Energy Resolution from a Silicon Detector’s Interstrip Regions

Abstract

:1. Introduction

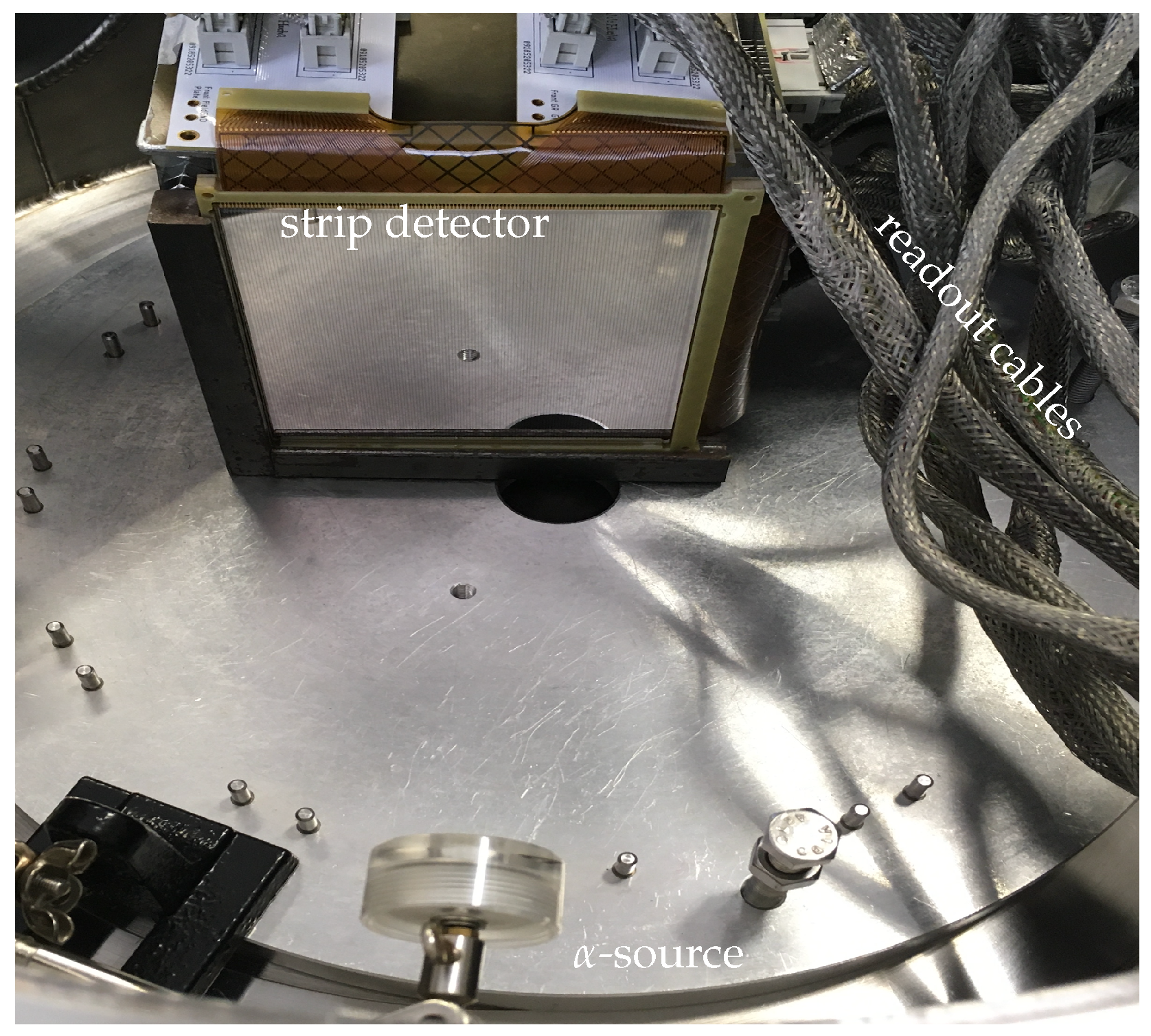

2. Materials and Methods

2.1. Silicon Strip Detectors

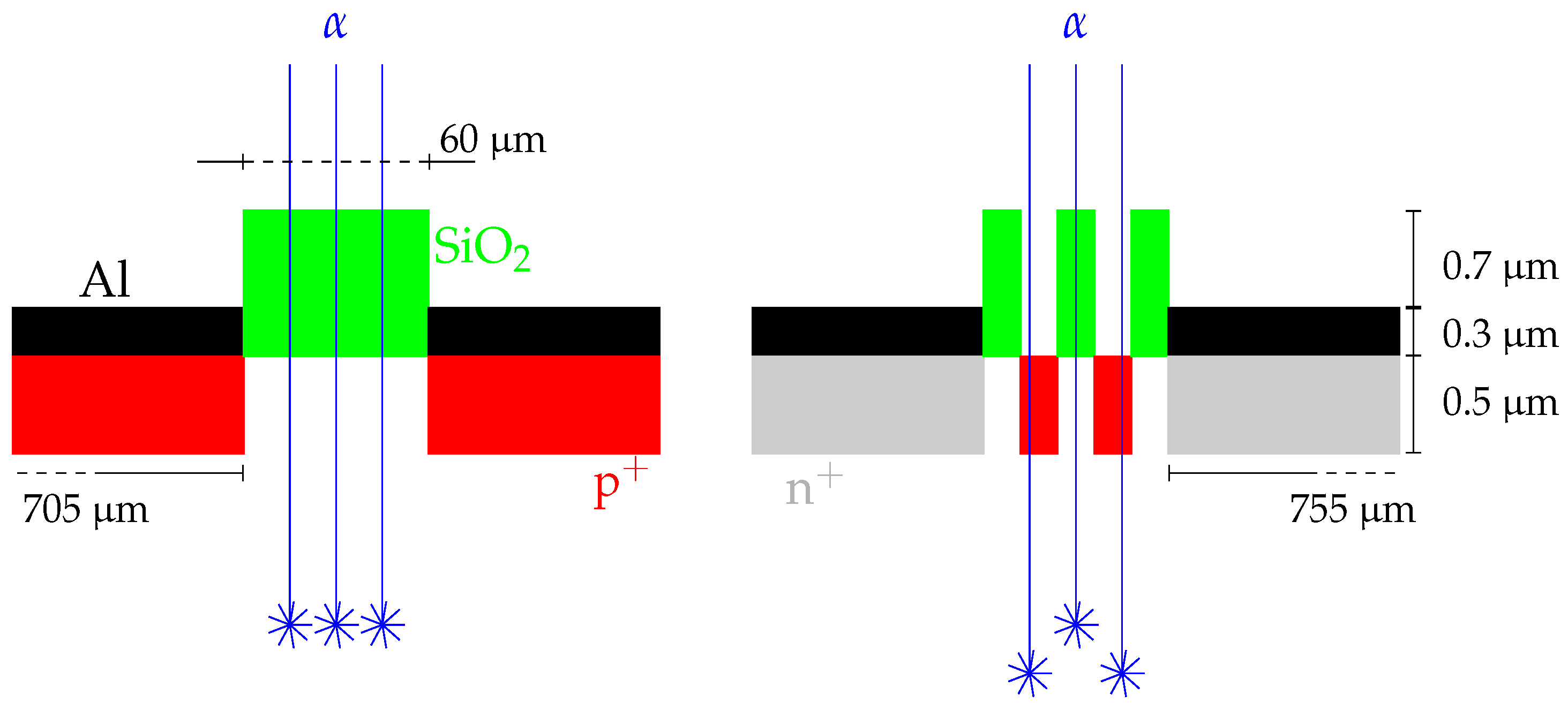

2.2. Particle Impinging Scenarios

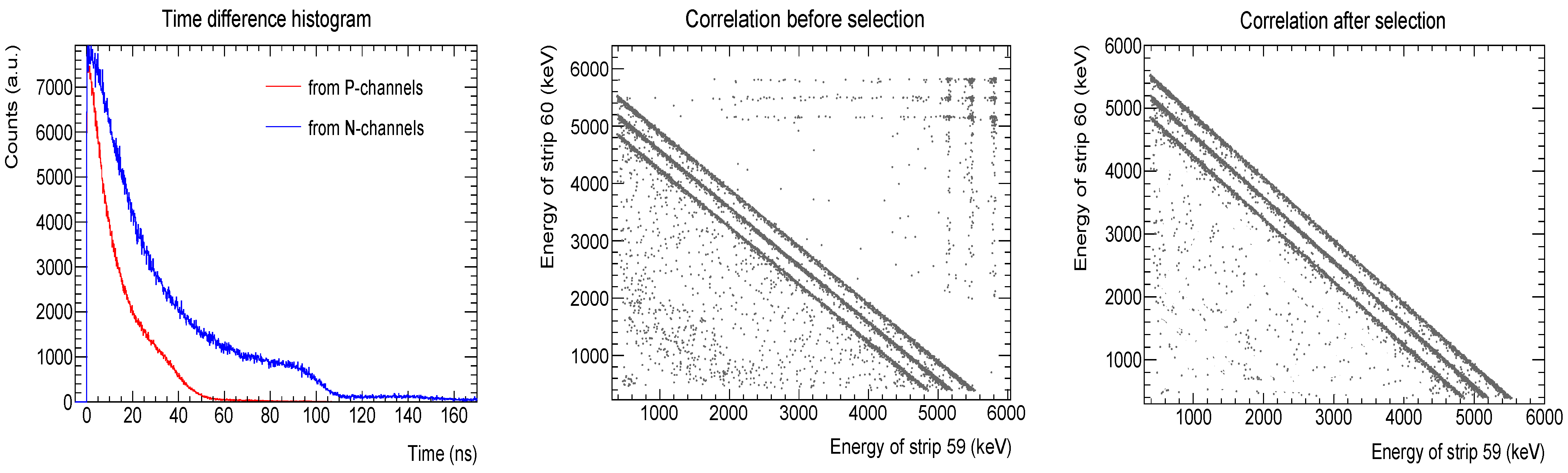

2.3. Selection of the Interstrip Events

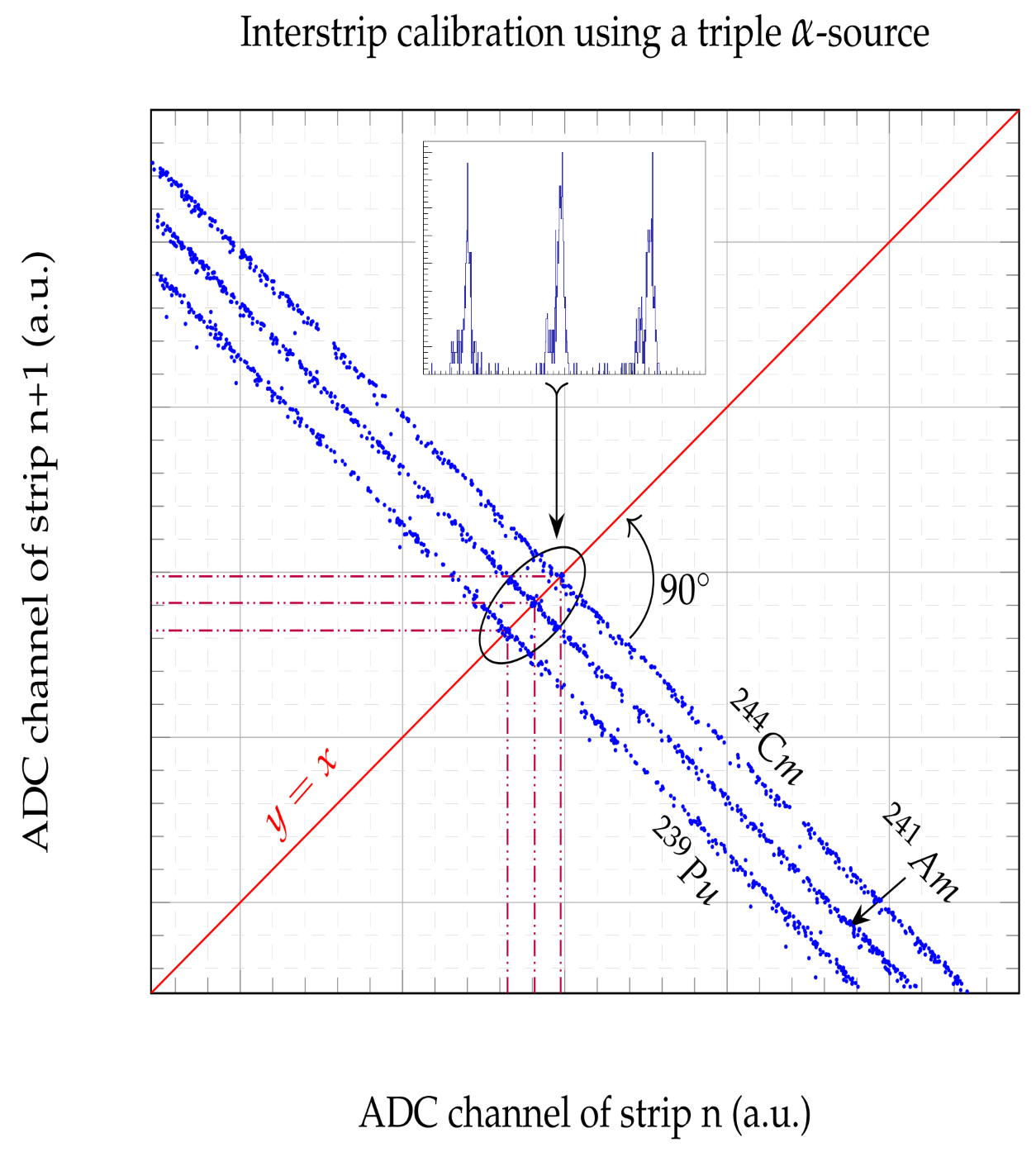

2.4. The Rotational Interstrip Energy Resolution

3. Results and Discussion

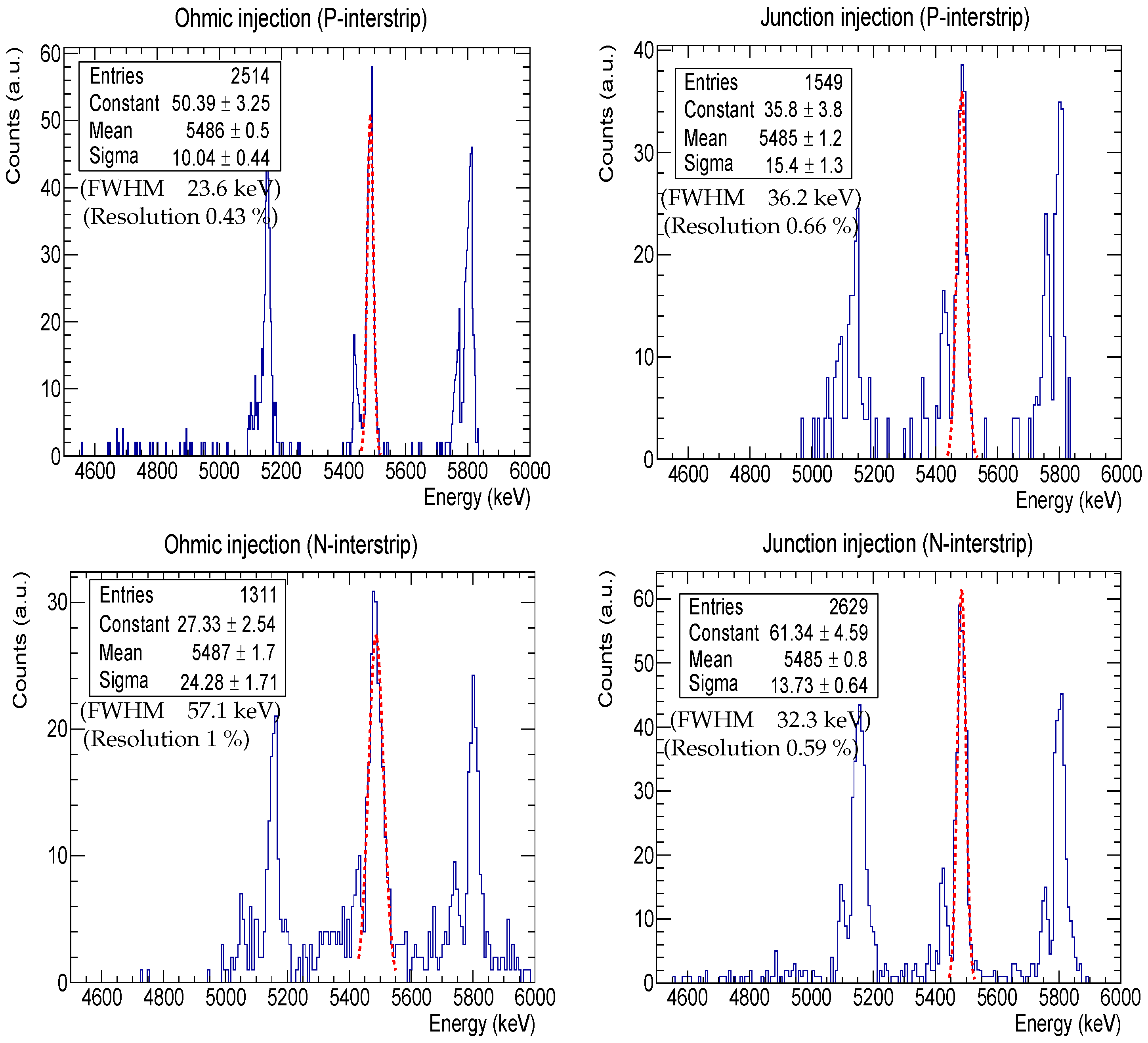

3.1. Strip Energy Resolution

3.2. Interstrip Energy Resolution

3.3. Resolution Comparison: Rotation vs. Addition

3.4. Particle Energy Determination within the Interstrip

4. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Heijne, E.H.M. A silicon surface barrier microstrip detector designed for high energy physics. Nucl. Instrum. Methods 1980, 178, 331–343. [Google Scholar] [CrossRef]

- Laegsgaard, E. Position-sensitve semiconductor detectors. Nucl. Instrum. Methods 1979, 162, 93–111. [Google Scholar] [CrossRef]

- England, J.B.A. A silicon strip detector with 12 μm resolution. Nucl. Instrum. Methods 1982, 196, 149–151. [Google Scholar] [CrossRef]

- Kraner, H.W. Charge collection in silicon strip detectors. IEEE Trans. Nucl. Sci. 1983, 30, 405–411. [Google Scholar] [CrossRef]

- Dabrowski, W. Charge division in silicon strip detectors with a large strip pitch. Nucl. Instrum. Methods 1994, 349, 424–430. [Google Scholar] [CrossRef]

- Torresi, D. Influence of the interstrip gap on the response and the efficiency of double sided silicon strip detectors. Nucl. Instrum. Methods 2014, 713, 11–18. [Google Scholar] [CrossRef]

- Grassi, L. Study of the inter-strip gap effects on the response of Double Sided Silicon Strip Detectors using proton micro-beams. Nucl. Instrum. Methods 2014, 767, 99–111. [Google Scholar] [CrossRef]

- Dueñas, J.A. Interstrip effects influence on the particle identification of highly segmented silicon strip detector in a nuclear reaction scenario. Nucl. Instrum. Methods 2014, 743, 44–50. [Google Scholar] [CrossRef]

- Dueñas, J.A. Characterization of an NTD double-sided silicon strip detector employing a pulsed proton microbeam. IEEE Trans. Nucl. Sci. 2017, 64, 2551–2560. [Google Scholar] [CrossRef]

- Smirnov, D. Application of a thin double-sided microstrip detector for the registration of β-delayed charge particles: The 6He β decay into the two-body continuum of 6Li. Nucl. Instrum. Methods 2005, 547, 480–489. [Google Scholar] [CrossRef]

- Lastovicka-Medin, G. Exploring the Interpad Gap Region in Ultra-Fast Silicon Detectors: Insights into Isolation Structure and Electric Field Effects on Charge Multiplication. Sensor 2023, 23, 6746. [Google Scholar] [CrossRef] [PubMed]

- Kuijer, P. The ALICE silicon strip detector system. Nucl. Instrum. Methods 2000, 447, 251–256. [Google Scholar] [CrossRef]

- ATLAS Collaboration. Technical Design Report for the ATLAS Inner Tracker Strip Detector, CERN-LHCC-2017-005, ATLAS-TDR-025. Available online: https://cds.cern.ch/record/2257755 (accessed on 9 December 2023).

- Ota, S. BlueSTEAl: A pair of silicon arrays and a zero-degree phoswich detector for studies of scattering and reactions in inverse kinematics. Nucl. Instrum. Methods 2023, 1059, 168946. [Google Scholar] [CrossRef]

- GRIT Web Page. Available online: http://grit.in2p3.fr (accessed on 9 December 2023).

- Dueñas, J.A. Test Bench for highly segmented GRIT double-sided silicon strip detectors: A detector quality control protocol. Sensor 2023, 23, 5384. [Google Scholar] [CrossRef] [PubMed]

- Micron Semidonductors Ltd. Home. Available online: http://micronsemiconductor.co.uk (accessed on 9 December 2023).

- Neindre, N. Comparison of charged particle identification using pulse shape discrimination and DE-E methods between front and rear side injection in silicon detectors. Nucl. Instrum. Methods 2013, 701, 145–152. [Google Scholar] [CrossRef]

- Pastore, G. Isotopic identification using Pulse Shape Analysis of current signals from silicon detectors: Recent results from the FAZIA collaboration. Nucl. Instrum. Methods 2017, 860, 42–50. [Google Scholar] [CrossRef]

- Tarasov, O.B. LISE++: Design your on spectrometer. Nuclear Phys. A 2004, 746, 411–414. [Google Scholar] [CrossRef]

| Parameter | Description |

|---|---|

| Wafer type | NTD silicon , size , No.: 3539-14, -17 & -19 |

| Substrate type | N-Type Silicon (NTD 5-degree off axis) |

| Resistivity | 7–10 kΩ·cm |

| Thickness | m, total thickness variation of m |

| Detector type | Double-sided ion implanted totally depleted structure |

| Implantation | Boron for junction side (P-strips) and phosphorus for ohmic side (N-strips) |

| Strip no. | 128 P-strips and 128 N-strips, i.e., |

| Strip pitch | m for P-strips and m for N-strips |

| Strip separation | m for both P- and N-strips |

| Isolation | 2 P-stop structure between N-strips |

| Metallizing | Aluminum 3000 Å |

| Dead layer | <m |

| PCB | mm2 |

| Outputs | via Molex 53916-0808 (Mouser Electronics, Mansfield, TX, USA) embedded in Kapton flex cable |

| Scenario | Electrical Signals Generated | Entrance Dead Layer |

|---|---|---|

| Ⓐ | 1 front + 1 rear | Al (m) + implant (m) |

| Ⓑ | 1 front + 2 rear | Al (m) + implant (m) |

| Ⓒ | 2 front + 2 rear | SiO2 (m) |

| Ⓓ | 2 front + 1 rear | SiO2 (m) |

| Detector | Vdepletion | Vbias | Itotal | FWHMjunction P-/N-Strip | FWHMohmic P-/N-Strip |

|---|---|---|---|---|---|

| 3539-14 | 115 V | 140 V | 510 nA | keV | keV |

| 3539-17 | 120 V | 140 V | 540 nA | keV | keV |

| 3539-19 | 115 V | 140 V | 650 nA | keV | keV |

| Material | Thickness | Energy Loss | () Energy Straggling | () Angular Straggling | Lateral Spread |

|---|---|---|---|---|---|

| SiO2 †† | 1 µm | keV | keV/u | mrad | m |

| Si implant † | 0.5 µm | keV | keV/u | mrad | m |

| Al § | m | keV | keV/u | mrad | m |

| Scenario | Resolution (%) by Adding Cal †/Cal ‡ | Resolution (%) by Rotating | Enhancement Factor § |

|---|---|---|---|

| Ohmic injection (P-interstrip) | |||

| Ohmic injection (N-interstrip) | 1 | ||

| Junction injection (P-interstrip) | |||

| Junction injection (N-interstrip) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dueñas, J.A.; Cobo, A.; Galtarossa, F.; Goasduff, A.; Mengoni, D.; Sánchez-Benítez, A.M. Energy Resolution from a Silicon Detector’s Interstrip Regions. Sensors 2024, 24, 2622. https://doi.org/10.3390/s24082622

Dueñas JA, Cobo A, Galtarossa F, Goasduff A, Mengoni D, Sánchez-Benítez AM. Energy Resolution from a Silicon Detector’s Interstrip Regions. Sensors. 2024; 24(8):2622. https://doi.org/10.3390/s24082622

Chicago/Turabian StyleDueñas, J. A., A. Cobo, F. Galtarossa, A. Goasduff, D. Mengoni, and A. M. Sánchez-Benítez. 2024. "Energy Resolution from a Silicon Detector’s Interstrip Regions" Sensors 24, no. 8: 2622. https://doi.org/10.3390/s24082622