actuator Disk Theory-Discontinuities in Thermo-Fluid Dynamics; McGraw-Hill, Inc.: New York, NY, USA, 1978. [Google Scholar]

- Kim, Y.H.; Park, S.O. Navier-Stokes simulation of unsteady rotor-airframe interaction with momentum source method. Int. J. Aeronaut. Space Sci. 2009, 10, 125–133. [Google Scholar] [CrossRef]

- Spalart, P.; Allmaras, S. A one-equation turbulence model for aerodynamic flows. In Proceedings of the 30th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1992; p. 439. [Google Scholar] [CrossRef]

- Ashford, G.; Powell, K. Adaptive unstructured triangular mesh generation and flow solvers for the Navier-Stokes equations at high Reynolds number. In Proceedings of the 12th Computational Fluid Dynamics Conference, San Diego, CA, USA, 19–22 June 1995; p. 1724. [Google Scholar] [CrossRef]

- Pan, Y.; Zhao, Z.; Zhao, R.; Fang, Z.; Wu, H.; Niu, X.; Du, L. High accuracy and miniature 2-D wind sensor for boundary layer meteorological observation. Sensors 2019, 19, 1194. [Google Scholar] [CrossRef] [PubMed]

- Shao, W.Y.; Zhang, Y.P.; Zhu, D.Z.; Zhang, T.Q. Drag force on a free surface-piercing yawed circular cylinder in steady flow. J. Fluids Struct. 2013, 43, 145–163. [Google Scholar] [CrossRef]

| Standard Crosswind Speed (m/s) | Simulation Crosswind Speed (m/s) at Ascent Speed of 0 m/s | Simulation Crosswind Speed (m/s) at Ascent Speed of 3 m/s | Simulation Crosswind Speed (m/s) at Ascent Speed of 5 m/s |

|---|---|---|---|

| 0 | 0.168 | 0.015 | 0.009 |

| 3 | 3.344 | 3.333 | 3.222 |

| 5 | 5.928 | 5.758 | 5.419 |

| 7 | 7.612 | 7.552 | 7.438 |

| 10 | 10.970 | 10.670 | 10.661 |

| 13 | 13.807 | 13.794 | 13.682 |

| 15 | 16.148 | 15.989 | 15.871 |

| 17 | 18.282 | 18.099 | 17.979 |

| 20 | 21.483 | 21.263 | 21.142 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Zhao, Z.; Fang, Z.; Li, Y.; Du, L. Correction of Error of Airborne Anemometers Caused by Self-Excited Air Turbulence. Sensors 2023, 23, 4288. https://doi.org/10.3390/s23094288

Liu J, Zhao Z, Fang Z, Li Y, Du L. Correction of Error of Airborne Anemometers Caused by Self-Excited Air Turbulence. Sensors. 2023; 23(9):4288. https://doi.org/10.3390/s23094288

Chicago/Turabian StyleLiu, Jianqiang, Zhan Zhao, Zhen Fang, Yong Li, and Lidong Du. 2023. "Correction of Error of Airborne Anemometers Caused by Self-Excited Air Turbulence" Sensors 23, no. 9: 4288. https://doi.org/10.3390/s23094288