PVC Based Selective Sensors for Ni2+ Ions Using Carboxylated and Methylated Porphine

Abstract

:Introduction

Experimental

Reagents

Preparation of membranes

Potential measurements

Saturated calomel electrodes (SCE) were used as reference electrodes. The response time of the membrane sensors is the time in which stable and constant potentials are obtained.

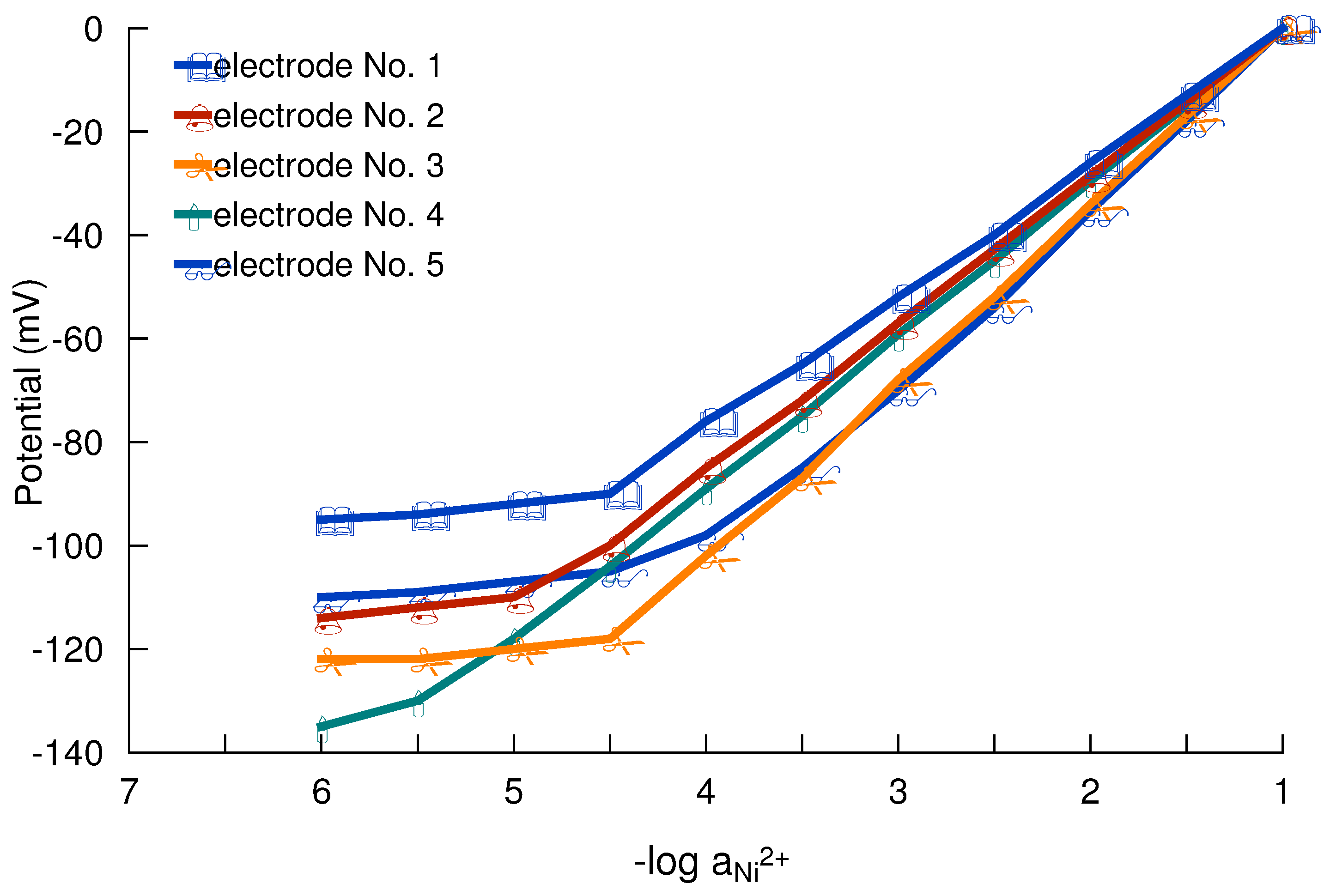

Saturated calomel electrodes (SCE) were used as reference electrodes. The response time of the membrane sensors is the time in which stable and constant potentials are obtained.| Electrode/ Membrane No. | %(w/w) of various components | Working concn. range, M | Slope, mV/decade of activity | Response time, sec | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TBAP | DBP | DOP | DBBP | CN | NaTPB | PVC | ||||

| 1 | 10 | - | - | - | - | 5 | 85 | 5.5 x 10-5 – 1.0 x 10-1 | 26.0 | 60 |

| 2 | 10 | 30 | - | - | - | 5 | 55 | 2.0 x 10-5 – 1.0 x 10-1 | 28.5 | 15 |

| 3 | 10 | - | 30 | - | - | 5 | 55 | 5.5 x 10-5 – 1.0 x 10-1 | 34.0 | 20 |

| 4 | 10 | - | - | 30 | - | 5 | 55 | 2.0 x 10-6 – 1.0 x 10-1 | 29.6 | 15 |

| 5 | 10 | - | - | - | 30 | 5 | 55 | 5.6 x 10-5 – 1.0 x 10-1 | 35.3 | 10 |

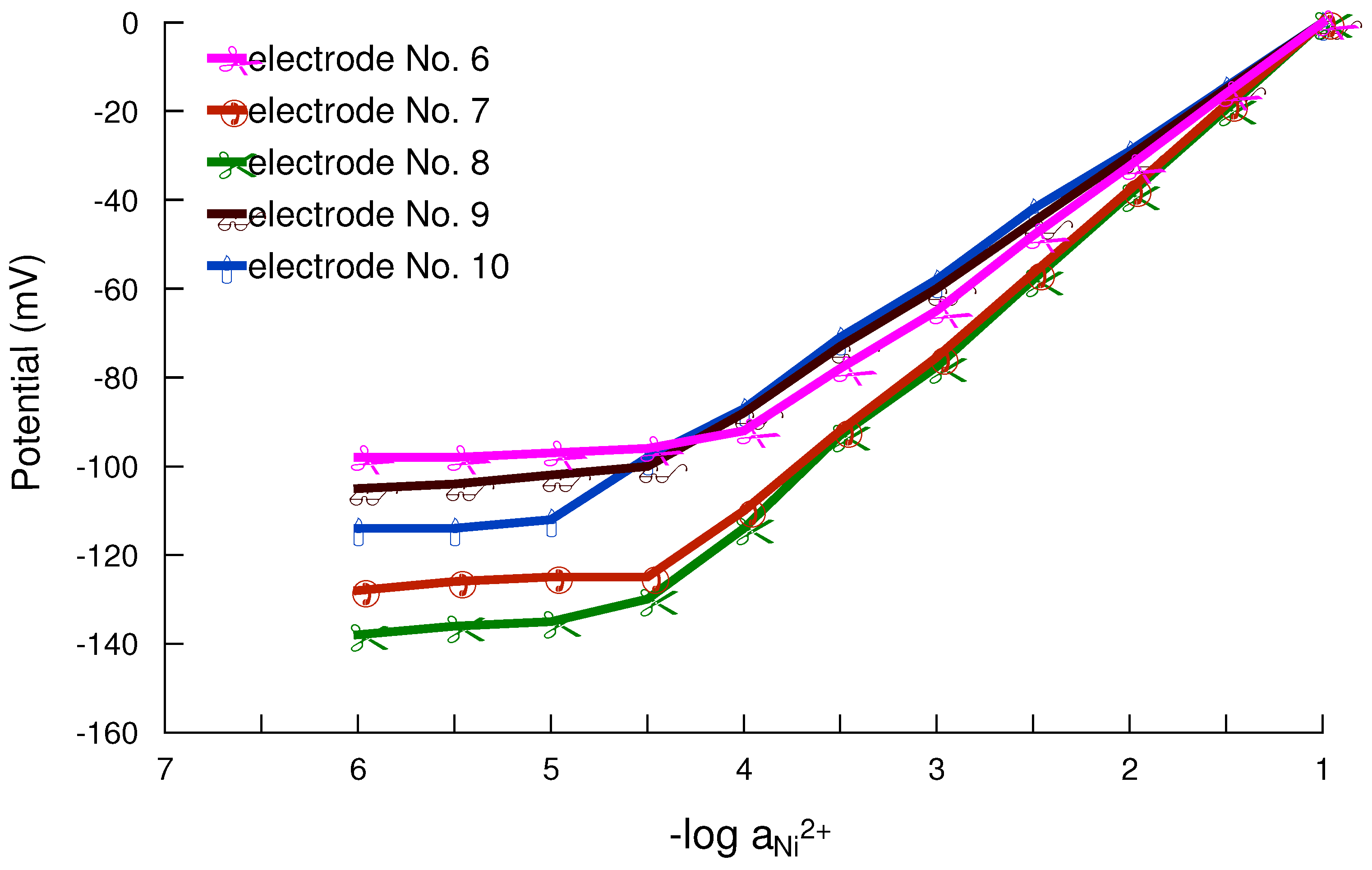

| Electrode/ Membrane No. | %(w/w) of various components | Working concen. Range, M | Slope, mV/decade of activity | Response time, sec | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| OMP | DBP | DOP | DBBP | CN | NaTPB | PVC | ||||

| 6 | 10 | - | - | - | - | 5 | 85 | 1.0 x 10-4 – 1.0 x 10-1 | 32.4 | 60 |

| 7 | 10 | 30 | - | - | - | 5 | 55 | 5.0 x 10-5 – 1.0 x 10-1 | 37.7 | 20 |

| 8 | 10 | - | 30 | - | - | 5 | 55 | 3.6 x 10-5 – 1.0 x 10-1 | 38.8 | 15 |

| 9 | 10 | - | - | 30 | - | 5 | 55 | 5.6 x 10-5 – 1.0 x 10-1 | 30.1 | 15 |

| 10 | 10 | - | - | - | 30 | 5 | 55 | 1.0 x 10-5 – 1.0 x 10-1 | 29.0 | 10 |

Results and Discussion

Working concentration range

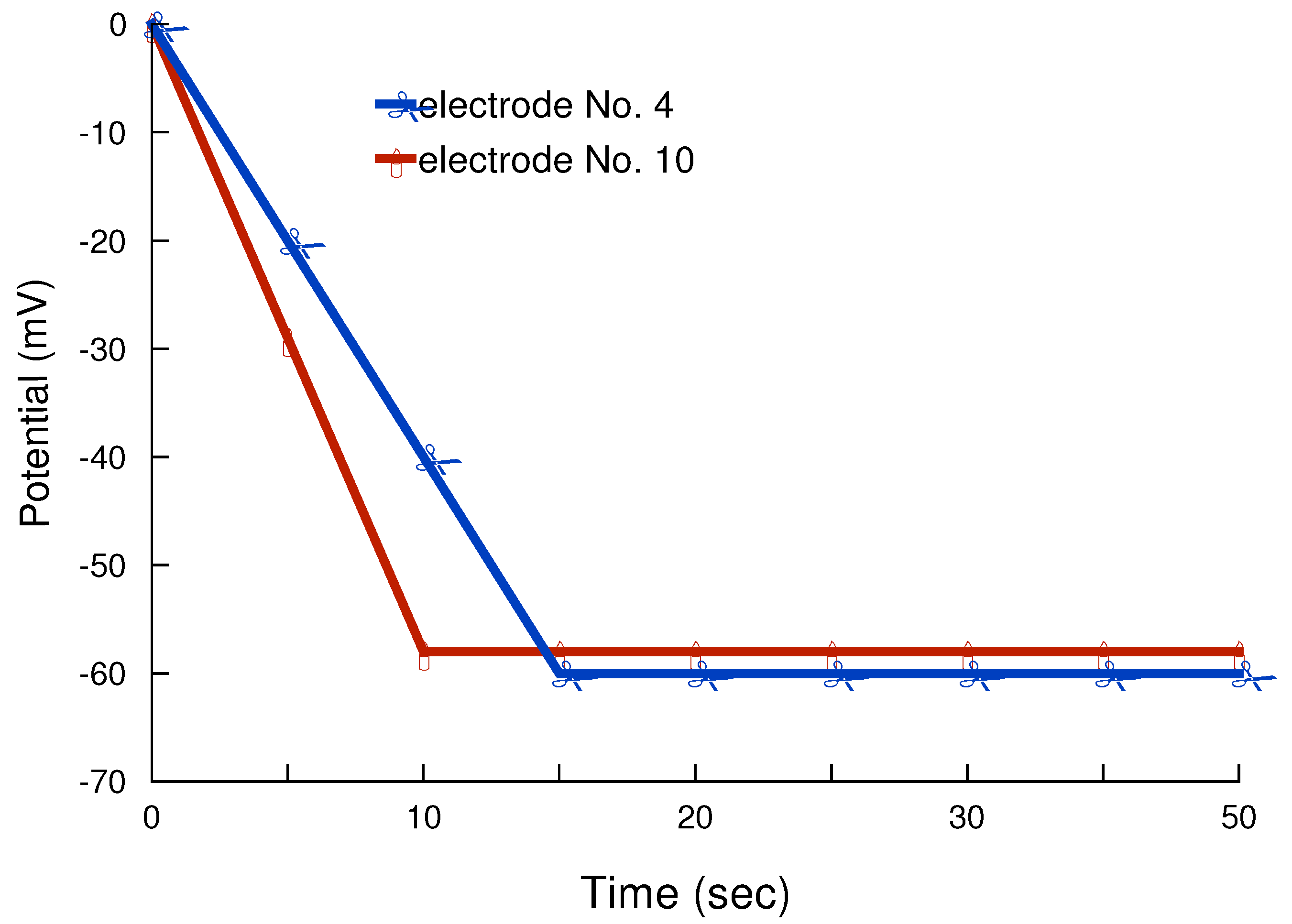

Response and lifetime

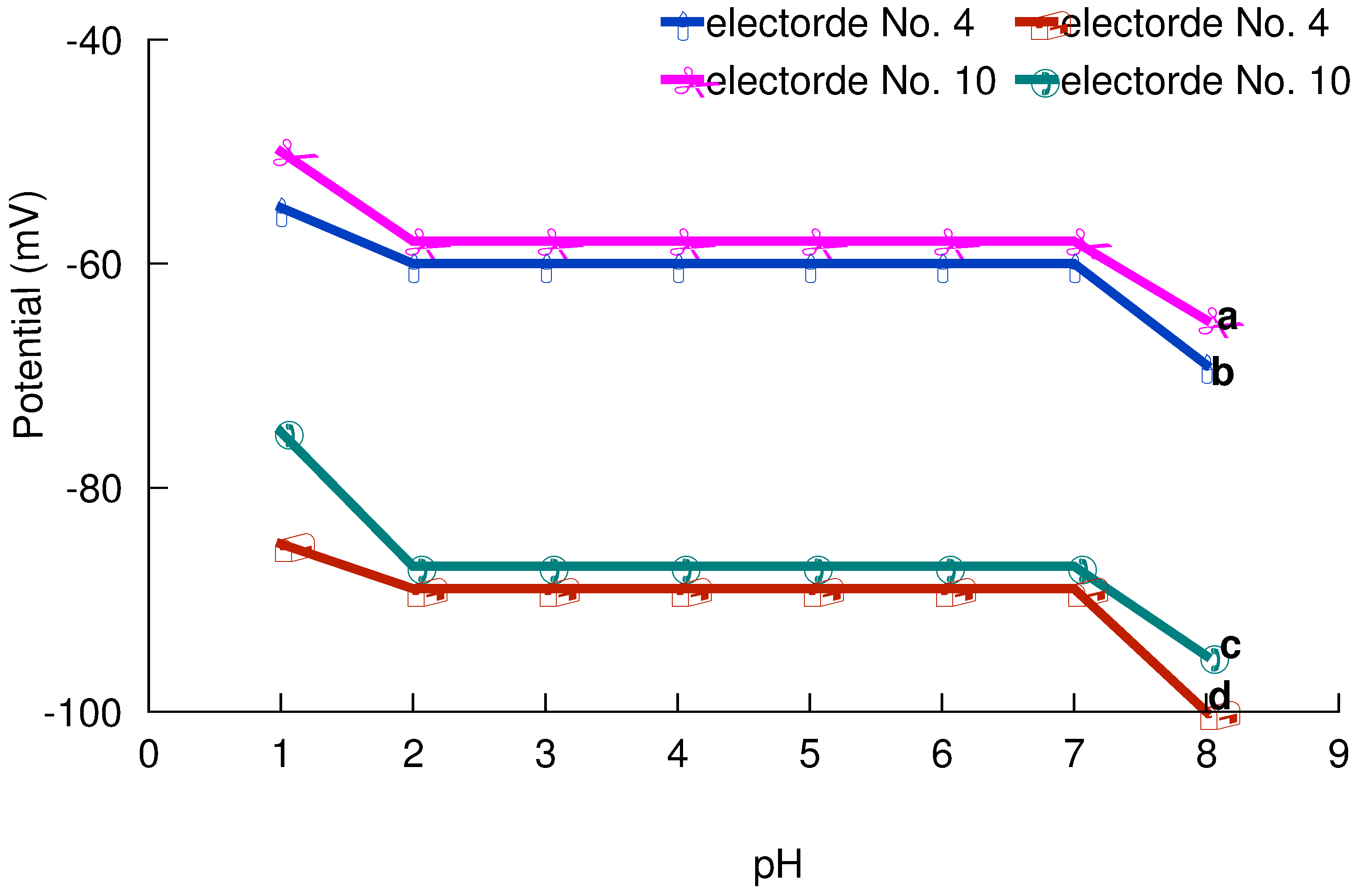

pH and non-aqueous effect

Potentiometric selectivity

for Ni2+ -selective sensors (electrode nos. 4 and 10) as calculated by Match Potential Method

for Ni2+ -selective sensors (electrode nos. 4 and 10) as calculated by Match Potential Method

| Interfering ion, B | Selectivity coefficients,  | |

|---|---|---|

| Electrode No. 4 | Electrode No. 10 | |

| NH4+ | 1.4 x 10-2 | 2.0 x 10-2 |

| Na+ | 9.0 x 10-2 | 8.2 x 10-2 |

| K+ | 5.3 x 10-2 | 2.0 x 10-2 |

| Tl+ | 3.2 x 10-2 | 1.9 x 10-2 |

| Cs+ | 4.7 x 10-2 | 1.4 x 10-2 |

| Cu2+ | 1.2 x 10-3 | 1.8 x 10-3 |

| Ca2+ | 1.4 x 10-3 | 1.2 x 10-3 |

| Sr2+ | 1.9 x 10-3 | 2.5 x 10-3 |

| Ba2+ | 2.0 x 10-3 | 2.0 x 10-3 |

| Mg2+ | 1.4 x 10-3 | 2.8 x 10-3 |

| Co2+ | 2.3 x 10-1 | 4.8 x 10-1 |

| Cd2+ | 2.6 x 10-3 | 2.4 x 10-3 |

| Zn2+ | 2.2 x 10-3 | 2.6 x 10-3 |

| Hg2+ | 1.4 x 10-3 | 1.4 x 10-3 |

| Pb2+ | 1.4 x 10-3 | 1.6 x 10-3 |

| Fe3+ | 1.8 x 10-3 | 1.4 x 10-3 |

| Al3+ | 2.0 x 10-3 | 1.9 x 10-3 |

| Ce3+ | 2.8 x 10-3 | 1.8 x 10-3 |

Analytical applications

Estimation of Ni2+ in effluents

| Samples | PH | Ni2+ as determined byAAS, mg l-1 | Ni2+ as determined by sensor 4, mg l-1 | |

|---|---|---|---|---|

| Found | after Adjustment | |||

| 1 | 6.80 | 3.70 | 44.0 | 47.0 |

| 2 | 6.65. | 3.80 | 43.5 | 47.0 |

| 3 | 6.70 | 3.65 | 43.0 | 46.0 |

| 4 | 6.90 | 3.75 | 42.0 | 45.0 |

Potentiometric titration

Conclusion

Acknowledgements

References

- Pungor, E.; Toth, K.; Havas, J. Acta. Chim. Acad. Sci. Hung. 1966, 48, 17.

- Buchanan, E.B.; Scago, J.L. Acta. Chim. 1968, 40, 517.

- Awasthi, S.P.; Kulkarni, V.T.; Sundaresan, M. J. Electrochem. Soc. India 1988, 37, 309.

- Lal, U.S.; Chattopadhyaya, M.C.; Dey, A.K. J. Ind. Chem. Soc. 1982, 49, 493.

- Materova, E.A.; Muchovikov, V.V.; Grigorieva, M.G. Anal. Lett. 1975, 8, 167.

- Luca, C.; Maria, P.; Nicolae, M. Rev. Chim. 1976, 27, 1088.

- Smirnova, E.V.; Petrukhin, O.M.; Rogatinskaya, S.L. Zh. Anal. Khim. 1982, 37, 2137.

- Hampton, M.D.; Peters, C.A.; Wellington, L.A. Acta. Chim. Acta. 1987, 194, 171. [CrossRef]

- Lebedera, O.A.; Jansons, E. Latv. PSR Zinat. Akad. Vestis. Kim. Ser. 1986, 4, 423.

- Rao, G.N.; Srivastava, S.K.; Singh, M. Talanta 1996, 43, 1821.

- Chaniotakis, N.A.; Chasser, A.M.; Meyerhoff, M.E. Anal. Chem. 1988, 60, 88.

- Jyo, A.; Minakami, R.; Kanda, Y.; Egawa, H. Sens. & Actuators B 1993, 13–14, 200.

- Gao, D.; Jun, G.; Yu, R.; Zheny, G. Analyst 1995, 120, 499.

- Singh, L.P.; Vardhan, H. Anal. Proc. 1995, 32, 193.

- Jain, A.K.; Gupta, V.K.; Singh, R.D.; Khurana, U.; Singh, L.P. Sens & Actuators B 1997, 40, 15.

- Gupta, V.K.; Jain, A.K.; Singh, L.P.; Khurana, U. Anal. Chim. Acta 1997, 335, 33. [CrossRef]

- Craggs, A; Moody, G.J.; Thomas, J.D.R. J. Chem. Edu. 1974, 51, 541.

- Assubai, F.N.; Moody, G.J.; Thomas, J.D.R. Analyst 1988, 113, 61.

- Chan, W.H.; Shiu, K.K.; Gu, X.H. Analyst 1993, 118, 863.

- Jain, A.K.; Gupta, V.K.; Singh, L.P.; Khurana, U. Analyst 1997, 122, 583.

- Saez de Viteri, F.J.; Diamond, D. Analyst 1994, 119, 749.

- Srivastava, S.K.; Gupta, V.K.; Jain, S. Analyst 1995, 120, 495.

- Srivastava, S.K.; Gupta, V.K.; Jain, S. Anal. Chem. 1996, 68, 1272.

- Jain, A.K.; Singh, L.P.; Jain, P.K. Sens & Actuators B 1995, 25, 729.

- Jain, A.K.; Gupta, V.K.; Sahoo, B.B.; Singh, L.P. Anal. Proc. 1995, 32, 99.

- Jain, A.K.; Gupta, V.K.; Singh, L.P. Anal. Proc. 1995, 32, 263.

- Sample Availability: Available from the authors.

© 2003 by MDPI (http://www.mdpi.org). Reproduction is permitted for noncommercial purposes.

Share and Cite

Singh, L.P.; Bhatnagar, J.M. PVC Based Selective Sensors for Ni2+ Ions Using Carboxylated and Methylated Porphine. Sensors 2003, 3, 393-403. https://doi.org/10.3390/s30900393

Singh LP, Bhatnagar JM. PVC Based Selective Sensors for Ni2+ Ions Using Carboxylated and Methylated Porphine. Sensors. 2003; 3(9):393-403. https://doi.org/10.3390/s30900393

Chicago/Turabian StyleSingh, L. P., and J. M. Bhatnagar. 2003. "PVC Based Selective Sensors for Ni2+ Ions Using Carboxylated and Methylated Porphine" Sensors 3, no. 9: 393-403. https://doi.org/10.3390/s30900393

APA StyleSingh, L. P., & Bhatnagar, J. M. (2003). PVC Based Selective Sensors for Ni2+ Ions Using Carboxylated and Methylated Porphine. Sensors, 3(9), 393-403. https://doi.org/10.3390/s30900393