Various Structures Based on Nickel Oxide Thick Films as Gamma Radiation Sensors

Abstract

:Introduction

Experimental Procedure

Results and Discussion

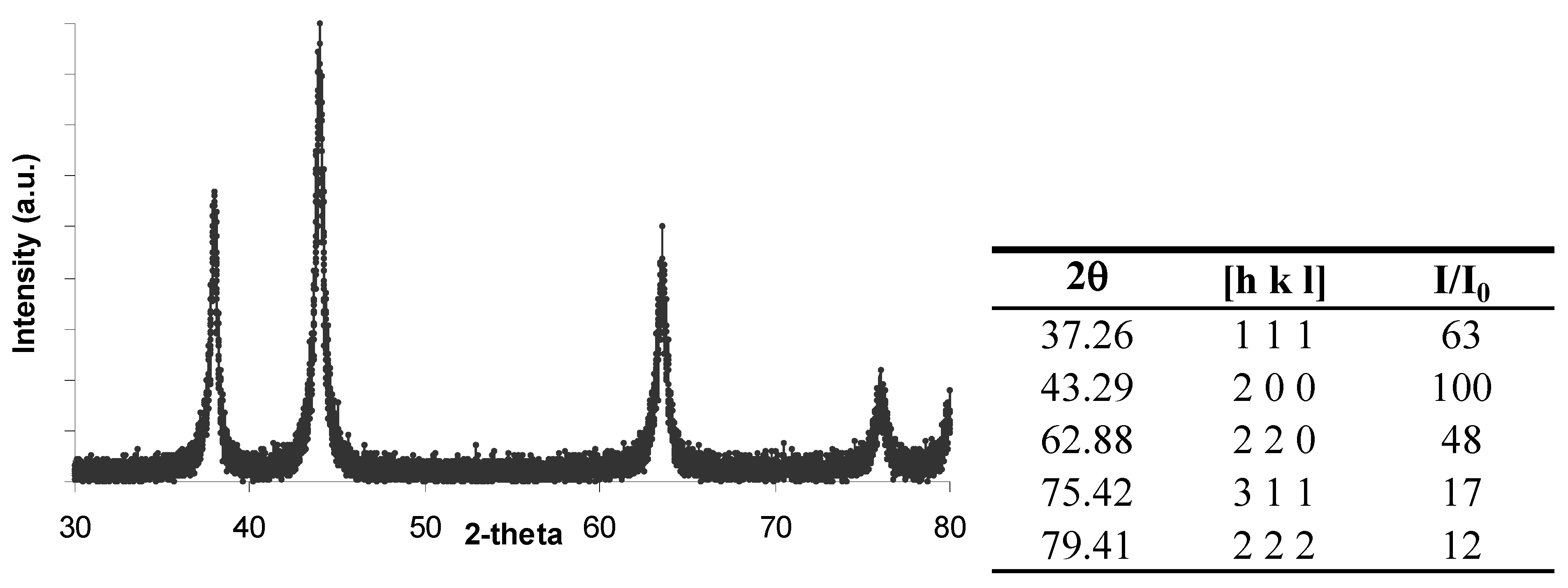

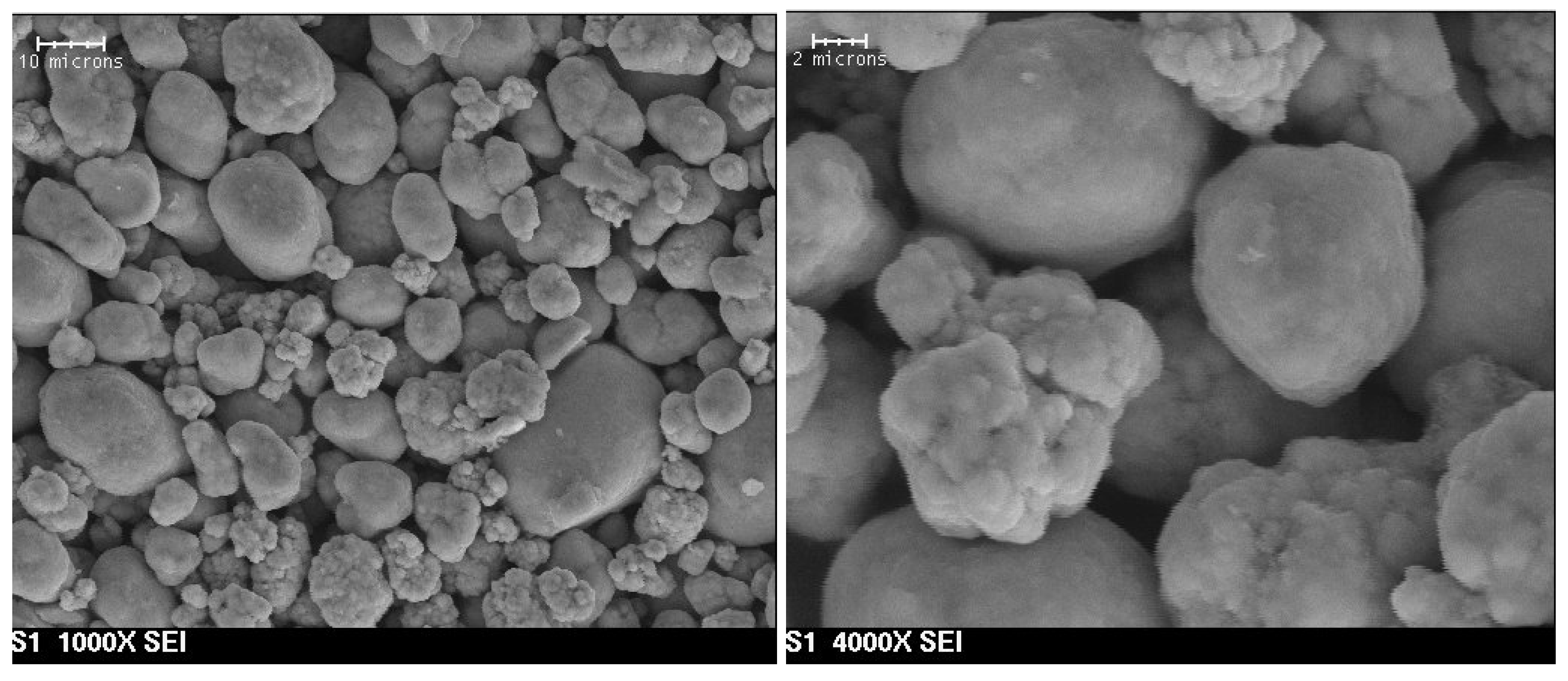

Structural Properties of NiO Thick Films

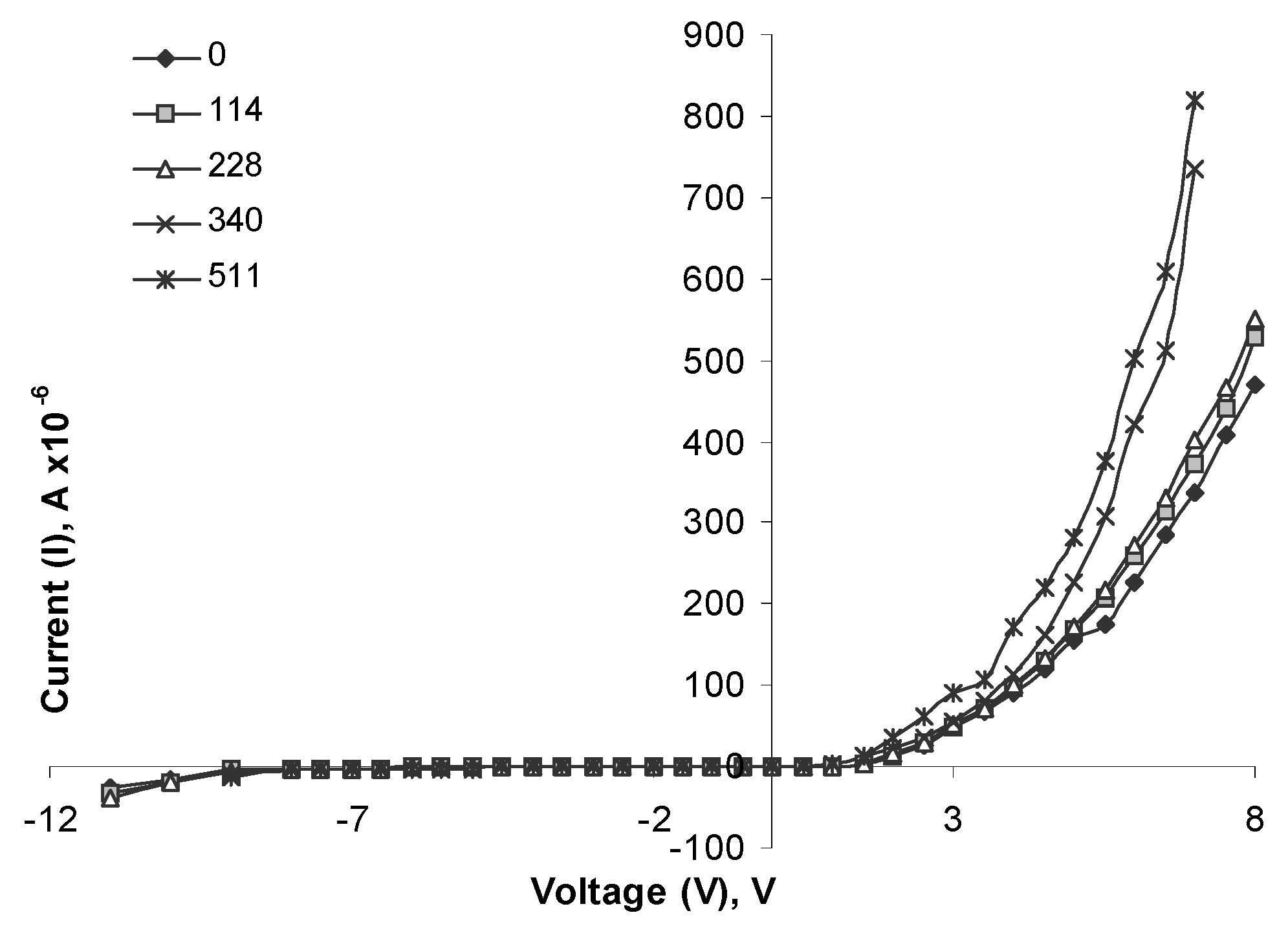

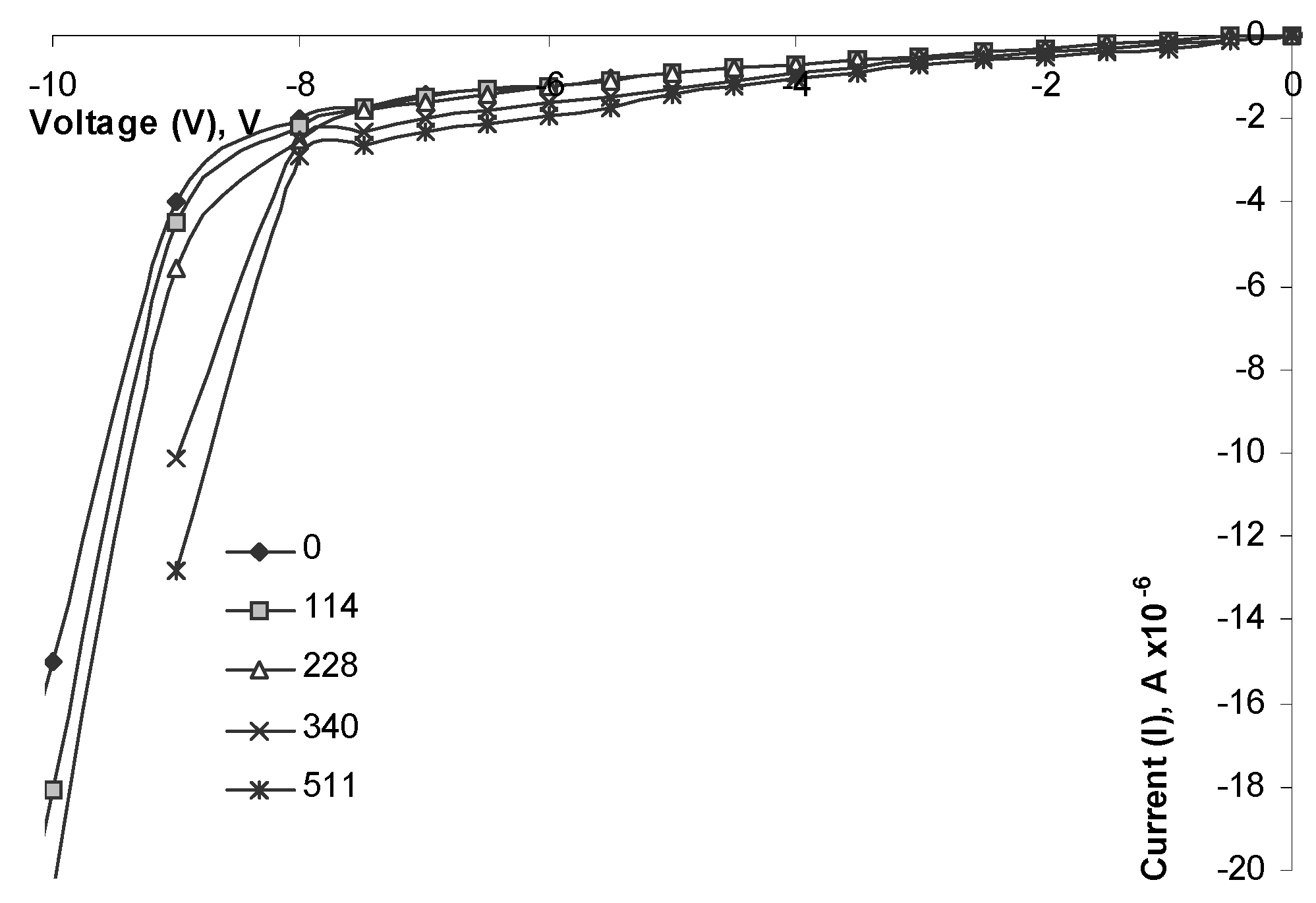

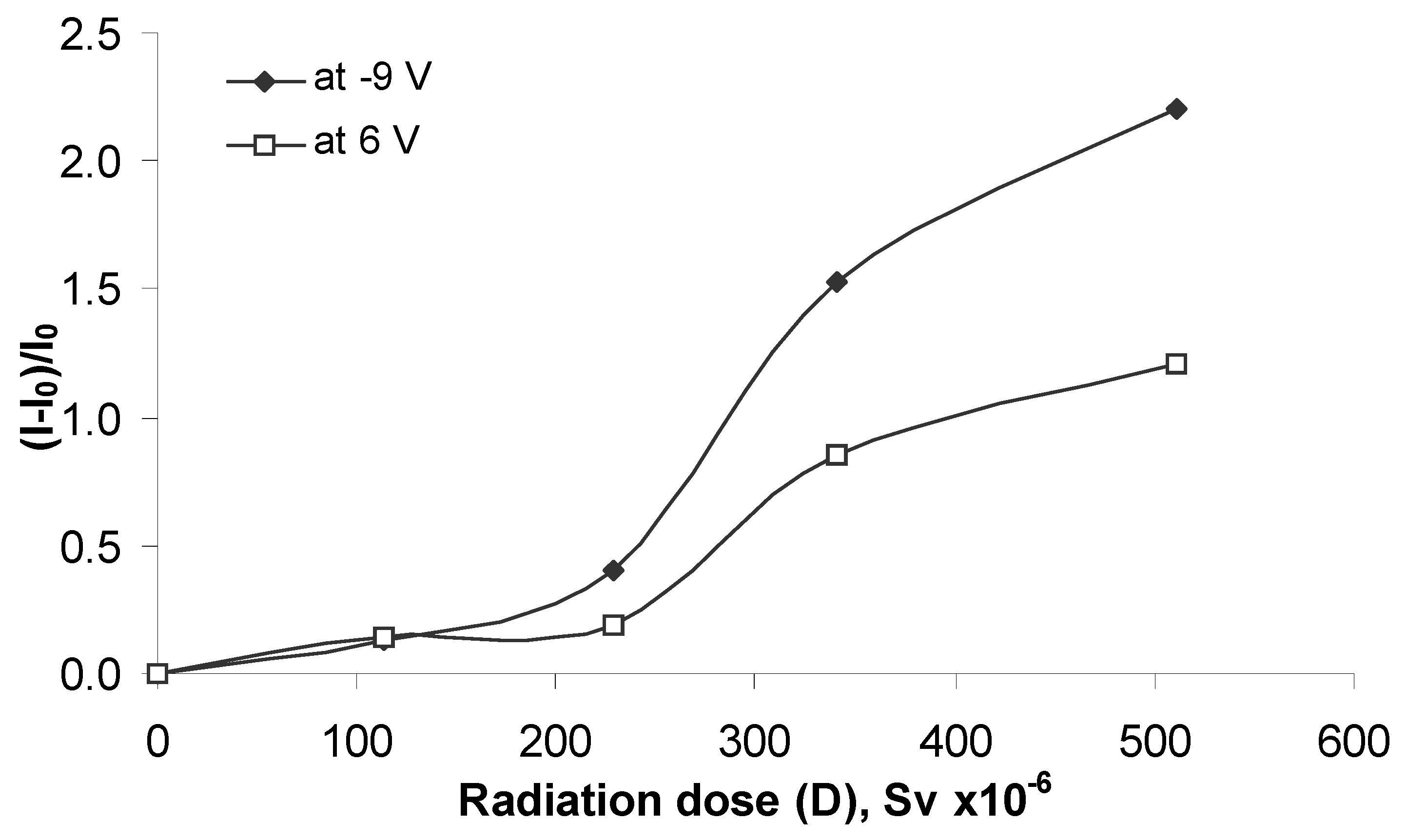

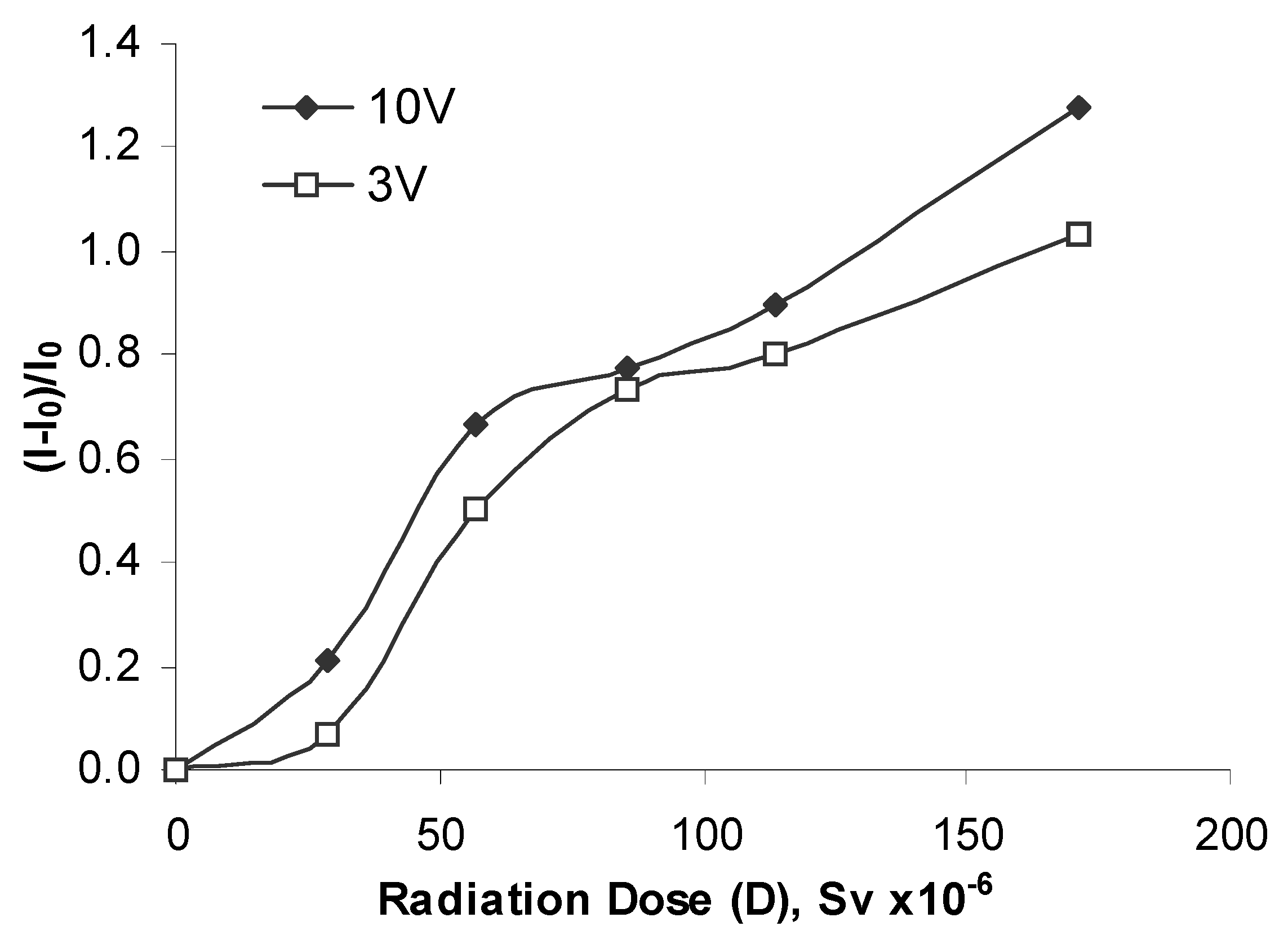

Effect of γ-radiation on NiO Diode Structures

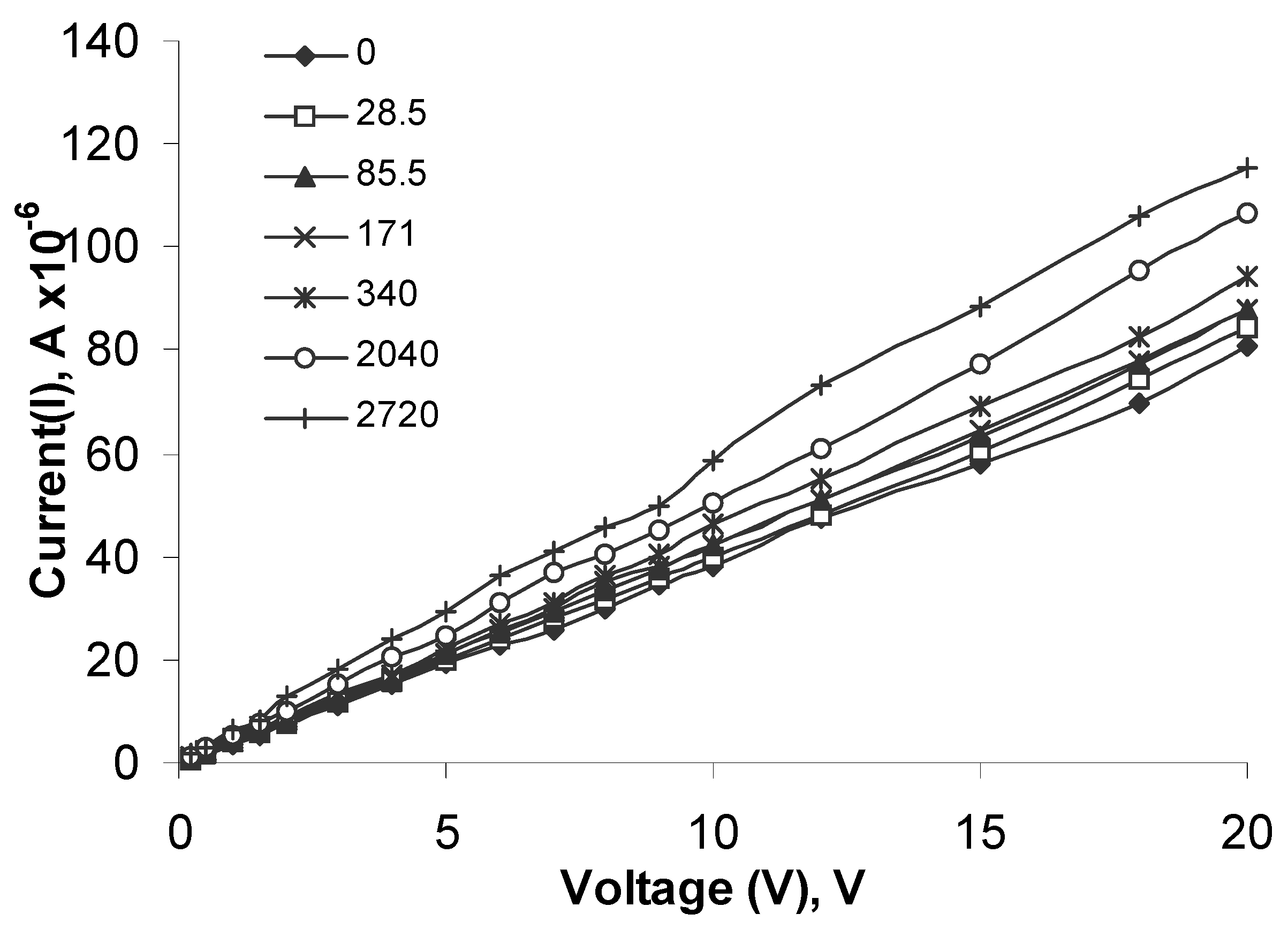

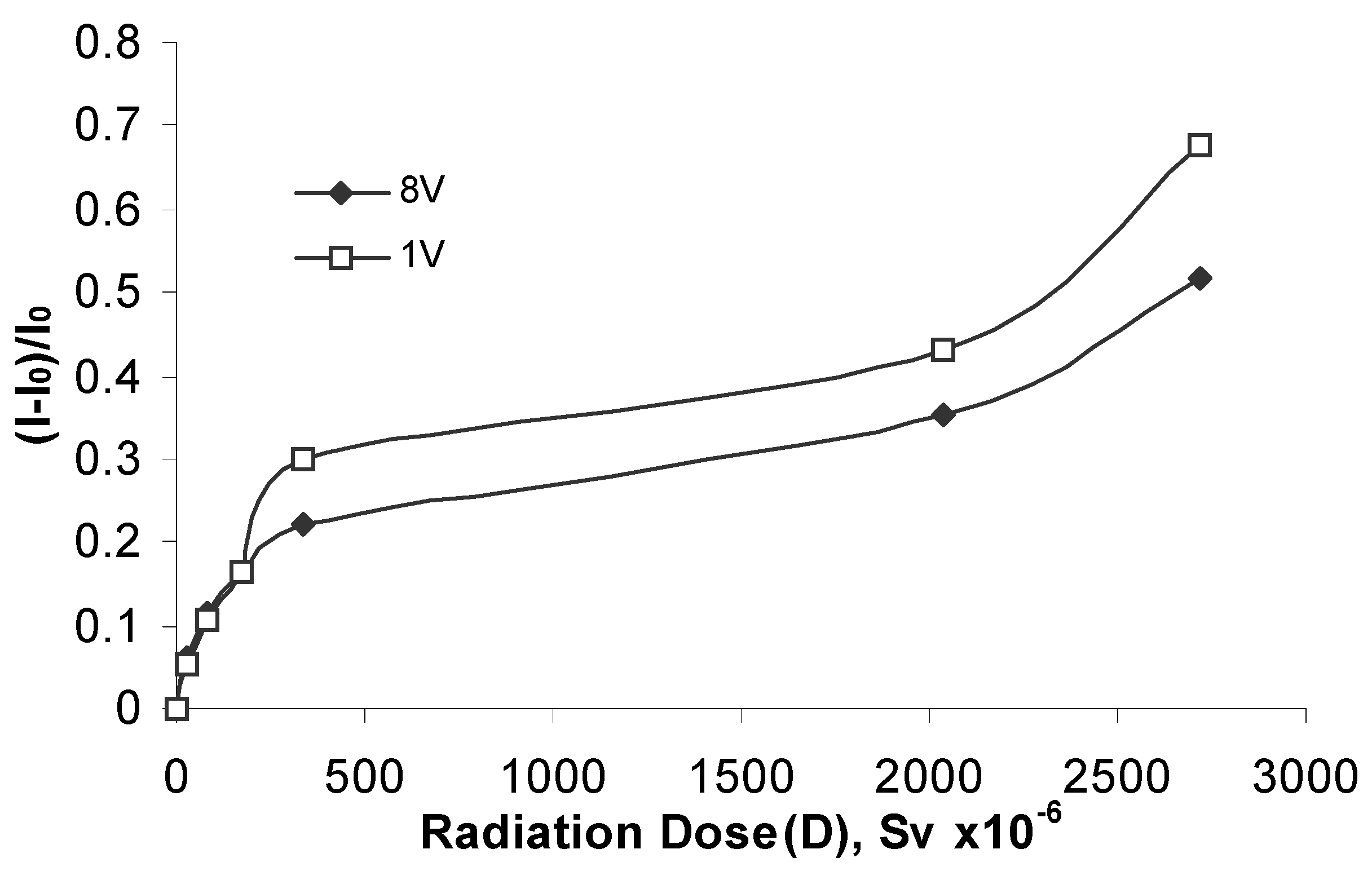

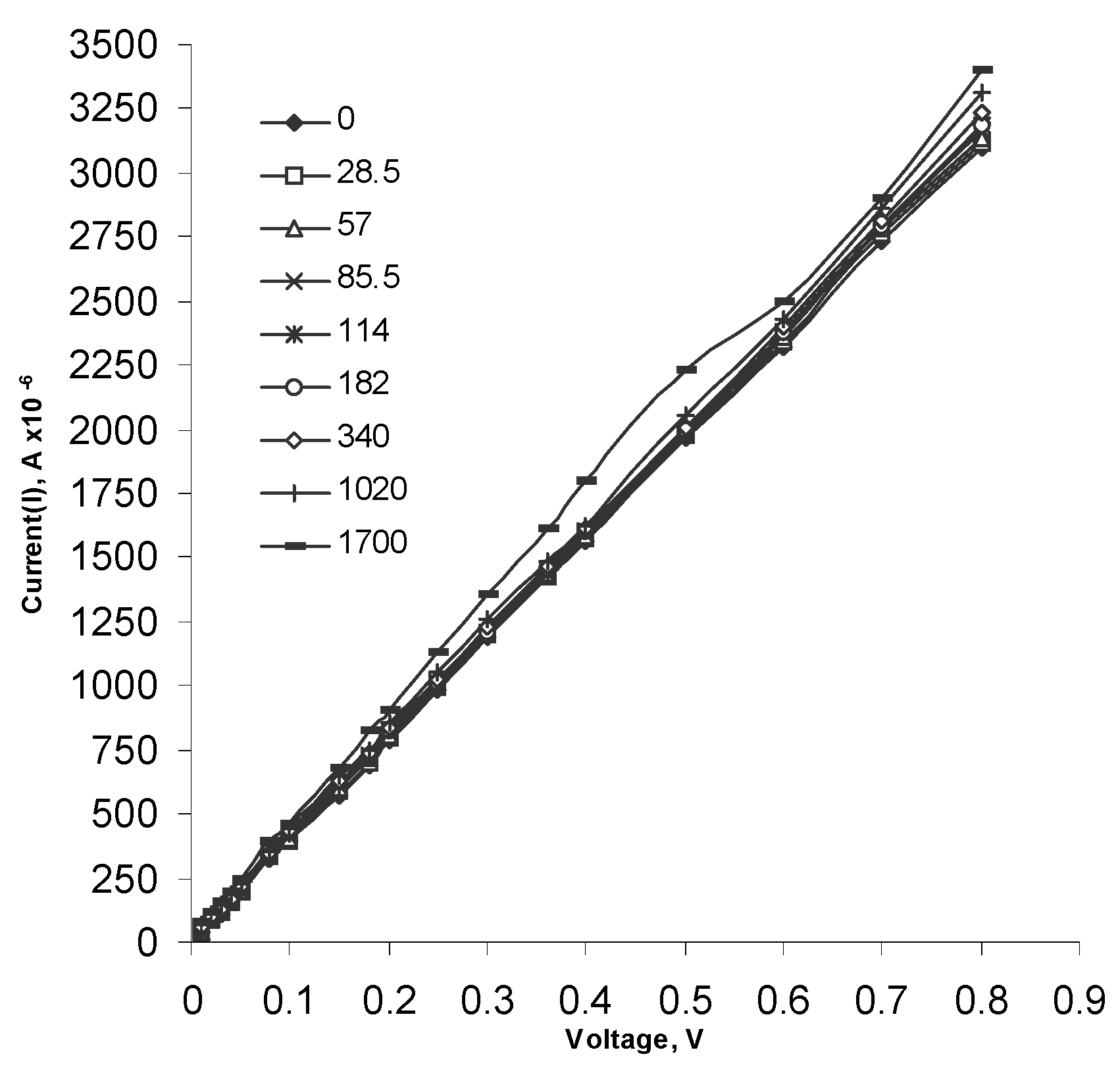

Effect of γ-radiation on Carbon-Filled NiO Planar Structures with Interdigitated Electrodes

Conclusion

Acknowledgments

References

- Heinrich, V. E.; Cox, P. A. The surface science of metal oxides; Cambridge University Press: Cambridge, 1994. [Google Scholar]

- Pacchioni, G. Ab initio theory of point defects in oxide materials: structure, properties, chemical reactivity. Solid State Sciences 2000, 2, 161–179. [Google Scholar] [CrossRef]

- Faia, P. M.; Pereira, M. A.; Nunes, A. M.; Furtado, C. S. Electronic noses, a different approach to the sensitivity and selectivity issues. Journal of the European Ceramic Society 1999, 19, 883–886. [Google Scholar] [CrossRef]

- Hockensmith, C. M.; Goldsby, J. C.; Kacik, T. Thermal studies of new precursors to indium-tin oxides for use as sensor materials in the detection of NOx. Thermochimica Acta 1999, 340-341, 315–322. [Google Scholar] [CrossRef]

- Ragan, D. D.; Svedlindh, P.; Granqvist, C. G. Electrochromic Ni oxide films studied by magnetic measurements. Solar Energy Materials and Solar Cells 1998, 54, 247–254. [Google Scholar] [CrossRef]

- Neubecker, A.; Pompl, T.; Doll, T.; Hansch, W.; Eisele, I. Ozone-enhanced molecular beam deposition of nickel oxide (NiO) for sensor applications. Thin Solid Films 1997, 310, 19–23. [Google Scholar] [CrossRef]

- Schlesinger, T. E.; Toney, J. E.; Yoon, H.; Lee, E. Y.; Brunett, B. A.; Franks, L.; James, R. B. Cadmium zinc telluride and its use as a nuclear radiation detector material. Materials Science and Engineering: R: Reports 2001, 32, 103–189. [Google Scholar] [CrossRef]

- Pacchioni, G.; Pescarmona, P. Structure and stability of oxygen vacancies on sub-surface, terraces, and low-coordinated surface sites of MgO:: an ab initio study. Surface Science 1998, 412-413, 657–671. [Google Scholar] [CrossRef]

- Zhu, R. y. Radiation damage in scintillating crystals. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment 1998, 413, 297–311. [Google Scholar] [CrossRef]

- Audet, S.; Steigerwald, J. Semiconductor Sensors; Sze, S. M., Ed.; John Wiley & Sons, Inc.: New York, Chichester, Brisbane, Toronto, Singapore, 1994; Vol. pp. 271–329. [Google Scholar]

- Arshak, K.; Korostynska, O.; Harris, J. Gamma radiation dosimetry using screen printed nickel oxide thick films. In Proceeding of MIEL 2002, 23rd International conference on Microelectronics; pp. 357–360(2002).

- Atanassova, E.; Paskaleva, A.; Konakova, R.; Spassov, D.; Mitin, V. F. Influence of γ− radiation on thin Ta2O5-Si structures. Microelectronics Journal 2001, 32, 553–562. [Google Scholar] [CrossRef]

- Mucka, V.; Podlaha, J.; Silber, R. NiO-ThO2 mixed catalysts in hydrogen peroxide decomposition and influence of ionizing radiation. Radiation Physics and Chemistry 2000, 59, 467–475. [Google Scholar] [CrossRef]

- Zhang, J. D.; Fung, S.; Li-Bin, L.; Zhi-Jun, L. Ti ion valence variation induced by ionizing radiation at TiO2/Si interface. Surface and Coatings Technology 2002, 158-159, 238–241. [Google Scholar] [CrossRef]

- Powder Diffraction File, Joint Committee on Powder diffraction, International Center for Diffraction Data, Swarthmore, PA, 1987, Card. 4-0835.

- Holmes-Siedle, A. G.; Adams, L. Handbook of radiation effects; Oxford University Press: Oxford; New York, 1993. [Google Scholar]

- Horowitz, Y. S. Theory of thermoluminescence gamma dose response: The unified interaction model. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms 2001, 184, 68–84. [Google Scholar]

- Deng, Q.; Yin, Z.; Zhu, R. Y. Radiation-induced color centers in La-doped PbWO4 crystals. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment 1999, 438, 415–420. [Google Scholar] [CrossRef]

- Sample Availability: Available from the authors.

© 2003 by MDPI (http://www.mdpi.net). Reproduction is permitted for noncommercial purposes.

Share and Cite

Arshak, K.; Korostynska, O.; Fahim, F. Various Structures Based on Nickel Oxide Thick Films as Gamma Radiation Sensors. Sensors 2003, 3, 176-186. https://doi.org/10.3390/s30600176

Arshak K, Korostynska O, Fahim F. Various Structures Based on Nickel Oxide Thick Films as Gamma Radiation Sensors. Sensors. 2003; 3(6):176-186. https://doi.org/10.3390/s30600176

Chicago/Turabian StyleArshak, Khalil, Olga Korostynska, and Farah Fahim. 2003. "Various Structures Based on Nickel Oxide Thick Films as Gamma Radiation Sensors" Sensors 3, no. 6: 176-186. https://doi.org/10.3390/s30600176