Further Structural Intelligence for Sensors Cluster Technology in Manufacturing

Abstract

:1. Introduction

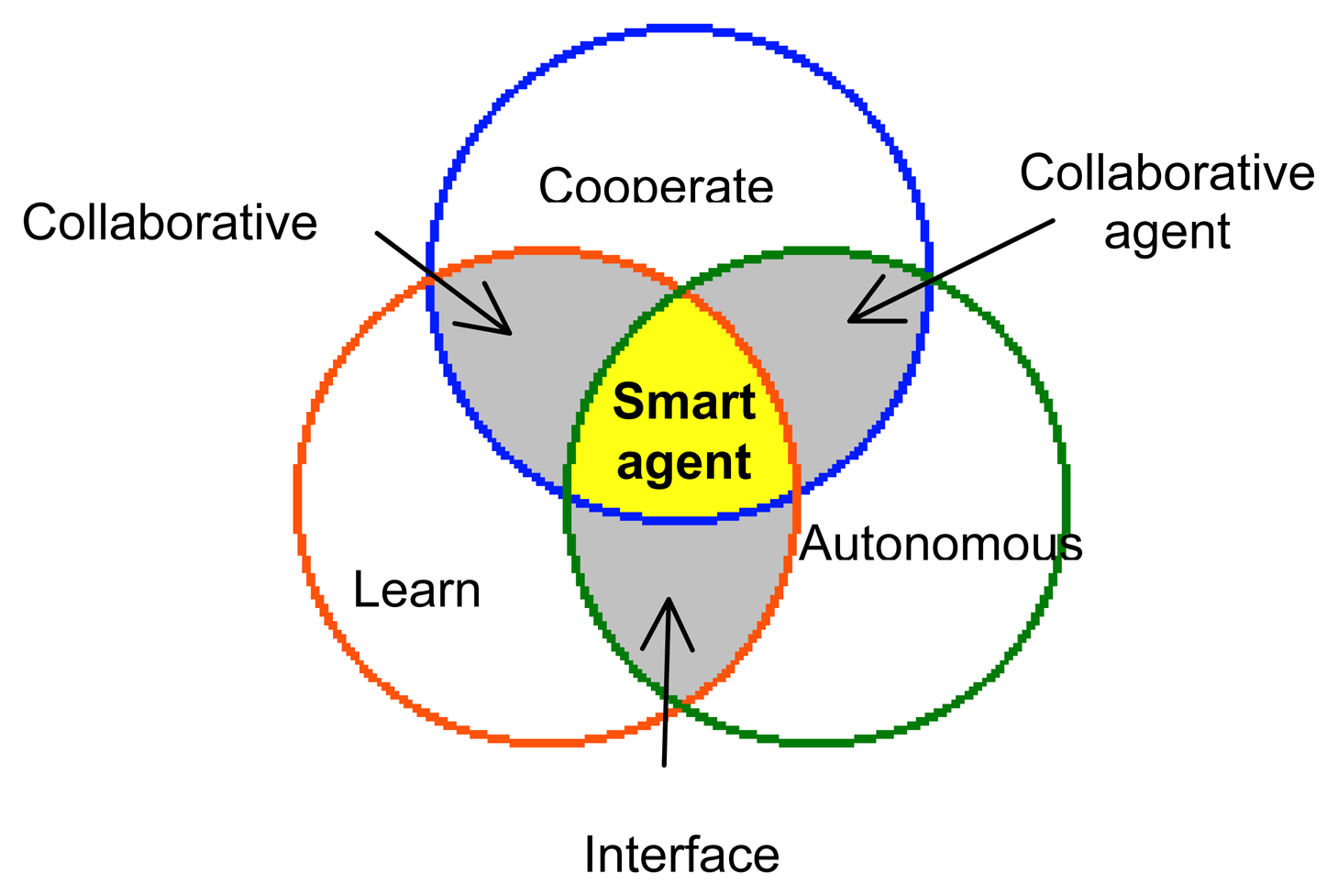

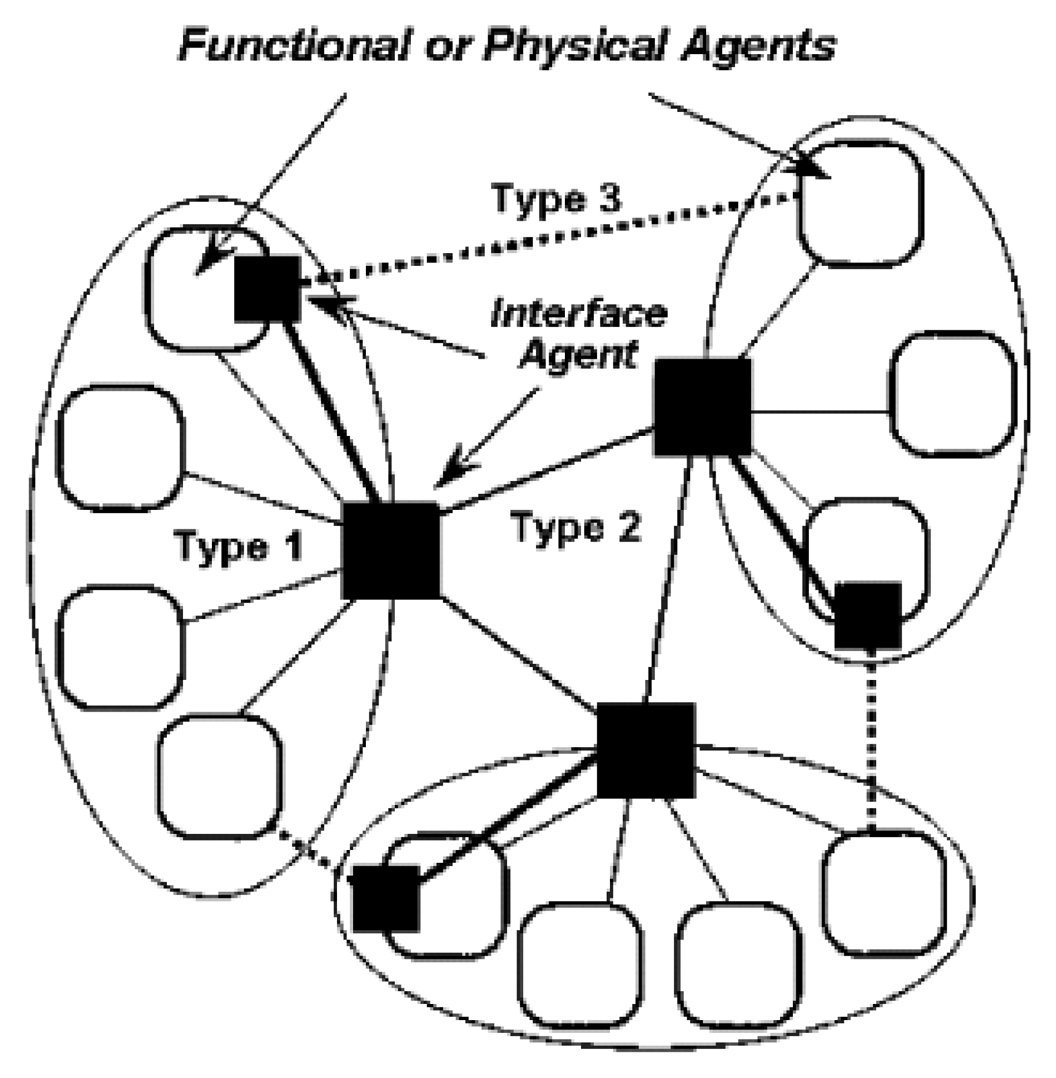

2 Structure and functions of an intelligent sensor

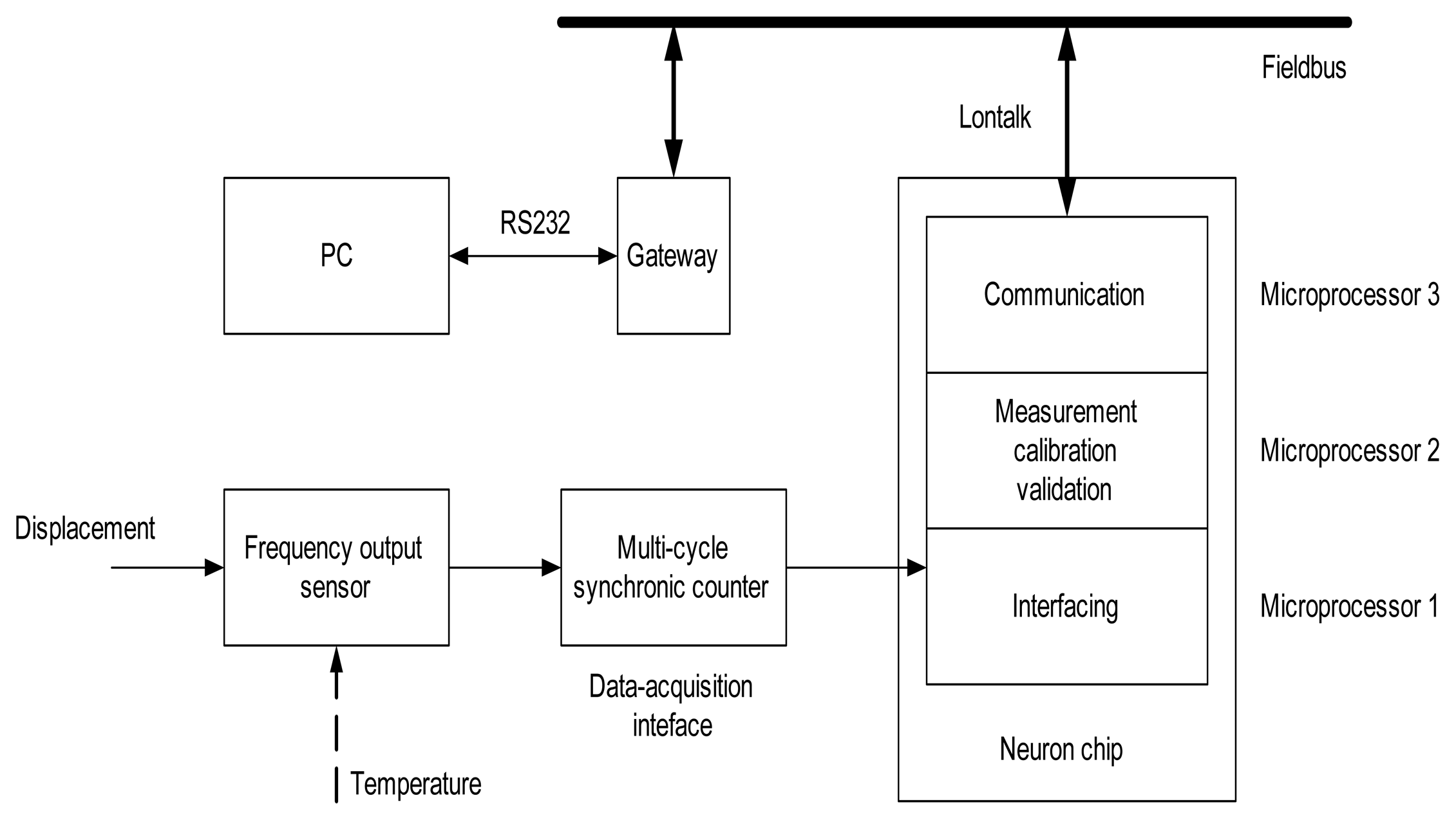

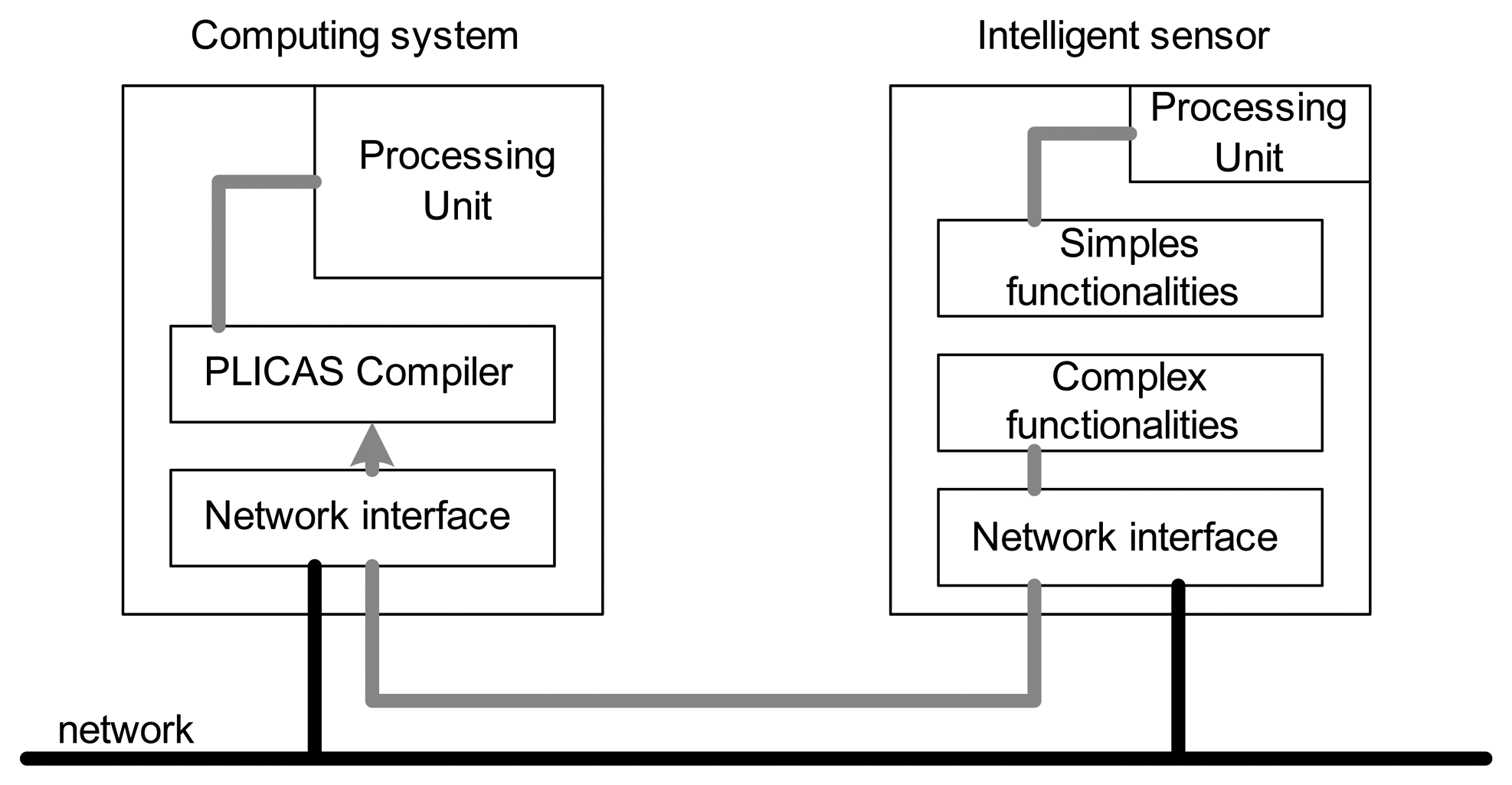

2.1 Intelligent sensor architecture

- (a)

- A sensing element that links the external world to a sensor system by generating electrical signal (e.g. voltage, current) with response to physical properties of the environment such as temperature, pressure, light intensity, sound, vibration, etc.

- (b)

- An interface element for signal conditioning and data conversion. The signal obtained from the sensing element is modified, enhanced and converted to a discrete time digital data stream before passing through a processing element.

- (c)

- A processing element that includes a microcontroller with an associated memory and software; this is the main component of the architecture where the incoming signal is processed.

- (d)

- A communication element, which provides a two-way communication between the processing element and users. The communication are wireless, optical fibres, serial buses, and interfacing to successful communication with the outside world.

- (e)

- A power source.

- ▪

- Reduced down time.

- ▪

- Fault tolerant systems.

- ▪

- Adaptability for self-calibration and compensation.

- ▪

- Higher reliability.

- ▪

- Master/Slave sensors mapping capability.

- ▪

- Lower weight.

- ▪

- Lower cost.

- ▪

- Lower maintenance.

2.2 Intelligent sensor functionalities

2.2.1 Compensation functionality

- (a)

- Non-linear compensation that linearises the relationship between input and output.

- (b)

- Cross-sensitivity compensation such as temperature control compensation.

- (c)

- Time based or long term drift compensation due to degradation of the sensor elements [18].

2.2.2 Processing functionality

2.2.3 Communication functionality

2.2.4 Validation functionality

2.2.5 Integration functionality

2.2.6 Data fusion functionality

2.3 Interface with the outside world

4. Applications of intelligent sensor and agents in manufacturing

5. Future requirements for a full process control

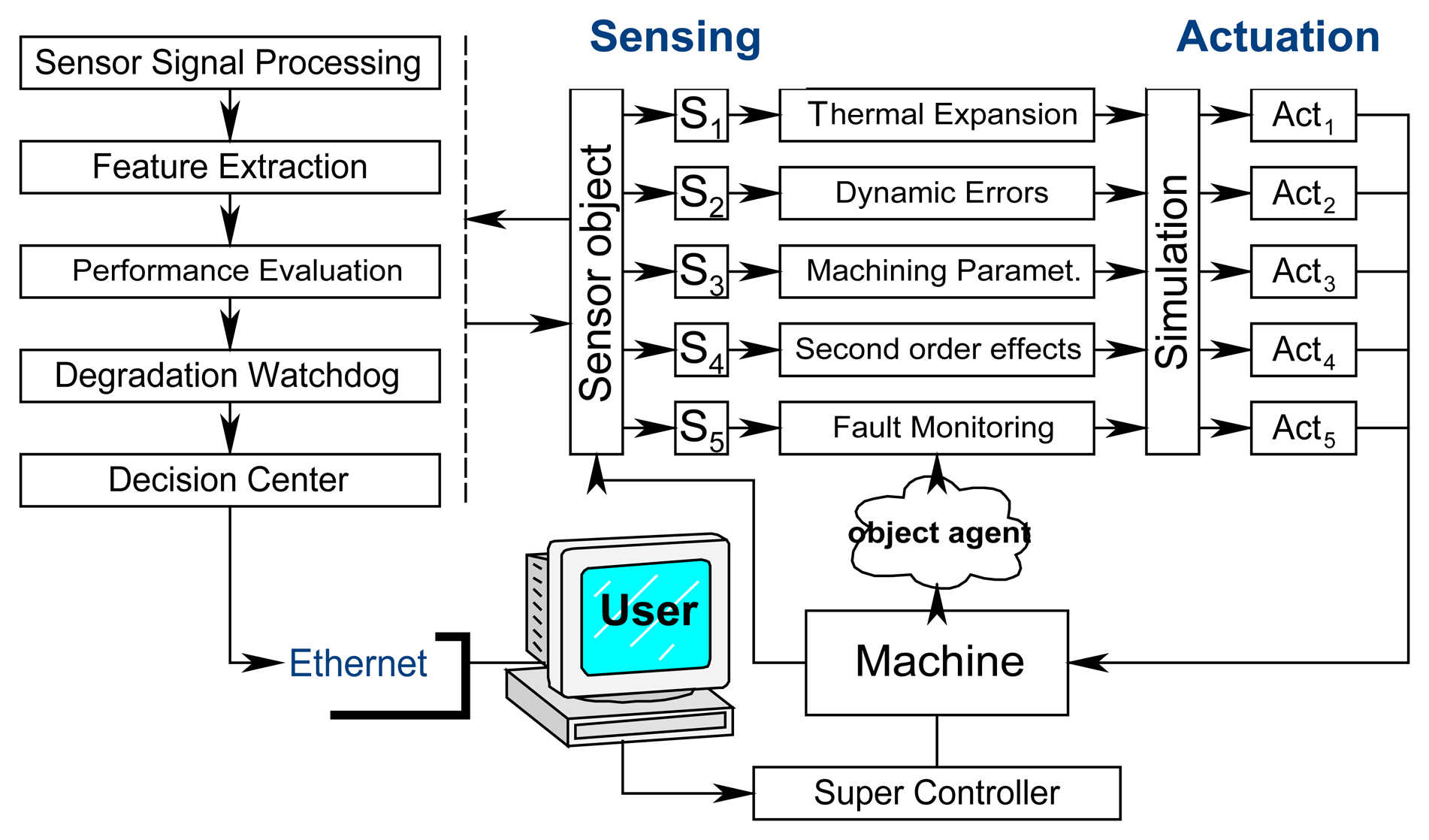

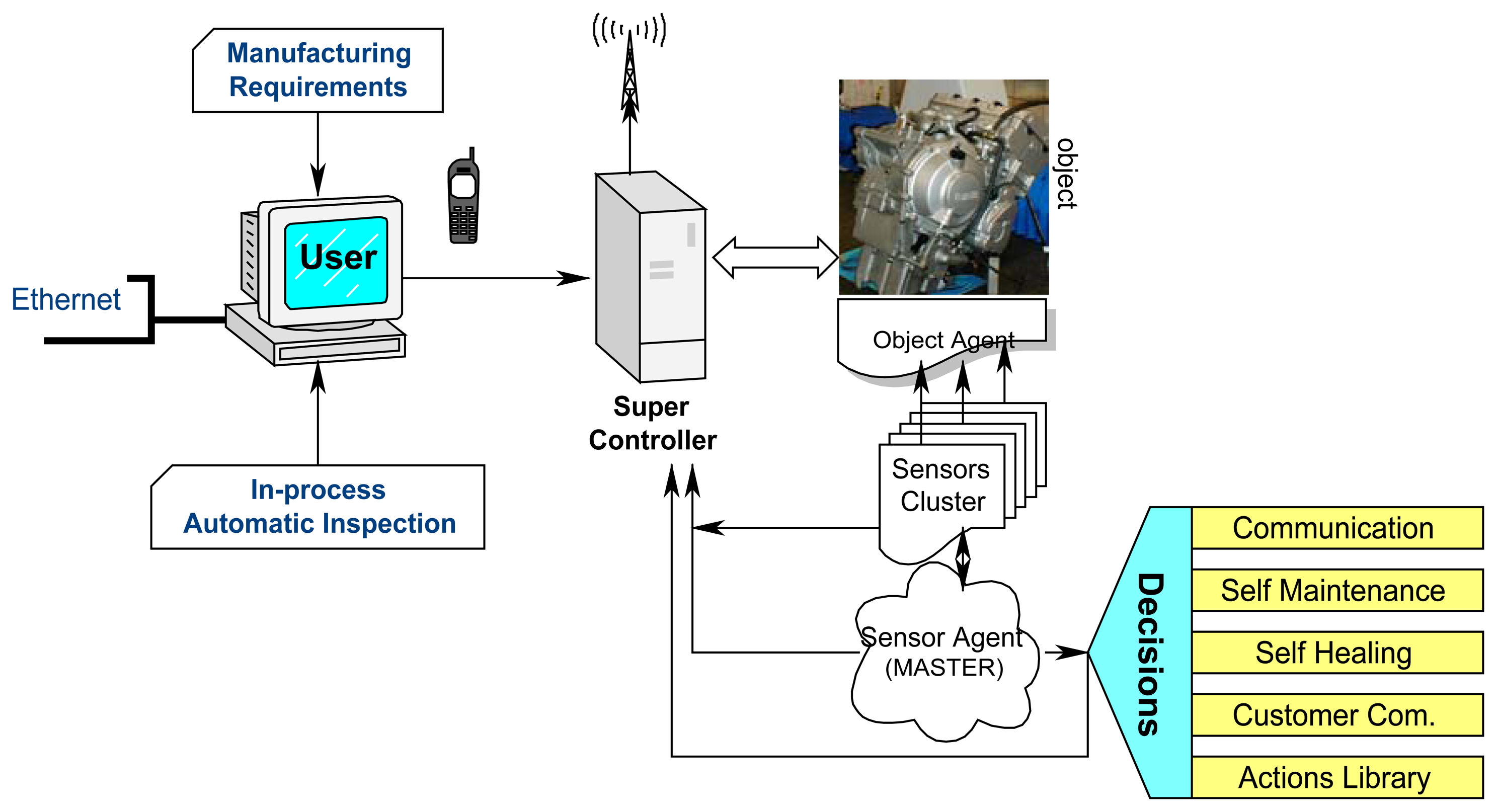

5.1 Sensor Master/clusters set-up for single/hybrid processes

5.2 In process Parameter evaluation

5.3 Extreme environment sensors for manufacturing processes and cutting interfaces

5.4 Plug and Play sensors with standardization of interfaces

5.5 Scalability and implementation in micro-systems

6. Conclusion

Acknowledgments

References and Notes

- Burl, M.C. Review of Literature on Smart Sensors. 1998. in http://www-aig.jpl.nasa.gov/public/mls/home/burl/smart_sensors.html (accessed 03/2005).

- Najafi, K. Smart Sensors. J. Micromech. & Microeng. 1991, vol. 1, 86–102. [Google Scholar]

- Expanding the Vision of Sensor Materials National Materials Advisory Board; National Academic Press: Washington, D.C., 1995.

- Schodel, H. Utilization of fuzzy techniques in intelligent sensors. Fuzzy Sets and Systems 1994, vol. 63, 271–292. [Google Scholar]

- Brignell, J. E. The future of intelligent sensors: a problem of technology or ethics? Sensors and Actuators A 1996, vol. 56, 11–15. [Google Scholar]

- Chita, M.-A.; Anghel, S.; Iorga-Siman, I. Some aspects concerning optically powered intelligent sensors. Proceedings of SPIE 2000, vol. 4068, 633–638. [Google Scholar]

- Takahashi, K.; Nozaki, S. From intelligent sensors to fuzzy sensors. Sensors and Actuators A 1994, vol. 40, 89–91. [Google Scholar]

- Nagel, D. J. Microsensor clusters. Microelectronics Journal 2002, vol. 33, 107–119. [Google Scholar]

- Glynme-Jones, P.; Tudor, M. J.; Beeby, S. P.; White, N. M. An electromagnetic, vibration-powered generator for intelligent sensor systems. Sensors and Actuators A 2004, vol. 110, 344–349. [Google Scholar]

- James, E.P.; Tudor, M. J.; Beeby, S. P.; Harris, N. R.; Glynne-Jones, P.; Ross, J. N.; White, N. M. An investigation of self-powered systems for condition monitoring applications. Sensors and Actuators A 2004, vol. 110, 171–176. [Google Scholar]

- Mitcheson, P. D. P.; Miao, B. H.; Stark, E. M.; Yeatman Holmes, A. S.; Green, T. C. MEMS electrostatic micropower generator for low frequency operation. Sensors and Actuators A 2004, vol. 115, 523–529. [Google Scholar]

- Roundy, S.; Wright, P. K.; Rabaey, J. A study of low level vibrations as a power source for wireless sensor nodes. Computer Communications 2003, vol. 26, 1131–1144. [Google Scholar]

- Al-Mohanadi, M. R.; Ross, J. N.; Brignell, J. E. Optical power and intelligent sensors. Sensors and Actuators A 1997, vol. 60, 142–146. [Google Scholar]

- B. F. S., Jr; Ruiz-Sandoval, M. E.; Kurata, N. Smart sensing technology: opportunities and challenges. Structural Control and Health Monitoring 2004, vol. 11, 349–368. [Google Scholar]

- Vaillant, O. R.; Garcia, C. PC-based natural gas flow computer using intelligent instrumentation and field bus. Measurement 2003, vol. 33, 259–271. [Google Scholar]

- Robert, M.; Riviere, J. M.; Noizette, J. L.; Hermann, F. Smart sensors in flexible manufacturing systems. Sensors and Actuators A 1993, vol. 37-38, 239–246. [Google Scholar]

- Meijer, G. C. M. Concepts and focus point for intelligent sensor systems. Sensors and Actuators A 1994, vol. 41-42, 183–191. [Google Scholar]

- Tian, G. Y.; Zhao, Z. X.; Baines, R. W. A fieldbus-based intelligent sensor. Mechatronics 2000, vol. 10, 835–849. [Google Scholar]

- Liu, J.-G. Self-correction algorithms and applications to digital signal processing. Measurement 2002, vol. 31, 107–116. [Google Scholar]

- Sorrentino, R. OLC - a signal conditioning and calibration technique for Magnetoelastic Sensors. Proceedings of SPIE 2004, vol. 5384, 108–119. [Google Scholar]

- Gao, Y.; Radha, H. A multistage camera self-calibration algorithm, Proceedings-IEEE International Conference on Acoustics. Speech, and Signal Processing 2004, vol. 3, 537–540. [Google Scholar]

- Taner, A. H.; Brignell, J. E. Aspects of intelligent sensor reconfiguration. Sensors and Actuators A 1995, vol. 46-47, 525–529. [Google Scholar]

- Kiyono, S.; Arai, Y.; Chetwynd, D. Self-calibration of sensors in software datum methods, 4thInt. EUSPEN conf. Glasgow 2004. [Google Scholar]

- Clarke, D. W. Intelligent instrumentation. Transactions of the Institute of Measurement and Control 2000, vol. 22, 3–27. [Google Scholar]

- Nelson, C. L.; Fitzgerald, D. S. Sensor fusion for intelligent alarm analysis. IEEE Annual International Carnahan Conference on Security Technology; 1996; pp. 143–150. [Google Scholar]

- Johnson, R. N.; Woods, S.P. Overview and Status Update for the IEEE 1451.2: Transducer to Microprocessor Communications Protocols and Transducer Electronics Data Sheet (TEDS) Formats. Proceeding Sensor Expo 2000, Anaheim, CA, May 9, 2000; pp. p. 17–24.

- IEEE Std 1451.2-1997. IEEE Standard for a Smart Transducer Interface for Sensors and Actuators – Transducer to Microprocessor Communication Protocols and Transducer Electronic Data Sheet (TEDS) Formats. IEEE Instrumentation and measurement Society, TC-9 Committee on Sensor Technology, Institute of Electrical and Electronics Engineers, New York, N.Y., Sept. 1998.

- Wiczer, J. Smart Interfaces for Sensors. In Proceeding Sensor Expo 2001; 2001; Chicago, IL, June. [Google Scholar]

- Bradshaw, J. M. Software Agents; 1997; AAAI Press / MIT Press. [Google Scholar]

- Jennings, N. J.; Wooldridge, M.J. 1998; Applications of Intelligent Agents, In Agent Technology - Foundations, Applications, and Markets; Jennings, N. R., Wooldridge, M. J., Eds.; Springer-Verlag: Berlin, Germany, 1977; pp. 3–28.

- Nwana, H.S. Software Agents: An Overview. Knowledge Engineering Review 1996, 11(3), 1–40. [Google Scholar]

- Andersson, L.; Rönnbom, Å. Intelligent Agents- A New Technology for Future Distributed Sensor Systems? MSc thesis, Göteborg University, 1999. [Google Scholar]

- Petrie, C. J. “Agent-Based Engineering, the Web, and Intelligence”. IEEE Expert/Intelligent Systems & Their Applications 1996, 11(6), 24–29. [Google Scholar]

- Brustoloni, Jose C. “Autonomous Agents: Characterization and Requirements,”. In Carnegie Mellon Technical Report CMU-CS-91-204; 1991; Pittsburgh; Carnegie Mellon University. [Google Scholar]

- Franklin, Stan. Artificial Minds; Cambridge, MA; MIT Press, 1995. [Google Scholar]

- Coen, M. http://www.ai.mit.edu/people/sodabot/slideshow/total/P001.html.

- Maes, Pattie. Artificial Life Meets Entertainment: Life like Autonomous Agents. Communications of the ACM 1995, 38(11), 108–114. [Google Scholar]

- Nwana, H.S. Software Agents: An Overview. Knowledge Engineering Review 1996, 11(3), 1–40. [Google Scholar]

- Foner, L.N. “What's an agent anyway?”. Proceedings of the First International Conference on Autonomous Agents (AA'97); 1997. [Google Scholar]

- Hayes-Roth, B. “An Architecture for Adaptive Intelligent Systems”. ArtificialIntelligence: special issue on agents and interactivity 1995, 72, 329–365. [Google Scholar]

- Stone, P.; Veloso, M. “Multi-agent Systems: A survey from a machine learning perspective”. 1997; In Technical Report 193; Department of Computer Science, Carnegie Mellon University: Pittsburgh, PA. [Google Scholar]

- Collier, T. C.; Taylor, C. Self-organization in sensor networks. Journal of Parallel and Distributed Computing 2004, vol. 64, 866–873. [Google Scholar]

- Benoit, E.; Foulloy, L. High functionalities for intelligent sensors, application to fuzzy colour sensor. Measurement 2001, vol. 30, 161–170. [Google Scholar]

- Bourahla, M.; Benmohamed, M. Formal Specification and Verification of Multi-Agent Systems. Electronic Notes in Theoretical Computer Science 2005, Volume 123, 5–17. [Google Scholar]

- Nahm, Y.-E.; Ishikawa, H. A hybrid multi-agent system architecture for enterprise integration using computer networks. Robotics and Computer-Integrated Manufacturing 2005, Volume 21(Issue 3), 217–234. [Google Scholar]

- Patra, J. C.; Bos, A. V. D. Modeling of an intelligent pressure sensor using functional link artificial neyral networks. ISA Transactions 2000, vol. 39, 15–27. [Google Scholar]

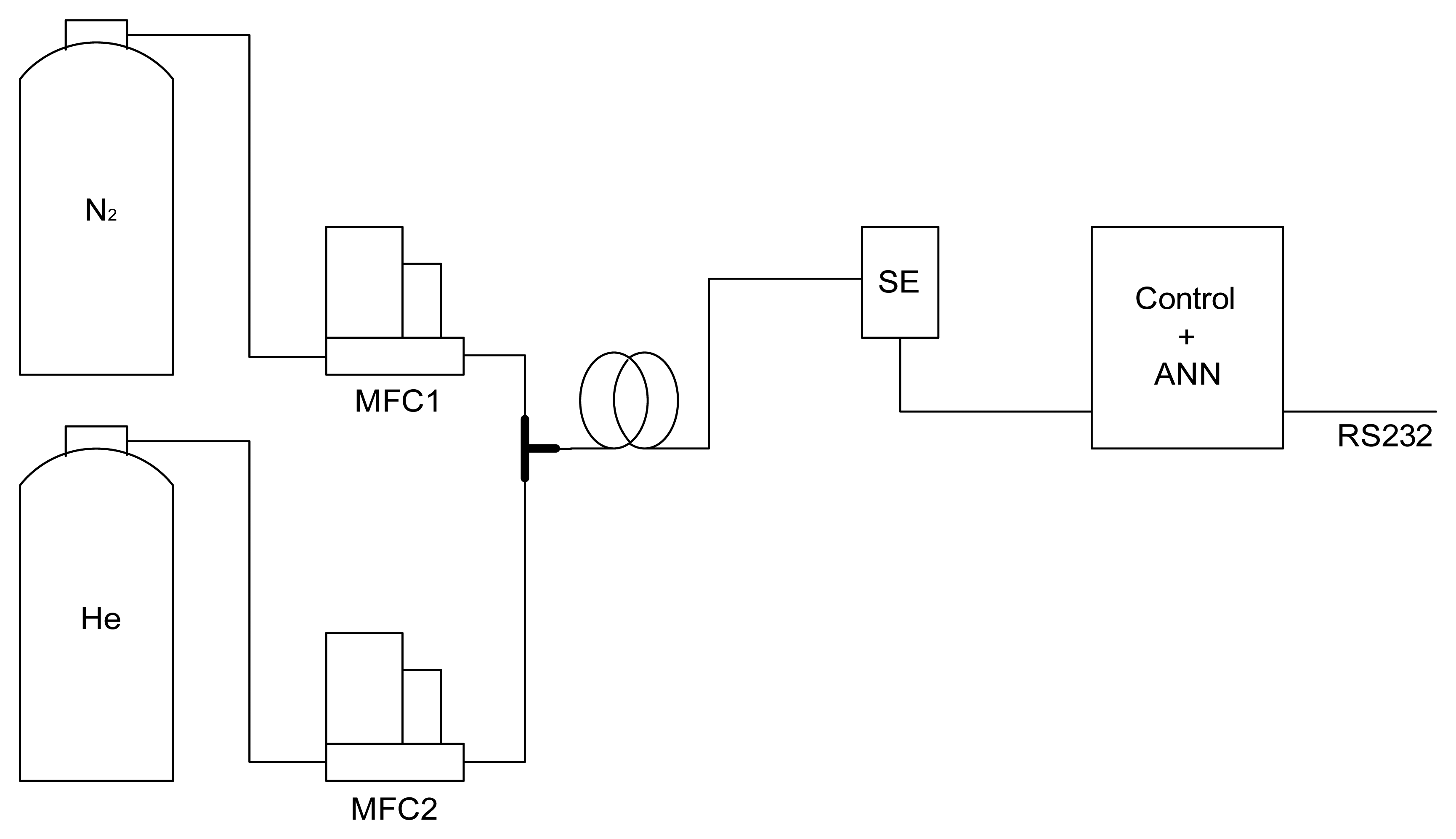

- Lammerink, T. S. J.; Dijkstra, F.; Houkes, Z.; Kuijk, J. V. Intelligent gas-mixture flow sensor. Sensors and Actuators A 1995, vol. 46-47, 380–384. [Google Scholar]

- Vacharanukul, K.; Mekid, S. In-process dimensional measurement sensors. Measurement 2005, volume 38, 204–218. [Google Scholar]

- Kim, I.H.; Jang, D.Y.; Kim, W.J.; Han, D.C. In-process sensing of tool wear and process states using a cylindrical displacement sensor in hard turning. Proceedings of the Institution of Mechanical Engineers Part B - Journal of Engineering Manufacture; 2001; Vol. 215, pp. 1673–1682. [Google Scholar]

- Bukkapatnam, S.T.S.; Kumara, S.R.T.; Lakhtakia, A. Fractal estimation of flank wear in turning. Journal of Dynamic Systems Measurement and Control - Transactions of the ASME 2000, 122(1), 89–94. [Google Scholar]

- Wang, L.T.; Mehrabi, M.G.; KannateyAsibu, E. Hidden Markov model-based tool wear monitoring in turning. Journal of Manufacturing Science and Engineering - Transactions of the ASME 2002, Vol. 124(3), 651–658. [Google Scholar]

- Shen, T.S.; Huang, J.; Menq, C.H. Multiple-sensor Integration for Rapid and High-precision Coordinate Metrology. IEEE/ASME Transactions on Mechatronics 2000, Vol. 5(2), 110–121. [Google Scholar]

- Nashman, M. Vision and touch Sensors for Dimensional Inspection. Manufacturing Review 1993, Vol. 6(2), 155–162. [Google Scholar]

- Lee, J. Smart prognostic and predictive maintenance systems course. Center for Intelligent Maintenance systems. 2004. [Google Scholar]

- Ulivieri, N.; Distante, C.; Luca, T.; Rocchi, S.; Siciliano, P. IEEE1451.4: A way to standardize gas sensor. Sensors and Actuators B 2006, volume 114, 141–151. [Google Scholar]

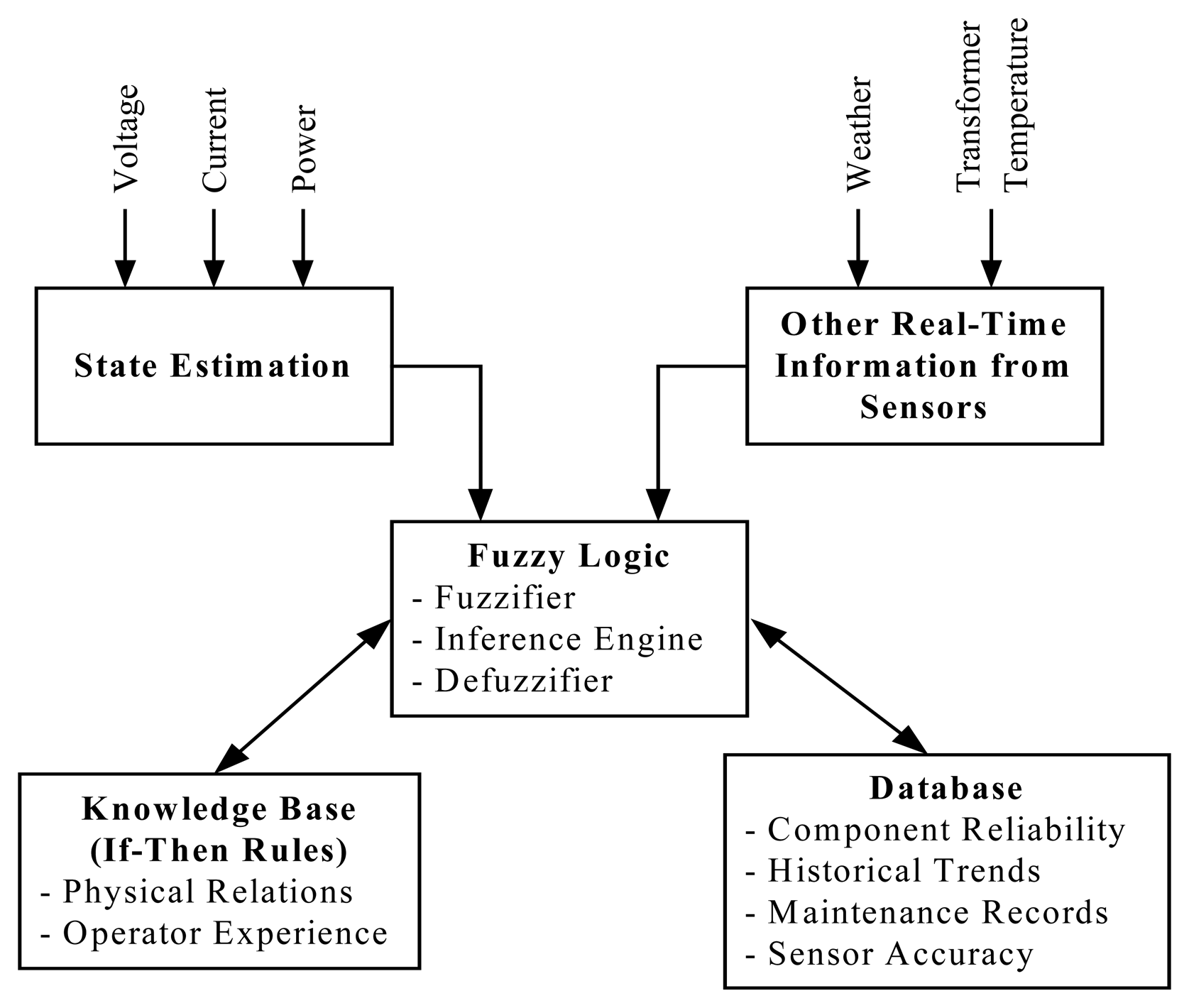

- Holbert, K.E.; Lin, K. Reducing State Estimation Uncertainty Through Fuzzy Logic Evaluation of Power System Measurements, 2004. 8th International Conference on Probability Methods Applied to Power Systems, Ames, Iowa; 2004; pp. 205–211. [Google Scholar]

- Petkovska, M.; Antov, D.; Zimmermann, W.; Schein, E. Dynamic calibration of a sensor gas calorimeter for measurement of heat generation rates during kinetic of adsorption experiments. Thermochimica acta 2004, volume 415, 21–25. [Google Scholar]

- Hauptmann, P. R. Selected examples of intelligent (micro) sensor systems: state-of-the-art and tendencies. Meas. Sci. Technol. 2006, 17(No 3), 459–466. [Google Scholar]

© 2006 by MDPI ( http://www.mdpi.org). Reproduction is permitted for noncommercial purposes.

Share and Cite

Mekid, S. Further Structural Intelligence for Sensors Cluster Technology in Manufacturing. Sensors 2006, 6, 557-577. https://doi.org/10.3390/s6060557

Mekid S. Further Structural Intelligence for Sensors Cluster Technology in Manufacturing. Sensors. 2006; 6(6):557-577. https://doi.org/10.3390/s6060557

Chicago/Turabian StyleMekid, Samir. 2006. "Further Structural Intelligence for Sensors Cluster Technology in Manufacturing" Sensors 6, no. 6: 557-577. https://doi.org/10.3390/s6060557