Research on an Equivalent Heat Source Model of the AC Arc in the Short Gap of a Copper-Core Cable and a Fire Risk Assessment Method

Abstract

:1. Introduction

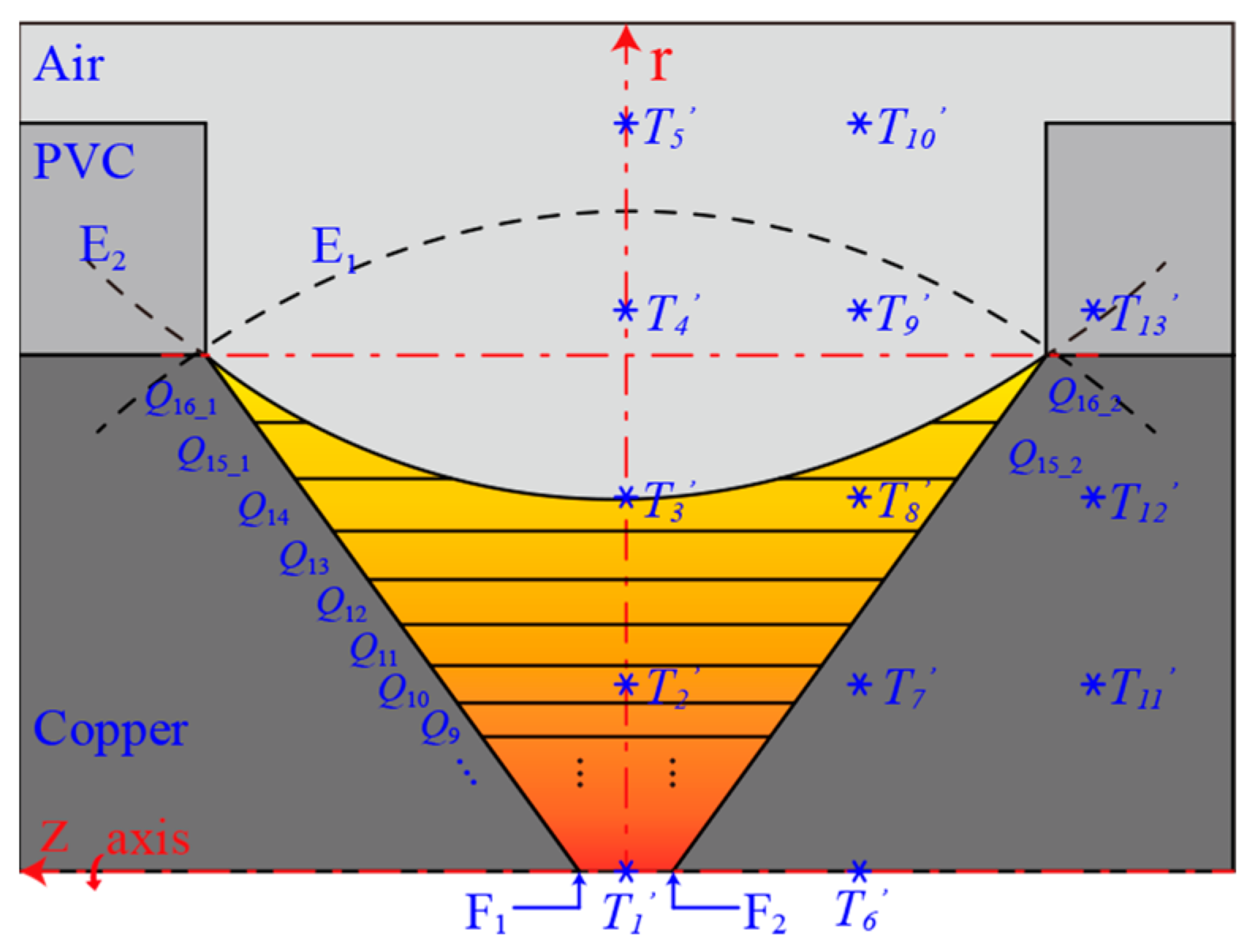

2. MHD Models and Experiments

2.1. Geometric Model and Material Physical Parameters

2.2. MHD Governing Equations and Boundary Conditions

- (1)

- The arc in the air is a plasma regarded as a continuous medium.

- (2)

- The arc is an equilibrium plasma during equilibrium discharge, which is in a local thermodynamic equilibrium state.

- (3)

- The arc plasma is a stable and incompressible fluid, and the flow of arc plasma is laminar.

- (4)

- The arc burning time is very short, regardless of the reaction between the electrode and the arc’s erosion of the electrode contact.

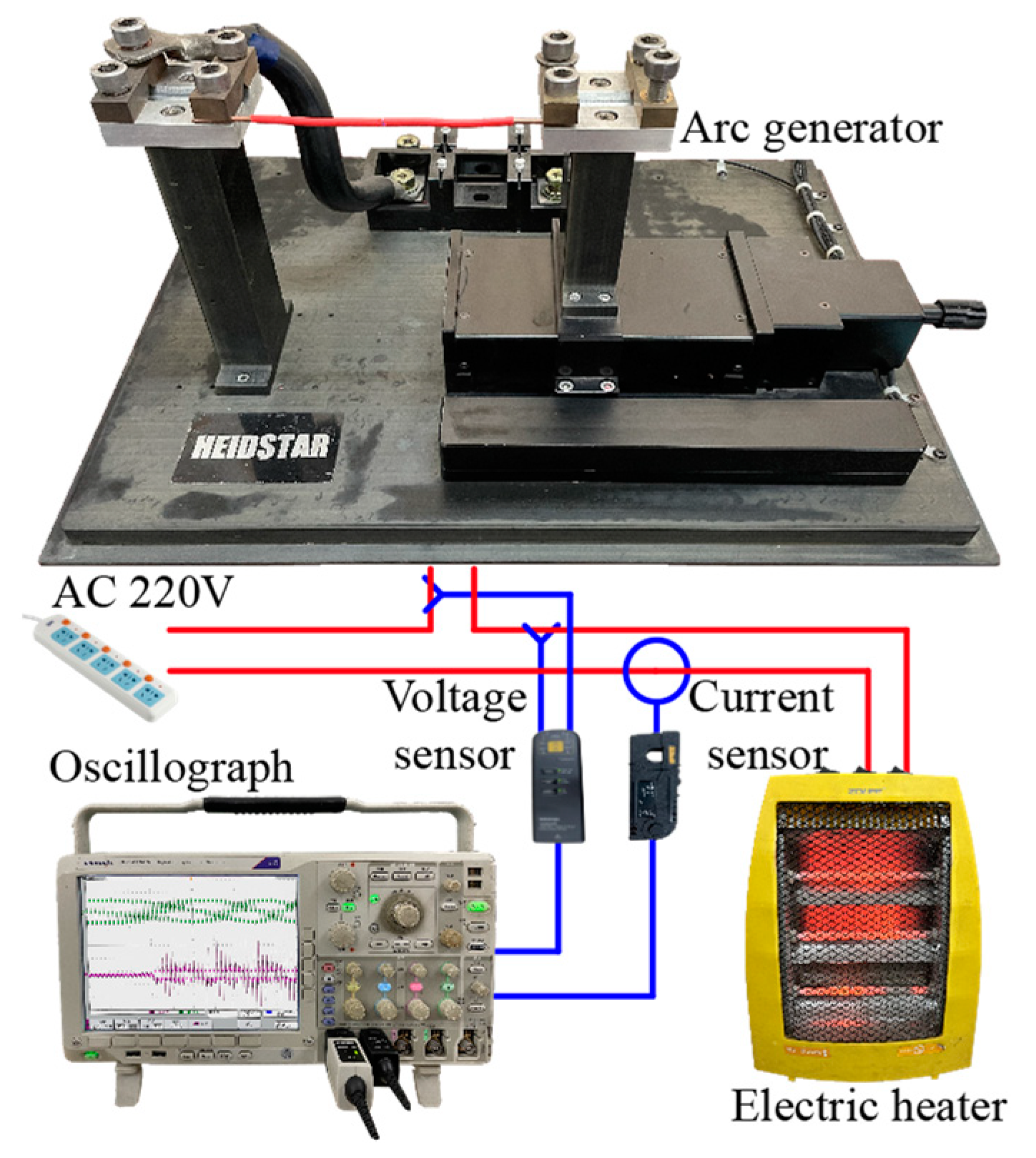

2.3. AC Arc Experimens

3. AC Arc EHS Model

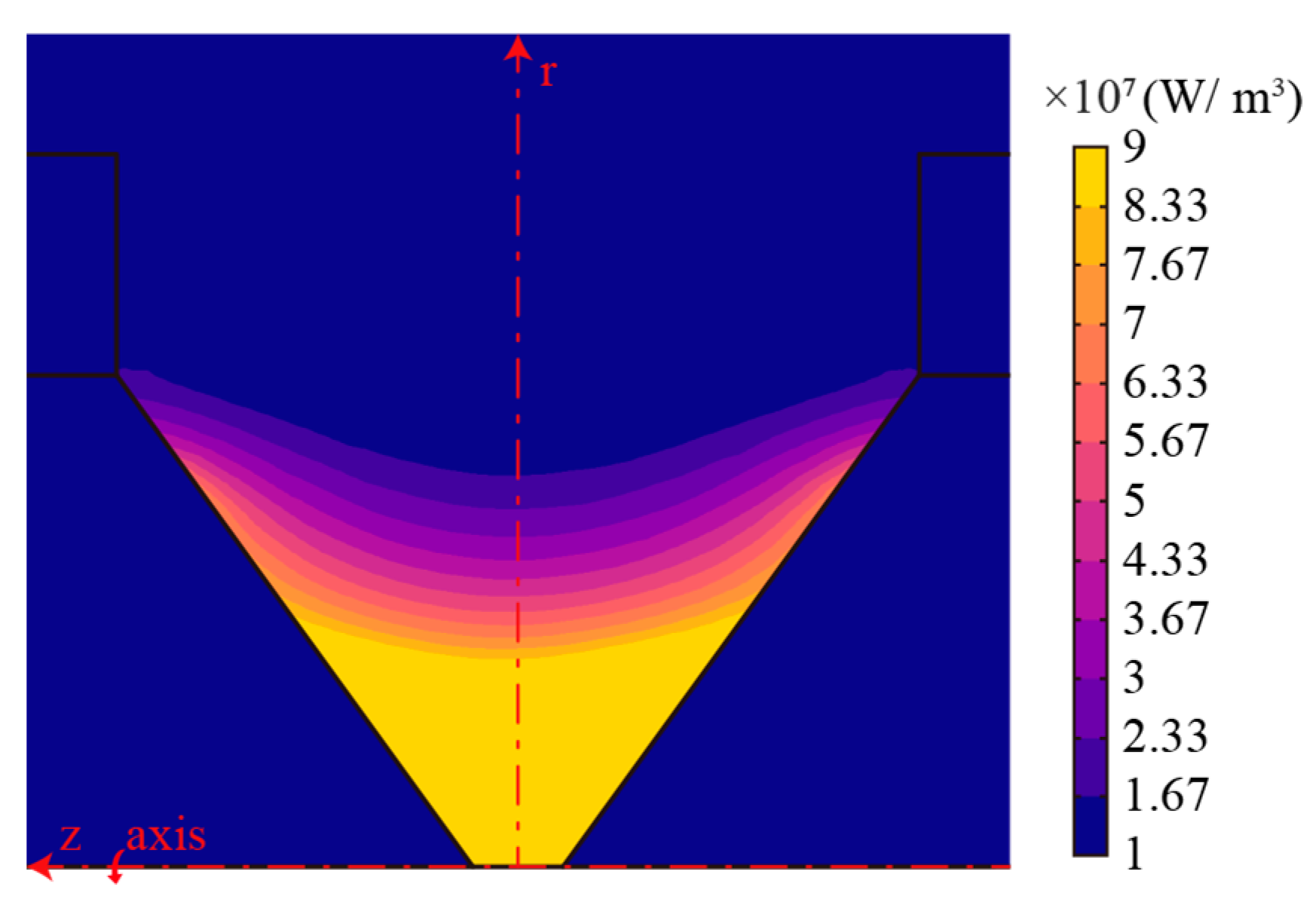

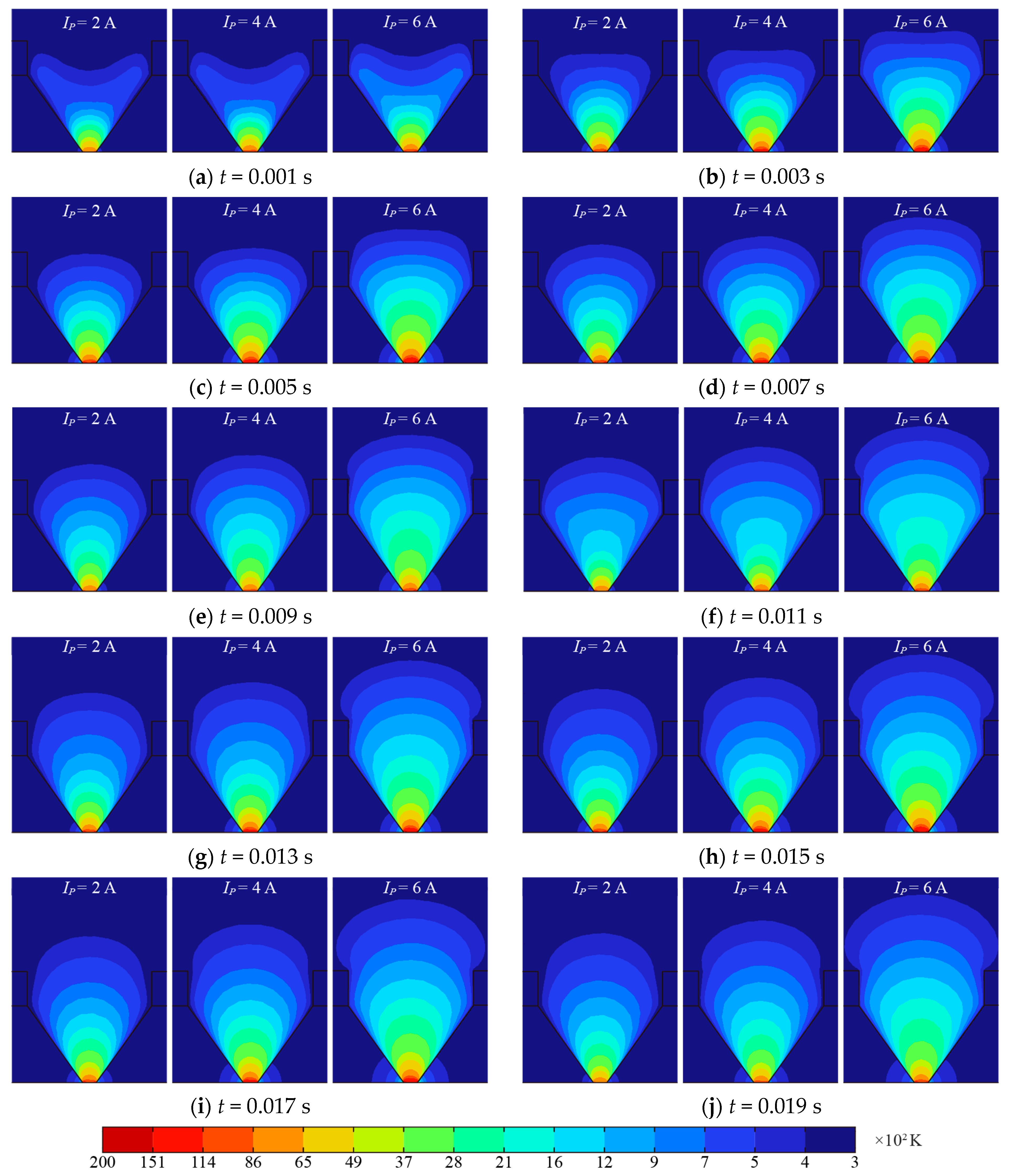

3.1. Heat Source Distribution of AC Arc

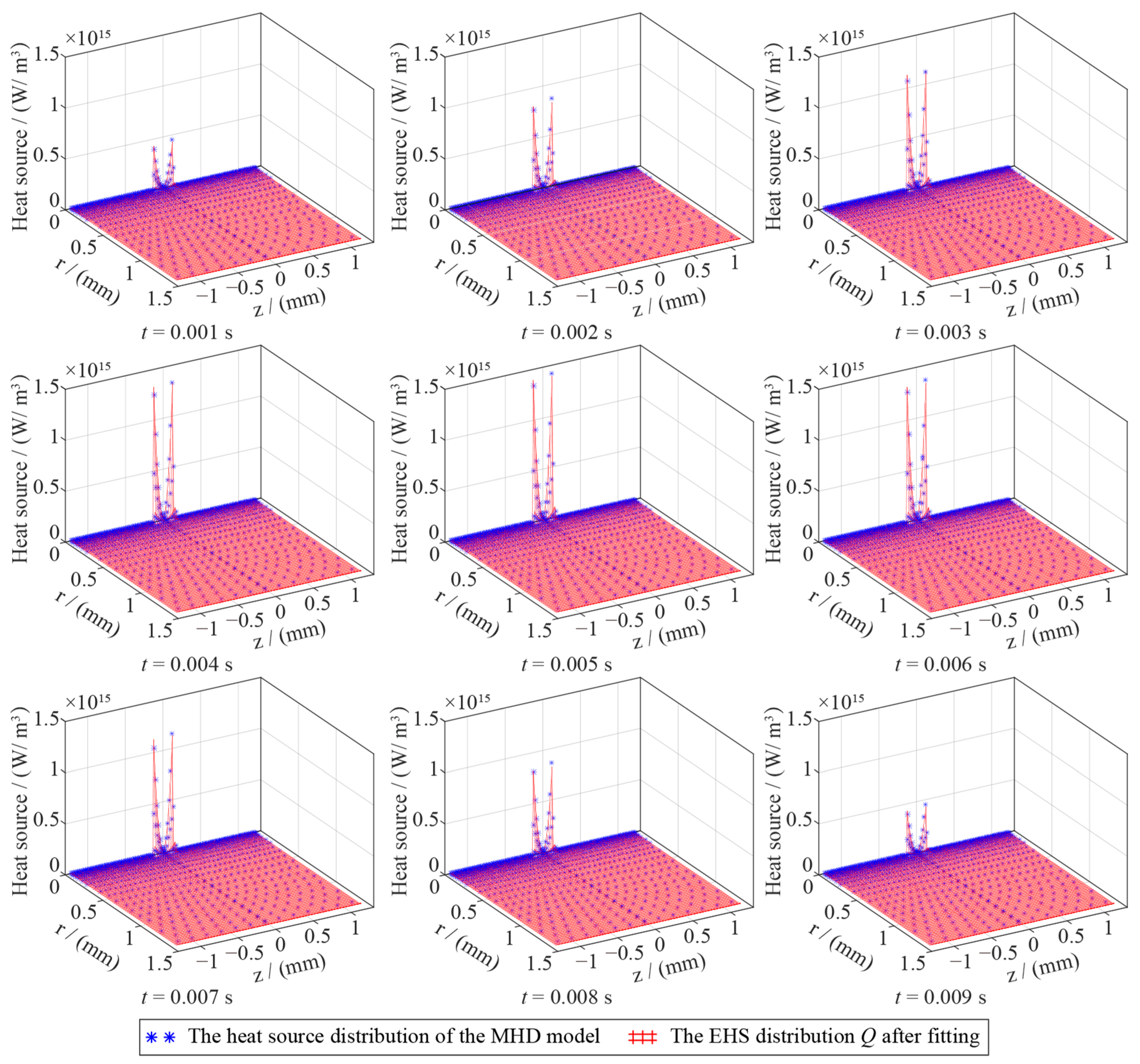

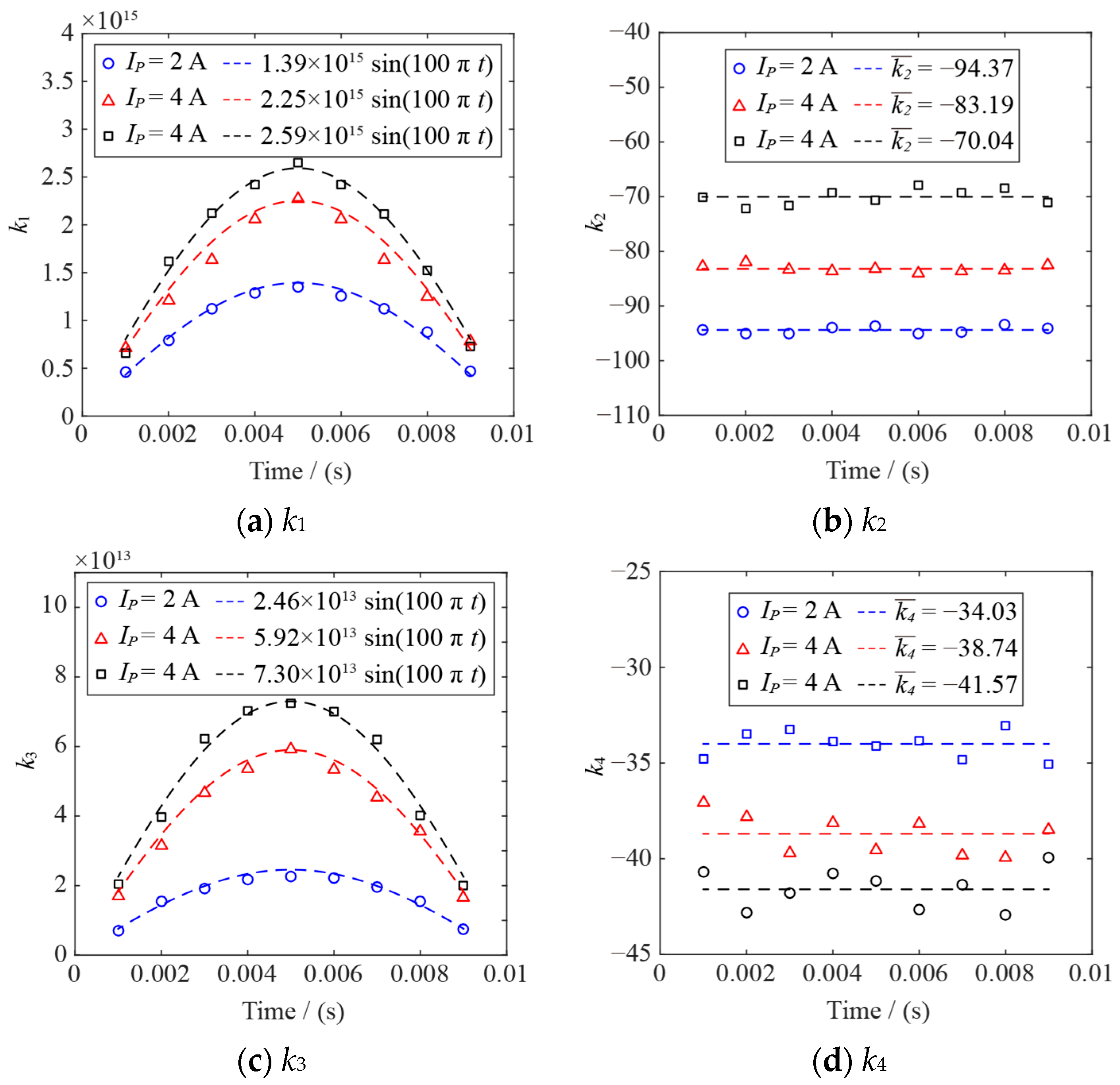

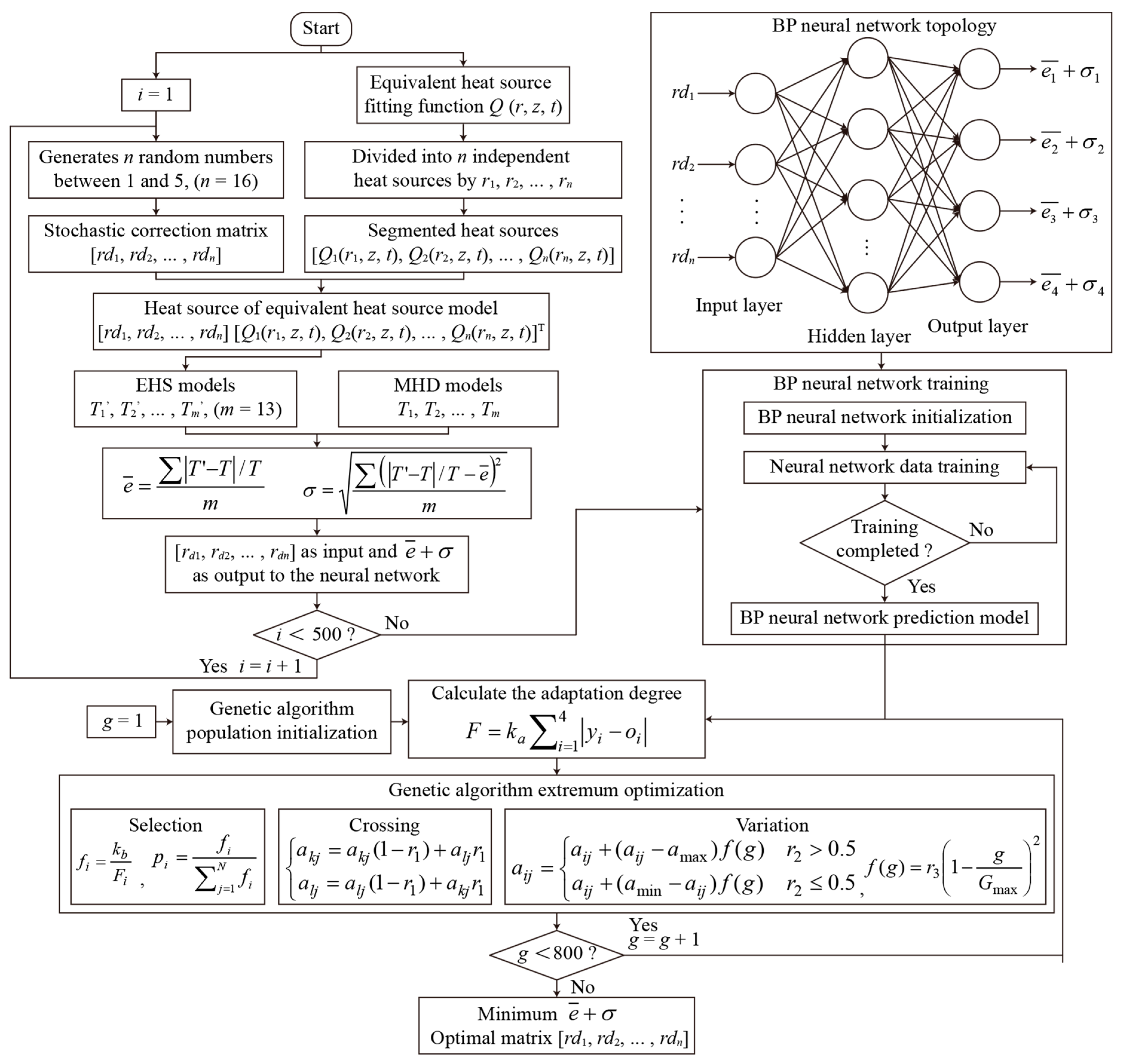

3.2. Optimization of EHS Model

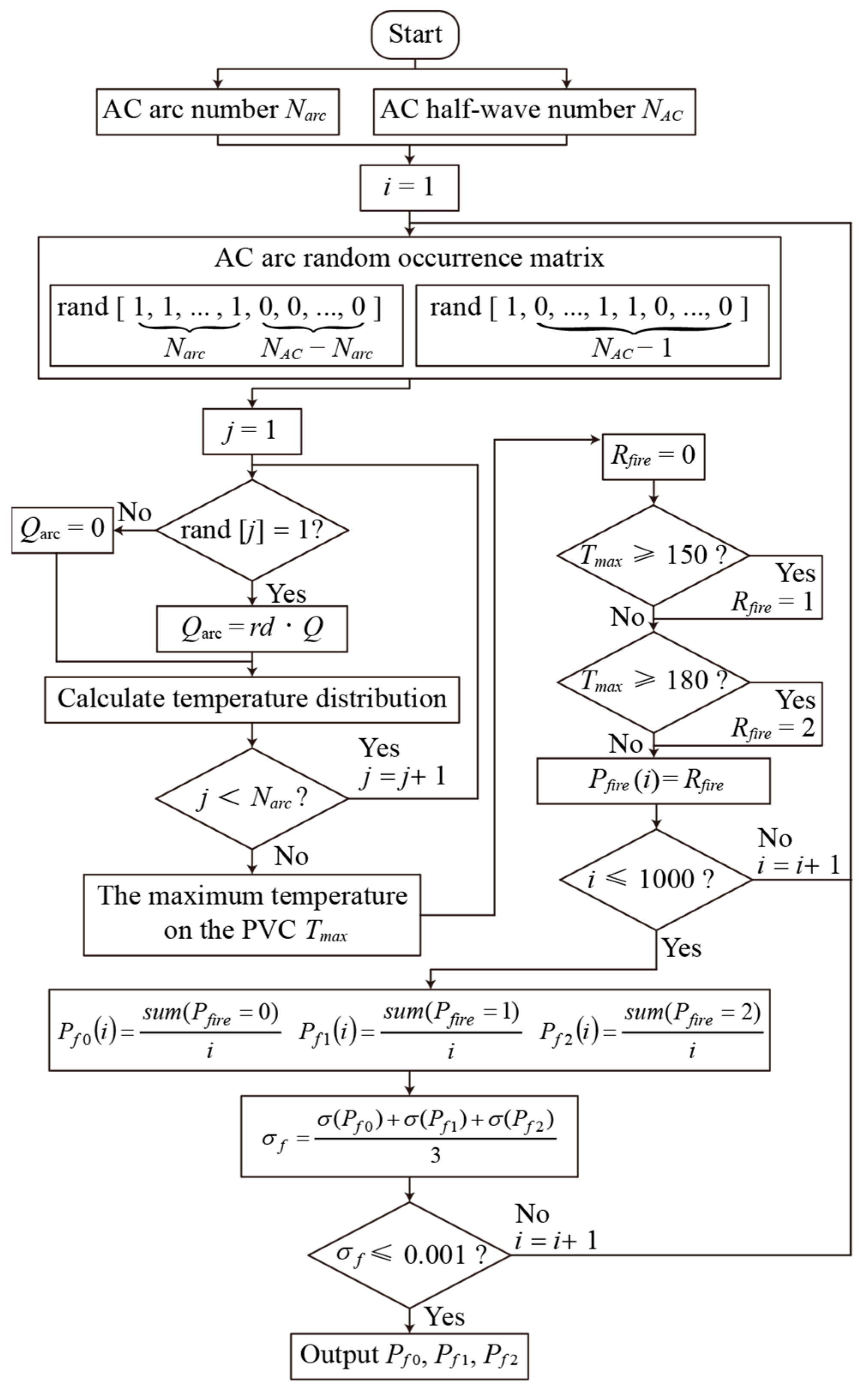

4. Fire Risk Assessment for an AC Arc

5. Conclusions

- (1)

- An AC arc MHD model coupled with thermal, flow, electric, and magnetic fields is constructed. The AC arc voltage and current obtained by the AC arc experiment are compared with the AC arc MHD model to prove its correctness. In an AC half-wave, the heat production in the electrode gap increases first and then decreases. The heat production near the electrode tip is much higher than that around it.

- (2)

- The heat source distribution obtained by the AC arc MHD model is used to obtain the EHS Q of the AC arc through fitting. The EHS Q is divided into 16 AC arc-segmented heat sources, and a correction matrix is constructed to optimize the AC arc EHS model. A BP neural network and a genetic algorithm obtain the optimal correction matrix of the AC arc’s segmented EHS model. The optimized EHS model of the AC arc is used to calculate the thermal characteristics of the AC arc, which can obtain the temperature errors of 5.8/4.4/4.2% when the MHD model in AC arc peak currents are 2/4/6 A. The calculation time of the MHD model can be significantly reduced by using the EHS model of AC arc with the double tips’ short gap proposed in this paper.

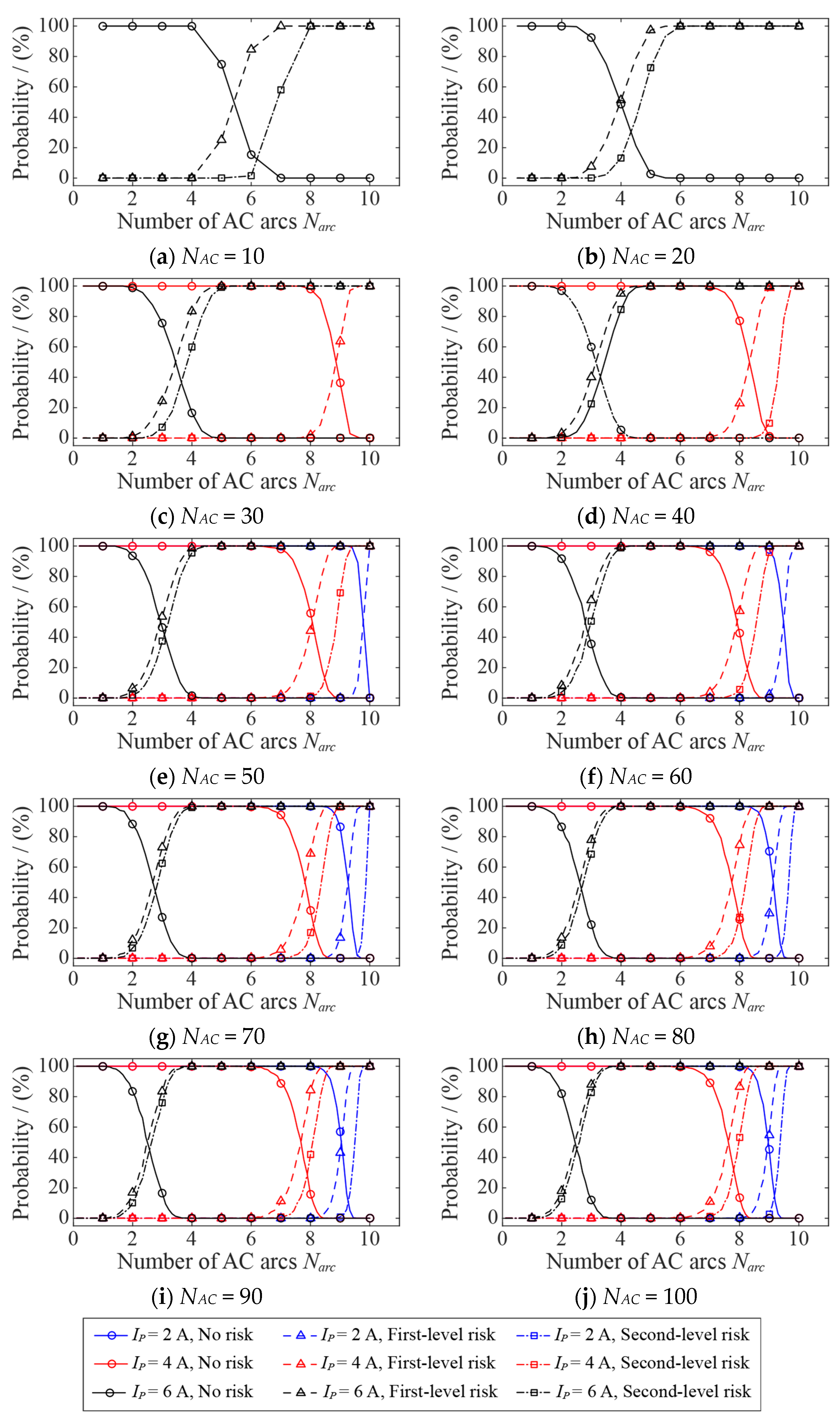

- (3)

- The EHS model of an AC arc is used to calculate the probability of PVC fire risk (no fire risk, first-level fire risk, second-level fire risk) caused by a random number of AC arcs generated in different AC half-wave numbers. It is worth noting that there is no fire risk when the number of AC arcs is small. With the same AC half-wave numbers, the probability of no fire risk decreases with the increase in the number of AC arcs and the arc current, and the probability of first-level fire risk and second-level fire risk increases with the increase in the number of AC arcs and the arc current. The fire risk probability provided in this paper can be used to judge the fire hazard caused by the AC arcs to the cable.

- (4)

- This study provides a research method for the AC arc EHS model and a method of AC arc fire risk assessment. The EHS model replaces the MHD model to calculate the arc’s temperature distribution between the cable’s short gaps quickly and accurately. The cable fire risk probability of random AC arcs can provide a reference for formulating AC arc detection standards and preventing electric fires.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, X.Y.; Nakamura, Y. A review of fundamental combustion phenomena in wire fires. Fire Technol. 2020, 56, 315–360. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, R.C.; Yang, J.H.; Liu, C.H.; Chen, S.H.; Zhang, F.J. A novel arc fault detector for early detection of electrical fires. Sensors 2016, 16, 500. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.Q.; Chen, X.Y.; Liu, F.; Wang, H.; Chai, Y.; Zheng, W.X.; Chen, H.T. A novel adaptive SMO-Based simultaneous diagnosis method for IGBT open-circuit faults and current sensor incipient faults of inverters in PMSM drives for electric vehicles. IEEE Trans. Instrum. Meas. 2023, 72, 3526915. [Google Scholar] [CrossRef]

- Li, M.; Wu, Y.; Wu, Y.F.; Liu, Y.F.; Hu, Y. MHD modeling of fault arc in a closed container. IEEE Trans. Plasma Sci. 2014, 42, 2714–2715. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Wang, L.J.; Yang, Z.; Luo, M.; Li, J.G. Numerical simulation of low-current vacuum arc jet considering anode evaporation in different axial magnetic fields. Plasma Sci. Technol. 2022, 24, 044002. [Google Scholar] [CrossRef]

- Liu, X.J.; Huang, X.; Cao, Q.C. Simulation and experimental analysis of DC arc characteristics in different gas conditions. IEEE Trans. Plasma Sci. 2021, 49, 1062–1071. [Google Scholar] [CrossRef]

- Wang, D.Q.; Wang, Y.J.; Liu, W.H.; Hua, C.; Yu, C.; Lu, H. Multiscale investigation of microstructure optimization in the arc additive manufacturing and arc welding by self-induced ultrasound. Int. J. Heat Mass Transf. 2021, 180, 121790. [Google Scholar] [CrossRef]

- Ji, Y.; Li, X.F.; Wu, T.F.; Chen, C. Theoretical and experimental study of radial velocity generation for extending bandwidth of magnetohydrodynamic angular rate sensor at low frequency. Sensors 2015, 15, 31606–31619. [Google Scholar] [CrossRef]

- Rehmet, C.; Fabry, F.; Rohani, V.; Cauneau, F.; Fulcheri, L. A comparison between MHD modeling and experimental results in a 3-phase AC arc plasma torch: Influence of the electrode tip geometry. Plasma Chem. Plasma Process. 2014, 34, 975–996. [Google Scholar] [CrossRef]

- Rau, S.H.; Zhang, Z.Y.; Lee, W.J. 3-D magnetohydrodynamic modeling of DC arc in power system. IEEE Trans. Ind. Appl. 2016, 52, 4549–4555. [Google Scholar] [CrossRef]

- Moralev, I.; Kazanskii, P.; Bityurin, V.; Bocharov, A.; Firsov, A.; Dolgov, E.; Leonov, S. Gas dynamics of the pulsed electric arc in the transversal magnetic field. J. Phys. D Appl. Phys. 2020, 53, 425203. [Google Scholar] [CrossRef]

- Lebouvier, A.; Iwarere, S.; Ramjugernath, D.; Fulcheri, L. MHD modeling of the tip-to-plane plasma arc behaviour at very high pressure in CF4. Plasma Chem. Plasma Process. 2015, 35, 91–106. [Google Scholar] [CrossRef]

- Huang, K.Y.; Sun, H.; Niu, C.P.; Wu, Y.; Rong, M.Z.; Yan, G.C.; Huang, G.M. Simulation of arcs for DC relay considering different impacts. Plasma Sci. Technol. 2020, 22, 21–30. [Google Scholar] [CrossRef]

- Bo, K.; Zhou, X.; Zhai, G.F. Investigation on arc dwell and restriking characteristics in DC high-power relay. IEEE Trans. Plasma Sci. 2017, 45, 1032–1042. [Google Scholar] [CrossRef]

- Valenzuela-Delgado, M.; Flores-Fuentes, W.; Rivas-López, M.; Sergiyenko, O.; Lindner, L.; Hernández-Balbuena, D.; Rodríguez-Quiñonez, J.C. Electrolyte magnetohydrondyamics flow sensing in an open annular ChannelA vision system for validation of the mathematical model. Sensors 2018, 18, 1683. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Nie, Y.M.; Lee, W.J. Approach of voltage characteristics modeling for medium-low-voltage arc fault in short gaps. IEEE Trans. Ind. Appl. 2019, 55, 2281–2289. [Google Scholar] [CrossRef]

- Wu, Q.R.; Yang, K.; Zhang, R.C.; Tu, R.; Zhou, X.J. Numerical study on instantaneous heat transfer characteristics of AC arc-fault. AIP Adv. 2021, 11, 095009. [Google Scholar] [CrossRef]

- Aissani, M.; Guessasma, S.; Zitouni, A.; Hamzaoui, R.; Bassir, D.; Benkedda, Y. Three-dimensional simulation of 304L steel TIG welding process: Contribution of the thermal flux. Appl. Therm. Eng. 2015, 89, 822–832. [Google Scholar] [CrossRef]

- Azar, A.S. A heat source model for cold metal transfer (CMT) welding. J. Therm. Anal. Calorim. 2015, 122, 741–746. [Google Scholar] [CrossRef]

- Ghosh, A.; Chattopadhyay, H. Mathematical modeling of moving heat source shape for submerged arc welding process. Int. J. Adv. Manuf. Technol. 2013, 69, 2691–2701. [Google Scholar] [CrossRef]

- Ghosh, A.; Yadav, A.; Kumar, A. Modelling and experimental validation of moving tilted volumetric heat source in gas metal arc welding process. J. Mater. Process. Technol. 2017, 239, 52–65. [Google Scholar] [CrossRef]

- García-García, V.; Camacho-Arriaga, J.C.; Reyes-Calderón, F. A simplified elliptic paraboloid heat source model for autogenous GTAW process. Int. J. Heat Mass Transf. 2016, 100, 536–549. [Google Scholar] [CrossRef]

- Mohanty, U.K.; Sharma, A.; Abe, Y.; Fujimoto, T.; Nakatani, M.; Kitagawa, A.; Tanaka, M.; Suga, T. Thermal modelling of alternating current square waveform arc welding. Case Stud. Therm. Eng. 2021, 25, 100885. [Google Scholar] [CrossRef]

- Liu, K.; Yang, F.; Wang, S.H.; Gao, B.; Xu, C. The research on the heat source characteristics and the equivalent heat source of the arc in gaps. Int. J. Heat Mass Transf. 2018, 124, 177–189. [Google Scholar] [CrossRef]

- Yang, F.; Liu, K.; Wang, S.H.; Gao, B.; Ai, S.G.; Zheng, X.L.; Le, Y.J.; Uilah, I. A thermal-stress field calculation method based on the equivalent heat source for the dielectric fitting under discharging. Appl. Therm. Eng. 2018, 138, 183–196. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L.; Wu, C.S. Simulation of keyhole plasma arc welding with electro-magneto-thermo-hydrodynamic interactions. Int. J. Adv. Manuf. Technol. 2019, 101, 2497–2507. [Google Scholar] [CrossRef]

- Das, A.; Kumar, A.; Shankhwar, K.; Gubeljak, N. A review of heat source and resulting temperature distribution in arc welding. J. Therm. Anal. Calorim. 2022, 147, 12975–13010. [Google Scholar] [CrossRef]

- Sun, J.; Klassen, J.; Nitschke-Pagel, T.; Dilger, K. Effects of heat source geometric parameters and arc efficiency on welding temperature field, residual stress, and distortion in thin-plate full-penetration welds. Int. J. Adv. Manuf. Technol. 2018, 99, 497–515. [Google Scholar] [CrossRef]

- Zheng, X.; Shan, X.J. Characteristic analysis and application research of low voltage AC arc voltage waveform at the current zero. Trans. China Electrotech. Soc. 2020, 35, 4717–4725. [Google Scholar]

- He, Z.P.; Li, W.L.; Deng, Y.K.; Zhao, H. The detection of series AC arc fault in low-voltage distribution system. Trans. China Electrotech. Soc. 2023, 38, 2806–2817. [Google Scholar]

- Yang, K.; Chu, R.B.; Zhang, R.C.; Xiao, J.C.; Tu, R. A novel methodology for series arc fault detection by temporal domain visualization and convolutional neural network. Sensors 2020, 20, 162. [Google Scholar] [CrossRef] [PubMed]

- Hemmi, R.; Yokomizu, Y.; Matsumura, T. Anode-fall and cathode-fall voltages of air arc in atmosphere between silver electrodes. J. Phys. D Appl. Phys. 2003, 36, 1097–1106. [Google Scholar] [CrossRef]

- Yin, J.N.; Liu, S.G.; Tang, F.; Lv, Q.S.; Li, X.W. Convection effect on an arc plasma evolution process in a two parallel contact system. Plasma Sci. Technol. 2020, 22, 045401. [Google Scholar] [CrossRef]

- Wang, Q. Fundamentals of Electrical Apparatuses; China Machine Press: Beijing, China, 1991; pp. 58–116. [Google Scholar]

- Li, C.M.; Gao, H.M.; Qiu, J.L.; Yang, Y.; Qu, X.Y.; Wang, Y.C.; Bi, Z.Q. Grey model optimized by particle swarm optimization for data analysis and application of multi-sensors. Sensors 2018, 18, 2503. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Li, B.Z.; Jia, H.Y.; Zhang, M.; Wang, D. Application of multi-objective genetic algorithm to optimize energy efficiency and thermal comfort in building design. Energy Build. 2015, 88, 135–143. [Google Scholar] [CrossRef]

- Li, Z.J.; Lu, Z.C.; Zhao, C.Y.; Liu, F.C.; Chen, Y. Heat source forecast of ball screw drive system under actual working conditions based on on-line measurement of temperature sensors. Sensors 2019, 19, 4694. [Google Scholar] [CrossRef]

- Zhong, K.; Han, B.; Han, M.; Chen, H.T. Hierarchical graph convolutional networks with latent structure learning for mechanical fault diagnosis. IEEE-ASME Trans. Mechatron. 2023, 28, 3076–3086. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Density of PVC/(kg/m3) | 5.0 × 102 |

| Heat capacity at constant pressure of PVC/[J/(kg·K)] | 1.0 × 103 |

| Thermal conductivity of PVC/[W/(m·K)] | 0.16 |

| Surface emissivity of PVC | 0.95 |

| Conductivity of PVC/(S/m) | 0 |

| Density of copper/(kg/m3) | 8.94 × 103 |

| Heat capacity at constant pressure of copper/[J/(kg·K)] | 3.85 × 102 |

| Thermal conductivity of copper/[W/(m·K)] | 4.0 × 102 |

| Surface emissivity of copper | 0.5 |

| Conductivity of copper/(S/m) | 5.998 × 107 |

| Boundary | Temperature T/(K) | Pressure P/(atm) | Flow Velocity v/(m/s) | Magnetic Vector Potential A/(Wb/m) |

|---|---|---|---|---|

| a | 1 | 0 | ||

| b, e | Equation (11) | 0 | ||

| c, d1, d2 | T = T0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhang, R.; Yang, K.; Qi, Y. Research on an Equivalent Heat Source Model of the AC Arc in the Short Gap of a Copper-Core Cable and a Fire Risk Assessment Method. Sensors 2024, 24, 1443. https://doi.org/10.3390/s24051443

Li Y, Zhang R, Yang K, Qi Y. Research on an Equivalent Heat Source Model of the AC Arc in the Short Gap of a Copper-Core Cable and a Fire Risk Assessment Method. Sensors. 2024; 24(5):1443. https://doi.org/10.3390/s24051443

Chicago/Turabian StyleLi, Yu, Rencheng Zhang, Kai Yang, and Yufan Qi. 2024. "Research on an Equivalent Heat Source Model of the AC Arc in the Short Gap of a Copper-Core Cable and a Fire Risk Assessment Method" Sensors 24, no. 5: 1443. https://doi.org/10.3390/s24051443